Integration of a Double-Concentrated Solar Cooking System Operable from Inside a Home for Energy Sustainability

Abstract

1. Introduction

2. Materials and Methods

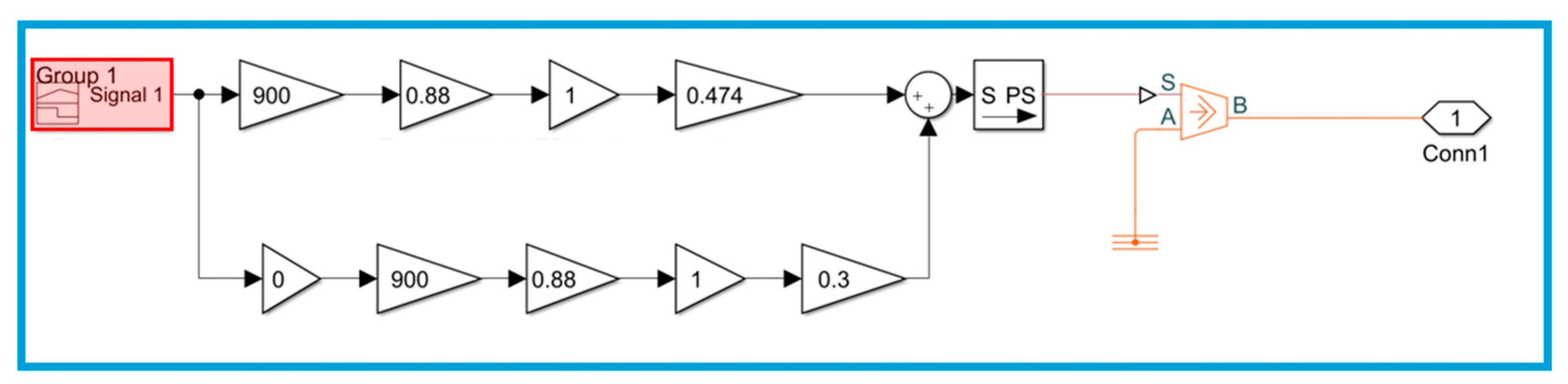

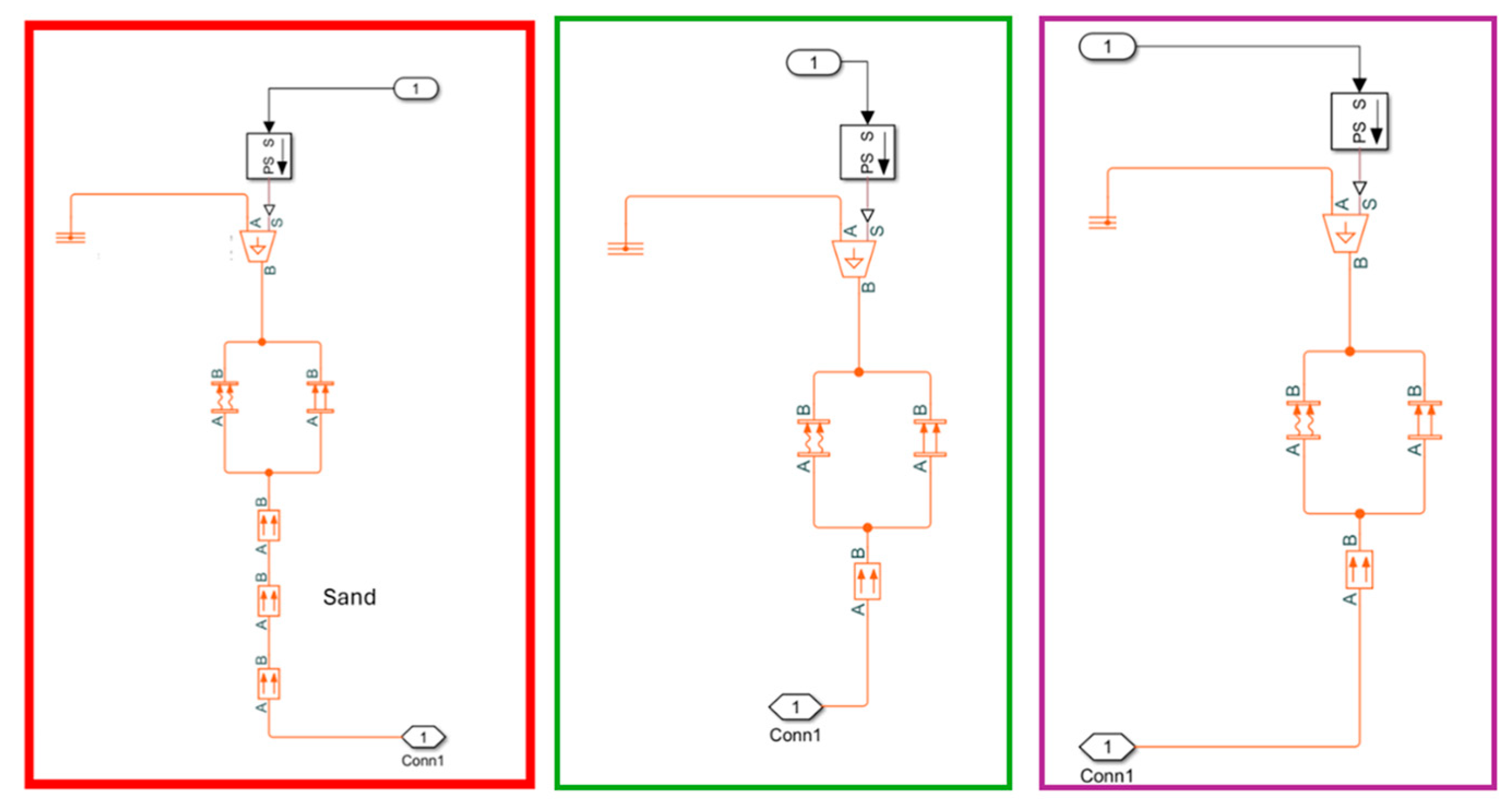

2.1. Simulation and Heat Balance

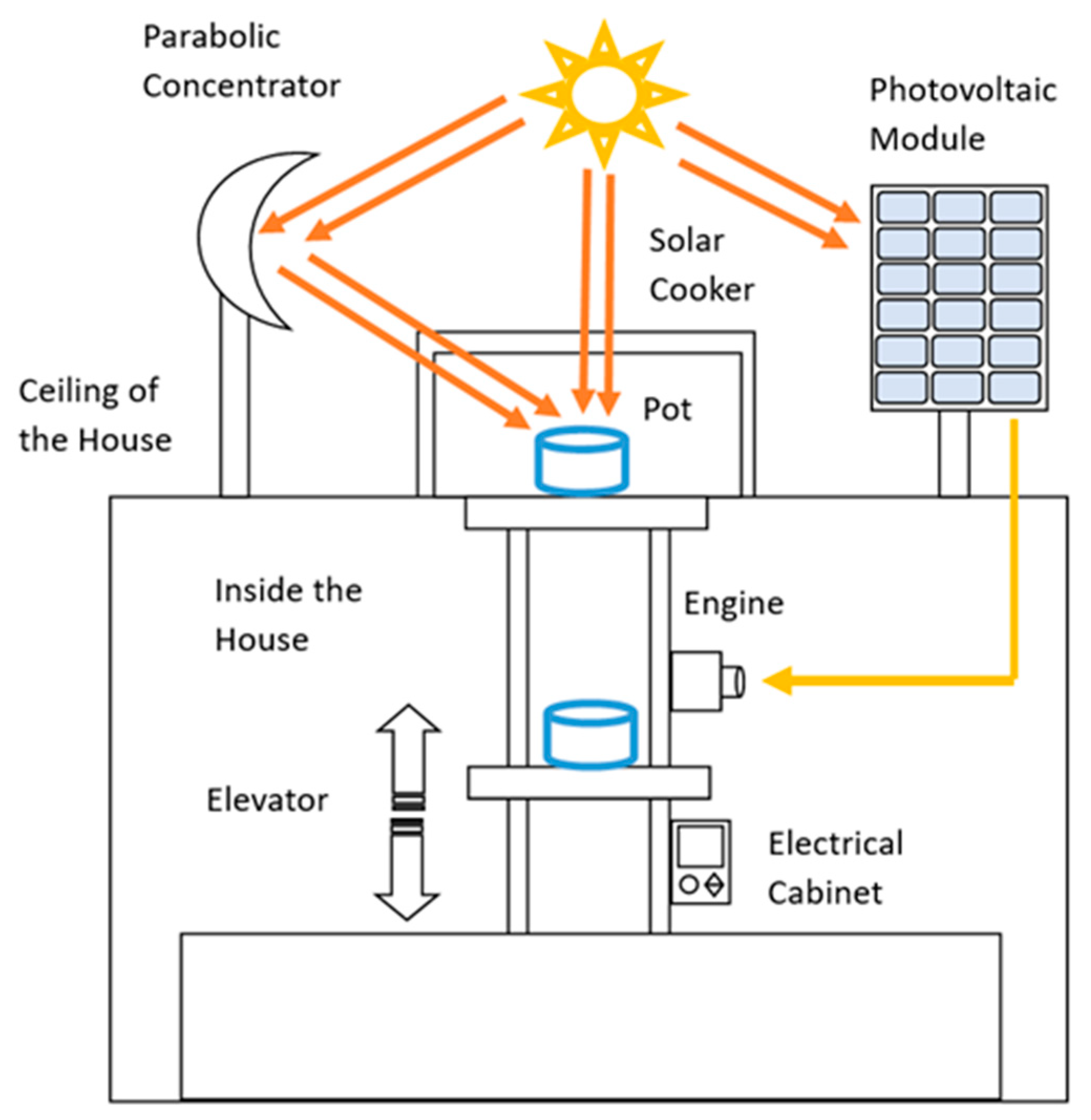

2.2. Systems Integration

