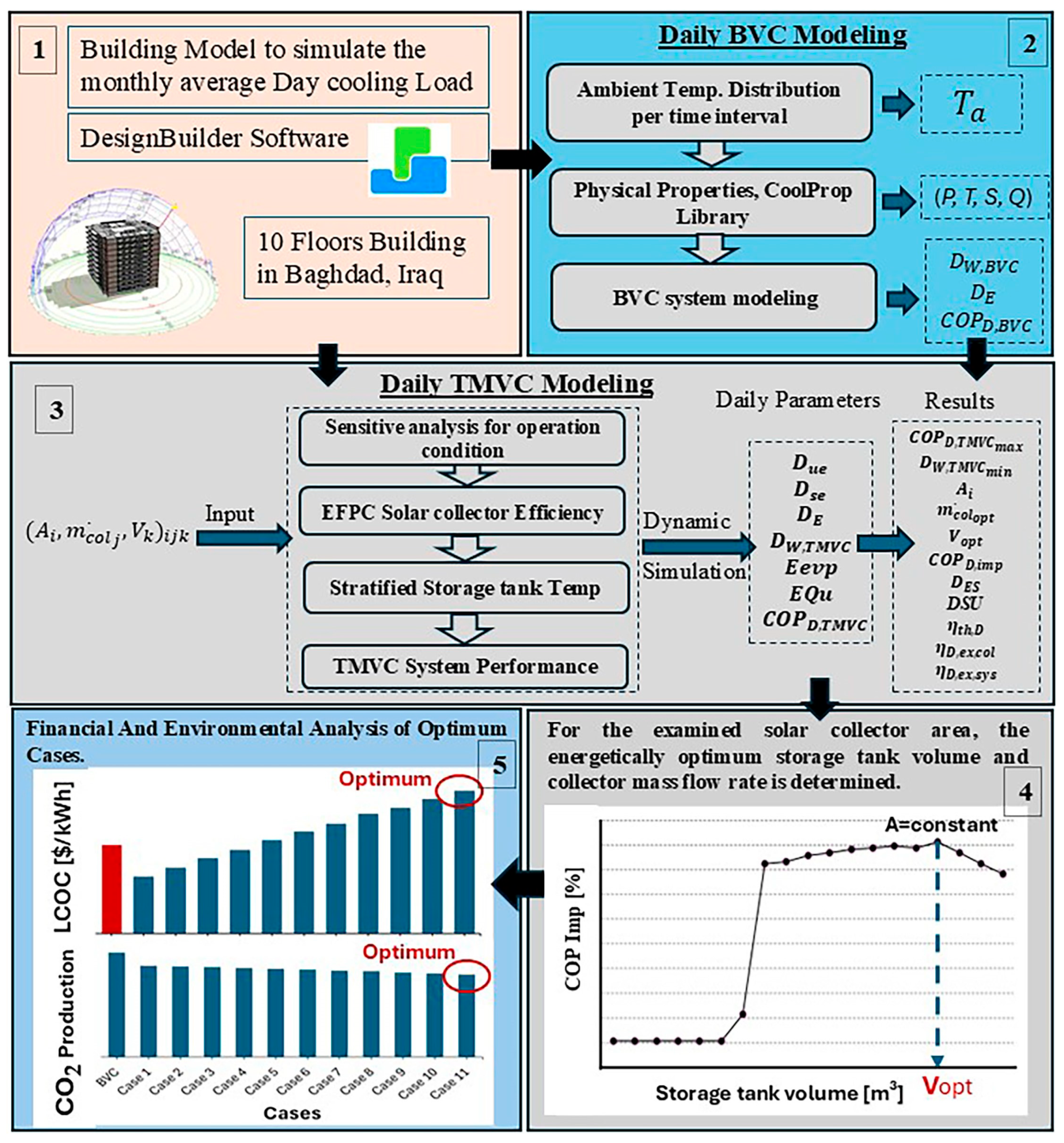

In this study, the daily performance of the solar-assisted air conditioning system was analysed and simulated to meet the building’s cooling demand. Various combinations of solar collector area, storage tank volume, and collector mass flow rate were considered. The objective is to identify the optimal storage tank volume and mass flow rate for each collector area to maximise system performance, energy savings, exergy efficiency, and the hourly utilisation of solar energy throughout the day. The results from this dynamic analysis were then used to compare the optimum configurations. Furthermore, the economic and environmental feasibility of each optimal design, including the associated CO2 emission reductions, was evaluated.

