Impact of Rock Elastic Properties on Fracture Geometry in Potential Enhanced Geothermal Systems in Poland

Abstract

1. Introduction

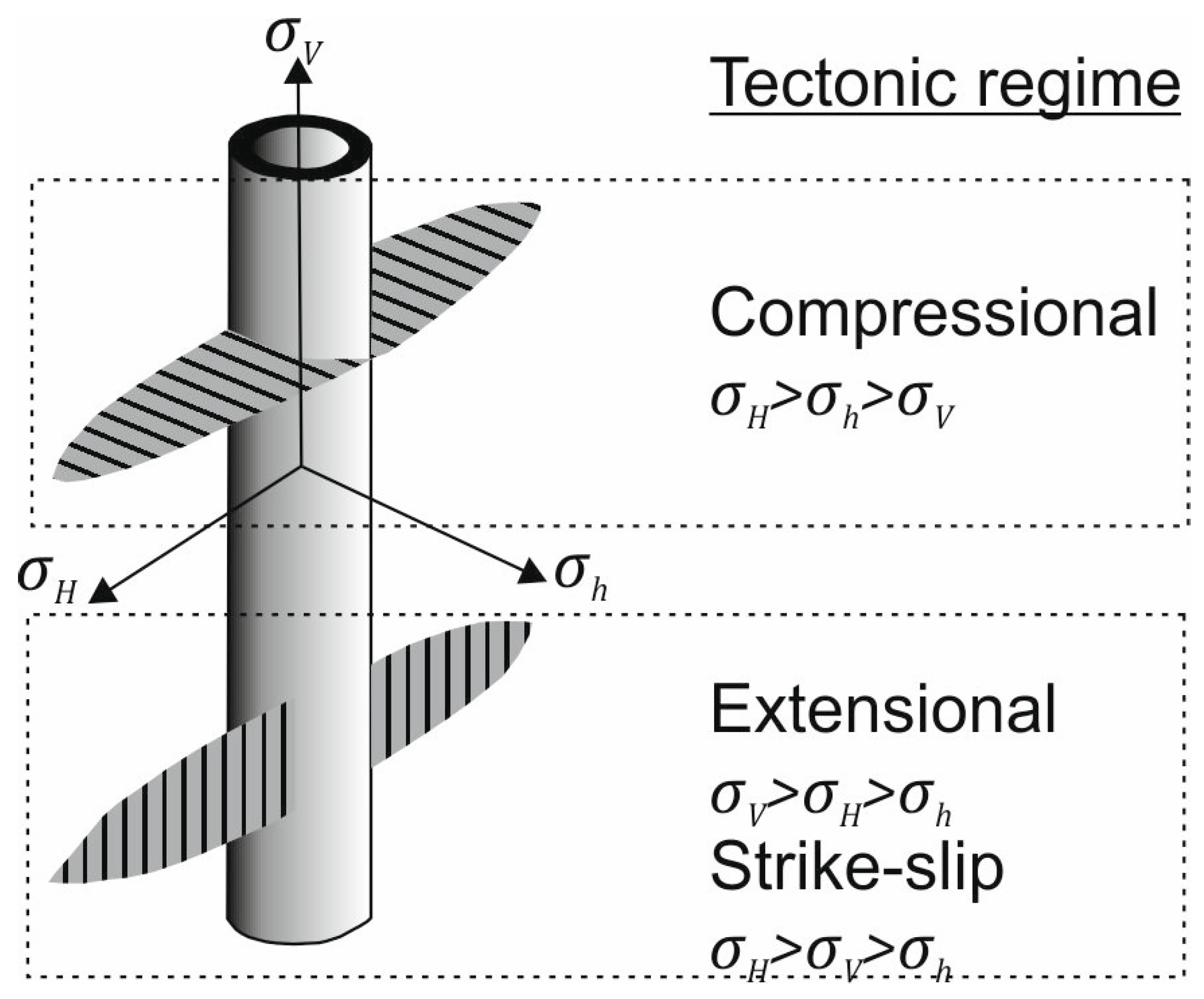

2. Geomechanical Issues of Hydraulic Fracturing in Hot Dry Formations

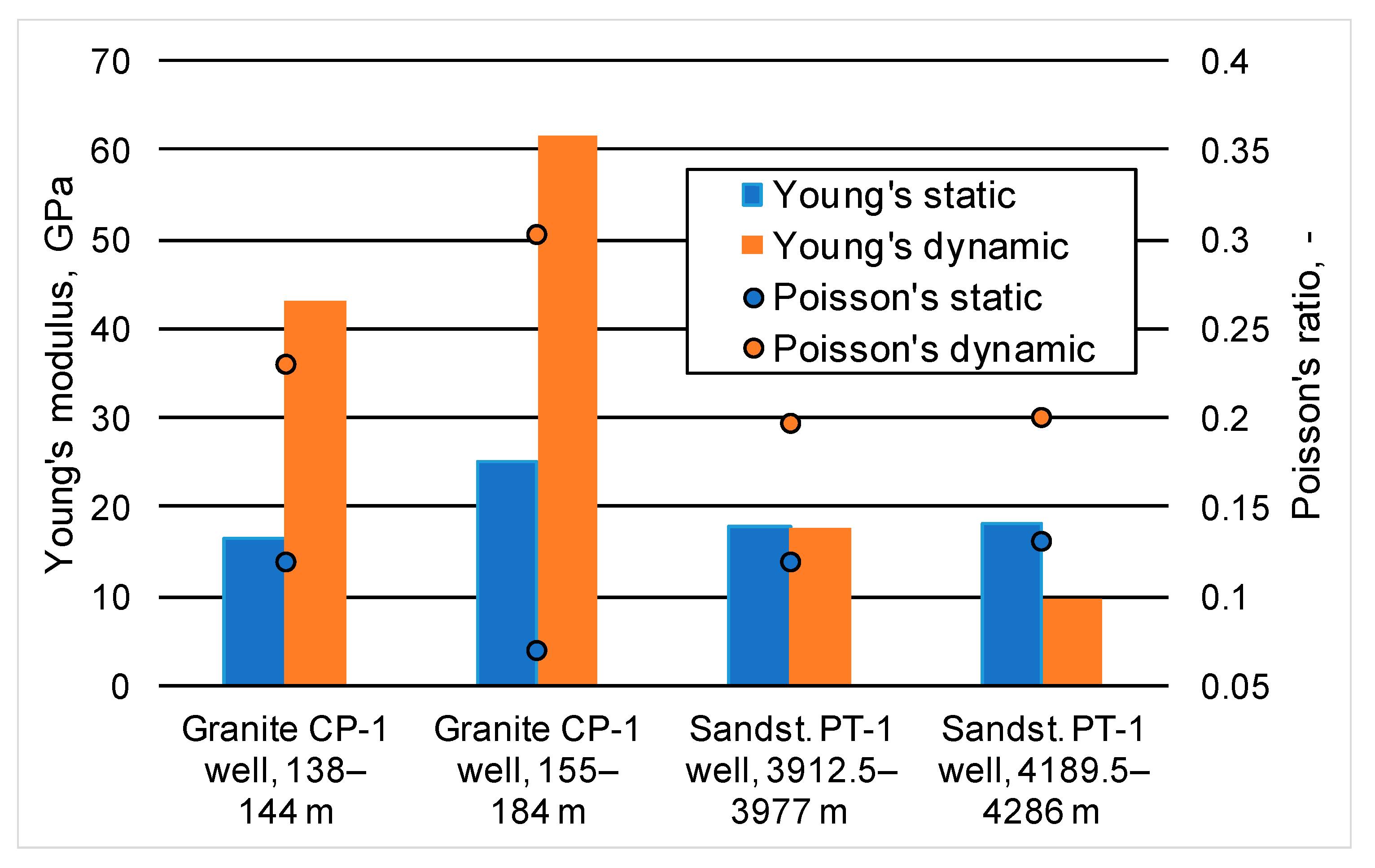

2.1. Laboratory Rock Elastic Parameter Determination

2.2. Relation Between Dynamic and Static Moduli

2.3. Modeling Hydraulic Fracture Geometry

3. Materials and Methods

