1. Introduction

Sustainable construction can be defined as the efficient use of resources [

1] with green design [

2]. Modern housing developments are constructed sustainably, that is, in a way that benefits residents as well as the environment [

3]. Sustainable building is not just a philosophy but a practical approach to creating residential and commercial spaces in harmony with nature [

4]. At the heart of this approach is the belief that it is possible to build in a way that simultaneously meets needs and protects the environment, promoting the health and well-being of people [

5]. It is important that the design, construction and use of buildings take into account aspects such as the use of efficient energy, environmentally friendly technologies, the reduction of water consumption [

6] and the choice of building materials that are both durable and environmentally friendly [

7]. The idea of sustainable construction is to bring long-term benefits to the environment and to the current and future generations. The pursuit of the aforementioned goals is taken into account at the stages of designing, building and using the developments. Specific solutions are a very important part of sustainable construction, as they bring real benefits to residents and the environment. They are divided into two groups [

8]: ecological [

9] and well-being [

10]. The group of green solutions includes renewable energy (e.g., photovoltaic panels) [

11], light-colored roofing or roofs covered with extensive vegetation [

12], rainwater collection systems, electric vehicle charging stations, solar benches, LED lighting, patios with greenery [

8], etc. Equally important are other parameters ensuring a quality living environment for people [

13], such as thermal and acoustic comfort [

14], access to daylight [

15], good ventilation, low levels of air pollution [

16], and outdoor relaxation areas [

17]. One of the pillars of sustainable construction is the building life cycle [

18]. Buildings are to be designed so that they can be refurbished, recycled and remanufactured or returned to the production cycle [

19].

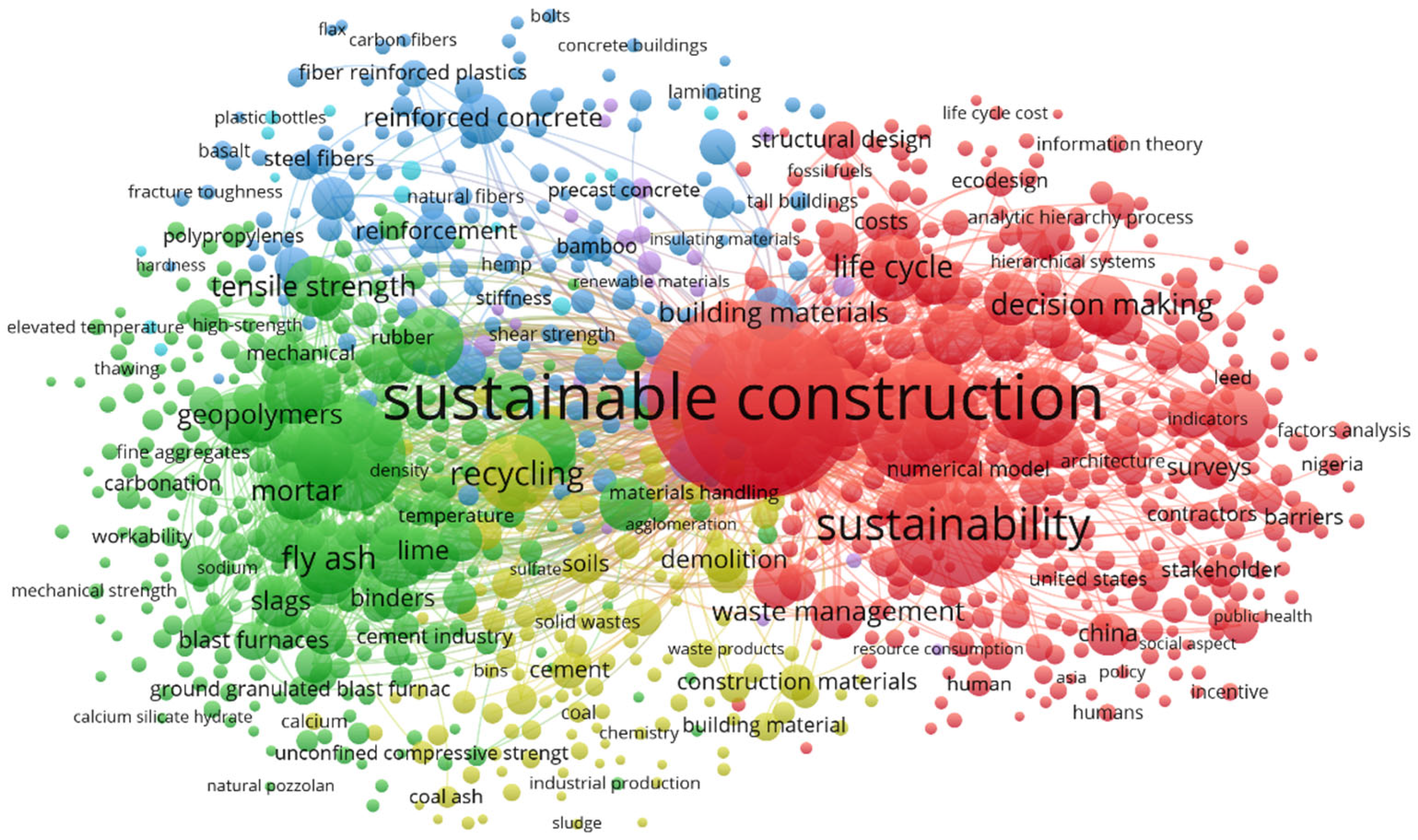

To overcome today’s social and environmental challenges, sustainable building requirements are needed right from the design stage; however, entrepreneurs, policy makers and technical professionals continue to ignore them [

20]. Organisational strategies, the level of sustainability maturity and the ability to change corporate values and beliefs play significant roles in this key movement. At the same time, external stakeholders, such as investors, banks, communities, suppliers, regulatory agencies and insurance companies, can impose certain behaviours on the market and influence change. In addition, organisations should build their sustainability strategy and implement sustainable project management [

21]. The article is of a review nature. In its construction, in addition to the study of the subject literature, a number of other research methods, techniques, and tools were also used. Their application was two staged, initially involving the processing of materials and subsequently the systematisation of the collected results. To achieve the above objectives, the following research methods were used: comprehensive SWOT-TOWS analysis, analysis and synthesis, abstraction, organisation, grouping, comparisons, induction and deduction, interpretation, definition, and selection. The work also utilised the VOSviewer program, version 1.6.20, a spreadsheet for SWOT calculations, and graphic software. A detailed analysis was conducted on the literature related to the research subject, including monographs, scientific publications, and online resources. The issues discussed in the article are still open topics and require further research in this area, including the use of other (empirical) research methods. In general terms, the SWOT-TOWS analysis was conducted based on the literature data. The main objectives of this study are outlined below.

presentation of current trends in sustainable construction and the direction of their development;

indication of the main barriers to the development of sustainable construction in relation to potential benefits;

