Theoretical Performance Study of a Novel Diffusion Absorption Heat Transformer Driven by a Jet Pump

Abstract

1. Introduction

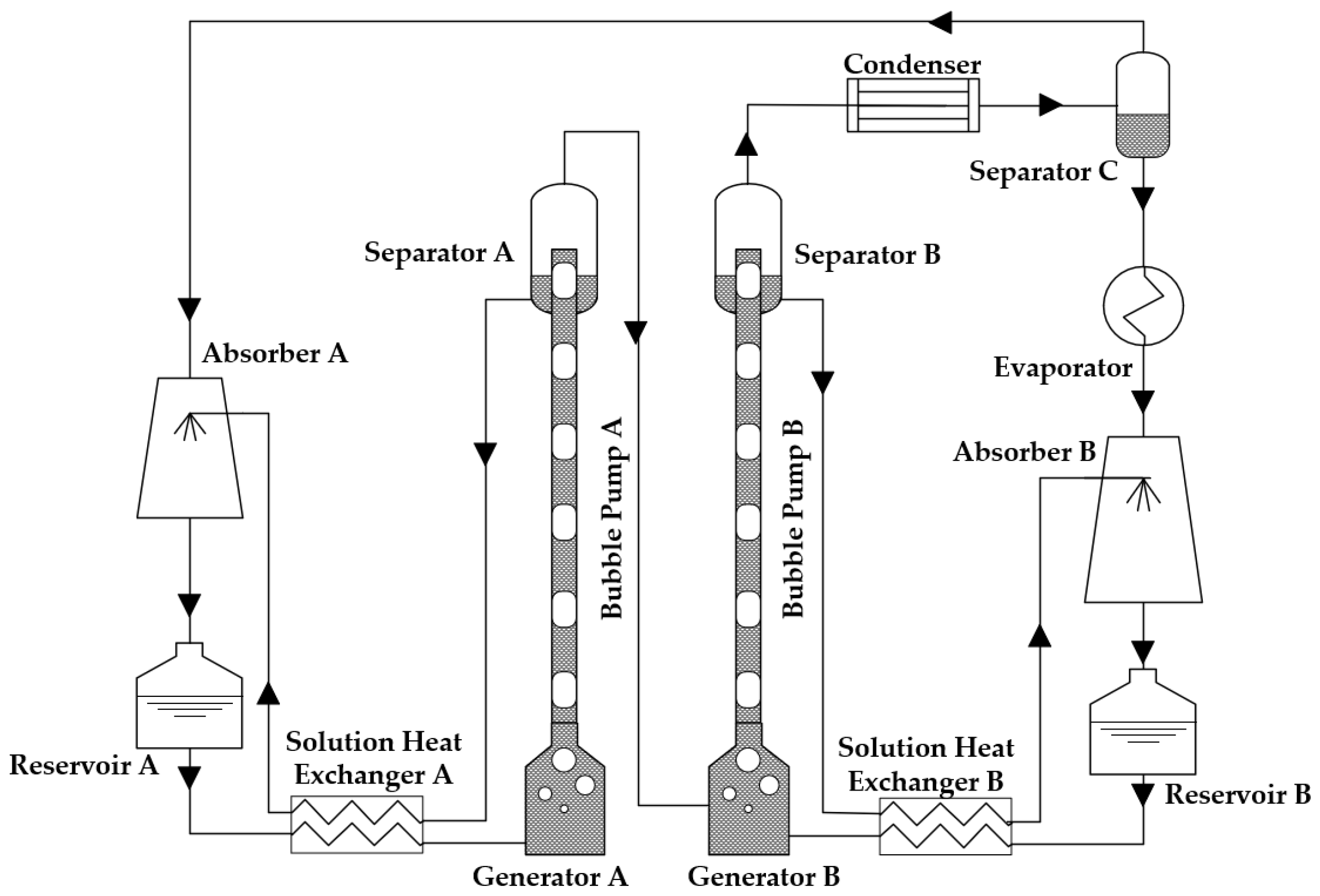

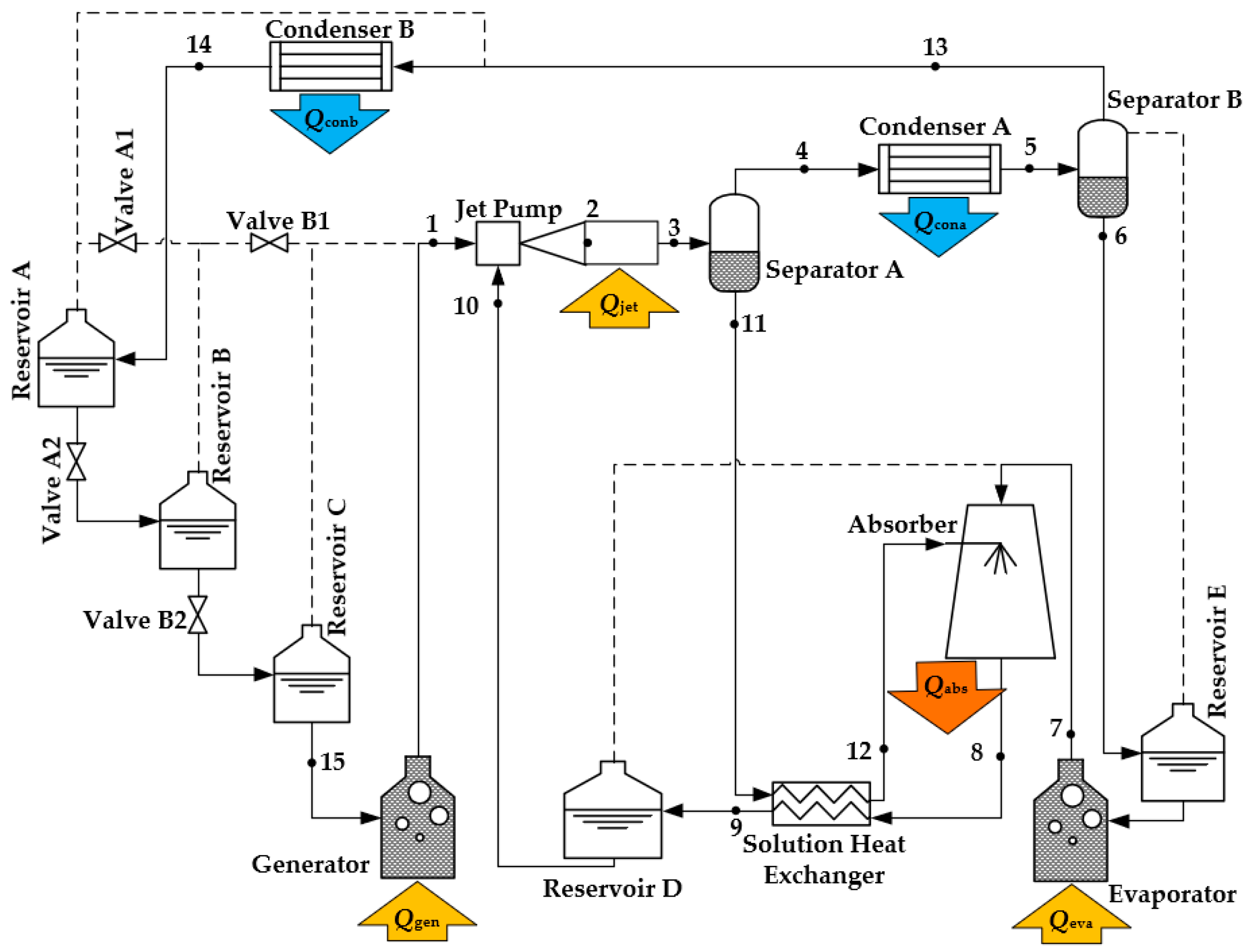

2. Cycle Description

3. Jet Pump and Cycle Model

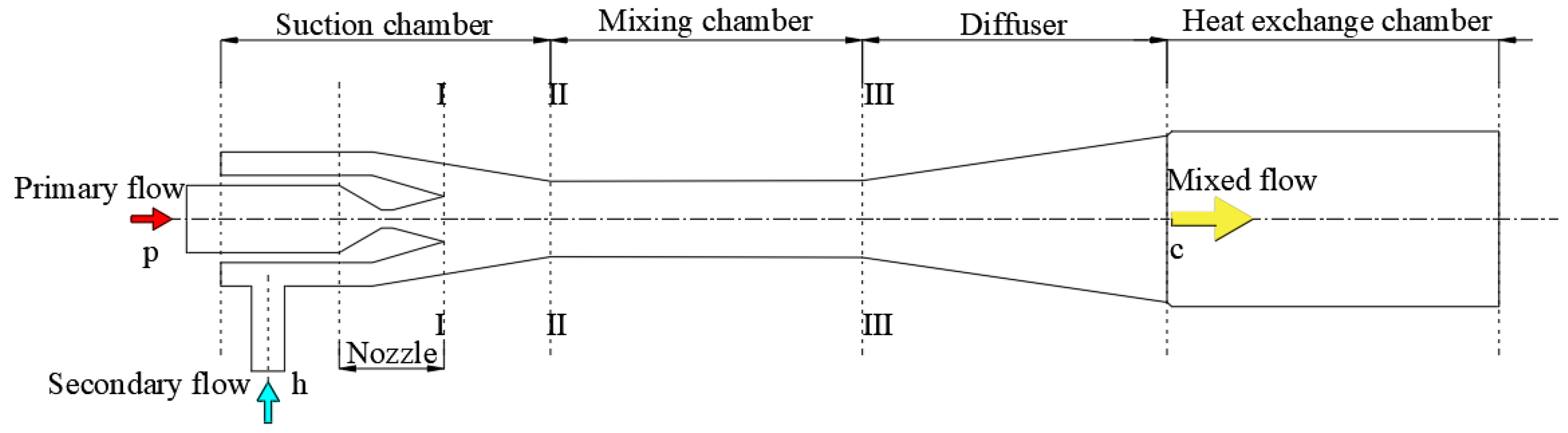

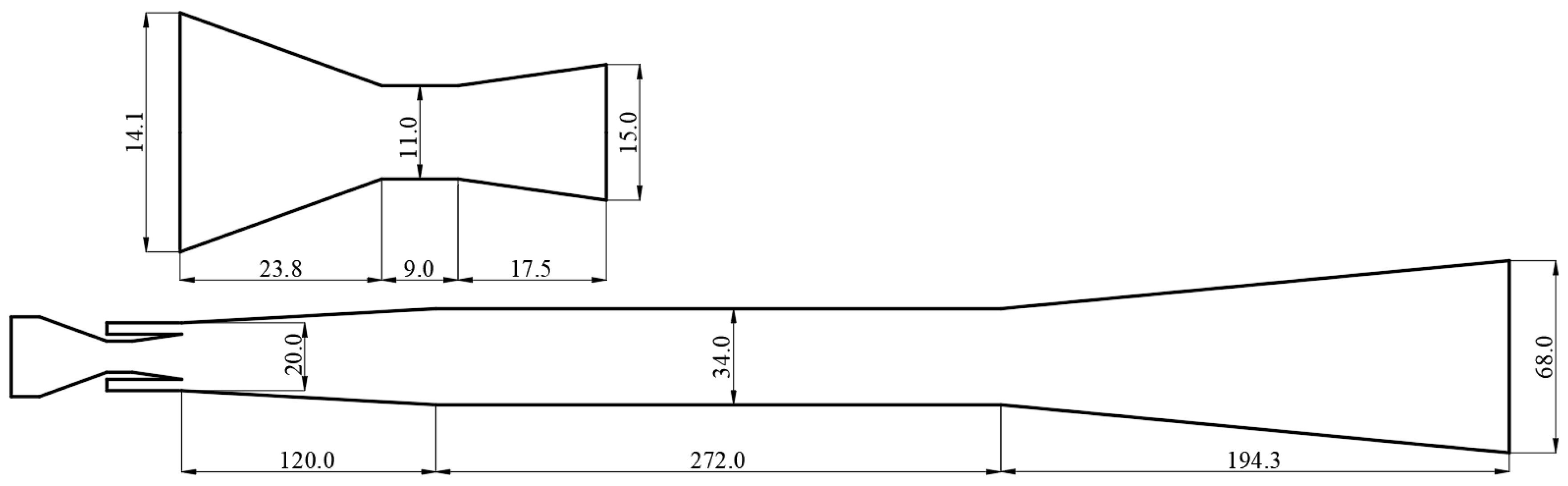

3.1. Jet Pump Model

3.2. Cycle Model

- (1)

- The temperatures of Jet Pump (Tjet), Generator (Tgen), Evaporator (Teva), Condenser A (Tcona), Condenser B (Tconb), and Absorber (Tabs) in the cycle are specified.

- (2)

- The minimum temperature difference of Solution Heat Exchanger is specified as 5 °C at the hot end.

- (3)

- In addition to the components that need heat exchange in the cycle, pipelines, separators, and reservoirs are all considered as adiabatic.

- (4)

- In addition to the pressure at the outlet of Generator, the pressure in the cycle is mainly determined by the saturated vapor pressure of H2O in Evaporator, while ignoring the flow pressure loss of heat exchange components, pipelines, separators, and liquid reservoirs caused by friction resistance.

- (5)

- The diffusant C5H10 is insoluble in liquid H2O or aqueous LiBr (or HCOOK) solution, namely, there is no C5H10 at state points 11 and 6 (the maximum molar concentration of C5H10 in liquid mixture of C5H10 and H2O was estimated to be very small, about 9.378 × 10−5%, by Peng-Robinson equation at 37 °C and 70.2 kPa, which is similar to the design condition at state point 6); LiBr and HCOOK do not volatilize, namely, there is no LiBr (or HCOOK) at state point 4. Therefore, C5H10 can be considered insoluble in H2O.

