An Integrated Building Energy Model in MATLAB

Abstract

1. Introduction

- -

- The model seamlessly integrates thermal and electrical aspects into a complete, physical description of the energy performance of a smart building;

- -

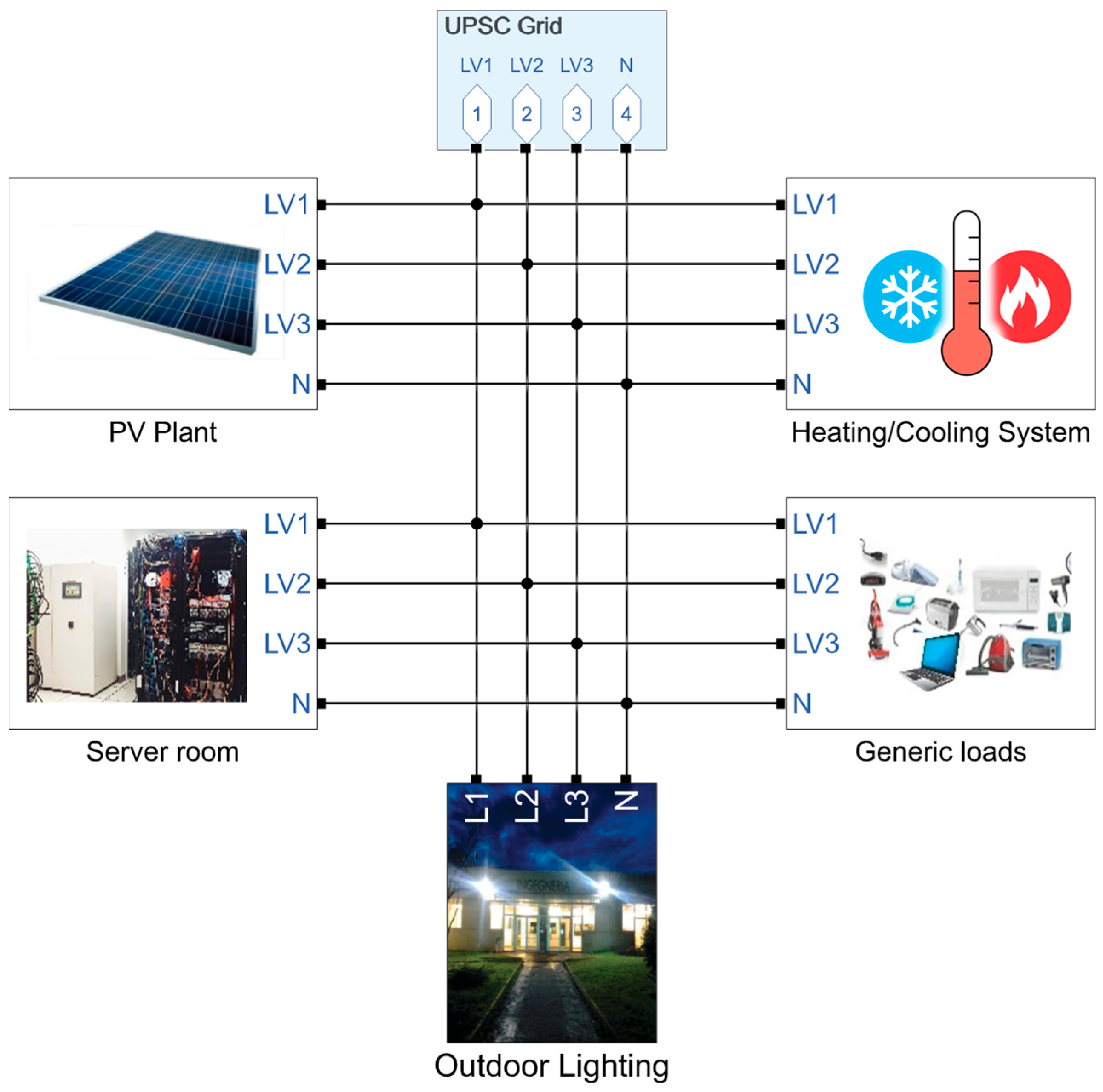

- The building model is inserted into a comprehensive electrical model of a micro-grid (namely, that of the University of Parma South Campus); given its standard smart building features of grid connection, PV rooftop generation, heat pump-based conditioning system, blueprint-based thermal exchange parameters, and generic load consumption description, the model can be instanced repeatedly within the micro-grid model with case-specific parameter settings;

- -

- Unlike other available models based on a data-driven approach, ours is based on physical/analytical descriptions of the components, which makes it easily adaptable and scalable and provides it with predictive capabilities in the planning phase;

- -

- the whole model (IBEM and micro-grid) is implemented in the MATLAB Simulink environment, thus being fully portable and exploitable within the very wide community of MATLAB users, including researchers, utility companies, educational institutions (e.g., the University of Parma provides free access to MATLAB to all of its students via a Campus Agreement License); this aspect is particularly relevant considering that most studies in the literature employ co-simulation environments involving multiple simulation software, which increases the framework’s complexity [22] and presents challenges in models’ synchronization and validation [23].

