1. Introduction

The world is currently facing an unprecedented global food crisis. Since the 1950s, the global population has grown from 2.5 billion to 8 billion and is projected to exceed 9 billion by 2050 [

1]. This exponential growth has compounded the worldwide problem of food production, making food security a global focus for sustainability [

2]. Compared to the 2014 baseline, the percentage of the human population suffering from malnutrition increased by 10.6% and 10.8% in 2015 and 2018, respectively [

3]. Hence, investments in agriculture have been increasing to reduce global hunger and ensure food security [

4]. In South Korea, arable land for growing crops is scarce, as two-thirds of the country is comprised of hills and mountains [

5]. This impediment to an open-field agricultural system coupled with the seasonal variation of outside weather conditions has invigorated the greenhouse industry [

6]. Although greenhouses provide a steady environment for meeting global food demand, maintaining profitable business operation is severely hampered by the high costs of heating and cooling [

7].

Primitively, the heating energy used in the agricultural sector is derived from fossil fuels, rendering the agricultural sector responsible for one-third of global greenhouse gas emissions [

8]. For instance, 80–90% of the heating energy in South Korea comes from oil-based heaters [

9] and, before joining the International Energy Agency (IEA), the country was ranked sixth in the world for oil consumption [

10]. As a requirement from all IEA members to work toward global energy stability, the South Korean government introduced several policies, one of which is the “2030 Greenhouse Gas Roadmap” detailing a plan to reduce carbon dioxide (CO

2) emissions by 3.6 million tons from six major sectors, including the agricultural sector [

11]. Moreover, during the United Nations (UN) conference of parties convened in Paris in 2015, the South Korean government committed to advancing renewable energy systems (RESs) as part of its pledge to contribute to the global effort to limit the average temperature increase to 1.5 °C by 2050 [

12]. This initiative aims to achieve a 20% increase in RESs, develop energy-independent cities, and promote the widespread adoption of photovoltaic thermal (PVT) collectors [

13].

The main obstacle to increasing RESs in most sectors is the difference between the demand for thermal energy and the availability of renewable energy sources that varies by season. For instance, the winter temperature in South Korea can be as low as

20 °C, and the summer temperature can be more than 30 °C [

5], creating an imbalance that influences the energy consumption pattern in most buildings including greenhouses. To overcome the challenge of seasonal mismatch between thermal energy demand and supply in the heating and cooling energy, different thermal energy storage (TES) systems are gaining popularity [

14,

15,

16]. In greenhouse applications, TES holds the potential for reducing loss and achieving significant energy savings [

17] and the suitable choice is influenced by factors like storage capacity, duration, and the required temperature for energy supply and demand. While short-term TES (STES) like phase change materials and tank TES (TTES) are designed to meet the heating load for some periods, long-term TES (LTES) like borehole TES (BTES), pit TES (PTES), and aquifer TES (ATES) cover the imbalance between solar energy generation and heating energy requirements [

18].

Extant studies on the implementation of hybrid renewable energy and thermal energy storage (HRETESS) differ depending on the available technologies, the needed energy levels, and the accessibility of renewable energy sources. Saloux et al. [

19] investigated the sizing and control of a BTES and two TTES within a solar district heating system. The study revealed that by decreasing or increasing the TTES volume, energy savings up to 36% can be achieved. In China, a pilot ATES is designed and implemented for greenhouse heating, utilizing solar energy stored in the soil [

20]. In comparison to other conventional solar heating systems, the integrated systems achieved energy savings of 27.8 kWh/m

2 annually when maintaining the greenhouse temperature above 12 °C throughout the year.

Irrevocably, the use of heat pumps in net-zero energy building (NZEB) application is steadily increasing, driven by the installation of various HRETESSs, which support the continuous operation of heat pump systems, alongside the abundant availability of thermal energy in the environment [

21]. Some notable studies have implemented heat pumps with different HRETESS configurations and evaluate the system performance. Yildirim et al. [

22] tested a hybrid system that included photovoltaic (PV) and ground-source heat pump (GSHP) for a net-zero energy greenhouse (NZEG) located in Turkey. The ratio of the PV electricity generated to the greenhouse’s energy demand (heating, cooling, and lighting) is very high and the electricity generated met the greenhouse energy demand by 33.2–67.2% in summer [

22]. Similarly, Jradi et al. [

23] assessed an underground soil-based thermal energy storage system (UTES) integrated with a PV-air source heat pump (PV-ASHP) system to supply heating needs to a 1000 m

2 residential floor in Denmark. The overall system heating coefficient of performance (COP

sys) is approximately 4.76, with energy efficiencies for a standalone PV system, combined PV-ASHP system, and PV-ASHP system incorporating a UTES to be 5.88%, 19.1%, and 22.2%, respectively.

