1. Introduction

Climate change and the urgent need to reduce energy demand in buildings, of which 36% of the energy consumption is related to greenhouse gas emissions [

1], accounting for approximately 40% of the total energy consumption in the European Union (EU), have triggered research that has the goal of achieving nearly-zero-energy buildings and net-zero-energy buildings (nZEB and/or NZEB) for new constructions [

2,

3,

4,

5,

6]. On the other hand, in Chile, buildings account for 22% of the country’s energy consumption [

7], and a national energy efficiency plan was established for the 2022–2026 period to immediately trigger policies and construction standards to reduce the energy demand towards achieving the NZEB target by 2050.

The principle of energy conservation inside buildings, based on minimizing heat losses and maximizing heat gains, has been one of the paradigms for building envelope design [

8,

9]. The design’s goal is to select a thermal resistance value for the envelope’s insulation that minimizes the annual total energy demand (heating + cooling). However, the chosen value is not the daily or even monthly optimum value but is rather a compromising value for the entire year; it is the equivalent of making a design for an average situation [

10,

11,

12]. Energy conservation principles have been derived for envelope designs that select, among other parameters, the same thermal resistance value for the whole envelope and for the whole year. The paradigm shift needed to achieve the nZEB goal consists of switching from static façades to adaptive façades for building envelope designs, where the envelope’s thermo-physical and/or thermo-optical characteristics could change and adapt throughout the year due to changing outdoor and/or indoor conditions, in order to improve the building energy performance [

13,

14,

15,

16,

17].

CABSs are capable of changing some of their functions, characteristics, or behaviors over time in response to changes in environmental conditions and user requirements in order to improve a building’s performance while maintaining human comfort inside the building [

18,

19]. “Intelligent” CABSs are capable of changing their behavior via an external (extrinsic) control signal driven by an algorithm or control logic that “decides” when and how the façade should change its characteristics in response to changing conditions [

9,

20] in order to minimize energy demand and maintain a certain degree of comfort.

Adaptive façades can be implemented in both the glazed and opaque parts of a building envelope [

9,

20,

21]. In recent years, several adaptive façade technologies have been developed for the glazed parts, such as motorized blinds, window frames, and (EC) glazing for solar shading, among others [

22,

23,

24,

25,

26,

27]. However, technologies based on variable thermal resistance for the opaque part of façades are still under development [

10,

12,

28], which limits the availability of experimental data. Consequently, building performance assessments for adaptive insulation are scarce and they are mostly theoretical and based on building performance simulation (BPS).

Considering that the available BPS software can be used to model and simulate the glazed sections of adaptive façades, several studies have been conducted using BPS software for such adaptive façades [

29], with different technologies being examined, including vertical, horizontal, baffle, and integrated louver shading [

30], perforated curved louvers [

26], movable window insulation and window frames [

31,

32,

33], and adaptive materials such as EC glass [

34,

35], photovoltachromic glass [

36], and thermochromic glass [

37,

38]. However, the evaluation of adaptive insulation based on variable thermal resistance for the opaque part of façades is complex. This is due to the lack of building simulation models for specific technologies among other limitations of BPS software which include the user interface, solution routines, control strategies, occupant influence, and domain integration [

39,

40]. Specifically, for the variable-thermal-resistance simulation of opaque façades, there are limitations in terms of the capability of BPS software to model the variable thermal resistance and to explicitly indicate the border conditions from the previous time step, which are the initial conditions for the next time step, specifically in systems that are dominated by the building’s time constant.

Moreover, there has not been any comparison between experimental measurements and simulated data for a specific adaptive insulation system [

12,

41]. By using the EnergyPlus “SurfaceControl:MovableInsulation” class list [

42], an Adaptive insulation model could be defined with the ability to change the insulation thickness during run time to achieve adaptation. This is in contrast with a non-adaptive model, where insulation thickness must be changed manually (via code modification) before a new simulation run and cannot be changed during run time.

However, it is desirable to have a validated model to simulate the opaque section of adaptive façades that takes into account not only the temperatures at the interface between the insulation layer and the concrete and along the concrete layer [

39] but also other variables of interest for building performance simulation, such as annual heating and cooling energy demand, peak heating, peak cooling, and indoor temperatures (maximum, minimum, and average) throughout the year-long period of study.

The objective of this research was to configure and validate a simplified office model based on the BesTest 900 and BesTest 900 Free Floating (FF) models, as specified in the ANSI/ASHRAE Standard 140-2011. This could be used to simulate an adaptive façade with variable thermal resistance via adaptive insulation thickness in its opaque section. To carry this out, a model was defined, and then, using the EnergyPlus “SurfaceControl:MovableInsulation” class list within the model, it was validated.

2. Materials and Methods

The model subjected to validation in this study was an “Adaptive” model based on a modified version of the BesTest 900 model [

43]. It was coded and simulated in EnergyPlus software version 9.5.0. using the Windows 10 operating system environment and compared to a “Static” model that was used as a reference. The study site was in the Stapleton neighborhood in Denver, Colorado, USA, as indicated in the BesTest 900 specifications, fully described in

Section 2.1. The “Static” and “Adaptive” versions, which are modified models of the original BesTest 900, are described in

Section 2.2 and their EnergyPlus code differences are fully detailed in

Appendix A.

The validation procedure of the “Adaptive” model presented in

Section 2.3 was based on a software-to-software comparison [

44] with the “Static” model that was previously validated for BesTest 900 and BesTest 900FF. For this validation study, the independent variable was the thermal resistance of the walls, which was modified by changing the insulation thickness, as explained in

Section 2.2. The dependent variables were cooling annual energy demand (kWh), heating annual energy demand (kWh), peak heating (W) and peak cooling (W) for BesTest 900, and maximum annual hourly zone temperature (°C), minimum annual hourly zone temperature (°C), and average annual hourly zone temperature (°C) for BesTest 900FF. These dependent variables were the results of a year-long simulation of the models with the parameters, site, climate, and definitions of BesTest 900 indicated in

Section 2.1. It should be noted that BesTest 900FF is a Free-Floating Temperature Test for BesTest900, and the construction model and simulation parameters are the same as those for BesTest 900 except that there is no mechanical heating or cooling system [

43].

2.1. BesTest 900

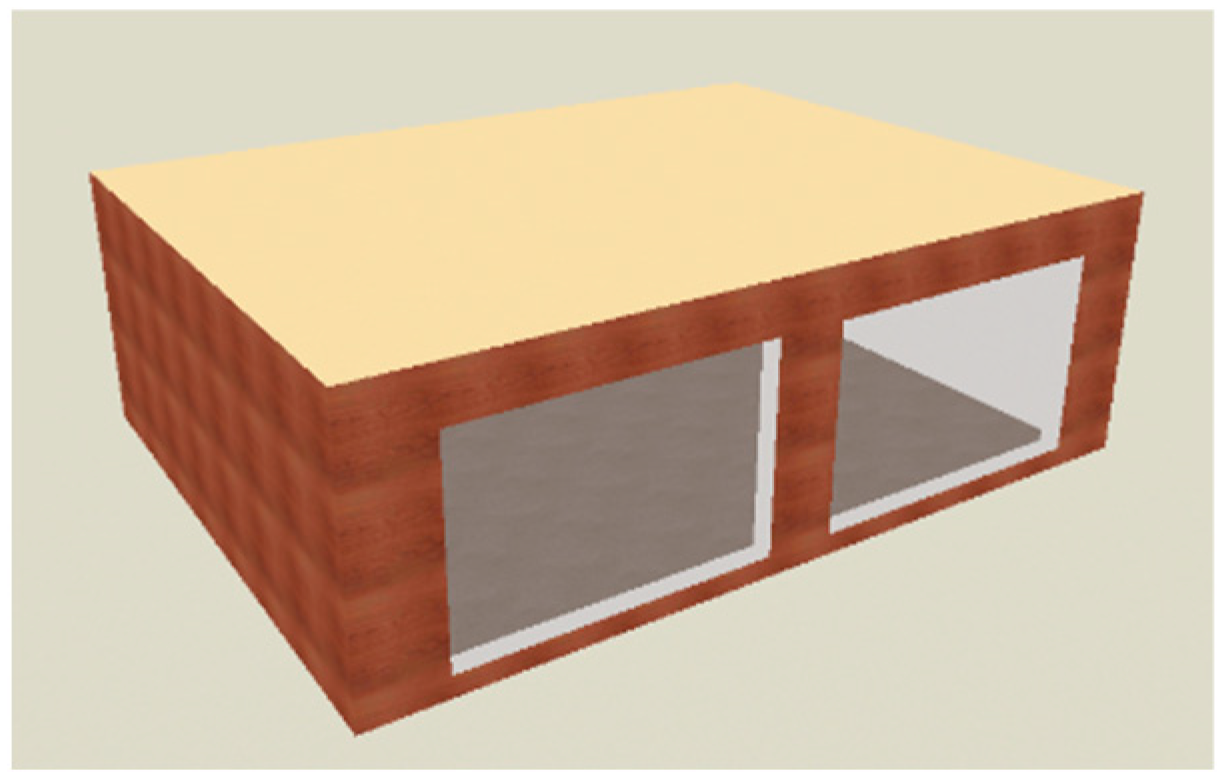

The basic testing building for BesTest 900 is shown in

Figure 1. It is a rectangular, single-zone structure (8 m wide × 6 m long × 2.7 m high) with no interior partitions and 12 m

2 of south-facing windows. It is located in the Stapleton neighborhood in Denver, Colorado, USA, and is one of the simplified models proposed by the ANSI/ASHRAE Standard 140-2011 [

43]. The climate is characterized as cold, with clear winters/hot dry summers and an average number of annual heating degree days = 2756, considering a base temperature of 15.5 °C and data from the past 5 years. The BesTest 900 model specifications are shown in

Table 1 and

Table 2.