2. Modeling Approach and Campus Micro-Grid Model

3. Integrated Building Energy Model

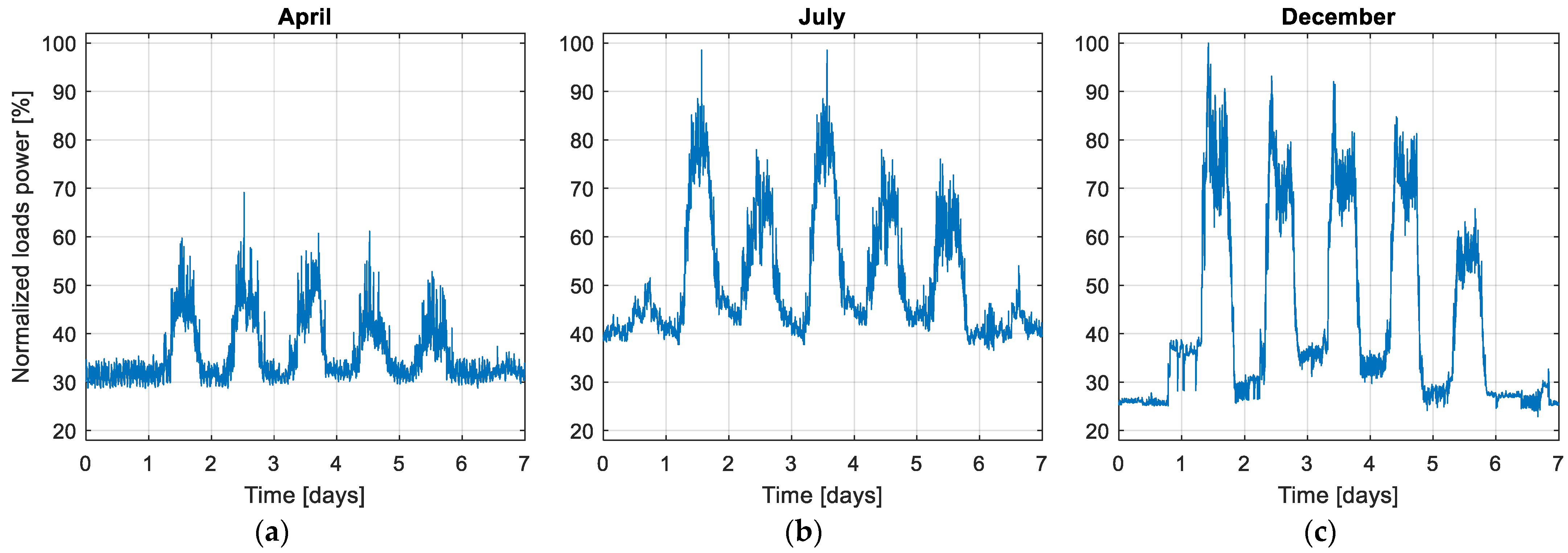

3.1. Load Modeling

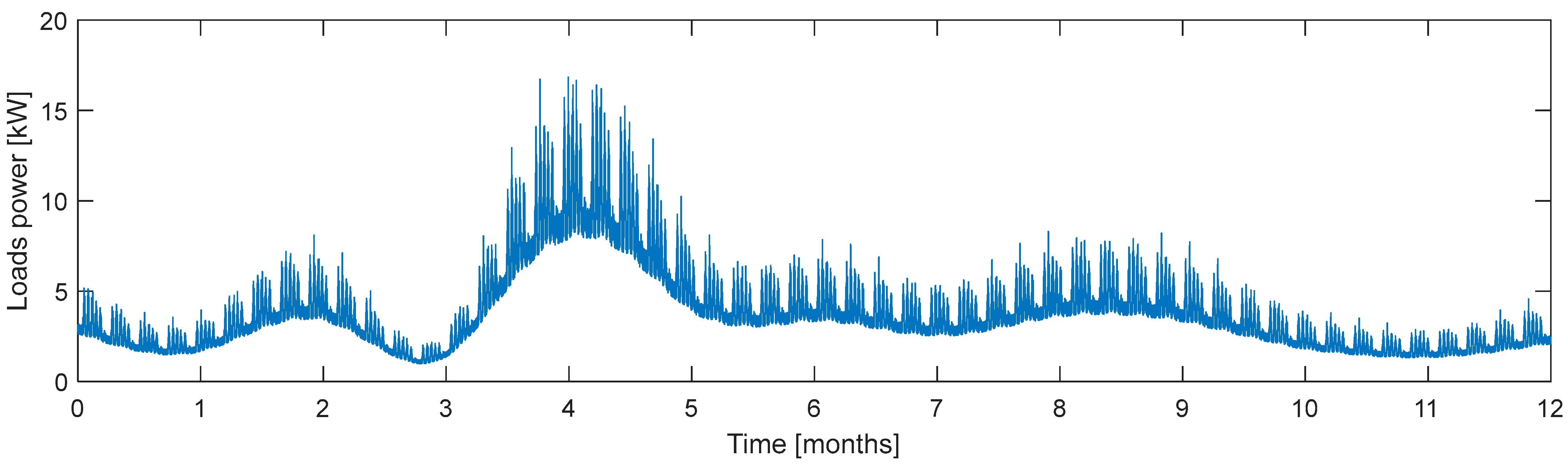

3.2. Building Heating/Cooling System Modeling

| computed thermal power in watts provided by the fan coil to the indoor air mass. | |

| fan thermal exchange capability (non-zero even when off, due to coil-to-air heat exchange). | |

| binary variable indicating the activation state of the conditioning system (when zero, it means that the recirculating liquid is also stopped). | |

| nominal thermal power in watts of a fan coil unit (different when heating or cooling). | |

