1. Introduction

Developing efficient cooling and heating devices is essential in many fields, including microelectronics [

1] and aerospace engineering [

2]. Increasing transistor density and continuously decreasing component sizes have led to a substantial rise in heat flux at the chip level [

3], requiring advanced thermal management solutions. The current high power densities and inadequate heat dissipation methods present a significant technological challenge. Therefore, understanding and enhancing the transport phenomena involved in microscale heat transfer is crucial to allow further technology miniaturization. Flow boiling in cooling channels offers significantly higher heat transfer efficiency compared to conventional single-phase cooling methods due to the utilization of the fluid’s large latent heat during the phase change. For situations where coolant fluids come into direct contact with heat-generating electronic components, dielectric fluids such as fluorocarbon fluids (e.g., FC-72) and hydrofluoroethers (e.g., Novec-7000) are commonly used because of their excellent electrical insulation, chemical compatibility, high dielectric strength, inert nature, stability, non-flammability, and non-reactivity. However, due to their low surface tension and high wettability these fluids tend to infiltrate deeply into nucleation sites, which often leads to higher incipient superheat values compared to traditional fluids like water. Surface modifications, such as the addition of microfins, microgrooves, coatings, porous layers, or hybrid structures, can improve boiling heat transfer performance at the micro- and nanoscales by influencing nucleation site density and dynamics, incorporating surface wettability and wickability. Knowing this, many different surface modification techniques have been explored in the literature. Direct coating techniques, including electrochemical deposition [

4], chemical vapor deposition [

5], and direct powder sintering [

6], have demonstrated significant enhancements in both the boiling heat transfer coefficient (HTC) and critical heat flux (CHF). Furthermore, advanced manufacturing techniques, including MEMS/NEMS technologies [

7] and additive manufacturing (AM) [

8], have also achieved notable enhancements in boiling heat transfer. In the literature, heat transfer coefficient enhancement degrees up to 100–200% over a reference plain surface have been reported using textured surfaces produced via a multitude of techniques. However, these percentages depend greatly on the reference surface quality (polished or not, aging effects), the channel dimension, and the operating conditions, so a direct comparison is not always fair. A comprehensive review of the state of the art related to flow boiling enhancement on textured surfaces can be found in [

9]. In this section, we briefly review the literature relevant to the textures selected for this study.

For artificial cavities to be active and stable nucleation sites, they must be capable of retaining vapor after bubble departure in order to bypass the energy barrier of vapor embryo formation. Vapor retention depends on both cavity geometry and the contact angle. Bankoff [

10] and Lorenz [

11] proposed a first criterion, where the contact angle should be greater than the cavity cone angle to entrap vapor. However, it was found that vapor can still be entrapped for highly wetting liquids as long as the critical embryo radius is smaller than the cavity’s mouth radius [

11,

12]. The current widely used Hsu nucleation criterion [

13] provides an estimate of the cavity radius range for cavities to be effective at given operating conditions. A cavity being effective is not a sufficient condition for it to be active, as this also depends on the environment around the cavity. For instance, when there are two cavities, both with favorable geometry but located very close to each other, the one with the shortest waiting period between bubble cycles would be preferred. This dominant one would be an active site and the other one would be an effective but inactive site. According to Griffith et al. [

14], the cavity mouth diameter determines the superheat needed to initiate boiling while its shape determines its stability once boiling has begun.

Grooved surfaces are often encountered in the literature at different scales and implementations [

15,

16,

17,

18,

19,

20]. In addition to the standard groove width, depth, spacing, and direction with respect to the flow, another parameter that can be varied is its inclination with respect to the surface level. This has not been widely explored as it usually adds significant manufacturing complexity. Several studies hint at the beneficial impact of inclined grooves. Das et al. [

21] demonstrated that the inclination angle of grooves significantly affects heat transfer performance. Their study involved experiments in a stirred pool of water using copper plates with micro-milled grooves inclined at 30°, 45°, 60°, and 90°, fabricated via wire electrical discharge machining. The results showed that inclined grooves enhanced heat transfer, with the 45° configuration yielding the best performance, achieving a 35% increase in the HTC. Additionally, the incorporation of a “re-entrant circular pocket” at the groove base led to further enhancement of heat transfer.

Moreira et al. [

22] studied water boiling on micro-milled dual-V-grooves (with one straight edge) in microchannels, which effectively enabled bubbles to move transversely with respect to the flow direction due to the evaporation momentum force, creating separated liquid and vapor pathways. Increasing the groove tilt angle from 30 to 60 degrees was seen to improve the overall heat transfer improvements. HTC enhancements of 200% were reported.

Fu et al. [

23] investigated the CHF during flow boiling of HFE-7100 on a saw-tooth grooved surface structure (tilted 45° to surface level). The CHF was enhanced by 36% and 44% with respect to an unmodified reference surface for a flow along and opposite to the groove inclination at low flow rates, and 20% and 8% at higher flow rates, respectively. The CHF enhancement was explained by visualizations indicating that the saw-tooth structures interrupt the boundary layer and restrain bubble coalescence.

