4.1. Design of GPC Controller for Inner Current Loop of DFVSPSU

- (1)

Control strategy design of inner current loop

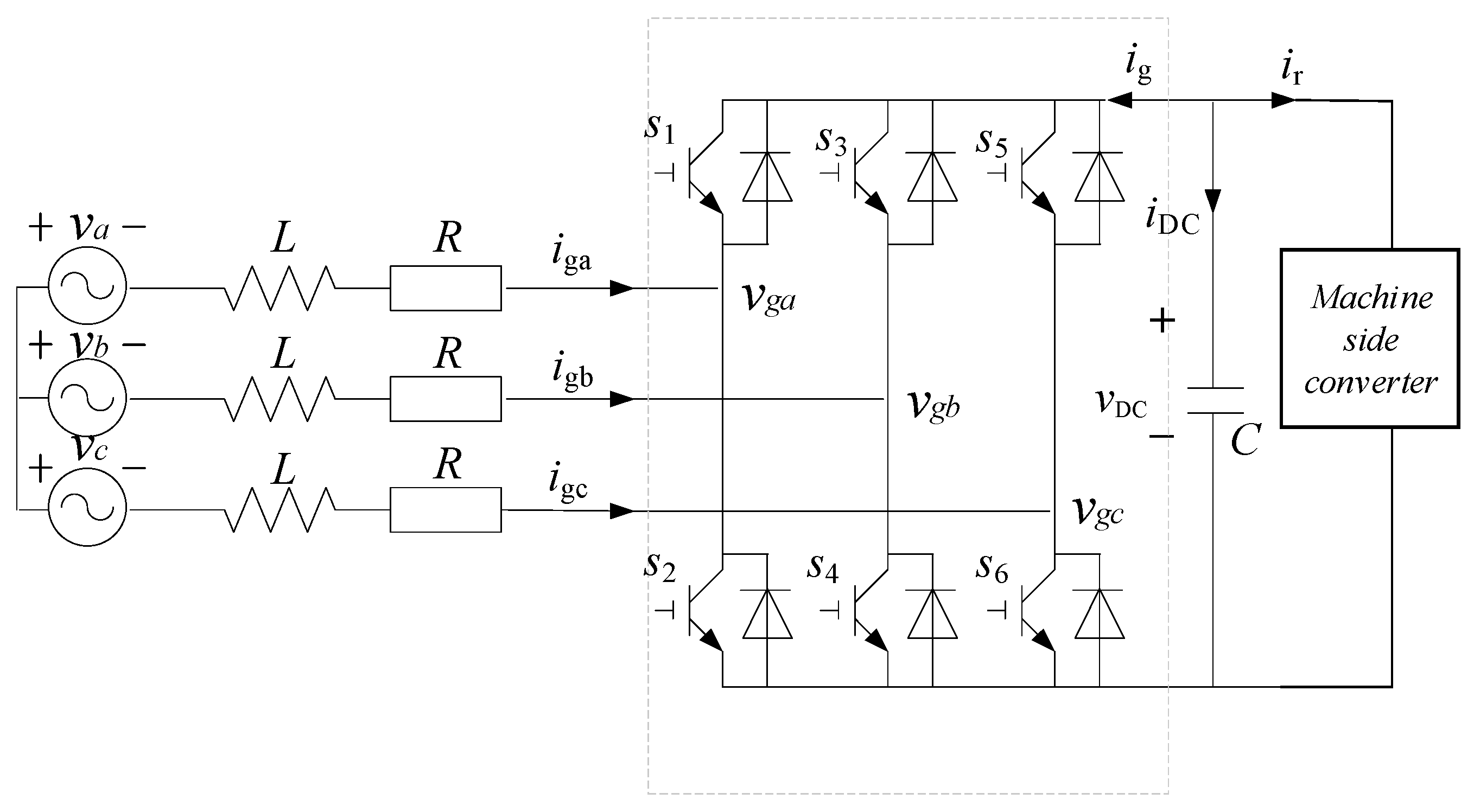

The stator flux-oriented vector control method, utilized by the machine-side converter of the DFIG, simplifies the control system. The method facilitates the decoupled control of the current. In the dq frame, the d-axis is synchronized with the stator flux linkage, where

From Equations (4), (6) and (24), it can be obtained that

where

represents the total flux leakage coefficient.

