Experimental Investigation of 2-Ethylhexyl Nitrate Effects on Engine Performance and Exhaust Emissions in Biodiesel-2-Methylfuran Blend for Diesel Engine

Abstract

1. Introduction

2. Experimental

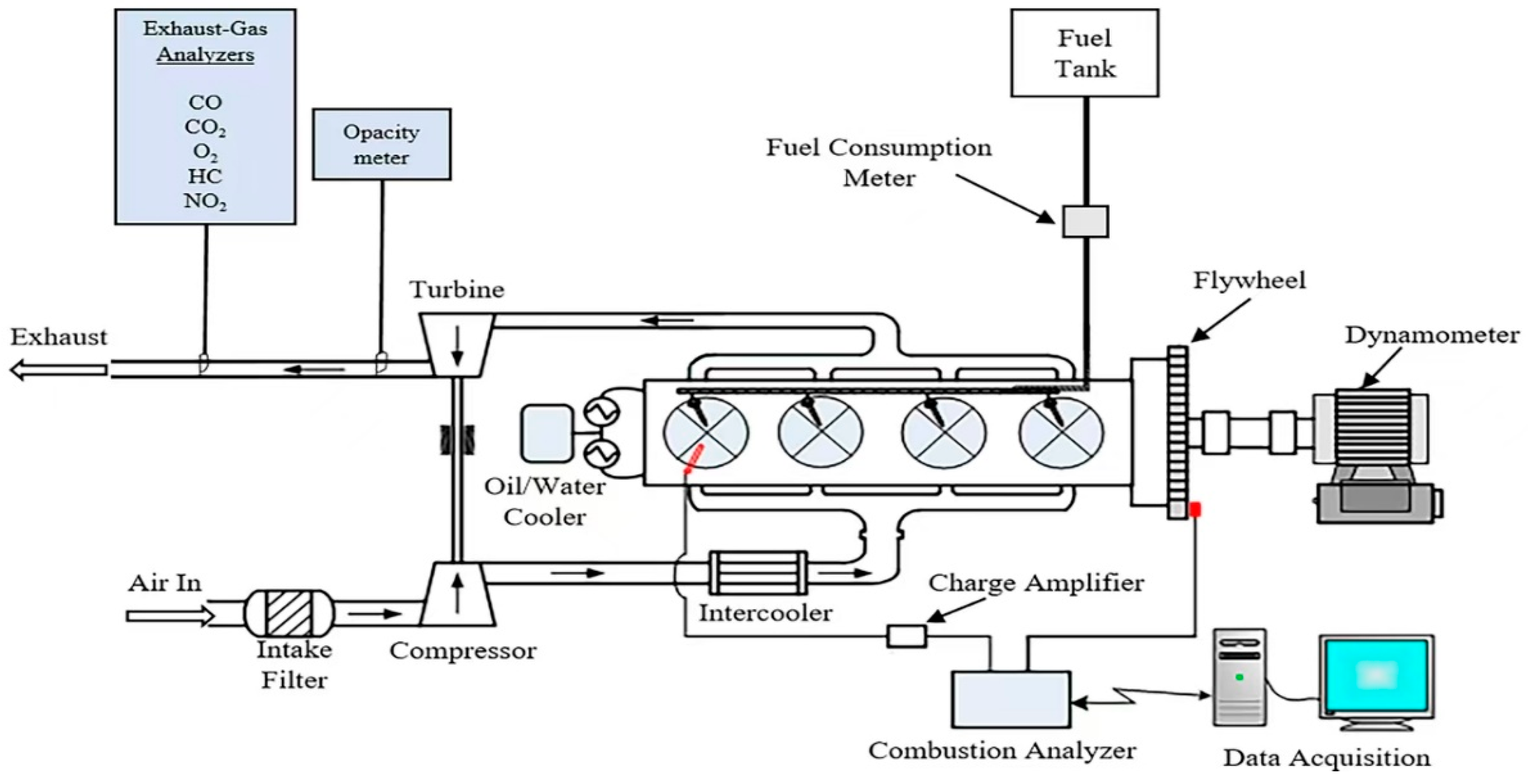

2.1. Engine Configuration and Instrumentation

- (a)

- Brake Thermal Efficiency (BTE):UBTE = BTE × [(Um˙f)2 + (UT)2 + (UN)2] 0.5;

- (b)

- Ignition Delay:UID = [U2SOI + U2SOC] 0.5.

