Abstract

This study proposes an innovative model for animal waste utilization in the largest Polish meat utilization plant, which assumes an integrated system that processes one part of the meat waste by anaerobic digestion and the second part into meat and bone meal via the hydrothermal method. The solution is based on implementing the concept of industrial symbiosis, using a purposefully directed flow of materials, waste, and energy to create a closed recycling cycle. This study analyzes the key strategic, organizational, and technical circular economy activities that enable the transformation of waste into valuable materials and energy, thanks to the use of closed-loop materials and energy cycles. It estimates the integrated system’s investment costs and economic and environmental outcomes. The presented method allows for biogas production from the bio-fermentation of 160,000 t/y of animal waste; this would more than cover the heat requirements for obtaining 110,000 t/y of meat and bone meal using the hydrothermal method.

1. Introduction

Livestock production and meat consumption are growing worldwide, especially in low- and middle-income countries, due to increased standards of living and population growth [1,2]. The meat supply reached 340 million tons in 2018, 300% more than the amount produced 50 years ago. Pork and poultry meat represent one-third each of global meat consumption, with beef at one-fifth, and the remainder coming from sheep, goats, and other animals [3].

Livestock farming is a significant source of greenhouse gases (GHGs) and contributes around 14.5% of global GHG emissions [4]. It is also a major driver of 10% of anthropogenic freshwater use and biodiversity loss in some areas [5,6]. Proper management of animal waste can minimize the environmental impact of livestock farming [7].

European Union (EU) countries produce 20 million tons of meat waste annually, including 70% low-risk and 30% high-risk material [8]. Caldeira [9] presented a system for calculating the amount of waste produced at the European macro-level. In 2011, the value chains of EU meat and waste producers were (in millions of tons/year) 61.7 tons of consumable meat and 14.2 tons of cumulative meat waste.

Animal waste produced in the EU is mainly processed into meat–bone meal (MBM) [10]. The EU produces 4.5 million tons of MBM annually, which is mainly used as biofuel [11,12] and as a multi-component fertilizer [13,14]. Polish law allows the use of MBM at a maximum dose of 5 tons/hectare, applied every two years. MBM should be applied before sowing and immediately mixed with the soil [13,15,16]. Fertilizing with MBM can decrease GHG emissions by up to 1 ton of CO2 equivalent (CO2eq) per ton of MBM [17]. An EC Regulation [18] permits animal protein obtained from MBM based on specific processing methods. The European Commission decided on 17 August 2021 to allow the feeding of farm animals with MBM based on the principle of cross-feeding (for example, pork meal for poultry and vice versa). Feeding the same type of animal protein to the same species is still prohibited [19,20].

In 2021, Poland produced 4.204 million tons of meat [21]. The amount of animal waste, evaluated according to the methodology [9], was estimated to be 967,000 tons per year, processed into MBM, mainly used as biofuel [22,23]. This allows for energy recovery and an overall GHG savings of 600–1000 kg CO2eq per ton of MBM used, primarily by substituting fossil fuels in the energy sector [17]. Animal waste contains large amounts of organic matter, water, and phosphorus compounds. Their recovery from animal waste is essential for the sustainable utilization of agricultural waste and circular economy (CE) strategies in many countries [24,25].

Meat waste classification and appropriate treatment technologies have been described. Meat waste is defined as whole bodies, animal parts, or animal-derived products not intended for human consumption [18,26,27]. According to [26], meat waste is divided into three categories based on the degree of public health and animal health risk, which determines the various utilization/processing techniques. The first, the high-risk category, includes all animals or parts of animals suspected of being diseased; the second, the medium-risk category, includes animal products recognized as unfit for human consumption. The third, low-risk category, includes carcasses or animal parts unfit for human consumption or due to trading reasons. This category contains heads, feet, feathers, and hides [10]. Long-distance transport of animal by-products raises concerns for biosecurity and the natural environment [28].

Animal waste can also be treated through anaerobic digestion [29]. The yield of anaerobic digestion can be increased, for example, through co-digestion, surfactant addition, pre-treatment, and optimal digester design [30]. Bio-fermentation significantly reduces GHG emissions and produces renewable energy in the form of biogas. In agricultural biogas plants, substrates from crops, raw biodegradable materials, by-products, and meat waste are used [31,32,33]. In 2023, 85,777 tons of Polish slaughterhouse waste were processed through bio-fermentation [34].

This approach promotes the main CE strategies, cleaner production (CP), and sustainable development (SD) [12,35,36]. Implementing industrial symbiosis (IS) at the microeconomic level in production companies leads to the development of strategic CE goals, aiming to maintain the highest value and utility of goods, raw materials, and by-products throughout their life cycles, improving manufacturing systems, reducing the use of natural resources, and providing new reuse and recycling methods for waste [37,38,39]. CP technologies prevent environmental pollution and use renewable materials in all stages of a product’s life cycle. The CP methods include reduction at the source, in-process, on-site, and off-site recycling, and substituting primary resources with waste [35,40,41].

This study proposes an innovative system for managing animal waste at Poland’s largest animal waste utilization plant, assuming the integrated processing of one part of the animal waste through anaerobic digestion and the other part through a hydrothermal method to produce MBM. A model was developed describing the integrated processing system of animal waste into MBM through the hydrothermal method and bio-fermentation into biogas and fertilizer. Key strategic, organizational, and technical CE, SD, and CP activities that consider the conversion of animal waste into valuable materials and energy, developed and implemented according to the new system, were also analyzed. Additionally, variants of the innovative model, estimated investment costs, and the economic and environmental effects of the developed integrated animal waste processing system are presented.

2. Materials and Methods

Proper meat waste utilization is connected with industrial symbiosis (IS), which uses production synergy to develop supply chains, increase economically effective circular loops, and improve resource efficiency through the cooperation of firms in terms of materials, waste, and energy cycles [42,43].

CE model activities involve developing and implementing new systems for product and material flows, using the value chain to manage waste more sustainably and profitably, thereby closing material cycles. High-quality technologies and equipment used for on-site or off-site recycling and reuse of processed waste to obtain bioenergy have facilitated the primary use of materials, reduced energy consumption, and decreased GHG emissions. The CP technologies used include reduction at the source, in-process recycling, waste reduction [44], emission reduction, substitution of natural raw materials with waste, and both on-site and off-site recycling [37,39].

Farmutil HS, the largest Polish meat waste utilization plant, processes 600,000 tons of meat waste annually into MBM using the hydrothermal method (over 60% of Polish meat waste produced). Modernized in recent years, Farmutil’s hydrothermal technology has made its MBM units among the most advanced in European countries. The modernization of the MBM installation, which implemented continuous production lines, reduced production costs by 10% due to lower electricity and steam consumption and more efficient processes. The 14 meat waste collection points are optimally located across Poland, enabling incentivized, high-quality recycling and environmentally safe transport to Farmutil. The OXIDOR system used at the MBM plant can combust all gaseous odors from individual technological operations and air from production rooms (total quantity: 200 million m3/year). This thermal method is the most effective, though expensive and rarely used [22,45]. Its implementation has improved the relationship between Farmutil and the public.