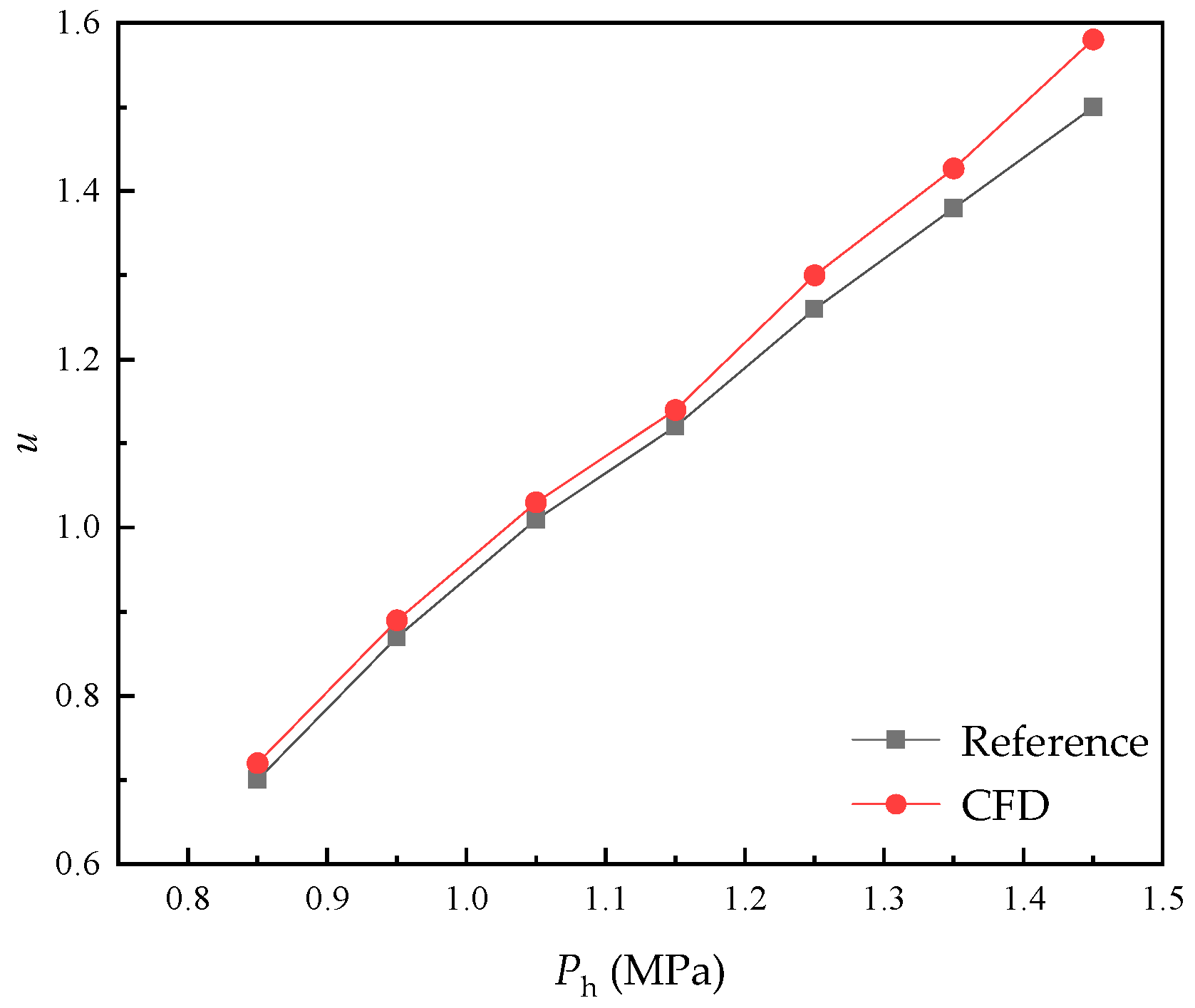

3.3. Validation of Jet Pump Flow Model

4. Results and Discussions

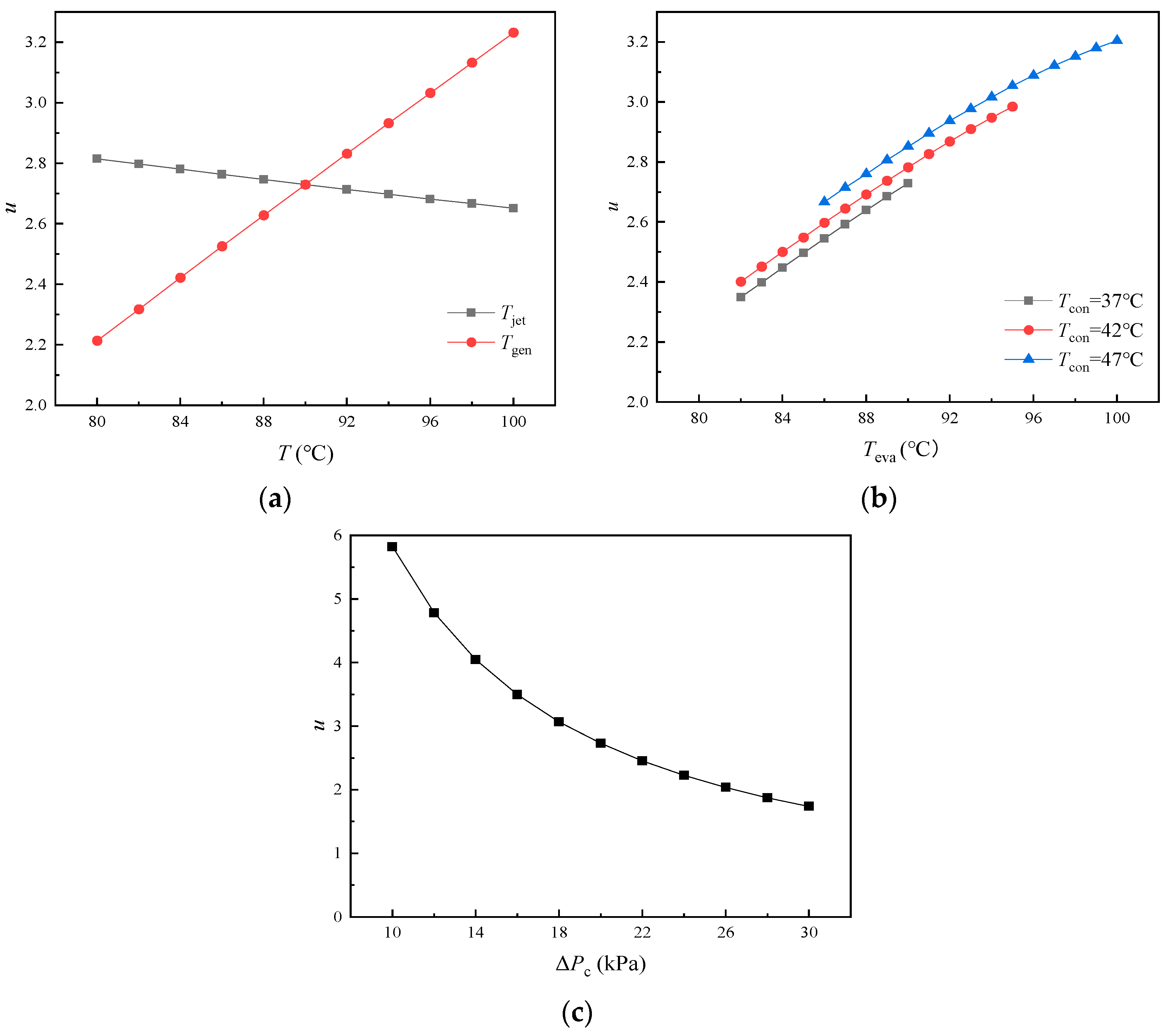

4.1. Effect of Temperature and Pressure Difference on u

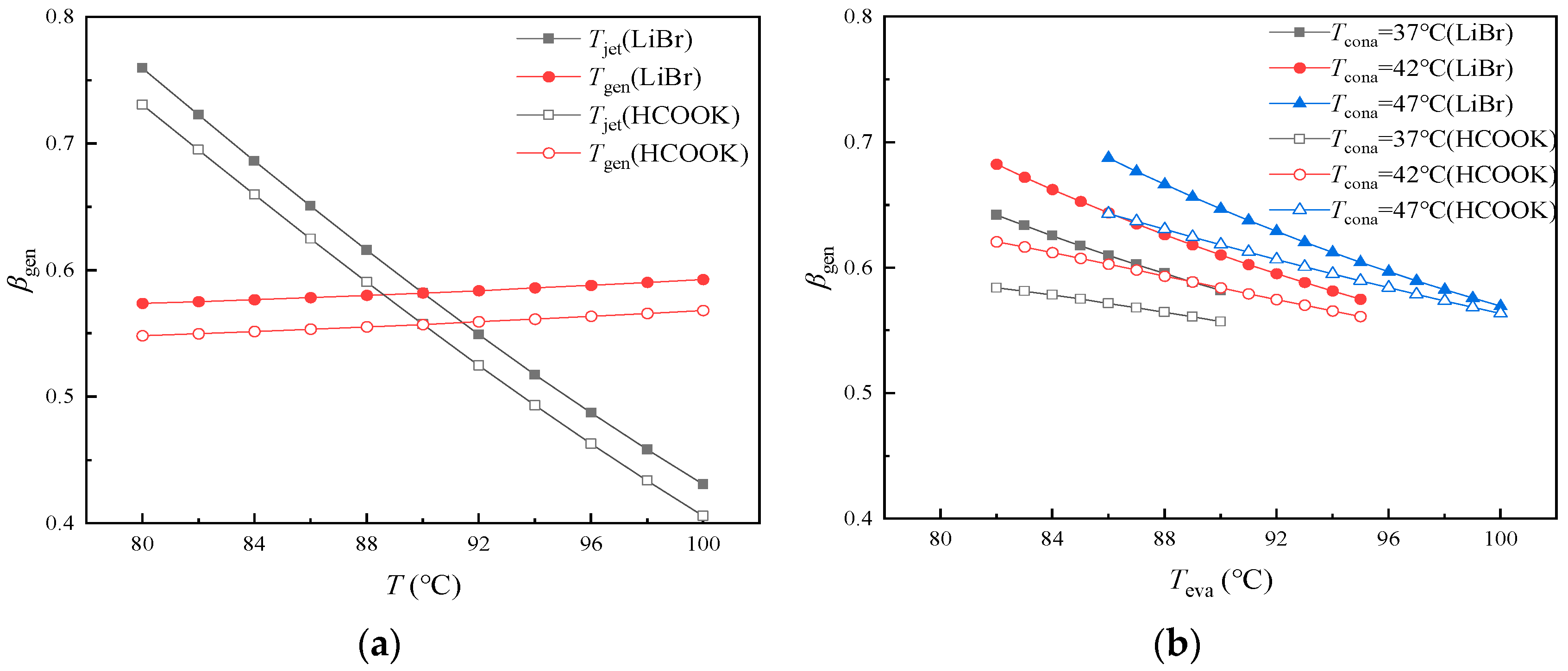

4.2. Effect of Temperature and Pressure Difference on βgen

4.3. Effect of Temperature and Pressure Difference on COP

5. Conclusions

- (1)

- High Tgen, Teva, and Tcona and low Tjet were conducive to the improvement of u, and u was more sensitive to the change in Tgen and Teva, while the change in Tabs and Tconb had almost no effect on u. High Tjet and Teva and low Tgen, Tcona, and Tabs were conducive to reducing βgen, and βgen was more sensitive to the change in Tjet and Tabs, while the change in Tconb had little effect on βgen. COP could also be improved at high Tjet and Teva and low Tcona and Tabs. COP was obviously influenced by the change in Tjet and Tabs but was hardly influenced by the change in Tconb and Tgen.

- (2)

- With the increase in ΔPc in a range of 10 kPa to 30 kPa, u decreased rapidly first but then decreased more and more slowly, βgen decreased slightly first and then increased slightly, and COP increased first and then decreased slightly.