8.2. System Optimisation

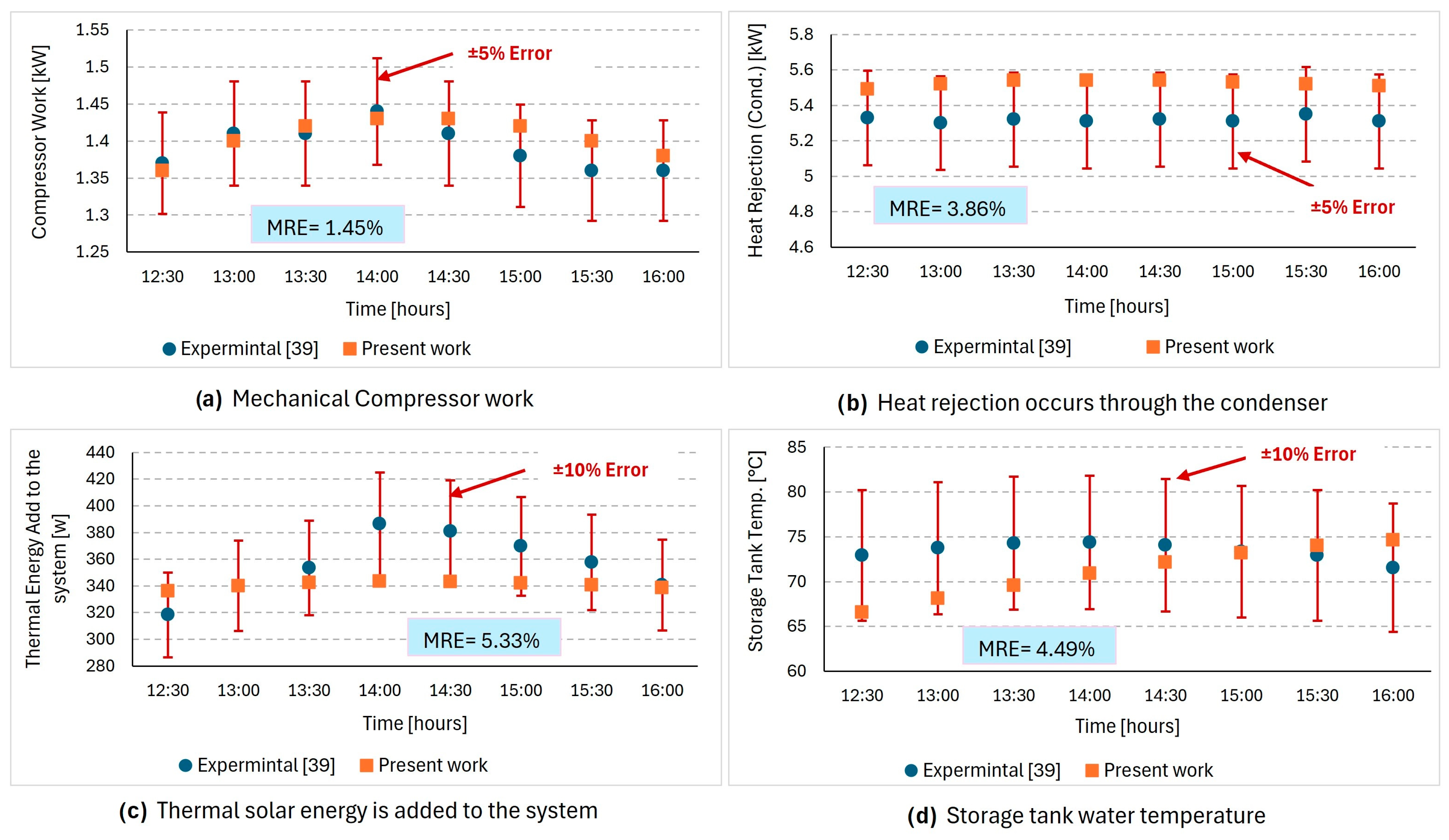

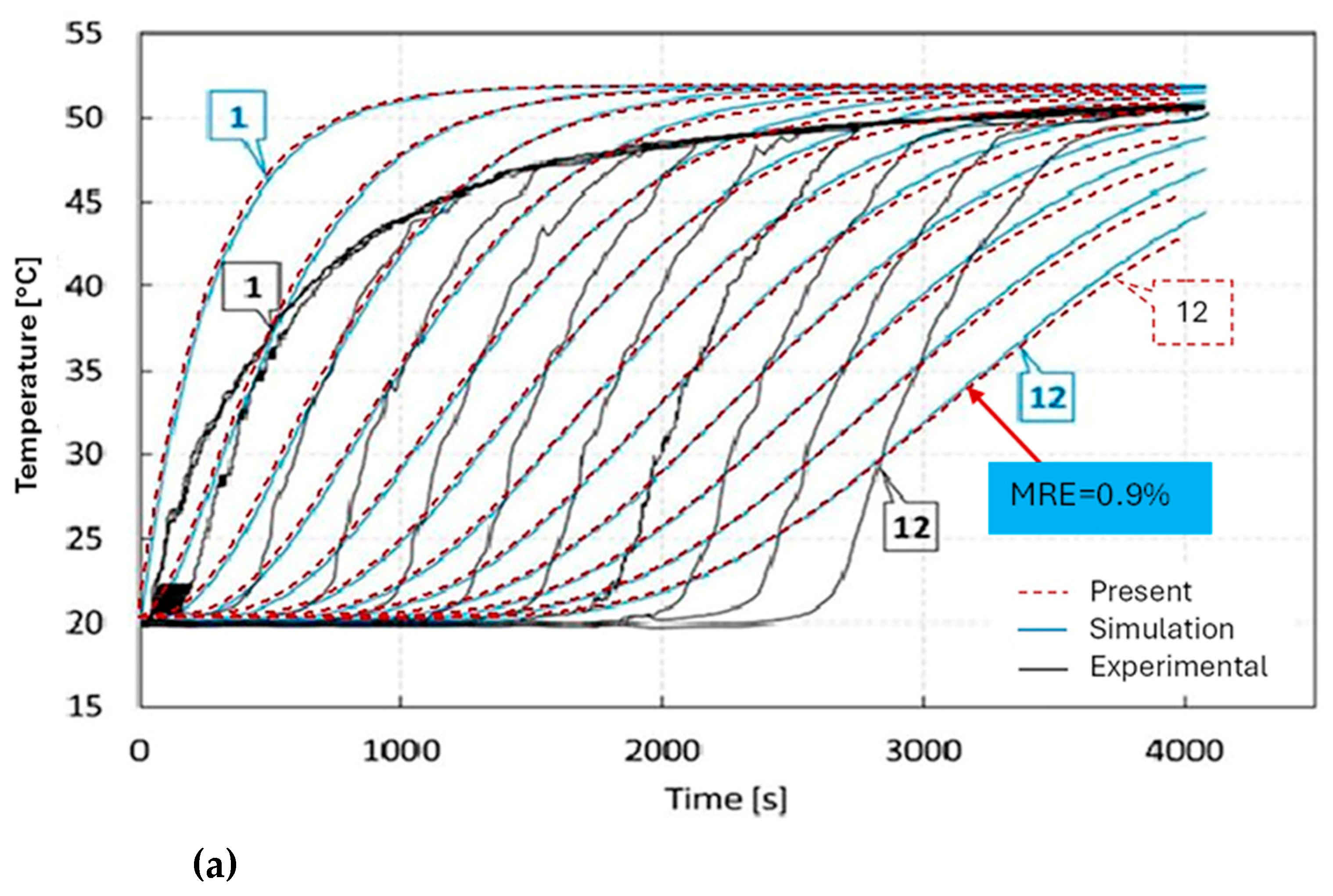

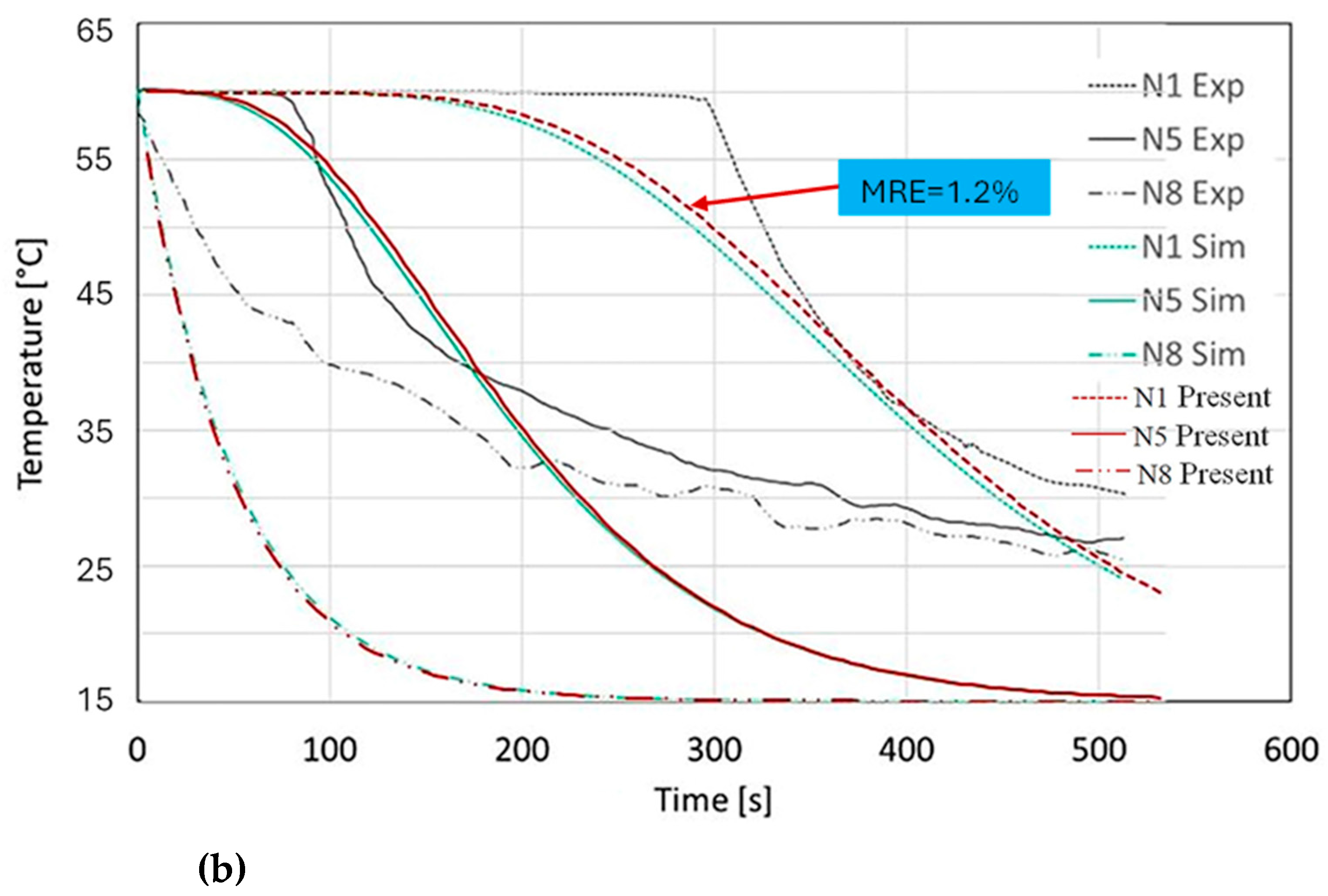

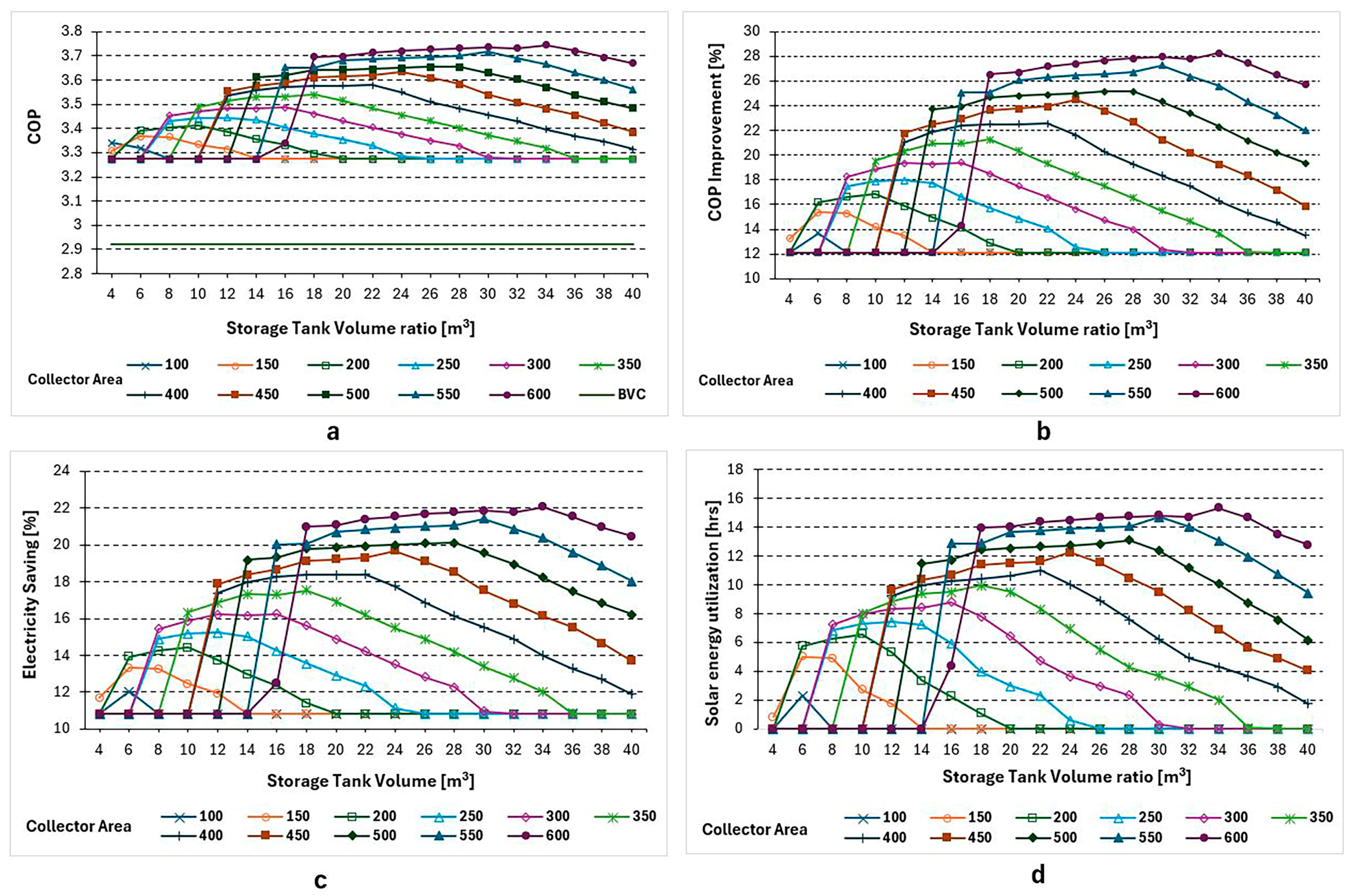

According to

Figure 10a–c, each collector area has an optimal storage tank volume that maximises the daily energy performance of the TMVC system. These figures illustrate the effect of collector area and storage tank volume, at a collector mass flow rate of (0.02 ×

Ac), on the COP, COP improvement, and energy savings of the TMVC system compared to the BVC system.

These figures show consistent trends, as for each collector area, there is a threshold storage tank volume at which the TMVC system starts utilising solar energy for thermal compression, leading to improved COP, and energy savings. This improvement continues until it reaches an optimum storage tank volume, providing maximum COP and energy savings. Beyond this point, performance declines either because the storage tank cannot supply sufficient heat for the thermal compressor or provides heat at a lower-than-optimal rate. For smaller collector areas (100–300 m2), COP improvement and energy savings begin at a small storage tank threshold, typically below 6 m3, and reach their peak at an optimum storage tank volume of around 4–16 m3. Beyond this point, COP decreases as the effect of thermal compression fades, eventually stabilising at approximately 12.13% COP improvement and 10.8% energy savings, driven primarily by the ejector’s performance.

Conversely, for larger collector areas (400–600 m2), both the COP improvement and energy savings increase as the storage tank volume increases. The highest improvements, peaking at 28% in COP and 22% in energy savings, are seen with a 34 m3 storage tank for a 600 m2 collector. These larger areas require a larger threshold storage tank size because smaller tanks cause the water temperature to rise above 170 °C, leading to boiling.

One of the key performance indicators for the solar-assisted air conditioning system is the number of hours it can utilise solar thermal energy daily across the examined configurations. As illustrated in

Figure 10d, with a collector area of 400 m

2 and a storage tank volume exceeding 14 m

3, the system can operate on solar thermal energy for more than 10 h per day. The reliance on solar energy increases significantly with larger collector areas. For instance, a configuration featuring a 600 m

2 collector and a storage volume of 34 m

3 enables solar energy utilisation for over 15 h daily. This demonstrates that when the collector area is increased, in conjunction with an adequately sized storage tank, the daily operational hours of solar-driven thermal compression increase, effectively supplying the heat required for the thermal compressor.