Amidst all this, there is a growing adoption of hybrid heat pumps (HHPs) to address the limitations of single-source heat pumps. Paradoxically, ASHPs are designed to provide higher temperatures but have lower efficiency during the winter period as a result of the low outside temperature. An early study by Ito et al. [

24] used outside air and water sources simultaneously to produce hot water. The dual heat sources achieve a higher heating coefficient of performance (COP

h) when both outside air and water sources are efficiently utilized until their combined temperature equals the evaporation temperature of the ASHP. Meanwhile, Kim et al. [

25] explored the energy-saving capabilities of a hybrid GSHP utilizing a thermal effluent source for greenhouse heating in South Korea. Three greenhouse growth conditions with low, medium, and high temperatures are investigated, and their thermal performance and energy usage during the heating season are contrasted. The results suggest that the hybrid GSHP could realize 17–20% greater energy savings compared to the conventional GSHP system.

Undoubtedly, greenhouses, employed in controlled-environment agriculture, have the potential to diminish carbon footprints by incorporating RESs, yielding positive outcomes for both the environment and farmers [

26]. The integration of TES with RESs enhances energy management efficiency by storing surplus energy during periods of excess capacity and releasing it during high demand. This reduces and optimizes overall energy usage. However, full-scale implementation of the integrated systems in the agricultural sector has been elusive. Moreover, studies on the performance of multi-TES systems with different renewable energy sources are currently lacking in the literature. Additionally, integrating HRETESSs in greenhouses offers a viable solution to lessen reliance on fossil fuels and improve energy efficiency given the pressing need for sustainable agricultural practices and the policy-driven push for the adoption of renewable energy across all sectors. Greenhouses can save a significant amount of energy while preserving ideal growing conditions by utilizing solar thermal (ST) and PVT collectors in conjunction with HHP and TES technology. The performance of such integrated systems in practice, especially in countries like South Korea that experience large seasonal fluctuations, is still a crucial research topic. By experimentally assessing a HRETESS installed in a NZEG in Yeoju-si, in the northwestern part of South Korea, this study helps bridge this knowledge gap. The results provide valuable insights regarding operational viability, system efficiency, and the possibility of expanding HRETESSs in other agricultural sectors to support energy independence and sustainable food production.