2.2. Tested Fuel and Experimental Conditions

2.3. Experimental Conditions

3. Results and Discussion

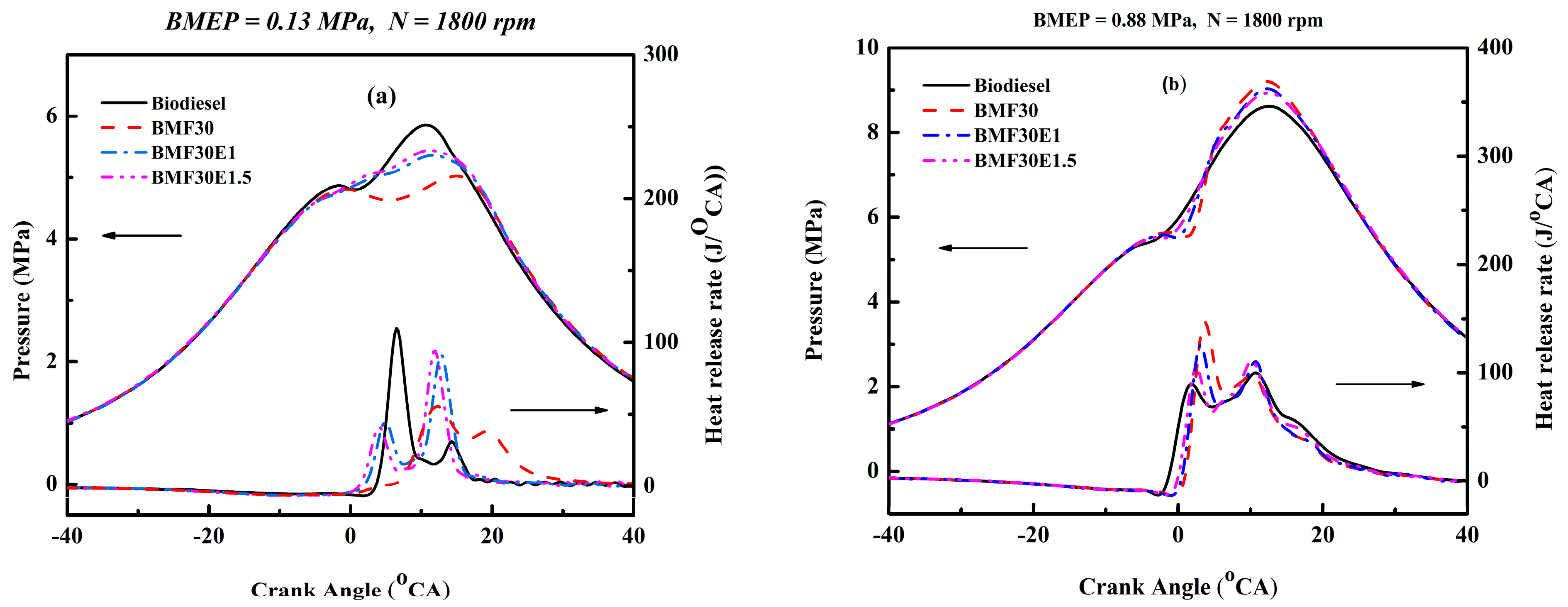

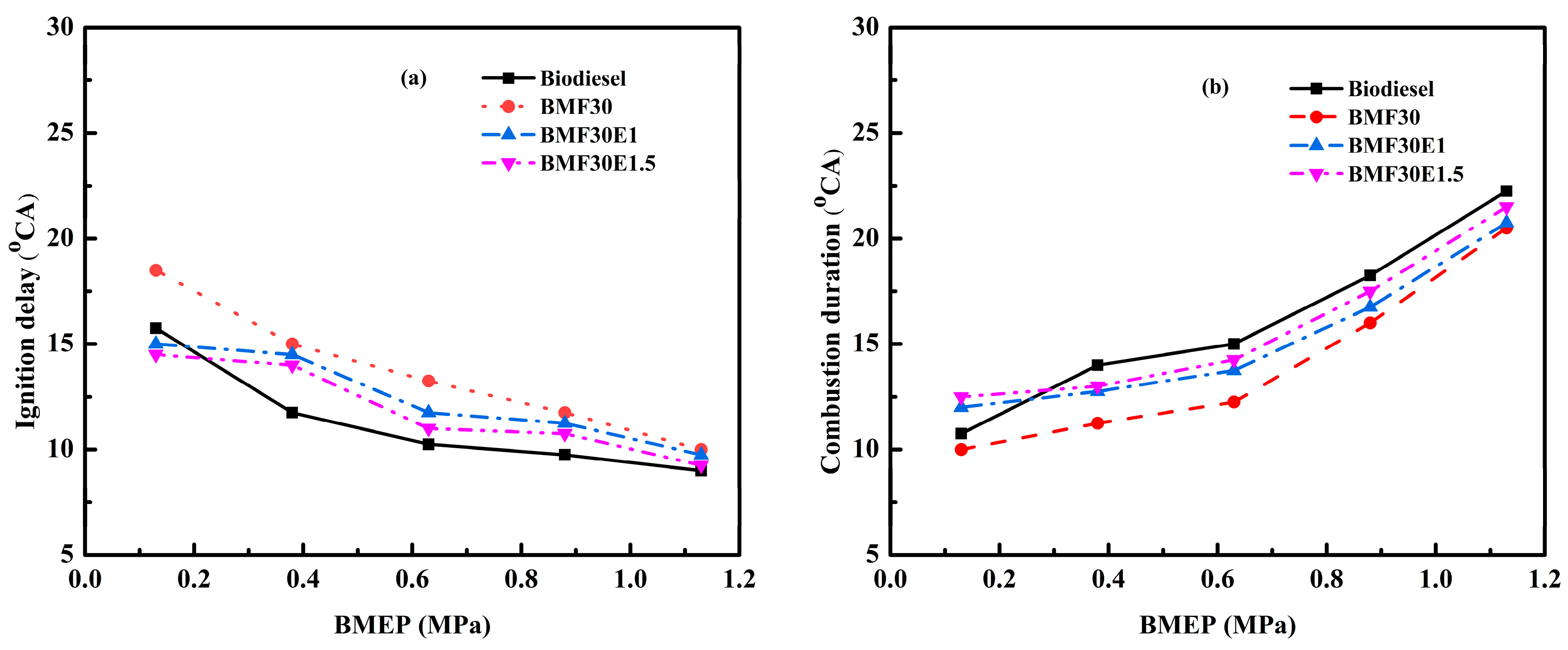

3.1. Effect of 2-EHN Additive on Burning Characteristics

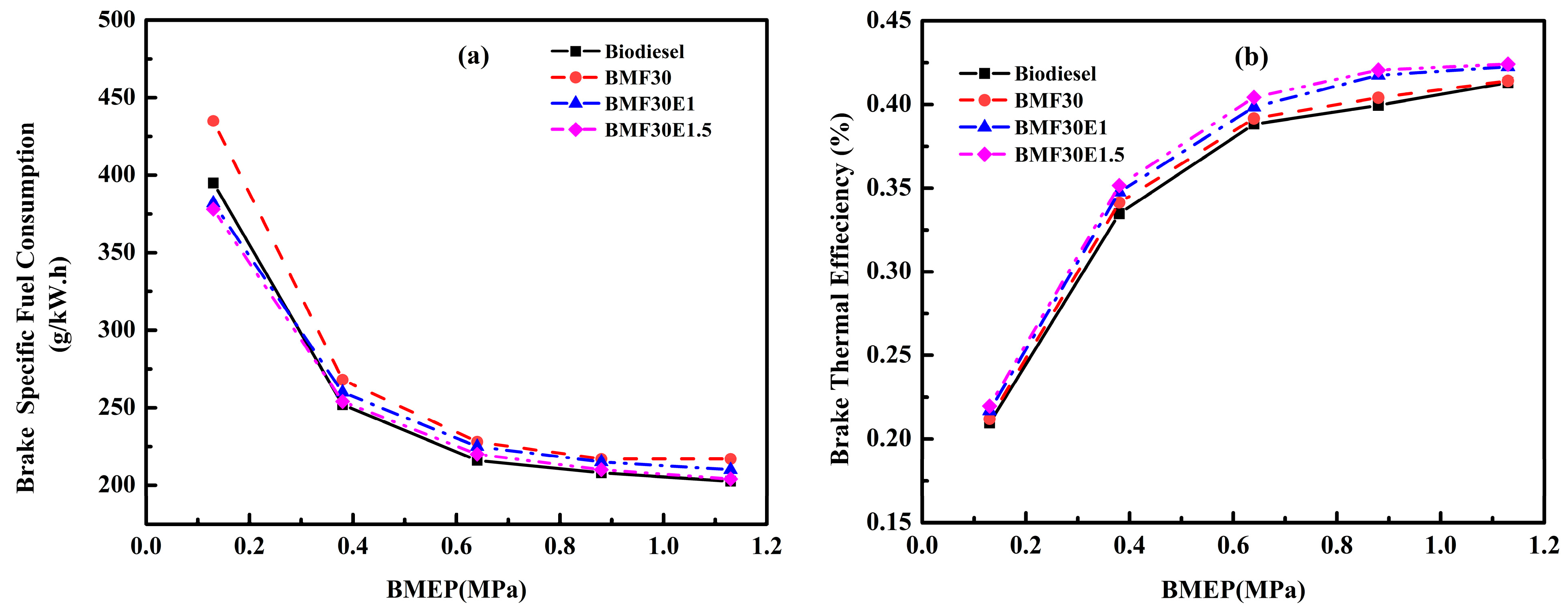

3.2. Influence of 2-EHN Addition on the BSFC and BTE

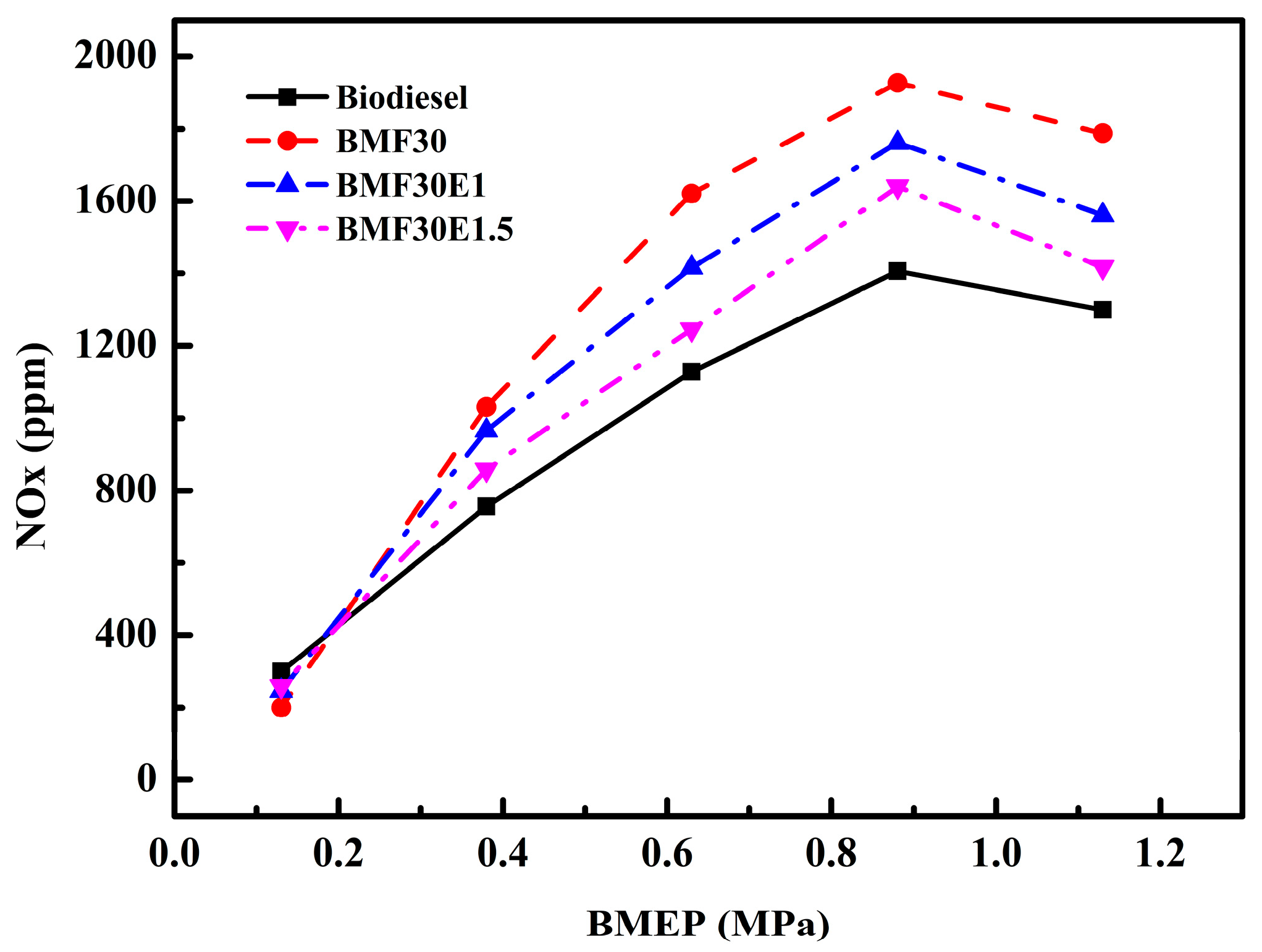

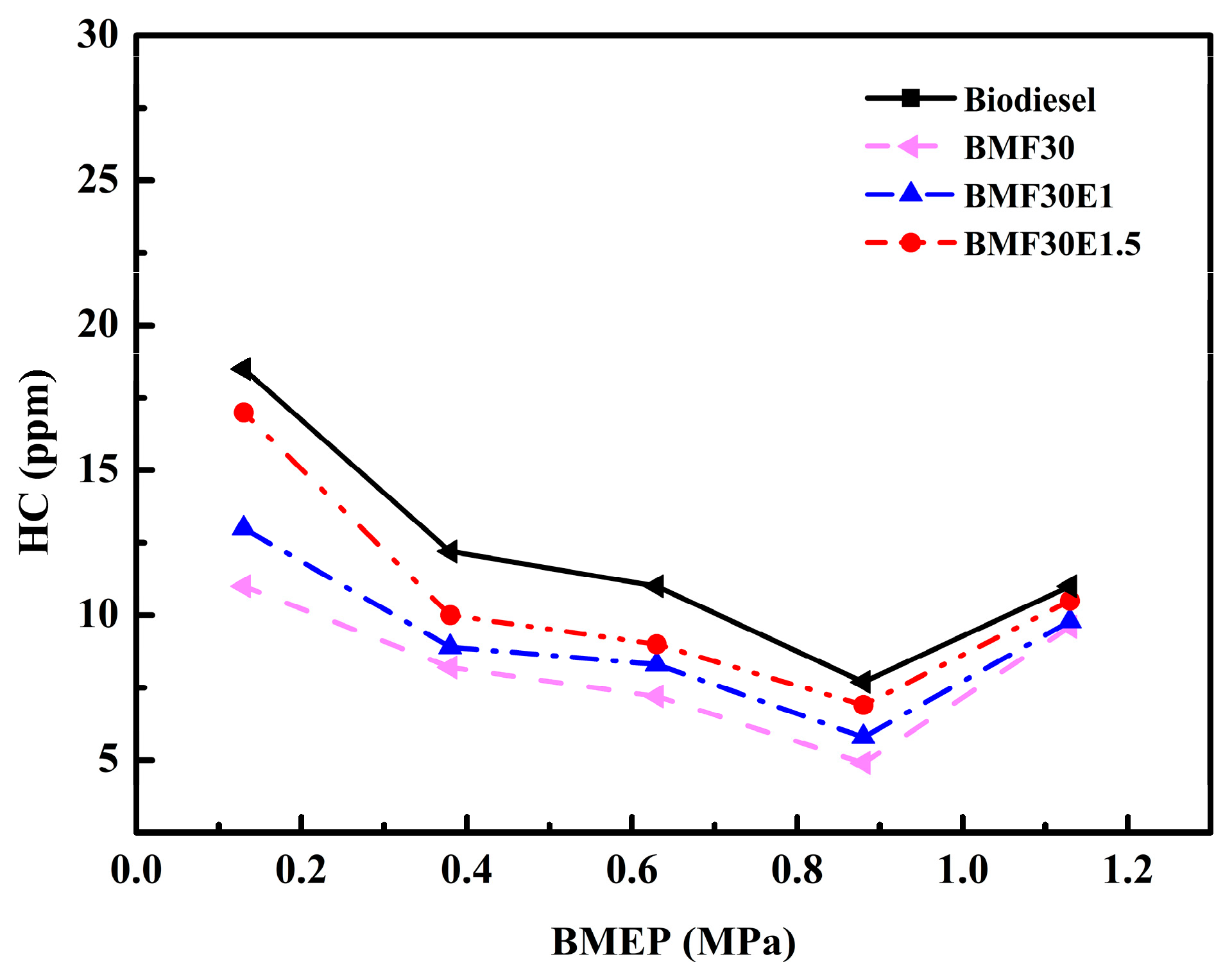

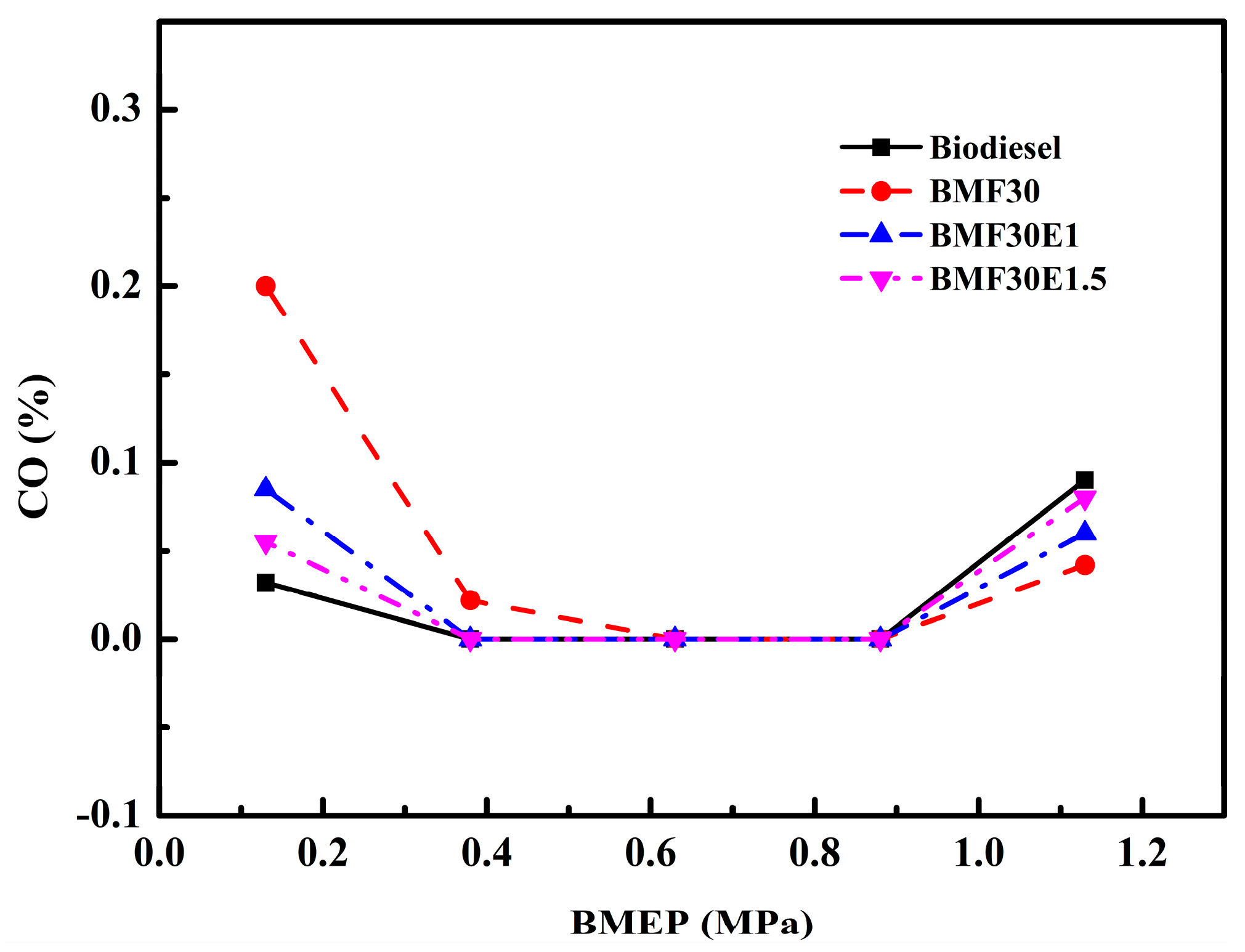

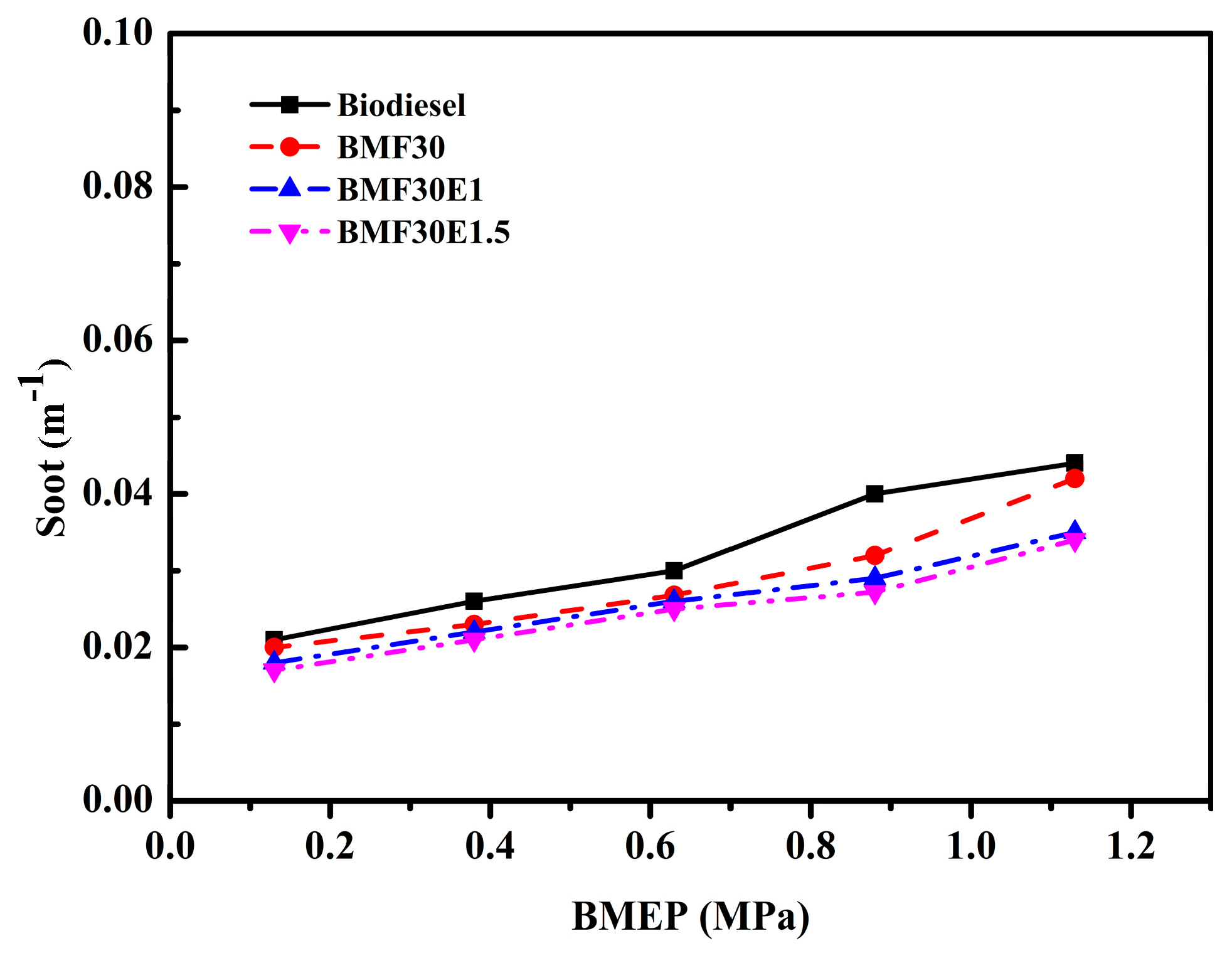

