Abstract

CO2-enhanced coalbed methane recovery (CO2-ECBM) represents a promising pathway within carbon capture, utilization, and storage (CCUS) technologies, offering dual benefits of methane production and long-term CO2 sequestration. This review provides a comprehensive analysis of CO2-ECBM from a full-chain perspective (Mechanism, Practices, and Outlook), covering fundamental mechanisms and key engineering practices. It highlights the complex multi-physics processes involved, including competitive adsorption–desorption, diffusion and seepage, thermal effects, stress responses, and geochemical interactions. Recent progress in laboratory experiments, capacity assessments, site evaluations, monitoring techniques, and numerical simulations are systematically reviewed. Field studies indicate that CO2-ECBM performance is strongly influenced by reservoir pressure, temperature, injection rate, and coal seam properties. Structural conditions and multi-field coupling further affect storage efficiency and long-term security. This work also addresses major technical challenges such as real-time monitoring limitations, environmental risks, injection-induced seismicity, and economic constraints. Future research directions emphasize the need to deepen understanding of coupling mechanisms, improve monitoring frameworks, and advance integrated engineering optimization. By synthesizing recent advances and identifying research priorities, this review aims to provide theoretical support and practical guidance for the scalable deployment of CO2-ECBM, contributing to global energy transition and carbon neutrality goals.

1. Introduction

Global climate change represents one of the most critical challenges facing modern human society, with greenhouse gas emissions—particularly CO2—widely recognized as a primary driver of global warming [1,2,3,4]. In light of the progress of international climate agreements, such as the Paris Agreement, achieving net-zero CO2 emissions and global carbon neutrality has emerged as a widely shared consensus among the global community [5,6,7]. Against this backdrop, the central challenge facing countries worldwide is how to effectively control carbon emissions while ensuring the security of energy supply.

CCUS is regarded as a key pathway for facilitating the low-carbon transition of energy systems. CCUS enables the efficient capture of CO2 from industrial sources and achieves significant emission reductions through secure geological storage or resource utilization [8,9,10,11,12,13] (Figure 1). CO2-ECBM represents a synergistic pathway within the broader framework of CCUS, simultaneously targeting enhanced coalbed methane recovery and long-term CO2 geological storage. This technology involves injecting CO2 into coal seams, where it preferentially adsorbs onto the coal matrix due to its stronger affinity compared with methane. This competitive adsorption mechanism displaces the adsorbed CH4, enabling its extraction, while securely storing CO2 within the coal structure. As a result, CO2-ECBM offers the dual benefits of energy production and greenhouse gas mitigation [14,15,16]. Compared with conventional coalbed methane extraction methods, CO2-ECBM offers multiple advantages. It causes minimal disruption to the geological formation, enables efficient methane release, and exhibits strong environmental compatibility and long-term storage stability. These characteristics make CO2-ECBM a promising technological bridge between energy development and climate mitigation. Globally, many coal-bearing regions are characterized by low permeability, complex pore structures, and limited methane desorption capacity, which often result in low recovery rates using traditional CBM extraction techniques—hindering their commercial viability [17,18,19]. In such contexts, CO2-ECBM demonstrates clear technical and economic advantages, particularly in deep and complex coal seams where conventional methods fall short. This approach not only provides a sustainable pathway for CBM resource development but also offers reliable geological space for CO2 sequestration.

Figure 1.

Schematic diagram of selected pathways for carbon dioxide capture, utilization, and storage.

In recent years, CCUS technologies have witnessed rapid advancement, with CO2-ECBM emerging as a focal point of interest across both academia and industry. Research on this technology spans multiple scales, ranging from the fundamental mechanisms of gas adsorption and the dynamics of diffusion and seepage to field experiments and engineering demonstrations (Figure 2) [20,21,22]. CO2-ECBM is currently transitioning from foundational studies to pilot-scale implementations, and is poised to move toward large-scale deployment. Nevertheless, this technology still faces numerous scientific and engineering challenges. This paper begins with a review of the fundamental mechanisms of CO2-ECBM, and, drawing on the recent research conducted by our team, systematically summarizes the current progress and practical developments. It further explores global engineering demonstrations, key influencing factors, and potential future trends. The objective is to provide a comprehensive reference for the ongoing optimization and implementation of CO2-ECBM, and to lay a solid foundation for its eventual large-scale application.

Figure 2.

Global distribution of selected CCUS demonstration projects.

2. Mechanisms of CO2-Enhanced Coalbed Methane Recovery

CO2-ECBM enhances methane recovery and enables carbon sequestration by injecting carbon dioxide into coal seams. The core mechanisms primarily involve two interrelated processes: adsorption–desorption behavior and diffusion–seepage transport. A schematic diagram of the CO2-ECBM mechanisms is shown in Figure 3.

Figure 3.

Mechanistic diagram of CO2-ECBM.

The adsorption–desorption mechanism is fundamental to CO2-ECBM. Coal exhibits a stronger adsorption affinity for CO2 than for CH4. Upon CO2 injection, a distinct competitive adsorption effect occurs—CO2 displaces CH4 previously adsorbed on the coal surface, thereby enhancing CH4 desorption. Concurrently, the increase in CO2 concentration and the decrease in CH4 concentration within the free gas phase disrupt the original adsorption–desorption equilibrium, further promoting CH4 release. To quantitatively describe this competitive adsorption behavior, the Ideal Adsorbed Solution Theory (IAST) is widely adopted. IAST provides a thermodynamic framework for predicting the multicomponent adsorption equilibrium based on pure-component isotherms, assuming the adsorbed phase behaves as an ideal solution. This approach enables accurate estimation of CO2 and CH4 uptake under varying pressure and composition conditions without requiring extensive multicomponent experiments. By incorporating IAST into gas adsorption modeling, researchers can more effectively characterize selective adsorption phenomena and optimize injection strategies. The extended Langmuir model is a theoretical framework for describing the competitive adsorption of multicomponent gases on solid surfaces. It modifies the classic Langmuir single-component model to account for the complexity of gas mixtures, where each component competes for the same adsorption sites. Adsorption is influenced by both the component’s own properties and the presence of other gases, with the model incorporating partial pressures and adsorption affinities to capture these interactions. This approach enables accurate prediction of gas adsorption behavior in porous media under complex conditions, such as CO2 sequestration and methane recovery in coal seams. Overall, this process not only facilitates methane desorption and recovery, but also results in the sequestration of CO2 in an adsorbed state within the coal matrix, establishing a synergistic “displacement–sequestration” mechanism [23,24,25].

In addition, the diffusion–seepage process governs the transport pathways and migration efficiency of desorbed methane and injected CO2. The desorbed CH4 molecules must diffuse through micropores into the cleat and fracture system, and then migrate via seepage flow toward the production wells to enable effective extraction. During this process, injected CO2 not only functions as a displacement agent but also establishes a localized pressure gradient that helps overcome the intrinsic low permeability of coal seams, thereby improving gas mobility. Notably, the common phenomenon of “compaction-induced permeability reduction” during conventional methane extraction can be mitigated under continuous CO2 injection. The sustained pressure around the wellbore helps preserve coal structure integrity, prevents pore closure, and ultimately enhances both permeability and flow capacity [26,27].

In summary, the CO2-ECBM process integrates coupled mechanisms of adsorption–desorption and diffusion–seepage: adsorption–desorption enables selective gas separation and long-term CO2 sequestration, while diffusion–seepage promotes CH4 displacement and recovery. This synergistic mechanism typically enhances methane production by around 20–30% compared with conventional CBM methods, with CO2 retention efficiencies after 10 years generally ranging from approximately 70% to 90%, depending on reservoir conditions.

3. Current Development of CO2-ECBM Technology

3.1. Experimental Research Progress on CO2-ECBM

Experimental research on CO2-ECBM aims to elucidate the adsorption, desorption, diffusion, and seepage mechanisms of CO2 within coal seam media at both microscopic and macroscopic scales, thereby assessing its effectiveness in enhancing coalbed methane recovery and carbon sequestration capacity. Current experimental efforts mainly focus on the characterization of reservoir properties in coal seams and surrounding rocks, simulation of CO2 sequestration mechanisms, and the evaluation of permeability and injectivity during the injection process [28,29,30].