3.1. Research Area

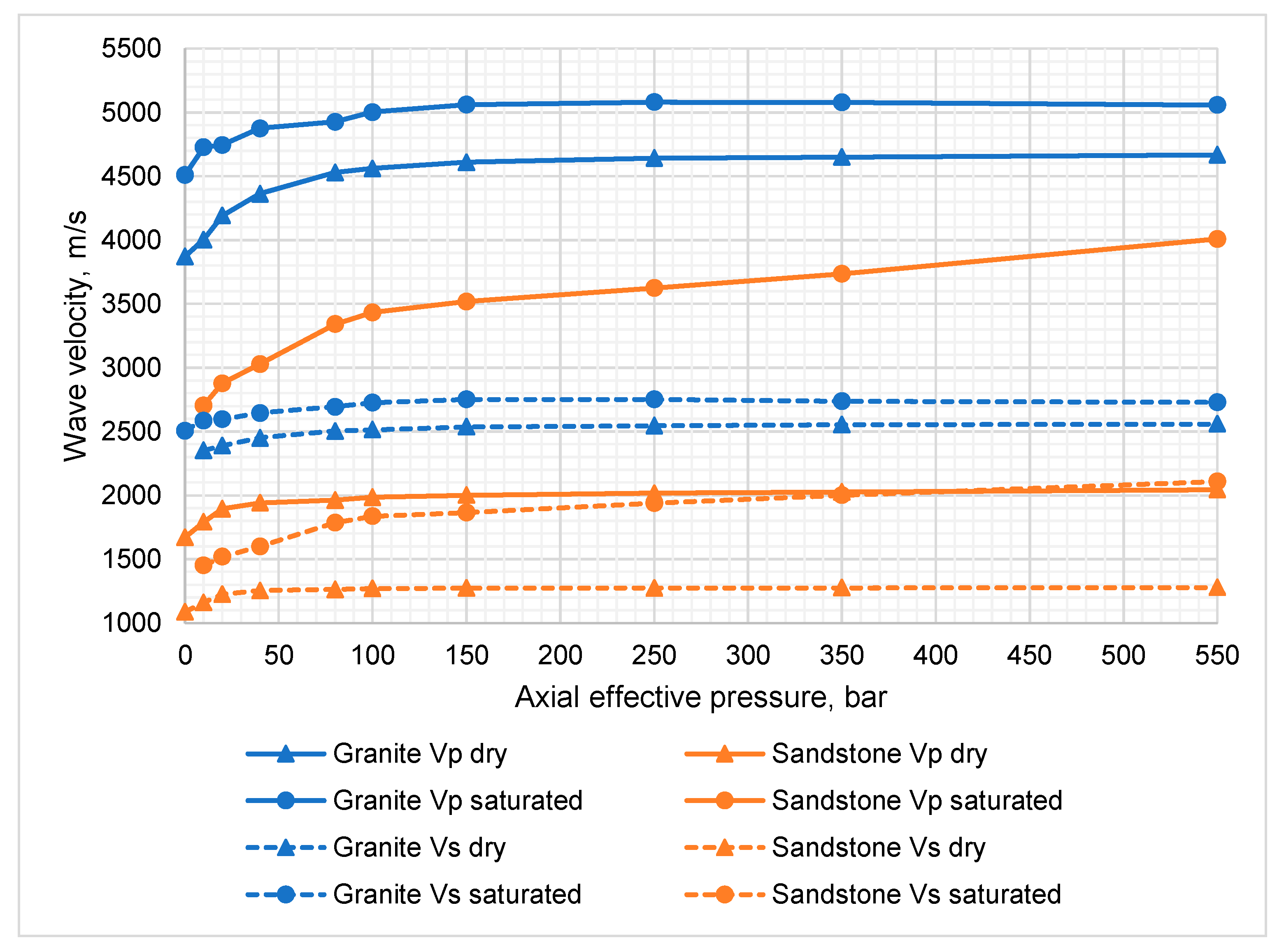

3.2. Determination of Dynamic Elastic Parameters

3.3. Determination of Static Elastic Parameters

3.4. Numerical Modeling of Fracture Geometry

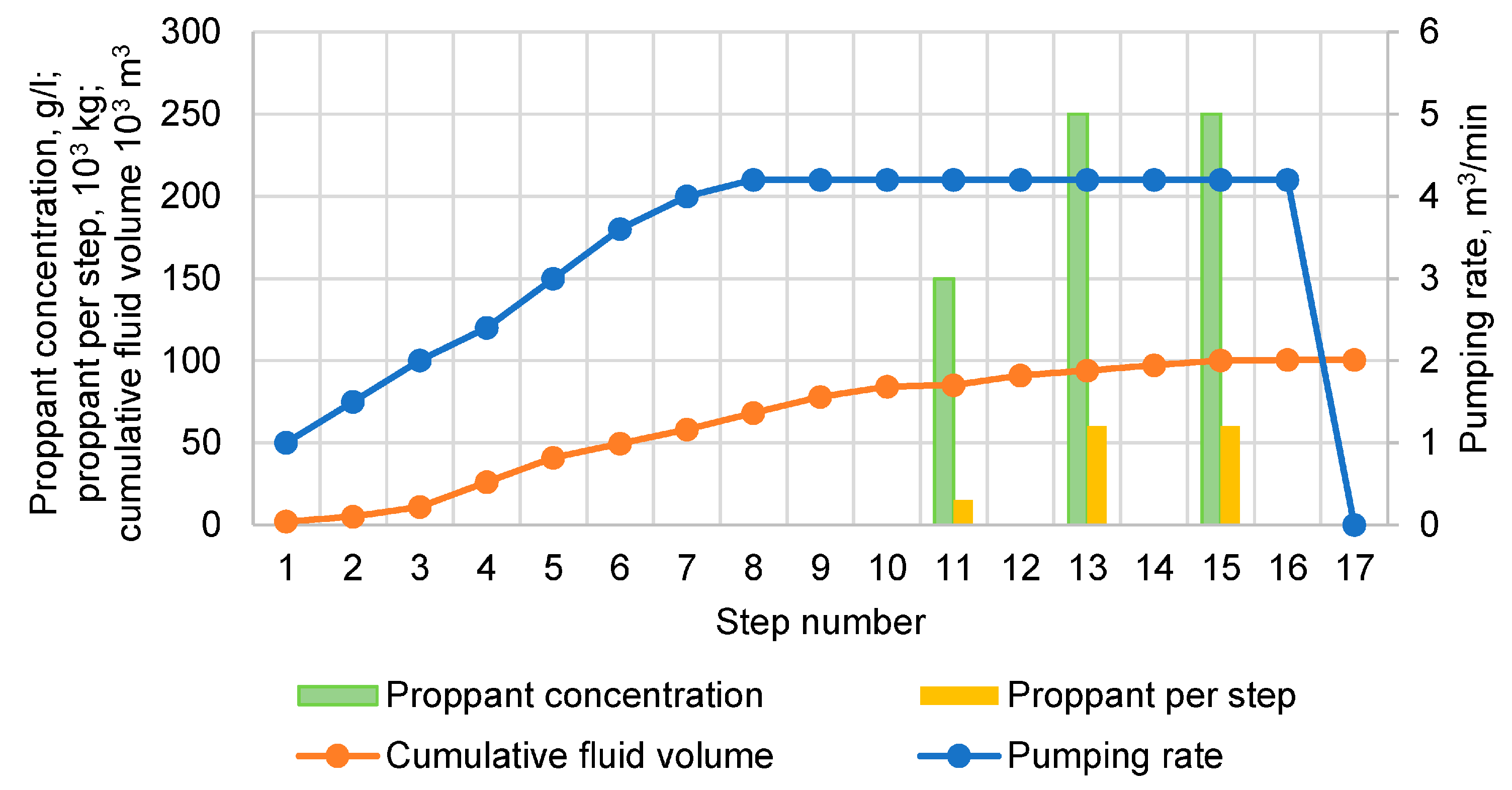

3.4.1. Mogilno-Łódź Trough Area, Sandstone Formation

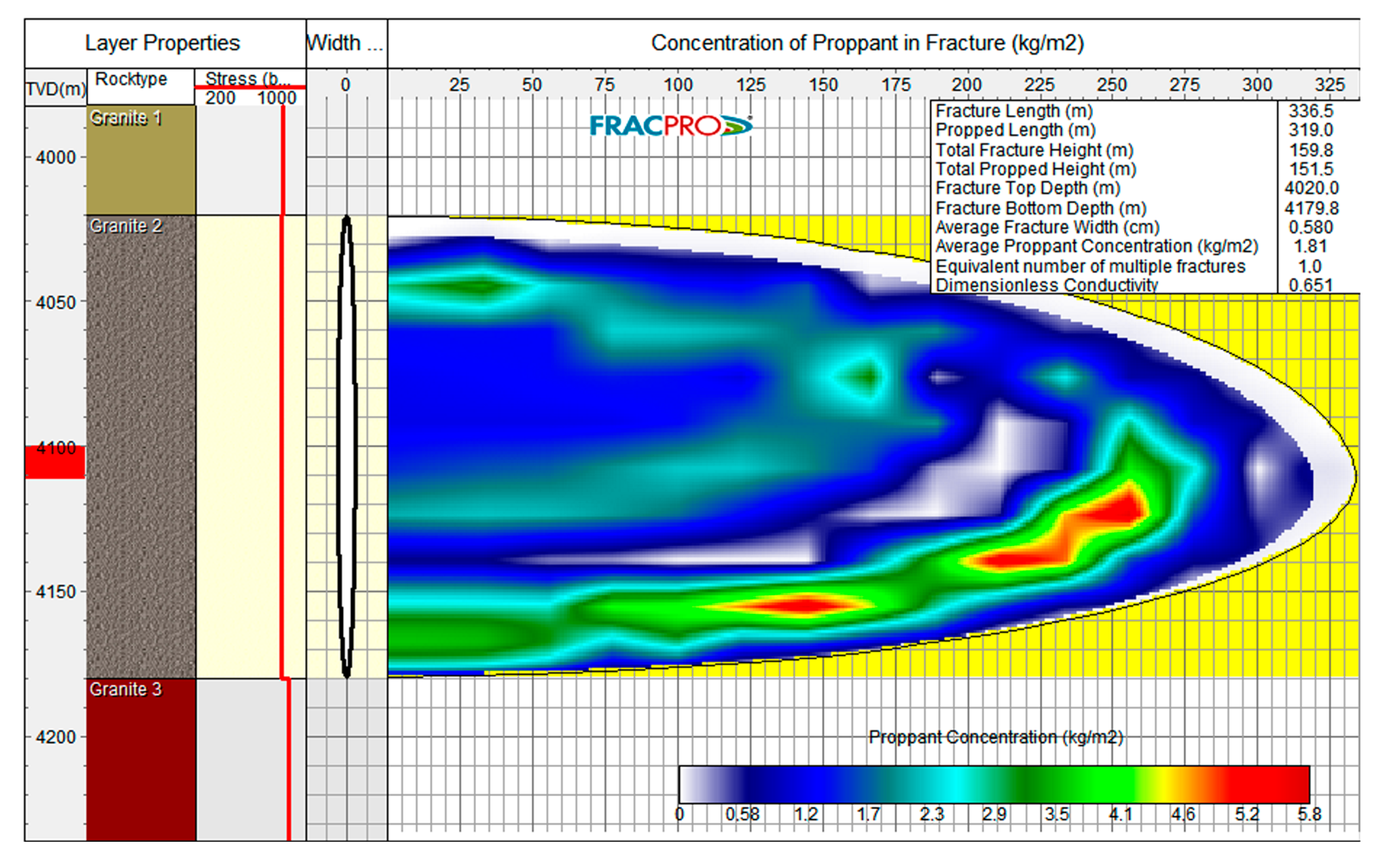

3.4.2. Karkonosze Mountains, Granite Formation

4. Results

5. Discussion

6. Conclusions

- (1)