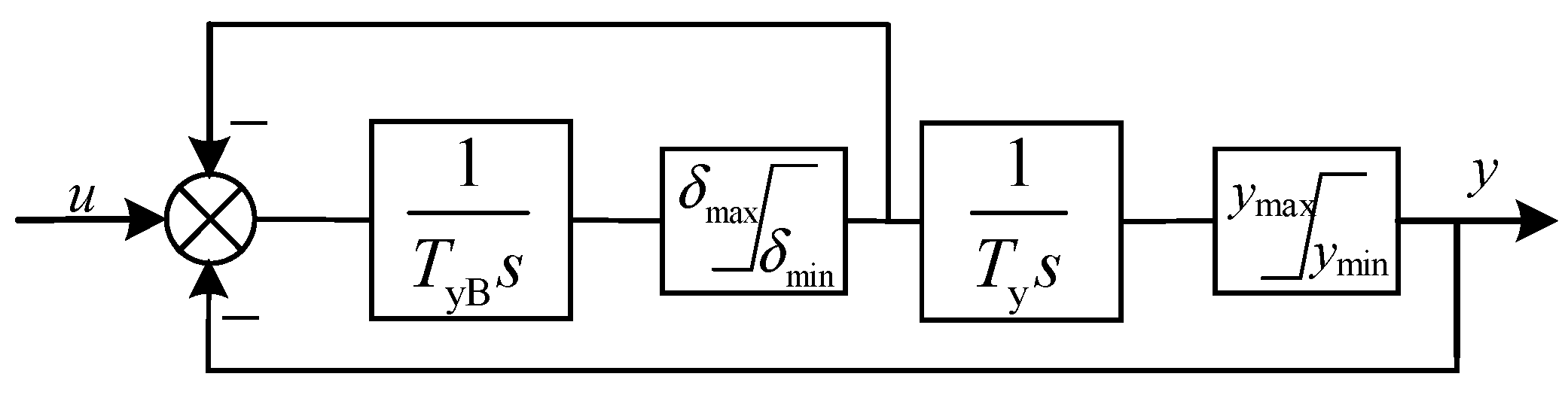

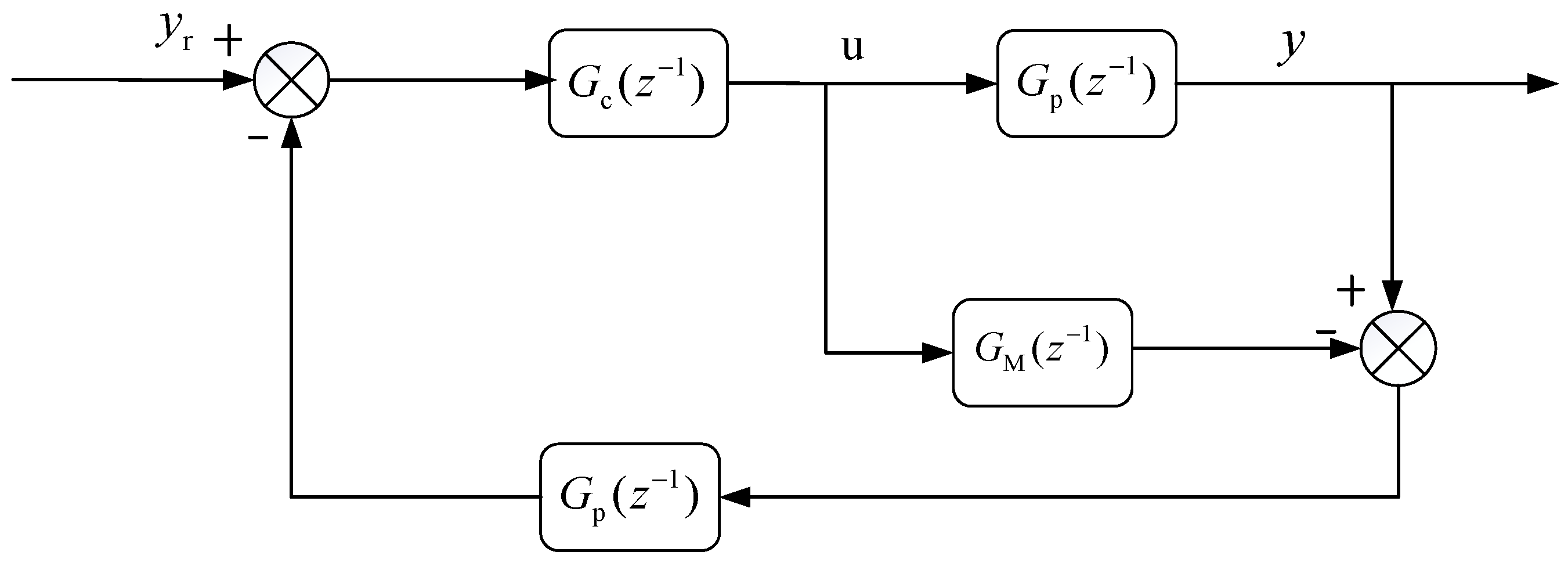

A significant observation is that there exists pronounced cross-coupling and interference between the transfer functions governing the rotor current control. These are primarily caused by the transformation among different frames. However, these cross-coupling and interference terms can be considered as disturbances. The controller compensates for these disturbances, as illustrated in

Figure 7.