Representative coal and surrounding rock samples are used to perform comprehensive rock mechanics and petrophysical property tests. With the aid of triaxial loading apparatuses, low-field nuclear magnetic resonance (LF-NMR) instruments, various gas adsorption analyzers, mercury intrusion porosimeters, and scanning electron microscopes (SEMs), key mechanical parameters such as elastic modulus, shear modulus, and Poisson’s ratio, along with physical properties including density, porosity, permeability, specific surface area, pore size distribution, pore volume, and CO2 adsorption capacity, can be quantitatively determined. Figure 4 presents mercury intrusion porosimetry results to characterize the pore size distribution of coal samples—an effective method for evaluating pore structure. These experiments are crucial for understanding the heterogeneity of reservoir properties across different geological formations and their influence on CO2 migration behavior.

Figure 4.

Pore size distribution of coal samples based on mercury intrusion porosimetry.

In terms of sequestration mechanisms, experimental studies are typically conducted under simulated reservoir conditions (e.g., temperature, pressure, and water saturation) to investigate three types of physical simulation experiments: adsorption-based, dissolution-based, and mineralization-based CO2 sequestration. Adsorption experiments employ high-pressure gas adsorption/desorption systems to evaluate the adsorption capacity and characteristics of CO2 on coal or rock surfaces and within pores. Dissolution experiments are conducted using CO2–water–rock reaction vessels to examine the dissolution behavior of CO2 in pore water and its subsequent reactions with minerals. Mineralization experiments focus on observing the formation, transformation, and stability of newly generated minerals after reactions, in order to assess the long-term sequestration potential.

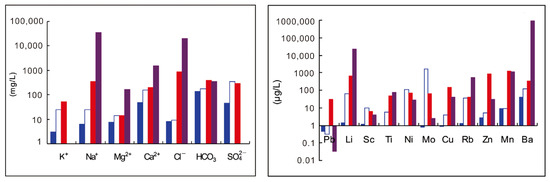

Moreover, to evaluate the injectivity and evolution characteristics of CO2 in coal seams, particular attention must be paid to geochemical effects and volumetric stress–strain responses [31,32,33]. For instance, CO2 injection simulation systems are used to monitor volumetric strain, fracture development, and permeability changes in rock samples during the injection process. These observations, combined with analytical techniques such as X-ray diffraction (XRD) and inductively coupled plasma optical emission spectrometry (ICP-OES), allow for detailed analysis of changes in fluid composition and provide a comprehensive understanding of the geochemical and mechanical responses induced by CO2 injection. Figure 5 presents the modifications in ion concentrations and trace element compositions that are observed across different samples following geochemical interactions. The data indicate that notable alterations in both major ion concentrations and trace element profiles do occur, suggesting that geochemical interactions have a definitive impact on the chemical properties of the samples.

Figure 5.

Combined concentration changes of major ions and trace elements before and after reactions.

In summary, these experimental studies not only elucidate the multiscale physicochemical behavior of CO2 within coal seams, but also offer robust experimental support for the assessment of CO2 storage capacity, suitability evaluation of CO2-ECBM, numerical simulation research, and injectivity analysis.

3.2. Current Research on CO2-ECBM Storage Capacity Assessment and Suitability Evaluation

In recent years, extensive research has been conducted by scholars to evaluate the storage capacity of CO2-ECBM, leading to the development of assessment models that encompass three primary sequestration states: adsorbed, dissolved, and free-phase. These models quantitatively describe the geological sequestration potential of CO2 in coal seams through theoretical calculations and calibration with experimental data. According to widely accepted approaches from previous studies, CO2 sequestration in coal seams predominantly occurs in the adsorbed phase, followed by dissolved and free phases, with the adsorbed phase typically accounting for the largest proportion [34,35,36,37,38]. Specifically, the assessment models are generally expressed in the following form [39]:

where Mcar is the CO2 storage capacity in t; Scar is the CO2 storage coefficient in the coal reservoir; ρcar is the CO2 density under standard conditions (101.325 kPa, 273.15 K), equal to 1.977 kg/m3; Mcoal is the proven coal reserves in t; mab is the amount of CO2 stored in the adsorbed state per unit mass of coal in m3/t; md is the amount of CO2 stored in the dissolved state per unit mass of coal in m3/t; and mf is the amount of CO2 stored in the free state per unit mass of coal in m3/t.

For a unit mass of coal, the CO2 sequestration potential in the adsorbed state within the reservoir can be expressed as [37,38,39]:

where p is the pressure of the deep coal reservoir, corresponding to the CO2 adsorption pressure in MPa; Tc is the critical temperature of CO2, 304.21 K; Z is the compressibility factor of CO2 (dimensionless), which can be estimated through multiparameter interpolation; pc is the critical pressure of CO2, 7.383 MPa; T is the temperature of the deep coal reservoir, also the CO2 adsorption temperature in K; and mex is the excess adsorption capacity of CO2 per unit mass of coal in m3/t, which can be calculated using the Dubinin–Radushkevich (D–R) adsorption model [37,38,39]:

where m0 is the maximum CO2 adsorption capacity per unit mass of coal determined from adsorption experiments in m3/t; ρf and ρa are the densities of free-phase and adsorbed-phase CO2 under the actual pressure and temperature conditions of the coal reservoir in kg/m3; D is the adsorption constant (dimensionless); and k is a constant related to Henry’s law (dimensionless).

The CO2 density in the coal reservoir is a function of pressure and temperature, expressed as ρg = f(p, T), and can be further expressed as [37,38,39]:

where δ = ρc/ρf is the reduced density of CO2 (dimensionless), with ρc being the critical density of CO2 (0.45 × 10−3 kg/m3); and τ = Tc/T is the reduced temperature (dimensionless). ϕ(δ,τ) denotes the Helmholtz free energy, which is governed by both temperature and density [37,38,39]:

where ϕ0(δ, τ) represents the Helmholtz free energy of the ideal fluid; and ϕ1(δ, τ) denotes the residual Helmholtz free energy of the real fluid.

In coal reservoirs, the solubility-based CO2 storage potential per unit mass of coal is a function of the coal seam porosity, water saturation, coal density, and the solubility of CO2 in water, and can be expressed as [37,38,39]:

where φ is the coal porosity in %; Sw is the water saturation of the coal seam in %; Scar is the solubility of CO2 in coal seam water in mol/cm3; and ρcoal is the coal density in kg/m3.

According to Boyle–Mariotte’s law, and taking into account the gas saturation of the coal seam, the free-phase CO2 storage potential per unit mass of coal in the reservoir can be expressed as [37,38,39]:

where Sg is the gas saturation of the coal seam in %; p0 is the standard atmospheric pressure; T0 is the temperature under standard conditions; and ρvisual is the apparent density of coal in kg/m3.

To address the issue of CO2 geological storage suitability, researchers generally advocate for the establishment of a comprehensive evaluation index system that integrates multiple dimensions and hierarchical levels [40,41,42,43,44,45]. This system should fully consider key factors such as reservoir security, storage capacity potential, and socio-economic acceptability. Reservoir security serves as the foundation for the sustainable operation of storage projects, and is primarily determined by regional crustal stability and caprock integrity. For crustal stability, assessments typically involve evaluating peak ground acceleration, historical seismic activity intensity, and the spatial distribution of active faults to determine the overall structural stability of the area. Caprock conditions, including lithology, thickness, continuity, and burial depth, directly affect the sealing performance and migration risk of CO2. In terms of storage capacity, the scale of the structural unit, reservoir physical properties, and theoretical storage potential are the core evaluation components. The area and thickness of the structural unit define the spatial boundary conditions of the storage site. Reservoir development conditions—such as thickness, porosity, and permeability—determine the CO2 injectivity and effective storage capacity. Storage potential usually refers to the estimated geological storage volume and storage capacity per unit area, reflecting the resource base of CO2 geological storage in a given region.