3.3. Impacts of 2-EHN Additive on the Emissions Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiao, H.; Guo, F.; Wang, R.; Yang, X.; Li, S.; Ruan, J. Combustion performance and emission characteristics of diesel engine fueled with iso-butanol/biodiesel blends. Fuel 2020, 268, 117387. [Google Scholar] [CrossRef]

- Abomohra, A.E.-F.; Elsayed, M.; Esakkimuthu, S.; El-Sheekh, M.; Hanelt, D. Potential of fat, oil and grease (FOG) for biodiesel production: A critical review on the recent progress and future perspectives. Prog. Energy Combust. Sci. 2020, 81, 100868. [Google Scholar] [CrossRef]

- Sreeharsha, R.V.; Dubey, N.; Mohan, S.V. Orienting biodiesel production towards sustainability and circularity by tailoring the feedstock and processes. J. Clean. Prod. 2023, 414, 137526. [Google Scholar] [CrossRef]

- Nyorere, O.; Oluka, S.I.; Onoji, S.E.; Nwadiolu, R.; Adepoju, T.F. Production of biodiesel from biocatalysis of agro-wastes in acidic environment. Sci. Afr. 2024, 24, e02154. [Google Scholar] [CrossRef]

- Srikumar, K.; Tan, Y.H.; Kansedo, J.; Tan, I.S.; Mubarak, N.M.; Ibrahim, M.L.; Yek, P.N.Y.; Foo, H.C.Y.; Karri, R.R.; Khalid, M. A review on the environmental life cycle assessment of biodiesel production: Selection of catalyst and oil feedstock. Biomass Bioenergy 2024, 185, 107239. [Google Scholar] [CrossRef]

- Mohebolkhames, E.; Kazemeini, M.; Sadjadi, S. Utilization of Salmon fish bone wastes as a novel bio-based heterogeneous catalyst-support toward the production of biodiesel: Process optimizations and kinetics studies. Mater. Chem. Phys. 2024, 311, 128522. [Google Scholar] [CrossRef]