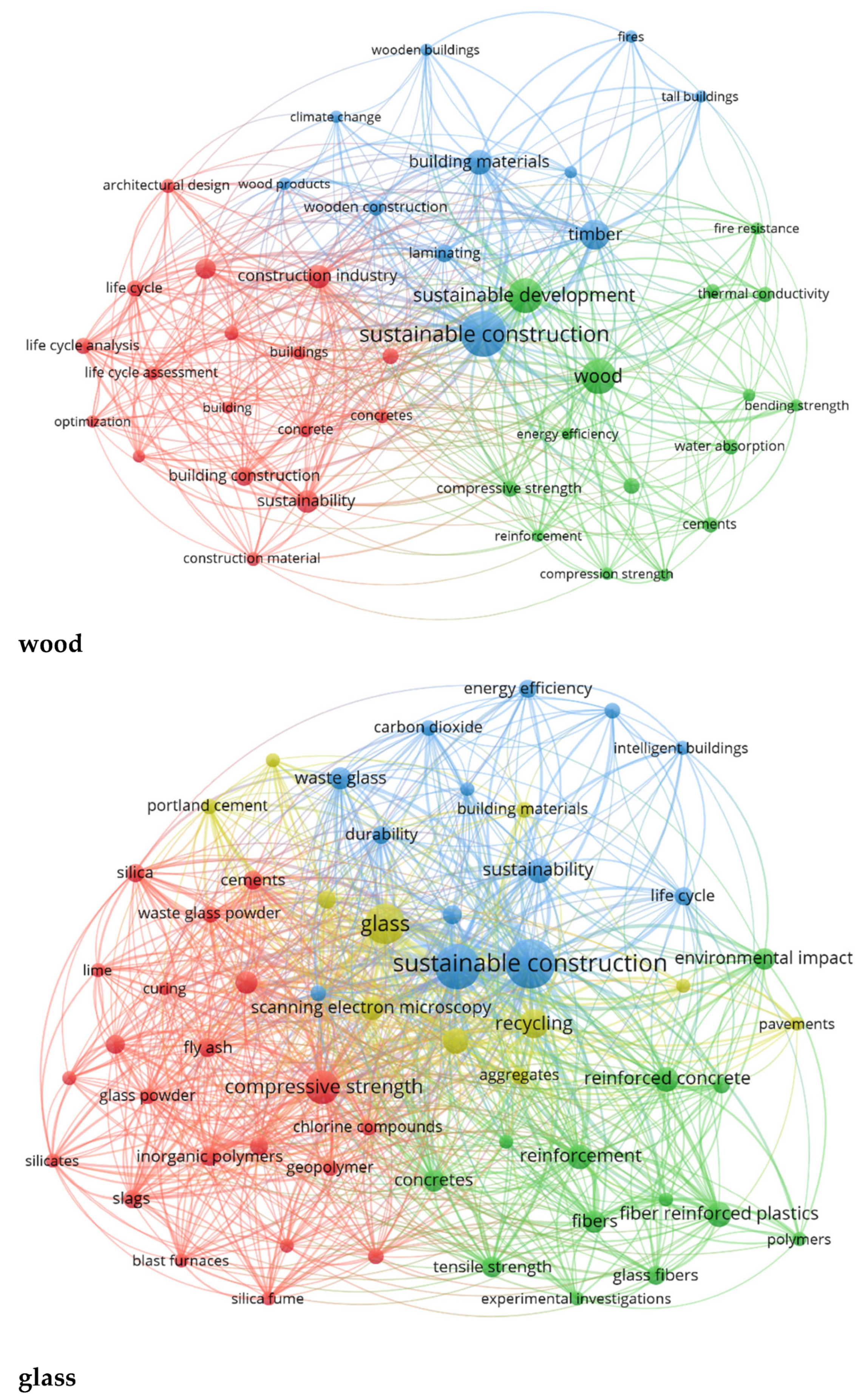

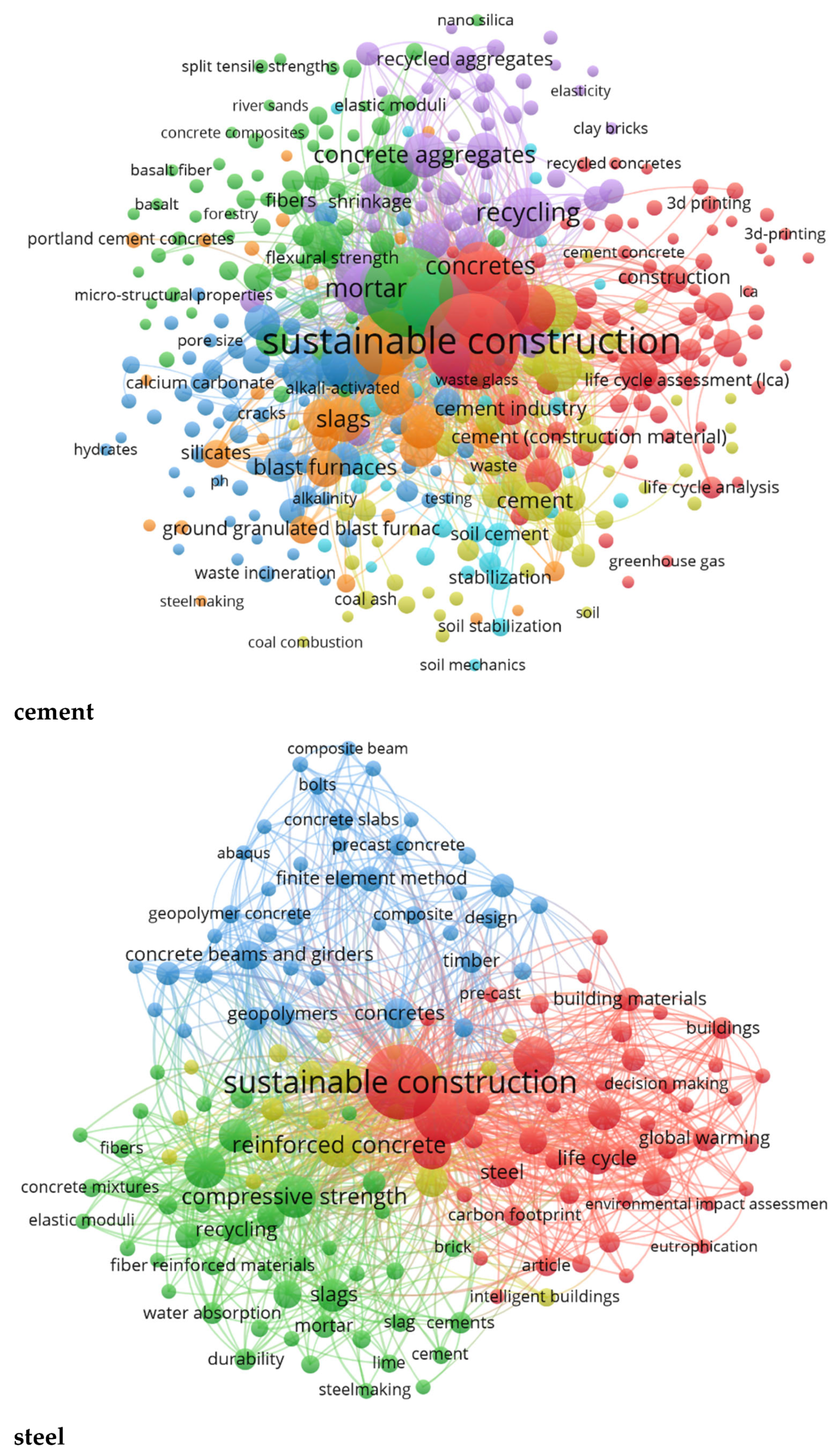

comprehensive comparison of selected building materials (concrete, steel, wood, glass) in terms of their use in sustainable construction;

indication of the strengths and weaknesses of individual construction materials as well as the opportunities and threats of their application in sustainable construction;

based on the conducted SWOT-TOWS analysis, identification of the most advantageous construction materials in the context of applications in sustainable construction;

indication of development strategies for individual construction materials in current socio-economic conditions.

Based on the current state of knowledge and the specified objective and research problem, the following research hypotheses have been formulated:

It is assumed that the trend in sustainable construction is moving towards an increasing use of various technologies and the integration of innovative solutions with traditional ones, in order to enhance, among other things, energy efficiency and the use of recycled materials. The future of construction may be shaped by designs that incorporate the use of technologies, such as solar panels and smart energy management, as well as the introduction of green architecture (e.g., green roofs, rainwater management systems). These actions indicate the growing need to strive for more sustainable development in construction practices.