In addition, the feasibility of CO2-ECBM must also consider socio-economic conditions, particularly carbon source distribution and public acceptance. Economically, proximity to large-scale CO2 emission sources helps reduce transportation costs and project complexity. Meanwhile, the level of public acceptance may influence the implementation and sustainability of engineering operations. Therefore, when constructing a CO2-ECBM suitability evaluation framework, it is essential to integrate technical, geological, and economic factors into a unified system. Figure 6 illustrates the suitability evaluation index system for CO2-ECBM constructed by the authors.

Figure 6.

Evaluation indicators for CO2-ECBM suitability assessment.

In practical suitability analyses, researchers often adopt a combination of the Analytic Hierarchy Process (AHP) and Fuzzy Comprehensive Evaluation (FCE). This approach enables the construction of a multi-level hierarchical model consisting of a target layer, a criterion layer, and an index layer. Expert judgment matrices are used to determine the weight of each indicator. Coupled with regional geological data, monitoring records, and sampling results, this method provides a quantified, comprehensive evaluation to offer a scientific basis for CO2-ECBM suitability assessments.

3.3. Monitoring Technologies and Regulatory Frameworks for CO2-ECBM

In response to the urgent need for CO2 leakage and migration surveillance, numerous researchers have conducted in-depth investigations into surface deformation and environmental changes induced by CO2 injection [46,47,48,49,50,51,52]. At present, a widely recognized strategy among Chinese scholars involves an integrated air–space–surface–downhole remote sensing-based monitoring system [53] (Figure 7).

Figure 7.

Air–space–surface–downhole integrated monitoring system.

Within the air and space segment, large-scale monitoring relies on optical and radar satellite platforms to acquire long-term, high-resolution InSAR datasets. These datasets enable all-weather tracking of surface micro-deformation and vegetation-related environmental dynamics, thereby revealing CO2 migration patterns and their potential ecological impacts. Simultaneously, unmanned aerial vehicles (UAVs) equipped with optical and thermal infrared sensors are employed for targeted, rapid surveillance of the injection zone. These systems can acquire surface models and high-resolution imagery, while also detecting potential leakage hotspots and anomalous reactions in a timely manner, ensuring real-time and accurate monitoring. The integration of satellite-based remote sensing and UAV observations provides both macro and micro perspectives on the CO2 storage site, forming a critical technological foundation for continuous and dynamic monitoring of CO2 migration and environmental responses at the regional scale.

For surface-based monitoring, long-term surveillance of production well arrays combined with passive seismic-based surveillance of near-surface dynamics enables the effective detection of fracture propagation and surface deformation induced by CO2 injection. With the aid of advanced passive seismic fracture tomography, subsurface rupture events and the evolution of CO2 plume fronts can be directly visualized. This provides crucial empirical data for understanding fluid behaviors and fault activation during the storage process. This technique also overcomes the limitations of traditional surface monitoring in terms of signal-to-noise ratio and resolution, significantly enhancing the ability to identify and provide early warnings of CO2 leakage risks.

In the downhole monitoring system, long-term deployment of fiber-optic sensors along high-angle wells allows for real-time, stratified gas–water sampling and precise tracking of temperature and pressure changes. Additionally, a multi-azimuth multicomponent time-lapse VSP analysis technique is introduced to quantify subsurface fluid dynamics and structural deformation responses. This system not only provides real-time feedback on the in-well CO2 storage status, but also—through the interpretation of time-lapse datasets—helps reveal the spatial distribution and evolution of CO2 migration under multi-physics coupling conditions. Together, these insights offer robust data support and scientific guidance for the optimization of CO2-ECBM deployment strategies.

In parallel with technological advancements, many countries, including China, the United States, and Australia, have progressively improved their policy support and management frameworks to promote the safe and orderly implementation of CO2-ECBM. These frameworks generally emphasize the importance of long-term environmental monitoring, risk prevention and control, and accountability mechanisms throughout the project lifecycle. In China, relevant departments have begun to explore coordinated regulatory approaches that integrate environmental supervision, project approval, and data reporting, aiming to enhance oversight efficiency and project transparency. The integration of advanced monitoring technologies with a sound governance structure plays a key role in improving risk management, fostering public trust, and facilitating the sustainable and large-scale development of CO2-ECBM projects.

3.4. Advances in Numerical Simulation of CO2-ECBM

Coal seams are characterized by strong heterogeneity and generally low permeability, making efficient CO2 injection and enhanced CH4 recovery the key technical challenges of CO2-ECBM. Numerical simulation has become a powerful tool to reproduce the production history of coalbed methane wells, quantitatively assess the potential of CO2-ECBM, and support the optimization of engineering schemes and evaluation of CH4 enhancement strategies. Due to its low cost and short research cycle, numerical modeling has attracted extensive attention in recent years. Research efforts have increasingly focused on developing and improving multi-physics coupled models to accurately describe the complex processes occurring within coal reservoirs, including gas adsorption, diffusion, seepage, heat transfer, geomechanical evolution, and geochemical reactions [54,55,56,57,58,59]. Early commercial simulators were primarily based on partial differential equations governing adsorption and flow fields. These models could effectively simulate isothermal adsorption and diffusion of gases within the coal matrix, as well as fluid flow in the fracture network. However, they often neglected the coupled effects of temperature fields, geostress variations, and mineral dissolution/precipitation reactions, thus limiting their applicability under the complex conditions of deep coal seams.

To address these limitations, our research team has recently developed a fully coupled adsorption–hydro–thermo–mechanical–chemical (AHTMC) model [57,58,59,60]. This type of model integrates equations of energy conservation, fluid dynamics, and geomechanics to comprehensively capture the interactions among multiple physical fields during the CO2-ECBM process [60]. In the AHTMC framework, adsorption behavior is typically described using a modified Langmuir isotherm, while gas diffusion within the coal matrix is governed by Fick’s law. Fluid transport in the fracture system is modeled using a combination of Darcy’s law and gas slippage effects. To characterize thermal responses driven by temperature fluctuations, the model incorporates terms for thermal conduction and convection, alongside thermodynamic effects such as adsorption heat release, dissolution exothermicity, and endothermic deformation of coal rock. The geomechanical response is modeled using the theory of poroelasticity, fully considering reservoir deformation resulting from changes in fluid pressure, temperature, and adsorption-induced strain. Some advanced models further integrate the dynamic dissolution of CO2 and CH4 in formation water to refine the representation of CO2 storage mechanisms in water-bearing coal seams.

Currently, finite element platforms such as COMSOL (Comsol multiphysics 6.2) multi-physics have emerged as important tools for simulating fully coupled CO2-ECBM processes. Their modular and flexible multi-physics environment allows researchers to construct and solve highly complex models with ease. In parallel, advancements in finite difference and open-source simulation platforms are providing new pathways for tackling multiscale and multi-physics coupling challenges. Overall, the scope of numerical simulation in this field has evolved from single-field representations to multi-physics coupling, while the application frontier has expanded to include the quantitative evaluation of key performance indicators—such as CH4 recovery efficiency and CO2 adsorption capacity These efforts offer substantial data support for engineering design and risk assessment in real-world projects. Despite these advances, numerical simulation in CO2-ECBM still faces major challenges, including high model complexity, intensive computational demands, and difficulties in obtaining accurate reservoir parameters. Future research should aim to further optimize model architecture, reduce computational costs, and validate simulations through field data, thereby enhancing their utility in guiding the engineering deployment and large-scale application of CO2-ECBM technology.

4. Global Demonstration Projects of CO2-ECBM

Overall, CO2-ECBM technology remains in the exploratory engineering stage both internationally and in China. A number of pilot projects have been carried out globally, which have, to some extent, demonstrated the technical feasibility of CO2-ECBM for both long-term CO2 sequestration and enhanced coalbed methane recovery [61,62,63,64,65,66,67] (Table 1). Although research in this field began earlier in several countries, and some projects have progressed to pilot-scale or limited commercial operation, the majority are still in the field-testing phase.

