Effect of Improved Combustion Chamber Design and Biodiesel Blending on the Performance and Emissions of a Diesel Engine

Abstract

1. Introduction

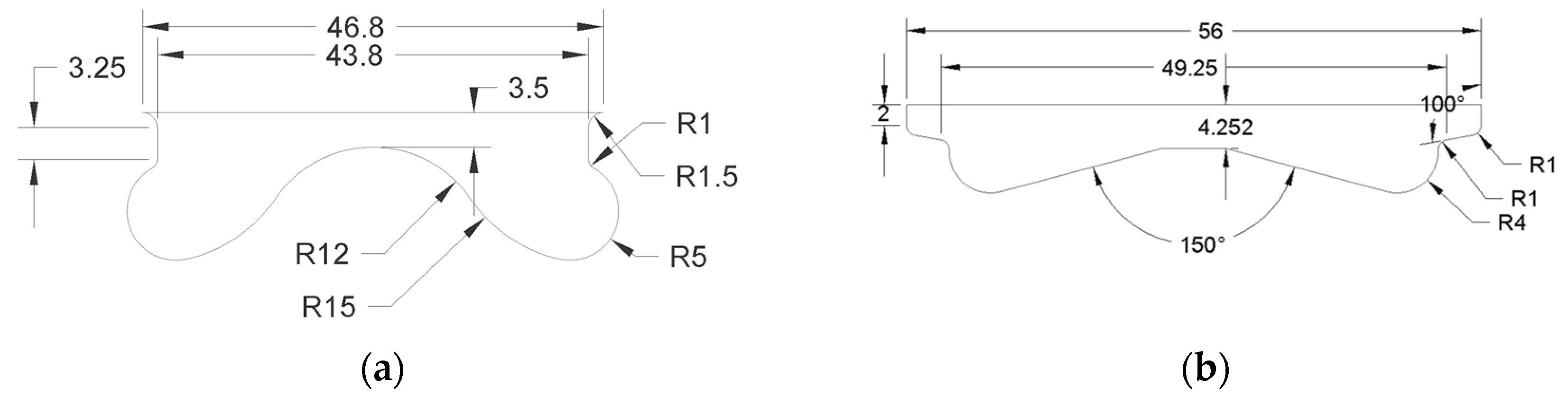

2. Materials and Methods

2.1. Simulation Model Parameter Settings

2.2. Test Oils

2.3. Simulation Model and Methodology

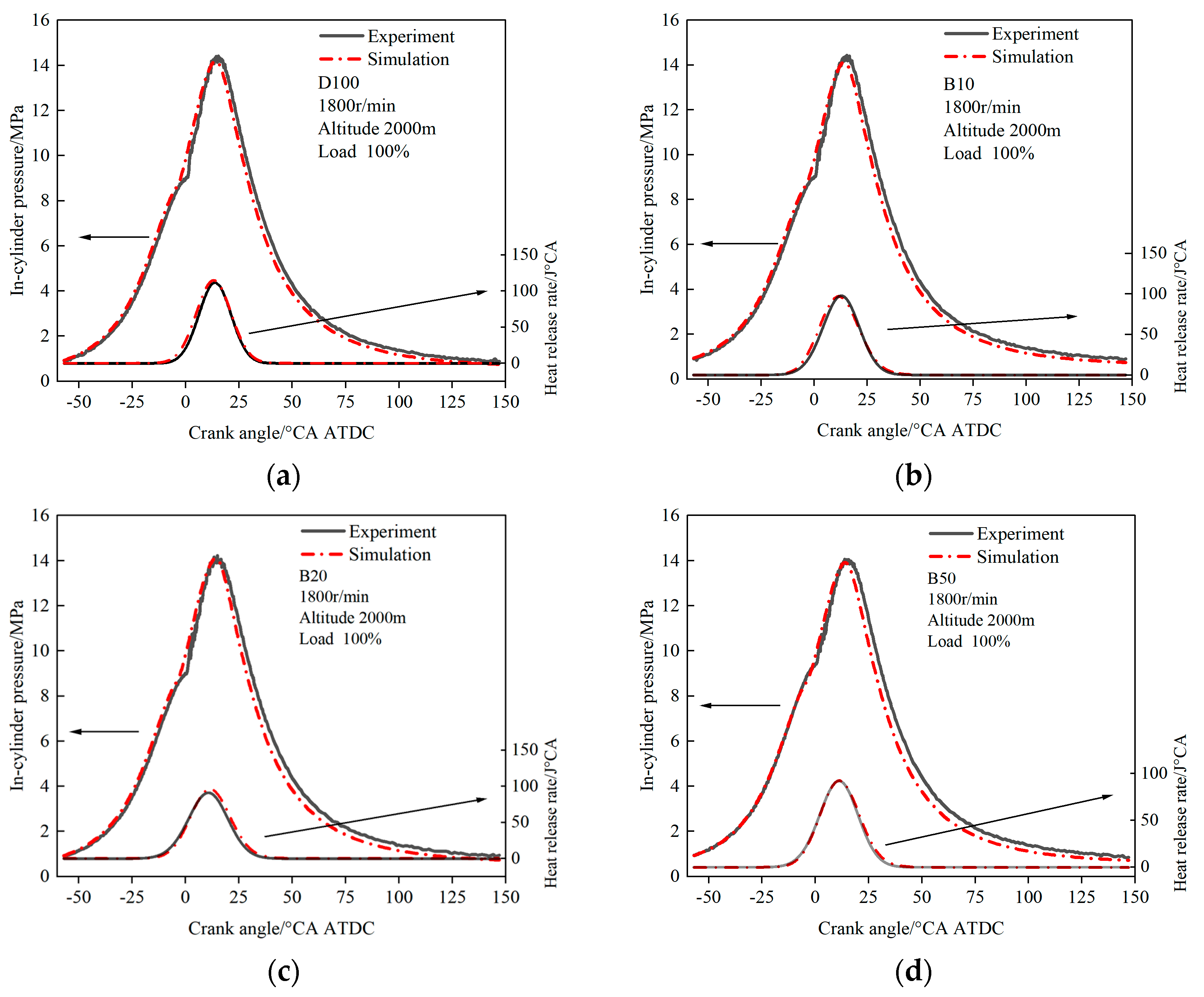

2.4. Validation of the Model

3. Results and Discussion

3.1. Combustion Characteristics

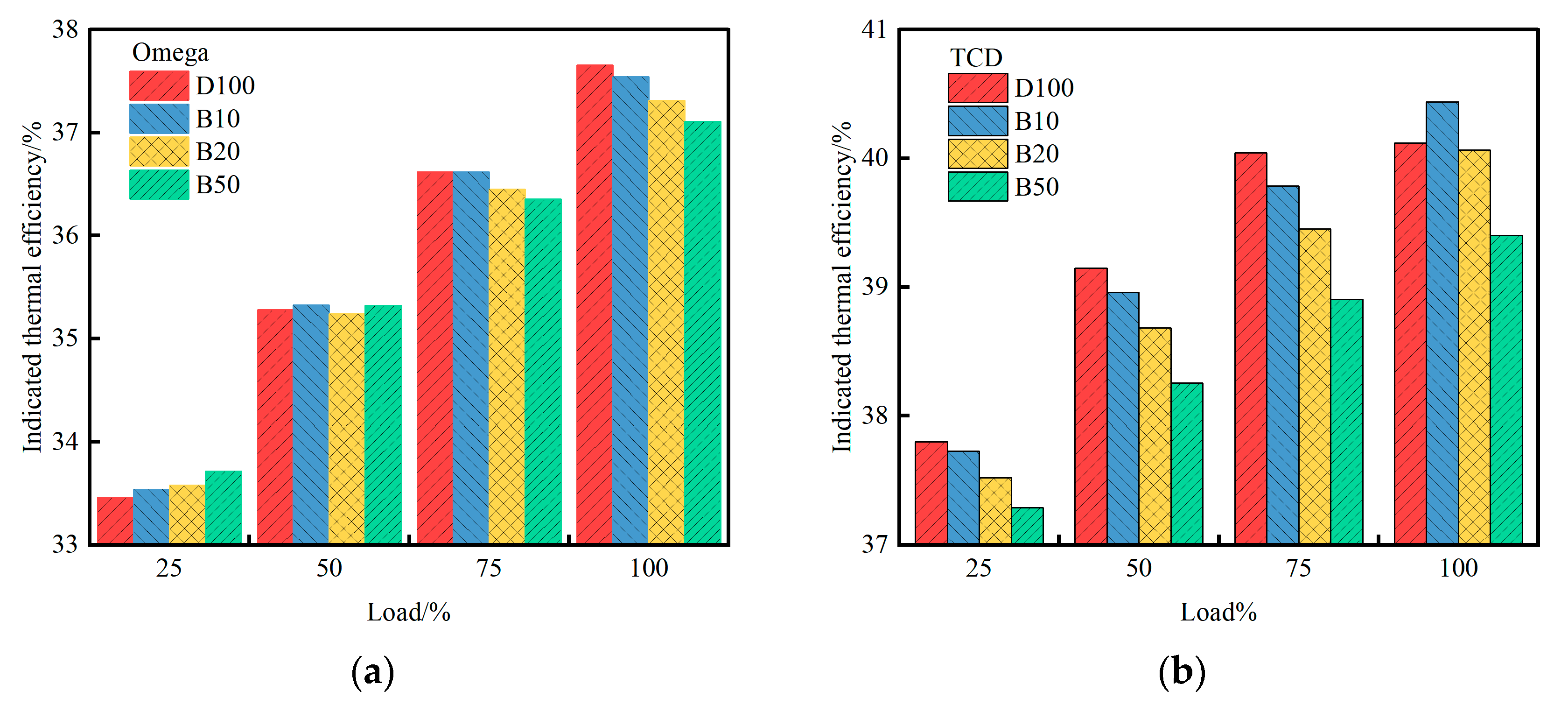

3.1.1. Indicative Thermal Efficiency

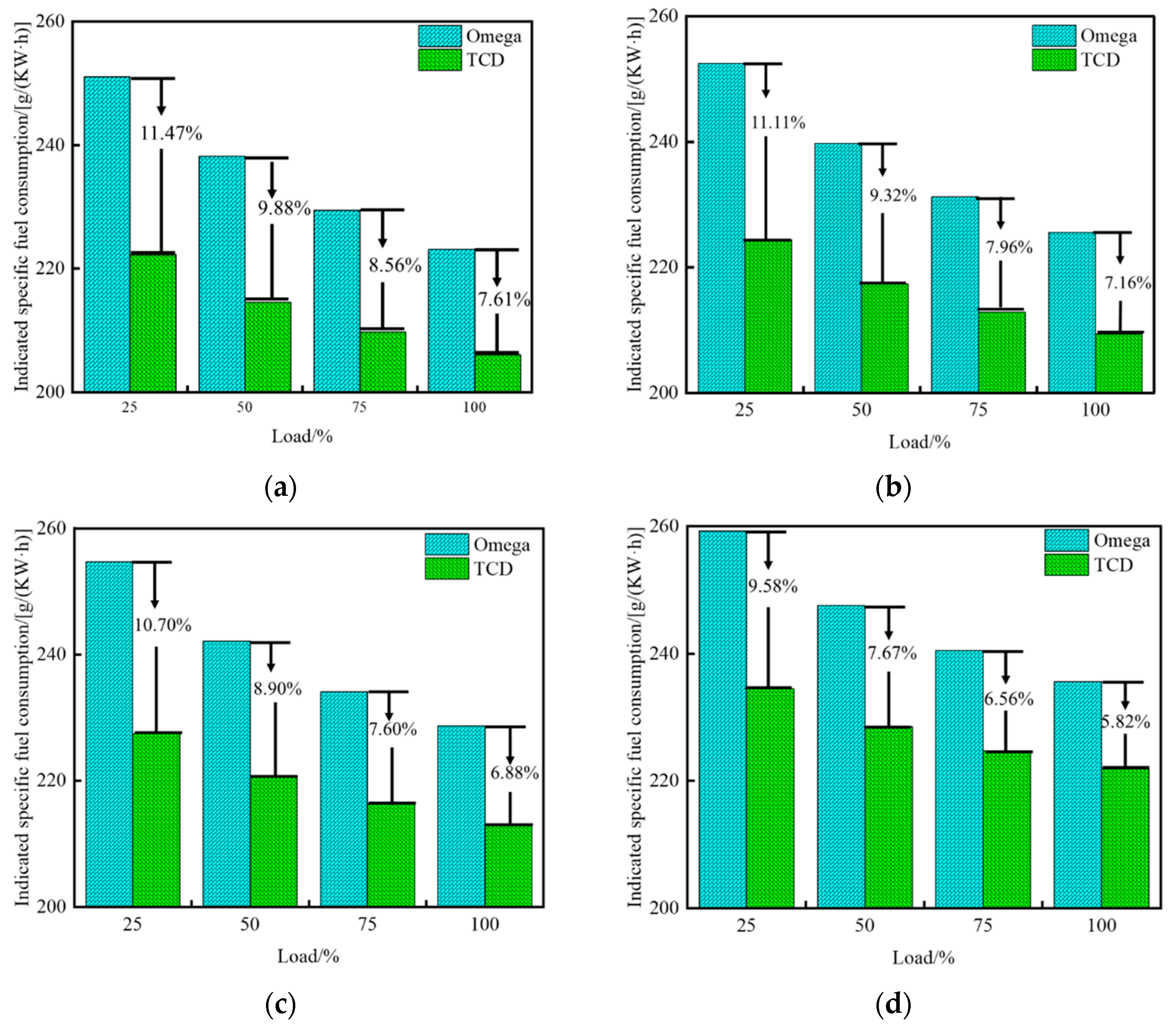

3.1.2. Indicated Specific Fuel Consumption

3.1.3. In-Cylinder Pressure

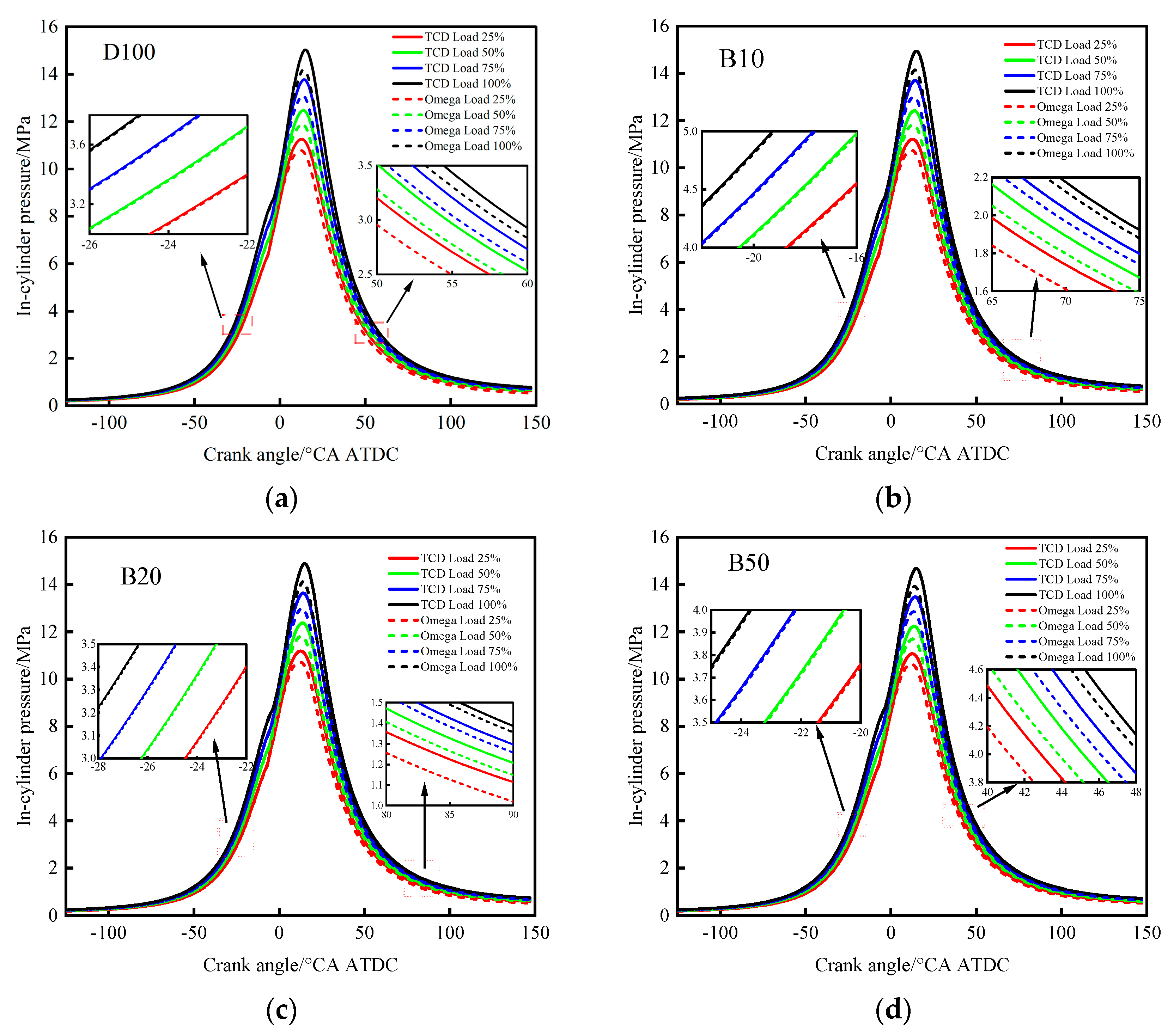

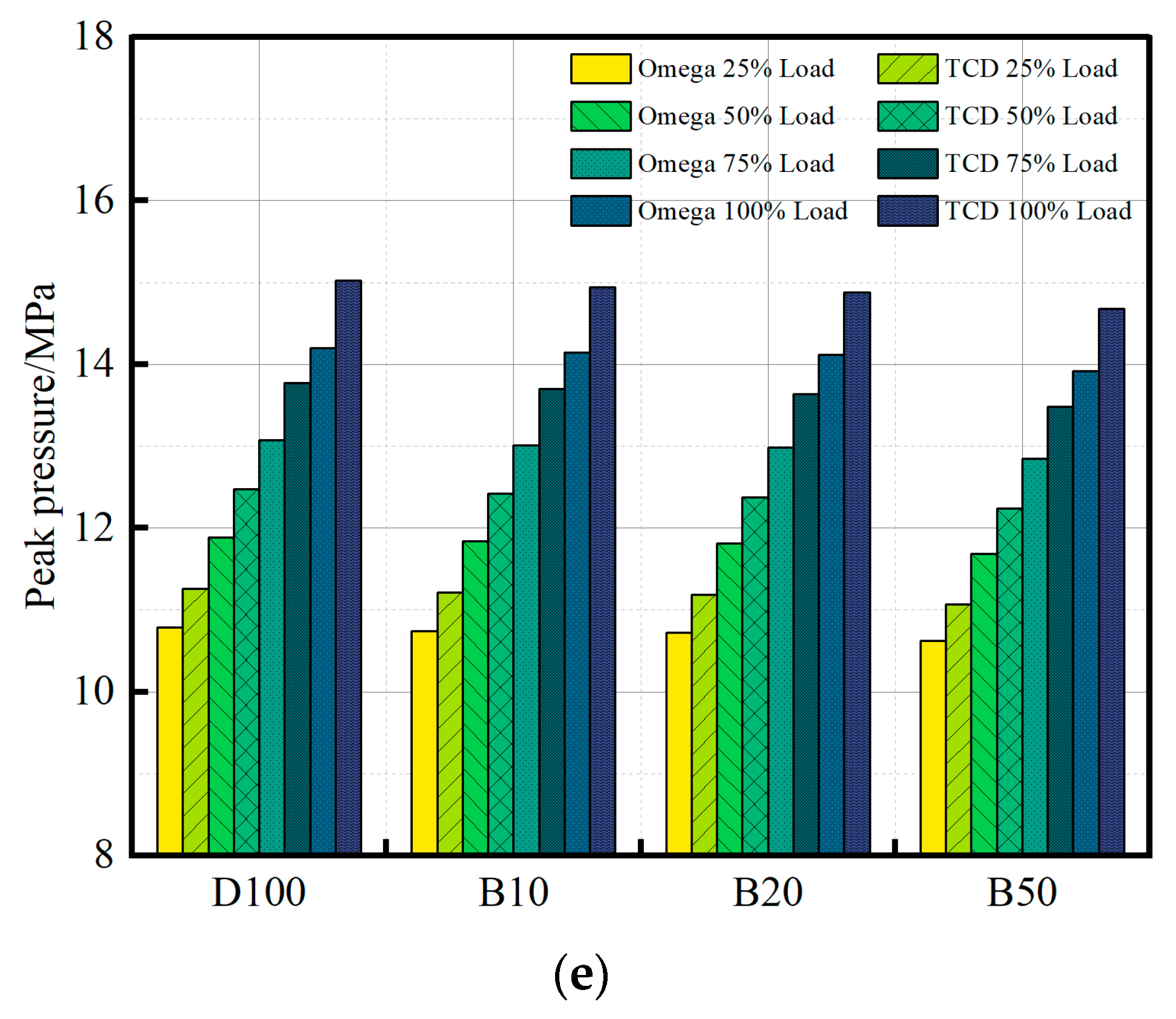

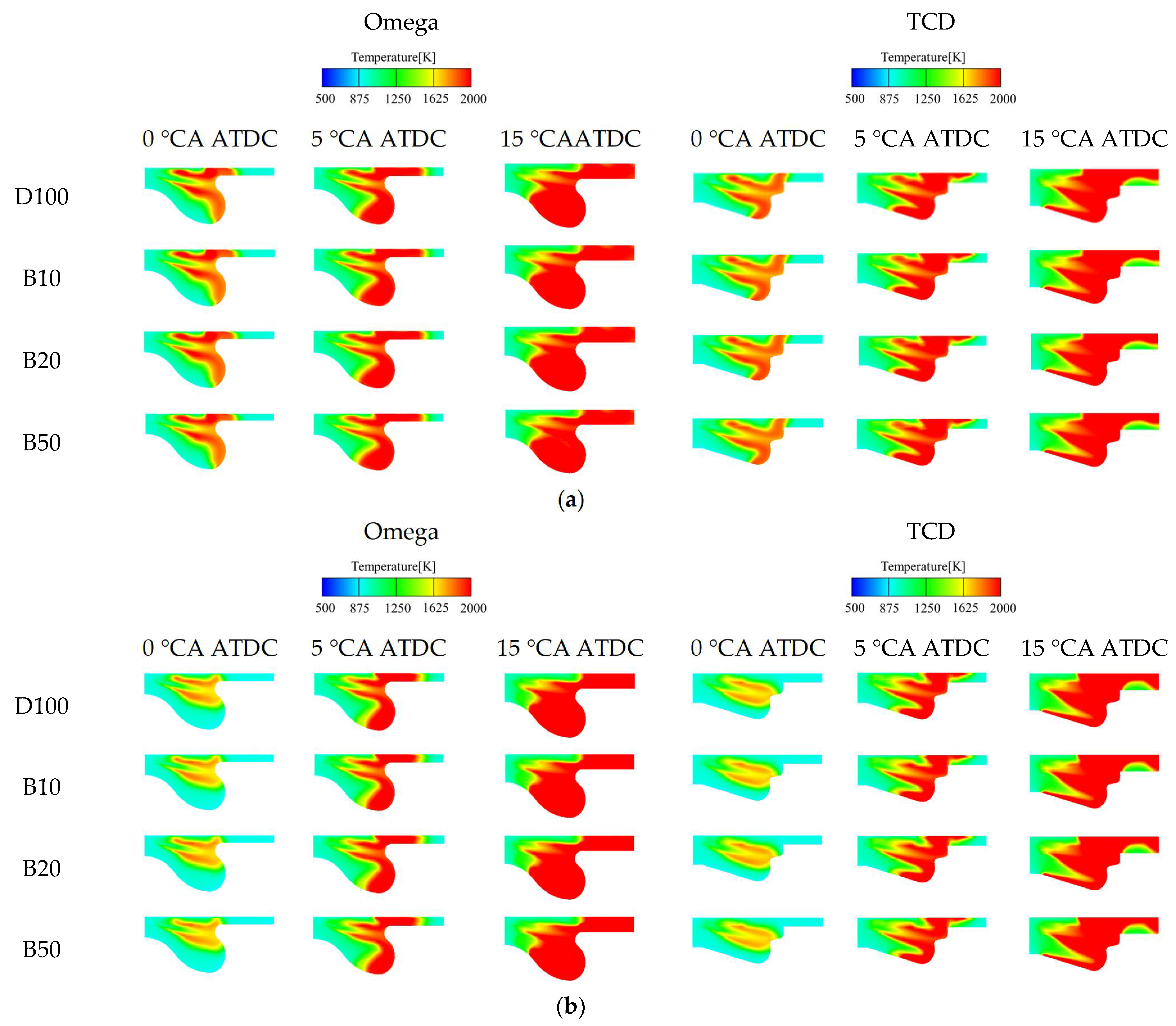

3.1.4. In-Cylinder Temperature

3.2. Emission Characteristics

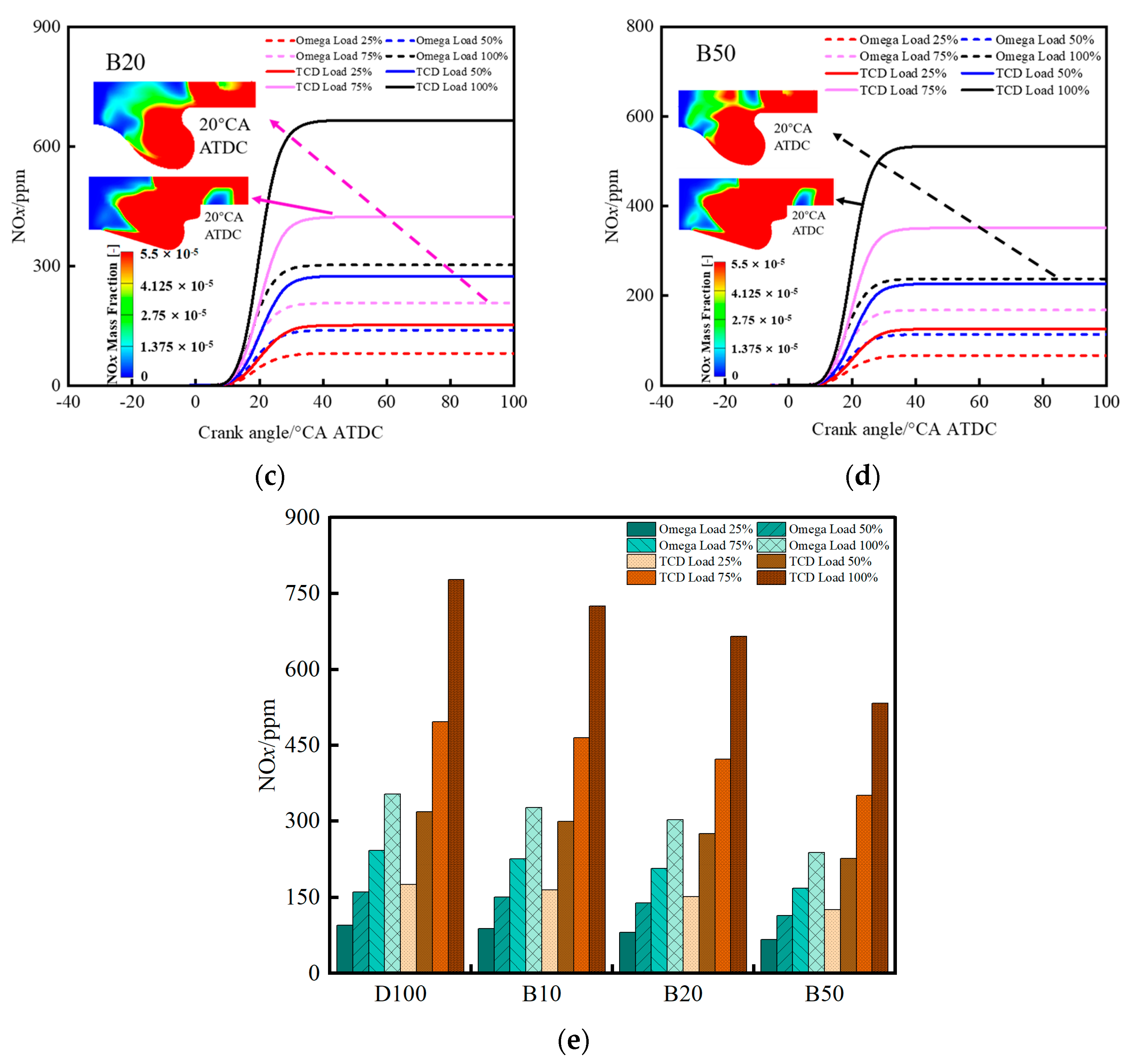

3.2.1. NOx Emissions

3.2.2. Soot Emissions

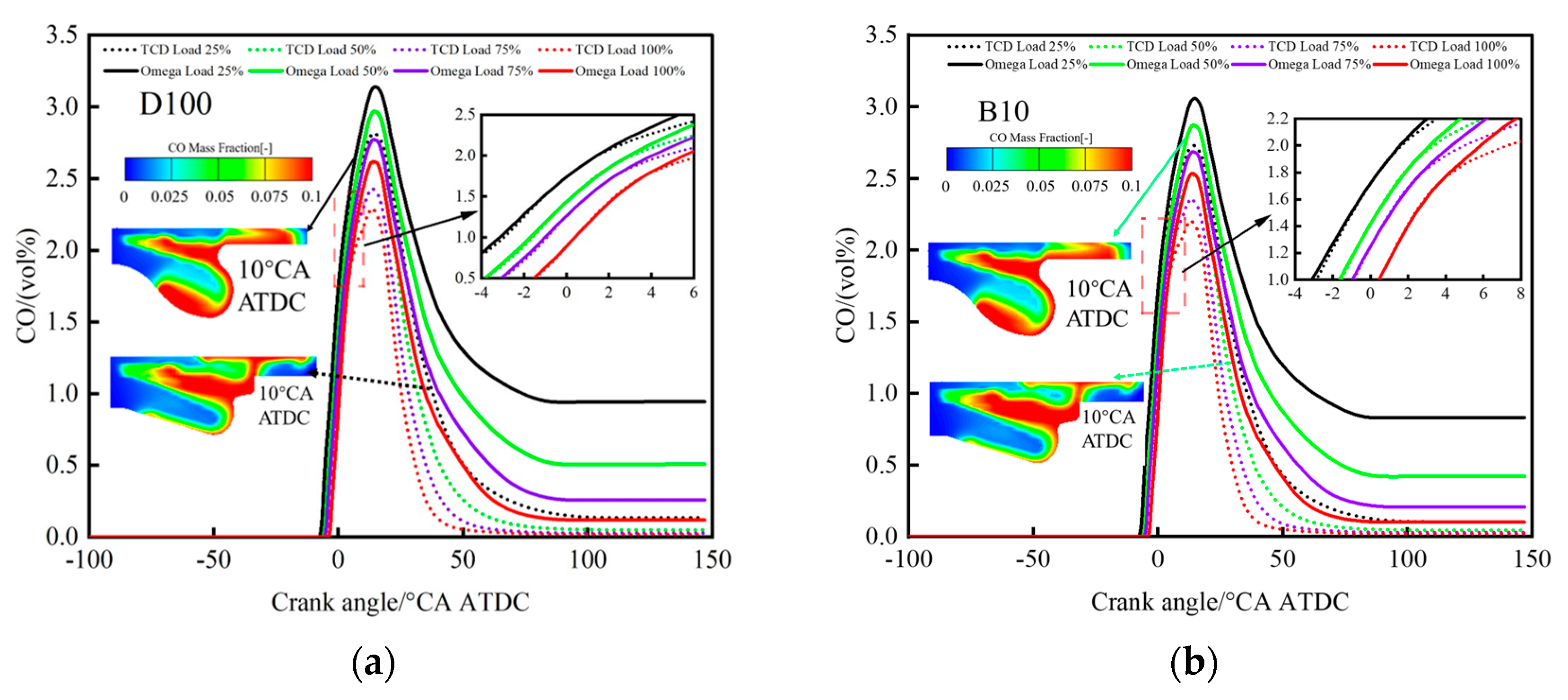