- (3)

- When HCOOK is used as the absorbent as a substitute for LiBr, u is hardly affected. In most cases, βgen is reduced and COP is improved. COP with HCOOK is only slightly smaller than that with LiBr at high Tjet and Teva and low Tabs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations: | |

| AHT | Absorption Heat Transformer |

| CFD | Computational Fluid Dynamics |

| COP | Coefficient of Performance |

| DAHT | Diffusion Absorption Heat Transformer |

| DAR | Diffusion Absorption Refrigeration |

| Parameters: | |

| C | specific heat capacity (kJ/(kg∙°C) |

| f | cross-section area (m2) |

| h | specific enthalpy (kJ/kg) |

| m | mass flow (kg/s) |

| k | adiabatic exponential |

| P | static pressure (Pa) |

| q | converted mass velocity |

| Q | heat capacity (kW) |

| T | temperature (°C) |

| u | entrainment ratio |

| w | fluid velocity (m/s) |

| z | mass fraction of the absorbent in the solution |

| β | proportion of the input heat |

| ε | relative density |

| λ | converted isentropic velocity |

| Π | relative pressure |

| ρ | density (g/cm3) |

| φ | velocity coefficient |

| Subscripts: | |

| * | critical condition |

| abs | Absorber |

| cona | Condenser A |

| conb | Condenser B |

| eva | Evaporator |

| gen | Generator |

| jet | Jet Pump |

| p, h, c | primary flow, secondary flow, and mixed flow |

| 1, 2 … 15 | state points |

| I, II, III | cross-section |

References

- Rivera, W.; Best, R.; Cardoso, M.J.; Romero, R.J. A review of absorption heat transformers. Appl. Therm. Eng. 2015, 91, 654–670. [Google Scholar] [CrossRef]

- Cudok, F.; Giannetti, N.; Ciganda, J.L.C.; Aoyama, J.; Babu, P.; Coronas, A.; Fujii, T.; Inoue, N.; Saito, K.; Yamaguchi, S.; et al. Absorption heat transformer—State-of-the-art of industrial applications. Renew. Sustain. Energy Rev. 2021, 141, 110757. [Google Scholar] [CrossRef]

- Parham, K.; Khamooshi, M.; Tematio, D.B.K.; Yari, M.; Atikol, U. Absorption heat transformers—A comprehensive review. Renew. Sustain. Energy Rev. 2014, 34, 430–452. [Google Scholar] [CrossRef]

- Wang, X.; Shi, L.; Yin, J.; Zhu, M.S. A two-stage heat transformer with H2O/LiBr for the first stage and 2,2,2-trifluoroethanol (TFE)/N-methy1-2-pyrrolidone (NMP)for the second stage. Appl. Energy 2002, 71, 235–249. [Google Scholar] [CrossRef]