It is assumed that the main barriers to sustainable construction are technological barriers. However, the main benefits of applying sustainable construction are ecological, and, consequently, also social.

It is assumed that materials, such as metals (aluminium and steel), plastics (polycarbonate), and composites (e.g., carbon fibre, ceramic materials) have the greatest technological utility. The greatest ecological benefits are biodegradable materials (bioplastics), secondary materials (glass, paper, metal), and wood. However, the greatest social utility is recycling materials and those with low energy consumption in production (some types of ceramics).

It is assumed that in the context of sustainable construction, wood and glass have the most strengths, while wood has the most threats.

It is assumed that the material with the best properties in terms of the studied factors for sustainable construction is glass.

It is assumed that an aggressive strategy concerns glass as a construction material, with strong expansion of opportunities and strengths.

3. Innovative Solutions in the Use of Building Materials

The materials used in sustainable construction can be divided in several ways. One common division is to distinguish three groups of materials:

Renewable materials can be included in the first group. These include materials of natural origin that can be renewed in a relatively short period of time. These include wood, bamboo, straw, mineral wool, flax, hemp and others.

Recycled materials: These materials are recycled in waste processing, making it possible to use resources that already exist and reduce waste. Examples include steel [

29], recycled concrete [

29], recycled glass [

30], recycled plastics and others.

Materials with low environmental impact: This group includes materials that have a lower overall environmental impact than traditional building materials. These may include, for example, low-carbon materials (e.g., concrete with cement replacements [

31]), low-embodied energy materials, such as stone, straw or burned wood, or materials produced in a more environmentally friendly manner [

32]. This group also includes traditional materials that have been subjected to innovative solutions.

Innovative solutions in the use of the traditional building material of cement include the following:

The use of cementitious materials containing iron-rich industrial waste (IWP) to support a nanophotocatalyst, such as titanium dioxide (TiO

2), to produce a visibly active Fe—TiO

2 composite exhibiting antibacterial properties [

33].

The use of recycled powder (RP) obtained from construction waste [

34].

The use of lithium slag (LS) as a precursor to geopolymer concrete, geopolymer technology uses alkali activators and aluminosilicate-rich materials, provides less environmental impact and shows performance comparable to traditional cement-based concrete, and most importantly contributes to a closed-loop economy in the construction industry [

35].

The use of recycled coarse aggregates (RCA) and construction and demolition waste (C&D) in sustainable concrete production [

36].

Cementitious mixtures, so-called “three-component” mixtures, consisting of mineral admixtures, limestone and clinker [

37].

The use of bauxite residue, commonly known as red mud, a byproduct of the Bayer process used in aluminium extraction, in concrete-based applications [

38].

The use of eggshell waste as a material to partially replace cement in clay and cement-based building materials; eggshell waste is among the most common agricultural waste from food processing plants [

39].

The use of various slags, including furnace slag, electric arc furnace slag (EAFS), steelmaking slag (SFS) and ground granulated blast furnace slag (GGBFS) in the development of sustainable building materials [

2].

The important cement replacements are geopolymers, which are primarily used in the production of concrete containing a binder formed on the basis of aluminosilicates instead of classic cement. The main difference between the two binders is the type of chemical reaction that causes them to harden and turns the plastic concrete mix into a solid. Furthermore, geopolymer concretes demonstrate high compressive strength, very low shrinkage and low creep, as well as high resistance to acid and sulfate corrosion. The apparent advantage of geopolymer binder over OPC Portland cement is certainly the low carbon footprint, rapid strength gain and its high values. In practice, the use of geopolymer concretes is still very limited due to their high price, which is determined by the use of relatively large amounts of sodium hydroxide and aqueous silicate solutions [

9,

40,

41]. There are many varieties of geopolymers, and recent studies have revealed that the incorporation of GO up to 1% can result in enhanced mechanical strength, durability, and reduced environmental impact.

The use of recycled glass (cullet), instead of sand and aggregate, is a solution to the shortage of river sand, which has so far been used as an ingredient in the concrete mix. In addition, finely ground glass has pozzolanic properties, which means that by binding with hydroxide, it improves the strength and durability of concrete and, by partially replacing cement in the mix, indirectly reduces CO

2 emissions during cement production. An additive described in both Polish (PN-EN 15167-1:2006 [

42]) and American (ASTM C989 [

43]) standards is ground granulated blast furnace slag (GGBFS)—a byproduct of iron and steel production that can be ground into a fine powder and used as a cementitious material in concrete mixes [

44]. The additive can improve the workability, strength and durability of concrete, and can reduce its heat of hydration, making it suitable for mass concrete applications. Materials such as geopolymers, fly ash, and glass are used in the latest technologies in 3D concrete printing (3DCP) that reduce costs, materials, and time, increase safety and minimise environmental pollution. In addition, 3D printing makes it possible to create complex and intricate designs [

45] that were previously difficult to achieve with traditional methods, particularly in areas such as precast concrete project analysis [

46], the study of the competitiveness of construction projects [

47], cloud computing for sustainability of small construction projects [

48] or modelling digital twins [

49]. The papers [

50,

51] present selected CO

2 capture technologies, such as amine scrubbing, calcium looping, oxyfuel combustion and direct separation, and their use in the production of concrete materials.