2.2.1. Furnace Design

2.2.2. Design of the Parabolic Dish Collector

2.2.3. System Programming and Automation

3. Results and Discussion

3.1. Simulation with MATLAB

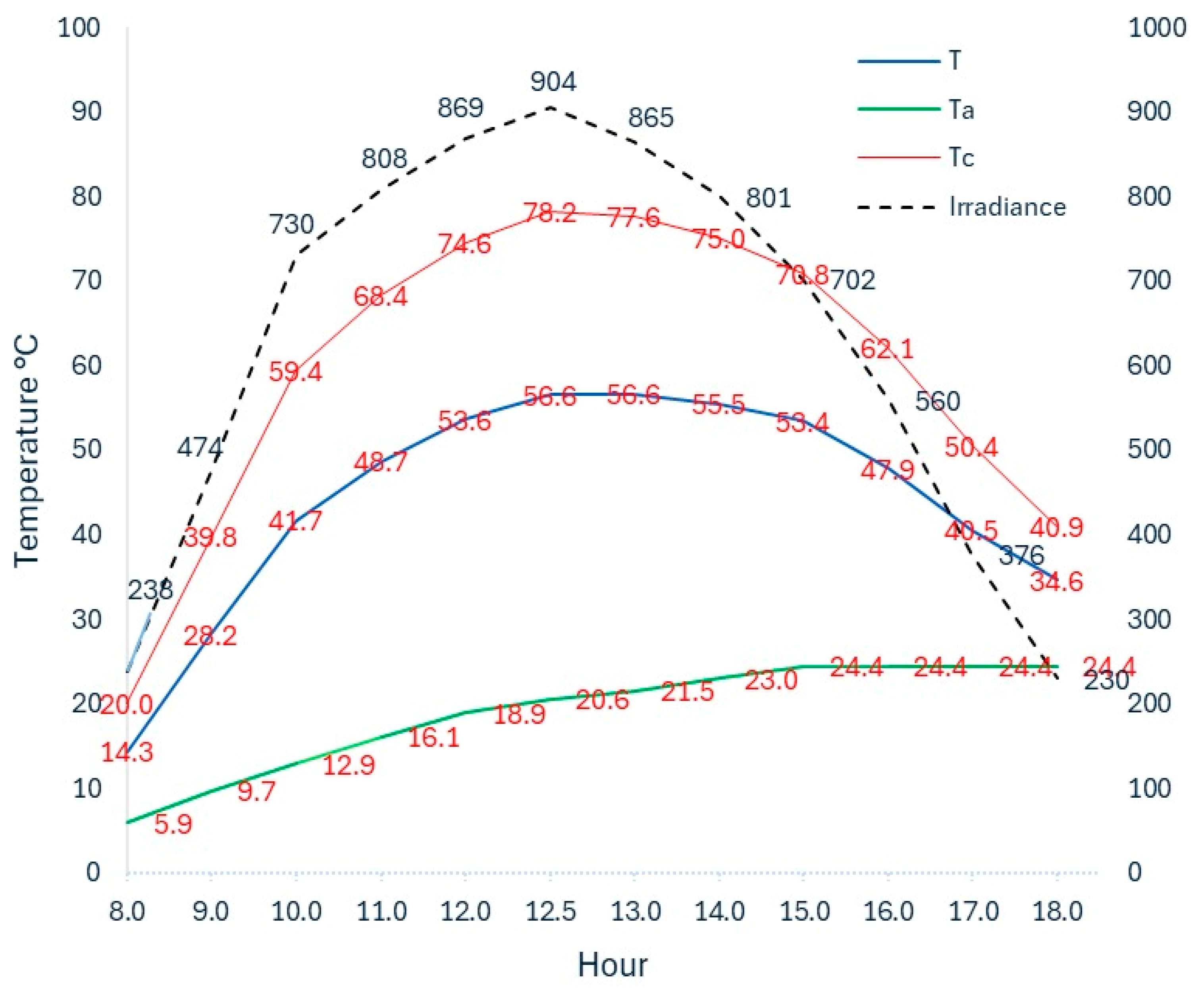

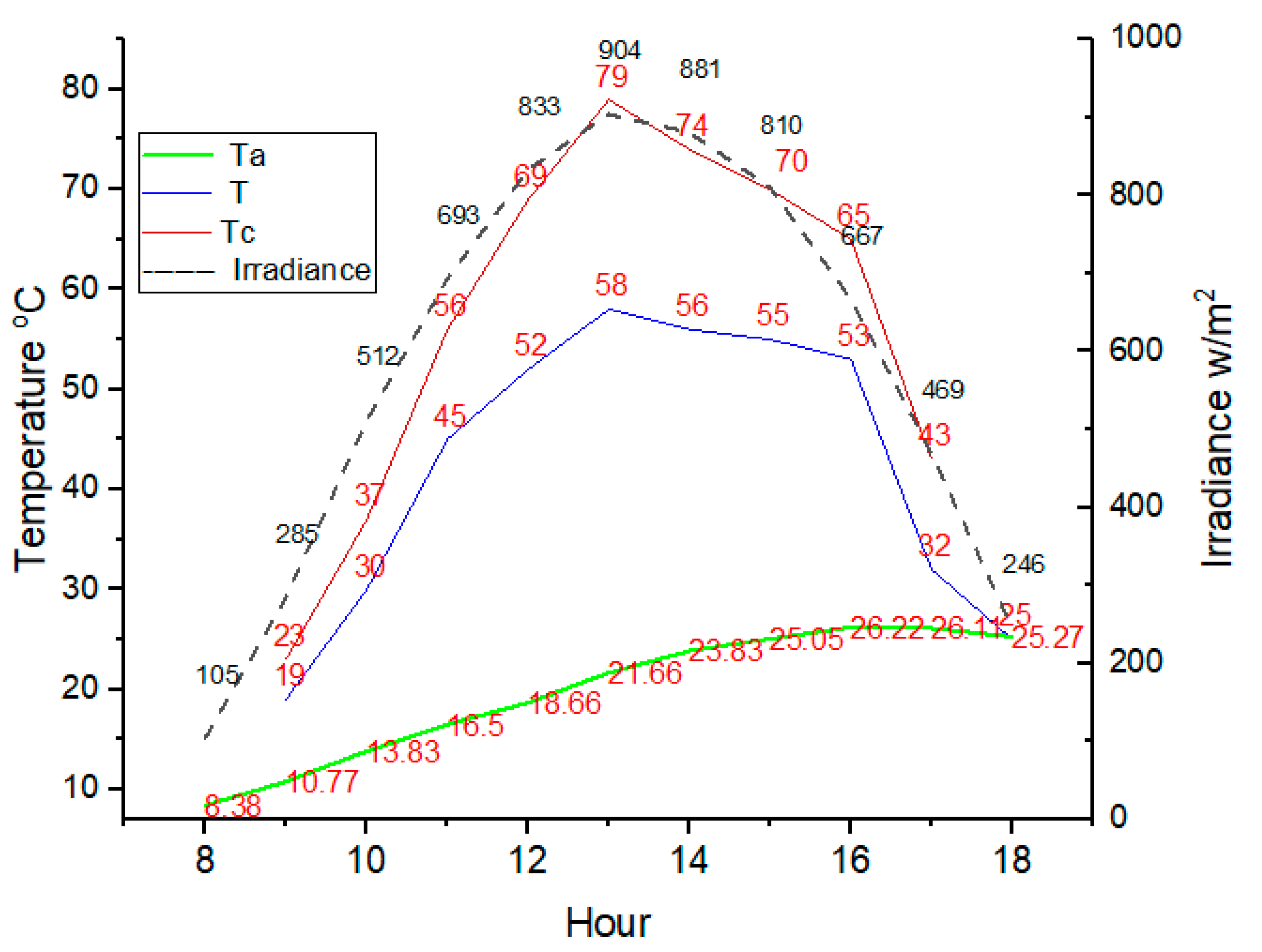

3.2. Thermal Evaluation of the Furnace and PDC