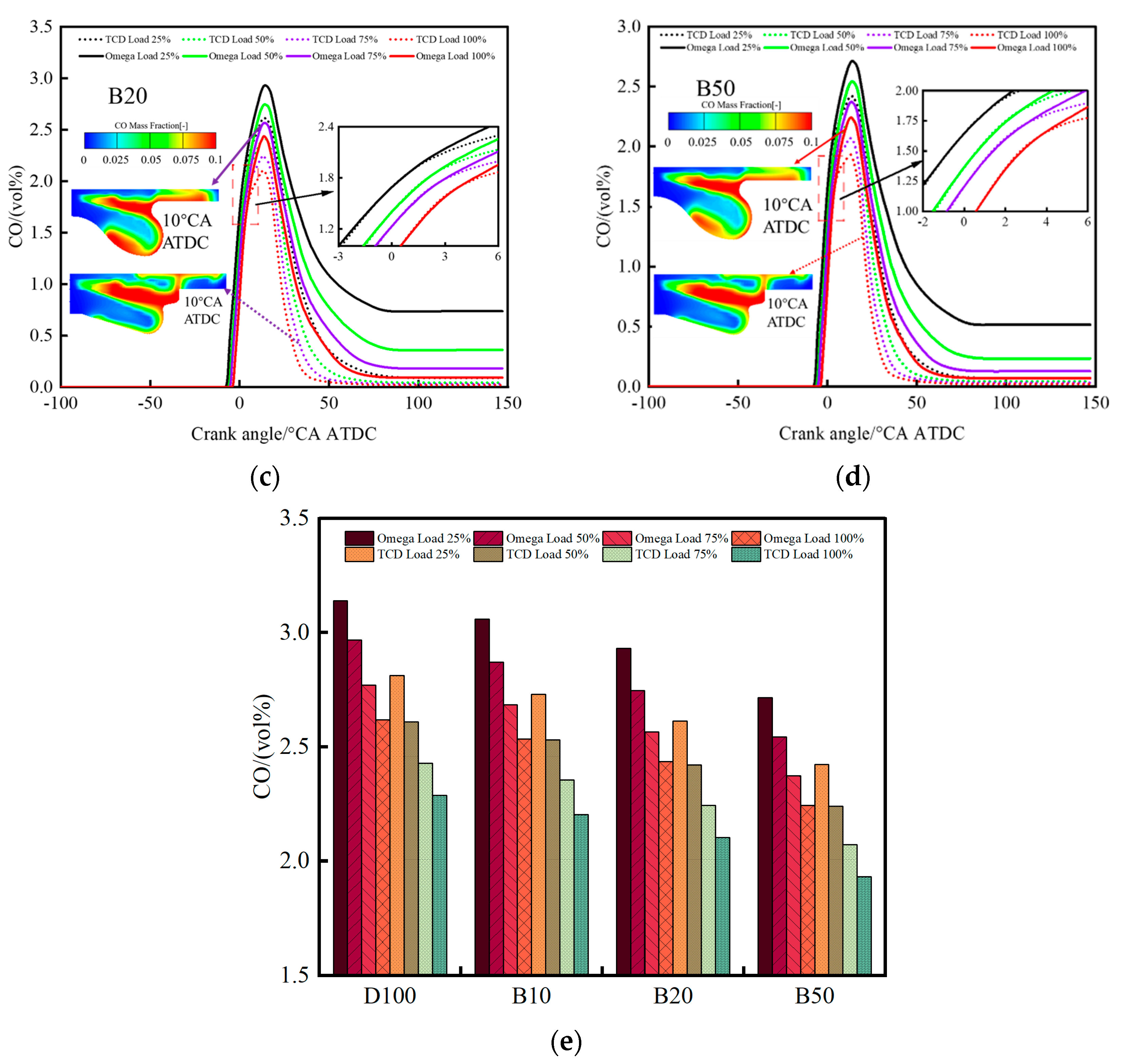

3.2.3. CO Emissions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| TCD | Turbocharger, charge air cooling, diesel particle filter |

| B10 | A blend of 10% biodiesel and 90% diesel by volume |

| B20 | A blend of 20% biodiesel and 80% diesel by volume |

| B50 | A blend of 50% biodiesel and 50% diesel by volume |

| D100 | 100% diesel by volume |

| ITE | Indicated thermal efficiency |

| ISFC | Indicated specific fuel consumption |

| DME | Dimethyl ether |

| BTE | Brake thermal efficiency |

| TRCC | Toroidal Re-entrant Combustion Chamber |

| HCC | Hemispherical Combustion Chamber |

| TCC | Toroidal Combustion Chamber |

| HPB | Hemispherical piston bowl |

| RPB | Re-entrant piston bowl |

| LSPB | Lateral swirl piston bowl |

| DSPB | Dual swirl piston bowl |

| LDSPB | Lateral and dual swirl piston bowl |

| FSCS | Forced swirl combustion system |

| MSCS | Multi-swirl combustion system |

| CFD | Computational fluid dynamics |