It is also known that grooves do not lead to fixed nucleation sites and can suffer greatly from bubble coalescence. For this reason, distinct cavities that are independent of each other can be used to separate and control the effects of bubble merging and nucleation. In the literature, artificial cavities have been investigated mainly in pool boiling [

24,

25]. Continuing the line of thought presented for the grooves, cavities inclined with respect to the surface level could also potentially lead to an increased HTC. However, etching and milling would no longer be suitable production methods.

More generally, one could even say that, despite significant reported enhancements, the utilized manufacturing techniques often face limitations like system complexity, high costs, limited scalability, and restricted applicability across various materials when considered for commercial or industrial implementation of boiling enhancement surfaces. Alternatively, laser surface texturing (LST) presents a promising approach, as it is a chemical-free, scalable, and versatile method (including control of texture inclination), making it suitable for developing boiling enhancement surfaces for commercial and industrial applications [

26]. For instance, Sommers and Yerkes [

27] compared microgrooves created through reactive-ion etching and laser ablation, finding that laser ablation yielded better performance. This improvement was attributed to enhanced nucleation due to a porous layer of sintered particles formed during the laser process. The heat transfer coefficients increased by 90–

, and the application of a hydrophobic coating led to a further

enhancement. Recently, ultrashort-pulse lasers, and specifically femtosecond lasers (with pulse durations typically under 10 picoseconds), have shown significant promise for creating precise micro- and nanoscale features on a wide range of materials. This is due to their high peak power, low ablation threshold, minimal heat-affected zone, and minimized thermal stress deposition [

28]. The effectiveness of femtosecond lasers is attributed to “cold” ablation, as the pulse duration is shorter than the electron–phonon relaxation time [

29]. A noteworthy phenomenon associated with femtosecond laser ablation is the creation of laser-induced periodic surface structures (LIPSSs), which are submicron “ripples” formed when the laser fluence is near the ablation threshold and multiple pulses are applied. As a result, femtosecond laser ablation can generate hierarchical surface features at different scales [

30], enhancing boiling performance by increasing heat transfer surface area, nucleation site density, and capillary wicking effects at the macroscale, microscale, and nanoscale, respectively [

31]. Lim et al. [

32], who investigated microgrooves produced by femtosecond laser ablation, found that a sample created with high laser fluence resulted in deeper, wider, hydrophilic grooves that significantly improved heat transfer performance (30% increase in HTC). In contrast, a sample produced with low laser fluence led to shallower, narrower, hydrophobic grooves, which reduced overall performance (20% decrease in HTC) due to inhibited liquid rewetting.

Focusing on surface wettability, Allahyari et al. [

33] demonstrated a progressive increase in the surface hydrophobicity with the femtosecond laser pulse fluence on copper. Martinez-Calderon et al. [

34] were able to maintain a high degree of hydophobicity at pitch distances below 50 µm and found a clear hydrophobizing effect related to hierarchical LIPSSs on stainless steel. On the other hand, Fang et al. [

35,

36] extensively showed that the formation of LIPSSs on the surfaces of micropillars and microholes significantly enhances the wicking capability and hydrophilicity of micropillar/microhole array structures. These structures were fabricated using femtosecond laser processing on Ti-6Al-4V alloy and aluminum surfaces with water as the working fluid.

It is clear that surface texture characteristics play a crucial role in enhancing boiling performance and that femtosecond (fs) laser texturing offers a highly flexible and precise approach for fabricating micro- and nanoscale features. It should always be remembered that the overall performance of such textured surfaces is influenced by several factors, including fluid properties, surface wettability, and the specific operating conditions. In this context, the present study investigates the effects of several novel inclined fs laser-manufactured hybrid micro/nanostructures on flow boiling of perfluorohexane (, PP1, FC-72), with a focus on heat transfer enhancement and bubble dynamics. To the best of the authors’ knowledge, this is the first study to explore the influence of inclined textures produced via fs laser processing on flow boiling heat transfer.