- Zabermawi, N.M.; Alsulaimany, F.A.S.; El-Saadony, M.T.; El-Tarabily, K.A. New eco-friendly trends to produce biofuel and bioenergy from microorganisms: An updated review. Saudi J. Biol. Sci. 2022; in press. [Google Scholar] [CrossRef]

- Huang, S.-Y.; Huang, W.-E.; Yu, B.-Y. Rigorous design, techno-economic and environmental analysis of two catalytic transfer hydrogenation (CTH) processes to produce bio-based 2-methylfuran (2-MF). Process Saf. Environ. Prot. 2024, 181, 429–441. [Google Scholar] [CrossRef]

- H S, A.P.; Mohanty, D.K. Enhancement of combustion, performance and emission characteristics of diesel engines fuelled with jatropha-karanja biodiesel using EGM and TGME as additive. Energy 2024, 300, 131523. [Google Scholar] [CrossRef]

- Anantha Padmanabha, H.S.; Mohanty, D.K. Impact of additive ethylene glycol diacetate on diesel engine working with jatropha-karanja dual biodiesel. Renew. Energy 2023, 202, 116–126. [Google Scholar] [CrossRef]

- Rial, R.C. Biofuels versus climate change: Exploring potentials and challenges in the energy transition. Renew. Sustain. Energy Rev. 2024, 196, 114369. [Google Scholar] [CrossRef]

- Estevez, R.; Aguado-Deblas, L.; López-Tenllado, F.J.; Luna, C.; Calero, J.; Romero, A.A.; Bautista, F.M.; Luna, D. Biodiesel Is Dead: Long Life to Advanced Biofuels—A Comprehensive Critical Review. Energies 2022, 15, 3173. [Google Scholar] [CrossRef]

- Li, J.; Ye, L.; Gong, S.; Deng, X.; Wang, S.; Liu, R.; Yang, W. Review on the combustion progress and engine application of tailor-made fuels from biomass. Renew. Sustain. Energy Rev. 2024, 192, 114242. [Google Scholar] [CrossRef]

- Wirawan, S.S.; Solikhah, M.D.; Setiapraja, H.; Sugiyono, A. Biodiesel implementation in Indonesia: Experiences and future perspectives. Renew. Sustain. Energy Rev. 2024, 189, 113911. [Google Scholar] [CrossRef]

- Elumalai, R.; Sumathy, S.; K, R.; Akhtar, M.N.; P V, E.; Khan, S.A.; Gupta, M.S.; Asif, M. Experimental investigation and gray relational optimization of engine parameters to improve the output characteristics of an ammonia biodiesel powered dual fuel combustion engine. Case Stud. Therm. Eng. 2024, 56, 104197. [Google Scholar] [CrossRef]

- Jain, A.; Bora, B.J.; Kumar, R.; Sharma, P.; Barik, D.; Balasubramanian, D.; Ramegowda, R.; Josephin Js, F.; Varuvel, E.G.; Nguyen Le, D.T.; et al. Impact of the operational parameters of a dual fuel engine operating on a blend of Water Hyacinth biodiesel and Mesua ferrea biodiesel with hydrogen–A clean development mechanism. Int. J. Hydrogen Energy 2024, 66, 689–702. [Google Scholar] [CrossRef]

- Xiao, H.; Yang, X.; Hou, B.; Wang, R.; Xue, Q.; Ju, H. Combustion performance and pollutant emissions analysis of a diesel engine fueled with biodiesel and its blend with 2-methylfuran. Fuel 2019, 237, 1050–1056. [Google Scholar] [CrossRef]

- Chaudhary, A.; Panchal, S.H.; Surana, A.; Sreekanth, M.; Ismail, S.; Feroskhan, M. Performance, emission and combustion characteristics of various biodiesel blends. J. Therm. Anal. Calorim. 2021, 147, 2455–2479. [Google Scholar] [CrossRef]

- Khujamberdiev, R.; Cho, H. Impact of Biodiesel Blending on Emission Characteristics of One-Cylinder Engine Using Waste Swine Oil. Energies 2023, 16, 5489. [Google Scholar] [CrossRef]

- Ibrahim, S.M.; Abed, K.; Gad, M.; Hashish, H.A. Performance and emissions of a diesel engine burning blends of Jatropha and waste cooking oil biodiesel. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 1157–1169. [Google Scholar] [CrossRef]

- Xiao, H.; Yang, X.; Wang, R.; Li, S.; Ruan, J.; Ju, H. The effects of exhaust gas re-circulation and injection timing on combustion performance and emissions of biodiesel and its blends with 2-methylfuran in a diesel engine. Therm. Sci. 2020, 24, 215–229. [Google Scholar] [CrossRef]

- Zheng, Z.; Wang, X.; Zhong, X.; Hu, B.; Liu, H.; Yao, M. Experimental study on the combustion and emissions fueling biodiesel/n-butanol, biodiesel/ethanol and biodiesel/2,5-dimethylfuran on a diesel engine. Energy 2016, 115, 539–549. [Google Scholar] [CrossRef]

- Gaur, A.; Dwivedi, G.; Baredar, P.; Jain, S. Influence of blending additives in biodiesel on physiochemical properties, engine performance, and emission characteristics. Fuel 2022, 321, 124072. [Google Scholar] [CrossRef]

- Zheng, Z.; Xia, M.; Liu, H.; Wang, X.; Yao, M. Experimental study on combustion and emissions of dual fuel RCCI mode fueled with biodiesel/n-butanol, biodiesel/2,5-dimethylfuran and biodiesel/ethanol. Energy 2018, 148, 824–838. [Google Scholar] [CrossRef]

- Erman, A.G.; Hellier, P.; Ladommatos, N. The impact of ignition delay and further fuel properties on combustion and emissions in a compression ignition engine. Fuel 2020, 262, 116155. [Google Scholar] [CrossRef]

- Ciniviz, M.; Örs, İ.; Kul, B.S. The effect of adding EN (2-ethylhexyl nitrate) to diesel-ethanol blends on performance and exhaust emissions. Int. J. Automot. Sci. Technol. 2017, 1, 16–21. [Google Scholar]