| ATDC | After top dead center |

| TDC | Top dead center |

References

- Shao, J.; Huang, S.; Lemus-Aguilar, I.; Ünal, E. Circular Business Models Generation for Automobile Remanufacturing Industry in China: Barriers and Opportunities. J. Manuf. Technol. Manag. 2019, 31, 542–571. [Google Scholar] [CrossRef]

- Wang, K.-H.; Su, C.-W.; Xiao, Y.; Liu, L. Is the Oil Price a Barometer of China’s Automobile Market? From a Wavelet-Based Quantile-on-Quantile Regression Perspective. Energy 2022, 240, 122501. [Google Scholar] [CrossRef]

- Sathiyamoorthi, E.; Lee, J.; Ramesh, M.D.; Nguyen, N.D.; Shanmuganathan, R. Biodiesel Production from Eggshells Derived Bio-Nano CaO Catalyst–Microemulsion Fuel Blends for up-Gradation of Biodiesel. Environ. Res. 2024, 260, 119626. [Google Scholar] [CrossRef]

- Li, W.; Liu, S.; Lu, C. An Evaluation Concentrated on Post-Peak Carbon Trend Scenarios Designing and Carbon Neutral Pathways in Hebei Province, China. J. Clean. Prod. 2024, 441, 140952. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W. The Impact of Ammonia and Hydrogen Additives on the Combustion Characteristics, Performance, Stability and Emissions of an Industrial DF Diesel Engine. Appl. Therm. Eng. 2024, 257, 124189. [Google Scholar] [CrossRef]

- Hu, R.; Cai, T.; Xu, W. Exploring the Technology Changes of New Energy Vehicles in China: Evolution and Trends. Comput. Ind. Eng. 2024, 191, 110178. [Google Scholar] [CrossRef]

- Rasul, M.J.M.A.; Kim, J. Comprehensive Review and Comparison on Battery Technologies as Electric-Powered Source in Marine Applications. J. Energy Storage 2024, 88, 111509. [Google Scholar] [CrossRef]

- Hivert, L. Short-Term Break in the French Love for Diesel? Energy Policy 2013, 54, 11–22. [Google Scholar] [CrossRef]

- Hao, C.; Zhang, Z.; Wang, Z.; Bai, H.; Li, Y.; Li, Y.; Lu, Z. Investigation of Spray Angle and Combustion Chamber Geometry to Improve Combustion Performance at Full Load on a Heavy-Duty Diesel Engine Using Genetic Algorithm. Energy Convers. Manag. 2022, 267, 115862. [Google Scholar] [CrossRef]