The BesTest 900 description of the heating and cooling systems, thermostat setpoints, and other parameters is the following:

Infiltration: 0.5 air change/hour.

Internal Load: 200 W continuous, 60% radiative, 40% convective, 100% sensible.

Mechanical System: 100% convective air system, 100% efficiency with no duct losses and no capacity limitation, no latent heat extraction, non-proportional-type dual-setpoint thermostat with deadband, heating < 20 °C, cooling > 27 °C.

Soil Temperature: 10 °C continuous.

2.2. Static and Adaptive Models

2.2.1. Static Model

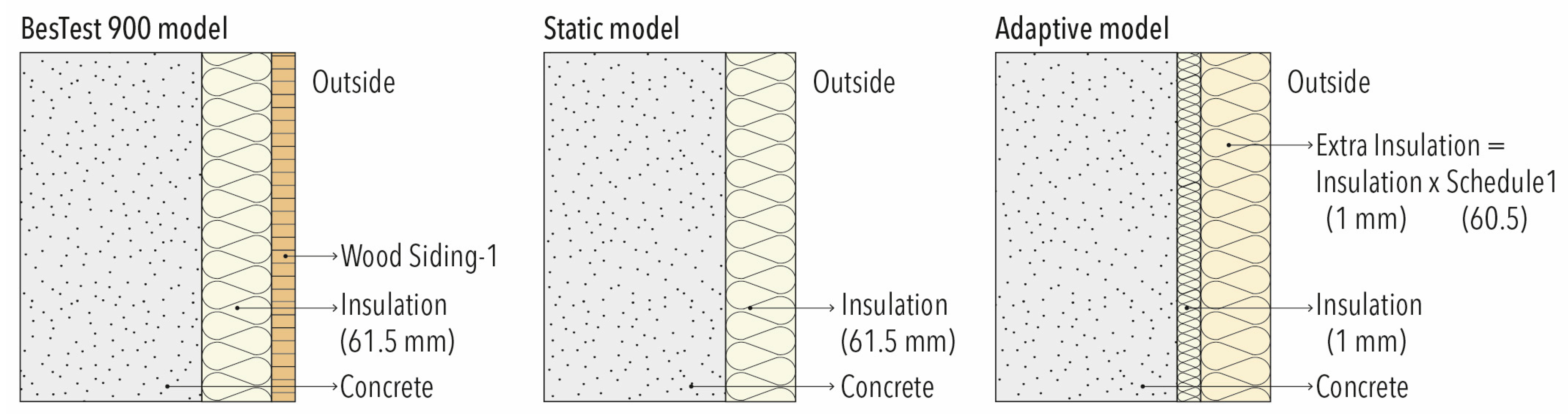

The model used as a reference for this study was the same BesTest 900 model, except for the “Wood Siding-1” shell, which was removed. This model variation is called “Static”, and the wall configuration is shown in

Figure 2. The external layer of the Static model is the insulation; thus, this modified model is similar to a heavyweight-mass wall with an EIFS. For this study, the model variation is called the “Static” model because, in this model, the thermal resistance of its walls is fixed. The thermal resistance also depends on the amount and type of insulation as well as the materials included in the layers specified in the material, construction, and building surface of these EnergyPlus objects, aspects that could not be changed during run time. The Static model is used as the reference model and is taken from the original BesTest900 model that was validated using the software-to-software comparison methodology described by the ANSI/ASHRAE Standard 140-2011 (BESTEST) [

43,

44]. The results of this Static model are consistent and logically coherent as the only difference with the original BesTest 900 is the external Wood Siding shell that was removed from the BesTest900 original model to set up the Static model.

2.2.2. Adaptive Model

The “Adaptive” model shown in

Figure 2 is an EnergyPlus model where the thermal resistance can be modified by changing the amount of extra insulation and during run time, by adjusting the “Schedule1” multiplier. The rest of the Adaptive model definitions are kept unchanged compared to those in the Static model.

The Adaptive model of

Figure 2 is an example where the total insulation is equal to 61.5 mm. If the Schedule1 multiplier is changed, different total insulations can be achieved.

The Adaptive model was obtained by modifying the Static model using EnergyPlus code. The EnergyPlus “SurfaceControl:MovableInsulation” class list was used to add the ability to change the extra insulation added to the Static EnergyPlus model, allowing the wall’s thermal resistance in the model to be adjusted during run time to achieve adaptation in response to climate and/or interior occupancy changes within the study period.

The EnergyPlus “SurfaceControl:MovableInsulation” class list allows the user to specify an additional amount of insulation on the inside, outside, or both surfaces of a wall by adding the definition of the multiplier Schedule1 (see example in

Figure 2). The actual insulation of the movable insulation that is added is equal to the insulation of the material layer times the current value in the movable insulation schedule [

45].

The total insulation of the Adaptive model (see example in

Figure 2) is calculated by adding the extra insulation that comes from multiplying the Schedule1 equal to 60.5 (example in

Figure 2) by the insulation of the material layer (1 mm):

Final insulation thickness = 1 mm + 1 mm × 60.5 = 61.5 mm.

The example in

Figure 2 shows that the Adaptive model is equivalent to the Static model, where the insulation thickness definition in the material layer is 61.5 mm.

The Adaptive model’s requirement is to achieve multiple insulation thicknesses to provide a variable-thermal-resistance model. For instance, if it is desirable for the Adaptive model to achieve a total insulation thickness of 30 mm, Schedule1 should be equal to 29 (1 mm + 1 mm × 29 = 30 mm); if it is desirable to achieve a total insulation thickness of 100 mm, Schedule1 should be equal to 99 (1 mm + 1 mm × 99 = 100 mm).

A detailed comparison of the EnergyPlus code differences for the Static and Adaptive models is presented in

Appendix A.

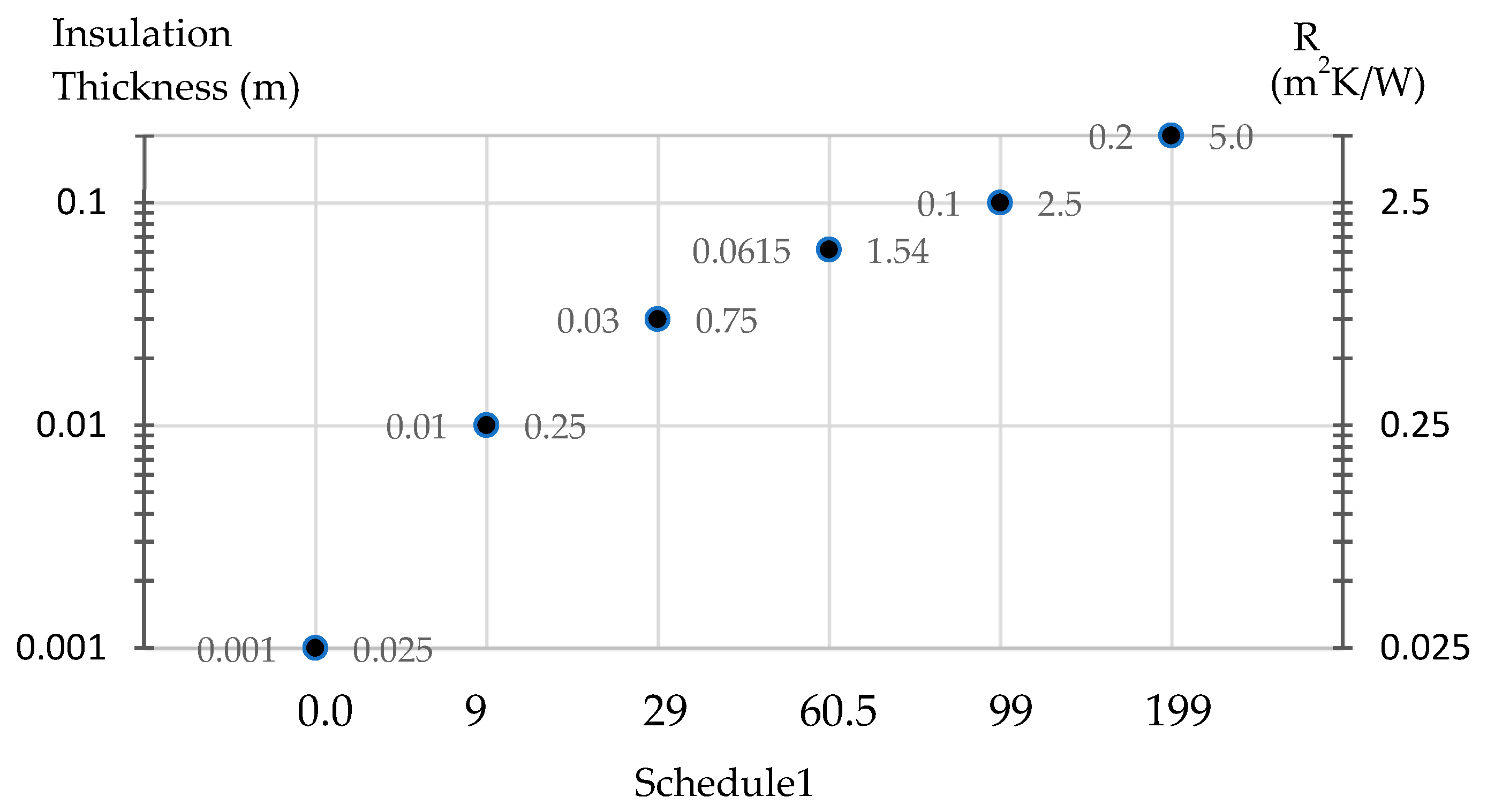

2.2.3. Criteria for Selecting Thermal Resistances for Adaptive Model Validation

For this study, it is assumed that variable-thermal-resistance technology similar to that described in [