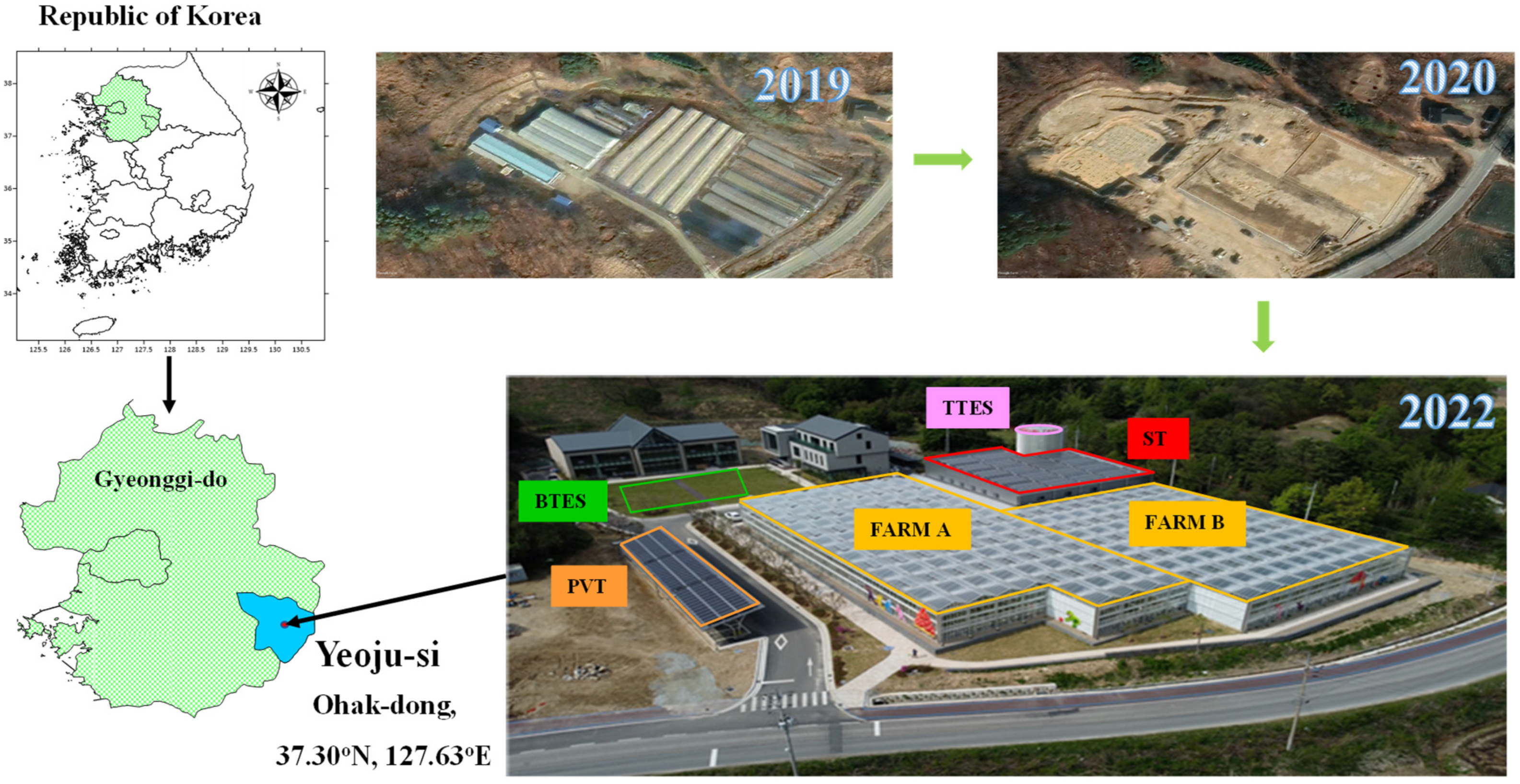

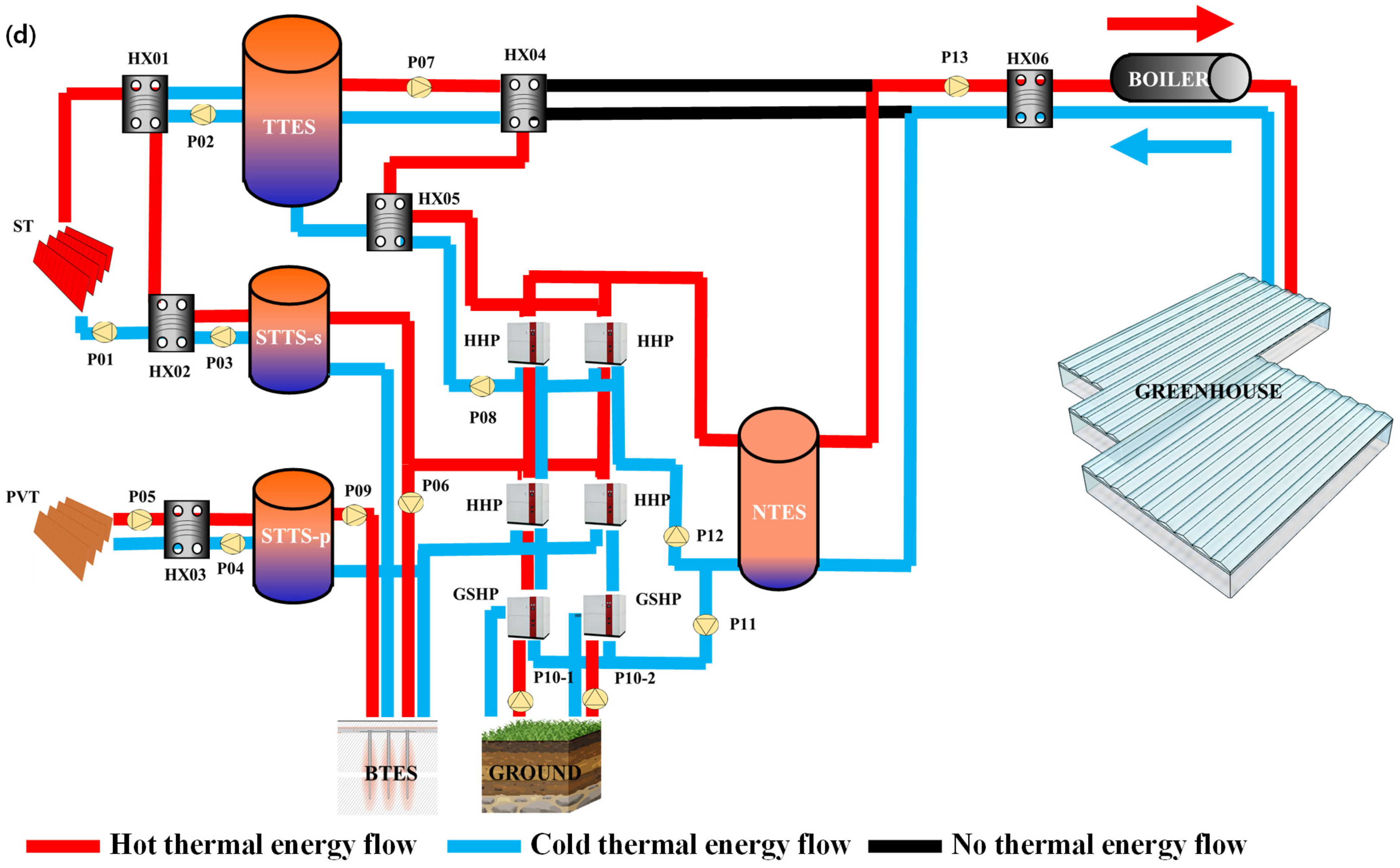

Thus, this paper presents the build-up and long-term performance test of a full scale HRETESS installed at Purme Social Farm (PSF) in Yeoju-si, South Korea, with emphasis on the TES performance, COP, and solar fraction. The HRETESS integrates solar and geothermal energy to meet the greenhouse thermal and electrical load. The generated electrical energy from the PVT is stored in battery packs, while the generated thermal energy from the PVT, ST, and heat pump systems is stored in a TTES, BTES, and night TES (NTES). Remarkably, the HRETESS reckoned on the strength of HHP systems by using the TTES and BTES as heat sources in the winter to provide heating energy and acting as an ASHP in the summer to provide cooling energy to the greenhouse. This study is distinguished by its real-world implementation and performance evaluation of a fully integrated, full-scale HRETESS within a commercial greenhouse environment, an aspect currently lacking in the literature, which predominantly depends on simulations or small-scale trials. The study examines the significant deficiency in long-term empirical data about solar thermal efficiency, seasonal COP fluctuations, and the function of thermal storage in facilitating net-zero energy objectives for agricultural facilities. The findings of the study offer useful insights for enhancing renewable energy adoption in the agriculture sector across diverse climatic conditions.

3. Results and Discussion