3.3. System Programming and Automation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hao, L.; Liu, N.; Niu, R.; Gong, J.; Tang, T. High-performance salt-resistant solar interfacial evaporation by flexible robust porous carbon/pulp fiber membrane. Sci. China Mater. 2022, 65, 201–212. [Google Scholar] [CrossRef]

- Obaideen, K.; Olabi, A.G.; Al Swailmeen, Y.; Shehata, N.; Abdelkareem, M.A.; Alami, A.H.; Rodriguez, C.; Sayed, E.T. Solar Energy: Applications, Trends Analysis, Bibliometric Analysis and Research Contribution to Sustainable Development Goals (SDGs). Sustainability 2023, 15, 1418. [Google Scholar] [CrossRef]

- Arunkumar, T.; Sathyamurthy, R.; Denkenberger, D.; Lee, S.J. Solar distillation meets the real world: A review of solar stills purifying real wastewater and seawater. Environ. Sci. Pollut. Res. 2022, 29, 22860–22884. [Google Scholar] [CrossRef]

- Han, J.; Dong, Z.; Hao, L.; Gong, J.; Zhao, Q. Poly(ionic liquid)-crosslinked graphene oxide/carbon nanotube membranes as efficient solar steam generators. Green Energy Environ. 2021, 8, 151–162. [Google Scholar] [CrossRef]