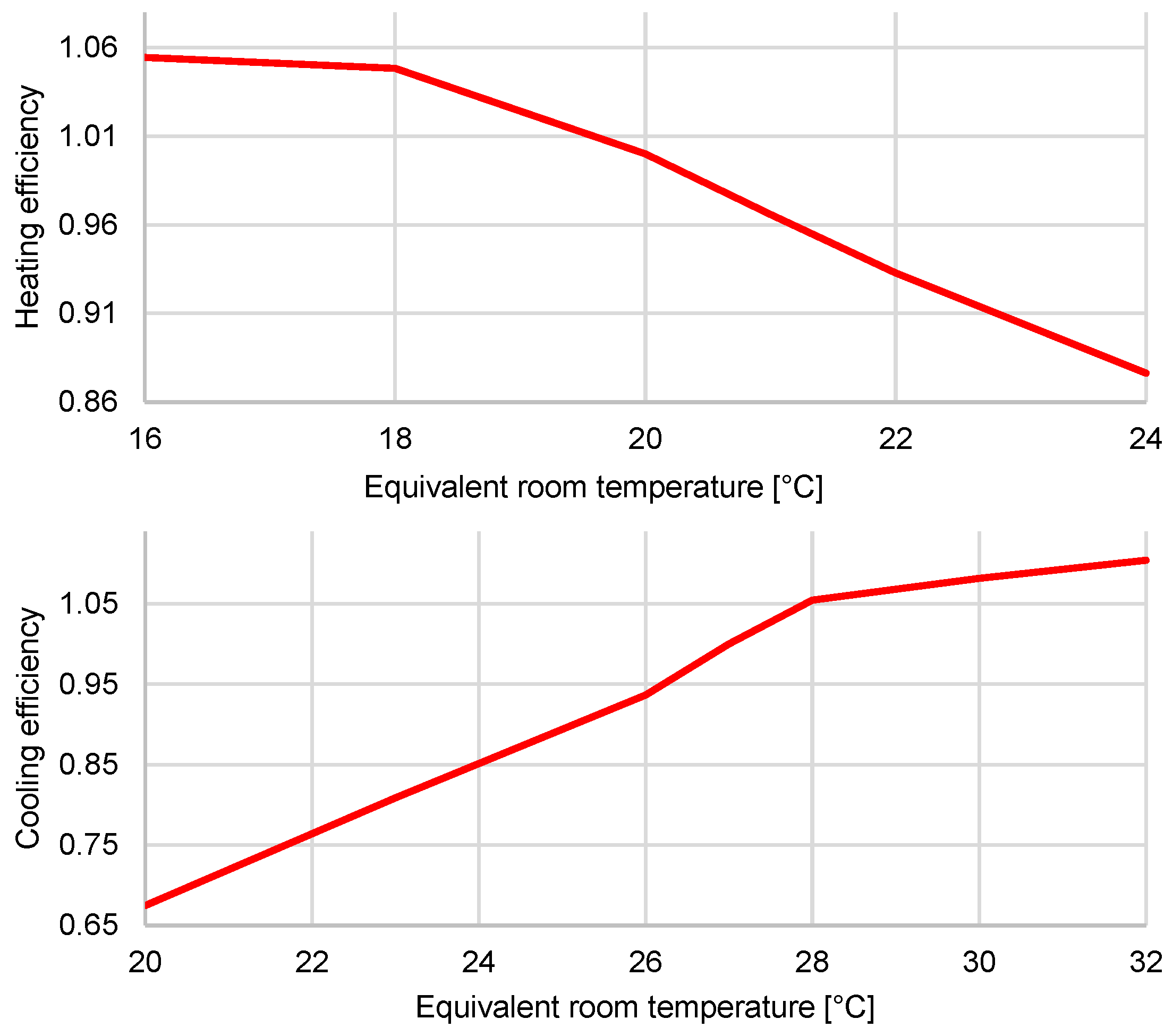

| non-linear efficiency/room temperature function of a fan coil unit (see Figure 6). | |

| computed equivalent room temperature in degrees Celsius. | |

| temperature of the air inside the building in degrees Celsius. | |

| temperature of the liquid inside the coil in degrees Celsius. | |

| reference temperature of the liquid inside the coil (50 °C when heating, 10 °C when cooling). | |

| computed amount of electrical power absorbed by the fan coil unit in watts. | |

| like , but applied to the electrical power absorbed by the unit. | |

| nominal electrical power rating (in watts) of a unit. | |

| fan speed setting (Table 3, L0 means that the fan is off). |

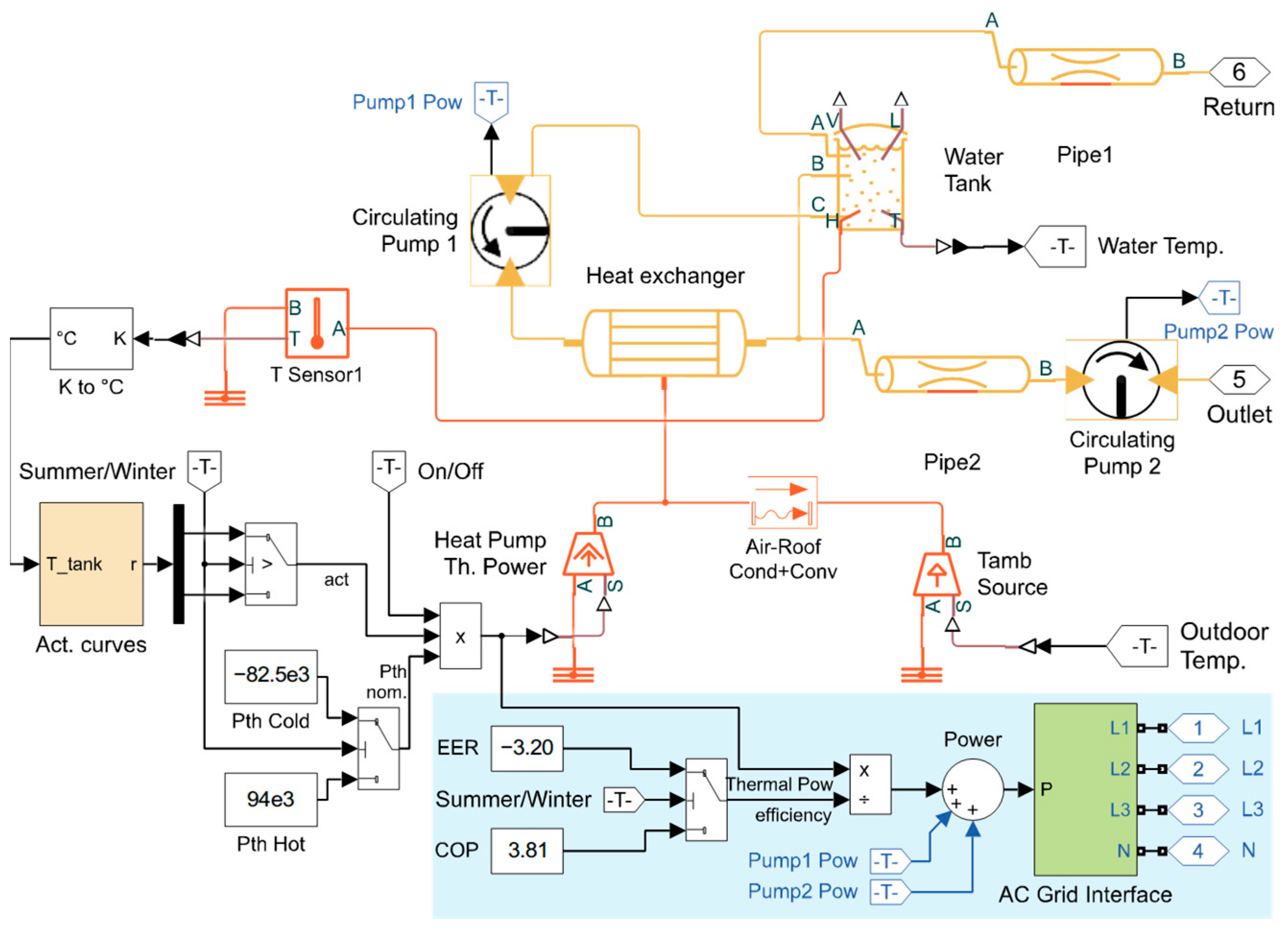

- A pair of pipes implementing a lumped model of the thermal liquid circuit.