PSF is designed to be an innovative solution to existing greenhouse structures that rely on fossil fuels in South Korea. The design is uniquely like the world-known Drake Landing Solar Community in Canada [

31], with the exclusion of the STES,—which stores only cold water—and the inclusion of the TTES and PVT collector. Its construction was completed in June 2021, apart from the PVT collector, which started operation in June 2022. A summary of the integrated operation of the HRETESS is presented in

Table 2, and the detailed results for each component of the HRETESS are explained in the following sub-section. The thermal losses presented in

Table 2 are calculated as the difference between the thermal energy supply to each loop and the actual heat consumed by the loop.

The average COPsystem during the first year decreases from 3.6 to 3.5. This reduction is attributed to the decrease in heating energy supplied to the greenhouse through the heat pump, from 543.4 MWh to 533.2 MWh, and the decrease in minimum outside temperatures from −18 °C to −20 °C. The decrease in outside temperatures also contributes to an increase in boiler consumption, rising from 28.3 to 59.5 MWh, and a decrease in solar energy supplied from the TTES, declining from 20.9 to 20.3 MWh, to meet the greenhouse heating energy demand. Consequently, there is a reduction in the solar fraction, decreasing from 41% in the first year to 37% in the second year. Hence, the investigated system directly produces 3.4% of the total heating energy supplied to the greenhouse from solar energy, 89.3% indirectly through electricity consumption from the heat pumps, and 7.3% from boiler consumption.