- Wojcieszyk, M.; Kroyan, Y.; Kaario, O.; Larmi, M. Prediction of Heavy-Duty Engine Performance for Renewable Fuels Based on Fuel Property Characteristics. Energy 2023, 285, 129494. [Google Scholar] [CrossRef]

- Yuksel, T. Experimental Investigation of the Emission and Performance of Preheated and Unheated Garlic Methyl Ester Fuels and Diesel Fuel in a Diesel Engine. Process Saf. Environ. Prot. 2024, 185, 239–255. [Google Scholar] [CrossRef]

- Prak, D.L.; Cowart, J. Physical Properties and Diesel Engine Combustion of Blends of Alcohols with Military Jet Fuel JP-5. Fuel 2024, 371, 132070. [Google Scholar] [CrossRef]

- Gülcan, H.E. Effect of Intake Valve Lift and Binary Alcohol (Bioethanol+isobutanol) Addition on Energy, Exergy, Sustainability, Greenhouse Gas Impact and Cost Analysis in a Hydrogen/Diesel Dual Fuel Engines. Int. J. Hydrogen Energy 2024, 77, 450–471. [Google Scholar] [CrossRef]

- Liu, J.; Guo, Q.; Guo, J.; Wang, F. Optimization of a Diesel/Natural Gas Dual Fuel Engine under Different Diesel Substitution Ratios. Fuel 2021, 305, 121522. [Google Scholar] [CrossRef]

- Guo, W.; Wang, H.; Chen, H.; Yu, B.; Wang, Y.; Zhao, J. Performance and Safety of Transport Vehicles Fueled with Alternative Fuels in Plateau Environment: A Review. J. Traffic Transp. Eng. Engl. Ed. 2022, 9, 930–944. [Google Scholar] [CrossRef]

- Temizer, I.; Cihan, O. An Experimental Investigation of New Chamber Geometry on the Combustion Characteristics, Performance and Emissions in a Light-Duty Diesel Engine. Fuel 2023, 345, 128160. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, Y.; Wang, J.; Tan, D.; Zhang, Z.; Yang, D. Effects of Different Biodiesel-Diesel Blend Fuel on Combustion and Emission Characteristics of a Diesel Engine. Processes 2021, 9, 1984. [Google Scholar] [CrossRef]