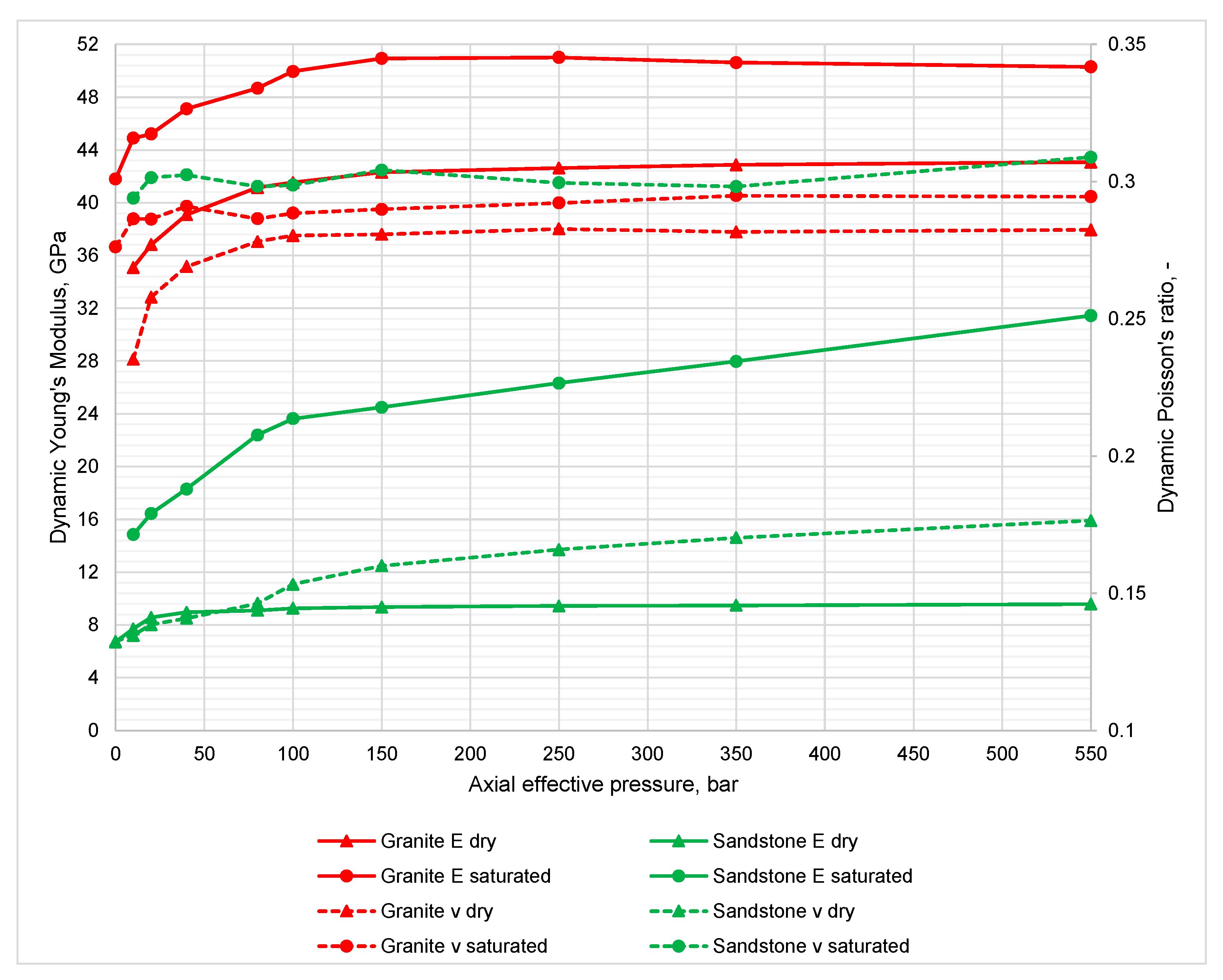

- Rock mechanics tests reveal large differences between the dynamic and static Young’s modulus and the Poisson’s ratio in granite formations from the Karkonosze Mountains, whereas these parameters in the sandstones of the Mogilno-Łódź Trough, especially the Young’s modulus, show less variation. For both lithology types, the best fit is given by a linear trend (R2 from 0.84 to 0.89 for sandstones and granites, respectively).

- (2)

- The saturation of the samples with brine causes a significant increase in the dynamic Young’s modulus compared to that of dry samples in both formations.

- (3)