As early as 1995–2001, the United States initiated the first CO2-ECBM field trial at the Allison Unit in the San Juan Basin. The project employed multi-well co-production techniques and successfully enhanced CBM recovery. This large-scale trial covered an area of approximately 1.295 × 106 m2, with four CO2 injection wells and 16 production wells, and a cumulative CO2 injection volume of 336,000 t [68,69]. Another prominent effort in the San Juan Basin, located in New Mexico, targeted the Upper Cretaceous Fruitland Formation, which has an average depth of approximately 900 m [70]. This test, initiated in 1995, aimed to assess the carbon sequestration potential of the Fruitland coal seams. The reservoir was categorized into four distinct subregions based on geological and production characteristics. The pilot area was located in a high-pressure, high-yield CBM zone. In addition to the San Juan Basin, other demonstration projects in the United States have been conducted in the Illinois and Appalachian Basins. These projects involved unmineable coal seams and lignite blocks, as well as the application of advanced technologies such as horizontal drilling and pre-fracturing, thereby contributing valuable field data and engineering experience to the development of CO2-ECBM.

China’s research and engineering application of CO2-ECBM started relatively late, but has developed rapidly in recent years with the support of national key scientific and technological programs. Since 2013, several pilot tests have been carried out under the leadership of China United Coalbed Methane Co., Ltd., focusing on both shallow and deep coal seams, ranging from single-well trials to multi-well group operations in the Qinshui Basin (Figure 8) and the Ordos Basin. China’s first pilot project was implemented in the Qinshui Basin between 2002 and 2006 through a joint initiative with the Canadian government. The trial involved intermittent CO2 injection and production in No. 3 coal seam, where a total of 192.8 t of liquid CO2 was injected, resulting in a significant increase in CBM recovery. From 2011 to 2012, a single-well injection-production test was conducted in a 560 m deep coal seam in Liulin, Shanxi Province, with a total CO2 injection of 460 t. Subsequently, during 2013–2015, a deeper coal seam test at a depth of 900 m achieved a cumulative CO2 injection of 4491 tonnes [71].

Figure 8.

Field operation view and inspection/maintenance of CBM facilities in the Qinshui Basin, China.

These pilot projects illustrate the evolution of China’s CO2-ECBM development from shallow, single-well tests to deep, multi-well group experiments. The technical maturity has steadily improved, confirming the feasibility of CO2-ECBM and revealing its promising potential for commercial-scale deployment. At the same time, these efforts have also highlighted the engineering challenges that must be overcome for widespread implementation of this technology.

Table 1.

Major CO2-ECBM projects worldwide [71].

Table 1.

Major CO2-ECBM projects worldwide [71].

| Country | Project Location | Injection Period | CO2 Injected (t) |

|---|---|---|---|

| USA | Allison Field, San Juan Basin | April 1995–August 2001 | 336,000 |

| USA | Pump Canyon, San Juan Basin | July 2008–August 2009 | 16,699.00 |

| USA | Tanquary Farm, Illinois Basin | 2008 | 92.3 |

| USA | Virginia, Central Appalachian Basin | January 2009–February 2009 | ~900.00 |

| USA | Lignite Block, Williston Basin | 2009 | 90 |

| USA | Black Warrior Basin | June 2010–August 2010 | 225 |

| USA | Marshall, Northern Appalachian Basin | September 2009–December 2013 | 4500.00 |

| USA | Buchanan, Central Appalachian Basin | July 2015–August 2015 | 1470.00 |

| China | Shizhuang South Block, Qinshui Basin | April 2004–June 2004 | 192.8 |

| China | Shizhuang North Block, Qinshui Basin | April 2010–May 2010 | 233.6 |

| China | Liulin Block, Eastern Ordos Basin | September 2011–March 2012 | 460 |

| China | Shizhuang North Block, Qinshui Basin | 2013–2015 | 4491.00 |

| China | Shizhuang South Block, Qinshui Basin | June 2020–June 2021 | 2001.04 |

| Canada | Fenn Big Valley, Alberta | 1998 | 201 |

| Canada | Alder Flats, Alberta | June 2006 | Unknown |

| Poland | Kaniow, Silesian Basin | August 2004–May 2005 | 760 |

| Japan | Ishikari Basin, Hokkaido | July 2004–September 2007 | ~800.00 |

5. Influencing Factors of CO2-ECBM

As previously discussed, coalbed methane, as a self-sourced and self-stored unconventional natural gas within coal seams, is not only a clean energy resource but also plays a vital role in mine safety and gas explosion prevention. Its rational development can generate substantial economic benefits. Against this backdrop, CO2-ECBM, which simultaneously enables long-term CO2 sequestration and enhanced methane recovery, holds significant theoretical and practical value. Investigating its influencing factors is essential for optimizing production strategies and improving recovery efficiency.

During CO2-ECBM, methane mainly exists in an adsorbed state within the micropores of the coal matrix, and the adsorption–desorption behavior is primarily controlled by gas partial pressure and temperature. After CO2 injection, due to its stronger adsorption affinity for coal than methane, CO2 is preferentially adsorbed onto the internal surfaces of the coal, displacing the adsorbed methane. This displacement effect significantly reduces the partial pressure of methane, promoting its desorption. The released free methane then migrates through the fracture and pore network under the pressure differential between injection and production wells, thereby enhancing the overall recovery rate [72,73,74,75]. In practical conditions, reservoir pressure, formation temperature, and CO2 injection rate all exert significant influence on this process. Lower pressures help break the adsorption equilibrium, facilitating greater methane desorption and production. Suitable temperatures provide gas molecules with sufficient thermal energy to accelerate the desorption process. In addition, higher CO2 injection rates can rapidly enhance the desorption rate and shorten the desorption time, playing a crucial role in improving methane recovery efficiency.

Geological conditions of the reservoir are fundamental to the feasibility and efficiency of CO2-ECBM implementation. Optimal coal seams should possess favorable continuity and structural integrity to ensure uniform CO2 distribution and effective contact with adsorbed methane. Specifically, laterally continuous coal seams facilitate homogeneous CO2 migration, enhancing the overall displacement efficiency while reducing the likelihood of preferential flow paths and uneven sweep. In contrast, structurally complex formations—such as those with intense faulting or folding—can compromise sealing capacity and introduce high-permeability conduits that serve as potential leakage pathways. These not only limit the interaction between injected CO2 and CH4 but also elevate the risk of CO2 escape, posing both environmental and operational safety concerns. Therefore, geologically stable, laterally extensive, and structurally simple coal reservoirs with low fault density and effective caprock integrity are considered the most suitable targets for CO2-ECBM, as they support both enhanced methane recovery and secure long-term CO2 storage [76,77,78]. In addition, permeability is a key parameter affecting injection efficiency, with higher permeability facilitating smoother fluid flow. Methane-saturated coal seams typically demonstrate better recovery outcomes, providing important guidance for the site selection and technical design of regional CO2-ECBM projects.

Overall, the CO2-ECBM process is governed by coupled multi-physical effects—including adsorption–desorption, diffusion and seepage, heat transfer, geomechanical evolution, and geochemical reactions—that collectively determine methane recovery and long-term CO2 sequestration performance. These factors are not independent; rather, they interact through energy exchange, mass transport, and structural deformation in a highly complex manner. Therefore, future research should focus on elucidating the interaction mechanisms among these variables. A comprehensive understanding of these interactions is essential for revealing the fundamental nature of the CO2-ECBM process, improving injection–production strategies, and achieving optimal technical and economic performance.

6. Discussion

6.1. Challenges in CO2-ECBM

Although CO2-ECBM has achieved a series of pilot-scale successes globally, numerous scientific and engineering challenges remain unresolved in practical applications. One critical issue is the development of efficient monitoring, measurement, and verification (MMV) technologies to accurately assess CO2 migration, leakage risk, and storage capacity during sequestration, thereby ensuring long-term subsurface storage security. Despite considerable progress internationally—particularly in the United States—risk control remains at the core of CO2-ECBM research. However, growing attention has been directed toward the associated environmental risks and sequestration costs.