- Cho, S.; Lopez-Pintor, D.; Goldsborough, S. Chemical kinetic interactions and sensitivity analyses for 2-ethylhexyl nitrate-doped PRF91 using a reduced mechanism. Fuel 2022, 329, 125503. [Google Scholar] [CrossRef]

- Song, T.; Wang, C.; Wen, M.; Liu, H.; Yao, M. Combustion mechanism study of ammonia/n-dodecane/n-heptane/EHN blended fuel. Appl. Energy Combust. Sci. 2024, 17, 100241. [Google Scholar] [CrossRef]

- Kuszewski, H.; Jaworski, A. Investigating the Effect of 2-Ethylhexyl Nitrate Cetane Improver (2-EHN) on the Autoignition Characteristics of a 1-Butanol–Diesel Blend. Energies 2024, 17, 4085. [Google Scholar] [CrossRef]

- Estevez, R.; López-Tenllado, F.J.; Montes, V.; Romero, A.A.; Bautista, F.M.; Luna, D. Characterization of Several 2-Ethylhexyl Nitrates with Vegetable Oil (Castor or Sunflower Oil) Blends in Triple Blends with Diesel, Working as Advanced Biofuels in C.I. Diesel Engines. Appl. Sci. 2024, 14, 11968. [Google Scholar] [CrossRef]

- Salmani, M.H.; Hussain, I.; Rehman, S.; Kumar, H. Environmental and performance impacts of 2-ethylhexyl nitrate and ethanol in diesel blends: A comprehensive study. J. Renew. Sustain. Energy 2024, 16, 043101. [Google Scholar] [CrossRef]

- Kuszewski, H. Effect of adding 2-ethylhexyl nitrate cetane improver on the autoignition properties of ethanol–diesel fuel blend—Investigation at various ambient gas temperatures. Fuel 2018, 224, 57–67. [Google Scholar] [CrossRef]

- Imdadul, H.K.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Kamruzzaman, M.; Shahin, M.M.; Rashed, M.M. Evaluation of oxygenated n-butanol-biodiesel blends along with ethyl hexyl nitrate as cetane improver on diesel engine attributes. J. Clean. Prod. 2017, 141, 928–939. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, X.; Zhang, Z.; Wu, Y.; Wang, C.; Chang, W.; Zheng, Z.; Yao, M. Effects of 2-ethylhexyl nitrate (EHN) on combustion and emissions on a compression ignition engine fueling high-pressure direct-injection pure methanol fuel. Fuel 2023, 341, 127684. [Google Scholar] [CrossRef]

- Ahmed, B.M.; Luo, M.; Elbadawi, H.A.M.; Mahmoud, N.M.; Sui, P.-C. Experimental Study of 2-Ethylhexyl Nitrate Effects on Engine Performance and Exhaust Emissions of Diesel Engine Fueled with Diesel–2-Methylfuran Blends. Energies 2025, 18, 98. [Google Scholar] [CrossRef]

- Tuan Hoang, A.; Viet Pham, V. 2-Methylfuran (MF) as a potential biofuel: A thorough review on the production pathway from biomass, combustion progress, and application in engines. Renew. Sustain. Energy Rev. 2021, 148, 111265. [Google Scholar] [CrossRef]

- Singh, E.; Shankar, V.S.B.; Tripathi, R.; Pitsch, H.; Sarathy, S.M. 2-Methylfuran: A bio-derived octane booster for spark-ignition engines. Fuel 2018, 225, 349–357. [Google Scholar] [CrossRef]

- Simsek, S.; Uslu, S. Investigation of the effects of biodiesel/2-ethylhexyl nitrate (EHN) fuel blends on diesel engine performance and emissions by response surface methodology (RSM). Fuel 2020, 275, 118005. [Google Scholar] [CrossRef]

- Ali Ijaz Malik, M.; Kalam, M.A.; Mujtaba Abbas, M.; Susan Silitonga, A.; Ikram, A. Recent advancements, applications, and technical challenges in fuel additives-assisted engine operations. Energy Convers. Manag. 2024, 313, 118643. [Google Scholar] [CrossRef]

- Santhosh, K.; Kumar, G.N.; Bedar, P. A novel approach to enhance the combustion quality of C5 alcohol with 2-Ethylhexyl nitrate as a cetane enhancer in common rail direct ignition diesel engine. J. Clean. Prod. 2024, 446, 141314. [Google Scholar] [CrossRef]

- Wei, L.; Cheung, C.S.; Ning, Z. Effects of biodiesel-ethanol and biodiesel-butanol blends on the combustion, performance and emissions of a diesel engine. Energy 2018, 155, 957–970. [Google Scholar] [CrossRef]

- Jin, Z.-H.; Chen, J.-T.; Li, W.; Song, S.-B.; Yang, J.-Z.; Tian, Z.-Y. Pyrolysis of 2-methylfuran/jet fuel surrogate blends: An experimental and kinetic modeling study. Combust. Flame 2021, 232, 111509. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Dong, R.; Zou, Z.; Gao, S.; Tan, D. Performance, combustion and emission characteristics investigations on a diesel engine fueled with diesel/ ethanol /n-butanol blends. Energy 2022, 249, 123733. [Google Scholar] [CrossRef]

- Kumar, H.; Sarma, A.K.; Kumar, P. Experimental investigation of 2-EHN effects upon CI engine attributes fuelled with used cooking oil-based hybrid microemulsion biofuel. Int. J. Environ. Sci. Technol. 2022, 19, 11051–11068. [Google Scholar] [CrossRef]

- Masera, K.; Hossain, A.K. Advancement of biodiesel fuel quality and NOx emission control techniques. Renew. Sustain. Energy Rev. 2023, 178, 113235. [Google Scholar] [CrossRef]

- Mirhashemi, F.S.; Sadrnia, H. NOX emissions of compression ignition engines fueled with various biodiesel blends: A review. J. Energy Inst. 2020, 93, 129–151. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S. Comparative evaluation of the combustion process and emissions of a diesel engine operating on the cetane improver 2-Ethylhexyl nitrate doped rapeseed oil and aviation JP-8 fuel. Energy Convers. Manag. X 2021, 11, 100106. [Google Scholar] [CrossRef]

- Hariharan, D.; Rajan Krishnan, S.; Kumar Srinivasan, K.; Sohail, A. Multiple injection strategies for reducing HC and CO emissions in diesel-methane dual-fuel low temperature combustion. Fuel 2021, 305, 121372. [Google Scholar] [CrossRef]