- A water tank, which is the thermal storage unit of the system.

- Two recirculation pumps.

- A heat exchanger, whereby the thermal power generated by the heat pump is transferred to the thermal liquid.

- A controlled thermal power source connected to the heat exchanger, representing the thermal pump heating action.

- A temperature source for outdoor temperature reference.

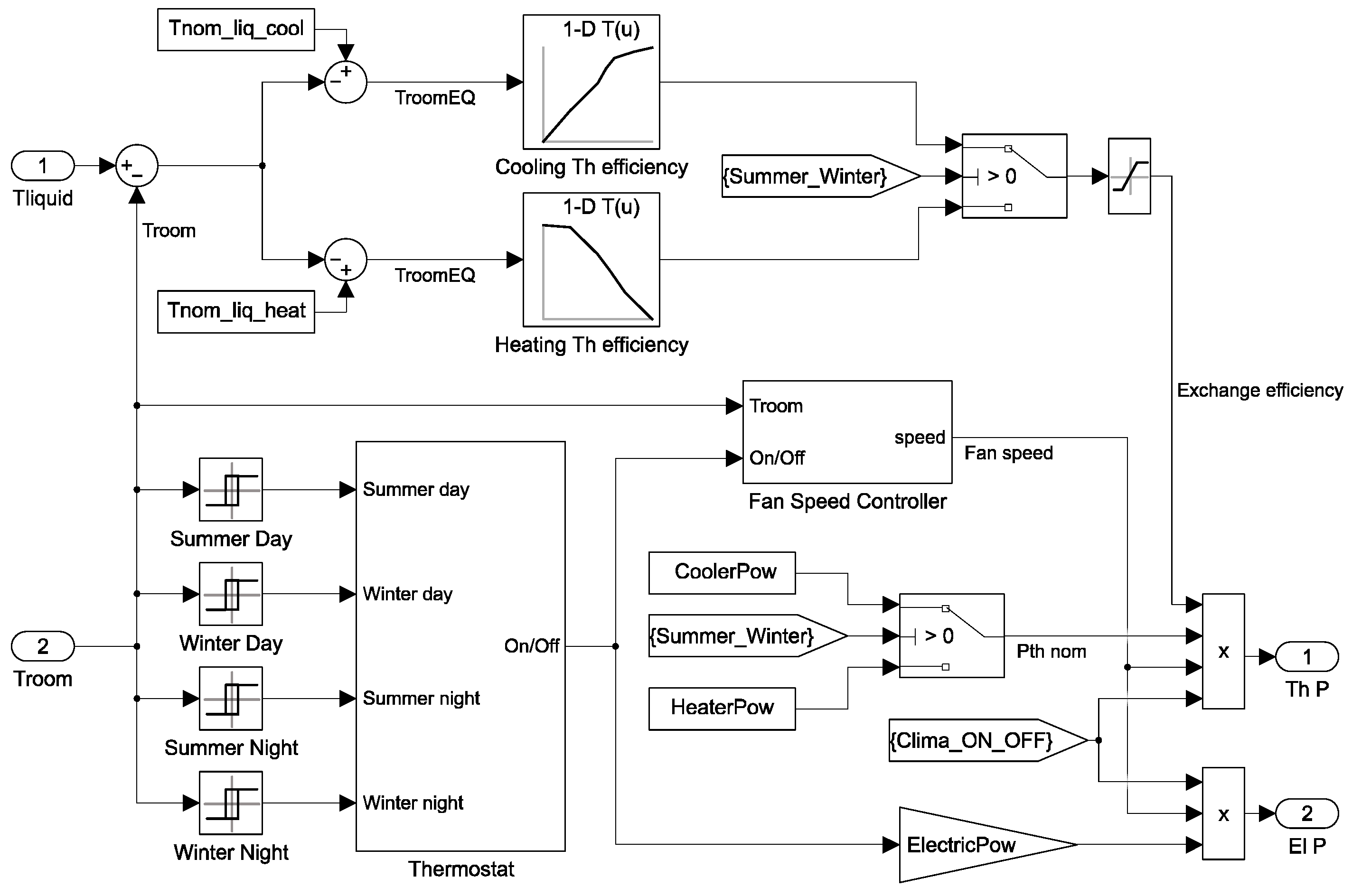

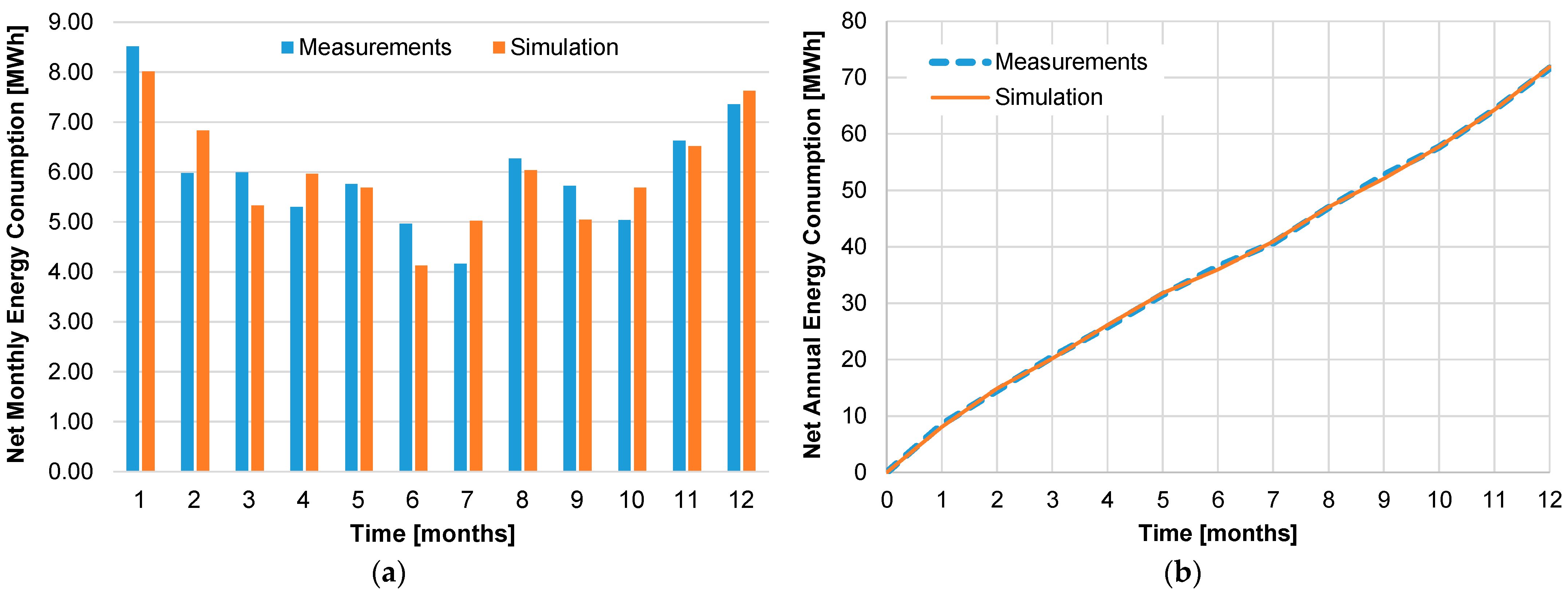

4. Simulation Results

- -

- The use of the constant-frequency discrete-time three-phase phasor-domain approach allowed us to keep the computational overhead within bounds compatible with the calculation of economic and environmental sustainability figures over long periods of time. On the other hand, this simplification prevents the electrical campus model from accounting for AC frequency variation due to changes in power consumption or generation and other non-steady-state phenomena. This is clearly a limitation as far as the simulation of the interaction between the building and the campus micro-grid is concerned.

- -

- Another significant limitation at the present stage of this activity is the lack of a pervasive metering network able to provide the model with building-specific power data taken at short time intervals. The deployment of metering units has just recently started and it is expected that consistent data collection will start being available in the coming months. This will provide us with the necessary information for evaluating the model’s accuracy and, if necessary, improving it.

- -

- It is also worth mentioning that we did not set out to develop a Building Energy Management System, so no optimization algorithm is presently included for energy efficiency or cost minimization.

5. Conclusions

- -

- We have developed a MATLAB Simulink IBEM model based on a physical description of all the relevant components, and seamlessly integrated it into our campus micro-grid model;

- -

- The physical, white-box approach we followed makes it straightforward to apply the building model to different specific instances, given its standard smart building features of grid connection, PV rooftop generation, heat pump-based conditioning system, blueprint-based thermal exchange parameters, and generic load consumption description, with a simple change of case-specific parameter settings;

- -