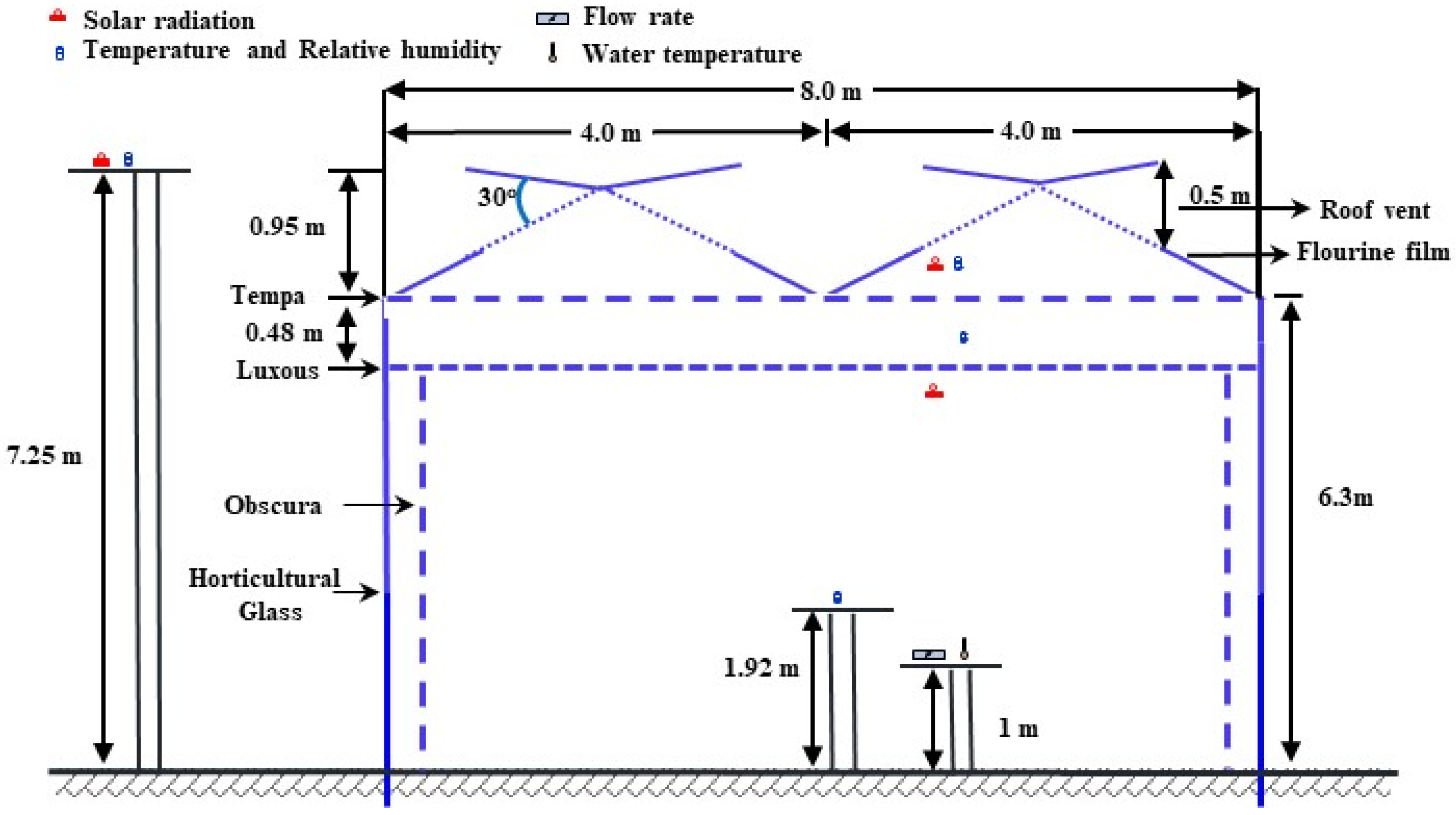

3.1. Solar Thermal Systems

During the period of investigation, the monthly solar energy incident on the ST collector ranged from 56.3 to 156.3 kWh/m

2 while that on the PVT collector ranged from 36.0 to 127.8 kWh/m

2. Based on the gross area of the ST and PVT collectors, the total incident solar energies on the ST and PVT collectors are 798 and 57 MWh, respectively, and the collected thermal energies by the ST and PVT collector loops are 381 and 24 MWh, respectively. As shown in

Figure 5, the mean monthly efficiency of the ST collector ranged from 25.3% to 68.5%, with the peak occurring in July 2022 when the total acquired solar energy from the ST collector is 40.8 MWh. Similarly, for the period when the PVT collector is in operation, the mean monthly efficiency ranged from 31.9% to 72.2%, with the peak occurring in September 2022 when the total acquired solar energy is 6.1 MWh. In the years 2022 and 2023, the average efficiencies of ST collectors decreased from 47% to 42% and over the study period when the PVT was in operation, the average efficiency was 46%. The decrease in solar collector efficiency can be attributed to the difference in the study periods. While the first-year data span a complete growth season, including both winter and summer months, the second-year data were limited to only the winter months, resulting in reduced solar energy accumulation.