- Rivera, W.; Huicochea, A.; Romero, R.J.; Lozano, A. Experimental assessment of double-absorption heat transformer operating with H2O/LiBr. Appl. Therm. Eng. 2018, 132, 432–440. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, X.; Ma, X. Thermodynamic performance of a double-effect absorption heat-transformer using TFE/E181 as the working fluid. Appl. Energy 2005, 82, 107–116. [Google Scholar] [CrossRef]

- Shen, Z.; Li, S.; Feng, L.; Jin, Z.; Du, K.; Li, Y.; Sheng, W. Performance research of a solution cross-type absorption-resorption heat transformer using NH3/H2O work fluid. Appl. Therm. Eng. 2024, 246, 122874. [Google Scholar] [CrossRef]

- Jin, P.; Li, S.; Jin, Z.; Li, Y. Thermodynamic analysis of an ammonia-water double absorption-resorption heat transformer system. Appl. Therm. Eng. 2024, 247, 123130. [Google Scholar] [CrossRef]

- Tashtoush, B.M.; Al-Nimr, M.A.; Khasawneh, M.A. A comprehensive review of ejector design, performance, and applications. Appl. Energy 2019, 240, 138–172. [Google Scholar] [CrossRef]

- Yadav, S.K.; Pandey, K.M.; Gupta, R. Recent advances on principles of working of ejectors: A review. Mater. Today Proc. 2021, 45, 6298–6305. [Google Scholar] [CrossRef]

- Shi, L.; Yin, J.; Wang, X.; Zhu, M.S. Study on a new ejection-absorption heat transformer. Appl. Energy 2001, 68, 161–171. [Google Scholar] [CrossRef]

- Sozen, A.; Arcaklioglu, E.; Ozalp, M.; Yucesu, S. Performance parameters of an ejector-absorption heat transformer. Appl. Energy 2005, 80, 273–289. [Google Scholar] [CrossRef]

- Sozen, A.; Arcaklioglu, E. Exergy analysis of an ejector-absorption heat transformer using artificial neural network approach. Appl. Therm. Eng. 2007, 27, 481–491. [Google Scholar] [CrossRef]

- Lin, S.; Chen, G.; Hong, D.; Yan, X.; Lin, W. Theoretical analysis of an ejection H2O-LiBr absorption heat transformer. Cryogenics 2012, 185, 19–24. [Google Scholar]

- Wang, Z.; Yang, B. Performance analysis of a novel ejector-absorption heat transformer. J. Eng. Therm. Energy Power 2016, 31, 29–33. [Google Scholar]

- Eriksson, K.; Jernqvist, A. Heat transformer with self-circulation: Design and preliminary operational data. Int. J. Refrig. 1998, 12, 15–20. [Google Scholar] [CrossRef]

- Abrahamsson, K.; Gidner, A.; Jernqvist, A. Design and experimental performance evaluation of an absorption heat transformer with self-circulation. Heat Recovery Syst. Chp 1995, 15, 257–272. [Google Scholar] [CrossRef]

- Wang, Q.; Gong, L.; Chen, G.M.; Hao, N.; Sun, S.F. A Double Bubble Pump Diffusion Absorption Heat Transformer. Chinese Patent CN102121762A, 4 July 2012. [Google Scholar]

- Wang, Q.; Liu, Y.; Luo, J.; Wang, S.; Tang, J.; Xu, X.; Chen, G. Theoretical investigations on the cycle performance of a single-pressure diffusion absorption heat transformer with LiBr–H2O-R134a-TEGDME. J. Clean. Prod. 2020, 277, 123303. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Y.; Chen, Y.; Wang, Q.; Xu, X.; Chen, G.; Deng, S. Experimental investigations on the temperature lift performance of a novel diffusion absorption heat transformer. Energy 2019, 170, 906–914. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Y.; Wang, Q. Investigations on the Cycle Performance of a Diffusion Absorption Heat Transformer Using HCOOK as an Alternative to LiBr. J. Therm. Sci. Eng. Appl. 2022, 14, 091017. [Google Scholar] [CrossRef]

- Zheng, R. Experimental Studies on the Vapor Pressures of Working Fluids HCOOK+H2O and CaCl2+H2O for Absorption Heat Pumps. Master’s Thesis, Zhejiang University, Hangzhou, China, 2019. [Google Scholar]

- Liu, Y. Theoretical and Experimental Studies on the Diffusion Absorption Heat Transformer with H2O-CaCl2-R134a-TEGDME. Doctor’s Thesis, Zhejiang University, Hangzhou, China, 2022. [Google Scholar]

- Luo, J.; Yang, H. Investigations on a bubble-pump-aided diffusion absorption heat transformer using deep eutectic solvent for harvesting and upgrading thermal energy. Appl. Energy 2023, 340, 121069. [Google Scholar] [CrossRef]

- Wang, S.; Jiang, S.; Wu, Z.; Li, Y.; Gao, H. Investigation on the cycle performance of a novel diffusion absorption heat transformer with ejection boost. Therm. Sci. Eng. Prog. 2024, 48, 102423. [Google Scholar] [CrossRef]