Figure 11 illustrates the overall exergy efficiency of the system, highlighting the effects of collector area and storage tank volume. A clear trend is observed where exergy efficiency decreases as the collector area increases. In contrast, exergy efficiency stabilises and exhibits minimal variation with increases in storage tank volume, particularly beyond a certain threshold.

The decline in exergy efficiency with increasing collector area is attributed to the increasing exergy destruction within the system, which occurs from irreversibilities such as temperature gradients between the heat source (solar collector) and the heat sink (environment). These irreversibilities become more pronounced as the collector area increases, leading to higher thermal losses and reduced overall exergy efficiency.

Additionally, when the storage tank fails to provide the required heat to the thermal compressor, the contribution of the solar thermal system diminishes. In such cases, the system’s exergy efficiency reverts to a baseline level comparable to a vapour compression system with an ejector, as the solar thermal system’s effect fades under less favourable conditions.

Figure 12a illustrates the daily thermal efficiency of the solar collector field. The results indicate that increasing the collector area while maintaining a lower storage tank volume leads to a decrease in collector thermal efficiency. This combination results in elevated mean temperatures within the storage tank layers, which, in turn, raise the inlet temperature of the solar collector. A higher inlet temperature negatively impacts the thermal performance of the collector by increasing thermal losses due to the larger temperature difference between the collector surface and the surrounding environment. Consequently, this reduces the overall thermal efficiency of the collector.

Furthermore, for each collector area, the efficiency curve follows a characteristic trend. It begins at a threshold storage tank volume, where the collector operates with minimal efficiency. As the storage tank volume increases, the efficiency improves, benefiting from a more balanced heat storage and supply. However, as the storage tank volume becomes excessively large, the system’s thermal energy potential diminishes, and it can no longer maintain the necessary heat to supply the thermal compressor effectively. This leads to the solar thermal system eventually ceasing operation.

For example, at a collector area of 600 m2 and a storage tank volume of 18 m3, the thermal efficiency is approximately 53.54%. However, with the same collector area and a larger storage tank volume of 40 m3, the efficiency improves significantly to 57.71%. This highlights the importance of balancing the collector area and storage tank volume to optimise thermal efficiency and minimise thermal losses.

