Comparative Energy and Environmental Analysis of Combined Cycle CHP Combustion Operations via Simulation for Biomass and Industrial Materials Derived from Waste

Abstract

1. Introduction

1.1. Importance of Combined Heat and Power (CHP) Operation

1.2. Challenges and Difficulties of Biomass Utilization for Combustion Application

1.3. Importance of Industrial Waste Biomass Combustion for CHP Applications

1.4. EBSILON Simulation with Different Types of Solid Fuel

1.5. Objective of Research Study

2. Methods

2.1. EBSILON Simulation Design Steps

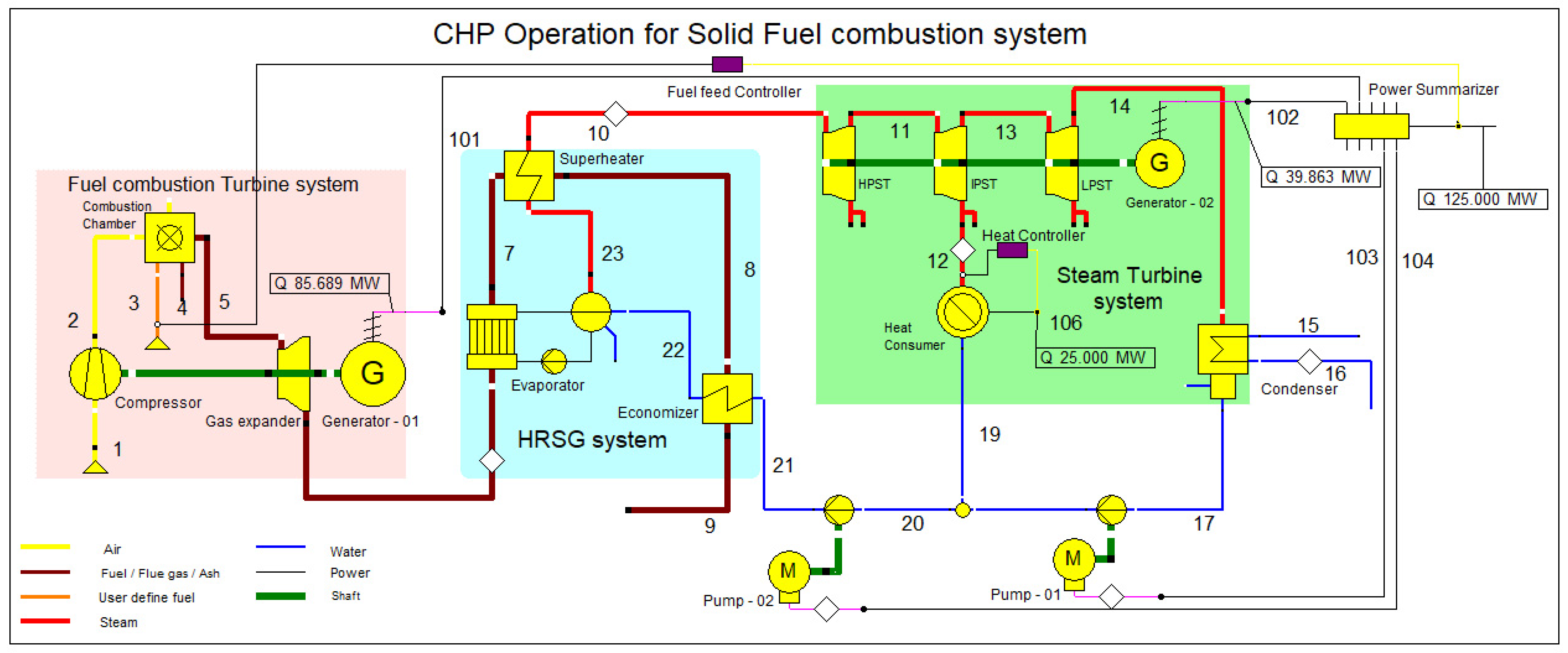

2.2. Fuel Combustion System

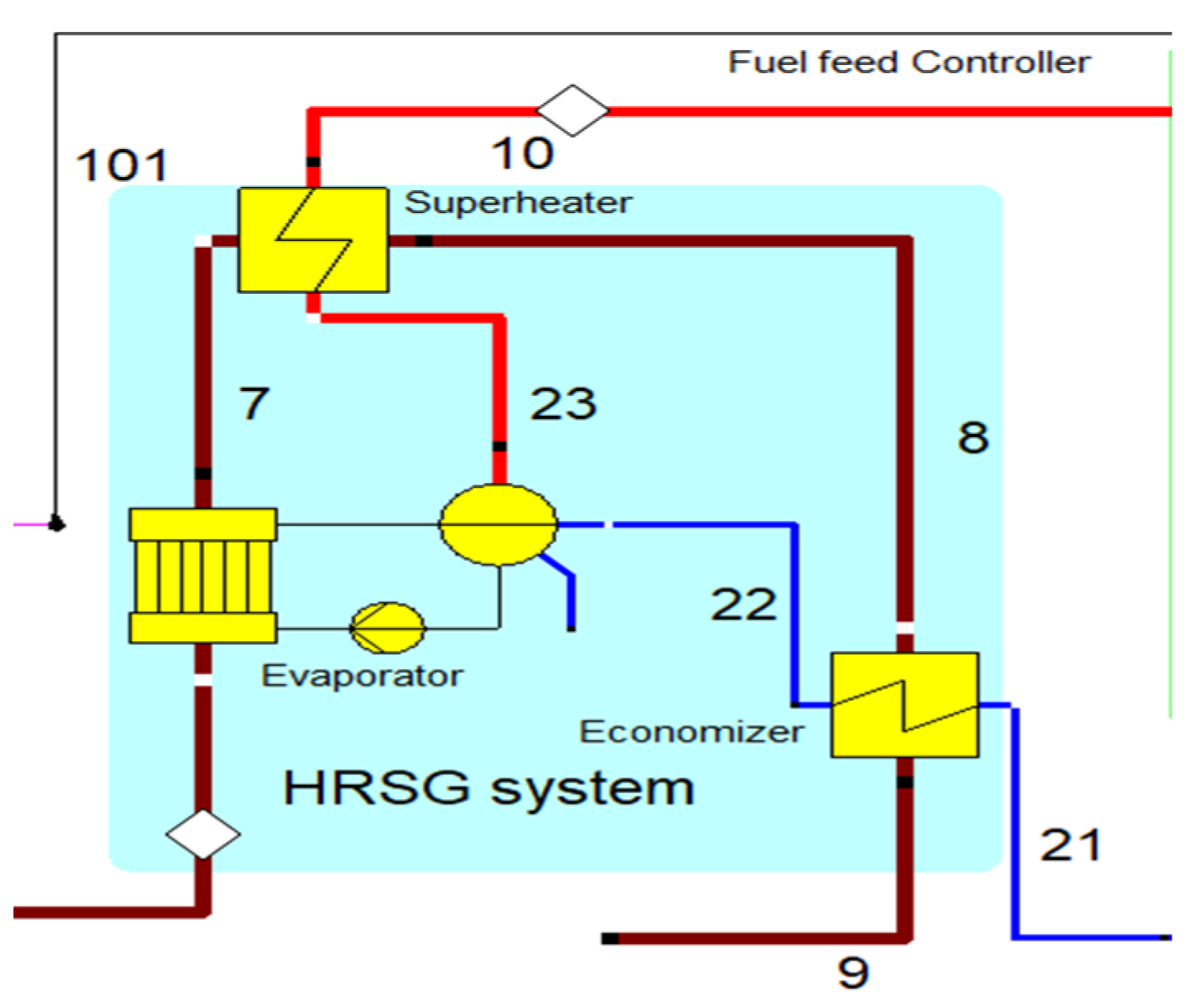

2.3. Heat Recovery Steam Generator (HRSG)

2.4. Steam Turbine System

2.5. Power Generation, Collection, and Consumption

2.6. Physical Data Analysis—Energy

2.7. Energy Efficiency Calculation

- ηel = electrical energy efficiency

- Pel = electrical power produced (kW or MW)