3. Results and Discussion

3.1. Influence of Textured Surfaces on Heat Transfer Performance

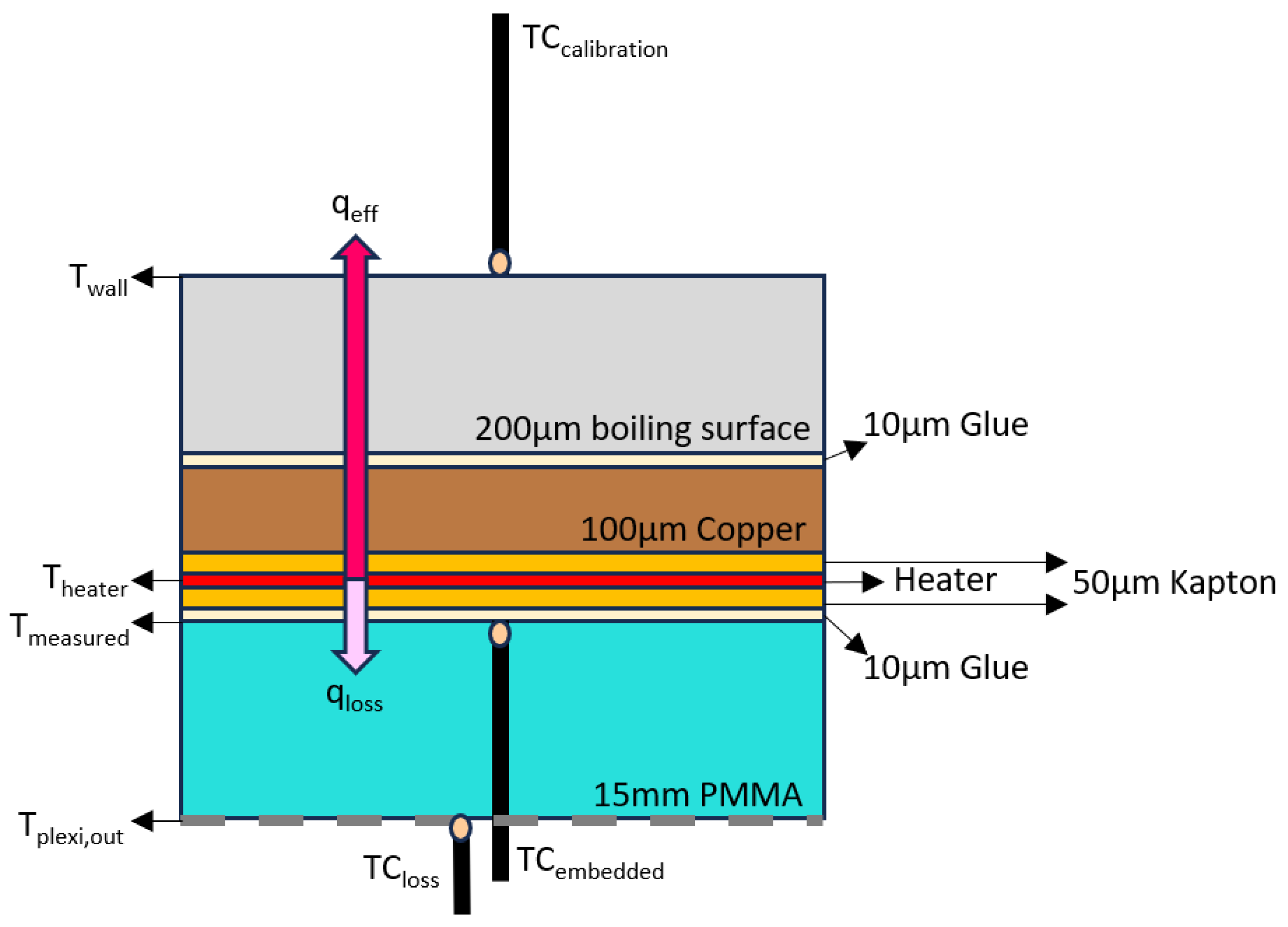

To investigate the impact of textured surfaces on flow boiling performance, this study analyzes changes in heat transfer coefficients (HTC), the onset of nucleate boiling (ONB), and bubble dynamics compared to a reference plain surface. A rigorous investigation of the critical heat flux (CHF) is out of the scope of this work. In particular, we present in this section a subset of the results obtained from the test campaigns, specifically focusing on the boiling and heat transfer coefficient (HTC) curves measured at a designated point on the surface, corresponding to the location of the second heater thermocouple (H2), as depicted in

Figure 4b. This location is chosen as H2 is positioned within the camera’s visualization area, facilitating a more accurate comparison of the onset of nucleate boiling. The trends observed from the other thermocouples are consistent with those of H2. A summary of the most important outcomes is presented in

Table 6, which reports the changes in average HTC (

) and the onset of boiling in terms of heat flux

and surface temperature

with respect to the reference surface. In particular,

is calculated as the average of the last six data points of the curves presented in the

Supplementary Material (Figures S1c–S5c) for each respective experimental condition.

To examine the influence of textured surfaces on the bubble dynamics, the mean number of bubbles

and the mean bubble diameter

(µm) were evaluated via image processing (circle-based detection). A total of 1000 frames with a spatial resolution of 20 µm/pixel were considered per experimental condition. The image analysis was performed for boiling regimes obtained in the lower-heat-flux region where the void fraction was low and bubble overlapping was limited. Examples of bubble visualizations are given in

Figure 6 for cases A4, A5, and A6 at a heat flux of 4 W/cm

2.