Figure 12b shows the variation in collector exergy efficiency with respect to collector area and storage tank volume. It is observed that as the collector area increases, the collector exergy efficiency generally improves, particularly for smaller storage tank volumes, indicating that larger collectors utilise solar energy more effectively. Conversely, for a fixed collector area, the efficiency tends to decrease with increasing storage tank volume. This decline can be attributed to higher thermal losses or reduced efficiency in heat utilisation associated with larger tank capacities. The highest efficiencies are achieved with smaller tank volumes and larger collector areas, with a peak value of 13.3% observed for a collector area of 500 m

2 and a tank volume of 14 m

3. This analysis highlights the importance of optimising the balance between the collector area and storage tank volume to achieve maximum exergy efficiency.

Figure 13 summarises the optimal cases, along with their daily energy and exergy results.

8.3. Dynamic Behaviour of the Optimum Cases

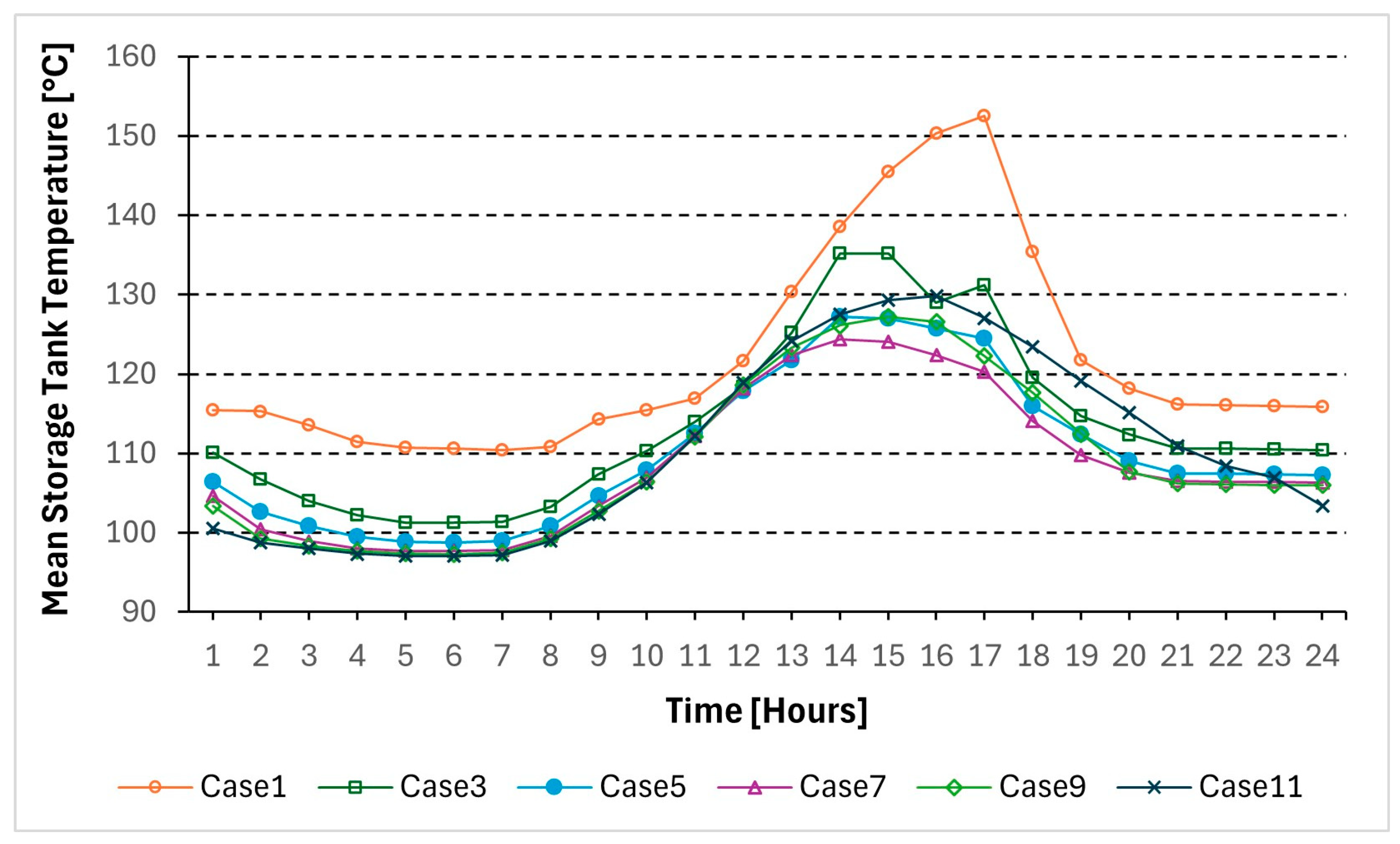

Figure 14 illustrates the mean distributed temperature inside the storage tank, providing insights into the behaviour of the TMVC system throughout the day. The temperature begins to rise around 7 a.m. as solar radiation becomes available, peaking at 3 p.m. During this period, the heat input from the solar source (charging) exceeds the heat output to the load (discharging), leading to an increase in temperature. Afterward, the temperature decreases as discharging surpasses charging, eventually reaching a steady state.

For Cases 5, 7, 9, and 11, the temperature curves exhibit smooth behaviour, indicating regular and successive charging and discharging cycles. This suggests that the heat acquired from the solar collector is sufficient to consistently supply heat from the storage tank to the load. Conversely, Case 3 exhibits fluctuating temperature profiles due to a lag between the charging and discharging processes. This lag indicates that the solar collector’s heat gain is initially insufficient to simultaneously increase the tank temperature and meet the load demand, causing fluctuations.

In case 1, while the mean temperature is higher, the smaller storage volume limits the total thermal energy that can be stored. This restriction prevents the system from sustaining a steady and sufficient heat supply to the TMVC system over time, particularly during high-demand periods or transient conditions. As a result, the temperatures in Cases 1 and 2 are higher than in the other cases, as the thermal compression process relies on adequate storage tank temperatures. These higher temperatures are accumulated over time due to delayed and irregular charging and discharging cycles.