46] is available and can reach up to 5.0 (m

2 K/W). From the table defined by Palacios and Bobadilla [

47] for an adaptive façade study, the thermal resistances that resulted in the most significant energy reduction were chosen for validation in this study. The BesTest900 thermal resistance used in the ANSI/ASHRAE Standard 140-2011 (BESTEST) is 61.5 mm, so this value was also included in the set. Considering the aforementioned study, the insulation thicknesses of 1 mm, 10 mm, 30 mm, 61.5 mm, 100 mm, and 200 mm were used as the chosen set to compare the simulation results of the Static model with those of the Adaptive model. It should be mentioned that BesTest 900 and 900FF use foam insulation. The insulation thickness and its thermal resistance value for the chosen set, considering a foam insulation lambda value of 0.040 (W/mK), are shown in

Figure 3.

The possible insulation thicknesses for the Adaptive model range from a 1 mm total insulation thickness when no extra insulation is added (Schedule1 = 0.0) to 200 mm of total insulation, which is achieved when 199 mm of insulation is added (Schedule1 = 199).

2.3. Model Validation Procedure

2.3.1. Static Model Validation

The BesTest 900 and BesTest 900FF EnergyPlus original code was provided by EnergyPlus in version 8.1.0 and was converted to EnergyPlus version 9.5.0 using the IDFVersionUpdater provided by the EnergyPlus software. This conversion was necessary because at the time of this study, the original EnergyPlus BesTest 900 and BesTest 900FF code was only available for EnergyPlus version 8.1.0., and the validation was performed using EnergyPlus version 9.5.0. After the conversion described above, to obtain the Static EnergyPlus model using BesTest900 EnergyPlus version 9.5.0, the “Wood Siding” from the BesTest900 model construction definition was removed.

First Validation (Static Model Validation) Procedure:

The software conversion was verified by comparing the dependent variable results provided by EnergyPlus for the original code in version 8.1.0, with the EnergyPlus 9.5.0 converted code results, by using the software-to-software comparative test criteria described by the ANSI/ASHRAE Standard 140-2011 (BESTEST) [

43,

44].

2.3.2. Adaptive Model Validation

The results comparison between the Static (validated) and Adaptive models’ results was performed using the following procedure:

Second Validation (Adaptive Model Validation) Procedure:

Select one of the insulation thicknesses from the set detailed in

Section 2.2.3 (1 mm, 10 mm, 30 mm, 61.5 mm, 100 mm, or 200 mm).

Adjust the Static model construction definition to achieve the chosen insulation.

In the Adaptive model, set the Schedule1 parameter to achieve the same total insulation chosen for the Static model. For example, if a 100 mm insulation thickness was chosen in step 1, then Schedule1 should be set to 99 to achieve a total insulation of 100 mm as explained in

Section 2.2.2. (

Figure 2).