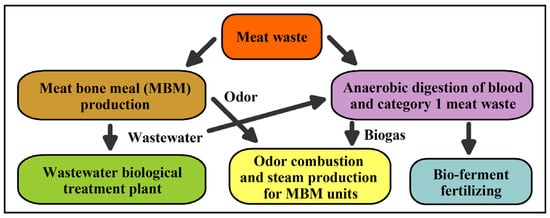

Farmutil’s management system fosters industrial symbiosis (IS). IS traditionally operates through separate entities, engaging in complex resource exchange interactions (materials, water, energy, and by-products). It allows for the full utilization of by-products through networks of independent enterprises exchanging by-products and sharing other common resources, thereby increasing processing efficiency and providing both economic and environmental benefits [35,37]. In the consortium management system, the transition towards CE, design for environment (DFE) [43,46,47], and CP are the main strategies used to promote CE. The basic integrated model of animal waste utilization proposed for Farmutil is presented in Figure 1 [22,48].

Figure 1.

The basic integrated model of animal waste utilization proposed for Farmutil HS.

Biogas production activities are compatible with a circular economy, mainly consisting of using waste in the anaerobic digestion process. The proposed solutions aim to bio-ferment as much meat waste as possible, especially because meat waste processed by hydrolysis into MBM can be difficult and expensive. The anaerobic digestion process should particularly target waste such as high-risk category meat waste, animal blood, bristles, hatching waste, wasted eggs, manure, screenings, waste fats, and sewage sludge. Another main advantage is replacing as much of the natural gas as possible that is used in MBM production with biogas generated during bio-fermentation.

2.1. Data Analysis

The proposed model assumes the possibility of utilizing meat waste at various scales, with different proportions of waste processed by the hydrothermal method into MBM and the bio-fermentation method. As a result, the amounts of biogas, wastewater, and odors produced may vary when using the integrated model. The equations below allow the calculation of these amounts at various scales of waste processing.

where:

QAW = QAW1 + QAW2

NAW2 = NAW1 · QAW1

BAW3 = BY · QAW2

- NAW1—Quantity of natural gas consumed when animal waste is processed with the hydrothermal method into MBM (as CH4 m3/t)

- NAW2—Quantity of natural gas consumed when animal waste is processed with the hydrothermal method into MBM (as CH4 m3)

- QAW—Quantity of animal waste processed (t/y)

- QAW1—Quantity of animal waste processed with the hydrothermal method into MBM (t/y)

- QAW2—Quantity of animal waste processed with the bio-fermentation method (t/y)

- BAW3—Biogas production when the integrated system is used (as CH4 m3/y)

- BY—Biogas yield from meat waste (as CH4 m3/t)

Equation (1) indicates the amount of processed animal waste QAW. Equation (2) calculates the quantity of natural gas used for MBM production at different animal waste capacities QAW1, and Equation (3) shows the biogas quantities obtained by the anaerobic digestion of animal waste at different animal waste capacities QAW2. A value of BAW3 > NAW2 means that, in the integrated model, biogas production is higher than natural gas consumption at a determined capacity QAW2 of waste processed by the bio-fermentation method and biogas yield BY from processed waste, which are independent variables. Equations (4) and (5) show the quantities of wastewater WAW3 and odors OAW3 obtained by the integrated system of waste processing, at the determined capacity QAW1 of waste processed into MBM and by anaerobic digestion QAW2, respectively. Equation (6) defines the amount of natural gas consumed in the integrated waste processing system.

where:

WAW3 = WAW1 · (QAW1 − QAW2)/QAW1

OAW3 = OAW1 · (QAW1 − QAW2)/QAW1

NAW3 = NAW1 ∙ (QAW1 − QAW2)

- WAW1—Quantity of wastewater from MBM (t/y)

- WAW3—Quantity of wastewater from MBM when the integrated system is used (t/y)

- OAW1—Quantity of odor emitted from MBM produced with the hydrothermal method (m3/y)

- OAW3—Quantity of odor emitted from MBM when the integrated system is used (m3/y)

- NAW3—Quantity of natural gas consumed when the integrated system is used (as CH4 m3/y)

2.1.1. Estimated Amounts of Biogas Obtainable from Meat Waste

Biochemical methane potential (BMP) tests were used to determine the methane yield of meat waste, indicating its biodegradability and its potential to produce methane via anaerobic digestion. This assesses the substrate quality and predicts the methane production by full-scale biogas plants. Indicators were obtained during laboratory tests of the bio-fermentation process of meat waste [49,50]. In [51], different biogas feedstock analysis methodologies were described, including the following essential analyses: pH, total solids/dry matter, volatile solids/organic dry matter, chemical oxygen demand, total Kjeldahl nitrogen, ammonia nitrogen, and biochemical methane potential. The biogas yield mainly depends on the type of waste. In the case of soft meat waste and bones, it ranged from 229 to 570 m3/t of raw waste. According to [32], the biogas yield was 450 m3 from meat waste and 316 m3 from sewage sludge per 1 t of dry organic mass.

2.1.2. Estimation of the Integrated System of Meat Waste Utilization in Terms of Used Circular Economy Strategic Data

The animal waste utilization method, based on the production of meat–bone meal with the hydrothermal method, and the integrated system combining the production of MBM with hydrothermal technology and parallel bio-fermentation of animal waste, was compared with assessed circular economy (CE) activities, sustainable development (SD) goals, and cleaner production (CP) methods. CE, CP, and SD activities allow for the development of new products or technologies without significant upfront investment, alongside cross-value chain cooperation. The developed integrated system of meat waste utilization wisely selects resources, technologies, and processes. In this model, CE promotes a series of actions, business models, and measures covering the entire lifecycle of the products and materials, from design through manufacturing, consumption, and waste management.

2.2. Utilization of Meat Waste to Produce MBM

One ton of MBM is obtained from approximately 4 tons of animal waste through hydrothermal technology. Due to the highly diversified types of waste, the characteristics of the produced meat meal also vary. MBM is commonly used in low-cost pet food formulations because of its high protein content. However, its nutrient characteristics can vary greatly, and often, additional processing is required [52]. The methods used to produce meat meals are widely discussed [15,45,53]. After pre-treatment (removing metal parts, grinding, and mixing), the feedstock is sterilized (133 °C, 0.3 MPa, for 30 min). Then, the by-products are dried, and the fat is separated by filtration. The solid fraction MBM from the filtration process is then ground and sieved. These process parameters meet EU conditions [45]. Meat waste is categorized into three risk categories [10,18], which are also used to determine the risk categories of the produced MBM. Possible elimination/valorization methods for MBM include incineration or co-incineration (categories 1–3), landfill (categories 2 and 3), biogas production (categories 1–3 after sterilization treatment), and uses as fuels (categories 1–3), organic fertilizers (categories 2 and 3), and animal feed (category 3). According to [15,53,54], meals can be divided in terms of total protein content (in %): meat meal (MM), 55.0; MBM, 40.0; bone meal (MB), 26.5; blood meal (BM) 89.5; skin meal (MS), 45.0; and liquex meal (ML) 70.0. The antioxidant content should be 100–400 mg/kg.