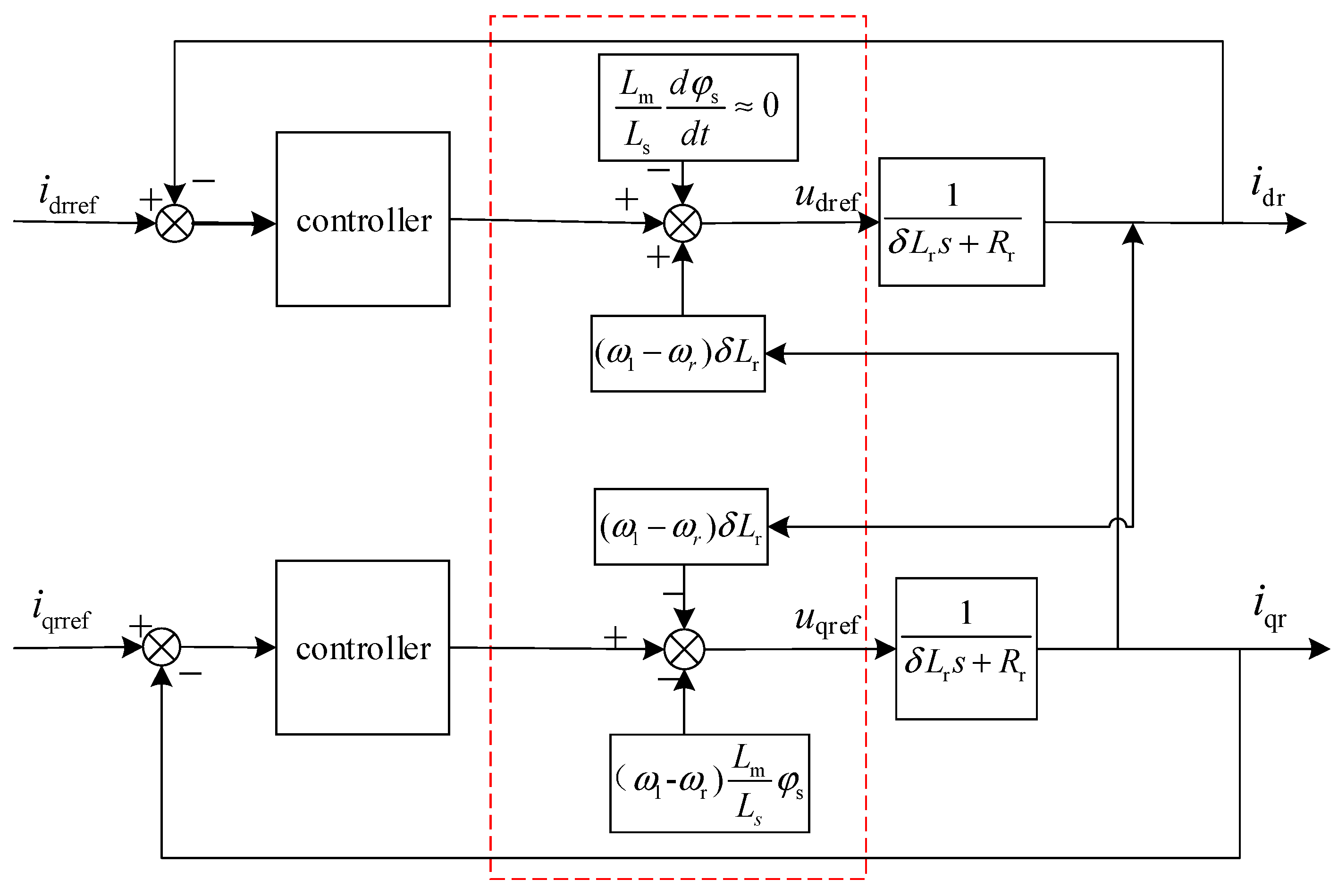

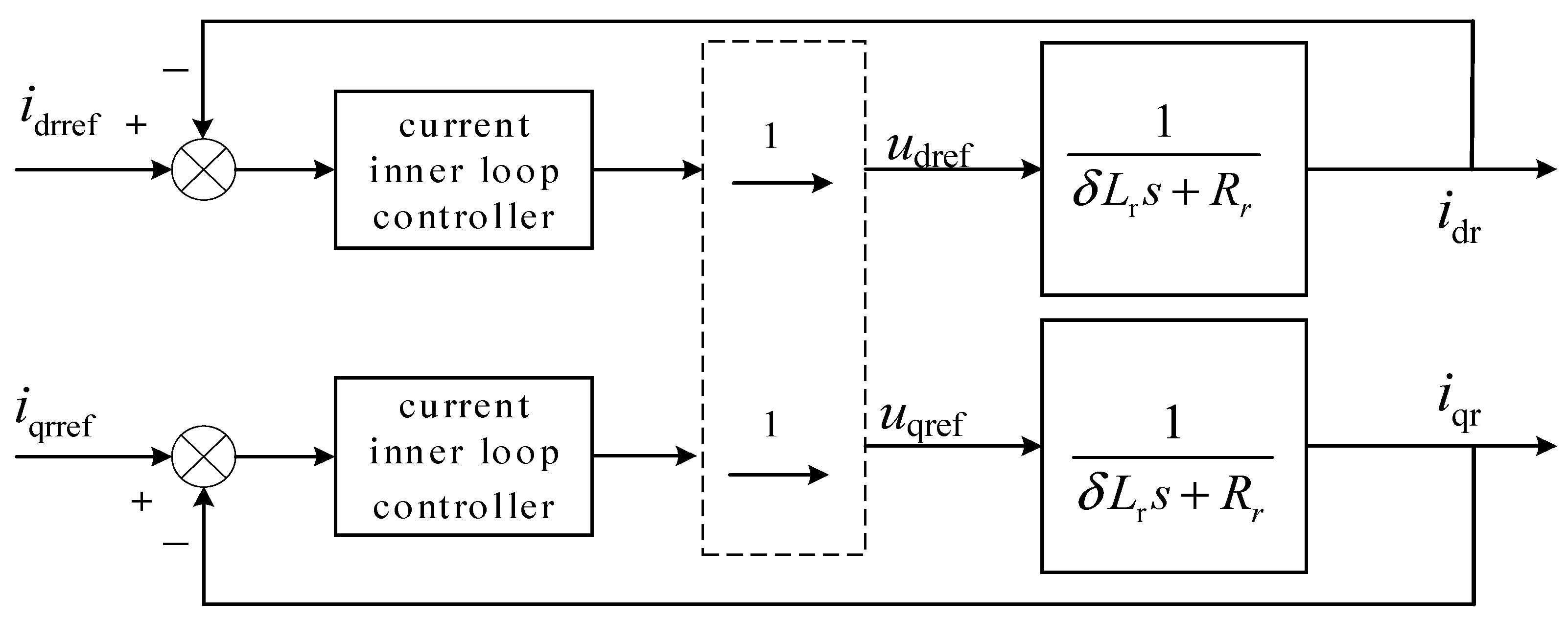

Ignoring the hysteresis generated by the controller, the disturbance term and cross-coupling inherent in the generator model, along with the feed-forward voltage compensation term, can effectively negate each other. Consequently, they can be represented by a straight line with a transfer function of one, further streamlining the structure of the control system.

Figure 8 depicts the simplified block diagram depicting rotor current control.

To achieve the desired control characteristics, it is crucial to accurately obtain various parameters. Derivative terms exist in Equation (30). Several systems directly omit this part to avoid disturbances caused by derivatives, potentially failing to achieve full compensation. However, because of the connection between the stator side of the DFIG and the grid, the stator excitation current can be considered constant in a steady state. Thus, the derivative term can be approximated as zero, avoiding scenarios wherein the term does not offer full compensation.

It can be expressed as a transfer function with voltage and current as the input and output, respectively.

where

The GPC CARIMA model of DFIG can be expressed as follows:

where

ξ(

k) represents the noise of the system. According to Equation (8), we obtain

where

,

.

- (2)

Simulation Verification and Analysis

To validate the effectiveness of the proposed controller, a simulation model of the DFVSPSU was developed in the simulation software, grounded in the control method and model. The designed nonlinear GPC controller was implemented for excitation control on the rotor side of the DFIG. Simulations were performed under different operating conditions. In comparing the control results of the traditional controller to those of the GPC controller, the viability of the designed controller is evident. The parameters for both the PI controller and the GPC controller were optimized using the GA intelligent algorithm by drawing upon actual operational data from a pumped storage power station in China. The parameters are listed in

Table 1,

Table 2 and

Table 3, and α and β are obtained by optimization.

In addition, in order to set the optimal parameters of PID, the objective function is defined as follows:

where overshoot is the overshoot percentage of the system response, which directly affects the stability. ITAE (integral time absolute error) measures the cumulative error of dynamic system regulation and reflects speed and accuracy.

In this study, the weight of overshoot (A = 80) is much higher than ITAE (B = 1) because the core goal of the paper is to improve the dynamic response and avoid overshoot and oscillation.

Where

λ denotes the forgetting factor. In principle, the value of the forgetting factor ranges from 0 to 1, but it is mostly between 0.9 and 1, which can effectively cope with the time-varying system of parameters [

29]. When the value is one, the algorithm becomes a simple least squares identification method.

β is an incremental factor, and the control increment is multiplied by a beta factor at every moment solved by the usual generalized predictive control algorithm, adding an adjustable control quantity β, which can be adjusted to increase the stability of the system.

α is the output flexibility coefficient, the value of which is between 0 and 1, which has a great influence on the stability of the closed-loop system. In general, the smaller the value of α, the faster the system reaches the set value, but it is easy to overshoot and cause system instability. Although the system stability is good, the response time is too long; therefore, the response speed should be considered, while the system stability should be compatible.

- (1)