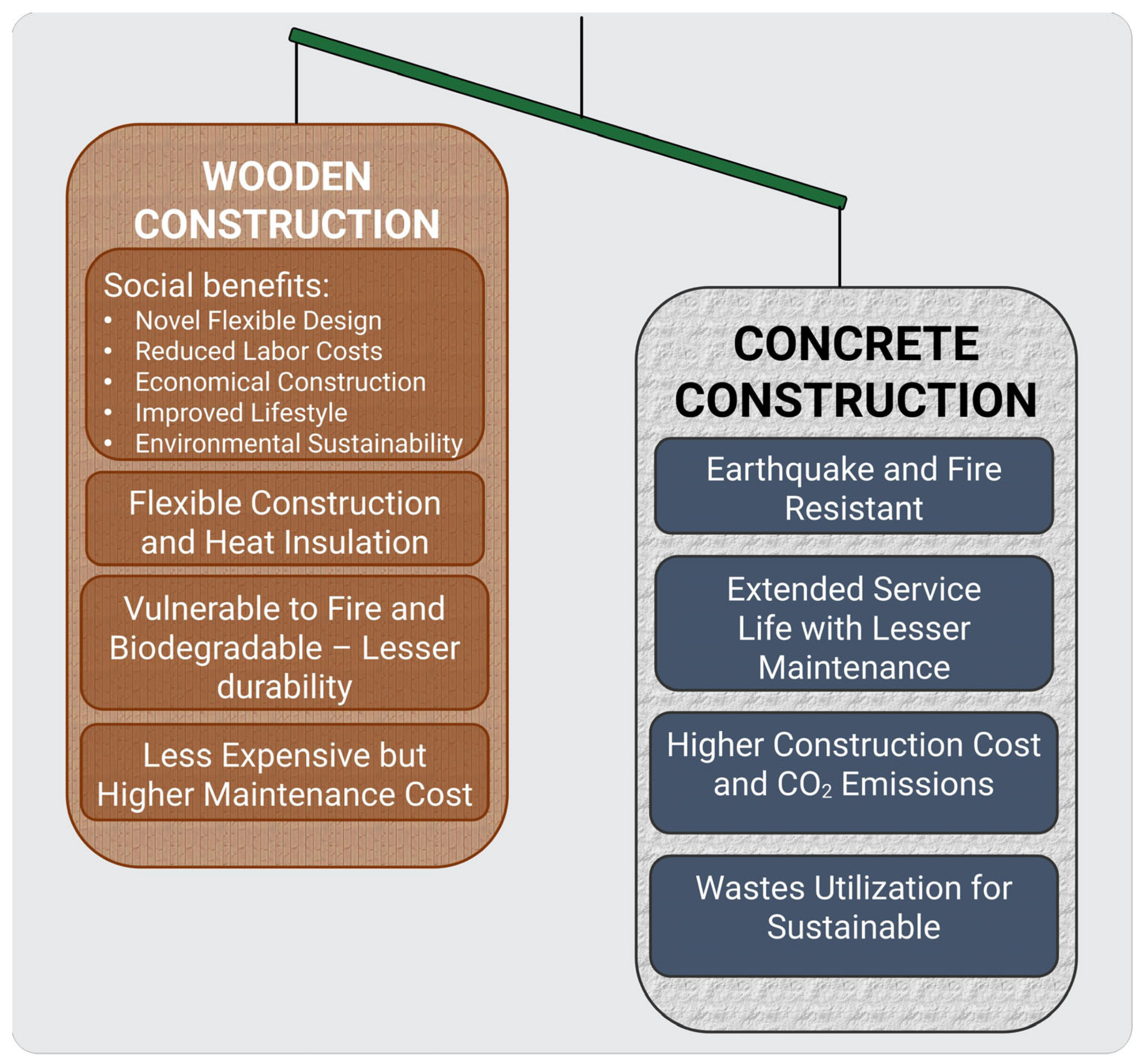

One of the many green alternatives aiming to replace structures made of energy-intensive materials [

52] is modern wooden structures [

53]. This type of construction is now very popular around the world [

54] and is already part of the standard of living in many countries [

55]. The potential inherent in the development of wood-based construction is currently not being fully exploited, so it is necessary to focus more on research and innovation in the wood construction sector (

Figure 4).

Current research conducted around the world addresses issues in the scope of innovation, indicating possible aspects of innovation for the construction sector and the innovation potential of various wood construction systems. In the work [

53], the parameters of wood as a construction material were presented, the most important of which is “construction time” (5.6), which is positively correlated with “price” (4.9). The next important parameter is “thermal and technical properties” (5.4), while the least important parameters are “environmental footprint” (4.5), “energy balance during use” (4.5), and “lifetime” (4.4). The less important are “acoustic properties” (3.6) and “fire resistance” (3.2). In addition, the authors of the article [

53] examined, from the point of view of the respondents, the advantages and disadvantages of wood as a construction material. The best rated were “impact on the environment” (100% of the respondents considered it an advantage), “renewable material”, “construction time”, “thermal-technical properties” and “energy balance” (according to the order of occurrence from 97% to 94%). The “price” parameter was considered an advantage by 72% of the respondents. The worst rated were “lifetime”, “acoustic properties” and “fire resistance” (from 67% to 52%). To sum up, wooden structures have great potential and are appreciated for their ecological character, lightness and speed of assembly; however, there are still concerns related to durability, acoustics and fire resistance. The market appears to be open to the development of this technology, although it requires a change in perception, legal support and technological innovations.

In addition to the standard uses of wood in construction, such as load-bearing structures, walls and ceilings, roofs, facades or interior finishes with wood, technologies are emerging to replace typical load-bearing structures in RES technologies, such as for wind turbines [

56]. The effect of using such materials is a reduction in CO

2 emissions i.e., significantly lowering the carbon footprint [

37] associated with the investment [

57].

In addition, when selecting materials in sustainable construction projects, it is important to take into account LCA and BIM, i.e., different levels of use of technologies for digital recording of physical and functional properties of a building, in parametric form. As part of the improvement of tools to support design processes, coupled with analysis methods such as LCA-BIM, are proposed [

29].

The sustainable building initiatives that are underway around the world include the following:

use of insulating biomaterials, such as products available in the region, i.e., agricultural waste [

58], such as grain straw, hemp and olives [

7];

improving the efficiency of energy-efficient management of industrial buildings through the use of artificial intelligence [

59];

optimising [

60] and retrofitting [

61] existing buildings for energy conservation and decarbonisation throughout the life cycle [

62];

cool roofs and airflow-enhancing technologies can also be mentioned—they are efficient, passive cooling methods that reduce energy demand and improve comfort for building occupants [

63].

Systematising and reviewing building materials with environmental aspects in mind are important topics that are gaining importance in the context of sustainable development and green building. It requires a holistic approach that takes into account the entire life cycle of materials and their impact on the environment. Promoting sustainable practices in construction can help reduce the negative impact on our planet and improve the quality of life of residents. The next section of the article presents several key points on this issue.

4. Environmental Aspects of Sustainable Construction

The path to sustainability is largely limited by the practices of the construction industry [

11], which is a significant generator of waste and other anthropogenic emissions [

64]. It follows that shifting to cleaner technologies and construction methods [

65] by implementing innovations that minimise consumption of resources and anthropogenic pollutants, such as greenhouse gases (GHG), aerosols, carbon dioxide, sulfur oxide, nitrogen oxide, benzene and other emissions that adversely affect humans and the environment, will promote the achievement of the Sustainable Development Goals [

66]. To ensure sustainability, it is imperative that the construction industry [

67], as a centre of economic development, seek solutions that are cost-effective, pragmatic and inclusive [

68]. There are many aspects through which modern construction supports sustainability and has a positive impact on the environment. The use of appropriate green technologies reduces greenhouse gas emissions [

69]. This is influenced, among others, by the reduction in energy consumption in sustainable buildings, good insulation performance and other elements that characterise green construction [

54]. In an era of shifting away from dependence on fossil fuels, the use of renewable energy sources is of utmost importance. As mentioned earlier, what is key to sustainable construction and sustainable development is the reduction in energy consumption through, among others, the efficient use of energy [

18]. The essence is to design the building so as to provide maximum comfortable thermal conditions [

70] with minimum energy consumption. In order to achieve such an effect, it is necessary to ensure adequate thermal insulation, airtightness of the building, eliminate thermal bridges and bring as much green energy into the building as possible. The energy efficiency of a sustainable building also depends on the entire life cycle of the building, not just the time of its target operation [

71], beginning with the construction of the building, through its upkeep and maintenance, to its demolition [

72].

Along with socioeconomic ones, the environmental aspects [

73] are one of the main groups of indicators for sustainability of the construction sector [

74].

Noteworthy is a study by Koengkan et al. [

8], which examined the impact of environmentally friendly homes on the economic development of the Lisbon metropolitan area. In their study, they analysed data from 18 municipalities over the period of 2014–2020, using regression analysis with ordinary least squares (OLS) and fixed effects. The results indicate that national policies promoting residential energy efficiency have a positive impact on economic development. Policies, such as grants, loans and tax credits, encourage homeowners to invest in energy-efficient technologies, increasing household disposable income and contributing to economic growth. The study found that an increase in the number of new buildings has a positive impact on economic development, leading to job creation and increased demand for construction materials and services. In addition, building environmentally friendly homes can reduce energy consumption by lowering energy costs for homeowners and businesses, and ultimately stimulating economic growth.

In the next part of the article, a SWOT analysis for construction materials was conducted, aimed at helping to understand the strengths and weaknesses, as well as the opportunities and threats associated with the construction materials market.

5. SWOT-TOWS Analysis for Construction Materials

SWOT-TOWS analysis was chosen for its practicality, universality, and ease of assessment. It is a comprehensive method because it presents all internal and external factors influencing the developmental potential of a given area in a single matrix. SWOT-TOWS allows for focusing attention on the most significant strategic development factors. A significant advantage of this method is also its modern perspective on the given problem. The disadvantage of this method is the subjective assessment in selecting factors and determining their weights and significance. It depends on the state of the knowledge possessed and/or access to information.

The SWOT method is a very popular tool, but it is not without its limitations. Insufficient data, frequent lack of objectivity from researchers who are unable to properly assess strengths and weaknesses, or, for example, underestimating threats while focusing on strengths and opportunities—these are some of the issues that should be taken into account when using this method.