MBM is thermally decomposed up to approximately 550 °C due to the combustion of organic substances in MBM, as evidenced by the high exothermic effect. The mass loss due to the incineration organic MBM phase is around 76%. The average moisture, phosphorus, and calcium contents of MBM samples were 2.43%, 5.8%, and 7.7%. The combustion heat of MBM is 19 MJ/kg [55]. In other studies, MBM samples were calcined in a chamber kiln. The weight loss was 70.0%, and the phosphorus content ranged from 14.5% to 15.0%. And the calcium ranged from 33.8% to 33.6%. Phase composition studies showed that the main crystalline phase of MBM is hydroxyapatite (Ca5(PO4)3OH), with low quantities of impurities such as SiO2, Ca3(PO4)2, and CaCO3 [24,56]. The phosphorus content in the ash is comparable to that in phosphorites, with 13.2% to 17.2% P [23].

Water removal is significant for rendering, and the produced aqueous stream represents about 65% of the feedstock mass [57,58]. The meat waste charge [23,45] used for MBM production typically contains ground pork bones with dimensions of 1–3 cm and 35.0–45.0% H2O, as well as the following components (in percent of dry mass): organic matter 34.0–39.0; fat 14.0–16.0; protein 18.0–23.0; phosphorus 10.0–14.0; and calcium 28.0–30.0. Its bulk density is 0.85 kg/dm3. The contents of cadmium, mercury, arsenic, chromium, lead, and copper were < 0.1 ppm [59]. These confirm the high quality of the obtained hydroxyapatite ashes and the very low amount of heavy metals [23].

2.3. Bio-Fermentation of Agricultural and Animal Waste

Anaerobic digestion utilizes microbiological processes to degrade organic matter, reduce volatile solid content, generate biogas for energy, and remove pathogens, as anaerobic digestion can deactivate them. The process yield depends on the technology parameters, such as temperature, pH, hydraulic retention time, and matter retention time. Salmonella sp. and Escherichia coli elimination increased as the solid retention time increased [60,61,62].

Anaerobic digestion is a composite reaction divided into four biodegradation stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis [61]. During hydrolysis, organic compounds (lipids, proteins, carbohydrates, etc.) are hydrolyzed into simple compounds (amino acids, sugars, fatty acids, etc.) by hydrolytic microorganisms. During acidogenesis, these hydrolyzed substances ferment into volatile fatty acids (VFA), such as butyric, propionic, acetic, and valeric acids, leading to a pH decrease. Acidogens, containing both facultative microbes and obligate anaerobes, manage this fermentation phase [63]. In acetogenesis, fermented acidogens form acetic acid, hydrogen, and carbon dioxide, with acetate being the main product. Methanogenesis is the final stage of anaerobic digestion, where methane is produced from methanol, acetic acid, hydrogen, and carbon dioxide. Two types of microbes are responsible for this phase: acetolactic methanogens, resulting in two-thirds of all methanation, and hydrogenotrophic methanogens, resulting in one-third of all methane production. The optimal pH for anaerobic digestion is 6.5–7.5 [64]. In an anaerobic digester, ammonia content is important for buffering and stabilizing the pH. However, its concentration in the solution should not exceed 1 g/L [65].

The carbon-to-nitrogen ratio (C/N) indicates the proportion of carbon and nitrogen in organic materials. Nitrogen is essential for microorganisms to multiply and create new cells. The optimal C/N ratio for methane production is 20–30, and this is achieved by mixing materials with different C/N ratios. Key parameters that determine the proper course of methane formation include an anaerobic atmosphere, temperature, pH, the chemical composition of the fermented materials, the homogeneity of the fermented pulp, the retention period of materials in the bio-fermentation tank, and the absence of reaction inhibitors (e.g., excess ammonium nitrogen). Methane production by anaerobic digestion occurs in two temperature ranges: 35–40 °C (mesophilic range) and 50–55 °C (thermophilic range) [66]. Thermophilic digestion produces 25–50% more methane than mesophilic digestion. Anaerobic digestion allows for the production of bioenergy and potential by-products, such as soil biofertilizers [29]. The process occurs naturally in the absence of oxygen and by using various types of materials, such as industrial and municipal wastewater, agroindustrial, municipal, food processing, and vegetal waste, to produce biogas [67,68]. Mesophilic units are more common than thermophilic ones, mainly used for wet digestion due to lower energy requirements for heating [65,69]. Methane formation involves anaerobic microorganisms catalyzing the breakdown of organic substances, followed by the generation of methane and carbon dioxide [70].

The energy demand of a biogas plant depends on factors such as the substrate characteristics, transport, storage, pre-treatment, technology used, and the treatment of biogas and residues [71]. Mesophilic fermentation typically has a positive energy balance, whereas thermophilic fermentation lasts 15–20 days, occurs above 40 °C in closed fermentation chambers, and has a negative energy balance. Biological pre-treatment with Bacillus and Lactobacillus bacteria integrated into the digestion process is an attractive strategy to improve the bio-fermentation of the organic fraction of slaughterhouse wastes [32].

Up to 500 L of biogas can be produced from 1 kg of organic material. The main components of biogas are CH4 (40–80%), CO2 (20–55%), H2S (0.1–5.5%), and trace amounts of H2, CO, N2, and O2 [32]. Bio-fermentation requires controlled conditions without access to oxygen and at elevated temperatures [68]. Hermetically sealed tanks ensure that odors from decomposing organic matter are captured and not detectable outside. Fermentation also eliminates pathogenic bacteria, such as Salmonella and E. coli [63]. An additional system often introduced is waste sterilization before processing the feedstock by bio-fermentation, due to the toxic characteristics of some types of meat waste. Bio-fermentation installations are modular, with scaling from 250 kW to 5 MW. A biogas plant requires a surface area of about 2000 m2.