- Rodriguez Miranda, S.; Gamboa, G.O.; Zamora-Antuñano, M.A.; Farrera-Vázquez, N.; García-García, R. CFD Evaluation of Thermal Conditioning in a House of Social Interest with a Solar Chimney Arrangement in Guanajuato, Mexico. Processes 2023, 11, 1286. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Z.; Song, C.; Wang, D. Heating load reduction characteristics of passive solar buildings in Tibet, China. Build. Simul. 2021, 15, 975–994. [Google Scholar] [CrossRef]

- Alghoul, S.K.; Rijabo, H.G.; Mashena, M.E. Energy consumption in buildings: A correlation for the influence of window to wall ratio and window orientation in Tripoli, Libya. J. Build. Eng. 2017, 11, 82–86. [Google Scholar] [CrossRef]

- Tiwari, P.; Manas, M.; Jan, P.; Nemec, Z.; Radovan, D.; Mahanta, P. A Review on Microgrid Based on Hybrid Renewable Energy Sources in South-Asian Perspective. Technol. Econ. Smart Grids Sustain. Energy 2017, 2, 10. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Hao, X. Solar cell efficiency tables (version 56). Prog. Photovolt. Res. Appl. 2020, 28, 629–638. [Google Scholar] [CrossRef]

- Jena, A.K.; Kulkarni, A.; Miyasaka, T. Halide perovskite photovoltaics: Background, status, and future prospects. Chem. Rev. 2019, 119, 3036–3103. [Google Scholar] [CrossRef]

- Shahiduzzaman, M.; Hossain, M.I.; Otani, S.; Wang, L.; Umezu, S.; Kaneko, T.; Iwamori, S.; Tomita, K.; Tsang, Y.H.; Akhtaruzzaman, M.; et al. Low-temperature treated anatase TiO2 nanophotonic-structured contact design for efficient triple-cation perovskite solar cells. Chem. Eng. J. 2021, 426, 131831. [Google Scholar] [CrossRef]

- Hossain, M.I.; Shahiduzzaman, M.; Ahmed, S.; Huqe, M.R.; Qarony, W.; Saleque, A.M.; Akhtaruzzaman, M.; Knipp, D.; Tsang, Y.H.; Taima, T.; et al. Near field control for enhanced photovoltaic performance and photostability in perovskite solar cells. Nano Energy 2021, 89, 106388. [Google Scholar] [CrossRef]

- Akhtaruzzaman, M.; Hossain, M.I.; Islam, M.A.; Shahiduzzaman, M.; Muhammad, G.; Hasan, A.K.M.; Tsang, Y.H. Nanophotonic-structured front contact for high-performance perovskite solar cells. Sci. China Mater. 2022, 65, 1727–1740. [Google Scholar] [CrossRef]

- Kim, J.Y.; Lee, J.-W.; Jung, H.S.; Shin, H.; Park, N.-G. High-efficiency perovskite solar cells. Chem. Rev. 2020, 120, 7867–7918. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.I.; Saleque, A.M.; Ahmed, S.; Saidjafarzoda, I.; Shahiduzzaman, M.; Qarony, W.; Knipp, D.; Biyikli, N.; Tsang, Y.H. Perovskite/perovskite planar tandem solar cells: A comprehensive guideline for reaching energy conversion efficiency beyond 30%. Nano Energy 2021, 79, 105400. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. State of the art of solar cooking: An overview. Renew. Sustain. Energy Rev. 2012, 16, 3776–3785. [Google Scholar] [CrossRef]

- Lo Piano, S.; Smith, S.T. Energy demand and its temporal flexibility: Approaches, criticalities and ways forward. Renew. Sustain. Energy Rev. 2022, 160, 112249. [Google Scholar] [CrossRef]

- Chien, F.; Huang, L.; Zhao, W. The influence of sustainable energy demands on energy efficiency: Evidence from China. J. Innov. Knowl. 2023, 8, 100298. [Google Scholar] [CrossRef]

- Arunachala, U.C.; Kundapur, A. Cost-effective solar cookers: A global review. Sol. Energy 2020, 207, 903–916. [Google Scholar] [CrossRef]