- mfuel = fuel feed rate (kg/s)

- LHV = lower heating value of the fuel (kJ/kg)

- ηCCHP = overall energy efficiency of the CCHP system

- = useful thermal energy produced (kW or MW)

3. Results and Discussion

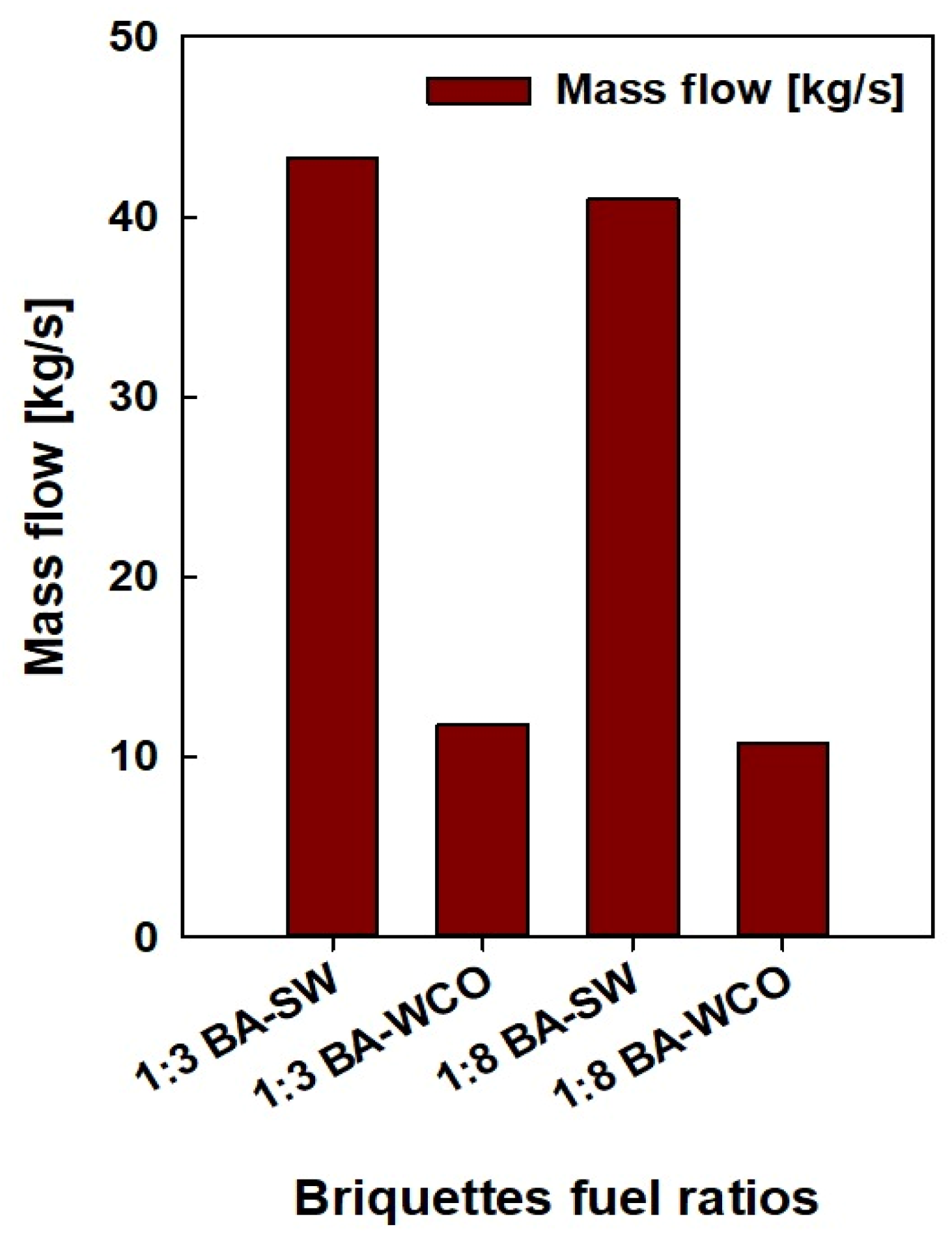

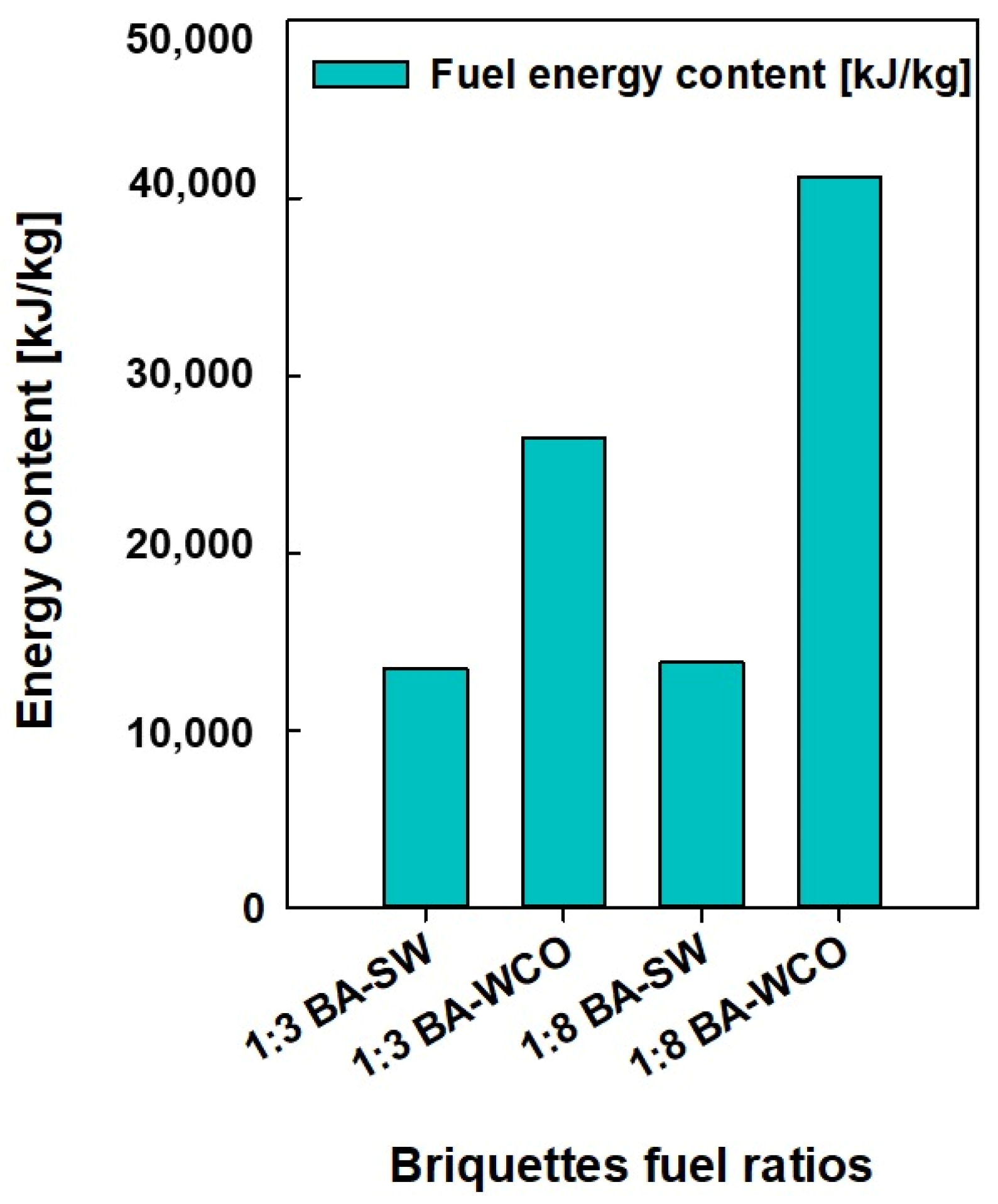

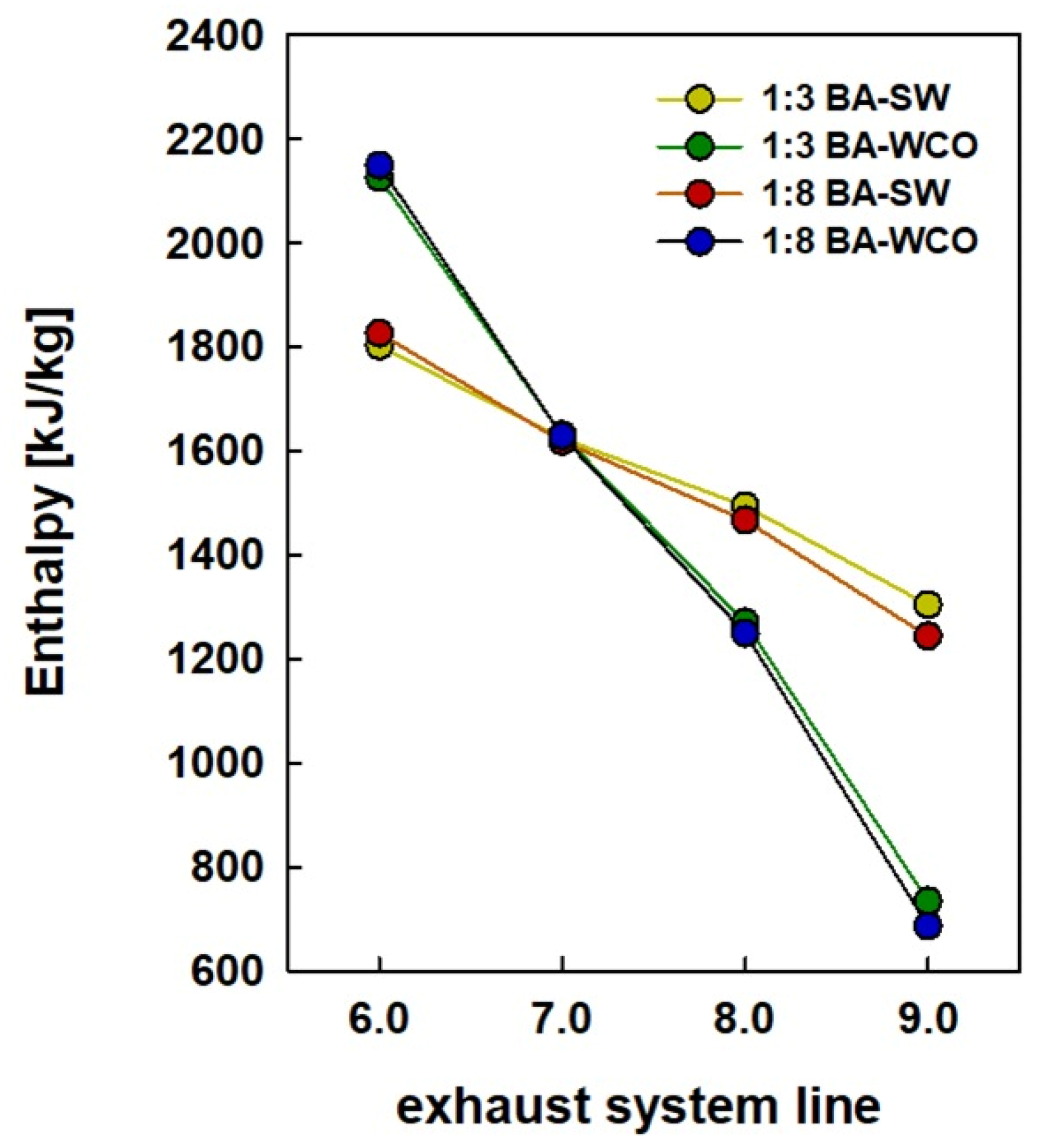

3.1. Fuel Consumption Variation

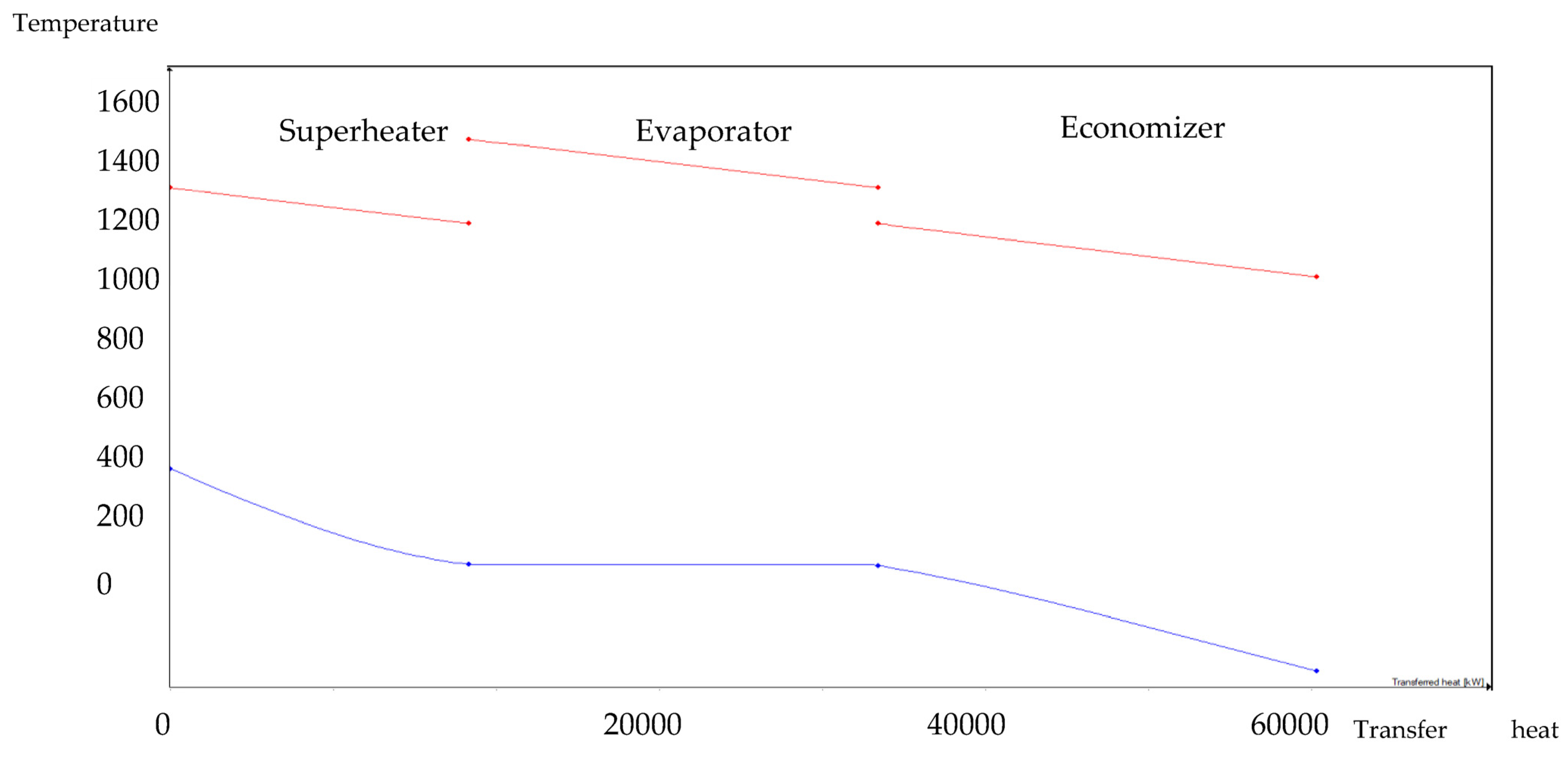

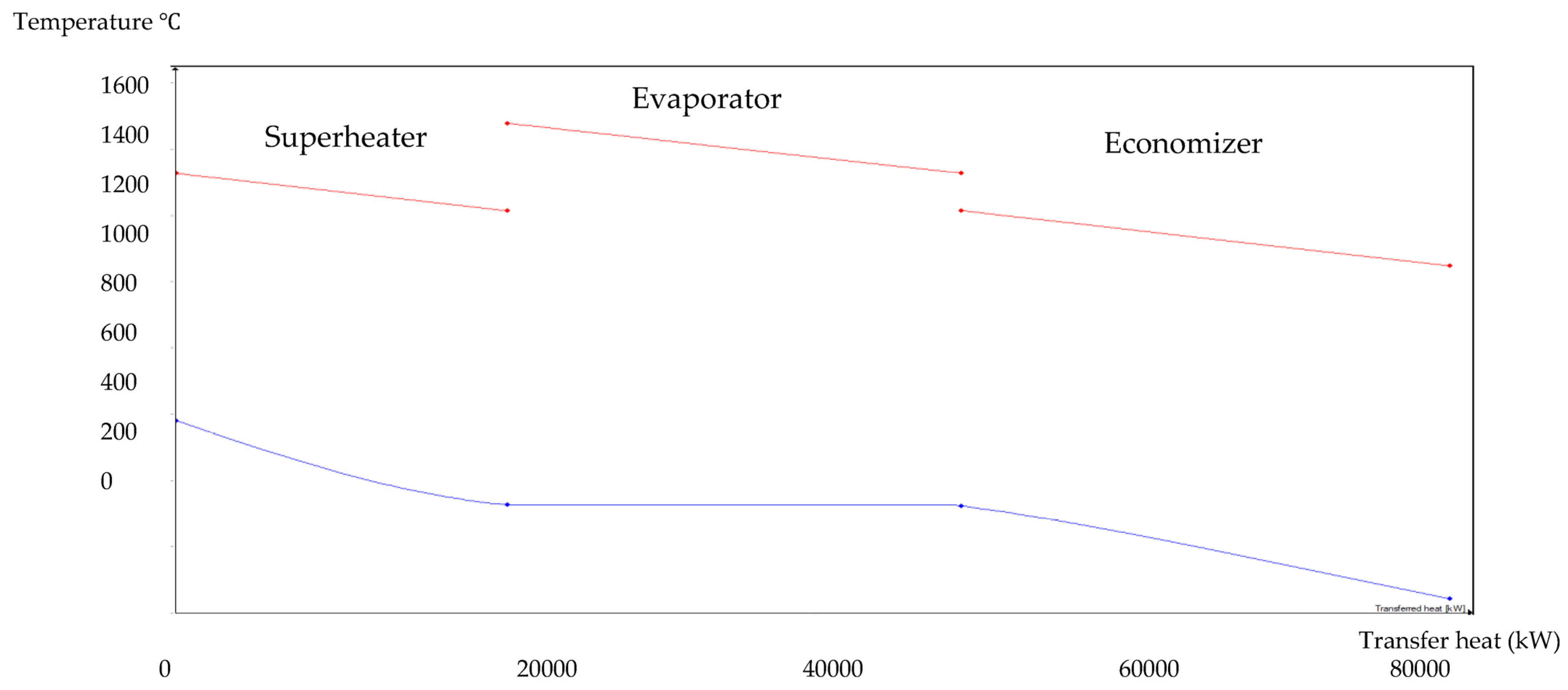

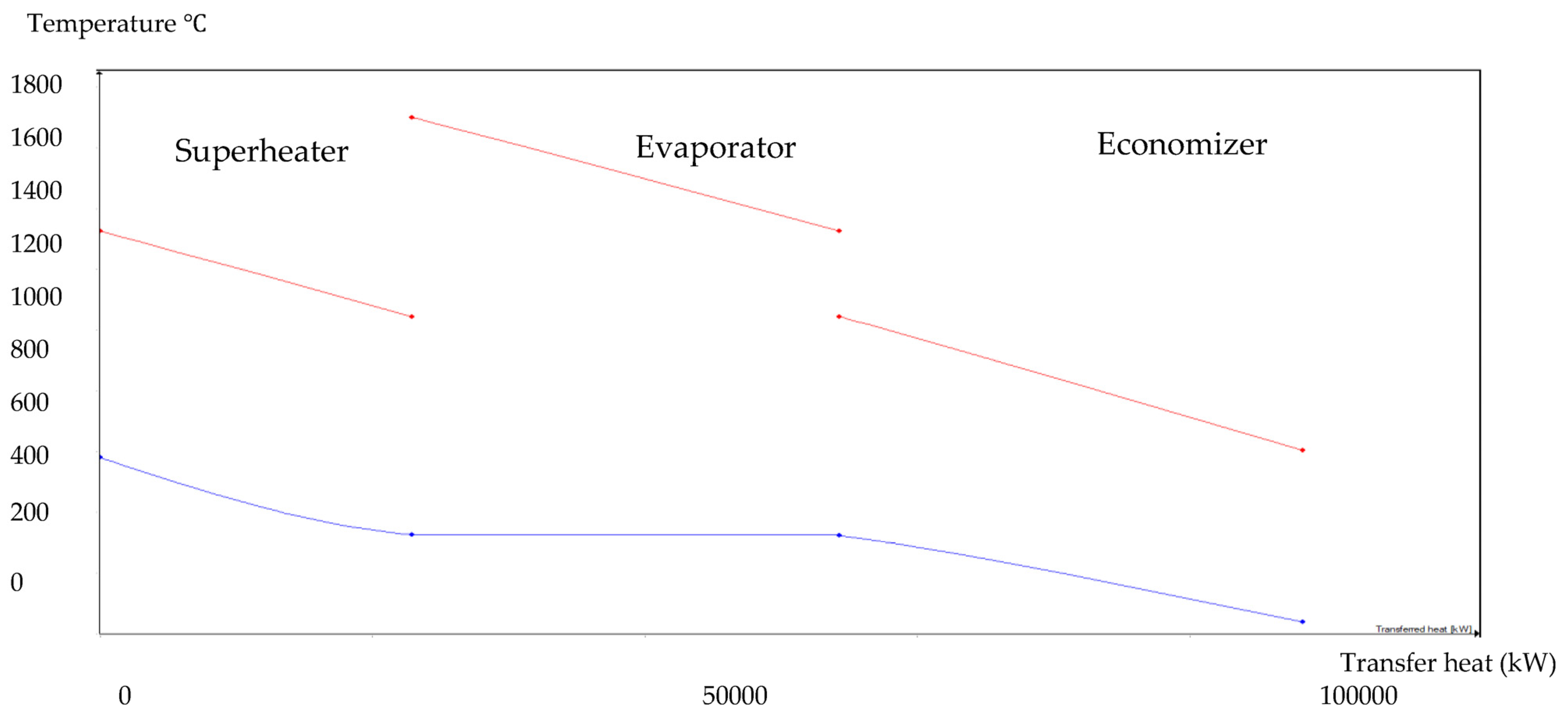

3.2. HRSG Diagram

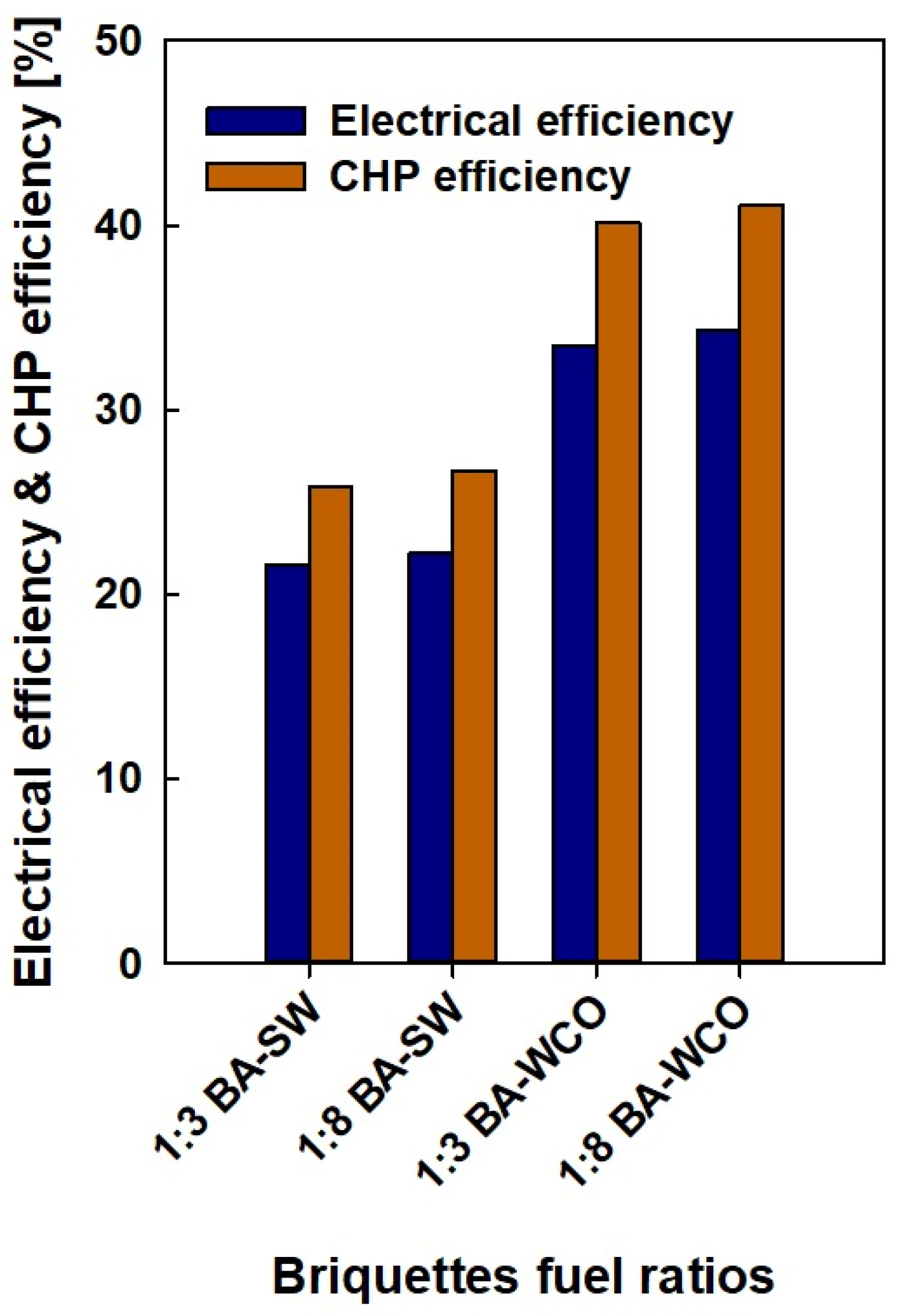

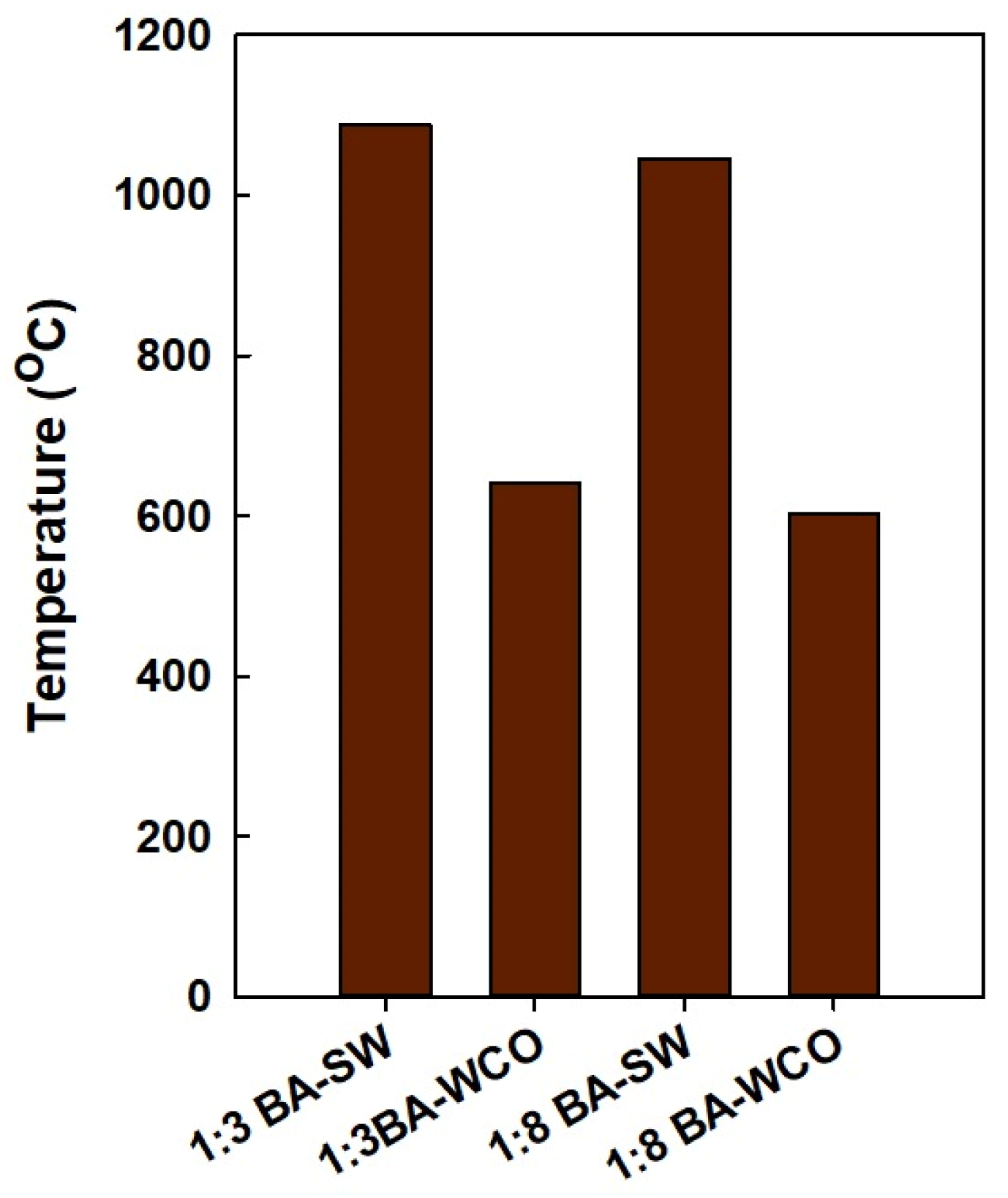

3.3. Energy Analysis