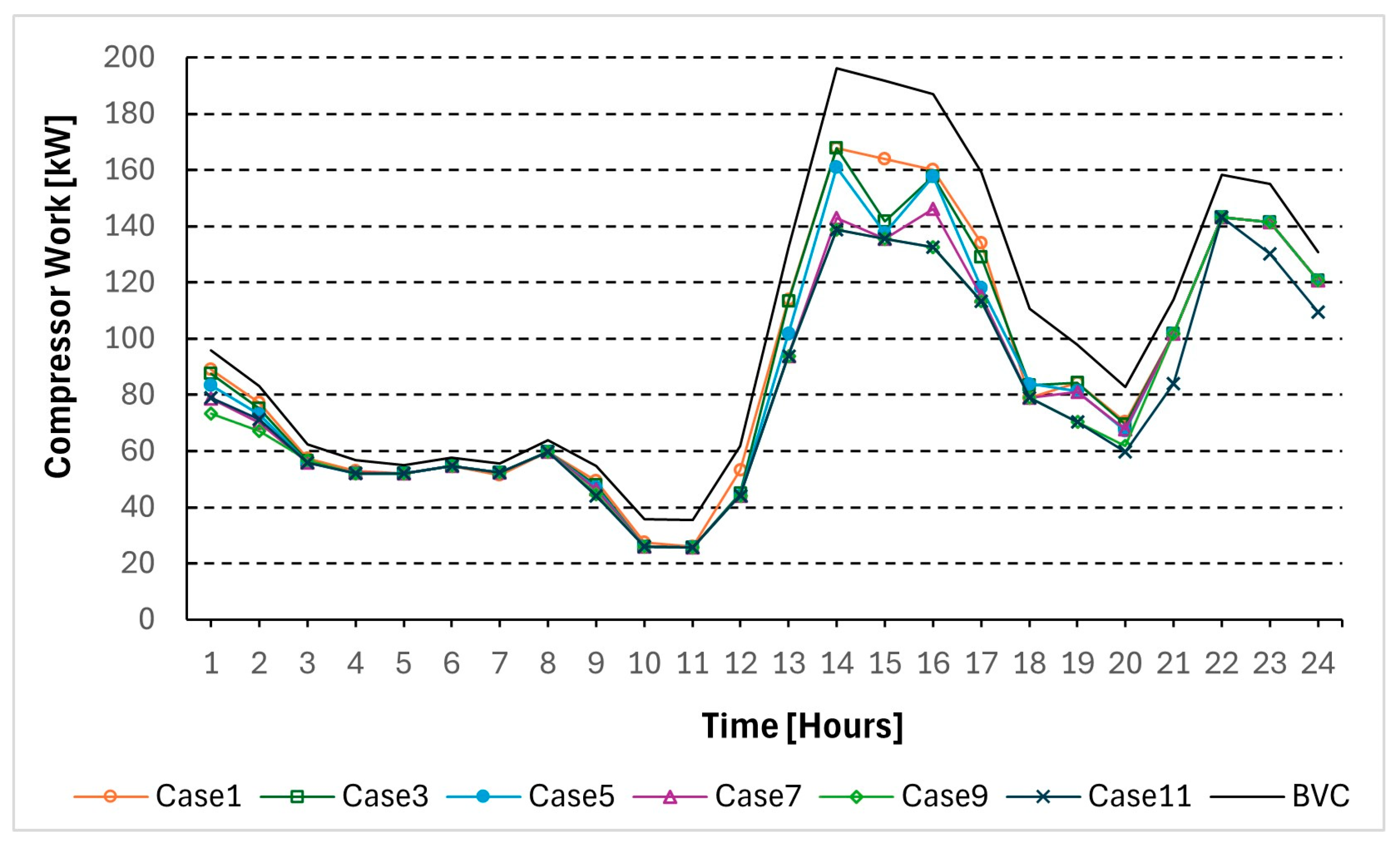

Figure 15 shows the hourly performance of the TMVC system varies across cases (Cases 1, 3, 5, 7, 9, and 11) and consistently outperforms the BVC in energy saving. During early hours (0–6 a.m.), all the TMVC cases show a lower compressor work average between (40–60 kW) compared to the BVC (50–70 kW), with Cases 9 and 11 performing slightly better due to larger storage volumes. From 7–11 h, Cases 7, 9, and 11 continue to demonstrate reduced work compared to other TMVC cases, reflecting improved thermal integration.

During peak hours (12–14), all the systems experience increased compressor work. However, TMVC cases, particularly Cases 9 and 11, maintain lower demands (140–160 kW) compared to the BVC (160–200 kW) and outperform Cases 1 and 3, which approach the BVC. In the afternoon (15–19), Cases 9 and 11 sustain moderate work levels (100–120 kW), while other TMVC cases and the BVC require more energy (130–160 kW). By evening (20–24), all TMVC cases reduce their work, with Cases 9 and 11 again showing the lowest values (60–100 kW) compared to other cases (~70–110 kW) and the BVC (70–130 kW). Overall, Cases 9 and 11 consistently achieve the best performance, emphasising the benefits of optimised storage and thermal management.

As illustrated in

Figure 16, the hourly COP analysis shows that the TMVC system consistently outperforms the BVC throughout the day. TMVC cases, particularly Case 11, maintain higher COP values due to greater heat gain during the charging mode and better temperature distribution within the storage tank, with values ranging from 4.0 to 4.7, compared to the BVC (3.7–4.3) during early hours (1–6). In the afternoon (13–18), TMVC cases sustain a COP of 3.3–3.5, while the BVC drops below 2.5. By evening (19–24), TMVC cases, especially Case 11, recover with COP values rising to 3.7–4.2, surpassing the BVC (2.6–3.5). Overall, the TMVC system demonstrates improved energy efficiency, with Case 11 performing the best during high-load periods.

Figure 17 illustrates the hourly thermal efficiency of the solar collector. All the optimal cases exhibit a similar trend: efficiency increases after sunrise as solar radiation becomes available, peaks around noon, and then gradually declines toward sunset. However, Case 11 shows a slight deviation to the left after noon. This deviation occurs due to the increasing temperature distribution, which raises the inlet water temperature to the collector, thereby reducing the collector’s efficiency.

Figure 18 shows the monthly average daily electricity consumption for all the months, comparing the BVC with the TMVC optimal case. Electricity consumption is highest in July and August due to higher mean ambient temperatures, which result in a lower COP. The BVC consistently demonstrates the highest compressor work, reflecting greater daily energy consumption compared to the TMVC cases. The integration of a thermal compressor in the TMVC cases demonstrates improved energy efficiency, particularly during high-load months.

8.4. Economic Analysis

An economic analysis was conducted for the optimal cases, comparing them to the basic vapour compression cycle (BVC) using the levelised cost of cooling (LCOC), including the total environmental penalty cost savings accrued over the system’s lifetime. This financial evaluation considers all summer months (April to October) to determine the electricity savings achieved through the implementation of the TMVC system.

One of the primary challenges impacting the economic feasibility of renewable energy projects in Iraq, particularly those targeting reductions in electricity consumption, is the government’s subsidy for residential electricity prices, which can be as low as $0.015 per kWh. This substantial subsidy makes it difficult for competing projects to achieve economic viability. To address this, the present study assumes an average electricity price of $0.15 per kWh for analysis.

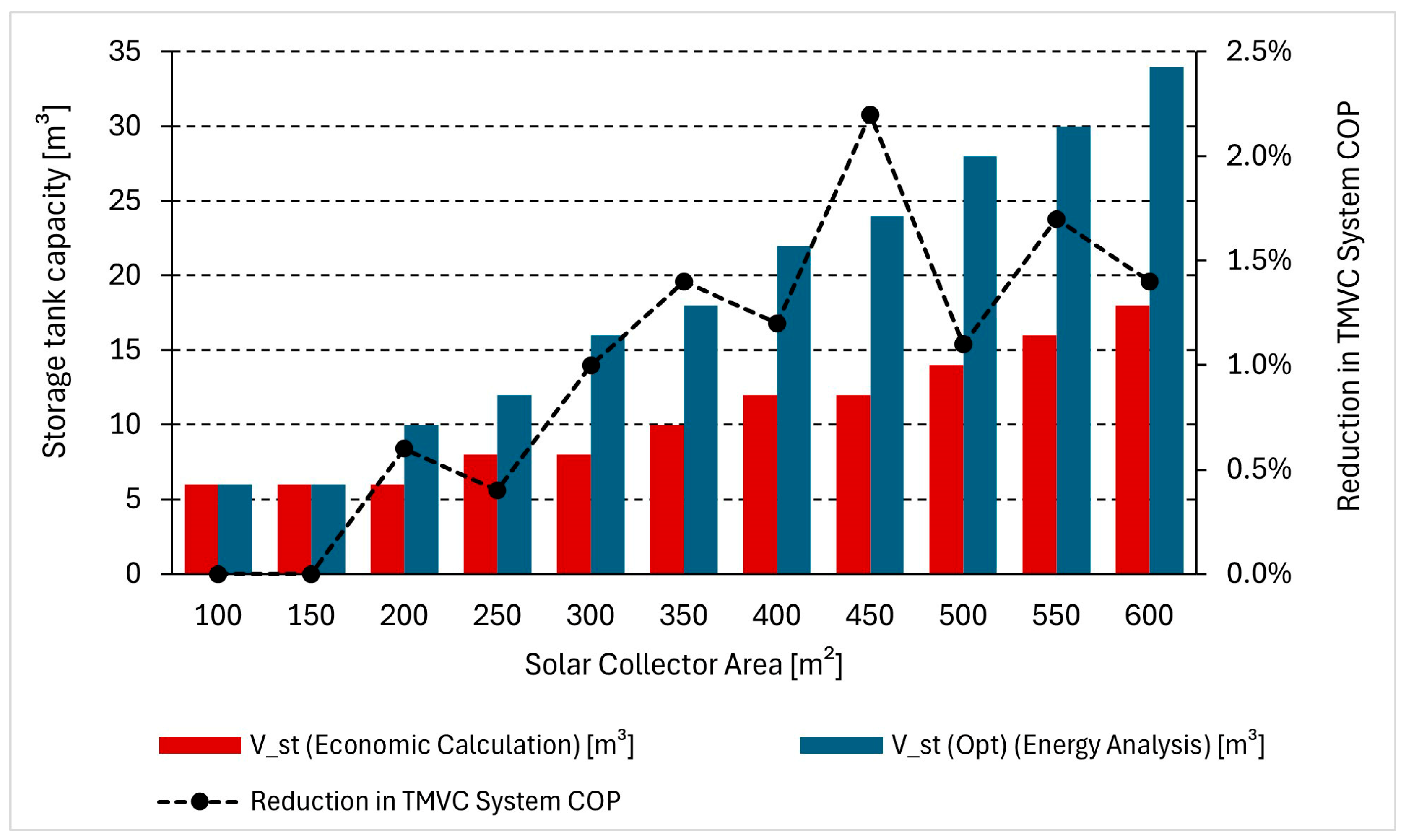

In order to reduce the capital cost and achieve acceptable economic results, a sensitivity analysis was conducted to evaluate the impact of reducing the storage tank volume per cubic meter on the TMVC system’s COP. The storage tank is the most expensive component of the system, making it a key focus for cost optimisation. The results, presented in