- The fact that the whole model (IBEM and micro-grid) is implemented in the MATLAB Simulink environment makes it fully portable and exploitable within the very wide community of MATLAB users, including researchers, utility companies, and educational institutions.

- -

- Future developments of this activity will follow these directions, in chronological order:

- -

- The IBEM will be enhanced by the introduction of a BESS;

- -

- The model validation will increasingly rely on field data coming from a metering network currently under deployment;

- -

- Algorithms will be introduced to maximize energy efficiency and minimize costs and carbon emissions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DER | Distributed Energy Resources |

| PV | Photovoltaic |

| BESS | Battery Energy Storage System |

| MG | Micro-Grid |

| UPSC | University of Parma South Campus |

| BEMS | Building Energy Management System |

| HVAC | Heating, Ventilation Air Conditioning System |

| EV | Electric Vehicle |

| CHP | Combined Heat and Power |

| FMI | Functional Mock-up Interface |

| IBEM | Integrated Building Energy Model |

| PCC | Point of Common Coupling |

| EER | Energy Efficiency Ratio |

| COP | Coefficient of Performance |

References

- Cao, J.; Spulbar, C.; Eti, S.; Horobet, A.; Yüksel, S.; Dinçer, H. Innovative Approaches to Green Digital Twin Technologies of Sustainable Smart Cities Using a Novel Hybrid Decision-Making System. J. Innov. Knowl. 2025, 10, 100651. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Ni, J.; Zhang, H. Integration of Smart Buildings with High Penetration of Storage Systems in Isolated 100% Renewable Microgrids. J. Energy Storage 2025, 105, 114633. [Google Scholar] [CrossRef]

- Kılkış, B.; Çağlar, M.; Şengül, M. Energy Benefits of Heat Pipe Technology for Achieving 100% Renewable Heating and Cooling for Fifth-Generation, Low-Temperature District Heating Systems. Energies 2021, 14, 5398. [Google Scholar] [CrossRef]

- Herrando, M.; Ramos, A. Photovoltaic-Thermal (PV-T) Systems for Combined Cooling, Heating and Power in Buildings: A Review. Energies 2022, 15, 3021. [Google Scholar] [CrossRef]

- Zhang, S.; Ocłoń, P.; Klemeš, J.J.; Michorczyk, P.; Pielichowska, K.; Pielichowski, K. Renewable Energy Systems for Building Heating, Cooling and Electricity Production with Thermal Energy Storage. Renew. Sustain. Energy Rev. 2022, 165, 112560. [Google Scholar] [CrossRef]