One frequently discussed concern is the potential for injection-induced geomechanical responses. CO2 injection alters the stress–pressure balance in the reservoir, potentially leading to surface uplift due to increased pore pressure and coal matrix swelling, or, conversely, surface subsidence from long-term compaction or pressure decline. Field evidence from the In Salah Krechba gas field in Algeria (Figure 9) demonstrates that sustained CO2 injection can cause measurable surface deformation—primarily uplift—highlighting the sensitivity of overburden to subsurface pressure changes. In addition, pressure perturbations may activate pre-existing faults and induce microseismicity, posing risks to both storage security and operational safety. These deformation responses underscore the importance of geomechanical assessment, integrated monitoring, and adaptive risk management strategies during large-scale CO2 geological sequestration [79]. Preventive measures such as optimizing injection rates, selecting structurally stable reservoirs, and implementing real-time pressure and deformation monitoring can significantly reduce the likelihood of leakage. In the event of leakage, which poses a significant safety risk during large-scale field implementations, remediation techniques—such as pressure relief through extraction wells or sealing of leakage pathways using sealants or cement—can help contain and mitigate its impact. While microfractures induced by injection may enhance reservoir permeability, they also raise concerns about seismic hazards and the integrity of geological storage.

Figure 9.

Surface deformation differences of the CCS injection site in Algeria In Salah Krechba gas field.

In addition, the potential environmental impacts of CO2 geological sequestration have attracted widespread attention. Once injected into coal seams, CO2 may react with chemical constituents in groundwater, forming acidic compounds that promote the dissolution or precipitation of minerals such as carbonates and pyrite. These geochemical reactions may alter the chemical properties of soil, vegetation, and aquifers, potentially degrading the local ecosystem. Furthermore, such reactions could adversely affect the pore structure of coal, leading to reduced gas recovery efficiency and compromised reservoir stability.

Economic cost remains another major barrier to the large-scale deployment of CO2-ECBM. The current implementation process requires CO2 capture, compression, and purification prior to its injection in liquid form into coal seams. The associated equipment investment and energy consumption result in high overall project costs. Although some studies propose using flue gas compression to reduce costs—while leveraging N2 in flue gas to improve coal permeability—this approach still entails additional expenses for separation and purification at later stages. Striking a balance between technical performance and economic feasibility is a critical challenge for future development.

Another key issue is the alteration of coal seam physical properties caused by CO2 injection. During the process, coal matrices undergo significant swelling and shrinkage, as CO2 exhibits a much stronger adsorption capacity than CH4. This leads to notable volumetric changes during desorption, affecting reservoir porosity and permeability, and ultimately reducing the effectiveness of gas recovery. In parallel, CO2-induced acid generation and subsequent mineral dissolution and precipitation can further alter the pore structure of coal seams, negatively impacting gas production. Moreover, the plasticizing effect of supercritical CO2 on coal becomes increasingly pronounced, leading to the softening of the coal’s physical and mechanical properties. Significant reductions in elastic modulus and compressive strength increase the likelihood of reservoir fracturing and leakage during injection and production operations.

6.2. Development Trends of CO2-ECBM Technology

The future development of CO2-ECBM technology will primarily focus on in-depth investigations of multi-physics coupling mechanisms, comprehensive upgrades of monitoring technologies, and the large-scale deployment of engineering application models. Firstly, as the decline in coal reservoir permeability after CO2 injection becomes increasingly significant, the effects of various injection parameters—such as injection volume, pressure, and method—on coal swelling and pore structure alteration have yet to be generalized into a universally applicable theoretical framework. Therefore, future research should systematically explore the complex coupling mechanisms among these influencing factors to provide scientific guidance for site selection and the optimization of injection-production schemes, ensuring sustained and stable CO2 injection as well as efficient methane recovery.

Uncertainties in coal cleat structure remain a key challenge for accurate risk prediction in CO2-ECBM. As cleats govern fluid flow and pressure responses, variations in their geometry and connectivity can significantly affect model reliability. However, their fine-scale heterogeneity makes precise characterization difficult. Meanwhile, current monitoring, measurement, and verification (MMV) technologies are still inadequate for fully tracking gas transport, leakage, and reservoir dynamics within coal seams. Improving imaging, in situ monitoring, and uncertainty-informed modeling will be essential to enhance risk assessment and ensure storage safety. In addition, there is a lack of large-scale, long-term field tests—particularly in coal seams deeper than 1000 m—leading to limited understanding of optimal operational conditions and engineering control strategies. Future efforts should prioritize the development of high-precision real-time monitoring tools and the implementation of cross-regional demonstration projects to expand data diversity and support the refinement of risk management frameworks for CO2-ECBM deployment.

Moreover, the industrial application of CO2-ECBM continues to face challenges related to high implementation costs and insufficient market incentives. Achieving a balance between technical performance and economic viability will be a central challenge in future technological transformation and large-scale deployment. Accordingly, it is urgent for national and regional governments to enhance policies related to coalbed methane development and utilization. Support should be given to the full-process technology chain of CO2 geological sequestration and utilization, as well as to cluster-based demonstration projects, aiming to establish industrial-scale applications with a capacity exceeding one million tons. Simultaneously, fundamental scientific research into CO2 geological storage and utilization must be strengthened to uncover the underlying mechanisms of source-sink matching, technology integration, and system optimization under various regional energy, resource, and environmental conditions. These efforts will provide theoretical foundations and practical guidance for the development of advanced and regionally adaptive CO2-ECBM technology models.

In summary, the future advancement of CO2-ECBM technology will rely on deeper insights into complex coupling mechanisms, innovations in monitoring technologies, and sustained implementation of large-scale engineering trials. Through policy support and integrated technological solutions, CO2-ECBM can achieve simultaneous improvements in storage security, methane recovery efficiency, and economic performance, ultimately promoting the healthy and widespread application of this technology on a global scale.

7. Conclusions

This study provides a comprehensive review of the fundamental mechanisms, experimental and numerical research progress, and current status of engineering demonstrations related to CO2-ECBM technology. It highlights the synergistic advantages of this approach in enhancing coalbed methane recovery while enabling long-term CO2 sequestration, thereby establishing an effective technological bridge between energy development and carbon emission reduction. Research indicates that the coupled multi-physical processes—including adsorption/desorption, diffusion, and seepage—play a critical role in the CO2-driven methane displacement process. The preferential adsorption of CO2 facilitates the displacement of adsorbed CH4, significantly reducing the partial pressure of CH4 in the coal matrix, promoting its desorption and migration toward production wells, and ultimately improving recovery efficiency.

Both experimental studies and numerical simulations have demonstrated that reservoir pressure, formation temperature, and CO2 injection flow rate significantly influence CBM recovery. Meanwhile, reservoir physical properties, structural conditions, and multi-physics coupling effects collectively determine the injection efficiency and long-term storage security of CO2. These findings provide critical references for assessing the storage capacity and site suitability of CO2-ECBM projects.

Although a number of pilot tests and demonstration projects have been conducted globally, and some have yielded preliminary successes, CO2-ECBM technology still faces several pressing challenges. These include insufficient monitoring and verification technologies, the risk of induced seismicity, potential environmental impacts, high economic costs, and changes in coal reservoir properties. These issues require further in-depth investigation. Future development efforts should focus on elucidating the complex multi-physics coupling mechanisms triggered by CO2 injection, enhancing the accuracy and real-time capabilities of monitoring technologies, and promoting large-scale, long-duration, and cross-regional field demonstrations. Based on integrated technologies and full-process optimization, CO2-ECBM can achieve coordinated improvements in storage safety, recovery efficiency, and economic viability, thus offering robust technical support for global energy transition and low-carbon development.