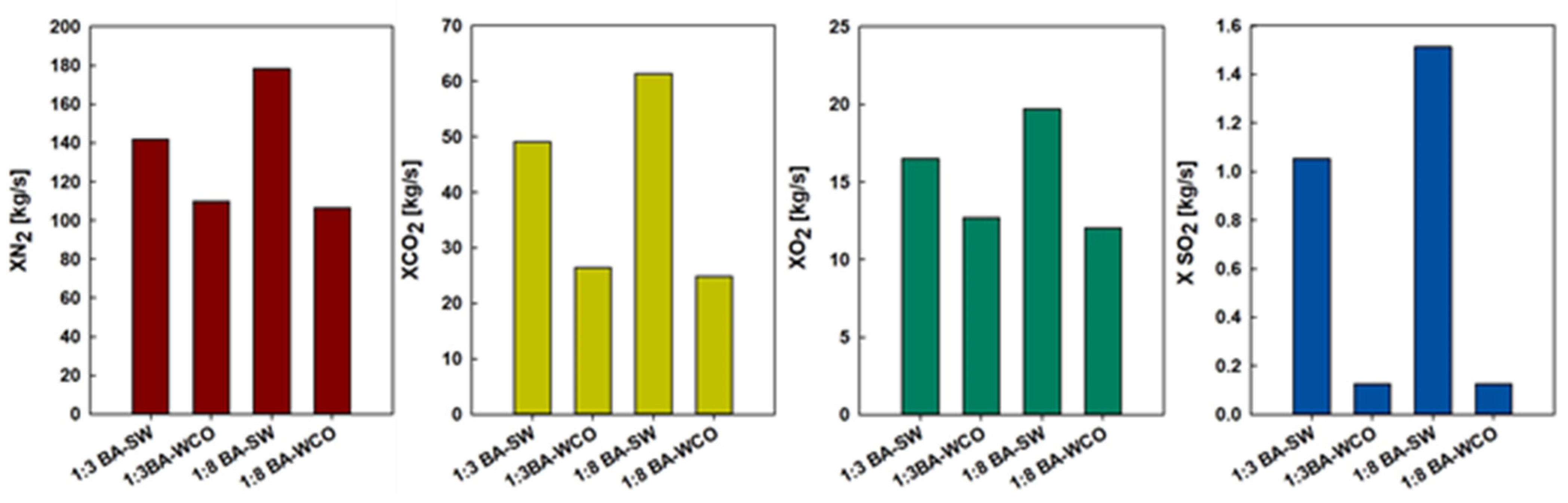

3.4. Environment Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Demirbas, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Byden-and-Fridlund-Carbon-Negative-Heat-and-Power-with-Biochar-Production-Sid-2020.pdf. Available online: https://www.vok.nu/wp-content/uploads/2021/04/byden-and-fridlund-carbon-negative-heat-and-power-with-biochar-production-sid-2020.pdf (accessed on 21 March 2025).

- Sammy, S.; Donald, J. Biomass Combustion. Report Number: FSA-1056, University of Arkansas Division of Agriculture Cooperative Extension Service. Biomass Combustion-FSA1056. 2010. Available online: https://www.uaex.uada.edu/publications/pdf/FSA-1056.pdf (accessed on 21 March 2025).