When preparing a SWOT analysis, it is also necessary to consider legal constraints that can sometimes affect the interpretation of research results, such as data protection and legal liability, as well as laws arising from violations of fair competition or intellectual property rights (which are not the subject of analysis in this article).

Due to growing concerns about environmental issues and resource and energy consumption in the construction sector, the development of “green buildings” which, as they are defined, result in a reduction in the negative environmental and human impacts, is becoming increasingly important. However, the escalation of sustainable construction faces a number of entry barriers and obstacles at the implementation stage. Undoubtedly, the first basic method useful in the broad analysis of sustainable construction in terms of its positive and negative aspects is benefit–cost analysis [

75]. Various methods—both objective and subjective ones—are used for estimating these two quantities. Unfortunately, they are often subject to measurement error or a lack of proper conditions for conducting the study, which also results in a wide variation in the evaluation of the costs and benefits of sustainable construction in general. According to a study conducted by [

76], the ambiguity of actual costs and benefits is a major obstacle to the development of green architecture. It should also be taken into account that, for example, green buildings, the costs that matter are different for investors than for unit owners or tenants. Construction costs are important for investors, while ongoing costs are important for users. Among others, this is the basis of the difficulty with specifying these figures. Methods of economic and non-economic analyses used in science and practice that seek to answer this nagging question of profitability and return, or the correlation between green strategies and green performance, also include, for example, interviews, surveys, statistical and economic analyses, experiments, and simulations, benchmarking, risk analysis, technological and ecological research, and other engineering studies [

75].