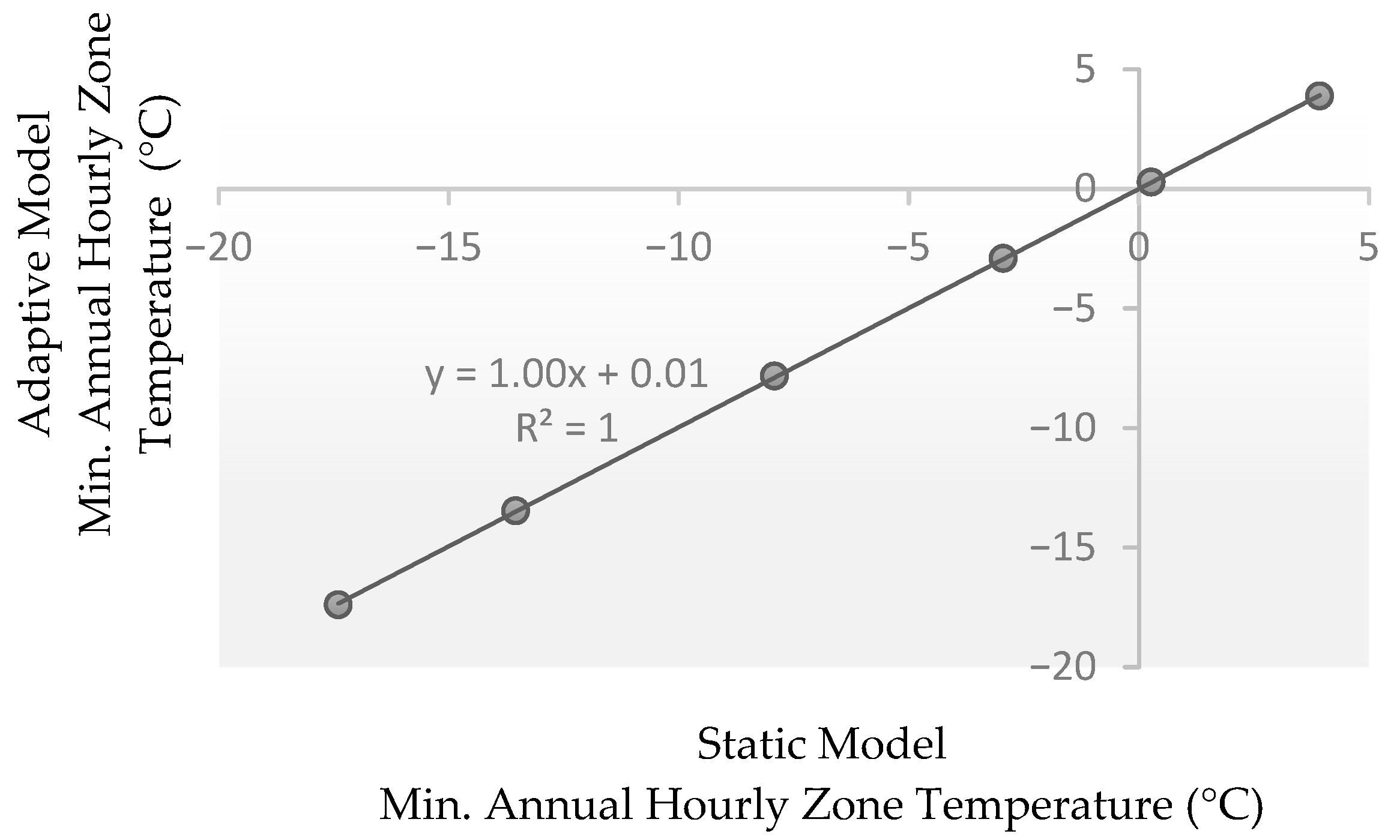

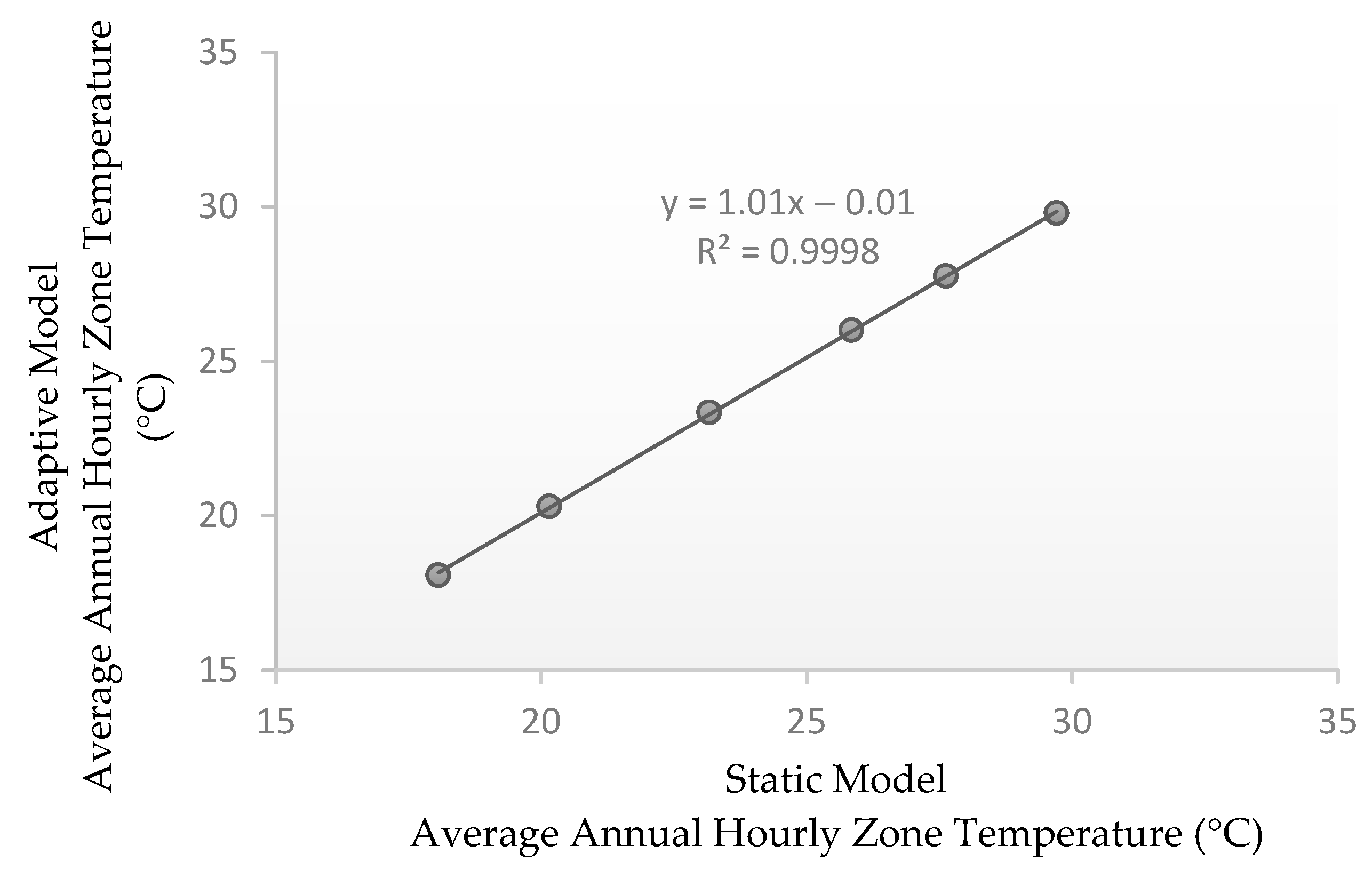

Simulate both cases (BesTest900 and 900FF) over a one-year period, for both the Static model and the Adaptive model, to obtain the dependent variables: cooling annual energy demand (kWh), heating annual energy demand (kWh), peak heating (W) and peak cooling (W) for BesTest 900, and maximum annual hourly zone temperature (°C), minimum annual hourly zone temperature (°C), and average annual hourly zone temperature (°C) for BesTest 900FF. It should be noted that when a specific total insulation of the set is chosen for comparison, the Adaptive model must be simulated using the chosen insulation for the entire one-year simulation period, as the insulation cannot be changed during run time in the Static model.

Repeat steps 1 through 4 for each insulation thickness in the selected set.