- Emissions from Biomass Combustion—Bioenergy. Available online: https://www.ieabioenergy.com/blog/publications/emissions-from-biomass-combustion/ (accessed on 21 March 2025).

- Goede, A.P.H. CO2 neutral fuels. EPJ Web Conf. 2018, 189, 00010. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Baxter, L.L.; Koppejan, J. Biomass Combustion. In Thermochemical Processing of Biomass, 1st ed.; Brown, R., Ed.; Wiley: Hoboken, NJ, USA, 2019; pp. 49–83. [Google Scholar] [CrossRef]

- Celebi, A.D.; Sharma, S.; Ensinas, A.V.; Maréchal, F. Next generation cogeneration system for industry—Combined heat and fuel plant using biomass resources. Chem. Eng. Sci. 2019, 204, 59–75. [Google Scholar] [CrossRef]

- Pashchenko, D. Integrated solar combined cycle system with steam methane reforming: Thermodynamic analysis. Int. J. Hydrogen Energy 2023, 48, 18166–18176. [Google Scholar] [CrossRef]

- Thorin, E.; Sandberg, J.; Yan, J. Combined Heat and Power. In Handbook of Clean Energy Systems, 1st ed.; Yan, J., Ed.; Wiley: Hoboken, NJ, USA, 2015; pp. 1–11. [Google Scholar] [CrossRef]

- Wang, J.; You, S.; Zong, Y.; Træholt, C.; Dong, Z.Y.; Zhou, Y. Flexibility of combined heat and power plants: A review of technologies and operation strategies. Appl. Energy 2019, 252, 113445. [Google Scholar] [CrossRef]

- Martinez, S.; Michaux, G.; Salagnac, P.; Bouvier, J.-L. Micro-combined heat and power systems (micro-CHP) based on renewable energy sources. Energy Convers. Manag. 2017, 154, 262–285. [Google Scholar] [CrossRef]

- Muazu, R.I.; Borrion, A.L.; Stegemann, J.A. Life Cycle Assessment Model for Biomass Fuel Briquetting. Waste Biomass Valor 2022, 13, 2461–2476. [Google Scholar] [CrossRef]

- Werther, J.; Saenger, M. Combustion of agricultural residues. Prog. Energy Combust. Sci. 2000, 26, 1–27. [Google Scholar] [CrossRef]