Figure 19, identify the optimum storage tank size for each case and count the percentage change in COP when the storage tank volume is reduced to an acceptable level that maintains the internal temperature within acceptable limits.

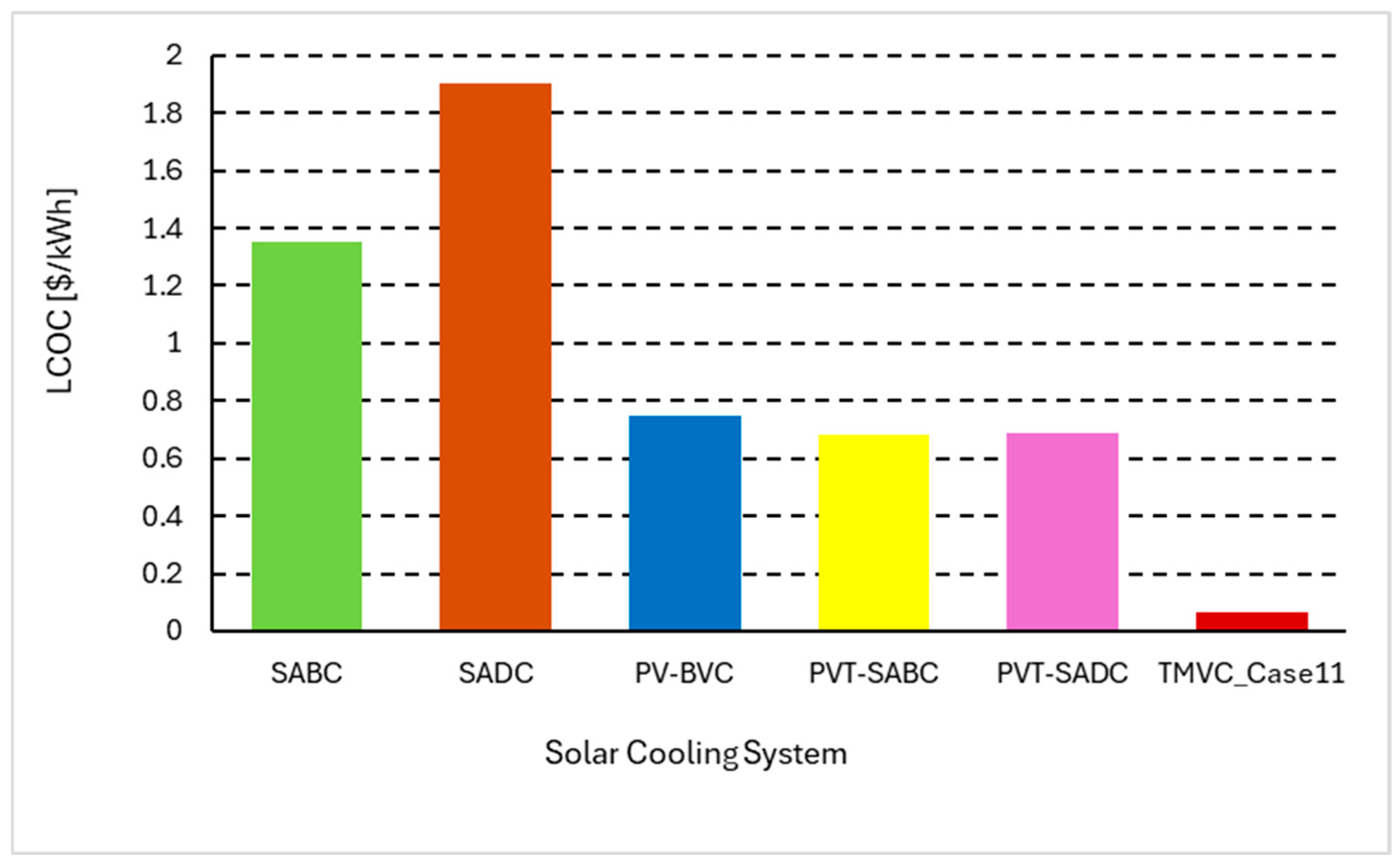

Figure 20 illustrates the levelised cost of cooling (LCOC) for various configurations of the TMVC system, compared to the baseline vapour compression cycle (BVC) as a reference. As the configurations progress from Case 1 to Case 11, the LCOC generally increases, indicating a rise in the cost of cooling. In configurations with smaller collector areas and storage tank volumes (Cases 1 to 3), the TMVC system achieves a noticeable cost reduction compared to the BVC. Notably, Case 4 achieves an LCOC of 0.053

$/kWh, closely matching the cost of the BVC. Beyond this point, the LCOC continues to rise, with Case 11 exhibiting the highest cost at

$0.063/kWh, representing a 16% increase over the baseline.