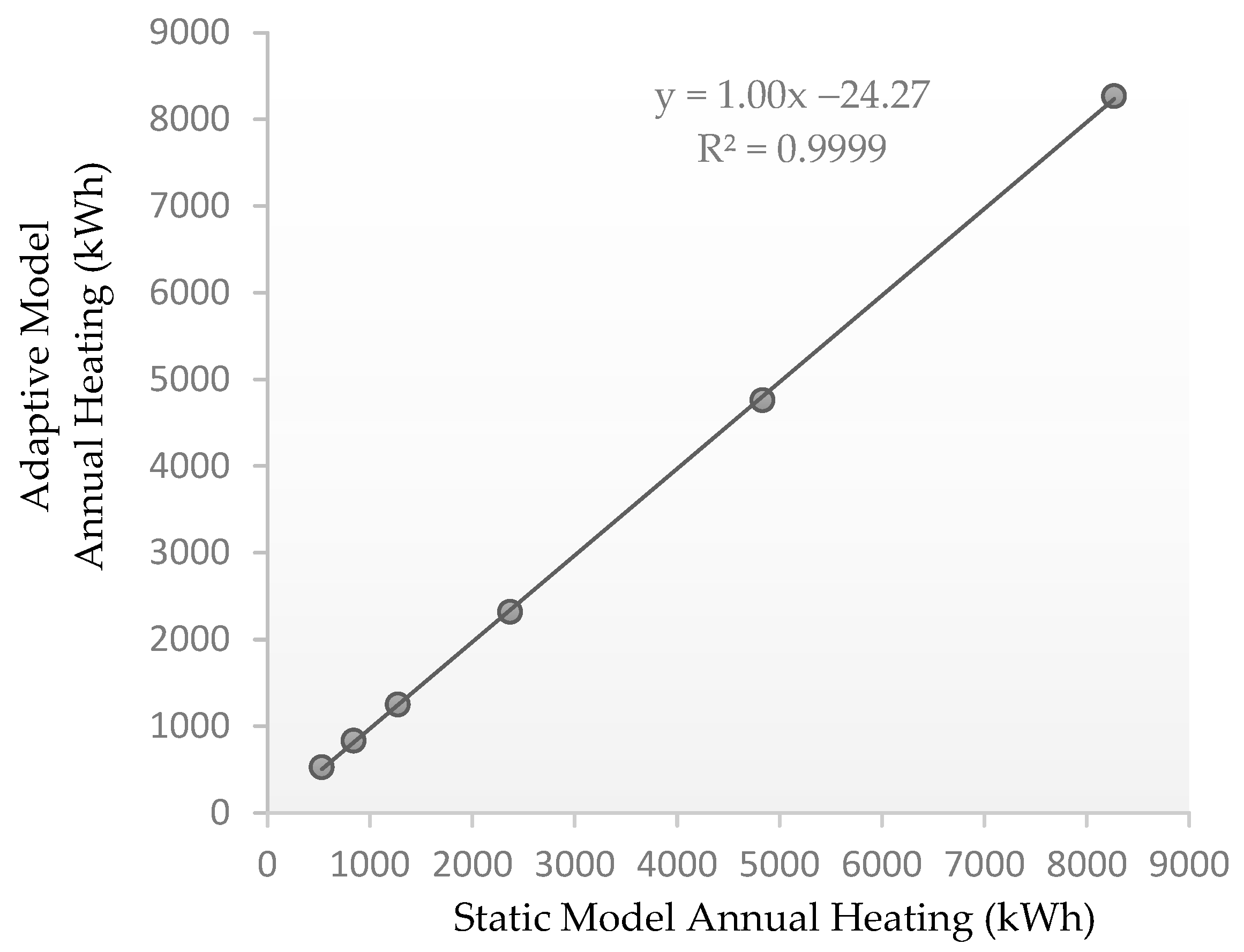

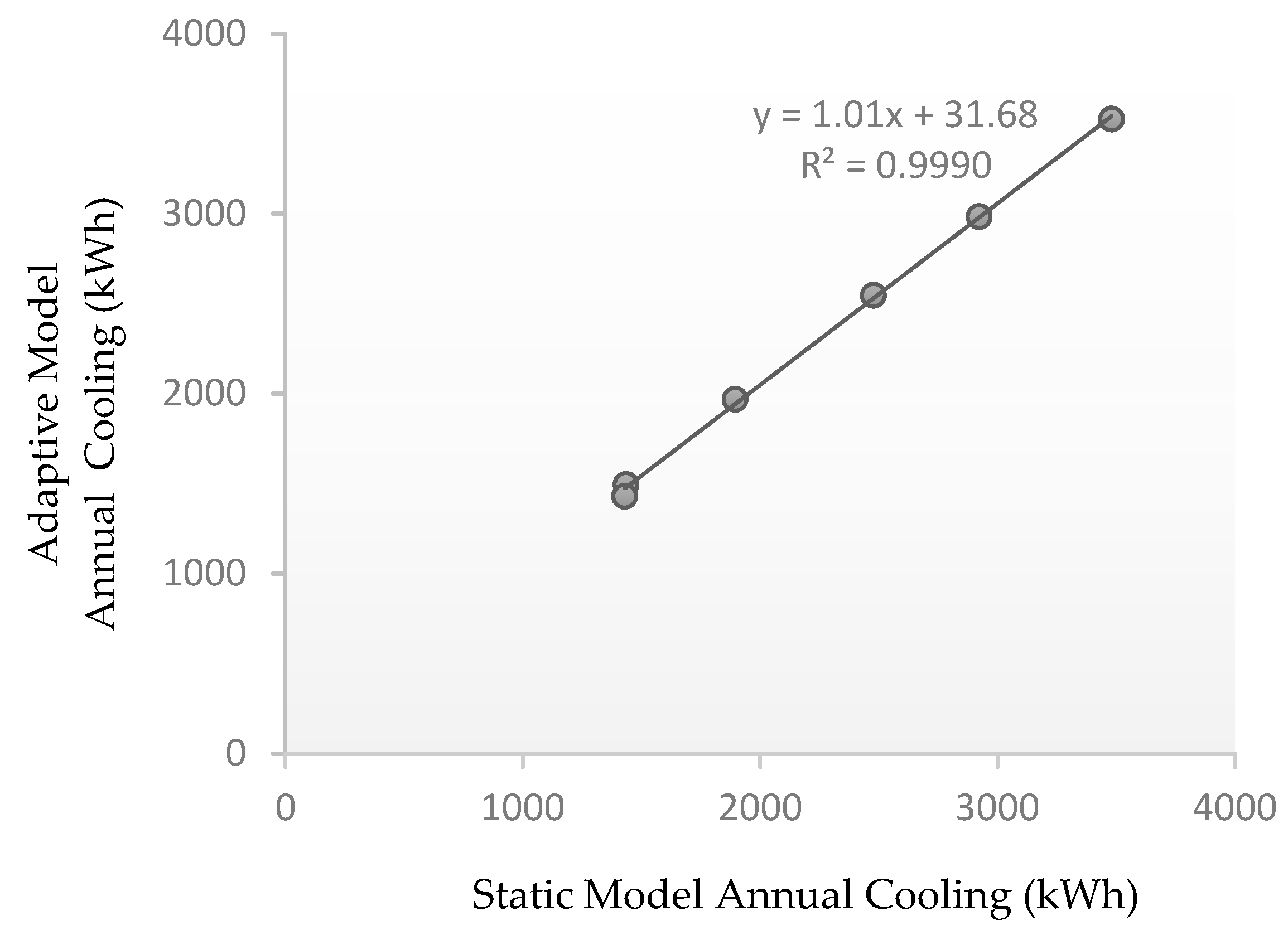

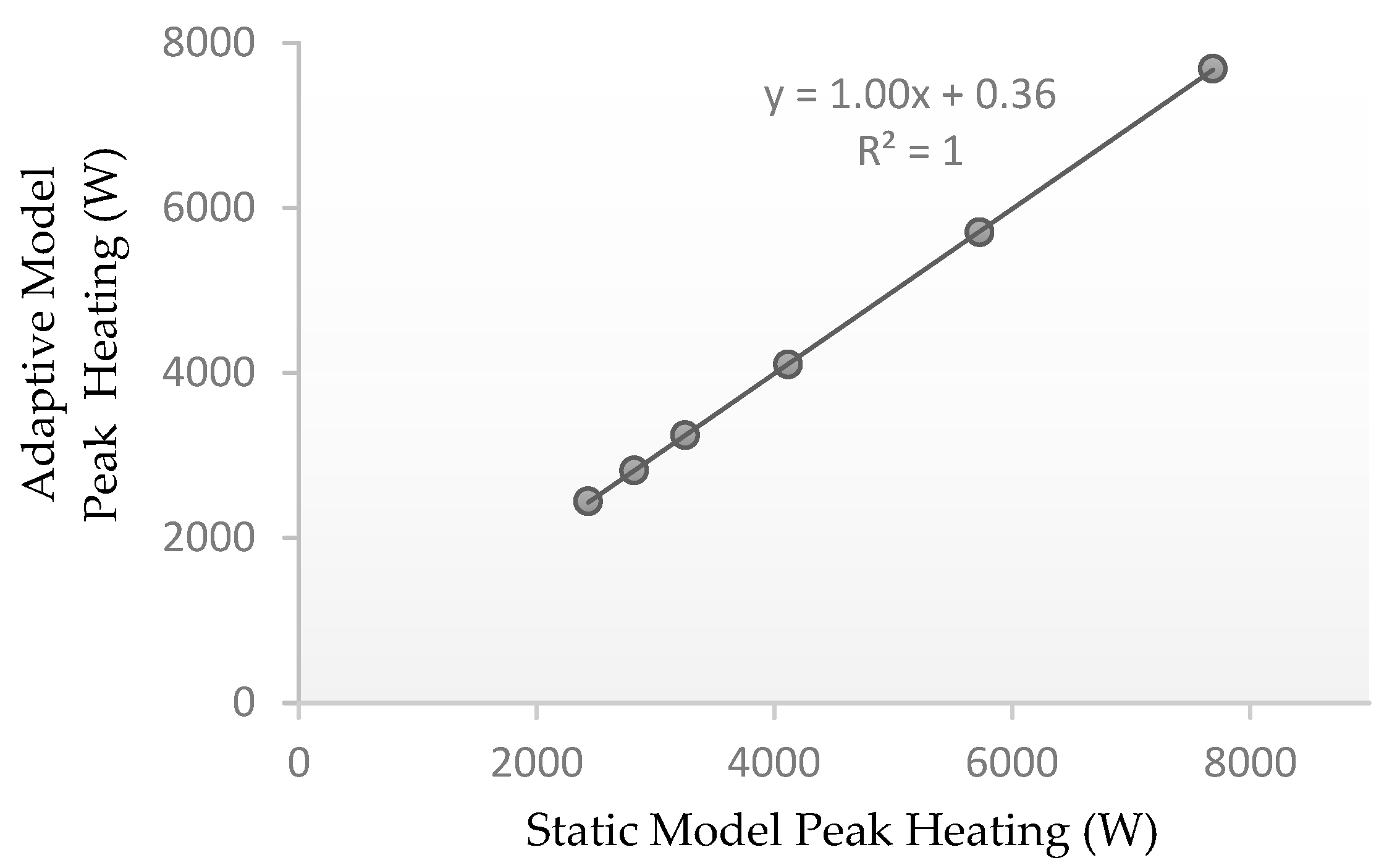

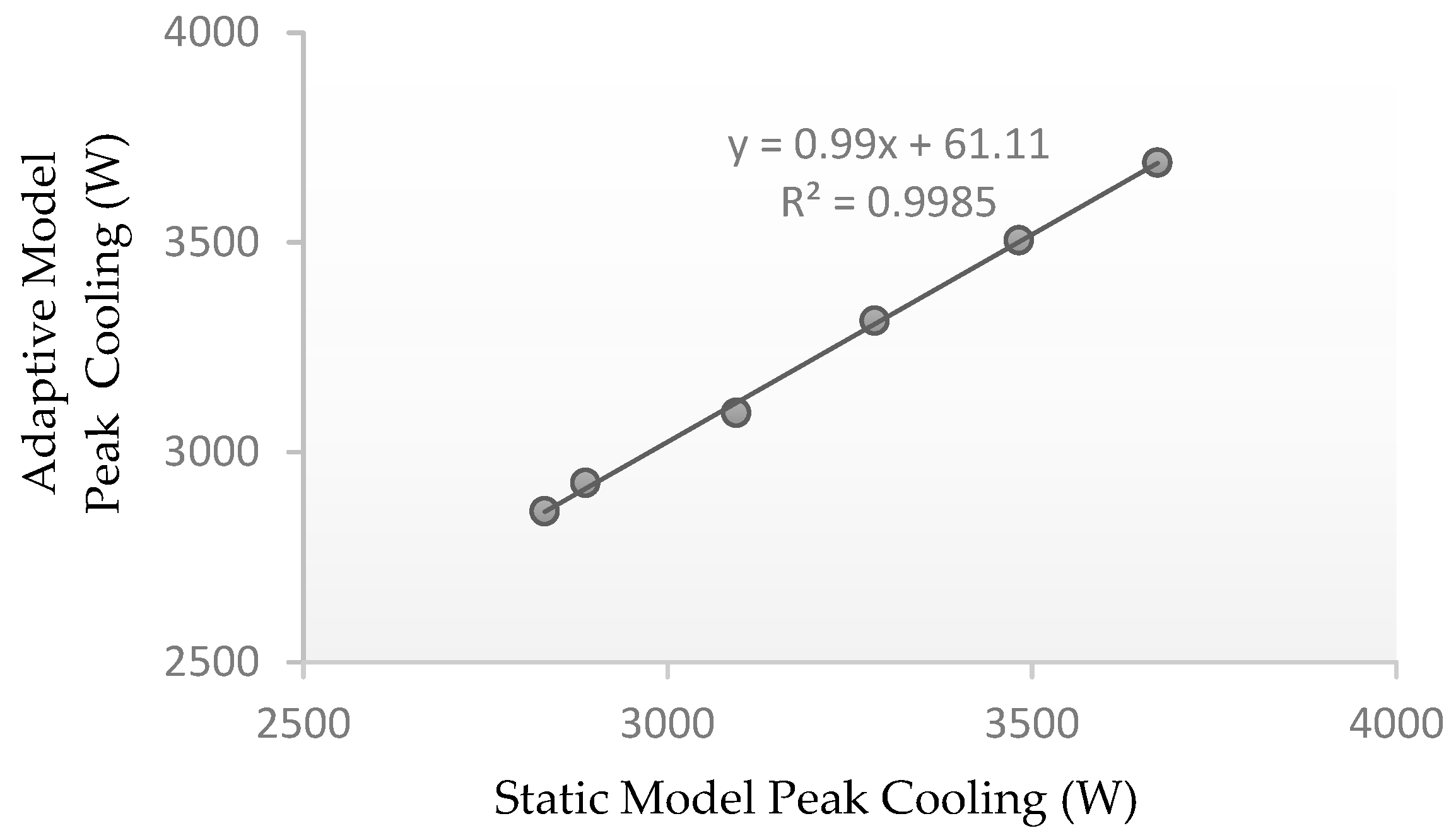

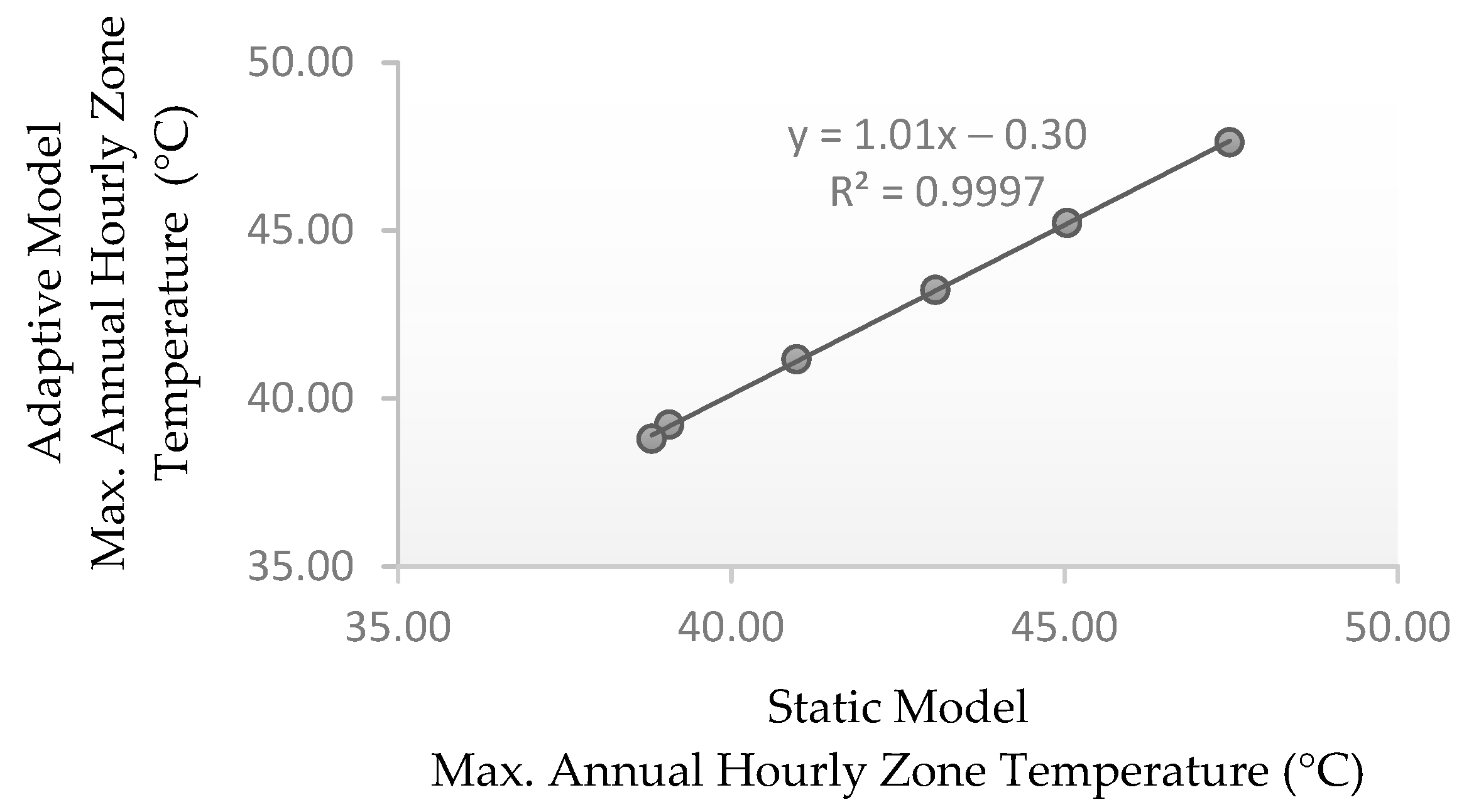

Compare the simulation results (dependent variables) by plotting the results for both Static and Adaptive models in the same chart, and adjust a linear regression model for each of the dependent variables. Use the corresponding R-squared (R2) value as a goodness-of-fit measure for the linear regression model to validate the results of the Adaptive model.

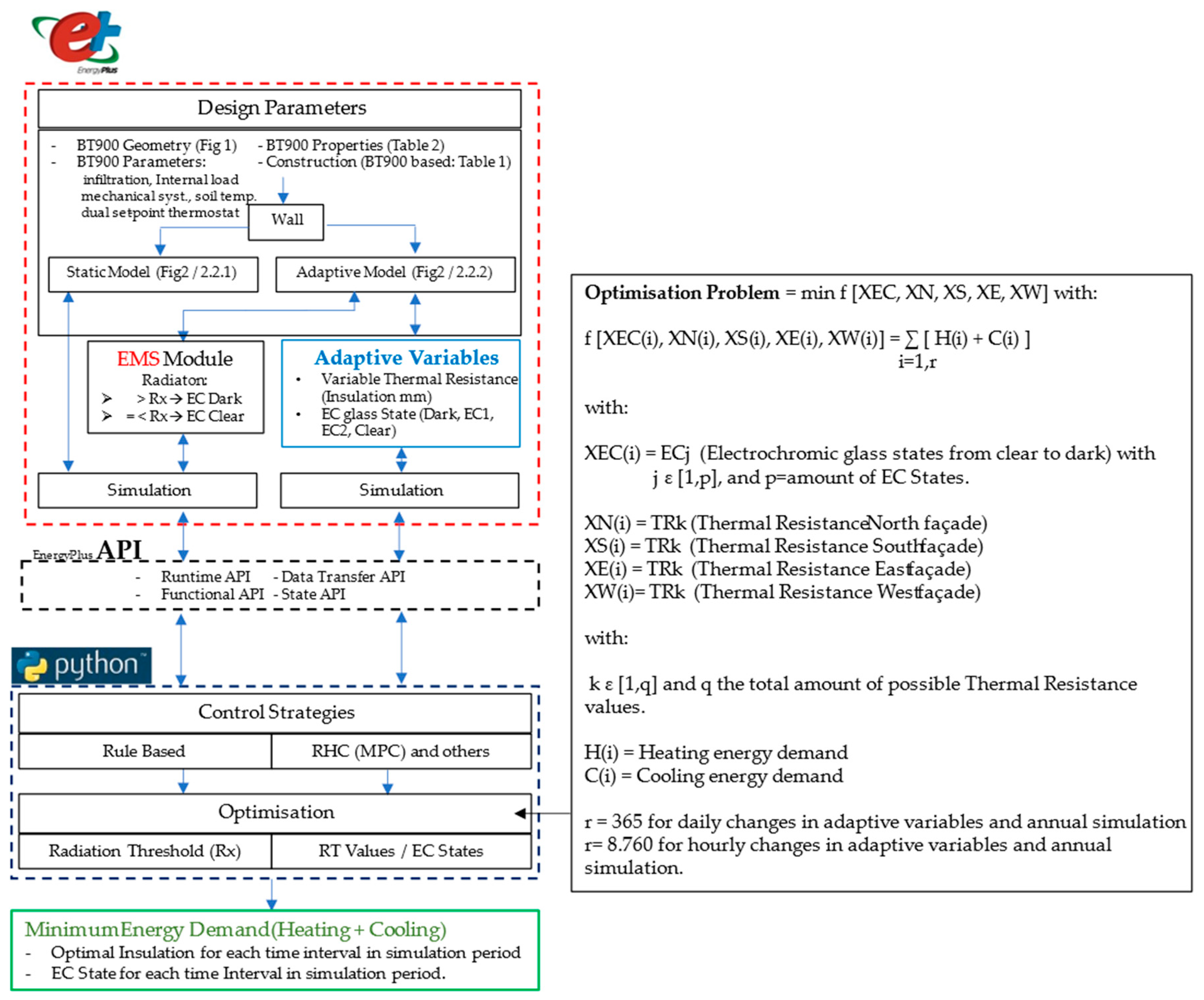

4. Adaptive Model Example and Software Framework

The Adaptive model presented and validated in this research, with the same climate, configuration, and parameters as described in

Section 2, was used to simulate the total energy demand reduction (heating + cooling) if an adaptive façade with variable thermal resistance for the opaque part of the façade was adopted in the model. First, the optimal insulation thickness for the Adaptive model was obtained and used as the reference for comparison with three other simulation alternatives. The four cases were the following:

Case A: Optimal insulation thickness for minimizing total energy demand (annual heating + annual cooling), considering the same insulation for all four walls (balanced insulation) of the Adaptive model and repeating this on every day of the 365-day simulation period.

Case B: Optimal insulation thickness for minimizing total energy demand (annual heating + annual cooling), considering that the insulation of each of the four walls of the Adaptive model could adopt a different thickness (unbalanced insulation). Each wall repeated the same insulation adopted, on every day of the 365 days of the simulation period.

Case C: Optimal insulation thickness for minimizing total energy demand (annual heating + annual cooling), considering that the insulation was the same for each wall (balanced insulation) and could change every day (adapt) during the 365-day simulation period for minimizing total energy demand.