The visualizations represent a 25 mm region located between thermocouples H2 and H3 (refer to

Figure 4b). The flow direction is from right to left. Thermocouple H2 is positioned on the right side, while thermocouple H3 is on the left side of each image.

Table 7 provides the average bubble count and size within the channel observation area for the cases shown in

Figure 6 at a heat flux of

.

3.1.1. Reference Surface—Plain

The results presented in the previous section show that, in the investigated heat flux range, the plain surface has the worst heat transfer performance along with fewer and larger bubbles. This is due to a lack of fixed and stable nucleation sites, leading to the observed higher and lower HTC.

3.1.2. Surface S1—LIPSS

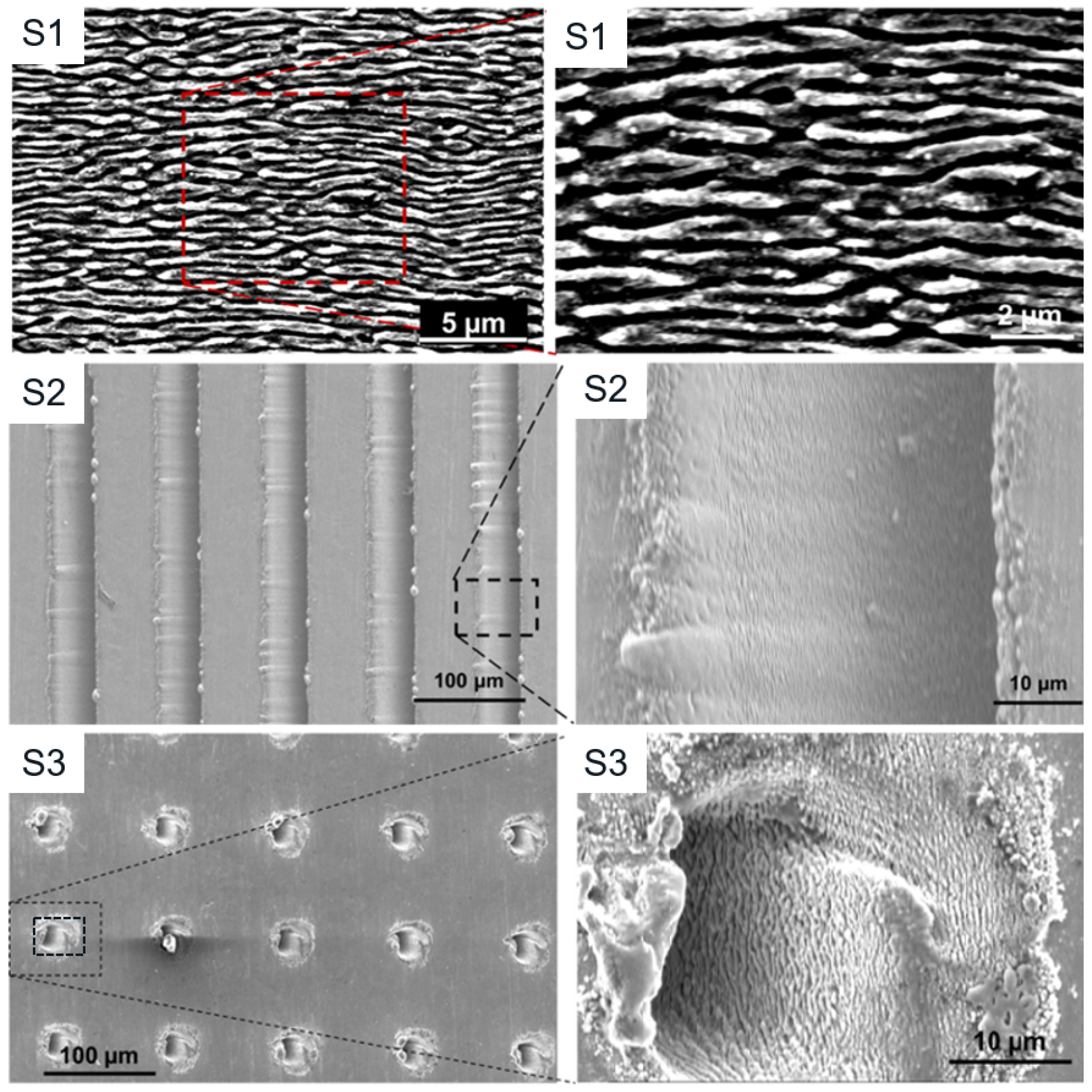

The femtosecond laser texturing approach inherently leads to hierarchical structures as the light–matter interaction leaves periodic submicron-scale ripples (LIPSSs) on the surface on top of any bigger microstructure created. Surface S1 consists of pure LIPSSs and thus only contains submicron-scale ripples, with no additional microstructures, as shown in

Figure 1(S1).