Funding

This research was funded by the National Natural Science Foundation of China (No. 42302194), the Natural Science Foundation of Jiangsu Province, China (No. BK20231084), the Applied Basic Research Programs of Xuzhou, China (No. KC23001), the open fund of the Key Laboratory of Deep Coalbed Methane Exploration and Development of Sinopec (No. SMKK202405), and the Postdoctoral Fellowship Program of CPSF (GZC20233002).

Conflicts of Interest

Authors Yinan Cui, Chao Li, Hequn Gao, Hui Li and Yaozu Zhang were employed by the East China Oil and Gas Company. Author Bin Miao was employed by the company Zaozhuang Mining Group Co., Ltd. Author Bei Zhang was employed by the company China Construction Eighth Engineering Division Guangxi Construction Co., Ltd. Authors Jinghui Zhao and Guangrong Zhang were employed by the company Linfen Coalbed Methane Branch, SINOPEC. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Yang, W.; Min, Z.; Yang, M.X.; Yan, J. Exploration of the implementation of carbon neutralization in the field of natural resources under the background of sustainable Development—An overview. Int. J. Environ. Res. Public Health 2022, 19, 14109. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.S. The view of technological innovation in coal industry under the vision of carbon neutralization. Int. J. Coal Sci. Technol. 2021, 8, 1197–1207. [Google Scholar] [CrossRef]

- Li, Y.L.; Wei, Y.F.; Zhu, F.Q.; Du, J.Y.; Zhao, Z.M.; Ouyang, M. The path enabling storage of renewable energy toward carbon neutralization in China. Etransportation 2023, 16, 100226. [Google Scholar] [CrossRef]

- Liu, X.H. Low-carbon utilization of coal gangue under the carbon neutralization strategy: A short review. J. Mater. Cycles Waste Manag. 2023, 25, 1978–1987. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, H.Y.; Lau, Y.Y.; Wang, T.N.; Wang, W.; Zhang, G.S. Climate change, carbon peaks, and carbon neutralization: A bibliometric study from 2006 to 2023. Sustainability 2023, 15, 5723. [Google Scholar] [CrossRef]

- Xu, G.W.; Bai, D.R.; Xu, C.M.; He, M.Y. Challenges and opportunities for engineering thermochemistry in carbon-neutralization technologies. Natl. Sci. Rev. 2023, 10, nwac217. [Google Scholar] [CrossRef]

- Wang, X.P.; Zhang, Z.M.; Guo, Z.H.; Su, C.; Sun, L.H. Energy structure transformation in the context of carbon neutralization: Evolutionary game analysis based on inclusive development of coal and clean energy. J. Clean Prod. 2023, 398, 136626. [Google Scholar] [CrossRef]

- Liu, X.Y.; Liu, X.M.; Zhang, Z.Q. Application of red mud in carbon capture, utilization and storage (CCUS) technology. Renew. Sust. Energ. Rev. 2024, 202, 114683. [Google Scholar] [CrossRef]

- Storrs, K.D.P.; Lyhne, I.; Drustrup, R. A comprehensive framework for feasibility of CCUS deployment: A meta–review of literature on factors impacting CCUS deployment. Int. J. Greenh. Gas Control 2023, 125, 103878. [Google Scholar] [CrossRef]

- Huang, S.P.; Liu, D.M.; Gomez-Rivas, E.; Griera, A.; Gan, Q.; Wang, M.Y.; Xing, Y.; Zhao, Y. Experimental insights into the nucleation and propagation of hydraulic fractures in anthracite coalbed methane reservoirs. Earth Energy Sci. 2025. [Google Scholar] [CrossRef]

- Li, M.X.; He, N.P.; Xu, L.; Peng, C.H.; Chen, H.; Yu, G.R. Eco-CCUS: A cost-effective pathway towards carbon neutrality in China. Renew. Sust. Energ. Rev. 2023, 183, 113512. [Google Scholar] [CrossRef]

- Mon, M.T.; Tansuchat, R.; Yamaka, W. CCUS technology and carbon emissions: Evidence from the United States. Energies 2024, 17, 1748. [Google Scholar] [CrossRef]

- Busch, A.; Gensterblum, Y. CBM and CO2-ECBM related sorption processes in coal: A review. Int. J. Coal Geol. 2011, 87, 49–71. [Google Scholar] [CrossRef]

- Li, Z.W.; Yu, H.J.; Bai, Y.S.; Wang, Y.J.; Hu, H.Q. Numerical study on the influence of temperature on CO2-ECBM. Fuel 2023, 348, 128613. [Google Scholar] [CrossRef]

- Fujioka, M.; Yamaguchi, S.; Nako, M. CO2-ECBM field tests in the Ishikari Coal Basin of Japan. Int. J. Coal Geol. 2010, 82, 287–298. [Google Scholar] [CrossRef]

- Sun, Y.F.; Zhao, Y.X.; Yuan, L. CO2-ECBM in coal nanostructure: Modelling and simulation. J. Nat. Gas Sci. Eng. 2018, 54, 202–215. [Google Scholar] [CrossRef]

- Mukherjee, M.; Misra, S. A review of experimental research on Enhanced Coal Bed Methane (ECBM) recovery via CO2 sequestration. Earth-Sci. Rev. 2018, 179, 392–410. [Google Scholar] [CrossRef]

- Zhang, L.; Li, J.H.; Xue, J.H.; Zhang, C.; Fang, X.Q. Experimental studies on the changing characteristics of the gas flow capacity on bituminous coal in CO2-ECBM and N2-ECBM. Fuel 2021, 291, 120115. [Google Scholar] [CrossRef]

- Asif, M.; Wang, L.; Naveen, P.; Longinos, S.N.; Hazlett, R.; Ojha, K.; Panigrahi, D.C. Influence of competitive adsorption, diffusion, and dispersion of CH4 and CO2 gases during the CO2-ECBM process. Fuel 2024, 358, 130065. [Google Scholar] [CrossRef]

- Mwakipunda, G.C.; Wang, Y.T.; Mgimba, M.M.; Ngata, M.R.; Alhassan, J.; Mkono, C.N.; Yu, L. Recent advances in carbon dioxide sequestration in deep unmineable coal seams using CO2-ECBM technology: Experimental studies, simulation, and field applications. Energy Fuels 2023, 37, 17161–17186. [Google Scholar] [CrossRef]

- Zheng, S.J.; Yao, Y.B.; Liu, D.M.; Cai, Y.D.; Liu, Y. Nuclear magnetic resonance surface relaxivity of coals. Int. J. Coal Geol. 2019, 205, 1–13. [Google Scholar] [CrossRef]

- Vishal, V.; Singh, T.N.; Ranjith, P.G. Influence of sorption time in CO2-ECBM process in Indian coals using coupled numerical simulation. Fuel 2015, 139, 51–58. [Google Scholar] [CrossRef]

- Liu, X.D.; Sang, S.X.; Zhou, X.Z.; Wang, Z.L.; Niu, Q.H.; Mondal, D. Modelling of geomechanical response for coal and ground induced by CO2-ECBM recovery. Gas Sci. Eng. 2023, 113, 204953. [Google Scholar] [CrossRef]

- Zheng, S.J.; Yao, Y.B.; Liu, D.M.; Cai, Y.D.; Liu, Y.; Li, X.W. Nuclear magnetic resonance T2 cutoffs of coals: A novel method by multifractal analysis theory. Fuel 2019, 241, 715–724. [Google Scholar] [CrossRef]

- Liu, S.Y.; Wang, J.L.; Li, H.Y.; Liu, J.R.; Xu, J.C.; Sun, W.Y.; Wang, X.P.; Chen, Z.H. A generalized adsorption model of CO2-CH4 in shale based on the improved Langmuir model. Fuel 2025, 379, 132971. [Google Scholar] [CrossRef]

- Liu, Z.D.; Lin, X.S.; Zhu, W.C.; Hu, Z.; Hao, C.M.; Su, W.W.; Bai, G. Effects of coal permeability rebound and recovery phenomenon on CO2 storage capacity under different coalbed temperature conditions during CO2-ECBM process. Energy 2023, 284, 129196. [Google Scholar] [CrossRef]