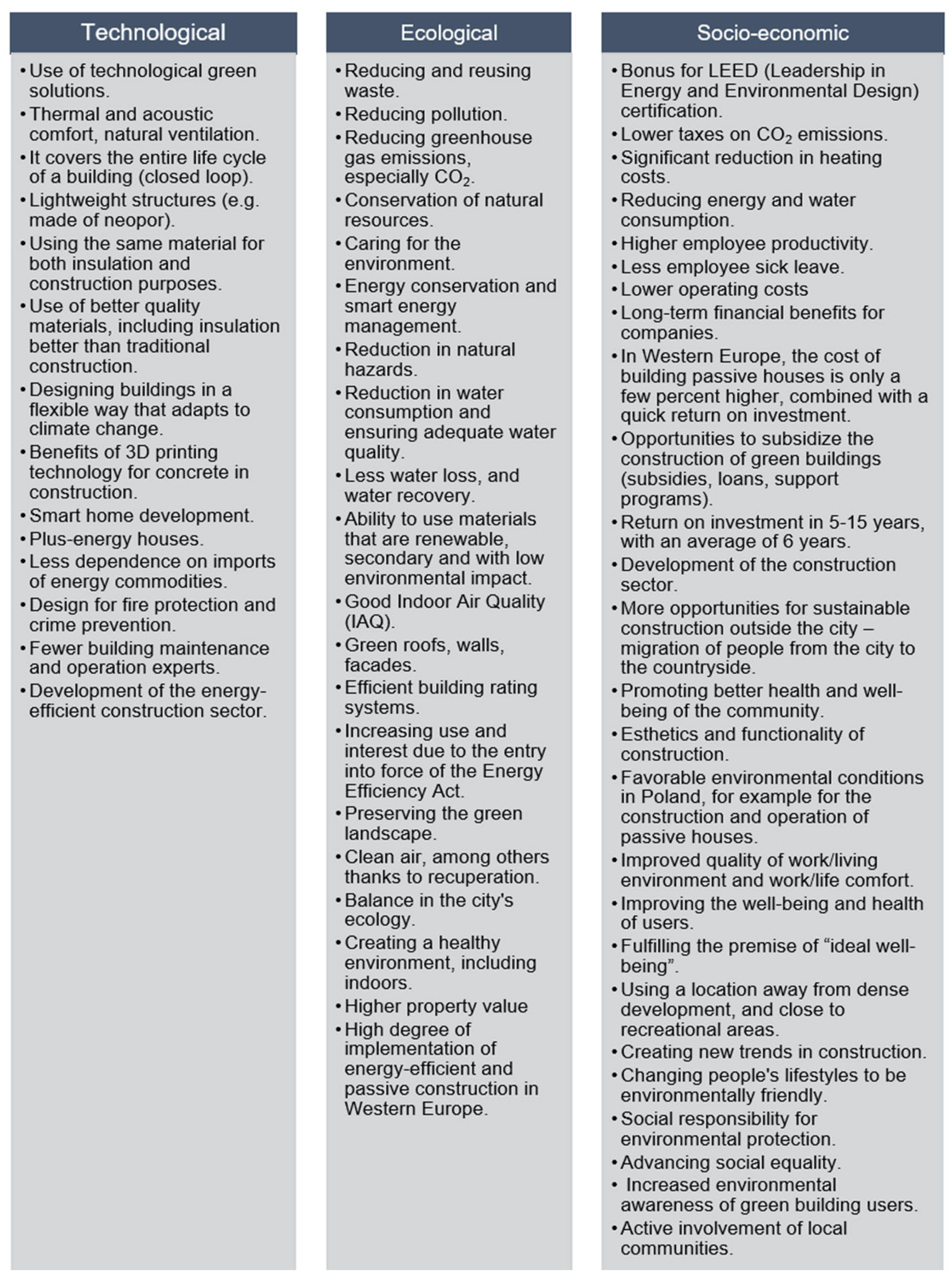

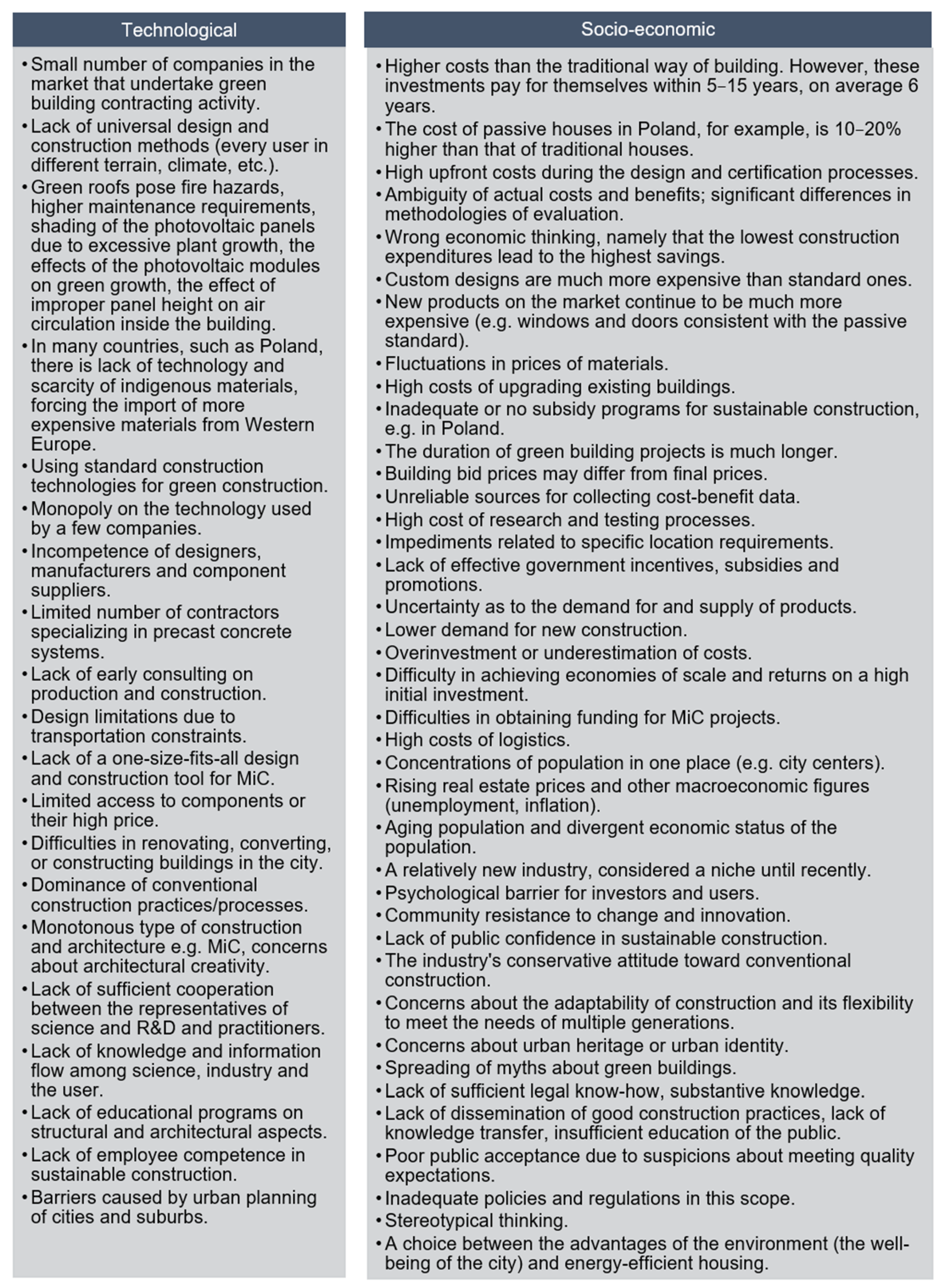

Based on cost–benefit analysis and on research using the above methods, as well as theoretical considerations derived from this work, the advantages and disadvantages of sustainable construction, both measurable and non-measurable, can be presented in general terms. Measurable aspects provide an opportunity to quantify the impact of implementation of sustainable construction intentions. They concern indirect (long-term) benefits and costs as well as direct (short-term—immediately perceptible) ones. Due to the difficulty with accurately estimating the benefits and costs of sustainable construction, non-measurable aspects are also included in this discussion. They are not subject to quantitative estimation and are primarily concerned with the general and social scope. Accordingly,

Table 1 shows the measurable advantages and disadvantages, while

Table 2 shows the non-measurable advantages and disadvantages of sustainable construction.

The identified advantages and disadvantages of sustainable construction were listed in the form of benefits and barriers, divided into technological, ecological and socio-economic factors, as shown in

Figure 5 and

Figure 6.

As can be seen from

Table 1 and

Table 2, this study identifies the most measurable advantages and non-measurable disadvantages of sustainable construction, in general. This means that in a holistic approach to the implementation and execution of “green construction”, the benefits far outweigh the costs. Nevertheless, a large number of socio-economic and technological barriers mean that this type of construction is still in its early stages. This is primarily due to the fact that the sustainable construction sector is still a new industry that the public is not fully convinced about, due to high initial costs, as well as a lack of knowledge and an information gap. However, analysing

Table 3 and

Table 4, it can be concluded that the dominant benefits relate primarily to ecological aspects and, consequently, social aspects. The scarcity of natural resources and the idea of a healthier and better life in a clean environment prevail over the stereotypical thinking of conventional construction as the only right and sustainable approach in this day and age. No environmental barriers to sustainable construction were noted.

A detailed analysis of the benefits and barriers of sustainable construction, divided into social, technological, and ecological factors, constitutes a database for identifying potential opportunities and threats, as well as the strengths and weaknesses of construction materials, and, thus, for conducting a SWOT-TOWS analysis (strengths, weaknesses, opportunities, threats—threats, weaknesses, opportunities, strengths) [

84,

85] for the main construction materials (glass, steel, wood, concrete). When comparing materials, technological, environmental and socioeconomic indicators were taken into account, such as the production factors of water, energy, material (including its consumption) and its recyclability, human resources, waste and its management, land use and biodiversity, environmental impact, pollution (water, air, noise), costs, material life cycle, construction and public safety, people and their well-being and working and living comfort, impact on local resources, local responsibility, economics and innovation [

73].

The rationale for choosing the SWOT-TOWS method was its versatility, practicality and simplicity in application [

86]. The results of the SWOT-TOWS analysis carried out allow for comparison of the above-mentioned materials in terms of their best and most effective application in sustainable construction (

Table 3,

Table 4,

Table 5 and

Table 6). The SWOT-TOWS analysis takes into account technological, environmental, and socio-economic factors. The weighting scale used was in the 0–1 range (0—lowest importance of the factor, 1—highest importance of the factor), while the rating scale for the factor was in the 1–5 range (1—lowest rating of the factor, 5—highest rating of the factor).

Table 7,

Table 8,

Table 9 and

Table 10 present the calculated values of individual factors from SWOT-TOWS analyses as a product of the weight and the assessment of a given factor.

As

Table 7 shows, the highest value in the SWOT-TOWS analysis for glass falls on factors W2, T1, O1, O3 and O5. Therefore, glass without a low-emission coating causes heat loss through low thermal insulating power, has high logistics costs, primarily of transportation, is synonymous with modern design and prestige, interior design and architecture in the broadest sense through spaciousness, minimalism and elegance, has increasing demand for reducing energy consumption, and creates warm and bright interiors that do not need to be additionally heated or illuminated—this, in turn, translates into better well-being of users.

As can be seen from

Table 8, the highest value in the SWOT-TOWS analysis for concrete falls on factors O1, O2, T1, W1, W3, W6. Therefore, respectively, concrete has great architectural possibilities—freedom in the design of the body, large and long experience in the market—is the traditional method and construction trends are changing towards eco-friendly materials, has high energy consumption during production, produces high CO

2 emissions, and generates large amounts of waste.

As shown in

Table 9, the highest value in the SWOT-TOWS analysis for steel falls on the S2, S3, S4, and W3 factors, i.e., homogeneity of structure and invariability of mechanical properties over time (the possibility of very accurate calculations for and use of structures), durability, tensile strength, compressive and bending strength, and high shear strength, allowing the use of only small amounts of the material, recyclability—demolition elements can be reused, or they are a valuable raw material for the manufacture of new steel products— and high CO

2 emissions.

As can be seen from

Table 10, the highest value in the SWOT-TOWS analysis for wood falls on factors O6, O7 and O10. Therefore, respectively, wood achieves a reduction in labour costs, improved living conditions, comfort, well-being, and health considerations; wood naturally stabilises the microclimate indoors, has a better lifestyle, is pro-environmental, and is more in harmony with nature.