- Kawabe, T.; Inoue, K.; Mori, K.; Ishikawa, T.; Kobashi, Y.; Shibata, G.; Ogawa, H. Mechanism of the Reduction in Afterburning and Thermal Efficiency Improvement with Highly Oxygenated Fuels in Diesel Combustion. Int. J. Engine Res. 2023, 24, 4362–4372. [Google Scholar] [CrossRef]

- Ooi, J.B.; Rajanren, J.R.; Ismail, H.M.; Swamy, V.; Wang, X. Improving Combustion Characteristics of Diesel and Biodiesel Droplets by Graphite Oxide Addition for Diesel Engine Applications. Int. J. Energy Res. 2017, 41, 2258–2267. [Google Scholar] [CrossRef]

- Hao, Y.; Wang, G.; Wang, Q.; And, X.L. Numerical Simulation on Structural Optimization Design of Combustion Chamber of High Strength Diesel Engine. Energy Sources Part. Recovery Util. Environ. Eff. 2022, 44, 9682–9702. [Google Scholar] [CrossRef]

- Zou, R.; Liu, J.; Jiao, H.; Zhao, J.; Wang, N. Combined Effect of Intake Angle and Chamber Structure on Flow Field and Combustion Process in a Small-Scaled Rotary Engine. Appl. Therm. Eng. 2022, 203, 117652. [Google Scholar] [CrossRef]

- Chen, Y.; Li, X.; Li, X.; Zhao, W.; Liu, F. The Wall-Flow-Guided and Interferential Interactions of the Lateral Swirl Combustion System for Improving the Fuel/Air Mixing and Combustion Performance in DI Diesel Engines. Energy 2019, 166, 690–700. [Google Scholar] [CrossRef]

- Chen, Y.; Li, X.; Li, X.; Zhao, W.; Liu, F. Verifying the Wall-Flow-Guided Assumption of the Lateral Swirl Combustion System in DI Diesel Engines. Fuel 2020, 266, 117079. [Google Scholar] [CrossRef]

- Jaffar Al-Mulla, E.A.; Issam, A.M.; Al-Janabi, K.W.S. A Novel Method for the Synthesis of Biodiesel from Soybean Oil and Urea. Comptes Rendus Chim. 2015, 18, 525–529. [Google Scholar] [CrossRef]

- de Araújo, C.D.M.; de Andrade, C.C.; e Silva, E.D.S.; Dupas, F.A. Biodiesel Production from Used Cooking Oil: A Review. Renew. Sustain. Energy Rev. 2013, 27, 445–452. [Google Scholar] [CrossRef]

- de Lima, A.L.; Ronconi, C.M.; Mota, C.J.A. Heterogeneous Basic Catalysts for Biodiesel Production. Catal. Sci. Technol. 2016, 6, 2877–2891. [Google Scholar] [CrossRef]

- Kalam, M.A.; Masjuki, H.H.; Jayed, M.H.; Liaquat, A.M. Emission and Performance Characteristics of an Indirect Ignition Diesel Engine Fuelled with Waste Cooking Oil. Energy 2011, 36, 397–402. [Google Scholar] [CrossRef]

- Tamrat, S.; Ancha, V.R.; Gopal, R.; Nallamothu, R.B. Study on the Effect of Dimethyl Ether and Diesel-Castor Biodiesel Blends on Emission and Combustion Characteristics. Fuel Commun. 2023, 17, 100098. [Google Scholar] [CrossRef]

- Babu, A.R.; Jeyandan, A.; Kumar, K.M.; Logesh, K.; Rayudu, J.V.; And, G.S.D.M. Experimental Investigation on the Performance and Emission Characteristics of CI Engine Using Waste Cotton Seed Biodiesel with ZNO as a Fuel Additive. Int. J. Ambient. Energy 2020, 41, 669–673. [Google Scholar] [CrossRef]

- Martin, M.L.J.; Prithviraj, D.; Velappan, K. Performance and Emission Characteristics of a CI Engine Fueled with Esterified Cottonseed Oil; SAE Technical Paper; SAE: Warrendale, PA, USA, 2005. [Google Scholar]

- Udayakumar, P.; Kasiraman, G. Performance and Emission of Ci Engine Fueled by Turpentine and Cottonseed Oil Blends at Various Injection Pressures. IOP Conf. Ser. Mater. Sci. Eng. 2020, 912, 42081. [Google Scholar] [CrossRef]

- Khandal, S.; Razak, A.; Veza, I.; Afzal, A.; Alwetaishi, M.; Shaik, S.; Ağbulut, Ü.; Rashedi, A. Hydrogen and Dual Fuel Mode Performing in Engine with Different Combustion Chamber Shapes: Modelling and Analysis Using RSM-ANN Technique. Int. J. Hydrogen Energy 2024, 52, 973–1005. [Google Scholar] [CrossRef]

- Gao, S.; Zhang, Y.; Zhang, Z.; Tan, D.; Li, J.; Yin, Z.; Hu, J.; Zhao, Z. Multi-Objective Optimization of the Combustion Chamber Geometry for a Highland Diesel Engine Fueled with Diesel/n-Butanol/PODEn by ANN-NSGA III. Energy 2023, 282, 128793. [Google Scholar] [CrossRef]

- Jyothi, U.; Reddy, K.V. Experimental Study on Performance, Combustion and Emissions of Diesel Engine with Re-Entrant Combustion Chamber of Aluminum Alloy. Mater. Today Proc. 2017, 4, 1332–1339. [Google Scholar] [CrossRef]

- Yaliwal, V.; Gaddigoudar, P.; Akki, S.; Devadas, V.; Jalihal, S.; Prasad, M.; Timmanagoudar, S.; Halewadimath, S.; Banapurmath, N. Influence of Piston Bowl Geometry on the Performance and Emission Characteristics of a Diesel Engine Operated on Single Fuel Mode Using Dairy Scum Oil Biodiesel. Mater. Today Proc. 2022, 52, 1223–1227. [Google Scholar] [CrossRef]

- Su, L.; Li, X.; Zhang, Z.; Liu, F. Numerical Analysis on the Combustion and Emission Characteristics of Forced Swirl Combustion System for DI Diesel Engines. Energy Convers. Manag. 2014, 86, 20–27. [Google Scholar] [CrossRef]

- Li, X.; Qiao, Z.; Su, L.; Li, X.; Liu, F. The Combustion and Emission Characteristics of a Multi-Swirl Combustion System in a DI Diesel Engine. Appl. Therm. Eng. 2017, 115, 1203–1212. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, J.; Guo, X.; Liu, X. Multi-Objective Optimization of the Structural Design of a Combustion Chamber of a Small Agricultural Diesel Engine Fueled with B20 Blend Fuel at a High Altitude Area. Sustainability 2023, 15, 11617. [Google Scholar] [CrossRef]

- Behera, P.; Murugan, S.; Nagarajan, G. Dual Fuel Operation of Used Transformer Oil with Acetylene in a DI Diesel Engine. Energy Convers. Manag. 2014, 87, 840–847. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D.; Li, X.; Shi, B.; Li, J. Mitigating NOx Emissions from an Ammonia-Fueled Micro-Power System with a Perforated Plate Implemented. J. Hazard. Mater. 2021, 401, 123848. [Google Scholar] [CrossRef]