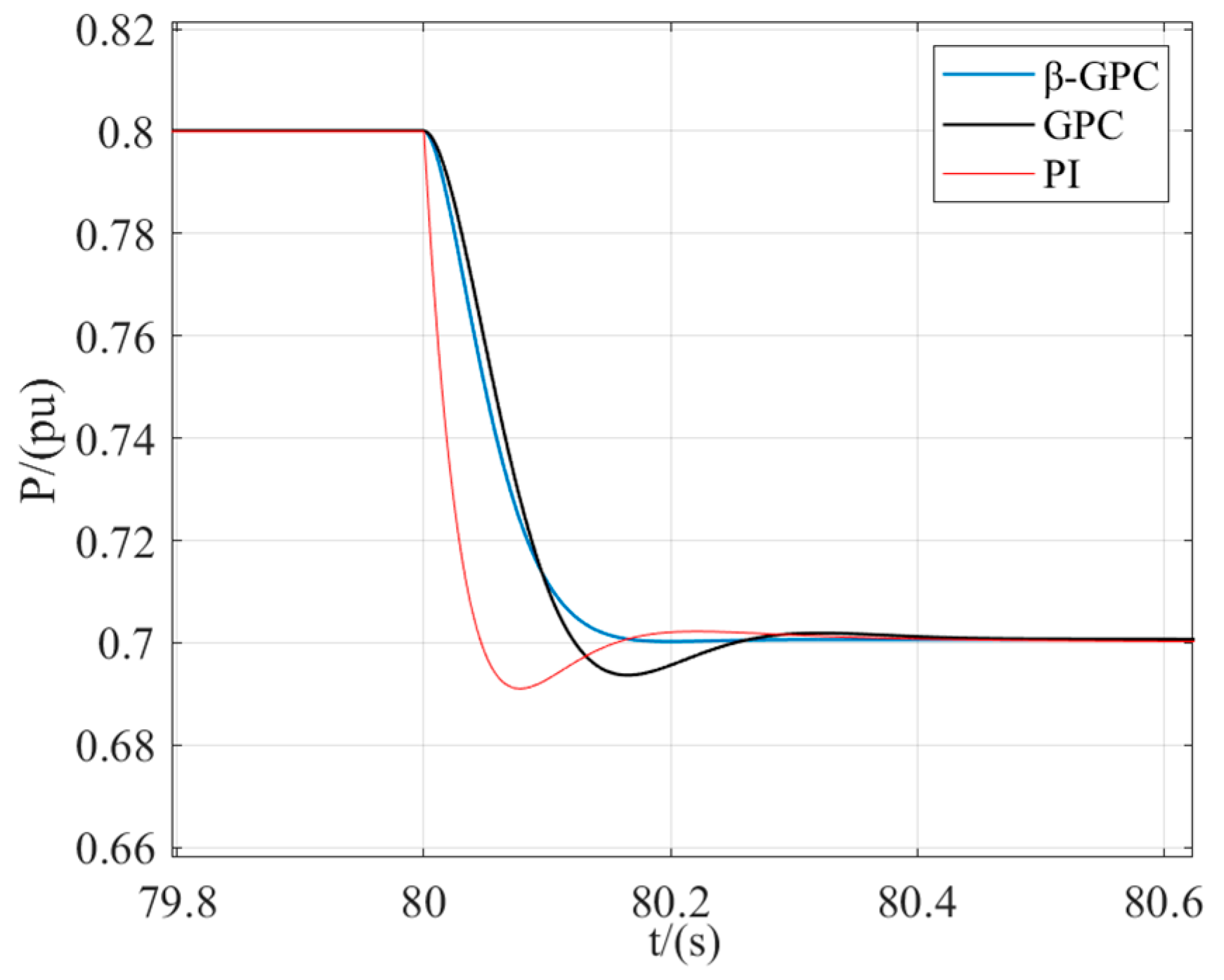

10% power disturbance

Initially, the simulation conditions were set with the following parameters: the power of the DFVSPSU at 0.8 pu, the head at 1.0 pu, the speed measures at 0.955 pu, and the generator operates with an efficiency of 96.1%. After 80 s, the reference power changes from 0.8 pu to 0.7 pu.

Figure 9 illustrates the operations of the DFSPUS under a 10% power disturbance with different control strategies. The conventional PI controller requires 0.46 s to stabilize, with an overshoot of 9.2% and a single oscillation. However, the traditional GPC controller stabilizes in 0.34 s and reduces the overshoot to 6.1%. In contrast, the improved GPC controller drastically shortens the settling time to 0.2 s, and it does not exhibit any overshoot or oscillations.