Case D: The same as Case C but with electrochromic glazing added on both windows of the Adaptive model. The electrochromic glazing considered had two states: fully clear (Clear) and fully tinted (Dark). The parameters were obtained from the SageGlass Classic panel and exported from the International Glazing Database (IGDB), published by the Lawrence Berkeley National Laboratory (LBNL) using the LBNL Window program.

The simulation of the Adaptive model coded in EnergyPlus was executed by a Python version 3.9 program that communicated with EnergyPlus via an EnergyPlus API to call EnergyPlus as a function from Python.

The electrochromic glazing simulation for Case D was carried out using the EnergyPlus Energy Management System (EMS). The EMS program, written in the EnergyPlus Runtime Language (Erl), switched from the Clear state to the Dark state when the Incident Solar Radiation exceeded a radiation threshold (Rx). The optimization to determine the insulation thickness daily values was performed in Python.

The software simulation platform for adaptive façades with variable thermal resistance and electrochromic (EC) glazing is presented in

Figure 11.

The results for Cases A, B, C, and D are presented in

Table 9.

For Cases C and D,

Table 10 shows the different values considered for the insulation thickness and the number of days in the year on which those values were adopted for minimizing energy demand.

The results for Case B show that if unbalanced insulation was considered for this climate, a 3% energy reduction was achieved compared to the balanced insulation of Case A. This was performed by increasing heating energy demand by 93 kWh and reducing cooling energy demand by 220 kWh. Although Cases A and B were not adaptive façade cases, it was interesting to explore the possibilities of unbalanced insulation thickness, such as moving energy demands from cooling to heating.