- Ou, X.; Xiaoyu, Y.; Zhang, X. Life-Cycle Energy Consumption and Greenhouse Gas Emissions for Electricity Generation and Supply in China. Appl. Energy 2011, 88, 289–297. [Google Scholar] [CrossRef]

- Ou, X.; Yan, X.; Zhang, X.; Liu, Z. Life-Cycle Analysis on Energy Consumption and GHG Emission Intensities of Alternative Vehicle Fuels in China. Appl. Energy 2012, 90, 218–224. [Google Scholar] [CrossRef]

- Zareei, J.; Rohani, A.; Alvarez, J.R.N. The Effect of EGR and Hydrogen Addition to Natural Gas on Performance and Exhaust Emissions in a Diesel Engine by AVL Fire Multi-Domain Simulation, GPR Model, and Multi-Objective Genetic Algorithm. Int. J. Hydrogen Energy 2022, 47, 21565–21581. [Google Scholar] [CrossRef]

- Chen, Y.; Li, X.; Shi, S.; Zhao, Q.; Liu, D.; Chang, J.; Liu, F. Effects of Intake Swirl on the Fuel/Air Mixing and Combustion Performance in a Lateral Swirl Combustion System for Direct Injection Diesel Engines. Fuel 2021, 286, 119376. [Google Scholar] [CrossRef]

- Aldarwish, Z.; Aghkhani, M.H.; Sadrnia, H.; Zareei, J. Investigation of the Optimal Timing and Amount of Fuel Injection on the Efficiency and Emissions of a Diesel Engine through Experimentation and Numerical Analysis. Heliyon 2024, 10, e38790. [Google Scholar] [CrossRef] [PubMed]

- Santhosh, K.; Kumar, G.; Shahapur, S. The Effect of Tri-Fuel Blends on Engine Characteristics of a Direct Injection Diesel Engine with Exhaust Gas Recirculation. Energy Sources Part Recovery Util. Environ. Eff. 2022, 44, 1227–1249. [Google Scholar] [CrossRef]

- Chen, H.; Xie, B.; Ma, J.; Chen, Y. NOx Emission of Biodiesel Compared to Diesel: Higher or Lower? Appl. Therm. Eng. 2018, 137, 584–593. [Google Scholar] [CrossRef]

- Al-lwayzy, S.H.; Yusaf, T. Chlorella Protothecoides Microalgae as an Alternative Fuel for Tractor Diesel Engines. Energies 2013, 6, 766–783. [Google Scholar] [CrossRef]

- Feng, R.; Yu, J.; Shu, X.; Deng, B.; Hua, Z. Can the World Harmonized Steady Cycle (WHSC) Accurately Reflect Real-World Driving Conditions for Heavy-Duty Diesel Engine Emission Valuations? A Comprehensive Experimental Study. Therm. Sci. Eng. Prog. 2025, 59, 103321. [Google Scholar] [CrossRef]

- Deng, B.; Cai, W.; Zhang, W.; Bian, L.; Che, X.; Xiang, Y.; Wu, D. A Comprehensive Investigation of EGR (Exhaust Gas Recirculation) Effects on Energy Distribution and Emissions of a Turbo-Charging Diesel Engine under World Harmonized Transient Cycle. Energy 2025, 316, 134506. [Google Scholar] [CrossRef]

- Knothe, G.; Sharp, C.A.; Ryan, T.W. Exhaust Emissions of Biodiesel, Petrodiesel, Neat Methyl Esters, and Alkanes in a New Technology Engine. Energy Fuels 2006, 20, 403–408. [Google Scholar] [CrossRef]

| Parameter | Numerical Value |

|---|---|

| Combustion chamber type | Direct injection ω-type combustion chamber |

| Bore × stroke (mm × mm) | 80 × 92 |

| Compression ratio | 16.5 |

| Calibration power/KW | 58 (2500 r/min) |

| Maximum torque/(N·m) | 265 (1800 r/min) |

| Number of spray holes | 6 |

| Hole diameter/mm | 0.122 |

| Injector hole angle/° | 156° |

| Parameter Name | Numerical |

|---|---|

| Initial pressure | 2.418 bar |

| Initial temperature | 340 K |

| Injection start—end moment | 353–378 °CA |

| Single-hole circulating oil injection volume | 9.55 mg |

| Clamping angle of oil bundle | 156° |

| Submodel Type | Select Model Name |

|---|---|

| Turbulence models | k-zeta-f Model |

| Spray model | Wave Model |

| Combustion model | ECFM-3Z Model |

| Soot generates models | Kinetic Model |

| NOx generation modeling | Extend Zeldovich Model |

| Fuel | Quality Indicators | ||||

|---|---|---|---|---|---|

| D100 | B100 | B10 | B20 | B50 | |

| Oxygen mass fraction/% | 0 | 10 | 1 | 2 | 5 |

| Lower heating value/MJ·kg−1 | 42.85 | 39.50 | 42.51 | 42.19 | 42.18 |

| Kinematic viscosity (40 °C)/mm2/s | 3.67 | 6.01 | 4.51 | 4.71 | 5.31 |

| Density (20 °C)/kg/m3 | 821.8 | 946.6 | 827.4 | 832.7 | 849.6 |

| Cetane number | 53.6 | 60.4 | 54.3 | 55.3 | 57.6 |

| Sulfur mass fraction/% | 0.0234 | 0.0013 | 0.0187 | 0.0143 | 0.0105 |

| Acidity/(mgKOH·(100 mL)−1) | 4.49 | 8.37 | 3.03 | 4.19 | 5.49 |

| Copper sheet corrosion (50 °C, 3 h)/level not more than | 1 | 1 | 1 | 1 | 1 |

| Flash point/° | 63 | 130 | 73 | 74 | 80 |

| Freezing point/° | −7 | −1 | −7 | −5 | −4 |

| Boiling point/° | 185 | 220 | 142 | 145 | 161 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Chen, Y.; He, C.; Wang, D.; Nie, Y.; Li, J. Effect of Improved Combustion Chamber Design and Biodiesel Blending on the Performance and Emissions of a Diesel Engine. Energies 2025, 18, 2956. https://doi.org/10.3390/en18112956

Wang Z, Chen Y, He C, Wang D, Nie Y, Li J. Effect of Improved Combustion Chamber Design and Biodiesel Blending on the Performance and Emissions of a Diesel Engine. Energies. 2025; 18(11):2956. https://doi.org/10.3390/en18112956

Chicago/Turabian StyleWang, Ziming, Yanlin Chen, Chao He, Dongge Wang, Yan Nie, and Jiaqiang Li. 2025. "Effect of Improved Combustion Chamber Design and Biodiesel Blending on the Performance and Emissions of a Diesel Engine" Energies 18, no. 11: 2956. https://doi.org/10.3390/en18112956

APA StyleWang, Z., Chen, Y., He, C., Wang, D., Nie, Y., & Li, J. (2025). Effect of Improved Combustion Chamber Design and Biodiesel Blending on the Performance and Emissions of a Diesel Engine. Energies, 18(11), 2956. https://doi.org/10.3390/en18112956