2.4. The Developed Strategy for Waste Bio-Fermentation at Farmutil HS

Biogas production activities are compatible with the CE, primarily consisting of using waste in the anaerobic digestion process and the rational use of the digestate [34]. The targeted solutions involve bio-fermenting as much meat waste as possible, especially because meat waste processed through hydrolysis into MBM can be difficult and costly. Replacing as much natural gas as possible for MBM production with biogas generated during anaerobic bio-fermentation supports the development of new methods for anaerobic bio-fermentation of animal blood. Typically, blood is the raw material used to produce meals in animal feeds, such as protein, milk, lysine supplements, and vitamin stabilizers [72]. Blood plasma gel contains 60.0% albumin [73]. Animal blood has a C/N ratio of ~3.5. For typical methane bio-fermentation, the optimal C/N ratio is 20–30. The research aimed to select appropriate raw materials for co-fermentation with blood to maximize biogas yield and the effectiveness of anaerobic digestion. In 2016, the U.S. meat industry discharged 41.8 million metric tons of slaughterhouse waste, of which blood accounted for 7–11% [74,75]. Blood is typically collected and shipped to rendering plants to produce bone meal (BM), an animal feed component. It is estimated that 39.7–41.4 kJ can be obtained from anaerobic digestion of blood waste from each kilogram of slaughtered livestock. Typical blood contains 19–21% solid matter and 13–15% proteins. In [74], a semi-technical scale study showed that the two-stage anaerobic digestion system has a methane yield of 135 m3/t of blood.

3. Results and Discussion

3.1. Expected Volumes of Biogas Generated from Animal Waste

Table 1 presents the indicators obtained from laboratory tests on the bio-fermentation process of meat waste. The biogas yield was primarily dependent upon the type of waste (as shown in Table 1). In the case of soft meat waste and bones, the yield ranged from 229 to 570 m3 per ton of raw waste. According to [32], the biogas yield was 450 m3 from meat waste and 316 m3 from sewage sludge per ton of dry organic mass. In the subsequent analysis, a biogas yield of 300 m3 per ton of raw meat waste was considered.

Table 1.

The biogas yield from different kinds of meat waste.

3.2. Obtaining Biogas from Meat Waste and Its Substitution for Natural Gas in MBM Production

The heat consumption at Farmutil is 655,000 GJ/y for the MBM production capacity of 100,000 t/y, and 982,500 GJ/y for 150,000 t/y [55]. Table 2 presents quantities of processed meat waste, with biogas yields ranging from 100 to 400 m3/t of raw meat waste for bio-fermentation unit capacities of 0.5–5 MW. At a biogas yield of 300 m3/t of raw meat waste, it is possible to substitute 72% of the natural gas used at Farmutil to produce 150,000 t/y MBM, with a bio-fermentation of 120,000 t/y of meat waste, and 120% of the natural gas used to produce 150,000 t/y MBM, with a bio-fermentation of 200,000 t/y of meat waste.

Table 2.

Biogas yield and production from meat waste for different biogas unit capacities and its consumption to fulfill the heat need for hydrolysis in producing 150,000 t/y of meat bone meal (MBM).

Bio-Ferment Management

The bio-ferment from the fermentation process has fertilizing value and can replace about 10% of the currently used artificial fertilizers on Farmutil’s arable lands. Table 3 presents the amounts of bio-ferment obtained at different meat waste-processing rates.

Bio-ferment (digestate) is an alternative to mineral and organic fertilizers, containing valuable plant nutrients. Its low organic dry matter content compared to liquid manure, neutral-to-alkaline pH, and high nitrogen, phosphorus, and potassium contents are some of the parameters that make this by-product an attractive fertilizer. The digestate dry matter content is 3.21–6.62%, and the organic matter is 60.96–76.47%. Its pH is alkaline (8.1–9.4) [76,77]. The chemical composition of the bio-ferment varied [in %], with a total nitrogen, 0.4–0.8; phosphorus, 0.1–0.28; potassium, 0.09–0.12; calcium, 0.22–0.43; magnesium, 0.06–0.17, and (in mg/kg); cadmium, 0.25–0.5; chromium, 1.14–4.55; nickel, 1.07–9.45; lead, 0.5–2.16; zinc, 27.8–105, and copper, 7.9–27.9. Digestate fertilizer from a biogas plant can reduce GHG emissions. Using 30 t of digestate per 1 ha of arable land would decrease GHG emissions by 25.8–44.5 t CO2eq [78].

Unfortunately, fertilization cannot be conducted year-round in Poland [22] due to limitations in fertilizing ability (9 months per year). Therefore, it should be stored in lagoons, but this is troublesome. Hence, the proposed integrated system provides for the treatment part (about 30%) of the digestate in the existing Farmutil biological treatment plant (processing 1,000,000 m3/y of wastewater from MBM production) when the bio-ferment cannot be used as fertilizer.

Table 3.

Material balance of bio-ferment production.

Table 3.

Material balance of bio-ferment production.

| Specification | Units | Amount |

|---|---|---|

| Meat waste charge (~86% H2O) | (t/y) | 120,000 160,000 200,000 |

| Bio-ferment (70% H2O) | (t/y) | 37,333 47,778 62,222 |

| The surface fertilized fields, at a dose of 30 t/ha * | (ha) | 834 1112 1390 |

* The dose used according to [78].

3.3. The Model of Processing Farmutil’s Meat Waste, with the Integrated System Using Jointly the Hydrothermal Method and Bio-Fermentation

Table 4 presents the balance of meat waste processing, with a bio-fermentation of 25% of this waste and 75% processed by hydrolysis into MBM.

Table 4.

Balance of meat waste utilization into meat bone meal (MBM) with the hydrolysis method and anaerobic digestion.

The quantities of waste proposed for bio-fermentation are estimated to be 160,000 t/y, and 440,000 t/y proposed for MBM processing. The charge for anaerobic digestion contains 85,000 t/y of I-risk category meat waste; 55,000 t/y of animal blood; and (t/y) bristles, 2883; hatching waste and eggs, 2800; manure, 500; screenings, 6000; waste fats 2400l; and sewage sludge 5617.

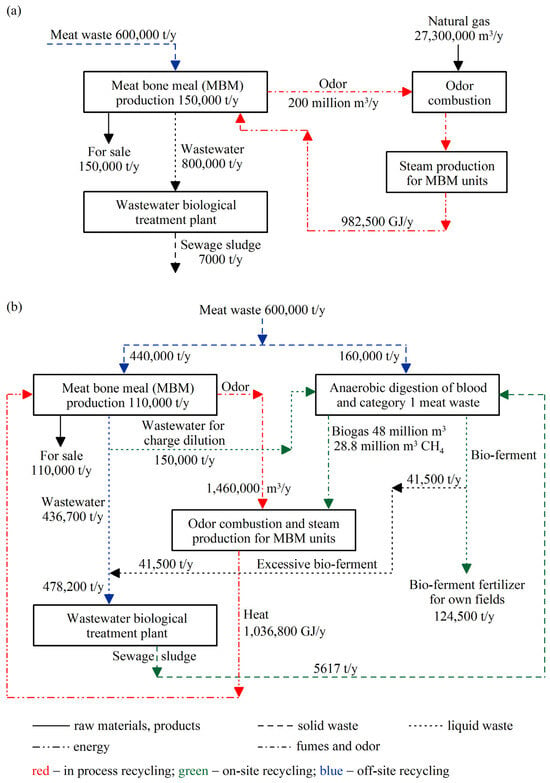

Figure 2 presents the balance data of the production of 150,000 t/y MBM by the hydrothermal method, in comparison to the integrated system of producing 110,000 t/y MBM by the hydrothermal technology, with simultaneous processing of 160,000 t/y of waste using bio-fermentation.