- Stamatellos, G.; Zogou, O.; Stamatelos, A. Interaction of a House’s Rooftop PV System with an Electric Vehicle’s Battery Storage and Air Source Heat Pump. Solar 2022, 2, 186–214. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Galas, K.; Piszcz, A. Advanced Deep Learning Algorithms for Energy Optimization of Smart Cities. Energies 2025, 18, 407. [Google Scholar] [CrossRef]

- Muse, L.P.; Routray, S.; Oleinikova, I. Smart Grids for Smart Cities. IEEE Smart Grid Bulletin 2022. [Google Scholar]

- Brown, A.; Foley, A.; Laverty, D.; McLoone, S.; Keatley, P. Heating and Cooling Networks: A Comprehensive Review of Modelling Approaches to Map Future Directions. Energy 2022, 261, 125060. [Google Scholar] [CrossRef]

- Olympios, A.V.; Kourougianni, F.; Arsalis, A.; Papanastasiou, P.; Pantaleo, A.M.; Markides, C.N.; Georghiou, G.E. A Holistic Framework for the Optimal Design and Operation of Electricity, Heating, Cooling and Hydrogen Technologies in Buildings. Appl. Energy 2024, 370, 123612. [Google Scholar] [CrossRef]

- Bayasgalan, A.; Park, Y.S.; Koh, S.B.; Son, S.-Y. Comprehensive Review of Building Energy Management Models: Grid-Interactive Efficient Building Perspective. Energies 2024, 17, 4794. [Google Scholar] [CrossRef]

- Hoseinpoori, P.; Olympios, A.V.; Markides, C.N.; Woods, J.; Shah, N. A Whole-System Approach for Quantifying the Value of Smart Electrification for Decarbonising Heating in Buildings. Energy Convers. Manag. 2022, 268, 115952. [Google Scholar] [CrossRef]

- Causone, F.; Scoccia, R.; Pelle, M.; Colombo, P.; Motta, M.; Ferroni, S. Neighborhood Energy Modeling and Monitoring: A Case Study. Energies 2021, 14, 3716. [Google Scholar] [CrossRef]

- Sola, A.; Corchero, C.; Salom, J.; Sanmarti, M. Simulation Tools to Build Urban-Scale Energy Models: A Review. Energies 2018, 11, 3269. [Google Scholar] [CrossRef]

- Simonazzi, M.; Delmonte, N.; Cova, P.; Ferrari, G.; Zanichelli, F.; Menozzi, R. Modeling of a University Campus Micro-Grid for Optimal Planning of Renewable Generation and Storage Deployment. In Proceedings of the 2021 IEEE International Smart Cities Conference (ISC2), Manchester, UK, 7–10 September 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–7. [Google Scholar]

- Simonazzi, M.; Delmonte, N.; Cova, P.; Menozzi, R. Models for MATLAB Simulation of a University Campus Micro-Grid. Energies 2023, 16, 5884. [Google Scholar] [CrossRef]

- Gambarotta, A.; Morini, M.; Rossi, M.; Stonfer, M. A Library for the Simulation of Smart Energy Systems: The Case of the Campus of the University of Parma. Energy Procedia 2017, 105, 1776–1781. [Google Scholar] [CrossRef]

- De Lorenzi, A.; Gambarotta, A.; Morini, M.; Rossi, M.; Saletti, C. Setup and Testing of Smart Controllers for Small-Scale District Heating Networks: An Integrated Framework. Energy 2020, 205, 118054. [Google Scholar] [CrossRef]

- Bianco, G.; Bracco, S.; Delfino, F.; Gambelli, L.; Robba, M.; Rossi, M. A Building Energy Management System Based on an Equivalent Electric Circuit Model. Energies 2020, 13, 1689. [Google Scholar] [CrossRef]

- Moya, F.; Torres-Moreno, J.; Álvarez, J. Optimal Model for Energy Management Strategy in Smart Building with Energy Storage Systems and Electric Vehicles. Energies 2020, 13, 3605. [Google Scholar] [CrossRef]

- Khan, M.H.; Asar, A.U.; Ullah, N.; Albogamy, F.R.; Rafique, M.K. Modeling and Optimization of Smart Building Energy Management System Considering Both Electrical and Thermal Load. Energies 2022, 15, 574. [Google Scholar] [CrossRef]

- Frank, S.; Ball, B.; Gerber, D.L.; Cu, K.; Othee, A.; Shackelford, J.; Ghatpande, O.; Brown, R.; Cale, J. Advances in the Co-Simulation of Detailed Electrical and Whole-Building Energy Performance. Energies 2023, 16, 6284. [Google Scholar] [CrossRef]

- Alfalouji, Q.; Schranz, T.; Falay, B.; Wilfling, S.; Exenberger, J.; Mattausch, T.; Gomes, C.; Schweiger, G. Co-Simulation for Buildings and Smart Energy Systems—A Taxonomic Review. Simul. Model. Pr. Theory 2023, 126, 102770. [Google Scholar] [CrossRef]

- Introducing the Phasor Simulation Method. Available online: https://it.mathworks.com/help/physmod/sps/powersys/ug/introducing-the-phasor-simulation-method.html (accessed on 1 August 2022).

- Song, Y.; Peskova, M.; Rolando, D.; Zucker, G.; Madani, H. Estimating Electric Power Consumption of In-Situ Residential Heat Pump Systems: A Data-Driven Approach. Appl. Energy 2023, 352, 121971. [Google Scholar] [CrossRef]

- Akbarzadeh, S.; Sefidgar, Z.; Sadegh Valipour, M.; Elmegaard, B.; Arabkoohsar, A. A Comprehensive Review of Research and Applied Studies on Bifunctional Heat Pumps Supplying Heating and Cooling. Appl. Therm. Eng. 2024, 257, 124280. [Google Scholar] [CrossRef]

- UNI 10077-1; Thermal Performance of Windows, Doors and Shutters—Calculation of Thermal Transmittance. UNI (Italian National Standards Body): Milan, Italy, 2018.

- UNI 10351; Building Materials—Thermo-Hygrometric Proprieties—Procedure for Determining the Design Values. UNI (Italian National Standards Body): Milan, Italy, 2021.