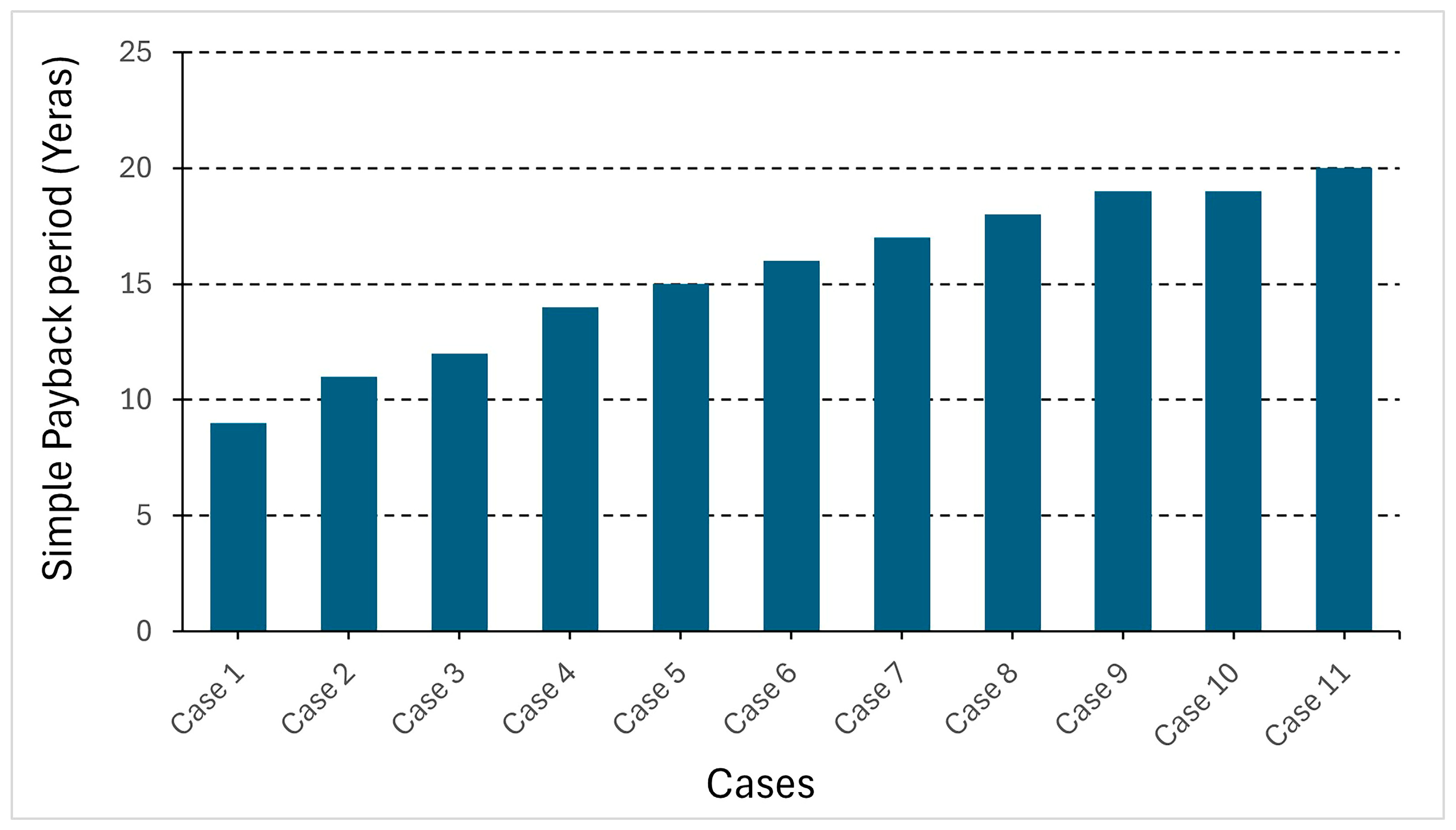

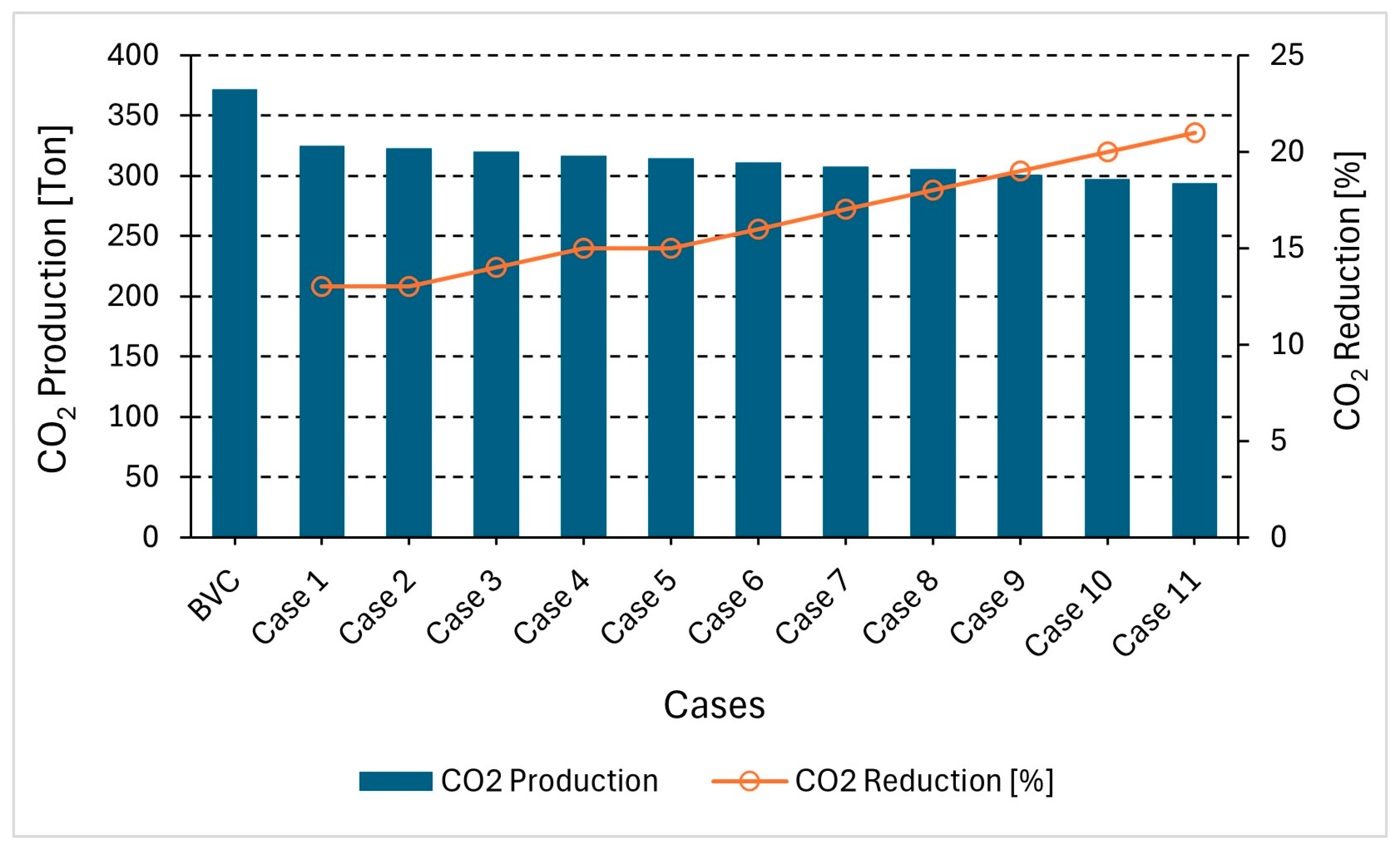

Figure 21 illustrates the simple payback period (SPBP) for the various TMVC system configurations. A clear trend is observed: as the collector area and storage tank volume increase across the cases, the SPBP correspondingly rises due to higher capital investment.

Case 1 offers the shortest payback period of 9 years, attributed to its relatively low system cost, while Case 11 exhibits the longest payback period of 20 years despite achieving the highest energy savings and environmental benefits. This highlights the economic-performance trade-off, where configurations with greater sustainability gains (e.g., Case 11) require a longer investment recovery period, whereas lower-cost systems (e.g., Case 1) yield faster returns but more modest energy and emissions reductions.