Figure 2.

Material and energy flow for meat waste utilization with hydrolysis (a) and integrated system (b) approaches. The biogas yield was 300 m3/t of meat waste and 30 m3/t of wastewater from MBM production.

Another alternative would be the bio-fermentation of 85,000 t/y of the I-risk category animal waste currently processed into 20,500 t/y of I-category risk MBM. The quantity of biogas generated in bio-fermentation of 150,000 t of waste (25% of all meat waste) would cover ~100% of the heat needed for MBM production from the remaining 450,000 t (75%) of meat waste. This indicates the need to build a bio-fermentation unit with a capacity of 4 MW.

The heat needed to produce 110,000 t of MBM is 720,500 GJ/y. The analysis showed that the biogas obtained by the bio-fermentation of 160,000 t/y of meat waste (1,036,800 GJ/y) would cover 144% of the heat for producing 110,000 t/y of MBM. The developed integrated system would reduce the amount of wastewater produced by Farmutil HS [79] by 321,800 m3/y (40%) and reduce odor emissions by 27%.

3.4. Analysis of an Integrated Meat Waste Utilization System in the Context of Circular Economy Strategy Data

The assessed circular economy (CE) activities, sustainable development (SD) goals, and cleaner production (CP) methods used for the estimation of animal waste management systems are shown in Table 5. CE, CP, and SD activities allow for the development of new products or technologies without high upfront investment and cross-value chain cooperation [22,35]. The use of the newly developed integrated system of meat waste utilization wisely selects resources and chooses technologies and processes. In this model, the CE promotes a series of actions, business models, and measures covering the whole lifecycle of products and materials, from design through manufacturing, consumption, and waste management.

Table 5.

Characteristics of circular economy (CE) activities, sustainable development (SD) goals, and cleaner production (CP) methods used for estimating animal waste management systems.

Economic growth would be achieved mainly through a combination of increased revenues from emerging circular activities and a lower cost of production due to a more productive utilization of inputs. To meet the CE assumptions, modern and innovative technologies allowing for the recovery of valuable materials were developed. Higher energy productivity and efficiency at the company level increased the economic value of the energy generated by a unit of material consumed. This includes the recovery of materials to serve as secondary raw materials for subsequent production and optimizing resource yields by circulating materials at the highest utility at all times in biological cycles [42].

3.5. The Economic and Environmental Effects of the Implementation of the Integrated System for Meat Waste Utilization

Table 6 shows the calculations for the model presented in Figure 2. Processing 600,000 t/y of meat waste using the integrated system would require building a 4 MW biogas plant. This would be a relatively simple investment and needs no more than 1 year to complete. The estimated investment cost is EUR 36.3 million. The average price of MBM in Poland is EUR 563/t [80]. The recommended dose of bio-ferment fertilizer is 30 t/ha, according to [76]. The amount of nitrogen, phosphorus, and potassium in bio-ferment is estimated at 6, 2, and 1 kg/t, respectively. Its value is EUR 13.5/t. The price of natural gas is EUR 0.78/m3 [81]. For comparison, the profit from a 1 MW biogas plant operating with slaughterhouse waste is EUR 536,651/y [34]. Relatively low investment costs result from the location of the bio-fermentation installation on one of the developed plots, with media connected, inside Farmutil. This reduces the investment cost by half, compared to the investment costs of a new, undeveloped plot. This resulted in a two-times shorter return on investment costs with gross profit. The implementation of the integrated model results in a 26.7% increased capacity of MBM production without investment costs.

Table 6.

Comparison of the economic effects of meat waste utilization in meat bone meal (MBM) production using hydrolysis and an integrated animal waste processing system.

The economic benefits are complemented by a positive impact on the natural environment. Managing waste from the agri-food industry under controlled conditions will significantly contribute to energy production and help mitigate climate change. Table 7 presents the environmental effects of meat waste utilization in MBM production using hydrolysis and the integrated system.

Table 7.

Comparison of the environmental effects of meat waste utilization in meat bone meal (MBM) production using hydrolysis and the integrated system of animal waste processing.

4. Conclusions

The developed model for meat waste management at Farmutil assumes an integrated system processing meat waste through bio-fermentation and into meat bone meal MBM via the hydrothermal method. The material and energy flows of processing 600,000 t/y of meat waste using the hydro-thermal method (for the production of 150,000 t/y of MBM), were compared with the material and energy flow in the integrated model, of processing 440,000 t/y of meat waste into 110,000 t/y of MBM via the hydrothermal method, and simultaneously 160,000 t/y of waste through bio-fermentation. The analysis of the integrated system model showed that biogas production would cover the heat requirements for producing 110,000 t/y of MBM with the hydrothermal method. Implementing the integrated management system would reduce the amount of wastewater produced by Farmutil by 350,000 m3/y (45%) and reduce emitted odors by 25%. Additionally, the spare capacity of Farmutil’s existing sewage treatment plant could be used to treat municipal sewage for approximately 6000 residents. The biogas plant investment is relatively straightforward, and the implementation time does not exceed 1 year. The estimated investment cost for a 4 MW biogas plant is EUR 36.3 million. In this case, the return on investment, with gross profit, would occur in less than 1 year, and the plant should be highly profitable.

Author Contributions

Conceptualization, Z.K.; methodology, Z.K.; software, A.M.; validation, Z.K. and A.M.; formal analysis, Z.K. and A.M.; investigation, Z.K. and A.M.; resources, Z.K.; data curation, Z.K.; writing—original draft preparation, Z.K. and A.M.; writing—review and editing, Z.K.; visualization, A.M.; supervision, Z.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rojas-Downing, M.M.; Nejadhashemi, A.P.; Harrigan, T.; Woznicki, S.A. Climate change and livestock: Impacts, adaptation, and mitigation. Clim. Risk Manag. 2017, 16, 145–163. [Google Scholar] [CrossRef]

- Godfray, H.C.J.; Aveyard, P.; Garnett, T.; Hall, J.W.; Key, T.J.; Lorimer, J.; Pierrehumbert, R.T.; Scarborough, P.; Springmann, M.; Jebb, S.A. Meat consumption, health, and the environment. Science 2018, 361, eaam5324. [Google Scholar] [CrossRef] [PubMed]

- Ritchie, H.; Rosando, P.; Roser, M. Our World in Data. Meat and Dairy Production. 2023. Available online: https://ourworldindata.org/meat-production (accessed on 10 January 2024).