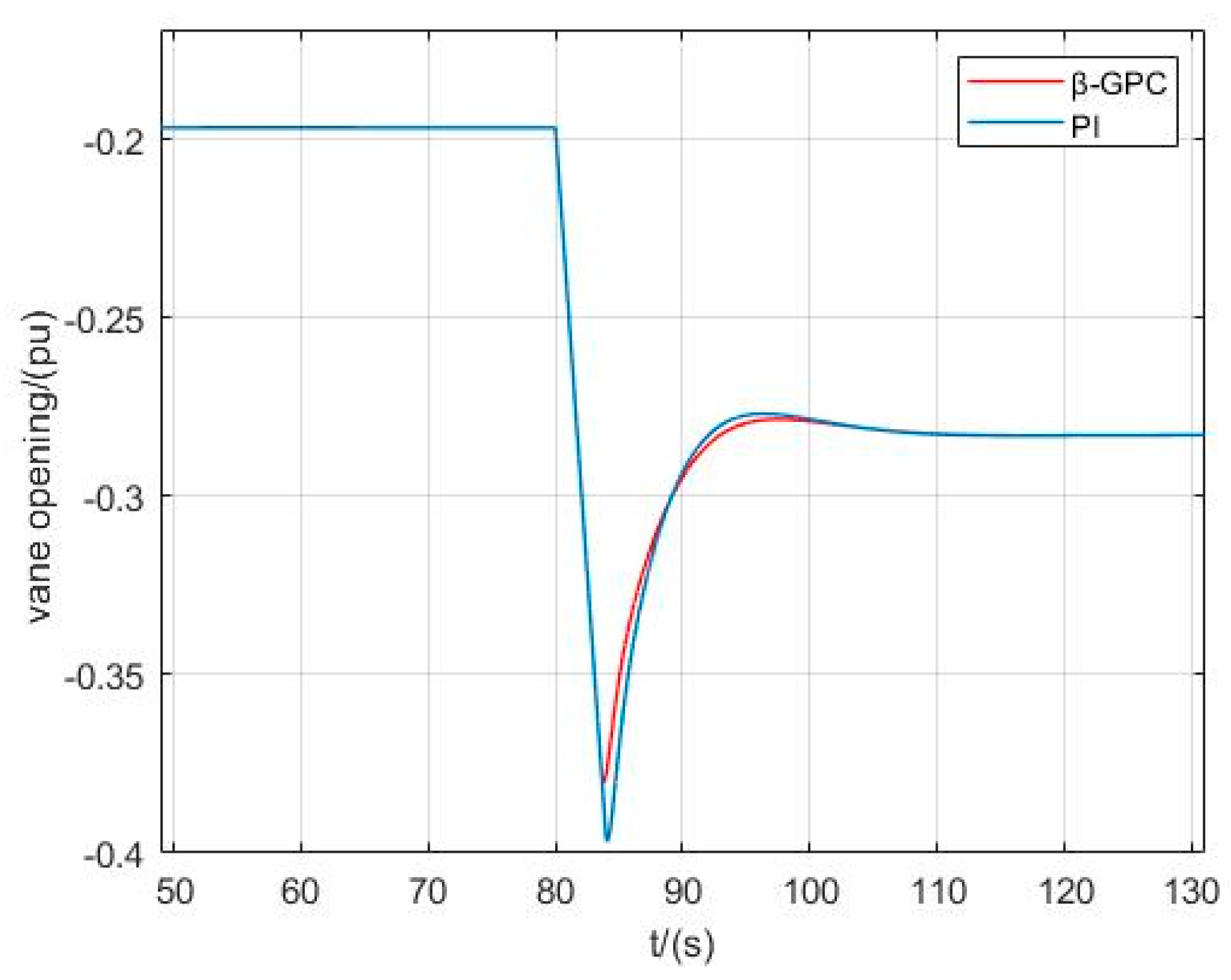

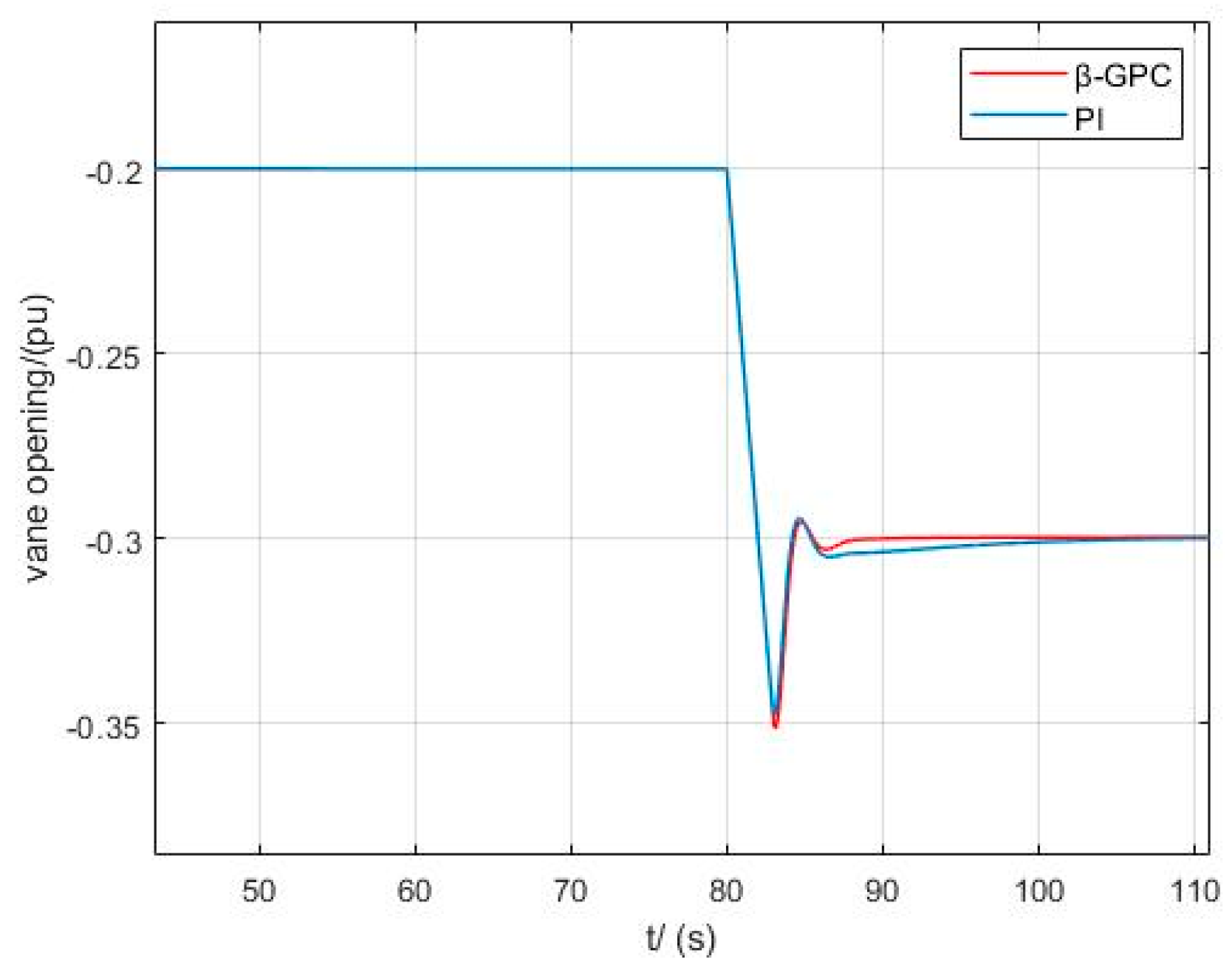

Figure 10 shows the variation of guide vane opening with different control strategies under 10% power interference. Both the traditional PI control and

β-GPC control require 28 s to reach stability, but the

β-GPC control has advantages over the traditional PI control in terms of overshoot.