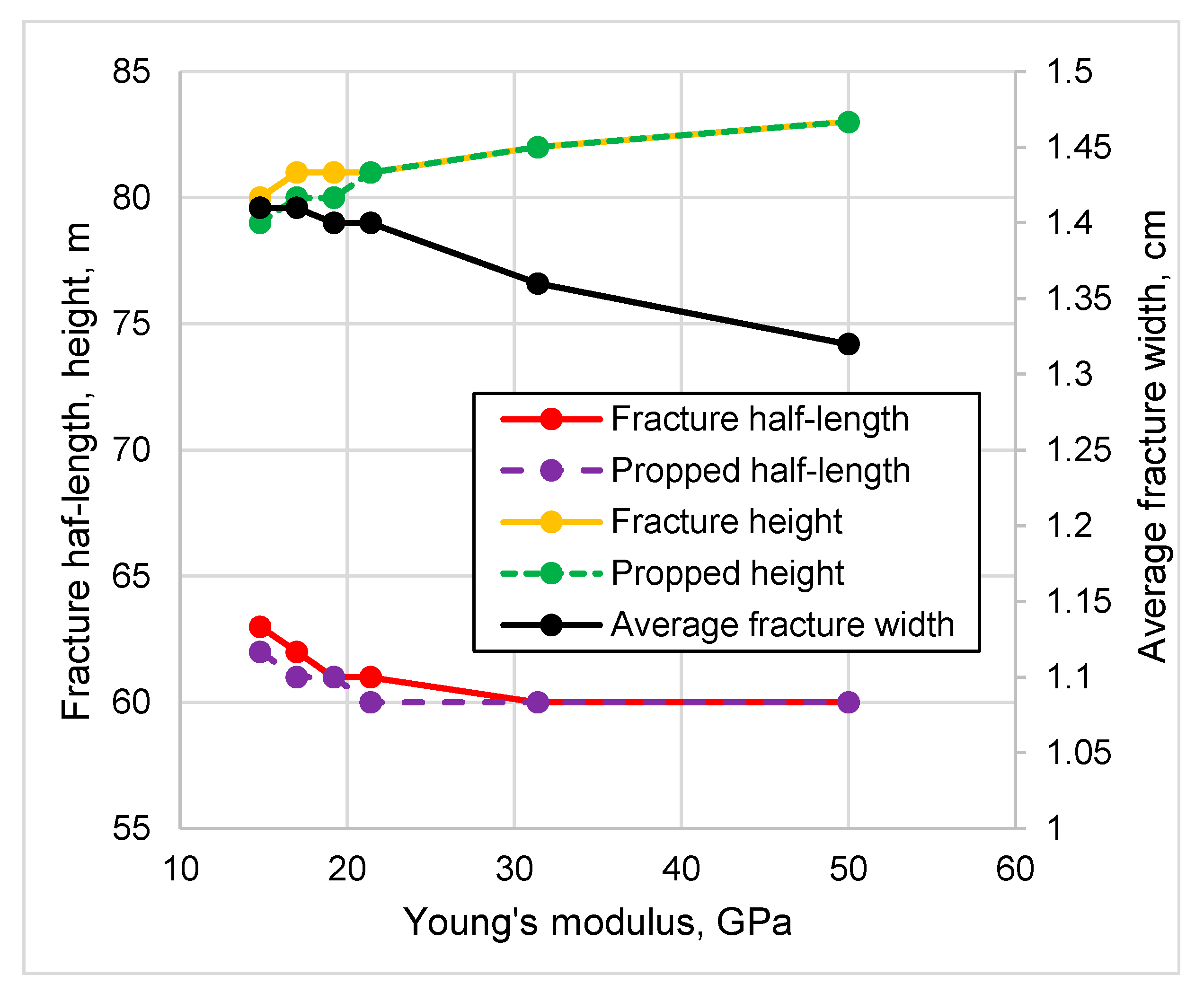

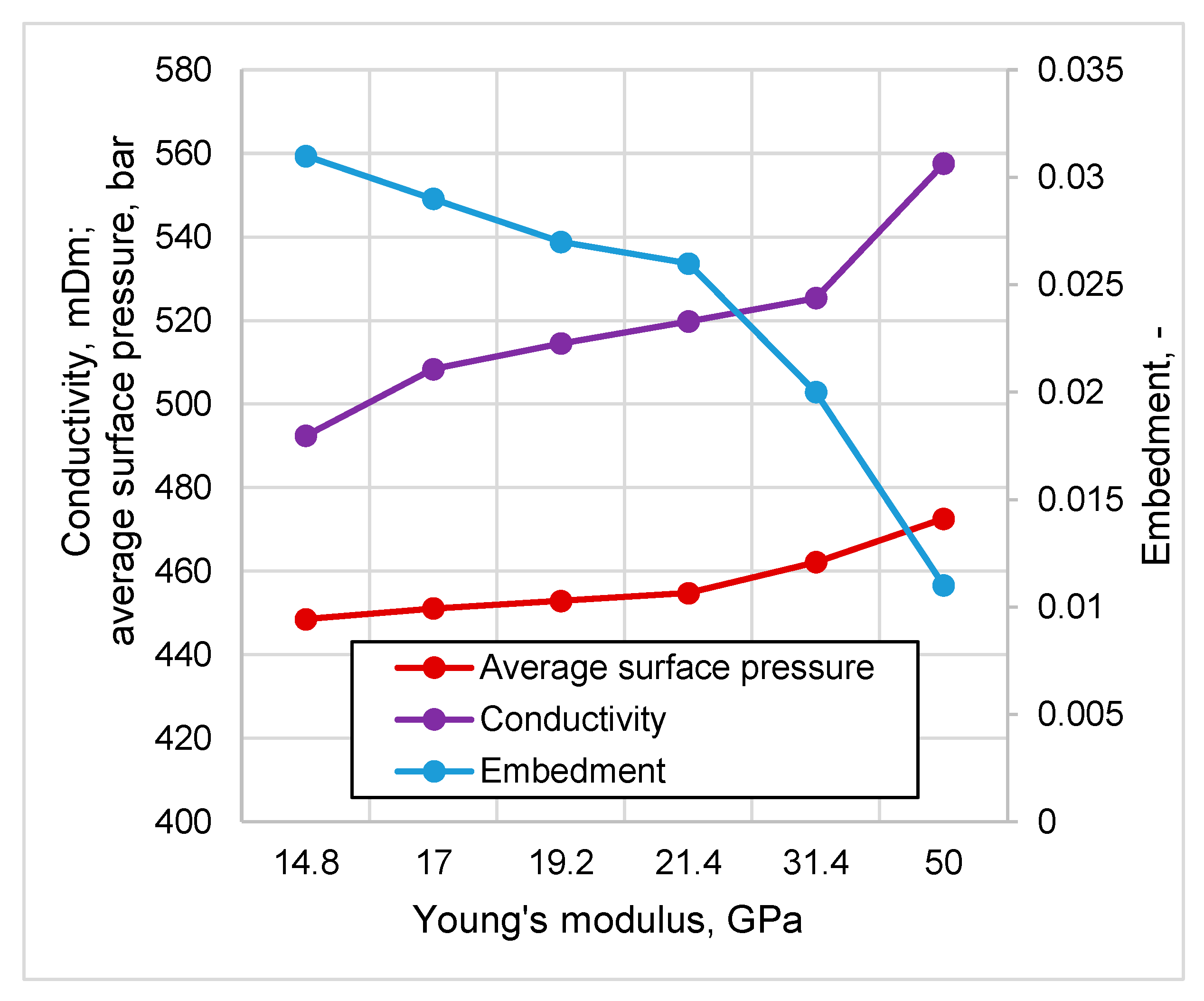

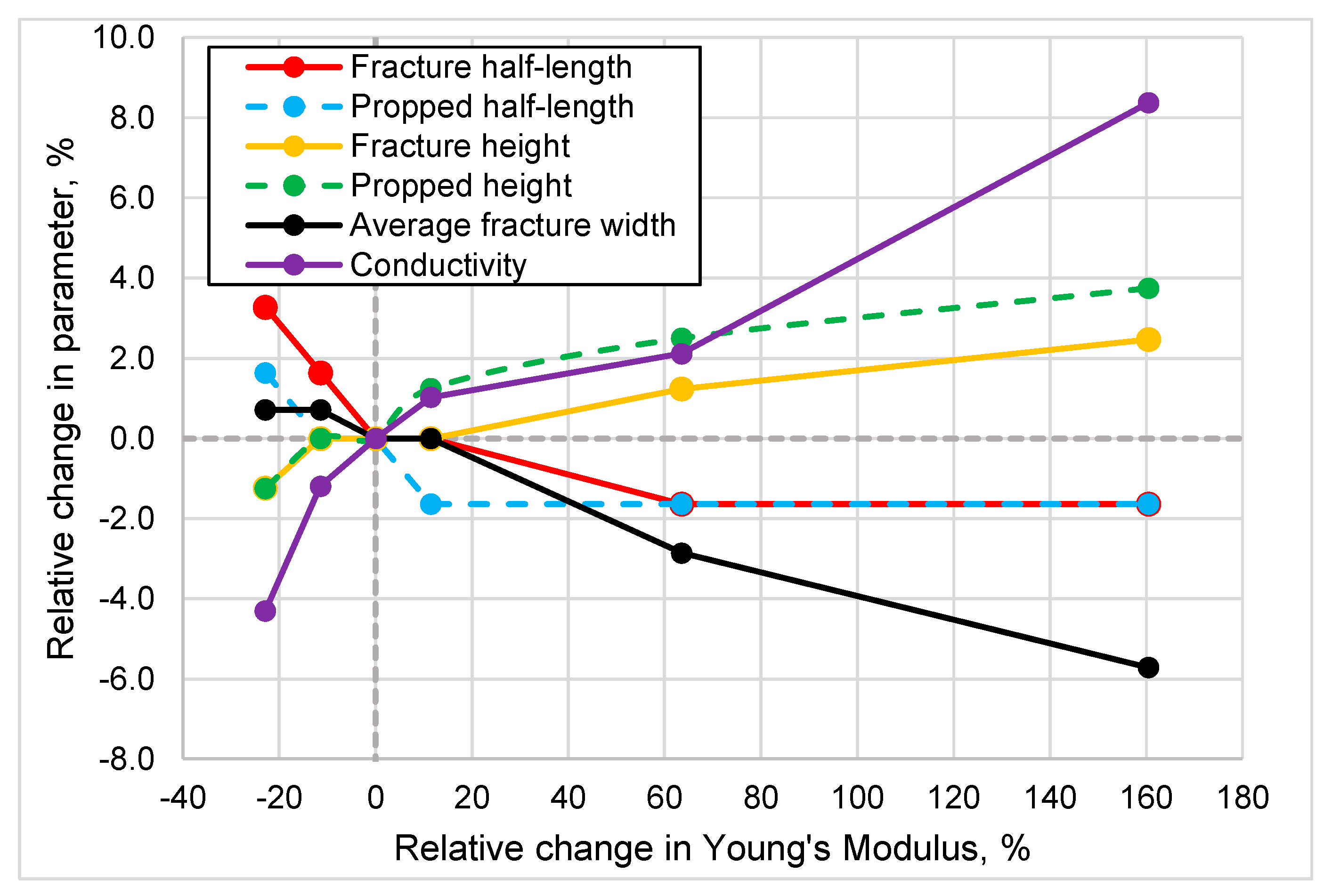

- Sensitivity analysis for Mogilno-Łódź sandstone shows that the increase in Young’s modulus from 14.8 to a 50.0 GPa leads to a decrease in the half-length of the fracture by 4.9% and in the width by 6.4%, as well as an increase in the height by 3.7% and in the conductivity by 12.7%. Variability in Poisson’s ratio (in the tested range from 0.1 to 0.35) leads to negligible changes in the propped fracture half-length and height, in the range below 1.6%.