- Gong, S.L.; Zhang, L.; Zhang, T.Y.; He, W.; Hu, W.Q.; Yin, H.C.; Ma, L.S.; Hong, X.; Zhang, W.; Zhang, B. Numerical simulation of CO2-ECBM for deep coal reservoir with strong stress sensitivity. Heliyon 2024, 10, e34818. [Google Scholar] [CrossRef]

- Yu, H.G.; Yuan, J.; Guo, W.J.; Cheng, J.L.; Hu, Q.T. A preliminary laboratory experiment on coalbed methane displacement with carbon dioxide injection. Int. J. Coal Geol. 2008, 73, 156–166. [Google Scholar] [CrossRef]

- Zheng, S.J.; Yao, Y.B.; Liu, D.M.; Cai, Y.D.; Liu, Y. Characterizations of full-scale pore size distribution, porosity and permeability of coals: A novel methodology by nuclear magnetic resonance and fractal analysis theory. Int. J. Coal Geol. 2018, 196, 148–158. [Google Scholar] [CrossRef]

- Zhang, C.L.; Wang, E.Y.; Li, B.B.; Kong, X.G.; Xu, J.; Peng, S.J.; Chen, Y.X. Laboratory experiments of CO2-enhanced coalbed methane recovery considering CO2 sequestration in a coal seam. Energy 2023, 262, 125473. [Google Scholar] [CrossRef]

- Lu, Y.J.; Han, J.X.; Yang, M.P.; Chen, X.Y.; Zhu, H.J.; Yang, Z.Z. Molecular simulation of supercritical CO2 extracting organic matter from coal based on the technology of CO2-ECBM. Energy 2023, 266, 126393. [Google Scholar] [CrossRef]

- Zhang, H.; Hu, Z.C.; Xu, Y.; Fu, X.X.; Li, W.; Zhang, D.F. Impacts of long-term exposure to supercritical carbon dioxide on physicochemical properties and adsorption and desorption capabilities of moisture-equilibrated coals. Energy Fuels. 2021, 35, 12270–12287. [Google Scholar] [CrossRef]

- Zhang, L.S.; Shan, Y.F. Quantitative Analysis of Fracture Roughness and Multi-Field Effects for CO2-ECBM Projects. Energies 2024, 17, 2851. [Google Scholar] [CrossRef]

- Asif, M.; Junussov, M.; Longinos, S.; Hazlett, R.; Satibekova, S. CO2 storage capacity of coal seams: A screening and geological review of carboniferous coal formations of Kazakhstan. Int. J. Coal Sci. Technol. 2025, 12, 18. [Google Scholar] [CrossRef]

- Scafidi, J.; Wilkinson, M.; Gilfillan, S.M.; Heinemann, N.; Haszeldine, R.S. A quantitative assessment of the hydrogen storage capacity of the UK continental shelf. Int. J. Hydrogen Energy 2021, 46, 8629–8639. [Google Scholar] [CrossRef]

- Zhang, K.Q.; Liu, L.R.; Huang, G.H. Nanoconfined water effect on CO2 utilization and geological storage. Geophys. Res. Lett. 2020, 47, e2020GL087999. [Google Scholar] [CrossRef]

- Thanh, H.V.; Sugai, Y.H.; Sasaki, K. Application of artificial neural network for predicting the performance of CO2 enhanced oil recovery and storage in residual oil zones. Sci. Rep. 2020, 10, 18204. [Google Scholar] [CrossRef]

- Bonto, M.; Welch, M.J.; Lüthje, M.; Andersen, S.I.; Veshareh, M.J.; Amour, F.; Afrough, A.; Mokhtari, R.; Hajiabadi, M.R.; Alizadeh, M.R.; et al. Challenges and enablers for large-scale CO2 storage in chalk formations. Earth-Sci. Rev. 2021, 222, 103826. [Google Scholar] [CrossRef]

- Fang, H.H.; Wang, Y.J.; Sang, S.X.; Yu, S.; Liu, H.H.; Guo, J.R.; Wang, Z.F. Potential assessment of CO2 source/sink and its matching research during CCS process of deep unworkable seam. Sci. Rep. 2024, 14, 17206. [Google Scholar] [CrossRef]

- Mi, Z.X.; Wang, F.G.; Yang, Y.Z.; Wang, F.; Hu, T.; Tian, H.L. Evaluation of the potentiality and suitability for CO2 geological storage in the Junggar Basin, northwestern China. Int. J. Greenh. Gas Control 2018, 78, 62–72. [Google Scholar] [CrossRef]

- Ye, J.; Afifi, A.; Rowaihy, F.; Baby, G.; De Santiago, A.; Tasianas, A.; Hamieh, A.; Khodayeva, A.; Al-Juaied, M.; Meckel, T.; et al. Evaluation of geological CO2 storage potential in Saudi Arabian sedimentary basins. Earth-Sci. Rev. 2023, 244, 104539. [Google Scholar] [CrossRef]

- Wang, J.Q.; Yuan, Y.; Chen, J.W.; Zhang, W.; Zhang, J.; Liang, J.; Zhang, Y.G. Geological conditions and suitability evaluation for CO2 geological storage in deep saline aquifers of the Beibu Gulf Basin (South China). Energies 2023, 16, 2360. [Google Scholar] [CrossRef]

- Zhan, J.; Su, Z.Z.; Fan, C.; Li, X.N.; Ma, X.L. Suitability evaluation of CO2 geological sequestration based on unascertained measurement. Arab. J. Sci. Eng. 2022, 47, 11453–11467. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, W.; Chen, J.; Jiang, D.Y.; Fan, J.Y.; Daemen, J.J.K.; Qiao, W.B. Large-scale CO2 disposal/storage in bedded rock salt caverns of China: An evaluation of safety and suitability. Energy 2022, 249, 123727. [Google Scholar] [CrossRef]

- Carlotto, V.; Dueñas, A.; Ingol-Blanco, E.; Santa-Cruz, S. A multi-criteria approach to the selection of geological storage of CO2 sites in Peru. Int. J. Greenh. Gas Control 2022, 114, 103600. [Google Scholar] [CrossRef]

- Fawad, M.; Mondol, N.H. Monitoring geological storage of CO2: A new approach. Sci. Rep. 2021, 11, 5942. [Google Scholar] [CrossRef] [PubMed]

- Fibbi, G.; Del Soldato, M.; Fanti, R. Review of the monitoring applications involved in the underground storage of natural gas and CO2. Energies 2022, 16, 12. [Google Scholar] [CrossRef]

- Cao, C.; Liu, H.J.; Hou, Z.M.; Mehmood, F.; Liao, J.X.; Feng, W.T. A review of CO2 storage in view of safety and cost-effectiveness. Energies 2020, 13, 600. [Google Scholar] [CrossRef]

- Gholami, R.; Raza, A.; Iglauer, S. Leakage risk assessment of a CO2 storage site: A review. Earth-Sci. Rev. 2021, 223, 103849. [Google Scholar] [CrossRef]

- Smith, E.; Morris, J.; Kheshgi, H.; Teletzke, G.; Herzog, H.; Paltsev, S. The cost of CO2 transport and storage in global integrated assessment modeling. Int. J. Greenh. Gas Control 2021, 109, 103367. [Google Scholar] [CrossRef]

- Raza, A.; Glatz, G.; Gholami, R.; Mahmoud, M.; Alafnan, S. Carbon mineralization and geological storage of CO2 in basalt: Mechanisms and technical challenges. Earth-Sci. Rev. 2022, 229, 104036. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, W.C.; Yang, R.Z.; Liu, Y.M.; Jafari, M. CO2 capture and storage monitoring based on remote sensing techniques: A review. J. Clean Prod. 2021, 281, 124409. [Google Scholar] [CrossRef]

- Zhang, S.R.; Sang, S.X.; Wu, J.; Zhou, X.Z.; Zhang, B.; Yang, R.Z.; Guo, J.C.; Liu, X.D.; Zhang, W.Q.; Li, Y. Progress and application of key technologies for CO2 enhancing coalbed methane. J. China Coal Soc. 2022, 47, 3952–3964. [Google Scholar]