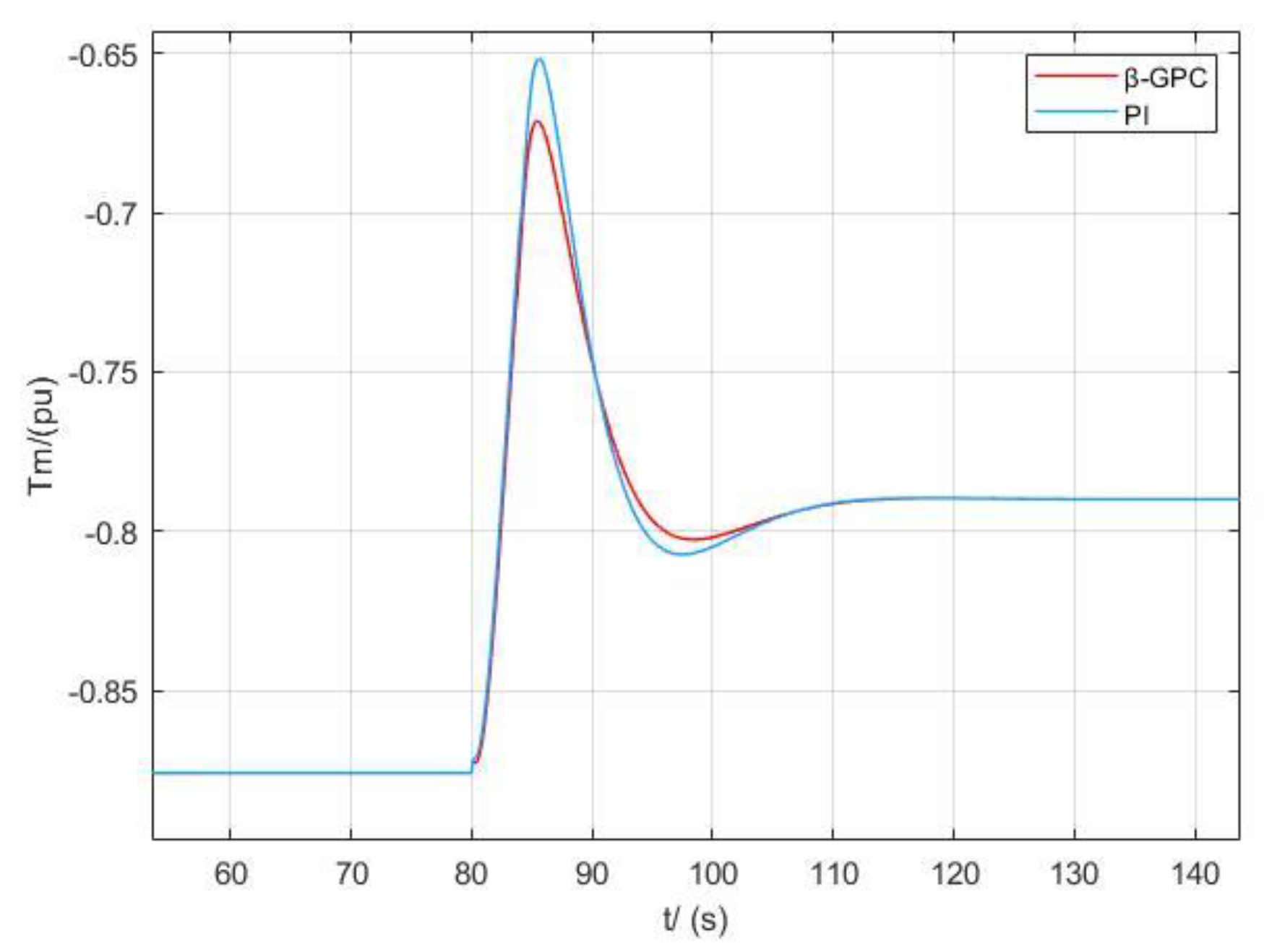

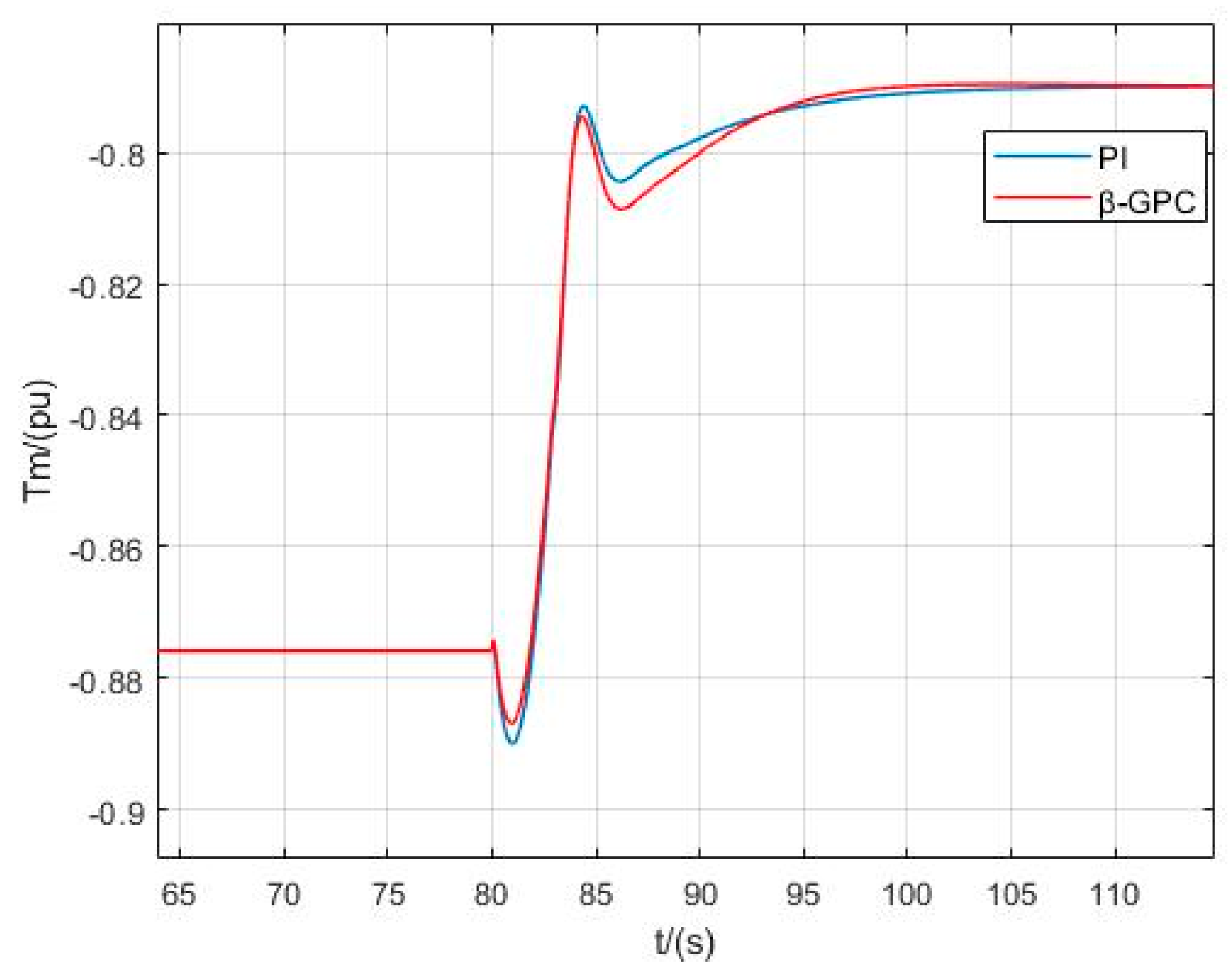

Figure 11 shows the change in the torque of different control strategies under 10% power interference. Both the traditional PI control and the β-GPC control require 35 s to stabilize, but the β-GPC control has advantages over the traditional PI control in terms of overshoot.

Figure 12 presents a comparison of the q-axis current error values, indicating that the improved GPC controller outperforms in terms of control effects. It offers a shorter settling time and fewer oscillations than the traditional PI controller.

- (2)

40% power disturbance

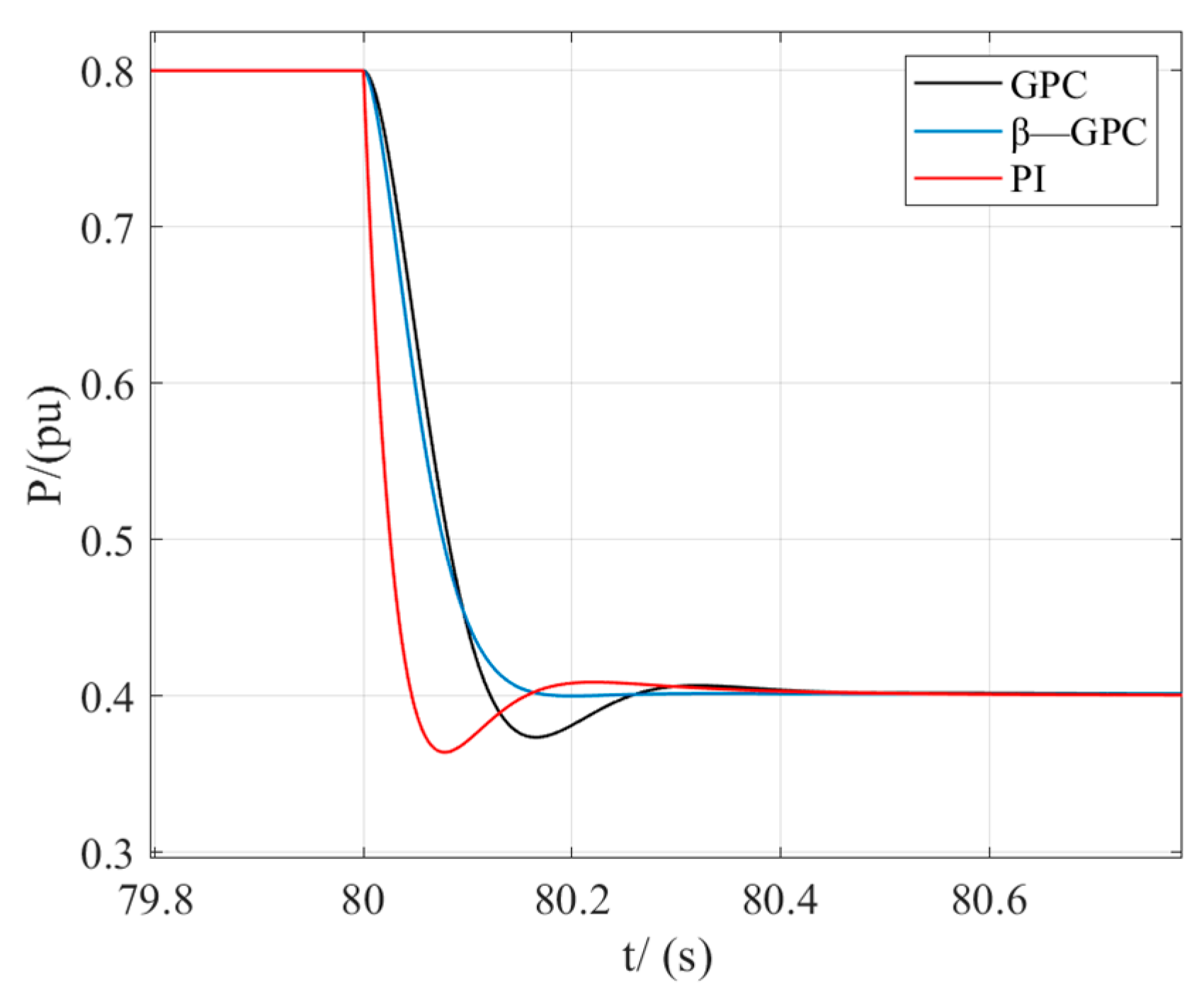

The initial simulation conditions are established with the following parameters: the output of the DFVSPSU is 0.8 pu, the head stands at 1.0 pu, the speed measures at 0.955 pu, and the generator has an efficiency of 96.1%. At 80 s, the power reference value steps from 0.8 pu to 0.4 pu.

Figure 13 presents the operations of DFSPUS using different control strategies under a 40% power disturbance. It can be seen that

β-GPC control strategy is significantly better than PI controller and traditional GPC controller in terms of stability time and overshoot.