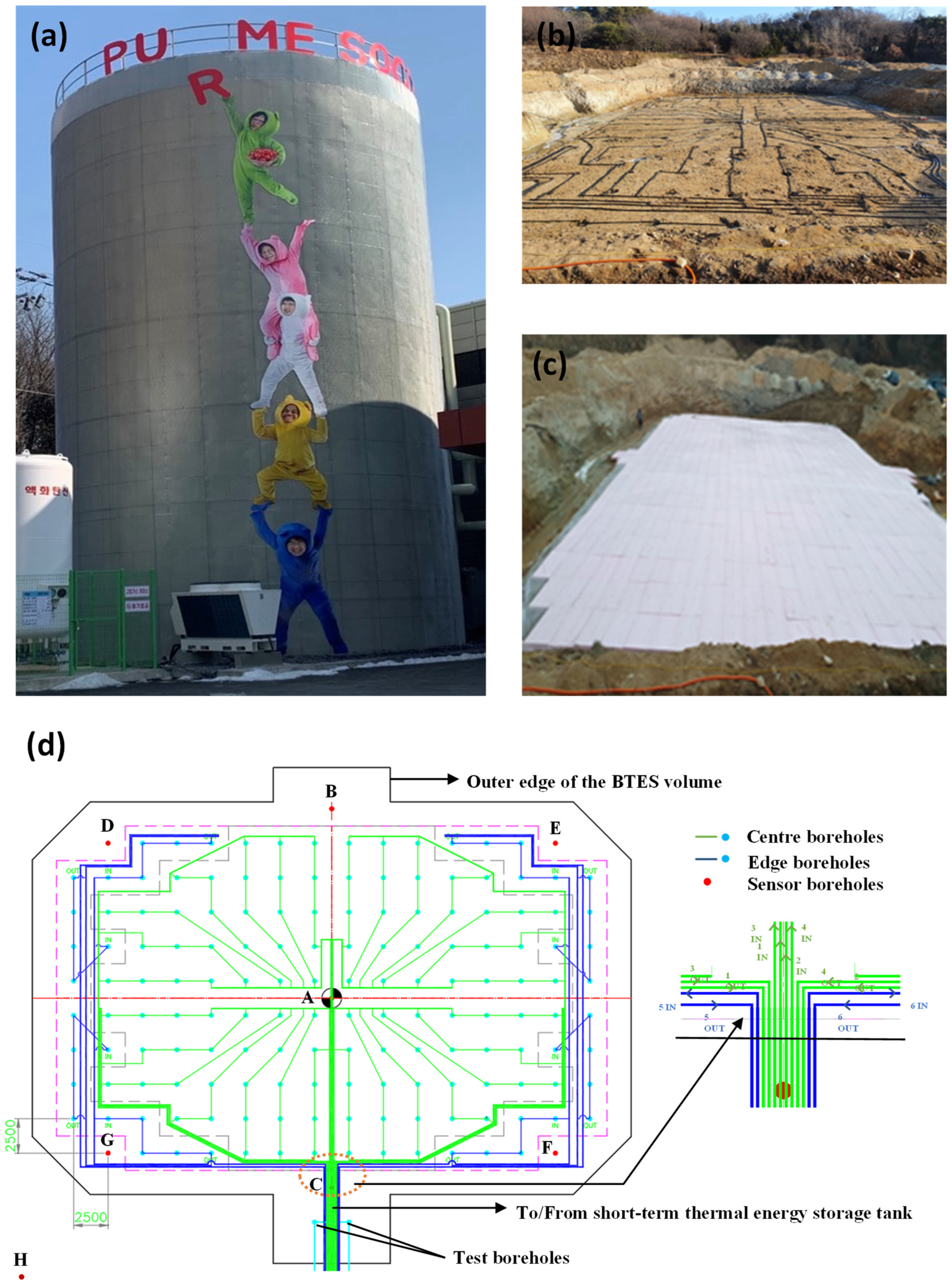

Continuous heat storage occurred in the TTES from the ST collector, and gradual heat storage occurred in the BTES from the ST and PVT collectors. During the solar energy storage period in the TTES and BTES, 64.8% of the thermal energy acquired from the ST collector is stored in the TTES, 11.6% is stored in the BTES, and 23.6% is lost in the ST collector loop pipe. Similarly, 92.5% of the solar energy acquired from the PVT collector is stored in the BTES and 7.5% is lost in the PVT collector loop pipe. The lower heat loss from the PVT collector is due to the lower temperature of the PVT loop compared with the ST loop. The TTES operates with a high degree of thermal stratification to allow the topmost node with the highest temperature and solar heat to be available for a direct heat supply to the greenhouse in early winter.

3.2. Thermal Energy Storage Systems

Figure 6 shows the mean monthly storage temperature of all TES systems, calculated as the average temperature of all sensors across the TES nodes, ranging from 10 °C to 90 °C. In October 2021, the average TTES temperature is 53 °C and it dropped to ~30 °C in November because of the direct heat supply to the greenhouse that occurred in the previous month. The TTES had a minimum temperature of 15 °C between January and March because of the indirect utilization of the water temperature by HP1 during the heating season. By April, the TTES temperature increased to ~20 °C due to solar absorption from the ST collector and continued to increase until the temperature peaked at ~70 °C. This high-temperature solar heat water is then supplied as a direct heat source at the beginning of winter. The temperature difference between the highest and lowest nodes in the TTES ranged from 40 °C to 70 °C and 10 °C to 60 °C, during the charging and discharging periods, respectively. The TTES and NTES temperatures exhibited a sinusoidal relation but with an opposite trend as shown in

Figure 6. During the summer when the TTES temperature is at the peak of storing hot water, the NTES temperature is at the minimum of storing cold water with temperatures ranging from 15 °C to 17 °C, prepared by the ASHP and GSHP. Regardless of the season, the average BTES, STTS-s, and STTS-p temperatures range between 12 °C

14 °C, 16 °C

26 °C, and 15 °C

30 °C, respectively.

The TES temperature is directly influenced by the charging and discharging of the storage systems.