- Sakadevan, K.; Nguyen, M.L. Chapter four-Livestock production and its impact on nutrient pollution and greenhouse gas emissions. In Advances in Agronomy, 1st ed.; Sparks, D.L., Ed.; Academic Press: Cambridge, MA, USA, 2017; Volume 141, pp. 147–184. [Google Scholar] [CrossRef]

- Makara, A.; Kowalski, Z.; Lelek, Ł.; Kulczycka, J. Comparative analyses of pig farming management systems using the Life Cycle Assessment method. J. Clean. Prod. 2019, 241, 118305. [Google Scholar] [CrossRef]

- Ockerman, H.W.; Basu, L. By-Products, Edible, for Human Consumption. Reference Module in Food Science. Encyclopedia of Meat Sciences, 2nd ed.; Academic Press: Oxford, UK, 2014; pp. 125–136. [Google Scholar] [CrossRef]

- Nweze, J.A.; Gupta, S.; Akor, J.; Nwuche, C.O.; Nweze, J.E.; Unah, V.U. Animal Waste: An Environmentally Sustainable Management Approach. In Climate Changes Mitigation and Sustainable Bioenergy Harvest Through Animal Waste; Arshad, M., Ed.; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- European Food Safety Authority, Animal By-Products. Available online: https://www.efsa.europa.eu/en/topics/animal-by-products (accessed on 15 February 2025).

- Caldeira, C.; De Laurentiis, V.; Corrado, S.; van Holsteijn, F.; Sala, S. Quantification of food waste per product group along the food supply chain in the European Union: A mass flow analysis. Resour. Conserv. Recycl. 2019, 149, 479–488. [Google Scholar] [CrossRef]

- Pinto, J.; Boavida-Dias, R.; Matos, H.A.; Azevedo, J. Analysis of the food loss and waste valorisation of animal by-products from the retail sector. Sustainability 2022, 14, 2830. [Google Scholar] [CrossRef]

- Kantorek, M.; Jesionek, K.; Polesek-Karczewska, S.; Ziółkowski, P.; Badur, J. Thermal utilization of meat and bone meals. Performance analysis in terms of drying process, pyrolysis and kinetics of volatiles combustion. Fuel 2019, 254, 115548. [Google Scholar] [CrossRef]

- Kowalski, Z.; Kulczycka, J.; Makara, A.; Mondello, G.; Salomone, R. Industrial symbiosis for sustainable management of meat waste: The case of Śmiłowo Eco-Industrial Park, Poland. Int. J. Environ. Res. Public Health 2023, 20, 5162. [Google Scholar] [CrossRef]

- Jeng, A.S.; Haraldsen, T.K.; Grønlund, A.; Pedersen, P.A. Meat and bone meal as nitrogen and phosphorus fertilizer to cereals and rye grass. Nutr. Cycl. Agroecosyst. 2006, 76, 183–191. [Google Scholar] [CrossRef]

- Sacha, M. Meat and Bone Meal. Natural Multi-Component Fertilizer. Farmer.pl. 2023. Available online: https://www.farmer.pl/produkcja-roslinna/nawozy/maczka-miesno-kostna-naturalny-nawoz-wieloskladnikowy,131476.html (accessed on 12 October 2024).

- Nogalska, A.; Załuszniewska, A. The effect of meat and bone meal applied without or with mineral nitrogen on macronutrient content and uptake by winter oilseed rape. J. Elem. 2020, 25, 905–915. [Google Scholar] [CrossRef]

- Silvasy, T.; Ahmad, A.A.; Wang, K.H.; Radovich, T.J.K. Rate and timing of meat and bone meal applications influence growth, yield, and soil water nitrate concentrations in sweet corn production. Agronomy 2021, 11, 1945. [Google Scholar] [CrossRef]

- Cascarosa, E.; Boldrin, A.; Astrup, T. Pyrolysis and gasification of meat-and-bone-meal: Energy balance and GHG accounting. Waste Manag. 2013, 33, 2501–2508. [Google Scholar] [CrossRef] [PubMed]

- Commission Regulation (EU) No 142/2011 of 25 February 2011 Implementing Regulation (EC) No 1069/2009 of the European Parliament and of the Council Laying Down Health Rules as Regards Animal By-Products and Derived Products Not Intended for Human Consumption and Implementing Council Directive 97/78/EC as Regards Certain Samples and Items Exempt from Veterinary Checks at the Border Under That Directive. Off. J. Eur. Union 2011, 54, 1–254. Available online: https://eur-lex.europa.eu/eli/reg/2011/142/oj/eng (accessed on 24 August 2024).

- Commission Regulation (EU) 2021/1372 of 17 August 2021 Amending Annex IV to Regulation (EC) No 999/2001 of the European Parliament and of the Council as Regards the Prohibition to Feed Non-Ruminant Farmed Animals, Other Than Fur Animals, with Protein Derived from Animals. Off. J. Eur. Union 2021, 295, 1–17. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32021R1372 (accessed on 24 August 2024).

- Yanuartono; Nururrozi, A.; Soedarmanto, I.; Purnamaningsih, H.; Ramandani, D. Meat bone meal as an alternative animal feed: A brief review. J. Peternak. Sriwij. 2020, 9, 35–54. [Google Scholar] [CrossRef]

- Central Statistical Office of Poland. 2021. Available online: https://www.statista.com/statistics/1036706/poland-deliveries-of-meat-product/ (accessed on 5 February 2021).

- Kowalski, Z.; Makara, A. The circular economy model used in the polish agro-food consortium: A case study. J. Clean. Prod. 2021, 284, 124751. [Google Scholar] [CrossRef]

- Kowalski, Z.; Kulczycka, J.; Makara, A.; Harazin, P. Quantification of material recovery from meat waste incineration–An approach to an updated food waste hierarchy. J. Hazard. Mater. 2021, 416, 126021. [Google Scholar] [CrossRef]

- Tan, Z.; Lagerkvist, A. Phosphorus recovery from the biomass ash: A review. Renew. Sust. Energ. Rev. 2011, 15, 3588–3602. [Google Scholar] [CrossRef]

- Leng, L.; Zhang, J.; Xu, S.; Xiong, Q.; Xu, X.; Li, J.; Huang, H. Meat & bone meal (MBM) incineration ash for phosphate removal from wastewater and afterward phosphorus recovery. J. Clean. Prod. 2019, 238, 117960. [Google Scholar] [CrossRef]

- Regulation (EC) No 1069/2009 of the European Parliament and of the Council of 21 October 2009 Laying Down Health Rules as Regards Animal By-Products and Derived Products Not Intended for Human Consumption and Repealing Regulation (EC) No 1774/2002 (Animal By-Products Regulation). Off. J. Eur. Union 2009, 300, 1–33. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32009R1069 (accessed on 24 August 2024).

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Off. J. Eur. Union 2008, 312, 1–28. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32008L0098 (accessed on 24 August 2024).