- Sokoloff, Z. Ejector; Science Press: Beijing, China, 1997; pp. 181–192. [Google Scholar]

- García Del Valle, J.; Sierra-Pallares, J.; Garcia Carrascal, P.; Castro Ruiz, F. An experimental and computational study of the flow pattern in a refrigerant ejector. Validation of turbulence models and real-gas effects. Appl. Therm. Eng. 2015, 89, 795–811. [Google Scholar] [CrossRef]

- Croquer, S.; Poncet, S.; Aidoun, Z. Turbulence modeling of a single-phase R134a supersonic ejector.Part l: Numerical benchmark. Int. J. Refrig. 2016, 61, 140–152. [Google Scholar] [CrossRef]

- Gu, P. Feasibility Study on Crude Oil Lifting Technology of Air Ejector. Master’s Thesis, Xi’an Shiyou University, Xi’an, China, 2018. [Google Scholar]

- Pátek, J.; Klomfar, J. A computationally effective formulation of the thermodynamic properties of LiBr–H2O solutions from 273 to 500K over full composition range. Int. J. Refrig. 2006, 29, 566–578. [Google Scholar] [CrossRef]

- Elmer, T. A Novel SOFC Tri-Generation System for Building Applications; Springer International Publishing: Cham, Switzerland, 2017; pp. 63–69. [Google Scholar]

| Component | Conservation Equation |

|---|---|

| Generator | |

| Jet Pump (heat exchange chamber) | |

| Separator A | |

| Condenser A | |

| Separator B | |

| Condenser B | |

| Evaporator | |

| Absorber | |

| Solution Heat Exchanger |

| Parameter | Value |

|---|---|

| Generator temperature Tgen (°C) | 90 |

| Jet Pump temperature Tjet (°C) | 90 |

| Evaporator temperature Teva (°C) | 90 |

| Condenser A temperature Tcona (°C) | 37 |

| Condenser B temperature Tconb (°C) | 30 |

| Absorber temperature Tabs (°C) | 120 |

| Pressure difference ΔPc (kPa) | 20 |

| Parameter | Value |

|---|---|

| Primary flow temperature Tp (°C) | 90.0 |

| Primary flow pressure Pp (kPa) | 358.4 |

| Secondary flow temperature Th (°C) | 96.2 |

| Secondary flow pressure Ph (kPa) | 50.2 |

| Mixed flow pressure Pc (kPa) | 70.2 |

| Compression ratio Πc | 1.4 |

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| H2O/LiBr | |||||

| m1 (kg/s) | 0.100 | m10 (kg/s) | 0.273 | m3 (kg/s) | 0.265 |

| m6 (kg/s) | 0.008 | z10 | 0.4935 | z11 | 0.5088 |

| ρ10 (g/cm3) | 1.483 | C10 (kJ/(kg∙°C)) | 2.24 | Qabs (kW) | 16.3 |

| Qjet (kW) | 17.3 | Qgen (kW) | 52.7 | Qeva (kW) | 20.6 |

| Qcona (kW) | 28.2 | Qconb (kW) | 46.1 | ||

| H2O/HCOOK | |||||

| m1 (kg/s) | 0.100 | m10 (kg/s) | 0.273 | m3 (kg/s) | 0.264 |

| m6 (kg/s) | 0.009 | z10 | 0.7004 | z11 | 0.7252 |

| ρ10 (g/cm3) | 1.416 | C10 (kJ/(kg∙°C)) | 2.14 | Qabs (kW) | 17.3 |

| Qjet (kW) | 18.3 | Qgen (kW) | 52.5 | Qeva (kW) | 23.5 |

| Qcona (kW) | 31.1 | Qconb (kW) | 46.0 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Wu, Z.; Jiang, S.; Li, Y.; Gao, H. Theoretical Performance Study of a Novel Diffusion Absorption Heat Transformer Driven by a Jet Pump. Energies 2025, 18, 2971. https://doi.org/10.3390/en18112971

Wang S, Wu Z, Jiang S, Li Y, Gao H. Theoretical Performance Study of a Novel Diffusion Absorption Heat Transformer Driven by a Jet Pump. Energies. 2025; 18(11):2971. https://doi.org/10.3390/en18112971

Chicago/Turabian StyleWang, Shikuan, Zhaojie Wu, Shaoqiu Jiang, Yuncheng Li, and Hongtao Gao. 2025. "Theoretical Performance Study of a Novel Diffusion Absorption Heat Transformer Driven by a Jet Pump" Energies 18, no. 11: 2971. https://doi.org/10.3390/en18112971

APA StyleWang, S., Wu, Z., Jiang, S., Li, Y., & Gao, H. (2025). Theoretical Performance Study of a Novel Diffusion Absorption Heat Transformer Driven by a Jet Pump. Energies, 18(11), 2971. https://doi.org/10.3390/en18112971