Figure 7 shows the total energy charge and discharge of the TES system. The variations in the LTTS differed from those of the STTS system. The NTES is designed to satisfy the daily greenhouse loads, and the total thermal energy charged within a given period is almost completely discharged during the same period. The thermal energies of the STTS-s and STTS-p systems are immediately discharged into the BTES when their setpoint temperatures are reached. The sudden fall in the TTES system thermal energy input in July and August is a result of the BTES charging via the STTS-s when the TTES target temperature is reached. Over the investigated months, 247.8 MWh and 60.5 MWh of energy is charged into the TTES and BTES, respectively, and 130.4- and 411.2-MWh energy discharged. The BTES exhibited a higher energy discharge than energy charge because it acted as a source for HP2 during the first year of operation when it is not charged. Naturally, the BTES requires an initial charging period to stabilize the ground temperature. From the total discharge energy from the TTES, 20.3 MWh of energy is directly supplied to the greenhouse in October 2021 and 2022. The total energies charged into the NTES, STTS-s, and STTS-p are 1297.7 MWh, 44.3 MWh, and 22.2 MWh, respectively, while the total energies discharged are 1232.4 MWh, 40 MWh, and 21 MWh, respectively.

The BTES is discharged in the first year when it is not charged by either the STTS-s or STTS-p. Therefore, accounting for the BTES efficiency for each year is difficult. However, during the charging and discharging period, the average efficiency of the BTES is 61.2%. Similarly, the STTS-s and STTS-p charging and discharging occur during the period of BTES charging, so STTS-s and STTS-p storage efficiencies for each year are also difficult to be accounted for. However, within the period when charging and discharging occurred, STTS-s and STTS-p average efficiency are 90% and 95%, respectively. Further, the average storage efficiency of the NTES and TTES over the considered period is 95% and 53%. The LTTS exhibits a lower efficiency than the STTS because the former must be heated to the highest temperature before heat is retrieved. The variation between the charging and discharging periods of the STTS and LTTS influences the storage efficiencies of these systems. The charging and discharging periods of the STTS are shorter, reducing the heat loss from the storage tank and increasing the TES efficiency.

3.3. Heat Pump Systems

The full-scale tests of the heat pump systems under different conditions across the season present a variety of results. In

Figure 8, the average COP

h for HP1, HP2, and HP3 during the heating seasons are 3.6, 2.5, and 3.3, respectively, as illustrated. When comparing these COPs with their respective COP

source values, reductions of 0.4, 0.2, and 0.7 are observed, respectively. HP3 exhibits a higher COP

source reduction. This is primarily due to the fact that more work is required on the source side of the GSHP compared to the source sides of HP1 and HP2, which utilize TTES and BTES heat sources, respectively. The heat source from the TTES also contributed to a higher COP

h for HP1 compared to HP2 assisted with a borehole. This emphasizes the significance of solar energy in the application of heat pumps.

During the cooling season, the average monthly COP

c of the ASHP consistently increases from 1.83, 2.43, and 2.83 in July, August, and September, corresponding to a decrease in the mean monthly outside temperature from 26.9 °C, 25 °C, and 21.2 °C, respectively as depicted in

Figure 9. In contrast, the GSHP records a higher mean monthly COP

c of 5.7, 5.4, and 5.3. This is attributed to the fact that the ground temperature is lower than the ambient temperature, resulting in a relatively higher COP

c for the GSHP compared to the ASHP. During the same period, the COP

source for the GSHP is 3.4, 3.5, and 3.7, respectively. For the three cooling months, the COP

source for the GSHP is 1.5 times higher than the average COP

source for the ASHP, primarily due to the higher power of the source pump in the GSHP. The source pump of the GSHP had a power of approximately 4000 kW, whereas the combined power of the two fans in the ASHP had a capacity of 1.8 kW.

The heat extraction rate differs from the heat rejection leading to a thermal imbalance in the ground. A ground thermal imbalance substantially impacts the soil temperature and causes the ground temperature to vary significantly over time, affecting the thermal performance of the GSHP. This accumulation of unbalanced heat mostly exceeds the thermal diffusivity of the soil. Hence, the soil temperature gradually increases. During the cooling season, there is an approximate 1 °C increase in ground temperature because of heat injection, as depicted in

Figure 10. The ground temperature exhibited a sinusoidal pattern in conjunction with the outside temperature, reaching a minimum value of 15.3 °C before cooling when the outside temperature is 36 °C. However, during the cooling operation at a lower outside temperature of 32 °C, the ground temperature rose to 15.8 °C. This increase in ground temperature persisted as heat is consistently injected into the ground during the cooling operation of the GSHP.