According to the values of the objective function

J in

Table 4, it can be seen that under 10% and 40% power disturbance conditions, the control performance of the

β-GPC controller is significantly better than that of the traditional PI and GPC controllers. Specifically,

β-GPC achieves the lowest

J value across all test conditions, which fully demonstrates its superior overall performance in overshoot suppression and dynamic error optimization, achieving an optimal balance between control accuracy and response speed.

In the aforementioned simulation verification, we compared the performance of traditional PI controllers, GPC controllers, and the improved β-GPC controller under different power disturbances. The results demonstrate that the improved β-GPC controller outperforms conventional controllers in terms of settling time, overshoot, and oscillation frequency. These performance enhancements are not only reflected in the dynamic response of the system, but also have significant implications for mechanical stress and converter losses in actual operation.

During the operation of doubly-fed induction generators (DFIGs), adjusting the rotor excitation through converters to achieve variable-speed operation is critical. However, during rapid power regulation (such as grid frequency modulation demands), the instantaneous imbalance between electromagnetic torque and mechanical torque exacerbates fluctuations. Particularly under low-load conditions, hydraulic instabilities in the turbine flow passage—such as vortices and flow separation—can induce random torque pulsations. These pulsations are transmitted to the DFIG rotor through the runner-shaft system, generating alternating torsional stress. When the pulsation frequency approaches the natural frequency of the shaft, torsional resonance may occur, amplifying stress amplitudes by three to five times. Furthermore, during variable-speed processes, torque fluctuations are transmitted to the generator set through couplings, subjecting bearings to asymmetric loads. Long-term torque fluctuations can lead to fatigue crack propagation in critical components such as shafts and blades.

Additionally, the stator current amplitude of DFIGs varies significantly with load changes, and the IGBT switching losses exhibit a quadratic relationship with the current. Harmonics in the motor current can also interact with the switching frequency of IGBTs in the converter, triggering high-frequency oscillatory currents. High-frequency components near the IGBT switching frequency increase the current rate of change (di/dt), thereby significantly raising switching losses. Therefore, precise control of motor current is essential for reducing converter switching losses.

The improved β-GPC controller effectively mitigates torque fluctuations and current errors through precise torque control and current tracking. This not only enhances the dynamic response performance of the system, but also significantly reduces mechanical stress and switching losses. Specifically, accurate torque control minimizes asymmetric loads on shafts and bearings, preventing torsional resonance, while precise current control reduces IGBT switching losses, improving overall system efficiency and reliability.

4.2. GPC Controller Design for Outer Speed Loop of DFVSPSU

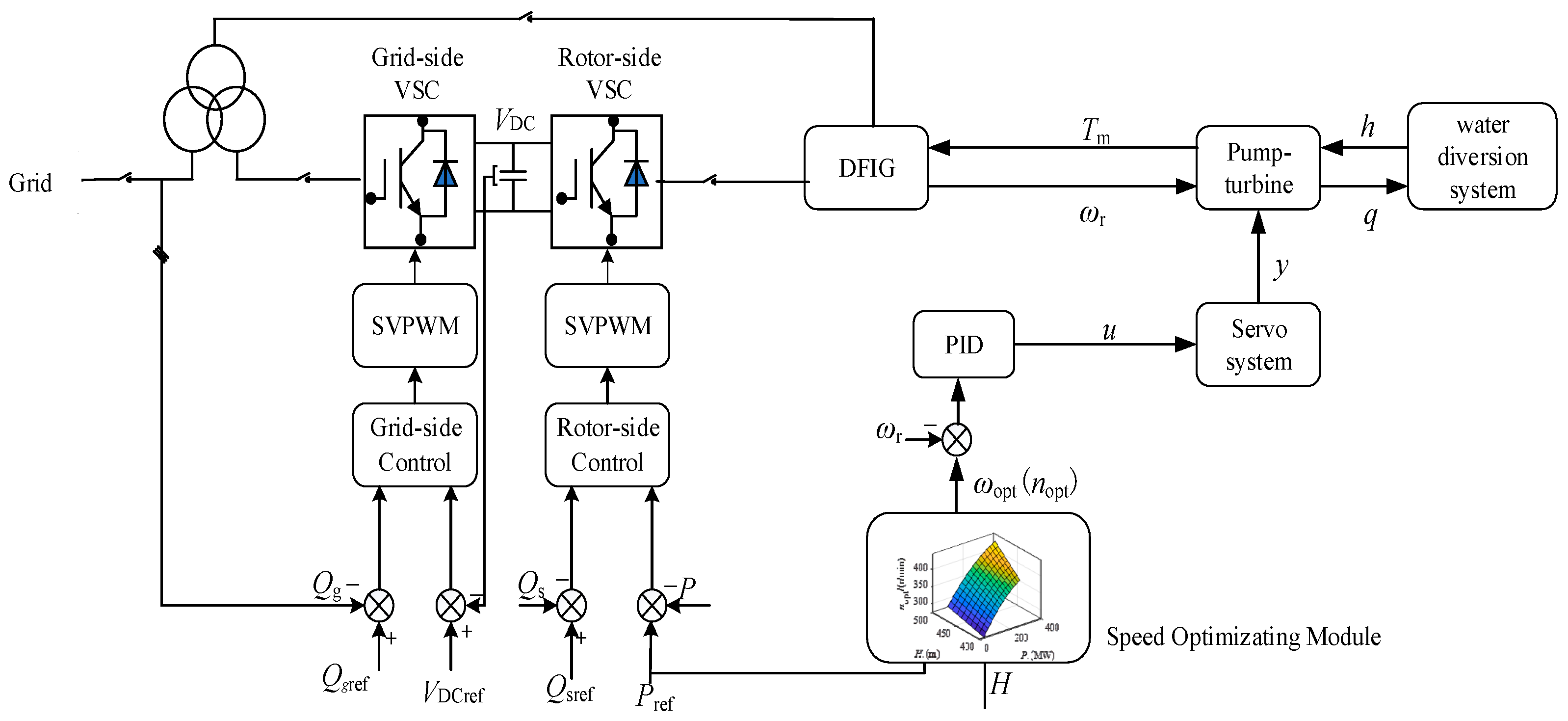

Based on current research for the control strategy of DFVSPSU, the speed master control approach exists in addition to the power master control method. The speed master control approach involves controlling speed via the excitation control system while managing power through the guide vane governing the system.

Within this method, any change in the power reference value prompts the optimal speed generator to determine the optimal speed that correlates with optimal efficiency. It is determined using the comprehensive characteristic curve of the pump turbine and the given reference power. The speed of the unit is swiftly adjusted to match the optimal speed reference via excitation control. A notable advantage of the speed master control method is its ability to fine-tune the load regulation of the DFVSPSU. This ensures the pump turbine consistently operates at its highest hydraulic efficiency, improving the overall efficiency of the pumped storage system. Meanwhile, the guide vane governing the system makes adjustments to stabilize the unit’s power around the set reference power. The control strategy for the speed master control method is depicted in

Figure 14.

The difference between ωerf and the actual feedback value is obtained by the PI controller to obtain the rotor side Q-axis current reference value iqrref, and then it is compared to the actual feedback value; through the second PI controller and the voltage compensation term Δvdr, the rotor side voltage reference value vqrref is finally obtained. In the control process of rotor side reactive power, the difference between Qref and the actual feedback value is obtained by the PI controller to obtain the rotor side D-axis current reference value idrref, and then compared to the actual feedback value, through the second PI controller and the voltage compensation term Δvqr, finally obtaining the rotor side voltage reference value of vdrref. vqrref and vdrref are transformed by 2r/2s to obtain vαrref and vβrref, and then the converter switch signal is obtained by SVPWM.