8.6. Comprehensive Evaluation Index

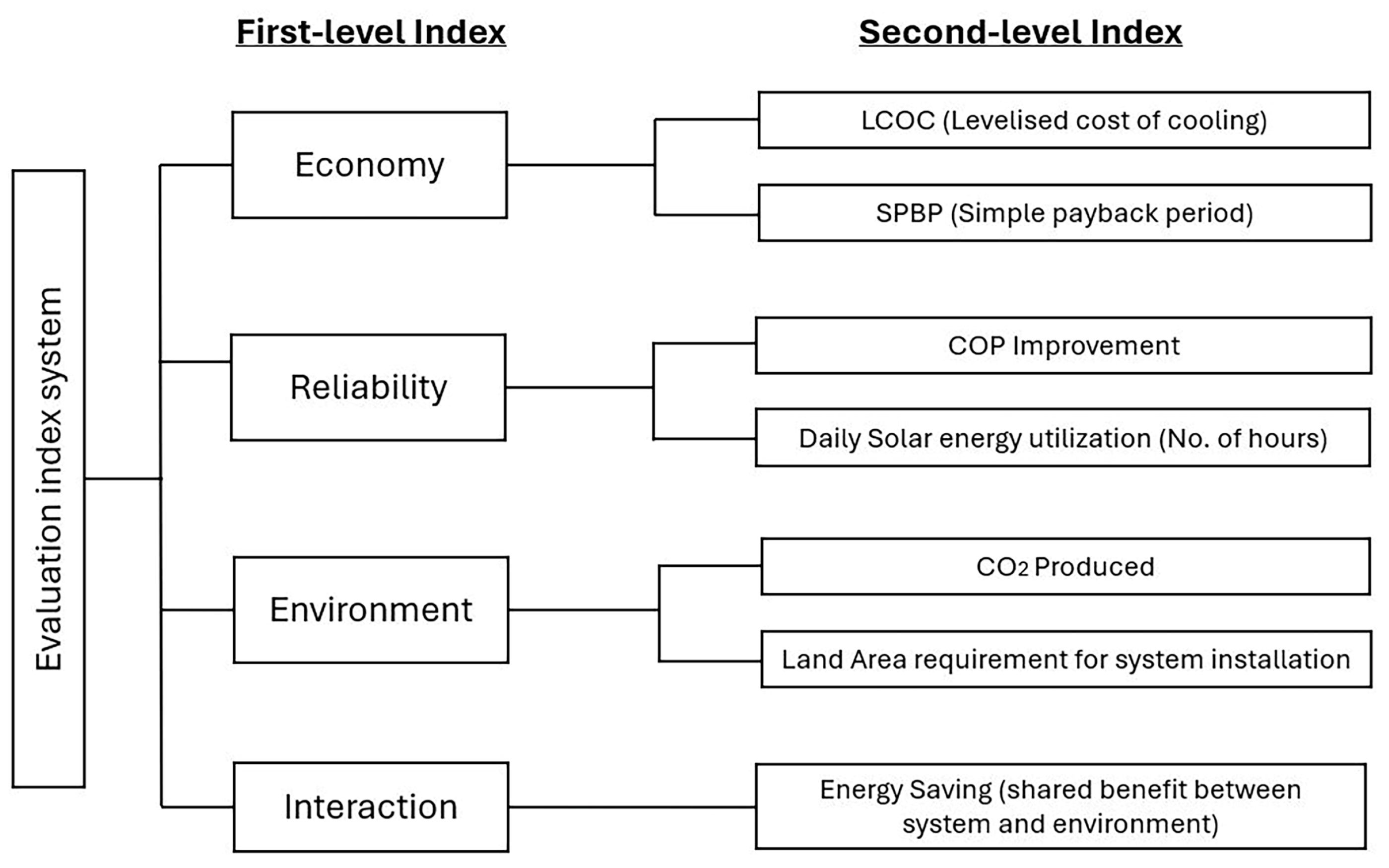

In this study, a comprehensive evaluation index method was implemented to rank 11 design cases of a TMVC system based on multiple performance indicators implemented as shown in

Figure 23, The approach is adapted from Liu et al., (2022) [

43], who proposed a hybrid AHP–entropy method for smart grid evaluation. To simplify and tailor the method for TMVC systems, a two-stage index structure is constructed. The first-level indicators include economy, reliability, environmental impact, and interaction, while the second-level indicators consist of COP improvement, energy saving, solar energy utilization hours, levelised cost of cooling (LCOC), simple payback period (SPBP), CO

2 produced, and required land area for solar equipment installation.

The evaluation framework integrates min–max normalisation and the analytic hierarchy process (AHP) to ensure both comparability and rational weighting of diverse criteria.

To ensure comparability across indicators, different units, and scales, min–max normalisation is applied. For benefit indicators like COP improvement, energy savings, and daily solar hours utilisation (

DSU), where higher values are preferable, normalisation is performed using the following:

For cost indicators (e.g., LCOC, SPBP, CO

2 emissions, and land area), where lower values are preferable, normalisation is inverted as follows:

This process transforms all values into a [0, 1] range, where 1 denotes the best performance.

The weighting of indicators is determined using the analytic hierarchy process (AHP), a structured decision-making technique that converts qualitative judgments into quantitative weights. Pairwise comparisons are performed between each pair of indicators to construct a judgment matrix. Construct the judgment matrix

wi, and its expression is denoted as follows:

Each column of the matrix was normalised by dividing each entry by the sum of its column. The weight vector for each indicator was then derived by taking the average of the normalised rows. The resulting weight of COP improvement, ES, DSU, LCOC, SPBP, CO2 production, and required land area for solar equipment installation are 0.15, 0.2, 0.15, 0.15, 0.1, 0.2, and 0.05, respectively. These weights align with Iraq’s national priorities, which promote sustainable investment and environmental protection. The relatively low weight assigned to the payback period reflects Iraq’s capacity to support long-term infrastructure development.

Using these AHP-derived weights

wi, the final comprehensive evaluation score for each TMVC system configuration is computed as a weighted sum of normalised indicator values, as follows:

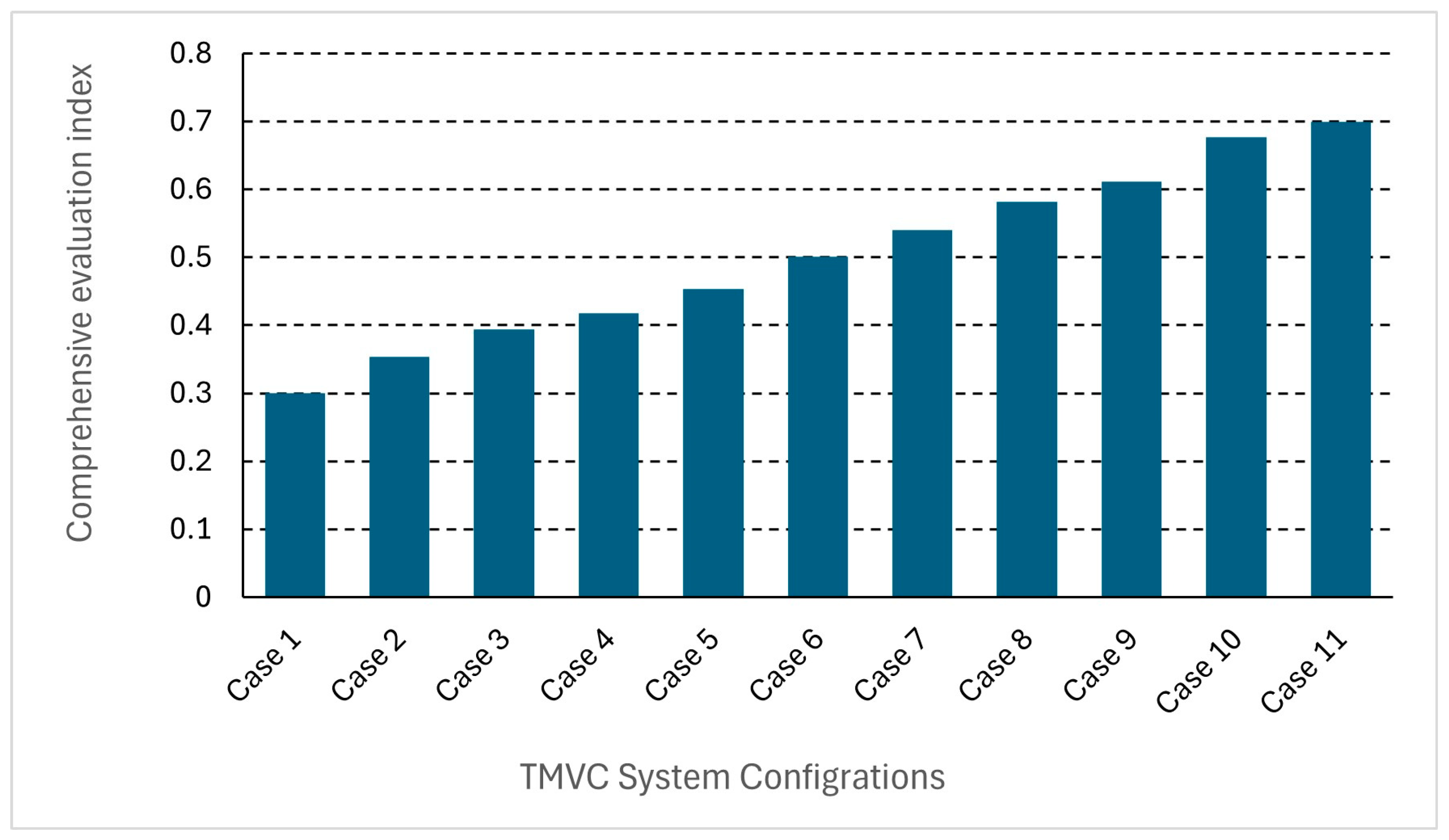

The final results, as shown in

Figure 24, revealed that Case 11 achieved the highest composite score (0.7), indicating the most balanced performance across technical, economic, and environmental criteria. This methodology provides a robust, transparent, and rational basis for multi-criteria decision-making in sustainable cooling system design.