When an adaptive façade was considered for the Adaptive model (Case C) and the thermal resistance could adapt by changing the insulation thickness once a day, while keeping the same value for the four walls during the day (balanced–adaptive), energy demand was reduced by 26% compared to the optimal insulation thickness of Case A. In Case C, 60% of the time, high (≥150 mm) or low insulation (≤10 mm) was the optimal insulation for reducing total energy demand (heating + cooling).

Finally, Case D (Case C with EC glazing added) led to a 54% energy demand reduction compared to Case A. The heating demand was almost the same as that in Case A, and the cooling energy demand was significantly reduced by switching the EC glazing to the EC Dark state. The presence of the highest insulation thickness (200 mm) was needed for 62% of the year to compensate for less radiation received through windows due to the lower solar transmittance of the EC Clear state compared with Glass Type 1 of the original glass.

5. Discussion

Research on BPS has been conducted in recent years using simplified models such as the ones presented in [

39,

50,

51,

52]. This has been performed due to multiple factors such as geometry modeling, result validation, result comparison, the complexity of working with a whole real building, and computation time. The U.S. Department of Energy requested Lawrence Berkeley National Laboratory to prepare a comparative test for the EnergyPlus software with simplified models, according to the ANSI/ASHRAE Standard 140-2011 (BESTEST) [

43,

44]. The advantage of the BesTest model is the possibility of comparing the results provided by the standard, with the same BesTest model that is being used in a research study, even if a different software is used to model BesTest. The standard considers a software-to-software comparison of the results that are expected to be within a range of acceptable values for software validation [

44].

A cellular office room model with and without the EnergyPlus “SurfaceControl:MovableInsulation” class list was analyzed in [

39], and as the author stated, “the main purpose of the analysis was to compare the temperatures at the interface between the insulation layer and the concrete, and along the concrete layer.” On the other hand, in this research, the Adaptive model is based on the standardized BesTest Case 900 and 900FF models, with the EnergyPlus “SurfaceControl:MovableInsulation” class list added. This research not only complements the results described in [

39] but also presents a quantitative validation for the “SurfaceControl:MovableInsulation” class list. However, adding the dependent variables related to energy demand, peak demand, and temperatures inside the model zone, and checking that the Adaptive model results compared with the expected results provided by BesTests, as part of the validation process, led to an EnergyPlus error that is described in the following paragraph. This error could not be found in [

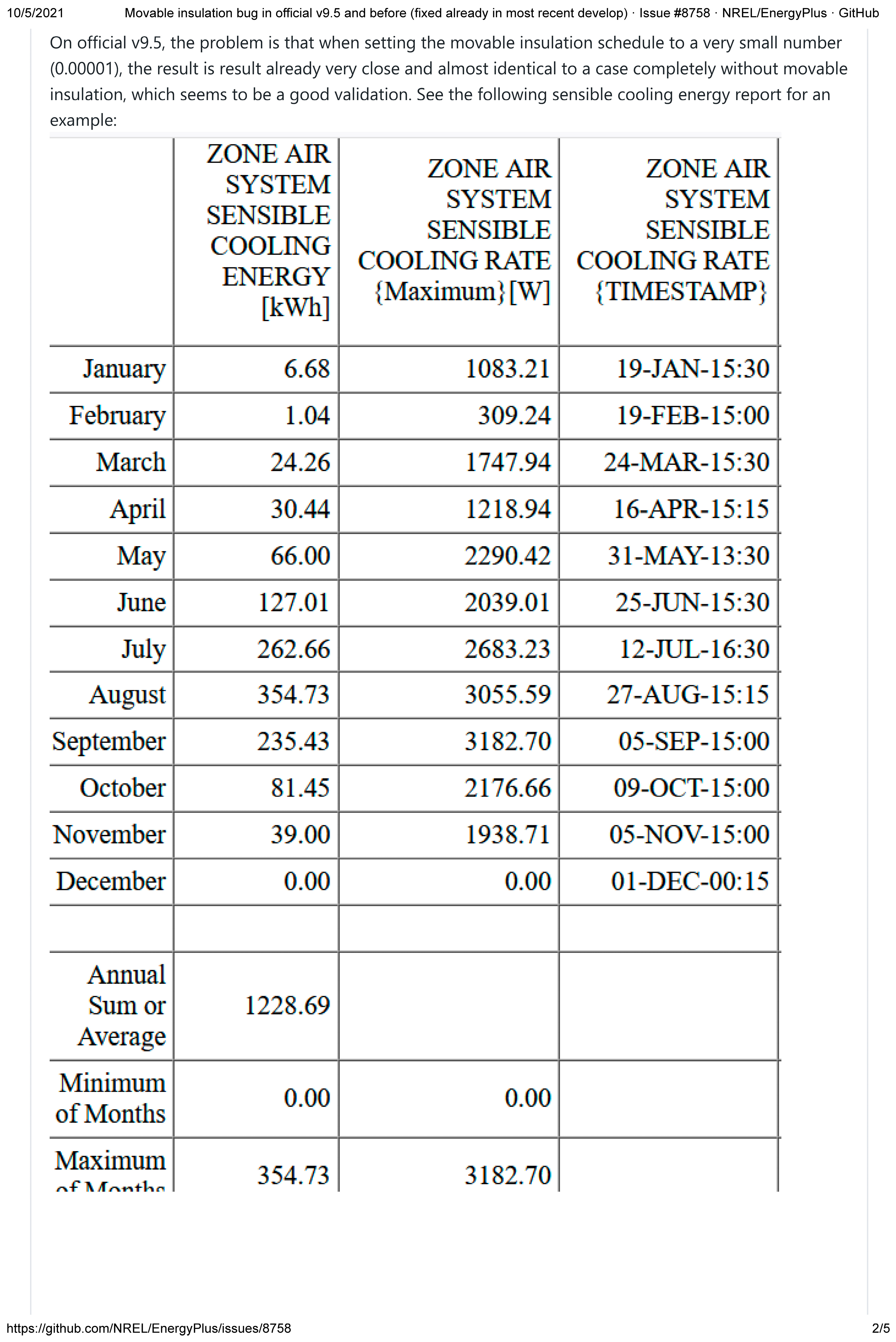

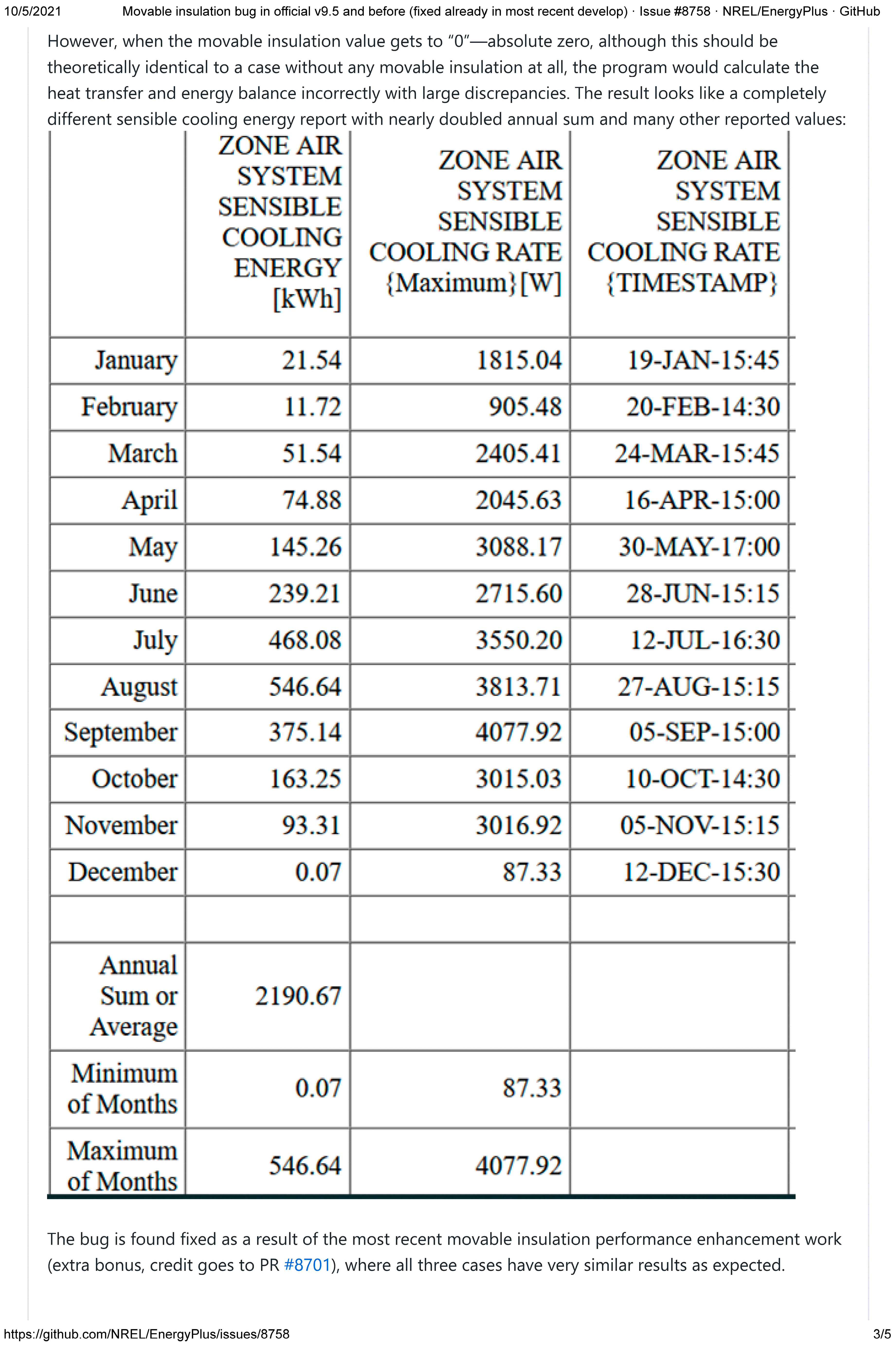

39] due to qualitative validation being used instead of quantitative validation. A transitory solution for using the “SurfaceControl:MovableInsulation” class list for a variable-thermal-resistance model, where no extra insulation was added, was also found and successfully used to obtain the result of the Adaptive model for a total insulation thickness of 1 mm.