- (4)

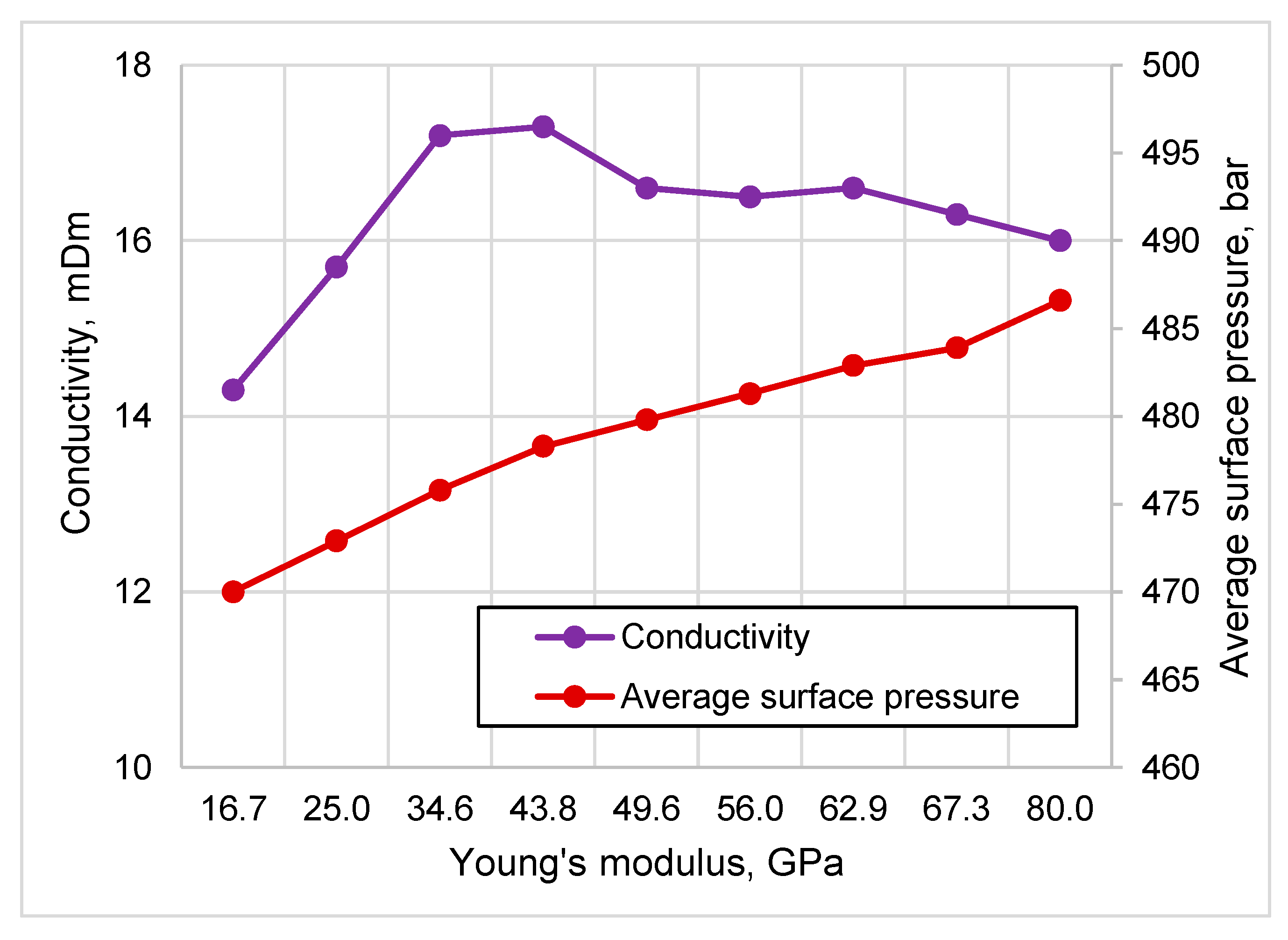

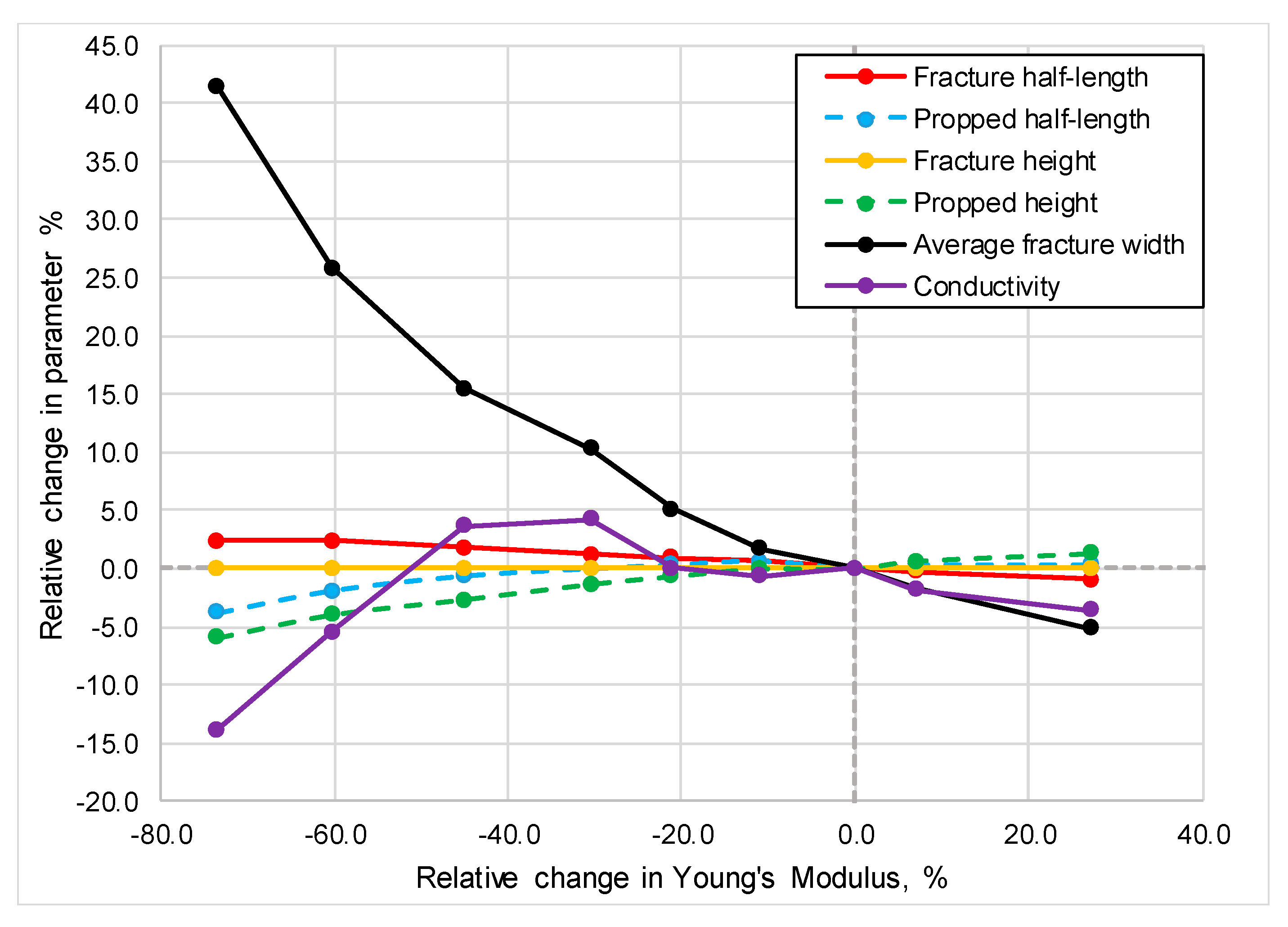

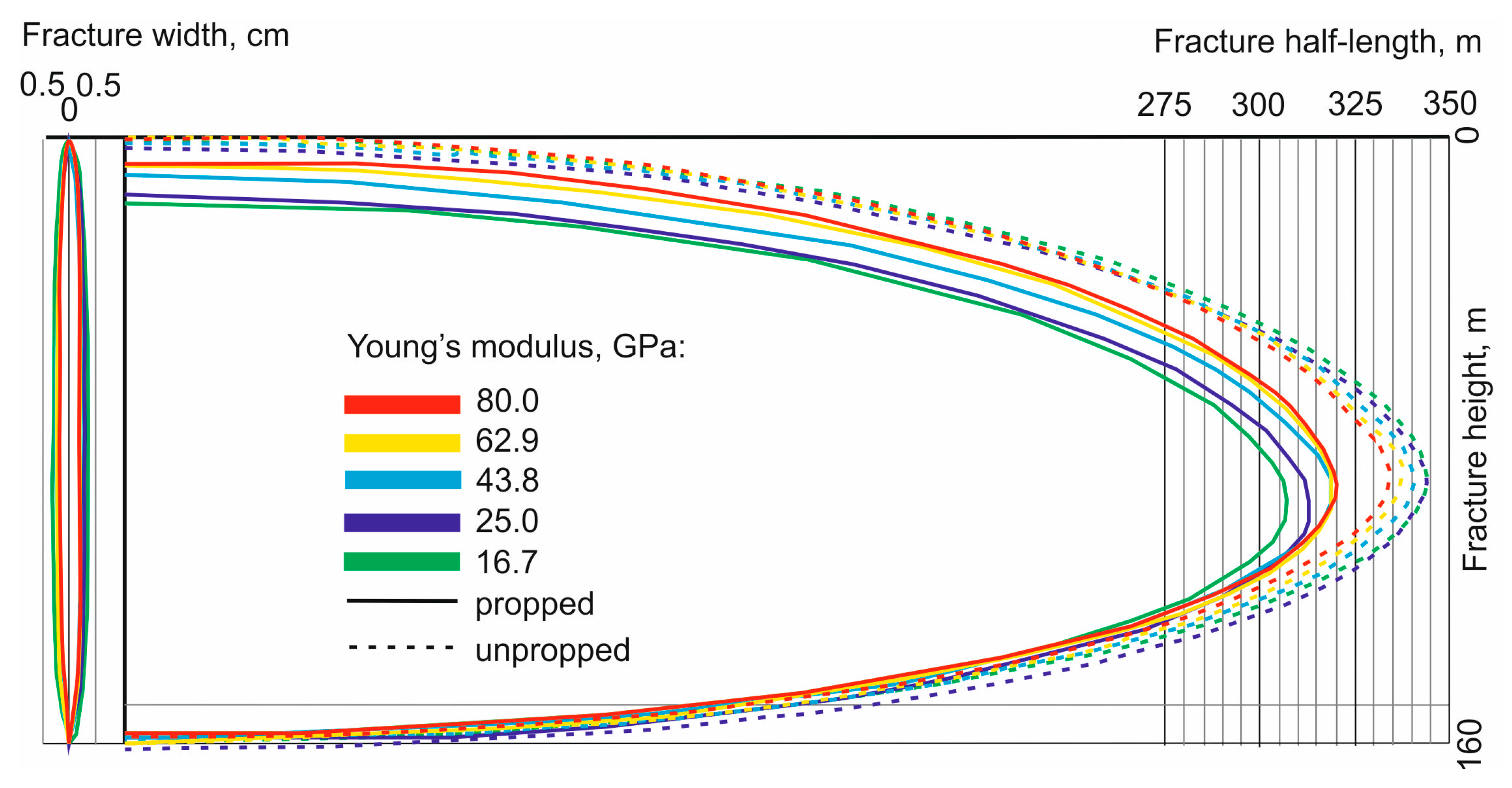

- In the case of the Karkonosze Mountains granite formation, the increase in Young’s modulus from 16.7 to a 80.0 GPa leads to decrease in half-length by 3.3% and in width by 46.4%, with an increase in propped half-length and height (4.1% and 7.3%, respectively). No influence is observed on the height of the fracture. Variability in Poisson’s ratio (in tested range from 0.7 to 0.37) leads to a negligible change the fracture half-length in the range below 1%, whereas fracture width varies more significantly (decreases by 7.9%).

- (5)

- Performing sensitivity analysis allows to determine that a relatively great variation in Young’s modulus and Poisson’s ratio leads to relatively little impact on fracture half-length and height in both of the hot dry formations tested. A stronger effect is observed only for fracture width in the granite formation.

- (6)

- The results of the Mogilno-Łódź hot dry rock model indicate that using similar fracturing operation parameters to those used in the Groß Schönebeck project, similar fracture geometry results can be obtained. However, in the case of the Karkonosze Mountains area, the obtained results should be considered a preliminary approximation due to software limitations, especially the disregarding of natural fracture stimulation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| HDR | Hot dry rock |

| EGS | Enhanced geothermal system |

| HF | Hydraulic fracturing |

| Young’s modulus in general/static/dynamic, Pa | |

| Poisson ratio in general/static/dynamic, dimensionless | |

| Bulk modulus, Pa | |

| Shear modulus, Pa | |

| Stress, Pa | |

| ε | Strain, m/m |

| Vertical principal stress, Pa | |

| Maximum horizontal stress, Pa | |

| Minimum horizontal stress, Pa | |

| Bulk density, g/cm3 | |

| Compressional wave velocity, m/s | |

| Shear wave velocity, m/s | |

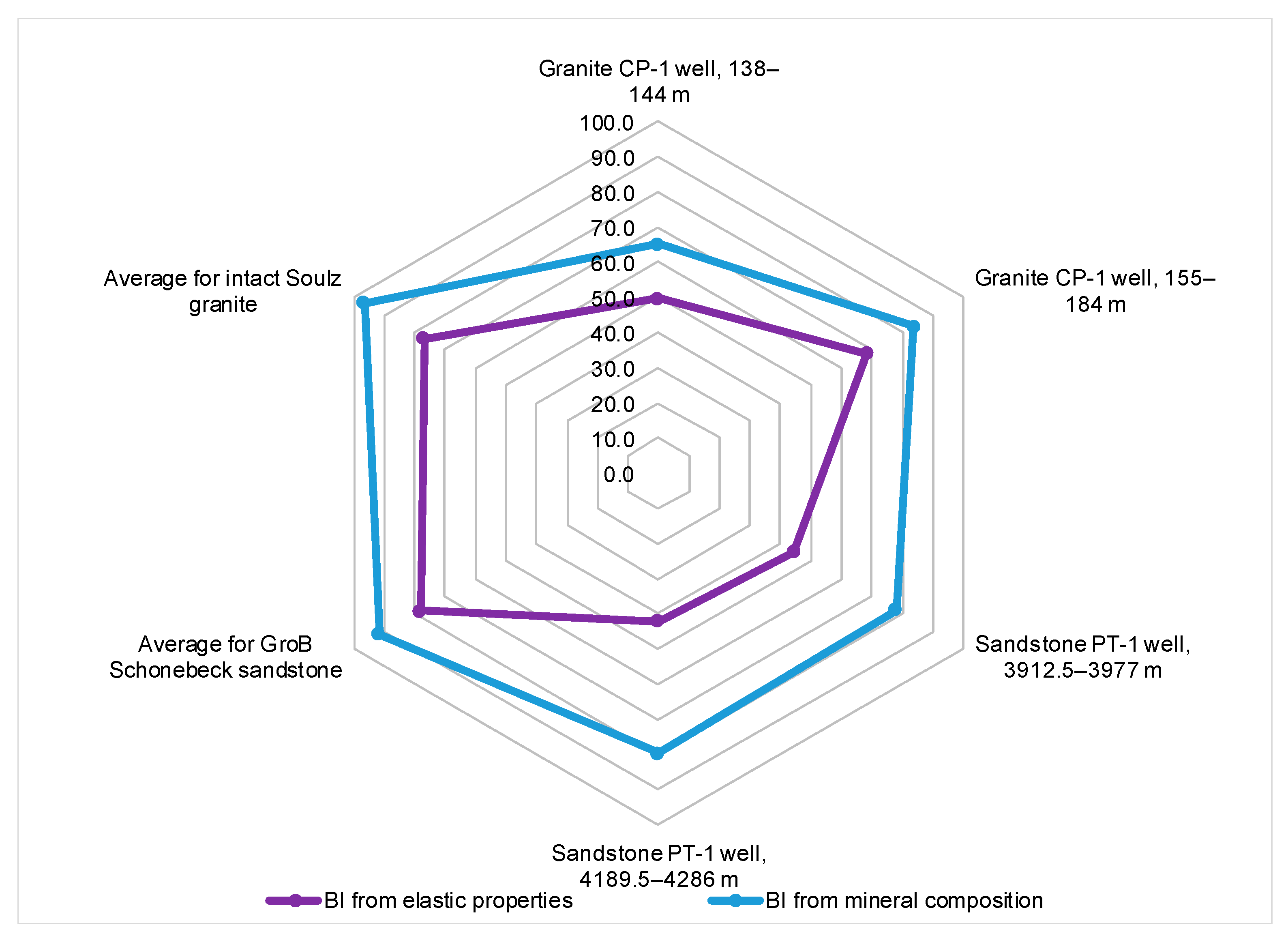

| BI | Brittleness index, % |

References

- Lu, S.-M. A global review of enhanced geothermal system (EGS). Renew. Sustain. Energy Rev. 2018, 81, 2902–2921. [Google Scholar] [CrossRef]