- Mohammed, A.S.; Ancha, V.R.; Atnaw, S.M.; Desta, M.; Bhandari, R. Analysis of Cylinder Pressure and Heat Release Rate Variation in Diesel Engine Fueled with Croton Macrostachyus (CMS) Seed Oil Biodiesel as an Alternative Fuel. Energies 2025, 18, 1449. [Google Scholar] [CrossRef]

- Olalere, R.K.; Zhang, G.; Liu, H.; Ma, X.; Xu, H. Experimental study of combustion and emissions characteristics of low blend ratio of 2-methylfuran/ 2-methyltetrahyrofuran with gasoline in a DISI engine. Fuel 2025, 382, 133799. [Google Scholar] [CrossRef]

- Chaurasiya, R.; Krishnasamy, A. A single fuel port and direct injected low temperature combustion strategy to reduce regulated pollutants from a light-duty diesel engine. Fuel 2023, 335, 127114. [Google Scholar] [CrossRef]

- Park, W.; Park, S.; Reitz, R.D.; Kurtz, E. The effect of oxygenated fuel properties on diesel spray combustion and soot formation. Combust. Flame 2017, 180, 276–283. [Google Scholar] [CrossRef]

- Wu, S.; Tay, K.L.; Li, J.; Yang, W.; Yang, S. Development of a compact and robust kinetic mechanism for furan group biofuels combustion in internal combustion engines. Fuel 2021, 298, 120824. [Google Scholar] [CrossRef]

- Pandey, R.K.; Rehman, A.; Sarviya, R.M. Impact of alternative fuel properties on fuel spray behavior and atomization. Renew. Sustain. Energy Rev. 2012, 16, 1762–1778. [Google Scholar] [CrossRef]

- Xu, L.; Wang, Y.; Liu, D. Effects of oxygenated biofuel additives on soot formation: A comprehensive review of laboratory-scale studies. Fuel 2022, 313, 122635. [Google Scholar] [CrossRef]

- Fang, J.; Liu, Y.; Wang, K.; Shah, H.R.; Mu, S.; Lang, X.; Wang, J. Sooting tendency analysis of oxygenate-diesel blended fuels by the affecting indicators of carbon number, oxygen content and H/C ratio. Fuel 2021, 290, 119789. [Google Scholar] [CrossRef]

| Items | Specifications |

|---|---|

| Engine Type | In-line 4-cylinder DICI |

| Bore × Stroke | 96 mm × 103 mm |

| Compression ratio | 17.5:1 |

| Displacement | 2982 mL |

| Rated power | 85 kW |

| Rated speed | 3200 rpm |

| Injection hole numbers | 7 |

| Type of cooling | Water-cooled |

| Injection hole diameter | 0.137 mm |

| Method of starting | Electric start |

| Measurement | In-Cylinder Pressure | Brake Torque | BSFC | BTE | HC | CO | NOX |

|---|---|---|---|---|---|---|---|

| Uncertainty (%) | ±0.1 | ±1.5 | ±1 | ±1.14 | ±5.5 | ±4 | ±5.7 |

| Parameters | Diesel | Biodiesel | 2-MF | 2-EHN |

|---|---|---|---|---|

| Chemical formula | C12–C25 | CH3(CH2)18COOCH3 | (C5H6O) | C8H17NO3 |

| Research Octane number | 20–30 | – | 103 | - |

| Cetane number | 52.1 | 46 | 9 | ≥76 |

| Oxygen content (% mass) | 0 | 10.8 | 19.51 | 27.43 |

| Stoichiometric air/fuel ratio | 14.3 | 12.54 | 10.05 | - |

| Density at 20 °C (kg/m3) | 827 | 871 | 913.2 | 963 |

| kinematic viscosity at 40 °C (mm2/s) | 2.47 | 4.24 | 0.48 | 2.21 |

| Water solubility at 20 °C (wt%) | N | N | N | - |

| Evaporation heat at 25 °C (kJ/kg) | 270–301 | 252–258 | 358 | 353.6 |

| Lower heating value (MJ/kg) | 42.5 | 38.5 | 31.2 | 15.7 |

| Boiling point (°C) | 180–370 | – | 64.7 | 307 |

| Flash point (°C) | 96 | 181 | −22 | 76 |

| Blend Fuel | 2-EHN (%) | Cetane Nunber | Viscosity at 40 °C (mm2/s) | Density at 20 °C (kg/m3) |

|---|---|---|---|---|

| BMF30 | 0 | 34.9 | 3.11 | 883.66 |

| BMF30E1 | 1 | 35.19 | 3.092 | 884.59 |

| BMF30E1.5 | 1.5 | 35.34 | 3.082 | 884.54 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, B.M.; Luo, M.; Elbadawi, H.A.M.; Mahmoud, N.M.; Sui, P.-C. Experimental Investigation of 2-Ethylhexyl Nitrate Effects on Engine Performance and Exhaust Emissions in Biodiesel-2-Methylfuran Blend for Diesel Engine. Energies 2025, 18, 2730. https://doi.org/10.3390/en18112730

Ahmed BM, Luo M, Elbadawi HAM, Mahmoud NM, Sui P-C. Experimental Investigation of 2-Ethylhexyl Nitrate Effects on Engine Performance and Exhaust Emissions in Biodiesel-2-Methylfuran Blend for Diesel Engine. Energies. 2025; 18(11):2730. https://doi.org/10.3390/en18112730

Chicago/Turabian StyleAhmed, Balla M., Maji Luo, Hassan A. M. Elbadawi, Nasreldin M. Mahmoud, and Pang-Chieh Sui. 2025. "Experimental Investigation of 2-Ethylhexyl Nitrate Effects on Engine Performance and Exhaust Emissions in Biodiesel-2-Methylfuran Blend for Diesel Engine" Energies 18, no. 11: 2730. https://doi.org/10.3390/en18112730

APA StyleAhmed, B. M., Luo, M., Elbadawi, H. A. M., Mahmoud, N. M., & Sui, P.-C. (2025). Experimental Investigation of 2-Ethylhexyl Nitrate Effects on Engine Performance and Exhaust Emissions in Biodiesel-2-Methylfuran Blend for Diesel Engine. Energies, 18(11), 2730. https://doi.org/10.3390/en18112730