In comparison with the plain surface, smaller bubbles and a higher average number of bubbles were observed (see

Table 7), as well as a consistent ONB inception at lower temperatures (3.3°C for condition A6 to 8.9 °C for condition A4). We speculate that this surface provides a higher wickability, enabling easier liquid supply to nucleation sites and consequently bubbles that detach at smaller diameters and higher frequencies. It is important to note that, since nucleation initiates abruptly, there is still a pronounced drop in wall temperature at boiling incipience, as also observed with the plain surface. This substantial temperature drop should be monitored as it could affect the structural integrity of the device by thermal shock or fatigue, potentially affecting long-term performance if not continuously operating in the nucleate boiling regime. The HTC enhancement with respect to the plain reference is rather limited (up to 8.4% for condition A5). Nonetheless, this enhancement is sustained at higher heat fluxes, indicating an improved replenishment of liquid facilitated by the LIPSS structures. However, nucleation site activation appears irregular and unstable.

3.1.3. Surface S2—Inclined Grooves

This surface features 45-degree-inclined microgrooves (IG) with a width of 37 µm, a depth of 41 µm, and a spacing of 100 µm, aligned parallel to the flow direction, as shown in

Figure 1(S2). The LIPSS structures formed on the walls of the inclined microgrooves during laser texturing are also oriented in the direction of the flow.

The addition of this texture significantly accelerates the ONB (8.6 °C for condition A3 to 13.4 °C for condition A2). For condition A6, the ONB occurs almost immediately, at K and at a heat flux of , marking it as the earliest ONB among all the examined textured surfaces in this work. The microscale grooves applied to the surface act as a line of potential cavities, where the locally higher temperatures and increased heat transfer area trigger nucleation at much lower superheat levels. Also, we observe no big temperature drop at ONB, indicating a more gradual onset, likely because of the spread of nucleation sites across the groove length having more freedom. This could be interesting for applications that are sensitive to strong and fast temperature variations.

When comparing high-speed camera (HSC) images of bubbles recorded on surface S2 and surface S1 (

Figure 6), we see that the first exhibits a higher density of smaller bubbles that detach at a higher frequency. This behavior might be associated with increased wettability, likely largely resulting from the additional LIPSS structure. However, due to the low contact angles with PP1, this could not be effectively measured. The grooves also enhance the wicking effect, allowing better liquid penetration, resulting in a more hydrophilic character of the surface and more effective replenishment of the surface with subcooled liquid, leading to faster bubble detachment at smaller sizes.

This surface also presents a clear HTC enhancement, going from 14.85% for condition A2 to 30.41% for condition A4. The earlier nucleation onset contributes to a temporary spike in enhancement, as observed in

Figures S1c–S5c. Although we observe an increase in nucleation site density, we speculate that bubbles that form in a nucleation site in the groove can easily disturb the activation of possible nucleation sites located downstream of it. This randomness of nucleation sites within the grooves still limits the possible degree of HTC enhancement.

3.1.4. Surface S3—Inclined Holes

This surface contains conical holes spaced 100 µm apart, inclined at 45 degrees and oriented perpendicular to the flow direction, as illustrated in

Figure 1(S3). Again, it should be emphasized that this surface exhibits a combination of microscale (holes) and submicron-scale (LIPSS) features, a result of the femtosecond laser texturing process. The presence of LIPSS on the inner walls of the microholes is clearly visible in

Figure 1(S3), where distinct periodic structures with a periodicity comparable to the laser wavelength can be observed.

An early ONB was observed for this surface. However, overall, S2 still seems to outperform it by presenting a lower and, more often than not, also a lower . The small size of the cavity in inclined holes, combined with the hydrophilic characteristics induced by LIPSSs, may be why a higher superheat is often required compared to inclined grooves. Only in case A4 does S3 present a superior with respect to S2, indicating a better ONB performance of surfaces with inclined holes at a lower subcooling degree.

The highest amount and smallest bubbles are observed for inclined holes. It is believed that, differently from what was observed for the surface with inclined grooves, the bubbles formed within these conical cavities are size-limited by the cavity radius. These bubbles detach very fast and do not slide across the surface. Furthermore, the cavity cones act as isolated nucleation sites that are fixed in space, unlike in the inclined grooves, where bubbles can nucleate anywhere along the groove. In inclined grooves, bubble growth can still occur along the groove as bubbles remain attached along the flow path, explaining the slightly larger bubble sizes observed for inclined grooves. Hence, a high density of smaller bubbles is expected for inclined holes, rising more slowly and condensing faster in the bulk subcooled flow due to their smaller volume.