- Yamada, K. 98/03888 Decentralized biomass combustion: State of the art and future development. Fuel Energy Abstr. 1998, 39, 364. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Baxter, L.L.; Jr, T.R.M.; Miles, T.R. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Sipilä, K. Cogeneration, biomass, waste to energy and industrial waste heat for district heating. In Advanced District Heating and Cooling (DHC) Systems; Elsevier: Amsterdam, The Netherlands, 2016; pp. 45–73. [Google Scholar] [CrossRef]

- Habib, M.A.; Khan, R. Environmental Impacts of Coal-Mining and Coal-Fired Power-Plant Activities in a Developing Country with Global Context. In Spatial Modeling and Assessment of Environmental Contaminants; Shit, P.K., Adhikary, P.P., Sengupta, D., Eds.; Environmental Challenges and Solutions; Springer International Publishing: Cham, Switzerland, 2021; pp. 421–493. [Google Scholar] [CrossRef]

- Levihn, F.; Nuur, C. Biomass and waste incineration CHP: The co-benefits of primary energy savings, reduced emissions and costs. In Energy Production and Management in the 21st Century: The Quest for Sustainable Energy; WIT Press: Southampton, UK, 2014; pp. 127–138. [Google Scholar] [CrossRef]

- Muhandiram, H.; Wijesekara, E.; Amarasinghe, A. Energy Densification of Bagasse as Briquettes for Bioenergy Production Through Integrated Utilization of Spent Wash. June 2024. Available online: http://dl.lib.uom.lk/handle/123/22598 (accessed on 21 March 2025).

- Alen, A.A. Cogenerations of Energy from Sugar Factory Bagasse. Am. J. Energy Eng. 2013, 1, 22. [Google Scholar] [CrossRef]

- Khalkar, K.M.; Gaikwad, K.N.; Khandbahale, D.S. Impact of Distillery Effluents on Growth Characteristics of Capscicum annum L. (Chilly) Plant. Int. J. Res. Anal. Rev. 2021, 8, 244–249. [Google Scholar]

- Hiranobe, C.T.; Gomes, A.S.; Paiva, F.F.; Tolosa, G.R.; Paim, L.L.; Dognani, G.; Cardim, G.P.; Cardim, H.P.; dos Santos, R.J.; Cabrera, F.C. Sugarcane Bagasse: Challenges and Opportunities for Waste Recycling. Clean Technol. 2024, 6, 662–699. [Google Scholar] [CrossRef]

- Lam, S.S.; Liew, R.K.; Cheng, C.K.; Chase, H.A. Catalytic microwave pyrolysis of waste engine oil using metallic pyrolysis char. Appl. Catal. B Environ. 2015, 176–177, 601–617. [Google Scholar] [CrossRef]

- Mohan, C.; Bashir, M.; Annachhatre, A.P. Anaerobic treatment of spentwash for recovery of clean energy. Mater. Today Proc. 2020, 32, 928–935. [Google Scholar] [CrossRef]

- Used Motor Oil Is a Big Contributor to the Pollution in Our Waterways and Drinking Water—Emagazine.com. Available online: https://emagazine.com/used-motor-oil-is-a-big-contributor-to-the-pollution-in-our-waterways-and-drinking-water/?utm_source=chatgpt.com (accessed on 21 March 2025).

- Yue, M.; Ma, G.; Shi, Y. Analysis of Gas Recirculation Influencing Factors of a Double Reheat 1000 MW Unit with the Reheat Steam Temperature under Control. Energies 2020, 13, 4253. [Google Scholar] [CrossRef]

- Wijesekara, D.; Amarasinghe, P.; Induranga, A.; Vithanage, V.; Koswattage, K.R. Energy, Exergy, and Environmental Impact Analysis and Optimization of Coal–Biomass Combustion Combined Cycle CHP Systems. Sustainability 2025, 17, 2363. [Google Scholar] [CrossRef]

- Abdalla, A.M.; Hassan, T.H.; Mansour, M.E. Performance of Wet and Dry Bagasse Combustion in Assalaya Sugar Factory—Sudan. Innov. Energy Res. 2018, 7, 179. [Google Scholar] [CrossRef]

- Messay, E.G.; Birhanu, A.A.; Mulissa, J.M.; Genet, T.A.; Endale, W.A.; Gutema, B.F. Briquette production from sugar cane bagasse and its potential as clean source of energy. Afr. J. Environ. Sci. Technol. 2021, 15, 339–348. [Google Scholar] [CrossRef]

- Kularathna, S.H.L.N.; Wijesekara, E.R.J.M.D.D.P. Production of High-Energy-Density Biomass Material Utilizing Bagasse and Waste Oil Derived from the Service Center Operations. Adv. Technol. 2025, 4, 8025. [Google Scholar] [CrossRef]

- Islam, M.M.; Hasanuzzaman, M.; Pandey, A.K.; Rahim, N.A. Modern energy conversion technologies. In Energy for Sustainable Development; Elsevier: Amsterdam, The Netherlands, 2020; pp. 19–39. [Google Scholar] [CrossRef]

- Jamilatun, S.; Amelia, S.; Pitoyo, J.; Ma’Arif, A.; Mufandi, I. Preparation and Characteristics of effective Biochar derived from sugarcane bagasse as adsorbent. Int. J. Renew. Energy Res. 2023, 13, 673–680. [Google Scholar] [CrossRef]

- Mohtaram, S.; Chen, W.; Zargar, T.; Lin, J. Energy-exergy analysis of compressor pressure ratio effects on thermodynamic performance of ammonia water combined cycle. Energy Convers. Manag. 2017, 134, 77–87. [Google Scholar] [CrossRef]

- Soltani, S.; Mahmoudi, S.M.S.; Yari, M.; Rosen, M.A. Thermodynamic analyses of a biomass integrated fired combined cycle. Appl. Therm. Eng. 2013, 59, 60–68. [Google Scholar] [CrossRef]

- Ata, A.B.; Seufert, P.M.; Heinze, C.; Alobaid, F.; Epple, B. Optimization of Integrated Gasification Combined-Cycle Power Plant for Polygeneration of Power and Chemicals. Energies 2021, 14, 7285. [Google Scholar] [CrossRef]

- Chin, H.H.; Wang, B.; Varbanov, P.S.; Klemeš, J.J.; Zeng, M.; Wang, Q.-W. Long-term investment and maintenance planning for heat exchanger network retrofit. Appl. Energy 2020, 279, 115713. [Google Scholar] [CrossRef]

- Fiehn, A.; Kostinek, J.; Eckl, M.; Klausner, T.; Gałkowski, M.; Chen, J.; Gerbig, C.; Röckmann, T.; Maazallahi, H.; Schmidt, M.; et al. Estimating CH4, CO2 and CO emissions from coal mining and industrial activities in the Upper Silesian Coal Basin using an aircraft-based mass balance approach. Atmos. Chem. Phys. 2020, 20, 12675–12695. [Google Scholar] [CrossRef]

| Fuel Feed Briquettes’ Sample Weight Ratios to Produce the 150 MW Energy | Moisture Content (w/w) of Dried Briquettes | Fuel Feed Composition % (w/w) | |||||

|---|---|---|---|---|---|---|---|

| C | H | O | N | S | Ref | ||

| Bagasse–Spent wash (w/w) 1:3 Briquettes fuel | 10.00% | 40.12 | 4.42 | 35.72 | 3.16 | 1.58 | [31,32] |

| Bagasse–Spent wash (w/w) 1:8 Briquettes fuel | 10.00% | 40.87 | 4.27 | 34.3 | 3.71 | 1.85 | [31,32] |