- Li, Z.W.; Yu, H.J.; Bai, Y.S. Numerical simulation of CO2-ECBM based on multi-physical field coupling model. Sustainability 2022, 14, 11789. [Google Scholar] [CrossRef]

- Fang, H.H.; Xu, H.J.; Sang, S.X.; Liu, S.Q.; Song, S.L.; Liu, H.H. 3D reconstruction of coal pore network and its application in CO2-ECBM process simulation at laboratory scale. Front. Earth Sci. 2022, 16, 523–539. [Google Scholar] [CrossRef]

- Ma, Q.Q.; Li, H.; Ji, K.; Huang, F.J. Thermal-hydraulic-mechanical coupling simulation of CO2 enhanced coalbed methane recovery with regards to Low-Rank but relatively shallow coal seams. Appl. Sci. 2023, 13, 2592. [Google Scholar] [CrossRef]

- Cheng, X.Y.; Gong, X.P.; Cheng, C.; Li, Q.G.; Li, Z.Q. Molecular Dynamics Simulation of CO2-ECBM Under Different Moisture Contents. Energies 2025, 18, 239. [Google Scholar] [CrossRef]

- Liu, M.Y.; Wen, H.; Fan, S.X.; Wang, Z.P.; Fei, J.B.; Wei, G.M.; Chen, X.J.; Wang, H. Experimental study of CO2-ECBM by injection liquid CO2. Minerals 2022, 12, 297. [Google Scholar] [CrossRef]

- Wang, Z.L.; Sang, S.X.; Zhou, X.Z.; Liu, X.D. Numerical study on CO2 sequestration in low-permeability coal reservoirs to enhance CH4 recovery: Gas driving water and staged inhibition on CH4 output. J. Pet. Sci. Eng. 2022, 214, 110478. [Google Scholar] [CrossRef]

- Liu, X.D.; Sang, S.X.; Zhou, X.Z.; Wang, Z.L. Coupled adsorption-hydro-thermo-mechanical-chemical modeling for CO2 sequestration and well production during CO2-ECBM. Energy 2023, 262, 125306. [Google Scholar] [CrossRef]

- Damen, K.; Faaij, A.; Bergen, F.V.; Gale, J.; Lysen, E. Identification of early opportunities for CO2 sequestration—Worldwide screening for CO2-EOR and CO2-ECBM projects. Energy 2005, 30, 1931–1952. [Google Scholar] [CrossRef]

- Godec, M.; Koperna, G.; Gale, J. CO2-ECBM: A review of its status and global potential. Energy Proc. 2014, 63, 5858–5869. [Google Scholar] [CrossRef]

- Gale, J.; Freund, P. Coal-bed methane enhancement with CO2 sequestration worldwide potential. Environ. Geosci. 2001, 8, 210–217. [Google Scholar] [CrossRef]

- Su, X.B.; Lin, X.Y.; Liu, S.B.; Zhao, M.J.; Song, Y. Geology of coalbed methane reservoirs in the Southeast Qinshui Basin of China. Int. J. Coal Geol. 2005, 62, 197–210. [Google Scholar] [CrossRef]

- Liu, D.M.; Jia, Q.F.; Cai, Y.D.; Gao, C.J.; Qiu, F.; Zhao, Z.; Chen, S.Y. A new insight into coalbed methane occurrence and accumulation in the Qinshui Basin, China. Gondwana Res. 2022, 111, 280–297. [Google Scholar] [CrossRef]

- Su, X.B.; Lin, X.Y.; Zhao, M.J.; Song, Y.; Liu, S.B. The upper Paleozoic coalbed methane system in the Qinshui basin, China. AAPG Bull. 2005, 89, 81–100. [Google Scholar] [CrossRef]

- Jiang, L.; Song, Y.; Zhao, W.; Bo, D.M.; Liu, S.B.; Hao, J.Q. Main controlling factor of coalbed methane enrichment area in southern Qinshui Basin, China. J. Pet. Explor. Prod. Technol. 2024, 14, 165–173. [Google Scholar] [CrossRef]

- Clarkson, C. The Allison Unit CO2-ECBM Pilot: A Reservoir Modeling Study. Retrieved April 2003, 7, 1–56. [Google Scholar]

- Shi, J.Q.; Durucan, S. A numerical simulation study of the Allison unit CO2-ECBM pilot: The impact of matrix shrinkage and swelling on ECBM production and CO2 injectivity. Greenh. Gas Control Technol. 7 2005, I, 431–439. [Google Scholar]

- Weber, M.; Wilson, T.H.; Akwari, B.; Wells, A.W.; Koperna, G. Impact of geological complexity of the Fruitland Formation on combined CO2 enhanced recovery/sequestration at San Juan Basin pilot site. Int. J. Coal Geol. 2012, 104, 46–58. [Google Scholar] [CrossRef]

- Liu, S.Q.; Huang, F.S.; Du, R.B.; Chen, S.H.; Guan, Y.T.; Liu, Y.H.; Wang, T. Progress and typical case analysis of demonstration projects of the geologic al sequestration and utilization of CO2. Coal Geol. Explor. 2023, 51, 158–174. [Google Scholar]

- Massarotto, P.; Golding, S.D.; Bae, J.S.; Iyer, R.; Rudolph, V. Changes in reservoir properties from injection of supercritical CO2 into coal seams—A laboratory study. Int. J. Coal Geol. 2010, 82, 269–279. [Google Scholar] [CrossRef]

- Ranathunga, A.S.; Perera, M.S.A.; Ranjith, P.G.; Rathnaweera, T.D.; Zhang, X.G. Effect of coal rank on CO2 adsorption induced coal matrix swelling with different CO2 properties and reservoir depths. Energy Fuels 2017, 31, 5297–5305. [Google Scholar] [CrossRef]

- Reisabadi, M.Z.; Sayyafzadeh, M.; Haghighi, M. Stress and permeability modelling in depleted coal seams during CO2 storage. Fuel 2022, 325, 124958. [Google Scholar] [CrossRef]

- Cao, B.; Fu, X.H.; Kang, J.Q.; Lu, J.L.; Tang, P.; Xu, H.; Huang, M. Mini-Review on Influence of CO2-Enhanced Coalbed Methane Recovery and CO2 Geological Storage on Physical Properties of Coal Reservoir. Energy Fuels 2024, 38, 23268–23280. [Google Scholar] [CrossRef]

- Shang, Z.; Wang, H.F.; Li, B.; Cheng, Y.P.; Zhang, X.H.; Wang, Z.Y.; Geng, S.K.; Wang, Z.Y.; Chen, P.; Lv, P.F.; et al. The effect of leakage characteristics of liquid CO2 phase transition on fracturing coal seam: Applications for enhancing coalbed methane recovery. Fuel 2022, 308, 122044. [Google Scholar] [CrossRef]

- Gordon, D.; Reuland, F.; Jacob, D.J.; Worden, J.R.; Shindell, D.; Dyson, M. Evaluating net life-cycle greenhouse gas emissions intensities from gas and coal at varying methane leakage rates. Environ. Res. Lett. 2023, 18, 084008. [Google Scholar] [CrossRef]

- Zhang, M.J.; Gao, L.; Wang, Q.D.; Xie, D.L.; Gao, J.; Wang, S.X.; Lu, X. Methane leakage measurement of natural gas heating boilers and greenhouse gas emissions accounting of “coal-to-gas” transition for residential heating in rural Beijing. Environ. Sci. Technol. Lett. 2022, 10, 93–97. [Google Scholar] [CrossRef]

- Rutqvist, J.; Birkholzer, J.T.; Tsang, C.F. Coupled reservoir-geomechanical analysis of the potential for tensile and shear failure associated with CO2 injection in multilayered reservoir-caprock systems. Int. J. Rock Mech. Min. Sci. 2008, 45, 132–143. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).