Inclined holes clearly exhibit the highest HTC, showing an increase of 36.89% (A6)–60.91% (A4) with respect to the plain reference surface, as indicated in

Figures S1c–S5c. This large improvement is likely due to the arrangement of holes, which can activate more nucleation sites, thus producing more vapor, as evidenced by an increased void fraction. Interestingly, the HTC enhancement declines at higher heat fluxes, most distinctly observed in

Figure S3c of the Supplementary Materials, representing case A4 having the lowest subcooling degree. At lower heat fluxes, the high amount of nucleation sites generates small bubbles that operate independently and are more resistant to coalescence due to the available room for growth. As the heat flux increases, larger and more bubbles form, which can disrupt this more ideal pattern of nucleation sites due to horizontal bubble interactions. Oversized bubbles begin to interact with adjacent sites, potentially inhibiting them, leading to less effective nucleation and a decrease in the HTC, as cavities can no longer act as discrete, uninfluenced nucleation sites. This indicates that optimal pattern spacing should exist for each operating condition, including heat flux as a main driver.

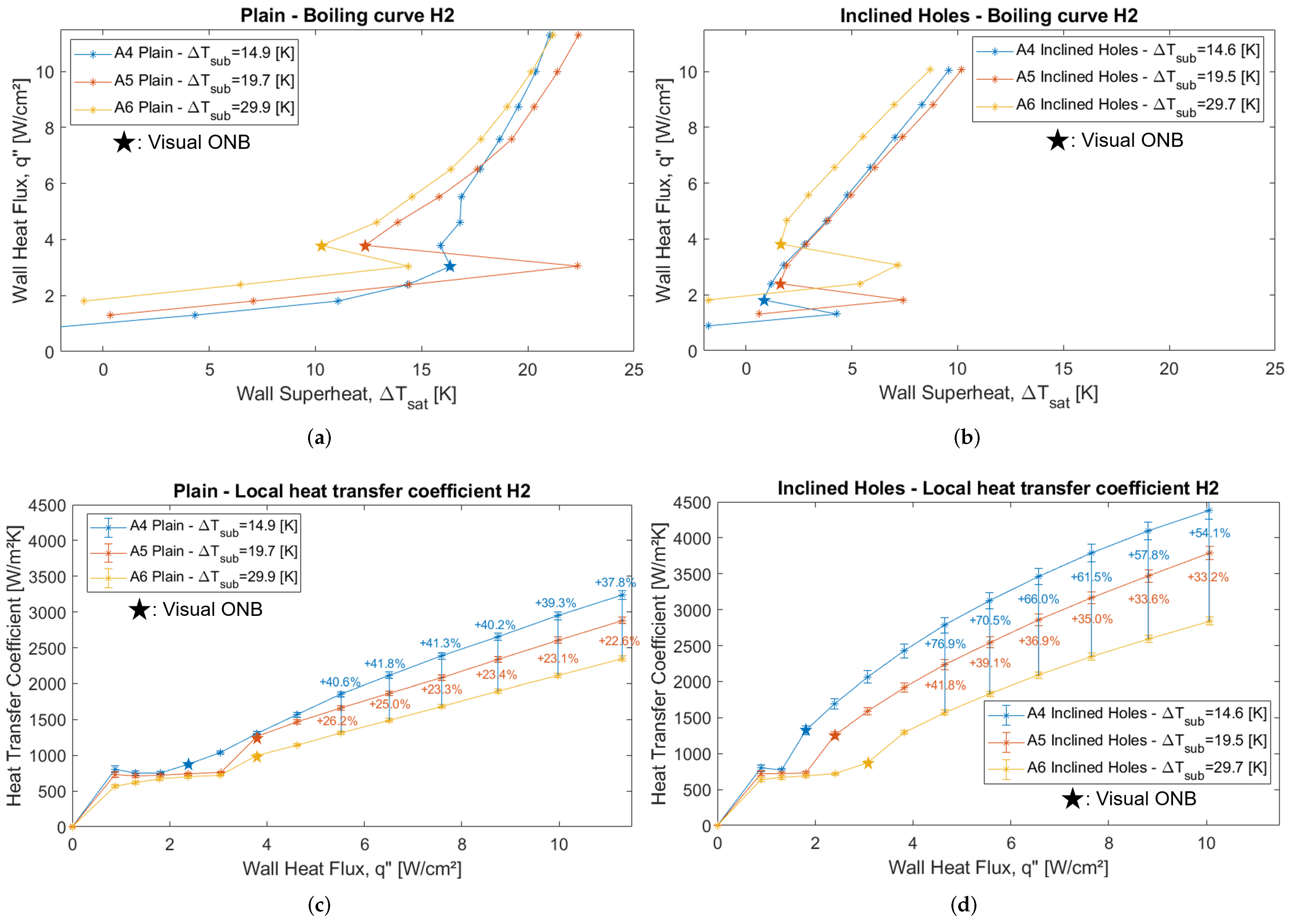

3.2. Influence of Subcooling on Heat Transfer Performance

This section briefly examines the influence of the degree of subcooling on the ONB, HTC, and bubble dynamics. Additionally, the effect of the degree of subcooling on the behavior of textured surfaces and their performance ranking is investigated. This is achieved using boiling curves and local HTC-q″ curves for both the plain and inclined hole surfaces at a constant Reynolds number (Re = 3000) and three different subcooling values (

K), corresponding to experimental conditions A4, A5, and A6 (see

Figure 7).