- Lei, Z.; Zhang, Y.; Zhang, S.; Shi, Y. Numerical study of hydraulic fracturing treatments and geothermal energy extraction from a naturally fractured granitic formation. Geothermics 2023, 111, 102692. [Google Scholar] [CrossRef]

- Tester, J.; Anderson, B.; Batchelor, A.; Blackwell, D.D.; DiPippo, R.; Drake, E.M.; Garnish, J.; Livesay, B.; Moore, M.C.; Nichols, K.; et al. The Future of Geothermal Energy-Impact of Enhanced Geothermal Systems (EGS) on the United States in the 21st Century; Massachusetts Institute of Technology: Cambridge, MA, USA, 2006. [Google Scholar]

- Brown, D.W.; Duchane, D.V.; Heiken, G.; Hriscu, V.T. Mining the Earth’s Heat: Hot Dry Rock Geothermal Energy; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Olasolo, P.; Juárez, M.C.; Morales, M.P.; D’Amico, S.; Liarte, I.A. Enhanced geothermal systems (EGS): A review. Renew. Sustain. Energy Rev. 2016, 56, 133–144. [Google Scholar] [CrossRef]

- Duffield, R.; Nunz, G.; Smith, M.; Wilson, M. Hot Dry Rock Geothermal Energy Development Program Annual Report, Fiscal Year 1980; Los Alamos National Laboratory: Los Alamos, NM, USA, 1980. [Google Scholar] [CrossRef][Green Version]

- Norbeck, J.H.; McClure, M.W.; Horne, R.N. Field observations at the Fenton Hill enhanced geothermal system test site support mixed-mechanism stimulation. Geothermics 2018, 74, 135–149. [Google Scholar] [CrossRef]

- Wakahama, H.; Mitoa, S.; Ohsumi, T.; Ueda, A.; Yajima, T.; Satoh, H.; Sugiyama, K.; Ozawa, A.; Ajima, S.; Todaka, N.; et al. A concept of CO2 georeactor sequestration at the Ogachi HDR site, NE Japan. Energy Procedia 2009, 1, 3683–3689. [Google Scholar] [CrossRef]

- Hogarth, R.; Holl, H.G. Lessons learned from the Habanero EGS project. GRC Trans. 2017, 41, 865–877. [Google Scholar]

- Legarth, B.; Huenges, E.; Zimmermann, G. Hydraulic fracturing in a sedimentary geothermal reservoir: Results and implications. Int. J. Rock. Mech. Min. Sci. 2005, 42, 1028–1041. [Google Scholar] [CrossRef]

- Zimmermann, G.; Moeck, I.; Blöcher, G. Cyclic waterfrac stimulation to develop an enhanced geothermal system (EGS)—Conceptual design and experimental results. Geothermics 2010, 39, 59–69. [Google Scholar] [CrossRef]