The power outer loop transformation equation is

The current inner loop transformation equation is

- (1)

Control Strategy Design of Outer Speed Loop

When considering the friction coefficient of DFVSPSU, the motion equation is

where

TL denotes the mechanical torque of the prime mover,

ωr symbolizes the speed of the prime mover,

J signifies the rotational inertia of the unit, and

Bm denotes the viscous friction coefficient. When adopting the control strategy with

id = 0,

Thus, when the mechanical torque is zero, the model obtained by taking the Laplace change on both sides of the equation is

Here, the input and output are the speed and current, respectively, after adding zero-order hold. Z-transform is used to obtain the following

Here, .

The load torque is regarded as the system disturbance, and then it is added into the equation, and the CARIMA model is constructed as follows:

Hence, the performance index function is

where

ωr denotes the actual speed and

ω0 is the reference speed. Accordingly, the control quantity is

Thus, the desired CARIMA model and the GPC controller are designed.

- (2)

Simulation Verification and Analysis

In the speed master control method, the parameters of the unit involved are the same as those presented in

Table 1, and the parameters of different controllers are optimized using the GA intelligent algorithm. The controller parameters are detailed in

Table 5 and

Table 6, and

α and

β are obtained by optimization.

- (1)

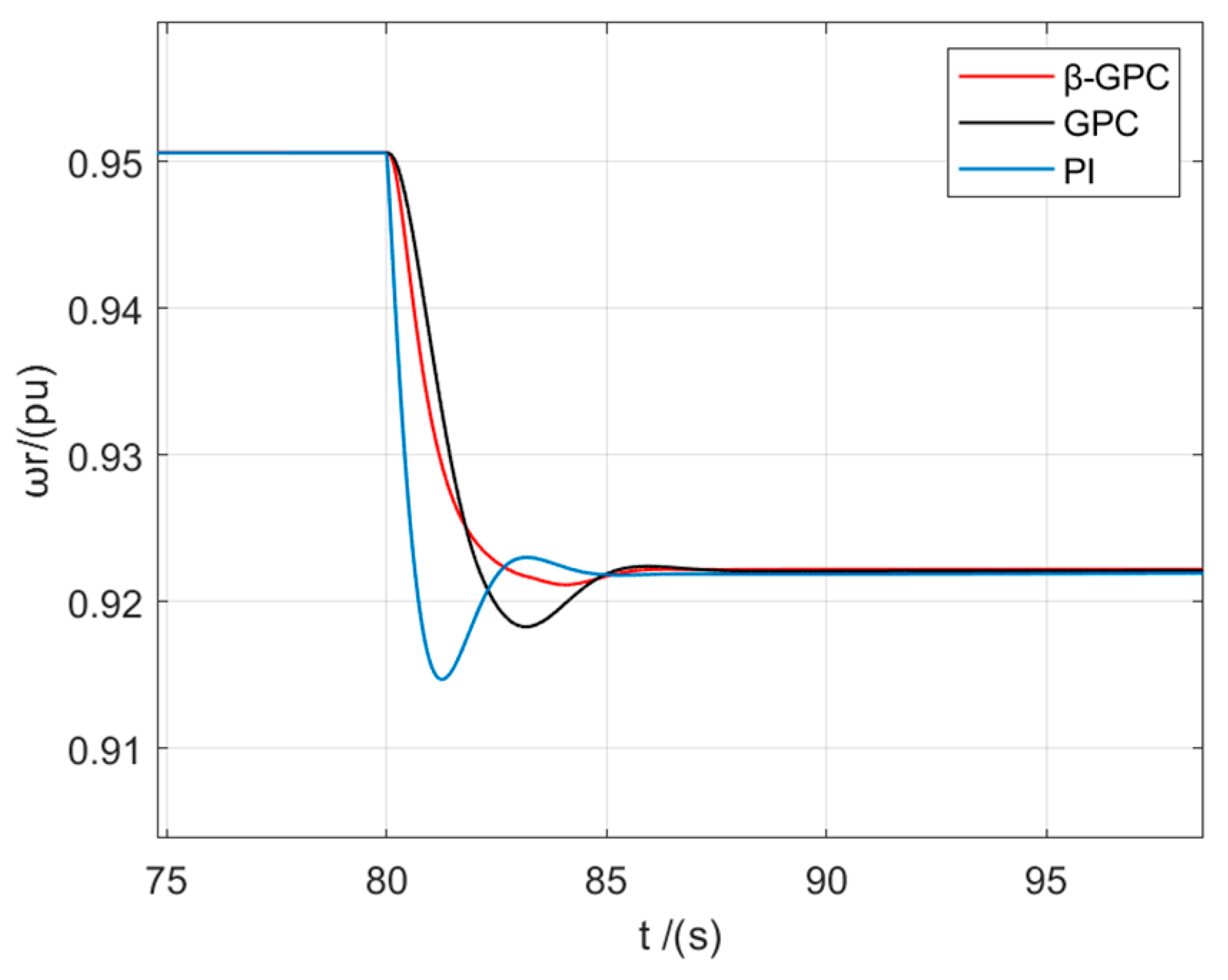

10% Power Disturbance

The initial simulation conditions are established with the following parameters: the output of the DFVSPSU is 0.8 pu, the head is 1.0 pu, speed is 0.9551 pu, and the generator efficiency is 96.1%. At 80 s, the power reference value steps from 0.8 pu to 0.7 pu.

Figure 15 shows the operation of DFVSPSU with different control strategies under 10% power disturbance. The traditional PI controller brings the DFVSPSU to a steady state in 8.48 s, exhibiting an overshoot of 22.4%, and then it undergoes two oscillations. When utilizing the traditional GPC controller, there is a reduction in the settling time of the speed to 7.08 s, and the overshoot decreases to 13.7%. In comparison, the improved GPC controller further decreases the response time by 3.19 s and achieves stabilization without any overshoot or oscillation.

Figure 16 shows the variation of guide vane opening (0.8–0.7) with different control strategies under 10% power interference. The traditional PI control needs 23 s to achieve stability, and the

β-GPC control only needs 9 s to achieve stability. There is little difference between the two methods in the performance of overshoot.

Figure 17 shows the change in the torque of different control strategies under 10% power interference. Both the traditional PI control and

β-GPC control require 27 s to achieve stability, but the

β-GPC control has advantages over traditional PI control in terms of overshoot.

- (2)

40% Power Disturbance

At the initial moment, the output of the DFVSPSU is 0.8 pu, the head is 1.0 pu, speed is 0.9551 pu, and the generator efficiency is 96.1%. At 80 s, the power reference value steps from 0.8 pu to 0.4 pu.

Figure 18 shows the operation of DFVSPSU under different control strategies with 40% power disturbance. It can be seen that

β-GPC control strategy is significantly better than PI controller and traditional GPC controller in terms of stability time and overshoot.

Table 7 compares the regulation performance of PI controllers, GPC controllers, and

β-GPC controllers under different power disturbance conditions. The numerical values based on the objective function

J show that the

β-GPC controller demonstrates significant advantages, as follows: under 10% and 40% power disturbances, its

J value is significantly lower than those of traditional PI and GPC controllers. These data fully validate the superior performance of

β-GPC in overshoot suppression and dynamic regulation.