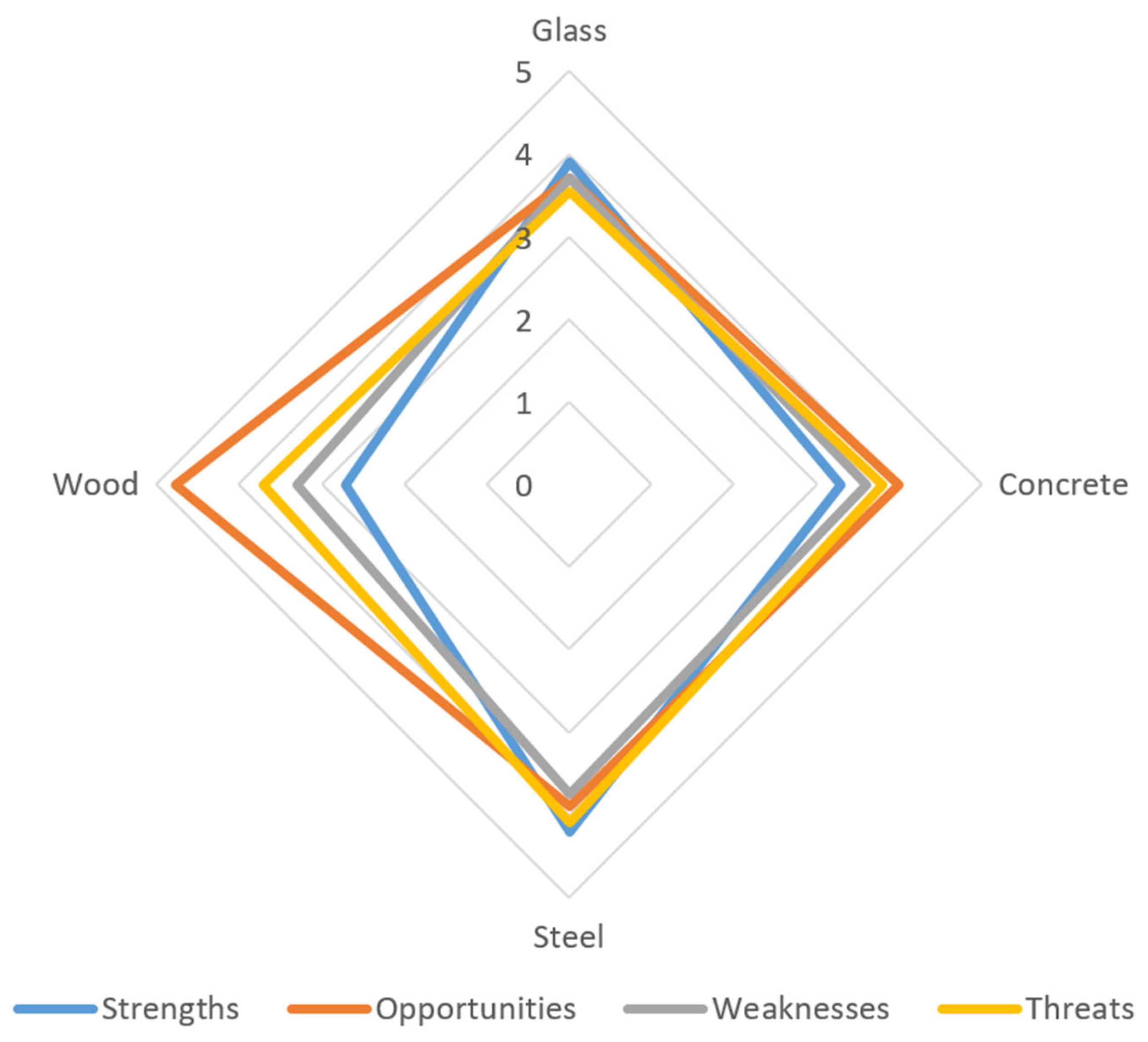

By analysing the above tables, the following can be noted:

The highest number of strengths was identified for wood (15) and the lowest for steel (8), while the highest number of weaknesses was noted for steel (10) and the lowest for glass (4). In contrast, the most numerous opportunities for development are for wood (18) and the least numerous for steel (6). The highest number of risks was recorded for wood (8) and the lowest for glass (5).

The largest sum of products of strengths is for steel (4.2), and the smallest for wood (2.71—among others, this is due to the very large number of factors identified), while the highest number of weaknesses is for steel (3.75) and the lowest is for wood (3.3). As for opportunities, the largest sum of products is undoubtedly for wood (4.77) and the smallest is for glass (3.7). The risks in the largest number of sums of the products of weights and ratings are for steel (4.1) and the smallest is for glass (3.55), as shown in

Table 11.

Glass is characterised by having the greatest number of strengths and opportunities; concrete, of weaknesses and opportunities; steel, of strengths and threats; and wood, of weaknesses and opportunities.

The most important strengths identified for glass are, first and foremost, 100% recycled raw material and a high degree of light transmittance. Weaknesses include high energy consumption during production and hardening. The most important opportunities are new methods of glass production that retain energy inside buildings and the architectural popularity of glass. The most important risks of glass include the generally high costs of production and logistics.

The most important identified strengths of concrete are, first and foremost, high weathering resistance and corrosion resistance. The weaknesses include high energy intensity and harmful emissions. The most important opportunities are many architectural possibilities and a long tradition of use. The most important threats to concrete are the shift in construction trends to eco-friendly ones.

The main strengths identified for steel are durability, strength and recyclability. Weaknesses include energy and emissions intensity as well as susceptibility to corrosion. The most important opportunities are all-weather performance and installation. Among the most important threats to steel is the change in construction trends to pro-environmental ones.

The most important strengths identified for wood are mainly good thermal insulation, a long life cycle and renewability of resources. Weaknesses include low resistance to climatic conditions and lower heat capacity. The most important opportunities are structural soundness and improved living conditions. The most important risks of wood include the problem of raw material availability and higher investment costs compared to other construction materials.

The analysis showed that the best construction material for sustainable construction is glass, due to the fact that it is a 100% recyclable raw material, and wood, due to the fact that it comes from renewable sources, stabilises the microclimate, and emits less carbon dioxide into the environment with low energy consumption. In turn, the material that does not perform well on its own in green construction is steel, due to its energy intensity and emission of harmful substances into the environment.

Due to the specific character of each of the materials in question, their properties and manufacturing technology, as well as their established position in the construction market, the number and selection of factors for the SWOT-TOWS analysis varies. The determination of their significance and their evaluation are subjective (typical for SWOT).

The results of the SWOT-TOWS analysis classify the construction materials into one of four types, [

93,

94,

95], namely:

Aggressive (maxi–maxi) strategy, consisting of strong expansion and diversified development; it includes activities that take advantage of assets and opportunities generated by the environment.

Conservative (maxi–mini) strategy, which involves maximizing the potential while minimizing the negative impact of the environment.

Competitive (mini–maxi) strategy, which involves eliminating weaknesses while taking advantage of the emerging opportunities.

Defensive (mini–mini) strategy, which involves eliminating weaknesses and avoiding threats.

As can be seen from

Figure 7, glass has the most strengths and the fewest threats, concrete has the most opportunities and the fewest weaknesses, steel has the most strengths and the fewest weaknesses, and wood has the most opportunities and the fewest strengths. The most strengths are for steel, the most opportunities for wood, the most weaknesses for steel, and the most threats for steel.

A graphical representation of the aforementioned strategies for the structural materials analysed is shown in

Figure 8.

Based on the analysis, the following strategy has been adopted for the selected construction materials to develop sustainable construction:

Glass—aggressive strategy—focusing on the strengths and their further development, such as glass recycling, favorable energy balance, good sound insulation, high light transmittance, resistance to environmental factors, production of heating glass, durability and strength, and opportunities, including new energy-efficient methods of glass production, and the fact that glass has now become synonymous with modern design and prestige (very high popularity of glass).

Steel—conservative strategy—focusing on the strengths of durability, strength, and recyclability of steel, and leveling the risks, mainly reducing the costs related to CO2 emissions and production.

Wood—competitive strategy—focus on eliminating the weaknesses of wood, such as low fire resistance and resistance to climatic factors, and developing the opportunities, including improving living conditions, structural soundness, planting new forests, and developing research on innovative wood construction.

Concrete—competitive strategy—focus on eliminating the weaknesses, including reducing technological breaks by changing the properties of concrete, reducing waste, reducing CO2 emissions and reducing energy consumption for production, and developing opportunities, such as supporting construction with semi-finished products and taking advantage of the economic attractiveness of concrete.

To summarise the section of the paper on the advantages and disadvantages of sustainable construction, barriers and benefits, strengths and weaknesses, opportunities and threats for selected construction materials, it should be noted that, due to the rapidly growing green building sector, these areas are bound to change. Hence, the issues considered in the article are still an open topic and require further research. In addition, in the near future, the presented SWOT analysis may also be slightly modified, taking into account the changing conditions of green construction, especially since this method is characterised by substantial subjectivity in the selection and evaluation of criteria and factors.