3.4. Integrated System Performance: Long-Term Operational Insights

The efficiency of the long-term thermal energy storage systems—TTES and BTES—is significantly influenced by climatic conditions, as their charging and discharging dynamics are directly linked to solar energy availability and the greenhouse’s thermal energy demand, both of which are location-specific and crop-dependent. For instance, in this study, direct discharging of solar heat from the TTES began in October during nighttime, when the monthly average outdoor temperature fell below 13.6 °C. Had the ambient temperature dropped below 15 °C earlier, discharging from the TTES would have commenced sooner, consequently affecting its seasonal energy storage and retrieval efficiency.

In the case of the BTES, without active thermal charging in the first year, it functioned as a conventional ground-source reservoir: acting as a heat source in winter (being warmer than the greenhouse air) and a heat sink in summer (being cooler than the greenhouse air). However, starting in July 2022, deliberate thermal charging of the BTES using excess solar energy enabled it to store more thermal energy for use during colder months. This thermal pre-conditioning is essential for improving the responsiveness of the HRETESS, especially under sudden weather fluctuations when the TTES alone may not meet the greenhouse’s heating requirements. These findings demonstrate that the seasonal operational performance of both the TTES and BTES, and ultimately the overall system efficiency, is significantly affected by variations in climate—including outdoor temperature patterns, solar radiation levels, and seasonal heating/cooling demand.

The relatively small reduction in solar energy supplied from the TTES during colder periods—despite falling outdoor temperatures—can be attributed to several factors. First, the TTES temperature in the second year was maintained at a higher level than in the first year, resulting in greater thermal reserves available for discharge. Second, the greenhouse setpoint temperature was lowered during colder periods in the second year, reducing overall heating demand and helping preserve the contribution of solar heat, both directly from the TTES and indirectly via heat pumps. Additionally, the control system prioritizes solar-derived heat—whether directly or via heat pumps—before switching to auxiliary heating. The TTES’s high level of insulation further reduces thermal losses to the environment, even at low ambient temperatures, thereby preserving stored energy over extended periods. Nevertheless, this higher TTES temperature contributed to a decline in solar collector efficiency in the second year. As the storage temperature increased, the temperature difference between the ST collector surface and the ambient air widened, resulting in greater heat losses and reduced collector efficiency. However, this operational choice was necessary to ensure sufficient solar energy supply under colder outdoor conditions. Maintaining the same TTES temperature as in the first year would have led to significantly lower usable solar energy. Hence, a trade-off emerged between maximizing the quantity of stored solar energy for heating and minimizing losses from solar collectors. To mitigate this efficiency loss, strategies such as employing advanced selective coatings on solar collectors and implementing dynamic collector control based on real-time TTES temperature conditions could be beneficial.

The higher COP observed for the TTES compared to the BTES is primarily due to the TTES’s ability to maintain higher storage temperatures. This reduces the temperature lift required by the heat pumps, thereby improving efficiency. In contrast, the BTES operates at lower temperatures, requiring more electrical energy to raise the fluid temperature to the required level, which reduces the system COP. Additionally, the integration of HHPs with solar-assisted thermal energy storage greatly enhances the system’s ability to adapt to varying outdoor conditions. The HHPs can dynamically switch between air-source, solar-assisted, and ground-source modes depending on the availability of thermal energy. For example, although solar heat stored in the TTES and BTES is not the primary source during cooling operations, the system is configured to draw from these sources when the cold water supplied by GSHPs or ASHPs is insufficient. This configuration enables the system to maintain stable operation under a wide range of environmental conditions.

These findings have broader implications for climates with more extreme temperature variations. In colder climates, preheated long-term storage (such as BTES) can improve the COP of heat pumps, while in hotter regions, the adaptive use of HHPs—particularly their transition between ASHP and solar-assisted modes—can enhance cooling performance by leveraging seasonal or diurnal solar energy availability. Therefore, the operational principles demonstrated in this study can inform the design of flexible, climate-resilient energy systems for greenhouses and other temperature-sensitive applications worldwide.

To further optimize the system and reduce boiler consumption under decreasing ambient temperatures, several strategies can be implemented:

- ●

Lowering the greenhouse setpoint temperature by 1–2 °C during peak heating periods, without compromising crop health, to reduce overall energy demand.

- ●

Implementing predictive control algorithms to dynamically adjust heat pump operations based on real-time demand and weather forecasts, ensuring priority use of renewable sources.

- ●

Upgrading to solar-tracking ST and PVT collectors, rather than fixed systems, to increase solar energy capture, thereby improving TES charging and system performance during colder periods.

In addition, the incorporation of alternative renewable energy resources, such as biomass and wind energy, can enhance the resilience of the system. Expanding the long-term thermal energy storage capacity would allow for greater accumulation of surplus solar energy, further reducing reliance on auxiliary heating and increasing the solar fraction. Improvements in TTES insulation and optimization of charging strategies would also enhance long-term storage efficiency. Ultimately, sustaining a high contribution of solar energy is essential for meeting net-zero energy goals and ensuring the economic and environmental sustainability of greenhouse operations