- Gwyther, C.L.; Williams, A.P.; Golyshin, P.N.; Edward-Jones, G.; Jones, D.L. The environmental and biosecurity characteristics of livestock carcass disposal methods: A review. Waste Manag. 2011, 31, 767–778. [Google Scholar] [CrossRef]

- Gadirli, G.; Pilarska, A.A.; Dach, J.; Pilarski, K.; Kolasa-Więcek, A.; Borowiak, K. Fundamentals, operation and global prospects for the development of biogas plants-A review. Energies 2024, 17, 568. [Google Scholar] [CrossRef]

- Alengebawy, A.; Ran, Y.; Osman, A.I.; Jin, K.; Samer, M.; Ai, P. Anaerobic digestion of agricultural waste for biogas production and sustainable bioenergy recovery: A review. Environ. Chem. Lett. 2024, 22, 2641–2668. [Google Scholar] [CrossRef]

- Woon, S.; Maazuza, O. The feasibility of anaerobic digestion of meat rendering waste. Int. J. Environ. Cult. Econ. Soc. Sustain. Annu. Rev. 2011, 7, 213–223. [Google Scholar] [CrossRef]

- Handous, N.; Gannoun, H.; Hamdi, M.; Bouallagui, H. Two-stage anaerobic digestion of meat processing solid wastes: Methane potential improvement with wastewater addition and solid substrate fermentation. Waste Biomass Valor. 2019, 10, 131–142. [Google Scholar] [CrossRef]

- Czekała, W.; Jasiński, T.; Dach, J. Profitability of the agricultural biogas plant operation in Poland, depending on the substrate use model. Energy Rep. 2023, 9, 196–203. [Google Scholar] [CrossRef]

- Czekała, W.; Pulka, J.; Jasiński, T.; Szewczyk, P.; Bojarski, W.; Jasiński, J. Waste as substrates for agricultural biogas plants: A case study from Poland. J. Water Land Dev. 2023, 56, 45–50. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Neves, A.; Godina, R.; Azevedo, S.G.; Matias, J.C.O. A comprehensive review of industrial symbiosis. J. Clean. Prod. 2020, 247, 119113. [Google Scholar] [CrossRef]

- Liu, C.; Côté, R.P.; Zhang, K. Implementing a three-level approach in industrial symbiosis. J. Clean. Prod. 2015, 87, 318–327. [Google Scholar] [CrossRef]

- Asif, F.M.A.; Lieder, M.; Rashid, A. Multi-method simulation based tool to evaluate economic and environmental performance of circular product systems. J. Clean. Prod. 2016, 139, 1261–1281. [Google Scholar] [CrossRef]

- Shi, L. Industrial symbiosis: Context and relevance to the sustainable development goals (SDGs). In Responsible Consumption and Production. Encyclopedia of the UN Sustainable Development Goals; Leal Filho, W., Azul, A.M., Brandli, L., Özuyar, P.G., Wall, T., Eds.; Springer: Cham, Switzerland, 2020; pp. 1–12. [Google Scholar]

- Cecchin, A.; Salomone, R.; Deutz, P.; Raggi, A.; Cutaia, L. Relating industrial symbiosis and circular economy to the sustainable development debate. In Industrial Symbiosis for the Circular Economy. Strategies for Sustainability; Salomone, R., Cecchin, A., Deutz, P., Raggi, A., Cutaia, L., Eds.; Springer: Cham, Switzerland, 2020; pp. 1–25. [Google Scholar]

- Sadeghpour, A.; Afshar, R.K. Livestock manure: From waste to resource in a circular economy. J. Agric. Food Res. 2024, 17, 101255. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy, Vol. 3: Accelerating the Scale-Up Across Global Supply Chains; Ellen Macarthur Foundation: Cowes, UK, 2014; Available online: https://www.ellenmacarthurfoundation.org/towards-the-circular-economy-vol-3-accelerating-the-scale-up-across-global (accessed on 12 November 2023).

- Leiva, H.; Julian, I.; Ventura, L.; Wallin, E.; Vendt, M.; Fornell, R.; Paniagua, F.G.; Ascaso, S.; Gomez-Perez, M. Advancing Sustainability Through Industrial Symbiosis: A Technoeconomic Approach Using Material Flow Cost Accounting and Cost–Benefit Analysis. Sustainability 2025, 17, 2730. [Google Scholar] [CrossRef]

- Makara, A.; Kowalski, Z. Selection of pig manure management strategies: Case study of Polish farms. J. Clean. Prod. 2018, 172, 187–195. [Google Scholar] [CrossRef]

- BREF. European Commission, Integrated Pollution Prevention and Control, Reference Document on Best Available Techniques in the Slaughterhouses and Animal By-Products Industries. 2005. Available online: https://eippcb.jrc.ec.europa.eu/sites/default/files/2020-01/sa_bref_0505.pdf (accessed on 25 August 2024).

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Kallipoliti, L. History of Ecological Design. Oxford Research Encyclopedias. Environ. Sci. 2018, 1–59. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- DIN 38 414-8; German Standard Methods for the Examination of Water, Waste Water and Sludge; Sludge and Sediments (Group S); Determination of the Amenability to Anaerobic Digestion (S 8). DIN–German Institute for Standarization e. V.: Berlin, Germany, 1985.

- VDI 4630; Fermentation of Organic Materials Characterisation of the Substrate, Sampling, Collection of Material Data, Fermentation Tests. The Association of German Engineers: Düsseldorf, Germany, 2016.

- Drosg, B.; Braun, R.; Bochmann, G.; Al Saedi, T. 3-Analysis and characterization of biogas feedstocks. In The Biogas Handbook. Science, Production and Applications; Wellinger, A., Murphy, J., Baxter, D., Eds.; Woodhead Publishing Series in Energy; Woodhead Publishing: Sawston, UK, 2013; pp. 52–84. [Google Scholar] [CrossRef]

- Hicks, T.M.; Verbeek, C.J.R. Chapter 3-Meat Industry Protein By-Products: Sources and Characteristics. In Protein Byproducts: Transformation from Environmental Burden into Value-Added Products; Dhillon, G.S., Ed.; Academic Press: Cambridge, MA, USA, 2016; pp. 37–61. [Google Scholar] [CrossRef]

- Buckley, M.; Penkman, K.E.H.; Wess, T.J.; Reaney, S.; Collins, M.J. Protein and mineral characterization of rendered meat and bone meal. Food Chem. 2012, 134, 1267–1278. [Google Scholar] [CrossRef]

- PN-R-64801:1999; Animal Feeding Stuffs. Feed Meals of Animal Origin. Polish Standard: Warsaw, Poland, 2013. (In Polish)

- Kowalski, Z.; Makara, A. Sustainable systems for the production of district heating using meat-bone meal as biofuel: A Polish case study. Energies 2022, 15, 3615. [Google Scholar] [CrossRef]