| Bagasse–WCO 1:3 (w/w) Briquettes fuel | 10.00% | 61.19 | 10.95 | 12.19 | 0.11 | 0.53 | [31,32] |

| Bagasse–WCO 1:8 (w/w) Briquettes fuel | 10.00% | 62.88 | 11.47 | 6.08 | 0.1 | 0.58 | [31,32] |

| Streamline Numbers | Description |

|---|---|

| 1 | Primary air inlet |

| 2 | Compressed air line |

| 3 | Fuel inlet line |

| 4 | Ash line |

| 5/6/7/8/9 | Exhaust flue gas line |

| 10/11/12/13/14/23 | Steam lines |

| 15 | Water inlet line for Condenser |

| 16 | Water outlet line from Condenser |

| 17/18/19/20/21/22 | Water lines |

| 101/102/103/104 | Electricity lines |

| 106 | Heat line |

| Component | Parameter | Value | Unit | Reference |

|---|---|---|---|---|

| Air compressor | Inlet air pressure | 1 | Bar | Environment condition |

| Inlet air temperature | 25 | °C | Environment condition | |

| Pressure ratio | 2:1 | - | [33,34] | |

| Isentropic efficiency | 85 | % | [33,34] | |

| Mechanical efficiency | 99 | % | Software derives | |

| Combustion unit | CV of bagasse-to-spent wash 1:3 | 12,364 | KJ/Kg | Experiment |

| CV of bagasse-to-spent wash 1:8 | 13,982 | KJ/Kg | Experiment | |

| CV of bagasse-to-WCO 1:3 | 26,465 | KJ/Kg | Experiment | |

| CV of bagasse-to-WCO 1:8 | 41,141 | KJ/Kg | Experiment | |

| Air-to-fuel ratio | 1:2 | - | Assumed | |

| Pressure drop | Negligible | Assumed | ||

| Slag temperature | 850 | °C | Software derives | |

| Heat loss | Negligible | - | Assumed | |

| Expander | Isentropic efficiency | 95 | % | [33,34] |

| Mechanical efficiency | 99 | % | Software derives | |

| Inlet temperature (BA–SW 1:3 combustion) | 1700 | °C | [34,35] | |

| Inlet temperature (BA–SW 1:8 combustion) | 1710 | °C | [34,35] | |

| Inlet temperature (BA–WCO 1:3 combustion) | 1944 | °C | [34,35] | |

| Inlet temperature (BA–WCO 1:8 combustion) | 1965 | °C | [34,35] | |

| Generator | Nominal efficiency | 98 | % | Assumed |

| Component | Parameter | Value | Unit | Reference | |

|---|---|---|---|---|---|

| Economizer | Upper terminal temperature difference Thermal transmittance area | 907.72 55.21 | °C kW/K | Software derives Software derives | |

| Effectiveness | 1:3 BA–SW | 25.69 | % | Software derives | |

| 1:8 BA–SW | 25.97 | ||||

| 1:3 BA–WCO | 40.64 | ||||

| 1:8 BA–WCO | 43.47 | ||||

| Evaporator | Pinch Point | 1000.00 | °C | Software derives | |

| Effectiveness | 1:3 BA–SW | 12.27 | % | Software derives | |

| 1:8 BA–SW | 14.1 | ||||

| 1:3 BA–WCO | 27.99 | ||||

| 1:8 BA–WCO | 29.03 | ||||

| Superheater | Upper terminal temperature difference Cold side pressure drop Hot side pressure drop Thermal transmittance area | 745.95 2 0.001 44.54 | °C Bar Bar kW/K | Software derives Software derives Software derives Software derives | |

| Effectiveness | 1:3 BA–SW | 31.52 | % | Software derives | |

| 1:8 BA–SW | 31.52 | ||||

| 1:3 BA–WCO | 31.52 | ||||

| 1:8 BA–WCO | 31.52 | ||||

| Component | Parameter | Value | Unit | Reference |

|---|---|---|---|---|

| Steam turbine | Inlet pressure HPST | 120 | Bar | [28,29] |

| Inlet temperature HPST | 580 | °C | [28,29] | |

| Inlet pressure IPST | 40 | Bar | [28,29] | |

| Inlet temperature IPST | 411 | °C | [28,29] | |

| Inlet pressure LPST | 5 | Bar | [28,29] | |

| Inlet temperature LPST | 176 | °C | [28,29] | |

| HPST isentropic efficiency | 88 | % | Software derives | |

| IPST isentropic efficiency | 88 | % | Software derives | |

| LPST isentropic efficiency | 88 | % | Software derives | |

| Generator efficiency | 98 | % | Assumed | |

| HRSG-to-HPST steam quality (Dryness) | 1 | - | Software derives | |

| HPST-to-IPST steam quality (Dryness) | 1 | - | Software derives | |

| IPST-to-LPST steam quality (Dryness) | 1 | - | Software derives | |

| LPST-to-condenser steam quality (Dryness) | 0.85 | - | Software derives | |

| Condenser | Condenser pressure | 0.05 | Bar | [28,29] |

| System | Gas Turning System Power Generation MW | Steam Turbine System Power Generation MW | Total Generated Power MW | Motor Pump 01 Power kW | Motor Pump 02 Power kW |

|---|---|---|---|---|---|

| 1:3 BA–SW | 75.78 | 49.89 | 125.67 | 20.91 | 649.44 |

| 1:3 BA–WCO | 45.88 | 80.16 | 126.04 | 35.81 | 1000.56 |

| 1:8 BA–SW | 68.62 | 57.14 | 125.76 | 24.48 | 733.59 |

| 1:8 BA–WCO | 44.74 | 81.32 | 126.06 | 36.38 | 1013.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wijesekara, D.; Kularathna, L.; Abesundara, P.; Lankathilaka, U.; Muhandiram, I.; Amarasinghe, P.; Abesinghe, S.; Galpaya, C.; Koswattage, K. Comparative Energy and Environmental Analysis of Combined Cycle CHP Combustion Operations via Simulation for Biomass and Industrial Materials Derived from Waste. Energies 2025, 18, 3062. https://doi.org/10.3390/en18123062

Wijesekara D, Kularathna L, Abesundara P, Lankathilaka U, Muhandiram I, Amarasinghe P, Abesinghe S, Galpaya C, Koswattage K. Comparative Energy and Environmental Analysis of Combined Cycle CHP Combustion Operations via Simulation for Biomass and Industrial Materials Derived from Waste. Energies. 2025; 18(12):3062. https://doi.org/10.3390/en18123062

Chicago/Turabian StyleWijesekara, Dasith, Lasitha Kularathna, Pawani Abesundara, Udayangani Lankathilaka, Imesha Muhandiram, Prasad Amarasinghe, Shakya Abesinghe, Chanaka Galpaya, and Kaveenga Koswattage. 2025. "Comparative Energy and Environmental Analysis of Combined Cycle CHP Combustion Operations via Simulation for Biomass and Industrial Materials Derived from Waste" Energies 18, no. 12: 3062. https://doi.org/10.3390/en18123062

APA StyleWijesekara, D., Kularathna, L., Abesundara, P., Lankathilaka, U., Muhandiram, I., Amarasinghe, P., Abesinghe, S., Galpaya, C., & Koswattage, K. (2025). Comparative Energy and Environmental Analysis of Combined Cycle CHP Combustion Operations via Simulation for Biomass and Industrial Materials Derived from Waste. Energies, 18(12), 3062. https://doi.org/10.3390/en18123062