- Blöcher, G.; Reinsch, T.; Henninges, J.; Milsch, H.; Regenspurg, S.; Kummerow, J.; Francke, H.; Kranz, S.; Saadat, A.; Zimmermann, G.; et al. Hydraulic history and current state of the deep geothermal reservoir Groß Schönebeck. Geothermics 2016, 63, 27–43. [Google Scholar] [CrossRef]

- Baujard, C.; Genter, A.; Dalmais, E.; Maurer, V.; Hehn, R.; Rosillette, R.; Vidal, J.; Schmittbuhl, J. Hydrothermal characterization of wells GRT-1 and GRT-2 in Rittershoffen, France: Implications on the understanding of natural flow systems in the Rhine Graben. Geothermics 2017, 65, 255–268. [Google Scholar] [CrossRef]

- Vidal, J.; Genter, A. Overview of naturally permeable fractured reservoirs in the central and southern Upper Rhine Graben: Insights from geothermal wells. Geothermics 2018, 74, 57–73. [Google Scholar] [CrossRef]

- Park, S.; Kim, K.-I.; Xie, L.; Yoo, H.; Min, K.B.; Kim, M.; Yoon, B.; Kim, K.Y.; Zimmermann, G.; Guinot, F.; et al. Observations and analyses of the first two hydraulic stimulations in the Pohang geothermal development site, South Korea. Geothermics 2020, 88, 101905. [Google Scholar] [CrossRef]

- Moska, R.; Labus, K.; Kasza, P. Hydraulic fracturing in enhanced geothermal systems—Field, tectonic and rock mechanics conditions—A review. Energies 2021, 14, 5725. [Google Scholar] [CrossRef]

- Moska, R.; Labus, K.; Kasza, P.; Moska, A. Geothermal potential of hot dry rock in south-east Baltic Basin countries—A review. Energies 2023, 16, 1662. [Google Scholar] [CrossRef]

- Moska, R.; Labus, K.; Kasza, P. Dynamic elastic properties, petrophysical parameters and brittleness of hot dry rocks from prospective areas of Central Europe. Adv. Geo-Energy Sci. 2024, 14, 90–105. [Google Scholar] [CrossRef]

- Li, S.; Wang, S.; Tang, H. Stimulation mechanism and design of enhanced geothermal systems: A comprehensive review. Renew. Sustain. Energy Rev. 2022, 155, 111914. [Google Scholar] [CrossRef]

- McClure, M.W.; Horne, R.N. An investigation of stimulation mechanisms in enhanced geothermal systems. Int. J. Rock. Mech. Min. Sci. 2014, 72, 242–260. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, X.-P.; Sun, W. A review of laboratory studies and theoretical analysis for the interaction mode between induced hydraulic fractures and pre-existing fractures. J. Nat. Gas. Sci. Eng. 2021, 86, 103719. [Google Scholar] [CrossRef]

- Dixit, N.C.; Hanks, C.L.; Wallace, W.K.; Ahmadi, M.; Awoleke, O. In situ stress variations associated with regional changes in tectonic setting, northeastern Brooks Range and eastern North Slope of Alaska. AAPG Bull. 2017, 101, 343–360. [Google Scholar] [CrossRef]

- Economides, M.J.; Nolte, K.G. Reservoir Stimulation, 3rd ed.; Wiley: Chichester, UK; New York, NY, USA, 2000. [Google Scholar]

- Rickman, R.; Mullen, M.; Petre, E.; Grieser, W.V.; Kundert, D. A practical use of shale petrophysics for stimulation design optimization: All shale plays are not clones of the Barnett shale. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar] [CrossRef]

- Masłowski, M.; Kasza, P.; Czupski, M.; Wilk, K.; Moska, R. Studies of fracture damage caused by the proppant embedment phenomenon in shale rock. Appl. Sci. 2019, 9, 2190. [Google Scholar] [CrossRef]

- Masłowski, M.; Labus, M. Preliminary studies on the proppant embedment in Baltic Basin shale rock. Rock. Mech. Rock. Eng. 2021, 54, 2233–2248. [Google Scholar] [CrossRef]

- Shen, S.; Gao, Y.; Jia, L. A Comparison of the relationship between dynamic and static rock mechanical parameters. Appl. Sci. 2024, 14, 4487. [Google Scholar] [CrossRef]

- Zoback, M. Reservoir Geomechanics; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- AL-Ameri, W.A.; Abdulraheem, A.; Mahmoud, M. Long-term effects of CO2 sequestration on rock mechanical properties. J. Energy Resour. Technol. 2016, 138, 012201. [Google Scholar] [CrossRef]

- Moska, R. Wpływ oddziaływania CO2 na dynamiczne parametry geomechaniczne w systemie geotermalnym. Nafta-Gaz 2023, 79, 199–212. [Google Scholar] [CrossRef]

- Grieser, B.; Bray, J. Identification of Production Potential in Unconventional Reservoirs. In Proceedings of the Production and Operations Symposium, Oklahoma, OK, USA, 31 March–3 April, 2007. [Google Scholar] [CrossRef]

- Brotons, V.; Tomás, R.; Ivorra, S.; Grediaga, A. Relationship between static and dynamic elastic modulus of calcarenite heated at different temperatures: The San Julián’s stone. Bull. Eng. Geol. Environ. 2014, 73, 791–799. [Google Scholar] [CrossRef]

- Davarpanah, S.M.; Ván, P.; Vásárhelyi, B. Investigation of the relationship between dynamic and static deformation moduli of rocks. Geomech. Geophys. Geo-Energy Geo-Resour. 2020, 6, 29. [Google Scholar] [CrossRef]

- Eissa, E.A.; Kazi, A. Relation between static and dynamic Young’s moduli of rocks. Int. J. Rock. Mech. Min. Sci. Geomech. Abstr. 1988, 25, 479–482. [Google Scholar] [CrossRef]

- Brotons, V.; Tomás, R.; Ivorra, S. Improved correlation between the static and dynamic elastic modulus of different types of rocks. Mater. Struct. 2016, 49, 3021–3037. [Google Scholar] [CrossRef]

- Bukowska, M.; Kasza, P.; Moska, R.; Jureczka, J. The Young’s modulus and Poisson’s ratio of hard coals in laboratory tests. Energies 2022, 15, 2477. [Google Scholar] [CrossRef]

- Meller, C.; Ledésert, B. Is there a link between mineralogy, petrophysics, and the hydraulic and seismic behaviors of the Soultz-sous-Forêts granite during stimulation? A review and reinterpretation of petro-hydromechanical data toward a better understanding of induced seismicity and fluid flow. J. Geophys. Res. Solid. Earth 2017, 122, 9755–9774. [Google Scholar] [CrossRef]

- Villeneuve, M.; Heap, M.; Kushnir, A.; Qin, T.; Baud, P.; Zhou, G.; Xu, T. Estimating in situ rock mass strength and elastic modulus of granite from the Soultz-sous-Forêts geothermal reservoir (France). Geotherm. Energy 2018, 6, 11. [Google Scholar] [CrossRef]

- Al-Shayea, N.A. Effects of testing methods and conditions on the elastic properties of limestone rock. Eng. Geol. 2004, 74, 139–156. [Google Scholar] [CrossRef]

- Lama, R.D.; Vutukuri, V.S. Handbook on Mechanical Properties of Rocks; Trans Tech Publications: Clausthal-Zellerfeld, Germany, 1978; Volume II. [Google Scholar]

- Yadali Jamaloei, B. A critical review of common models in hydraulic-fracturing simulation: A practical guide for practitioners. Theor. Appl. Fract. Mech. 2021, 113, 102937. [Google Scholar] [CrossRef]

- Legarth, B.; Tischner, T.; Huenges, E. Stimulation experiments in sedimentary, low-enthalpy reservoirs for geothermal power generation, Germany. Geothermics 2003, 32, 487–495. [Google Scholar] [CrossRef]

- Zimmermann, G.; Reinicke, A. Hydraulic stimulation of a deep sandstone reservoir to develop an enhanced geothermal system: Laboratory and field experiments. Geothermics 2010, 39, 70–77. [Google Scholar] [CrossRef]

- Lei, Z.; Zhang, Y.; Zhang, S.; Fu, L.; Hu, Z.; Yu, Z.; Li, L.; Zhou, J. Electricity generation from a three-horizontal-well enhanced geothermal system in the Qiabuqia geothermal field, China: Slickwater fracturing treatments for different reservoir scenarios. Renew. Energy 2020, 145, 65–83. [Google Scholar] [CrossRef]

- Guo, T.; Gong, F.; Wang, X.; Lin, Q.; Qu, Z.; Zhang, W. Performance of enhanced geothermal system (EGS) in fractured geothermal reservoirs with CO2 as working fluid. Appl. Therm. Eng. 2019, 152, 215–230. [Google Scholar] [CrossRef]

- Guo, T.; Tang, S.; Liu, S.; Liu, X.; Zhang, W.; Qu, G. Numerical simulation of hydraulic fracturing of hot dry rock under thermal stress. Eng. Fract. Mech. 2020, 240, 107350. [Google Scholar] [CrossRef]

- Aliyu, M.D.; Archer, R.A. Numerical simulation of multifracture HDR geothermal reservoirs. Renew. Energy 2021, 164, 541–555. [Google Scholar] [CrossRef]