- Kowalski, A.; Banach, M.; Makara, A. Optimization of the co-combustion of meat–bone meal and sewage sludge in terms of the quality produced ashes used as substitute of phosphorites. Environ. Sci. Pollut. Res. 2021, 28, 8205–8214. [Google Scholar] [CrossRef]

- Meeker, D.L. Essential Rendering, All About the Animal By-Products Industry; National Renderers Association: Alexandria, VA, USA, 2006. [Google Scholar]

- Campos, I.; Valente, L.M.P.; Matos, E.; Marques, P.; Freire, F. Life-cycle assessment of animal feed ingredients: Poultry fat, poultry by-product meal and hydrolyzed feather meal. J. Clean. Prod. 2020, 252, 119845. [Google Scholar] [CrossRef]

- Bustillo-Lecompte, C.F.; Mehrvar, M. Slaughterhouse wastewater characteristics, treatment, and management in the meat processing industry: A review on trends and advances. J. Environ. Manag. 2015, 161, 287–302. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Wang, Y.; Jiao, P.; Zhang, M.; Deng, Y.; Jiang, C.; Liu, X.W.; Lou, L.; Li, Y.; Zhang, X.X.; et al. Microbiome-functionality in anaerobic digesters: A critical review. Water Res. 2024, 249, 120891. [Google Scholar] [CrossRef] [PubMed]

- Uddin, M.M.; Wright, M.M. Anaerobic digestion fundamentals, challenges, and technological advances. Phys. Sci. Rev. 2022, 8, 2819–2837. [Google Scholar] [CrossRef]

- Shin, S.G.; Yoo, S.; Hwang, K.; Song, M.; Kim, W.; Han, G.; Hwang, S. Dynamics of transitional acidogenic community along with methanogenic population during anaerobic digestion of swine wastewater. Process Biochem. 2011, 46, 1607–1613. [Google Scholar] [CrossRef]

- Chen, Y.; Fu, B.; Wang, Y.; Jiang, Q.; Liu, H. Reactor performance and bacterial pathogen removal in response to sludge retention time in a mesophilic anaerobic digester treating sewage sludge. Bioresour. Technol. 2012, 106, 20–26. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, R.; El-Mashad, H.M.; Dong, R.; Liu, X. Biogasification of green and food wastes using anaerobic-phased solids digester system. Appl. Biochem. Biotechnol. 2012, 168, 78–90. [Google Scholar] [CrossRef]

- Bareha, Y.; Girault, R.; Guezel, S.; Chaker, J.; Trémier, A. Modeling the fate of organic nitrogen during anaerobic digestion: Development of a bioaccessibility based ADM1. Water Res. 2019, 154, 298–315. [Google Scholar] [CrossRef]

- De Baere, L. Will anaerobic digestion of solid waste survive in the future? Water Sci. Technol. 2006, 53, 187–194. [Google Scholar] [CrossRef]

- Węglarzy, K.; Skrzyżala, I.; Pellar, A. Agricultural biogas plant in Kostkowice. First experiences. J. Res. Appl. Agric. Eng. 2011, 56, 189–192. [Google Scholar]

- Kythreotou, N.; Florides, G.; Tassou, S.A. A review of simple to scientific models for anaerobic digestion. Renew. Energy 2014, 71, 701–714. [Google Scholar] [CrossRef]

- Cieślik, M.; Dach, J.; Lewicki, A.; Smurzyńska, A.; Janczak, D.; Pawlicka-Kaczorowska, J.; Boniecki, P.; Cyplik, P.; Czekała, W.; Jóźwiakowski, K. Methane fermentation of the maize straw silage under meso- and thermophilic conditions. Energy 2016, 115, 1495–1502. [Google Scholar] [CrossRef]

- Świątek, M.; Lewicki, A.; Szymanowska, D.; Kubiak, P. The effect of introduction of chicken manure on the biodiversity and performance of an anaerobic digester. Electron. J. Biotechnol. 2019, 37, 25–33. [Google Scholar] [CrossRef]

- Hakawati, R.; Smyth, B.M.; McCullough, G.; De Rosa, F.; Rooney, D. What is the most energy efficient route for biogas utilization: Heat, electricity or transport? Appl. Energy 2017, 206, 1076–1087. [Google Scholar] [CrossRef]

- Jayathilakan, K.; Sultana, K.; Radhakrishna, K.; Bawa, A.S. Utilization of byproducts and waste materials from meat, poultry and fish processing industries: A review. J. Food Sci. Technol. 2012, 49, 278–293. [Google Scholar] [CrossRef]

- Silva, V.D.M.; Silvestre, M.P.C. Functional properties of bovine blood plasma intended for use as a functional ingredient in human food. LWT Food Sci. Technol. 2003, 36, 709–718. [Google Scholar] [CrossRef]

- Wang, S.; Hawkins, G.L.; Kiepper, B.H.; Das, K.C. Treatment of slaughterhouse blood waste using pilot scale two-stage anaerobic digesters for biogas production. Renew. Energy 2018, 126, 552–562. [Google Scholar] [CrossRef]

- Kumar, D.J.P.; Mishra, R.K.; Chinnam, S.; Binnal, P.; Dwivedi, N. A comprehensive study on anaerobic digestion of organic solid waste: A review on configurations, operating parameters, techno-economic analysis and current trends. Biotechnol. Notes 2024, 5, 33–49. [Google Scholar] [CrossRef]

- Chojnacka, K.; Moustakas, K.; Witek-Krowiak, A. Bio-based fertilizers: A practical approach towards circular economy. Bioresour. Technol. 2020, 295, 122223. [Google Scholar] [CrossRef]

- Czekała, W.; Lewicki, A.; Pochwatka, P.; Czekała, A.; Wojcieszak, D.; Jóźwiakowski, K.; Waliszewska, H. Digestate management in Polish farms as an element of the nutrient cycle. J. Clean. Prod. 2020, 242, 118454. [Google Scholar] [CrossRef]

- Kowalczyk-Juśko, A.; Pochwatka, P.; Mazurkiewicz, J.; Pulka, J.; Kępowicz, B.; Janczak, D.; Dach, J. Reduction of greenhouse gas emissions by replacing fertilizers with digestate. J. Ecol. Eng. 2023, 24, 312–319. [Google Scholar] [CrossRef] [PubMed]

- Makara, A.; Kowalski, Z.; Saeid, A. Treatment of wastewater from production of meat-bone meal. Open Chem. 2015, 13, 1275–1285. [Google Scholar] [CrossRef]

- Tridge, Meat and Bone Meal (MBM) Global Wholesale Market Price Today, Report Date December 8, 2023. Available online: https://www.tridge.com/intelligences/meat-and-bone-meal-mbm (accessed on 24 August 2024).

- Comparic, Gas for Companies in 2024–How Much Will You Pay? Available online: https://comparic.pl/gaz-dla-firm-w-2024-ile-zaplacisz/ (accessed on 24 August 2024). (In Polish).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).