- Panja, P.S.; Samdarshi, S.K.; Sagade, A.A.; Jamal, M.R. Inclusivity of thermal performance parameters for evaluation of solar cookers and the necessity of uniformity in the appraisal using generalized test procedure for different designs. Sustain. Energy Technol. Assess. 2024, 68, 103847. [Google Scholar] [CrossRef]

- Misra, N.; Anand, A.; Pandey, S.; Kant, K.; Shukla, A.; Sharma, A. Box-Type Solar Cookers: An Overview of Technological Advancement, Energy, Environmental, and Economic Benefits. Energies 2023, 16, 1697. [Google Scholar] [CrossRef]

- Apaolaza-Pagoaga, X.; Carrillo-Andrés, A.; Jiménez-Navarro, J.P.; Rodrigues Ruivo, C. Experimental evaluation of the performance of new Copenhagen solar cooker configurations as a function of solar altitude angle. Renew. Energy 2024, 229, 120782. [Google Scholar] [CrossRef]

- Aquilanti, A.; Tomassetti, S.; Coccia, G.; Muccioli, M.; Di Nicola, G. Experimental characterization and performance comparison of four prototypes of panel solar cooker for low to high sun elevations. J. Clean. Prod. 2023, 390, 136158. [Google Scholar] [CrossRef]

- Kumar Goyal, R.; Eswaramoorthy, M. Theoretical and experimental analysis of box-type solar cooker with sensible heat storage. Sol. Energy 2024, 268, 112273. [Google Scholar] [CrossRef]

- Angappan, G.; Pandiaraj, S.; Alrubaie, A.J.; Muthusamy, S.; Said, Z.; Panchal, H.; Katekar, V.P.; Shoeibi, S.; Kabeel, A.E. Investigation on solar still with integration of solar cooker to enhance productivity: Experimental, exergy, and economic analysis. J. Water Process Eng. 2023, 51, 103470. [Google Scholar] [CrossRef]

- Thamizharasu, P.; Shanmugan, S.; Gorjian, S.; Pruncu, C.I.; Essa, F.A.; Panchal, H. Improvement of Thermal Performance of a Solar Box Type Cooker Using SiO2/TiO2 Nanolayer. Silicon 2020, 14, 557–565. [Google Scholar] [CrossRef]

- Hosseinzadeh, M.; Faezian, A.; Mirzababaee, S.M.; Zamani, H. Parametric analysis and optimization of a portable evacuated tube solar cooker. Energy 2020, 194, 116816. [Google Scholar] [CrossRef]

- Gautam, A.; Saini, R.P. A review on sensible heat based packed bed solar thermal energy storage system for low temperature applications. Sol. Energy 2020, 207, 937–956. [Google Scholar] [CrossRef]

- Kumar, K.H.; Daabo, A.M.; Karmakar, M.K.; Hirani, H. Solar parabolic dish collector for concentrated solar thermal systems: A review and recommendations. Environ. Sci. Pollut. Res. 2022, 29, 32335–32367. [Google Scholar] [CrossRef]

- Abubakkar, A.; Selvakumar, P.; Rajagopal, T.; Tamilvanan, A. Development of concentrating dish and solar still assembly for sea water desalination. Mater. Today Proc. 2021, 45, 974–980. [Google Scholar] [CrossRef]

- Alnaqi, A.A.; Alsarraf, J.; Al-Rashed, A.A.A.A. Numerical investigation of hydrothermal efficiency of a parabolic dish solar collector filled with oil based hybrid nanofluid. J. Taiwan Inst. Chem. Eng. 2021, 124, 238–257. [Google Scholar] [CrossRef]

- Lentswe, K.; Mawire, A.; Owusu, P.; Shobo, A. A review of parabolic solar cookers with thermal energy storage. Heliyon 2021, 7, e08226. [Google Scholar] [CrossRef] [PubMed]