A SWOT analysis conducted this way can help companies develop strategies that take into account both internal and external factors influencing the construction materials market.

7. Conclusions

In light of regulations and environmental challenges, particularly climate neutrality by 2050, many industries, including the construction sector, face the challenge of incorporating sustainable practices into their projects so that the project, once implemented, is not only economically beneficial but also has a positive impact on the environment and society [

97]. Numerous studies and analyses are being undertaken around the world to estimate the impact of various factors on carbon emissions, construction waste, and project costs [

46]. Sustainable construction is now one of six markets with the potential for innovation, fostering competitiveness and job creation in the European economy. It aims to increase the energy efficiency of buildings, the use of building products that meet environmental criteria and clean technologies. However, it is worth remembering that it begins with an analysis of the needs of the investor and users of the building, and ends with the commissioning of the building, settlement and completion of all work, and the dissolution of organizational structures related to the execution of the project [

81]. At the current stage of development of construction technology, it is not possible to completely eliminate traditional engineering materials, such as concrete, steel (reinforced concrete) or glass, due to their structural properties (strength, durability, resistance to environmental factors, such as temperature and corrosion, among others) and economic attractiveness. Therefore, for these groups of materials, the conclusions from both the SWOT analysis (the first three conclusions) and the literature review are presented below.

- 1.

As a result of the SWOT-TOWS analysis conducted under current conditions, the construction material that best meets the requirements of sustainable construction is glass. We have identified the greatest strengths and opportunities for further development in this area. The construction materials that recorded more opportunities than threats but fewer strengths than weaknesses are concrete and wood. None of the analysed materials exhibited a predominance of weaknesses and threats. Steel ranks in a position where strengths and threats dominate. The most developmental strategy, which focuses on strengths and growth opportunities, is the aggressive strategy, which is attributed to glass. On the other hand, the conservative strategy pertains to steel, while the competitive strategy concerns wood and concrete.

- 2.

Based on the literature and SWOT-TOWS analysis, the following future research directions can be identified:

the costs of sustainable construction;

new trends in sustainable construction in changing socio-economic conditions;

survey studies directed at society regarding the lack of interest and social concerns in this area.

The following limitations can be identified:

lack of empirical research;

restrictions regarding the choice of available construction materials;

limited research on the effectiveness of using construction materials in the long-term process;

article length restrictions;

access to specific quantitative data;

difficulties in comparing costs and benefits in a measurable aspect;

possibilities for funding investments dedicated to sustainable construction, grants, etc.;

availability of materials and legal regulations (e.g., wood).

- 3.

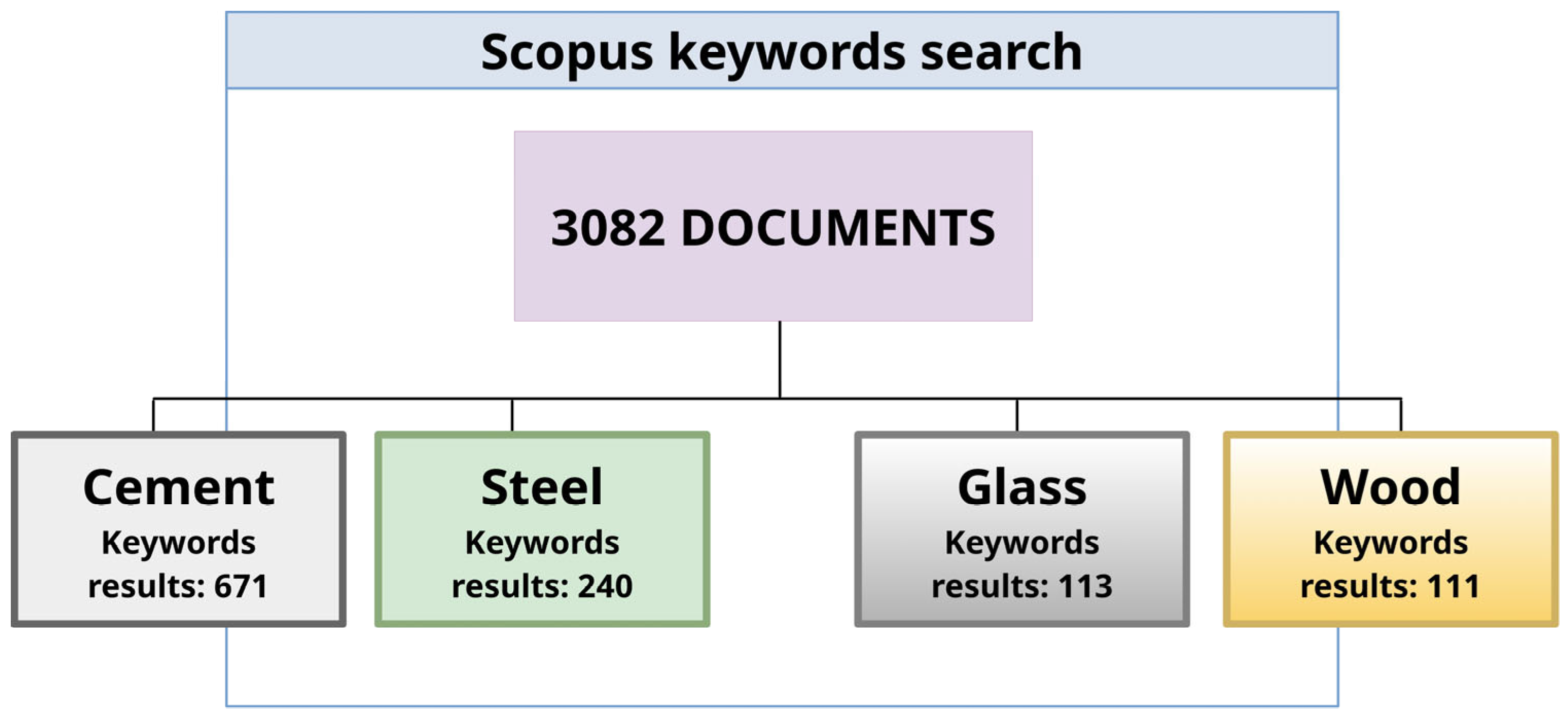

The limitations of SWOT analysis boil down to the analysis of four construction materials—wood, concrete, steel, and glass—in terms of social, technological, and environmental factors. Other aspects and materials were not analysed. Furthermore, the analysis was based on literature data from the subject literature database, Scopus.

- 4.

Filling the information gap, which has both scientific and practical dimensions in the field of sustainable construction, the authors attempted to address social concerns primarily arising from ignorance related to environmental, economic, and technological issues. Identifying the research gap is critical for the further development of modern solutions in the construction industry. Research in the field of sustainable construction focuses on designing and building structures that will be used in an environmentally friendly manner. Due to the multitude of factors affecting the construction industry in this matter, the authors have reviewed selected materials and technological possibilities on this topic; however, this is an issue that will be developed and continued in further publications.

- 5.

The study’s findings contribute to the academic discourse and practical applications listed below:

Didactic dimension—the article serves as a knowledge base for educational purposes.

Practical dimension—identifying the strengths and weaknesses, opportunities, and threats of individual construction materials can serve as a basis for the broader application of these materials in construction and the development of the industry.

Educational goal—expanding knowledge about ecology and raising public awareness about pro-ecological issues.

The article can serve as a database and subject literature for other researchers and scientists, students, and practitioners.

To sum up, modern ways of building houses make it easier to construct energy-efficient and low-cost buildings. Excellent thermal insulation, as well as the use of collectors, solar panels, heat pumps, recuperation and a system to control the installation, allow us to create houses that are functional and comfortable for daily use.