In the Adaptive model validated in this research, to have a final insulation of 1 mm, the Schedule1 parameter should equal 0.0 so that an extra amount of insulation is not added (see

Section 2.2), and the final insulation is the 1 mm base insulation that is always present (see

Figure 2). It is important to note that when Schedule1 = 0.0 was set in the EnergyPlus Adaptive model, the results were very different from those of the Static model and also outside the logical range of expected results, as seen in note (a) of

Table 5. In contrast, the other results (total insulation = 10 mm, 30 mm, 61.5 mm, 100 mm, 200 mm) were very close to the Static model results. EnergyPlus documentation for version 9.5.0 indicates that the multiplier could be any positive real number starting from 0.0. If a value for Schedule1 = 0.0000001 was set, the model results for 1 mm insulation thickness were the same for both the Static and Adaptive models, as shown in

Table 5 and

Table 7. Moreover, a Schedule1 floating value greater than 0.0, such as 0.001, produced results very near the Static model results. Considering the results of

Table 5 note (a), setting Schedule1 = 0.0 in the SurfaceControl:MovableInsulation class list produced an EnergyPlus malfunction, and a partial solution consisted of considering a floating value greater than 0.0 but very close to it. The error was fully documented and sent to EnergyPlus support. On May 7th, 2021, it was confirmed to be a “code bug for the official EnergyPlus v9.5 and before” (see

Appendix B for the report to EnergyPlus support and

Appendix C for the official answer and confirmation from EnergyPlus regarding the software malfunction reported). The error was fixed, and the new code was included in the following EnergyPlus versions. It was also confirmed from EnergyPlus that using a Schedule1 positive floating value very close to 0.0 would give results “very close and almost identical to a case completely without movable insulation, which seems to be a good validation”. After finding a solution for the case Schedule1 = 0.0, where no extra insulation was added for setting up the Adaptive model for a total insulation = 1 mm,

Table 5 and

Table 7’s results for this case were generated using Schedule1 = 0.0000001 and were confirmed by EnergyPlus to be good validation. It is relevant that all previous research that used the SurfaceControl:MovableInsulation class list produced an EnergyPlus malfunction when Schedule1=0.0 was set (no extra insulation added), so those results were not correct for those simulations.

The framework presented in this study is entirely based on open-source free software: EnergyPlus, Python, and an EnergyPlus API for communication between them, with all the capabilities described in other frameworks like the one described in [

39], which is based on the commercial software MATLAB 2013b and the free software EnergyPlus. One of the advantages of using Python is the availability of a collection of modules and fully documented applications, such as optimization algorithms and functions. There is a large software and research community around Python that develops and tests a wide range of applications that could be used to implement levels 1, 2, and 3 described in [

39]. Moreover, the EnergyPlus API used in this research allows Python code to call and use EnergyPlus as a function, with almost unlimited possibilities for new technologies and model simulations, the implementation of new algorithms, and full statistical analysis and database management using existing modules and applications already developed in Python with free access and support. Finally, communicating EnergyPlus with Python is easier with the EnergyPlus API than with the software for MATLAB for communicating and co-simulating with EnergyPlus. The capability of Python with an API to call EnergyPlus as a function provides a powerful platform for building performance simulations of adaptive façades.

From the examples described in

Section 4, although from an energy point of view, unbalanced insulation (Case B) is more effective than balanced insulation (Case A), the adoption of an unbalanced insulation design alternative depends on local regulations and the convenience after a comparative cost analysis is made (energy savings versus the amount of insulation costs), among other technical issues, such as thermal bridging risks. In countries like Chile, regulations and standards are based on the amount of insulation that walls must provide according to the climate zone where a projected building will be constructed. An unbalanced insulation design option could lead to an insulated wall that falls below the local regulations, and the rest of the walls exceed the standard.

The example described in

Section 4, in Case D, illustrates the potential of an adaptive façade in its opaque and glazed parts to reduce energy demand towards 15 kWh/m

2-year or less, expected for an nZEB building. The energy reduction could be higher if more states for the EC were considered. Additional improvement could be achieved if an algorithm such as Receding Horizon Control (RHC) was used to command the EC switching decision from one state to another, providing a solution to an optimization problem. In the example of

Section 4, the EC switched when the Incident Solar Radiation exceeded a certain threshold (“rule-based” control strategy), and this was not the result of a simultaneous optimization problem solution, considering the insulation thickness and the EC state.

6. Conclusions

A simplified office model for simulating a variable-thermal-resistance façade was proposed based on the validated model of BesTest Cases 900 and 900FF. A minor modification of BesTest Case 900 was made by adding the EnergyPlus SurfaceControl:MovableInsulation class list and removing the Wood Siding present in the Case 900 model, obtaining a model similar to an EIFS with variable thermal resistance. The model and the EnergyPlus “SurfaceControl:MovableInsulation”class list used were quantitatively validated, and the process was fully documented, including EnergyPlus code modification. Moreover, the validation process allowed the discovery of an EnergyPlus software bug for the mentioned class list. The error condition and an example were reported to EnergyPlus, including a partial solution for using the class list. The bug was confirmed and the partial solution validated by EnergyPlus, after which the final solution was implemented in the following versions of EnergyPlus.

The results for the converted BesTest Case 900 and BesTest 900FF, shown in

Table 3 and

Table 4, were within the range of software comparison results presented in [

48], so the converted model (coded in EnergyPlus version 9.5.0) was validated according to those criteria. This was expected because the only difference between the validated model and the converted model is the new version of EnergyPlus (version 9.5.0) used in the converted model code, also considering that the conversion was performed using an EnergyPlus version conversion program.

The results for the Static model and the Adaptive model, shown in

Table 5 and

Table 7, were statistically compared using “goodness-of-fit linear regression”. The R

2 values presented in

Table 6 and

Table 8 show that the Adaptive model behavior was equivalent to the Static model behavior, so the proposed Adaptive variable thermal resistance model, which uses the EnergyPlus “SurfaceControl:MovableInsulation”, was successfully validated according to the software comparison criteria and considering the output variables used in BesTest Case 900 and Case 900FF (annual heating, annual cooling, peak heating, peak cooling, maximum annual hourly zone temperature, minimum annual hourly zone temperature, and average annual hourly zone temperature).

The example presented in

Section 4 was simulated in one climate only. Considering that the energy reduction potential of an adaptive façade is climate-dependent, changes in the adaptive façade performance are expected when changing the location to another climate. Further research could evaluate the results of the Adaptive model described in this research for different climates and with different layers for the building construction envelope, comparing them with a Static model and also addressing the thermal bridging effect in a variable-thermal-resistance model. A second limitation of this study is the use of a simplified geometry instead of a complete building example. Since the variable-thermal-resistance technology is still under development, it is also desirable to have a study of the potential of this technology for different full-scale building topologies (i.e., buildings with different Window-to-Wall Ratios and orientations) and compare cooling and heating energy demand parameters such as kWh/m

2-year of each topology with a simplified model based on a BesTest Case, to have a clear view of the possible limitations of using a simplified model for each full-scale building topology. To help better integrate the model into real-world applications, a future experimental validation should be conducted using a real-scale model that incorporates energy consumption data collection for results comparison.

Another limitation of the research is the number of modules considered for unbalanced insulation. Only four modules were considered, and each of them covered the entire North, South, East and West walls. The validated model presented in this study could also be used to investigate the effect of configuring each wall with several small panels to reduce energy demand, thereby improving convection for natural ventilation.

The Adaptive model validated in this research could be used to explore the energy reduction potential of an adaptive façade in its opaque and glazed parts. As shown in the example in

Section 4, the energy demand was reduced from 79 kWh/m

2-year to 36 kWh/m

2-year if both technologies were used simultaneously. The reduction could be higher and move towards the expected 15 kWh/m

2-year or less for an nZEB, if an RHC algorithm is used. In this scenario, the adaptive frequency of a daily change is reduced to 1 h, more states for the EC glazing are considered, and the state switching decision for the EC glazing responds to an optimization problem solved in conjunction with the insulation thickness decision.

The results from the model simulation for various climates and different thermal resistances, presented like those in

Table 10, serve as a reference for developers of variable-thermal-resistance technologies applicable to building façades. Developers could focus on achieving the thermal resistance values that significantly reduce energy demand. Moreover, these findings provide a foundation for the development of tailored variable-thermal-resistance products specifically designed to address particular climate groups.

Emerging technologies or those under development like variable-thermal-resistance adaptive façades could be accelerated if research results yield interesting energy demand reductions that could help achieve building performance goals.