- El-Khozenadar, H.J.; Khatib, T.; Attaee, B.; El-Khozondar, R.J. Assessment of solar e-cookers social acceptance in Gaza Strip. Sci. Rep. 2022, 12, 17226. [Google Scholar] [CrossRef] [PubMed]

- Lecuona-Neumann, A.; Nogueira-Goriba, J.I.; Famiglietti, A.; Rodríguez-Hidalgo, M.d.C.; Boubour, J. Solar Photovoltaic Cooker with No Electronics or Battery. Energies 2024, 17, 1192. [Google Scholar] [CrossRef]

- Lane, K.; Daouda, M.; Yuan, A.; Olson, C.; Smalls-Mantey, L.; Siegel, E.; Hernández, D. Readiness for a clean energy future: Prevalence, perceptions, and barriers to adoption of electric stoves and solar panels in New York city. Energy Policy 2024, 194, 114301. [Google Scholar] [CrossRef]

- Kumar, S.; Doda, D.K.; Pandey, V.K. Design of solar cooking models to enhance energy utilization and environment protection with their cost–benefit analysis: A case study of an institutional area in the state of Rajasthan, India. Environ. Sci. Pollut. Res. 2024. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Hinken, D.; Rauer, M.; Hao, X. Solar cell efficiency tables (Version 60). Prog. Photovolt. Res. Appl. 2022, 30, 687–701. [Google Scholar] [CrossRef]

- Tina, G.M.; Amr, O. PVSails: Harnessing Innovation With Vertical Bifacial PV Modules in Floating Photovoltaic Systems. Prog. Photovolt. Res. Appl. 2024, 32, 872–888. [Google Scholar] [CrossRef]

- Sivakumar, R.; Sakthivel, G.; Mohanraj, T.; Lakshmipathi, J.; Jeagdesshwaran, R.; Manickavasagam, P.; Govardhan, Y. Solar thermal cooking device for domestic cooking applications: Bridging sustainable development goals and innovation. Heliyon 2024, 10, e38415. [Google Scholar] [CrossRef]

- Wollele, M.B.; Hassen, A.A. Design and experimental investigation of solar cooker with thermal energy storage. AIMS Energy 2019, 7, 957–970. [Google Scholar] [CrossRef]

- Karthikeyan, A.; Nimay, K.S.S.; Dinesh, C.H.; Jayaprabakar, J.; Jacob, A. Performance enhancement of solar thermal systems using phase change materials—A review. Mater. Today Proc. 2023, in press. [CrossRef]

- Bhave, A.G.; Kale, C.K. Development of a thermal storage type solar cooker for high temperature cooking using solar salt. Sol. Energy Mater. Sol. Cells 2020, 208, 110394. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García Uribe, R.A.; Rodríguez Miranda, S.; Vital López, L.; Zamora Antuñano, M.A.; García García, R. Integration of a Double-Concentrated Solar Cooking System Operable from Inside a Home for Energy Sustainability. Energies 2025, 18, 2673. https://doi.org/10.3390/en18112673

García Uribe RA, Rodríguez Miranda S, Vital López L, Zamora Antuñano MA, García García R. Integration of a Double-Concentrated Solar Cooking System Operable from Inside a Home for Energy Sustainability. Energies. 2025; 18(11):2673. https://doi.org/10.3390/en18112673

Chicago/Turabian StyleGarcía Uribe, Raul Asher, Sergio Rodríguez Miranda, Lourdes Vital López, Marco Antonio Zamora Antuñano, and Raúl García García. 2025. "Integration of a Double-Concentrated Solar Cooking System Operable from Inside a Home for Energy Sustainability" Energies 18, no. 11: 2673. https://doi.org/10.3390/en18112673

APA StyleGarcía Uribe, R. A., Rodríguez Miranda, S., Vital López, L., Zamora Antuñano, M. A., & García García, R. (2025). Integration of a Double-Concentrated Solar Cooking System Operable from Inside a Home for Energy Sustainability. Energies, 18(11), 2673. https://doi.org/10.3390/en18112673