- UNI 10355; Chemical Analysis of Ferrous Materials—Inductively Coupled Plasma Optical Emission Spectrometric Analysis of Unalloyed and Low Alloyed Steels—Determination of Si, Mn, P, Cu, Ni, Cr, Mo and Sn, Following Dissolution with Nitric and Sulphuric Acids [Routine Method]. UNI (Italian National Standards Body): Milan, Italy, 2013.

- The Global Electricity Data Platform. Available online: https://app.electricitymaps.com/zone/IT-NO/72h/hourly (accessed on 14 February 2025).

- ARPAE Emilia Romagna Dext3r. Available online: https://simc.arpae.it/dext3r/ (accessed on 18 June 2024).

- Simonazzi, M.; Chiorboli, G.; Cova, P.; Menozzi, R.; Santoro, D.; Sapienza, S.; Sciancalepore, C.; Sozzi, G.; Delmonte, N. Smart Soiling Sensor for PV Modules. Microelectron. Reliab. 2020, 114, 113789. [Google Scholar] [CrossRef]

| Parameter | Roof | Walls and Floor | Windows | Internal Volume |

|---|---|---|---|---|

| Heat transfer coefficient [W·m−2·K−1] | 12 | 24 | 25 | - |

| Thermal conductivity [W·m−1·K−1] | 0.038 | 0.038 | 0.78 | - |

| Area [m2] | 770 | 800 | 60 | - |

| Thickness [m] | 0.2 | 0.2 | 0.01 | - |

| Mass of the air [kg] | 4925 | 307,200 | 1620 | 9475 |

| Specific heat [J·K−1·kg−1] | 835 | 835 | 840 | 1005 |

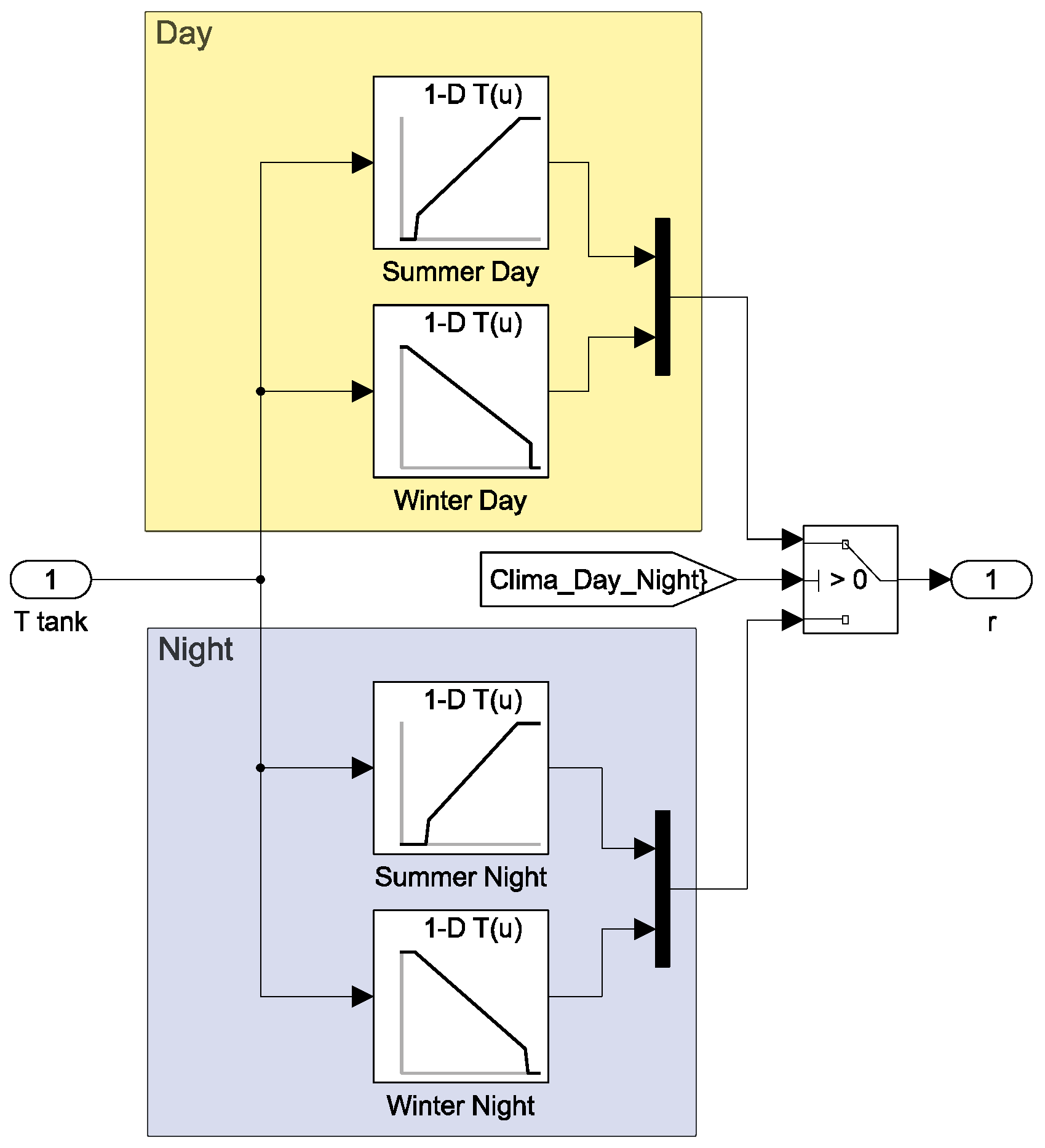

| Season | |||

|---|---|---|---|

| Summer | Winter | ||

| Mode | Normal | 22 ÷ 23 °C | 20 ÷ 21 °C |

| Quiet | 26 ÷ 28 °C | 13 ÷ 14 °C | |

| ΔT = Troom − Tset | Fan Speed Level |

|---|---|

| ΔT ≤ 0.5 °C | L1 (30% of max speed) |

| 0.5 °C < ΔT ≤ 1.5 °C | L2 (70% of max speed) |

| ΔT > 1.5 °C | L3 (max speed) |

| Season | |||

|---|---|---|---|

| Summer | Winter | ||

| Mode | Normal | 10 ÷ 18 °C | 40 ÷ 50 °C |