From

Figure 7, a delay in the ONB can be observed with an increase in the degree of subcooling for both the plain and textured surfaces, as expected. A higher degree of subcooling means that the fluid enters the test section at a lower temperature. The larger temperature difference between the wall and the bulk liquid necessitates more energy to heat the liquid near the wall towards saturation. A higher degree of subcooling removes a larger portion of the heat flux as sensible heat, leaving a smaller amount to be extracted as latent heat. A lower bulk temperature of the fluid also limits bubble growth and detachment as the subcooled liquid can condense the formed vapor at the liquid–vapor interface. These factors result in fewer, smaller bubbles that quickly condense at higher degrees of subcooling. Conversely, lower degrees of subcooling allow more latent heat extraction, resulting in more nucleation sites and a higher bubble density. This increased bubble formation at lower subcooling leads to a higher HTC.

Figure 7 demonstrates a notable enhancement in the boiling heat transfer coefficient (HTC) with a reduction in the inlet subcooling, achieving a maximum increase of

for the plain surface and

for inclined holes for condition A4 with respect to A6. Somewhat counterintuitively, a lower degree of subcooling corresponds with a higher wall temperature and an elevated HTC. This is logical as, especially at lower heat fluxes, colder fluid significantly reduces the wall temperature due to its enhanced cooling effect but simultaneously suppresses boiling. At higher heat fluxes, the cooling capacity of the colder incoming stream can be offset by extensive vapor formation, which also rapidly increases the local bulk fluid temperature. Consequently, the influence of inlet subcooling diminishes for increasing heat flux.

Furthermore, the HTC curve for inclined holes again substantiates the previous findings. The surface encounters an “ideal” heat transfer performance when small bubbles can nucleate from the nucleation sites independently, corresponding to a certain heat flux range. At lower degrees of subcooling, this “ideal” heat transfer performance is achieved at lower heat fluxes compared to those for higher degrees of subcooling. Interactions among nucleation sites occur sooner at a lower subcooling, thus marking a more significant decrease in HTC with increasing heat flux between conditions A4 and A6 compared to the plain surface.

In conclusion, much like the impact of flow velocity, the degree of subcooling does not significantly affect the performance ranking of the textured surfaces. Inclined holes consistently demonstrate the best heat transfer performance, with their maximum enhancement reaching under experimental condition A4. Following inclined holes, inclined grooves consistently outperform laser-induced periodic surface structures, which in turn offer only slight improvements over the plain surface.

3.3. Influence of Mass Flow Rate on Heat Transfer Performance

This section explores the impact of the mass flow rate, represented by the Reynolds number, on the ONB, HTC, and bubble dynamics. The Reynolds number relies on temperature-dependent fluid properties, so the mass flow rate needs to be adapted accordingly when using different degrees of subcooling. This section comments on whether the Reynolds number impacts the behavior of the examined textured surfaces and their relative performance ranking. This is achieved using boiling curves and local HTC-q″ curves for both plain surfaces and inclined holes at a constant degree of subcooling and varying Reynolds numbers (Re = 1000 and Re = 3000), corresponding to experimental conditions A3 and A6.

As seen in

Figure 8, an increase in the flow rate delays the ONB to a higher heat flux. A higher mass flow rate enhances the single-phase heat extraction, leading to lower wall temperatures and suppression of nucleate boiling.

The liquid accumulates more heat at a lower Reynolds number, thereby losing its condensing capacity further downstream. The thermal boundary layer thickens along the flow direction, enhancing evaporation and bubble growth. Consequently, a higher density of larger bubbles is obtained. Additionally, bubbles have more time to interact and coalesce. Conversely, at a high Reynolds number, the excessive inertial forces result in the formation of smaller bubbles that are more likely to initially move along the surface rather than rise.

The most significant impact of a change in the mass flow rate remains within the single-phase heat transfer region, where forced convection is enhanced at a higher flow rate, leading to a higher HTC value (+20.4% for plain and +24.9% for inclined holes). However, the HTC effects in the two-phase region are very slim. As heat flux is increased and nucleate boiling starts to dominate, the influence of the mass flow rate quickly diminishes, implying that the HTC is primarily governed by latent heat removal rather than residual forced convection. In addition, an increase in the mass flow rate increases the critical heat flux by delaying vapor from coalescing into an insulating vapor blanket on the surface.

Lastly, the mass flow rate does not alter the performance ranking among textured surfaces in the examined range of Reynolds numbers, similar to the degree of subcooling. Inclined holes consistently demonstrate the best heat transfer performance, followed by inclined grooves. Laser-induced periodic surface structures still perform slightly better than plain surfaces.

3.4. Pressure Drop Observations

The associated pressure drop over the boiling section is another important performance parameter. The overall enhancement degrees must also account for any additional pumping power requirements, given by Equation (

9).