- Cheng, Q.; Wang, X.; Ghassemi, A. Numerical simulation of reservoir stimulation with reference to the Newberry EGS. Geothermics 2019, 77, 327–343. [Google Scholar] [CrossRef]

- Xue, Z.; Wei, Z.; Ma, H.; Sun, Z.; Lu, C.; Chen, Z. Exploring the role of fracture networks in enhanced geothermal systems: Insights from integrated thermal-hydraulic-mechanical-chemical and wellbore dynamics simulations. Renew. Sustain. Energy Rev. 2025, 215, 115636. [Google Scholar] [CrossRef]

- Ulusay, R.; Hudson, J. The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring:1974–2006; ISRM Turkish National Group: Ankara, Turkey, 2007. [Google Scholar]

- Gentier, S.; Rachez, X.; Dezayes, C.; Blaisonneau, A.; Genter, A. How to understand the effect of the hydraulic stimulation in term of hydro-mechanical behavior at Soultz-sous-Forêts (France)? GRC Trans. 2005, 29, 159–166. [Google Scholar]

- Schindler, M.; Baumgärtner, J.; Gandy, T.; Hauffe, P.; Hettkamp, T.; Menzel, H.; Penzkofer, P.; Teza, D.; Tischner, T.; Wahl, G. Successful hydraulic stimulation techniques for electric power production in the Upper Rhine Graben, Central Europe. In Proceedings of the World Geothermal Congress, Bali, Indonesia, 25–30 April 2010. [Google Scholar]

- Bujakowski, W.; Barbacki, A.; Miecznik, M.; Pająk, L.; Skrzypczak, R. A structural-thermal model of the Karkonosze Pluton (Sudetes Mountains, SW Poland) for Hot Dry Rock (HDR) geothermal use. Arch. Min. Sci. 2016, 61, 917–935. [Google Scholar] [CrossRef]

- Lógó, A.; Vásárhelyi, B. Theoretical Relationship between the Confining Pressure and Poisson’s Ratio of Intact Rock. Period. Polytech. Civ. Eng. 2022, 66, 1114–1121. [Google Scholar] [CrossRef]

- Molina, O.; Vilarrasa, V.; Zeidouni, M. Geologic carbon storage for shale gas recovery. Energy Procedia 2017, 114, 5748–5760. [Google Scholar] [CrossRef]

- Lake, L. Petroleum Engineering Handbook; Society of Petroleum Engineers: Richardson, TX, USA, 2007. [Google Scholar]

- Bourbié, T.; Coussy, O.; Zinszner, B. Acoustics of Porous Media; Editions Technip: Paris, France, 1987. [Google Scholar]

- Yang, S.; Tian, W.; Elsworth, D.; Wang, J.G.; Fan, L.F. An Experimental Study of Effect of High Temperature on the Permeability Evolution and Failure Response of Granite Under Triaxial Compression. Rock. Mech. Rock. Eng. 2019, 53, 4403–4427. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, Y.; Zhang, Y.; Yu, Z.; Zhang, J. Experimental investigation of granite properties under different temperatures and pressures and numerical analysis of damage effect in enhanced geothermal system. Ren. Energy 2018, 126, 107–125. [Google Scholar] [CrossRef]

- Paul, S.; Chattopadhyaya, S.; Raina, A.K.; Sharma, S.; Li, C.; Zhang, Y.; Kumar, A.; Tag-Eldin, E. A Review on the Impact of High-Temperature Treatment on the Physico-Mechanical, Dynamic, and Thermal Properties of Granite. Sustainability 2022, 14, 14839. [Google Scholar] [CrossRef]

- Waliy, F.; Buntoro, A.; Lukmana, A.H.; Rahma, A.A. The Effect of Poisson’s Ratio and Young’s Modulus on Fracture Geometry of 2D Model PKN: Case Study of Unconventional Reservoir; IATMI: Jakarta, Indonesia, 2020. [Google Scholar]

- Suryadinata, M.D.; Ratnaningsih, D.R.; Ariadi, I.K.; Waliy, F.; Nugroho, W.A. Rock mechanics effect on fracture geometry and dimensionless fracture conductivity of 2D model KGD (Khristianovic-Geertsma-de Klerk) in Air Benakat formation, Meruap field. Int. J. Pet. Gas. Explor. Manag. 2021, 5, 1–14. [Google Scholar]

- Osman, T.; Bilgesu, H.I. Impact of Geo-Mechanical Properties on the Fracture Treatment of Utica Shale. In Proceedings of the SPE Eastern Regional Meeting, Morgantown, WV, USA, 13–15 October 2015. [Google Scholar] [CrossRef]

- Fernando, B.F.; Wellington, C.; Braga, M.B.; Bothelho, M.O.A.; Freitas, A.C.D.; Braga, L.F.Q.F.; Frota, R.A. Hydraulics and geomechanics parameters for hydraulic fracturing optimization in production’s developments of shale gas/shale oil in North America. J. Pet. Environ. Biotechnol. 2020, 11, 399. [Google Scholar] [CrossRef]

- Ngoma, M.C.; Kolawole, O.; Olorode, O. Geothermo-mechanical alterations due to heat energy extraction in enhanced geothermal systems: Overview and prospective directions. Deep Undergr. Sci. Eng. 2024, 3, 256–268. [Google Scholar] [CrossRef]

| Induced Fracture Parameters | Sandstone, Mogilno-Łódź Trough | Granite, Karkonosze Mountains | ||

|---|---|---|---|---|

| Young’s Modulus | Poisson’s Ratio | Young’s Modulus | Poisson’s Ratio | |

| Half-length | − | No influence | − | − |

| Propped half-length | − | − | + | Not clear |

| Height | + | No influence | No influence | No influence |

| Propped height | + | + | + | Not clear |

| Width | − | No influence | − | − |

| Conductivity | + | Not clear | Not clear | Not clear |

| Surface pressure | + | + | + | + |

| Embedment | − | No influence | − | No influence |

| Treatment Parameter | GroßSchönebeck E GrSk 3/90 Vertical Well (2002) Gel/Proppant Frac I | Groß Schönebeck Gt GrSk 4/05 A (2) Horizontall Well (2007) Gel/Proppant Frac I | Groß Schönebeck Gt GrSk 4/05 A (2) Horizontal Well (2007) Gel/Proppant Frac II | Mogilno-Łódź Sedimentary HDR Numerical Model, Vertical Well Gel/Proppant Frac |

|---|---|---|---|---|

| Duration, h | 9.3 | 1.5 | 2 | 1.6 |

| Frac interval, m | 4140–4200 | 4204–4208 | 4118–4122 | 4060–4080 |

| Completion | Open hole | Perforated liner | Perforated liner | Perforated liner |

| Max. flow rate, m3/h | 138 | 240 | 210 | 240 |

| Cumulative volume, m3 | 107 | 280 | 310 | 317 |

| Max. head pressure, bar | 452 | 350 | 400 | 533 |

| Gel type | HTU/brine | Cross-linked | Cross-linked | Cross-linked |

| Proppant type | Carbo-Lt | High strength | High strength | CarboHSP |

| Mesh size | 20/40 | 20/40 | 20/40 | 20/40 |

| Proppant mass, kg | 8796 | 95,000 | 113,000 | 103,497 |

| Fracture dimensions | ||||

| Half-length, m | 32 | 57 | 60 | 61 |

| Height, m | 72 | 115 | 95 | 81 |

| Width, cm | 0.16 | 0.53 | 0.53 | 1.4 (average) |

| Treatment Parameter | Soultz GPK2 | Soultz GPK4 | Landau GtLa2 | Landau GtLa2 | Karkonosze Mountains Igneous HDR Numerical Model, Vertical Well |

|---|---|---|---|---|---|

| Massive Fracturing | Low-Rate Injection | Hydraulic Stimulation | High-Rate Stimulation | Massive Fracturing | |

| Duration, h | 144 | 84 | few hours | few hours | 55 |

| Max. flow rate, m3/h | 180 | 108 | up to 310 | up to 684 | 252 |

| Cumulative volume m3 | 23,400 | 9300 | 4060 | 6600 | 10,041 |

| Max. net pressure, bar | 150 | 170 | 100 | 100 | 37 |

| Fluid type | Fresh water | Fresh water | Fresh water | Fresh water | Slickwater |

| Proppant type | - | - | - | - | High strength |

| Mesh size/proppant mass, kg | - | - | - | - | 40/70/135,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moska, R.; Labus, K.; Kasza, P. Impact of Rock Elastic Properties on Fracture Geometry in Potential Enhanced Geothermal Systems in Poland. Energies 2025, 18, 2869. https://doi.org/10.3390/en18112869

Moska R, Labus K, Kasza P. Impact of Rock Elastic Properties on Fracture Geometry in Potential Enhanced Geothermal Systems in Poland. Energies. 2025; 18(11):2869. https://doi.org/10.3390/en18112869

Chicago/Turabian StyleMoska, Rafał, Krzysztof Labus, and Piotr Kasza. 2025. "Impact of Rock Elastic Properties on Fracture Geometry in Potential Enhanced Geothermal Systems in Poland" Energies 18, no. 11: 2869. https://doi.org/10.3390/en18112869

APA StyleMoska, R., Labus, K., & Kasza, P. (2025). Impact of Rock Elastic Properties on Fracture Geometry in Potential Enhanced Geothermal Systems in Poland. Energies, 18(11), 2869. https://doi.org/10.3390/en18112869