| Quiet | 16 ÷ 20 °C | 38 ÷ 42 °C | |

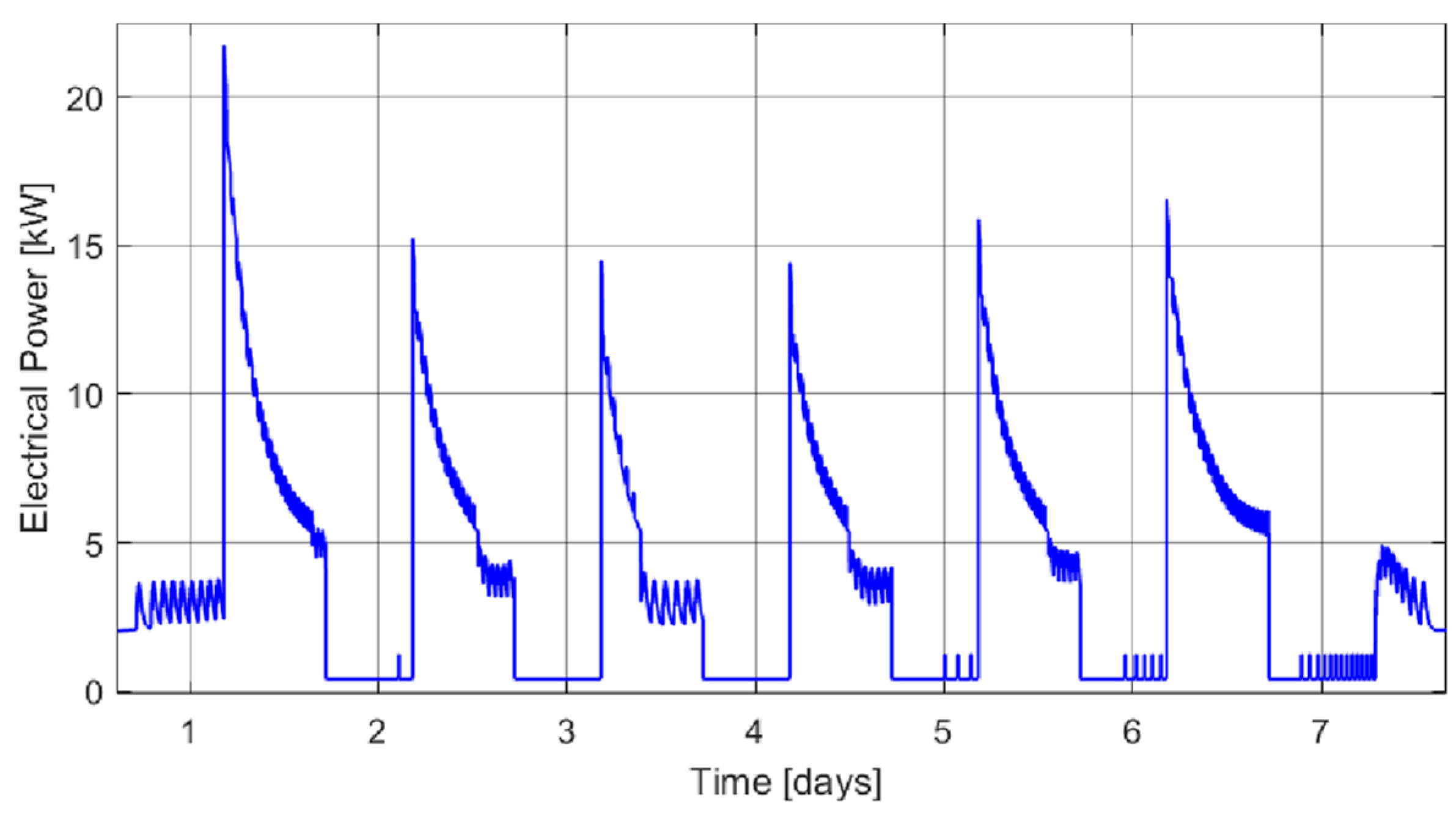

| Heat Transfer Coefficient | Thermal Conductivity | COP | EER | Electrical Energy (Eel) | ΔEel [%] |

|---|---|---|---|---|---|

| Table 1 | Table 1 | 3.81 | 3.20 | 23.65 MWh/year | |

| +10% | Table 1 | 3.81 | 3.20 | 24.38 MWh/year | +3.1% |

| Table 1 | +10% | 3.81 | 3.20 | 24.12 MWh/year | +2.0% |

| +10% | +10% | 3.81 | 3.20 | 24.89 MWh/year | +5.2% |

| Table 1 | Table 1 | +10% | +10% | 21.83 MWh/year | −7.68% |

| +10% | Table 1 | +10% | +10% | 22.50 MWh/year | −4.83% |

| Table 1 | +10% | +10% | +10% | 22.26 MWh/year | −5.86% |

| +10% | +10% | +10% | +10% | 22.97 MWh/year | −2.86% |

| Table 1 | Table 1 | −10% | −10% | 25.87 MWh/year | +9.38% |

| +10% | Table 1 | −10% | −10% | 26.67 MWh/year | +12.78% |

| Table 1 | +10% | −10% | −10% | 26.38 MWh/year | +11.56% |

| +10% | +10% | −10% | −10% | 27.23 MWh/year | +15.13% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simonazzi, M.; Delmonte, N.; Cova, P.; Menozzi, R. An Integrated Building Energy Model in MATLAB. Energies 2025, 18, 2948. https://doi.org/10.3390/en18112948

Simonazzi M, Delmonte N, Cova P, Menozzi R. An Integrated Building Energy Model in MATLAB. Energies. 2025; 18(11):2948. https://doi.org/10.3390/en18112948

Chicago/Turabian StyleSimonazzi, Marco, Nicola Delmonte, Paolo Cova, and Roberto Menozzi. 2025. "An Integrated Building Energy Model in MATLAB" Energies 18, no. 11: 2948. https://doi.org/10.3390/en18112948

APA StyleSimonazzi, M., Delmonte, N., Cova, P., & Menozzi, R. (2025). An Integrated Building Energy Model in MATLAB. Energies, 18(11), 2948. https://doi.org/10.3390/en18112948