Pressure drops were monitored with a differential pressure sensor and average values obtained for cases A4, A5, and A6 are presented in

Figure 9.

Although the pressure drop increases up to 90% on the textured surfaces with respect to the plain surface, the values always remain very low (<400 Pa) with respect to the channel scale, resulting in an associated pumping power below 3 mW. For the low-flow-rate cases A2 and A3, the pressure drop remains below 50 Pa, thus falling into the sensor uncertainty limits, which is why they are omitted in this analysis. It is clear that the pressure drop increases with heat flux due to increased vapor generation. Furthermore, it can be seen that the addition of a surface texture increases the pressure drop, partly because of the additional surface roughness but mainly because of the increased vapor generation. The textured surface pressure drop increases more quickly as a function of the applied heat flux. This effect is illustrated in

Table 8, which presents the observed differential pressure increase from the lowest to highest applied heat flux for each surface.

The inclined holes present the highest pressure drops, followed by the inclined grooves, LIPSSs, and ultimately, the plain surface. Also, a lower subcooling degree increases the pressure drop rise over the same heat flux range due to an increased vapor fraction. Lastly, since the pressure drops are so low, the used sensor becomes less accurate and more noisy. A part of the recorded pressure drop differences may also be attributed to different machining quality on the inlet/outlet manifold pieces for different surfaces. So, while the absolute values may not be entirely representative, the pressure drop increases in

Table 8 should remain representative. A higher-resolution sensor should be employed for a deeper quantitative analysis, which was not in the scope of this work. In conclusion, the increased pressure drop for the examined textured surfaces does not offset their significant gain in heat transfer performance. Note that the impact of the pressure drop could be more severe in very long or narrow boiling channels and would require more attention.

4. Conclusions and Perspectives

The use of novel inclined femtosecond laser-textured surfaces significantly alters the boiling dynamics and heat transfer performance in flow boiling experiments. Increasing nucleation site density and accelerating the onset of nucleate boiling lead to higher heat transfer coefficients compared to a plain reference surface. The boiling curves for all the textured surfaces shift to the left with respect to the plain reference surface. The bubble dynamics reveal that surface texturing not only promotes localized turbulence but also improves wetting properties. These textures ensure more consistent and frequent bubble nucleation. The pressure drop increased up to 90% for the textured surfaces, mainly associated with increased vapor generation, but the actual values remained low (<400 Pa) and did not offset the performance gains. There is a clear flow boiling heat transfer enhancement potential when using surface texturing as a passive enhancement technique.

The following key points were observed for each surface:

The tested surface with only LIPSS features resulted in smaller bubbles and an earlier ONB (max −8.9 °C in condition A4), but failed to create fixed nucleation sites, keeping the performance in terms of HTC close to the plain reference. A limited HTC enhancement of a maximum of 8.4% was measured in condition A5, indicating the need for microscale cavities for substantial enhancement.

The tested inclined grooves along the flow direction resulted in an increase in the nucleation site density, smaller bubbles, an earlier ONB (max −13.4 °C in condition A2), and an overall increase in HTC from 14.8% (A2) to 30.4% (A4) over the plain reference. The enhancement was still limited by non-fixed nucleation sites, as vapor can move along the groove and disturb other nucleation sites, keeping them from continuous operation. Also, bubbles in grooves can stay attached to their borders due to surface tension, allowing further growth while moving along the groove and improving heat transfer. The very early ONB is also very attractive, and no “thermal shock” at boiling incipience was observed.

The tested inclined hole sample showed the best performance of the tested surfaces, exhibiting the most substantial enhancement at lower heat fluxes. Its enhancement degree diminished at higher fluxes due to nucleation site interactions. An earlier ONB (max −13.5 °C for condition A4) was observed. On average, HTC improvements from 36.9% (A6) to 60.9% (A4) were observed over the plain surface. Bubbles were seen to be very small and abundant, and nucleation was more stable, increasing effective nucleation site density. It is apparent that optimal hole spacing should exist for a given operating condition to prevent premature bubble coalescence on the surface.

To conclude, the observed heat transfer improvements have promising implications for various thermal management applications, including high-performance cooling systems in power electronics, data centers, and aerospace. The ability to tune texture parameters for specific operating conditions opens up avenues for customized thermal solutions tailored to different industries. However, for widespread adoption, further investigation is needed to optimize surface patterns and establish a clearer understanding of the relationship between cavity geometrical parameters and heat transfer performance. Scalability and long-term stability under real-world conditions remain critical concerns, along with the durability of the textures and the repeatability of the manufacturing process. In particular, while not observed with PP1 as the working fluid, surface degradation due to fluid impurities and fouling could significantly reduce long-term performance. Ultimately, no single texture design can be universally optimal, and instead, surfaces should be engineered to meet the specific demands of their intended applications and operating conditions to maximize performance benefits.