Integration of Recent Prospective LCA Developments into Dynamic LCA of Circular Economy Strategies for Wind Turbines

Abstract

1. Introduction

2. Materials and Methods

2.1. Literature Review of Underlying Concepts

2.1.1. Overarching CE Strategies

2.1.2. Dynamic Life Cycle Assessment

2.1.3. Recent Advancements in Prospective Life Cycle Assessment

2.2. Method for Integrating pLCA Elements into dLCA

2.2.1. Integrating Prospective LCA Elements into a Dynamic Goal and Scope

2.2.2. Integrating Prospective LCA Elements into a Dynamic LCI

2.2.3. Integrating Prospective LCA Elements into a Dynamic LCIA and Its Interpretation

2.3. Goal of the Case Study

3. Results

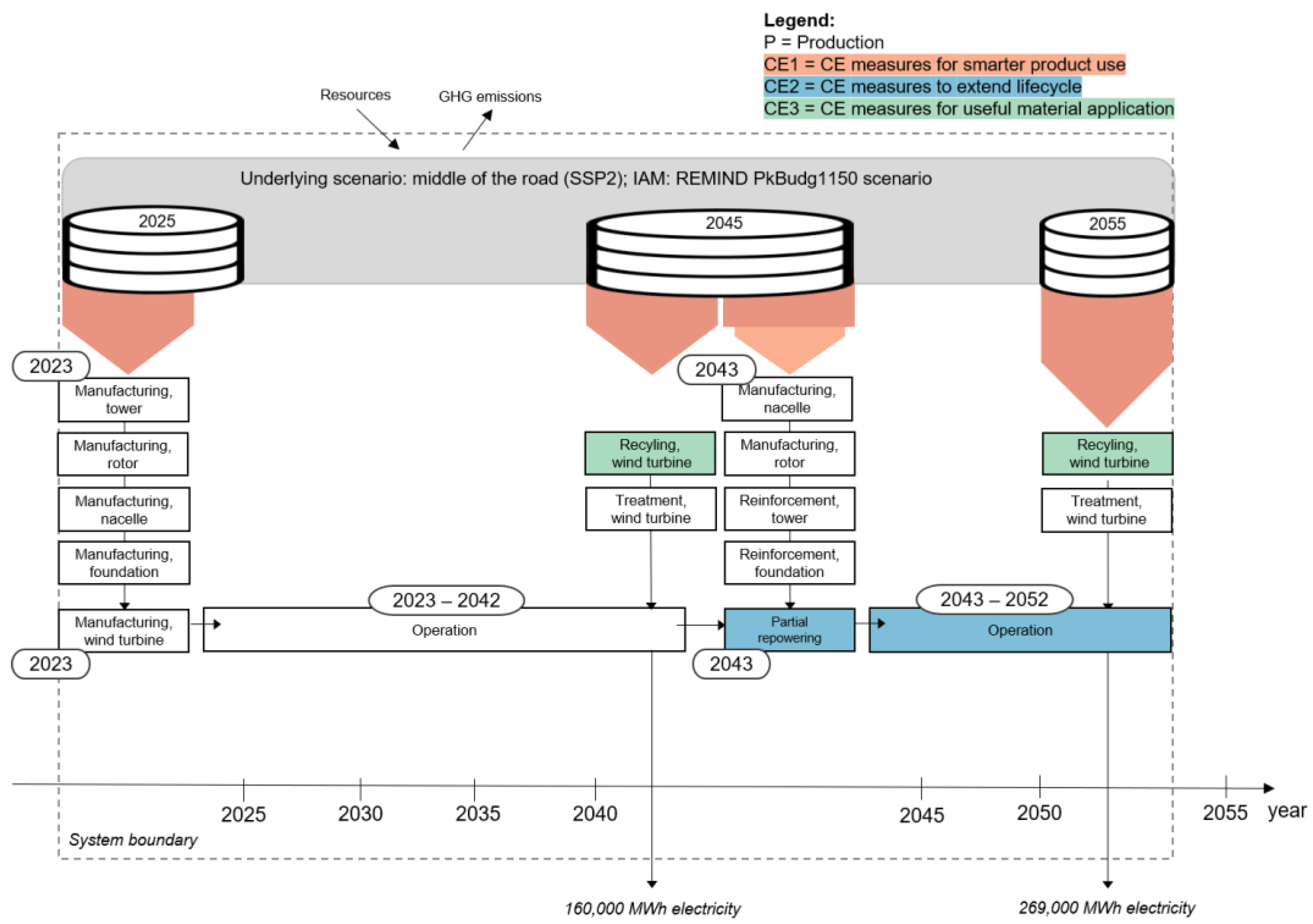

3.1. Goal and Scope

3.2. Life Cycle Inventory

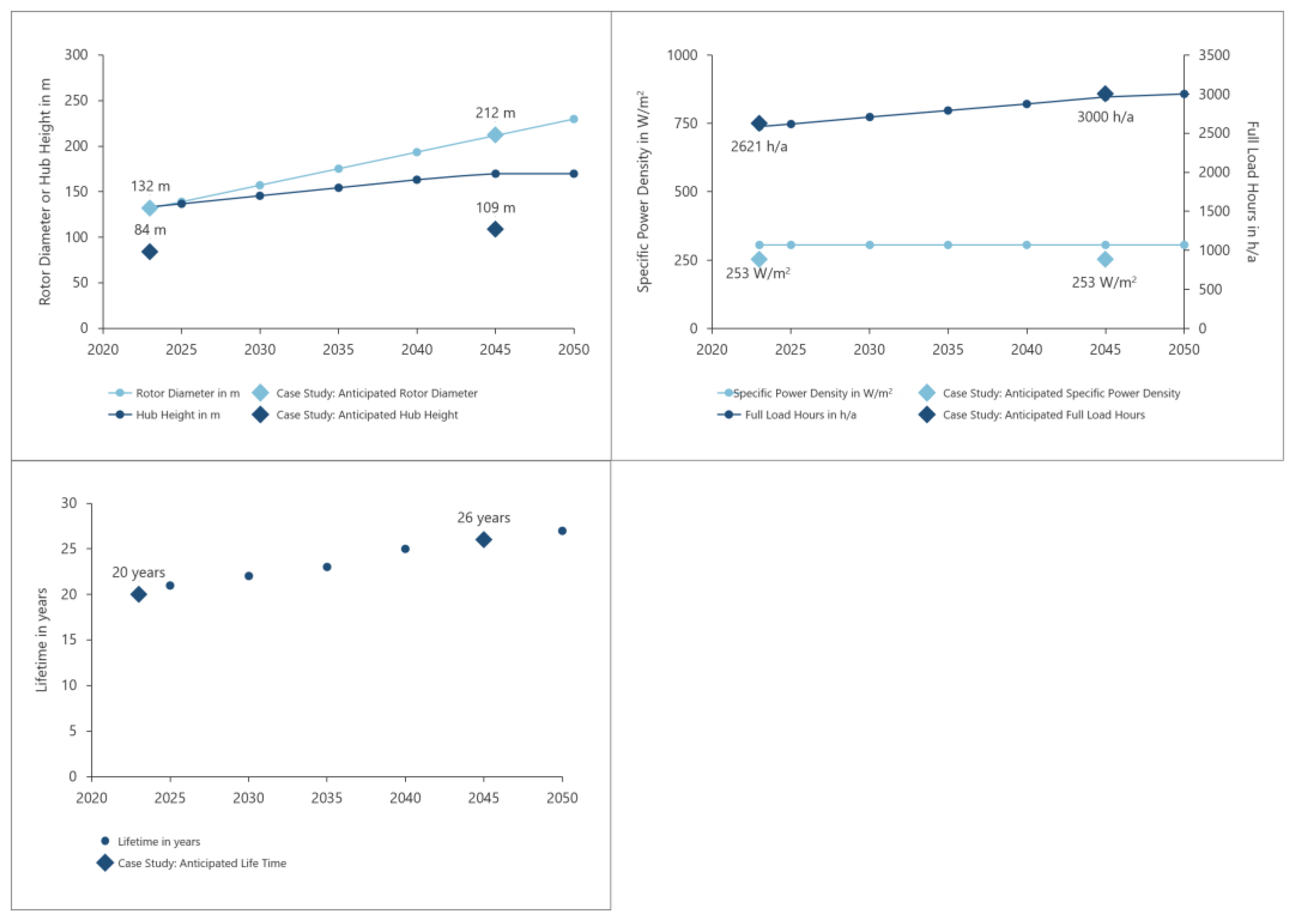

3.2.1. Foreground System

3.2.2. Background System

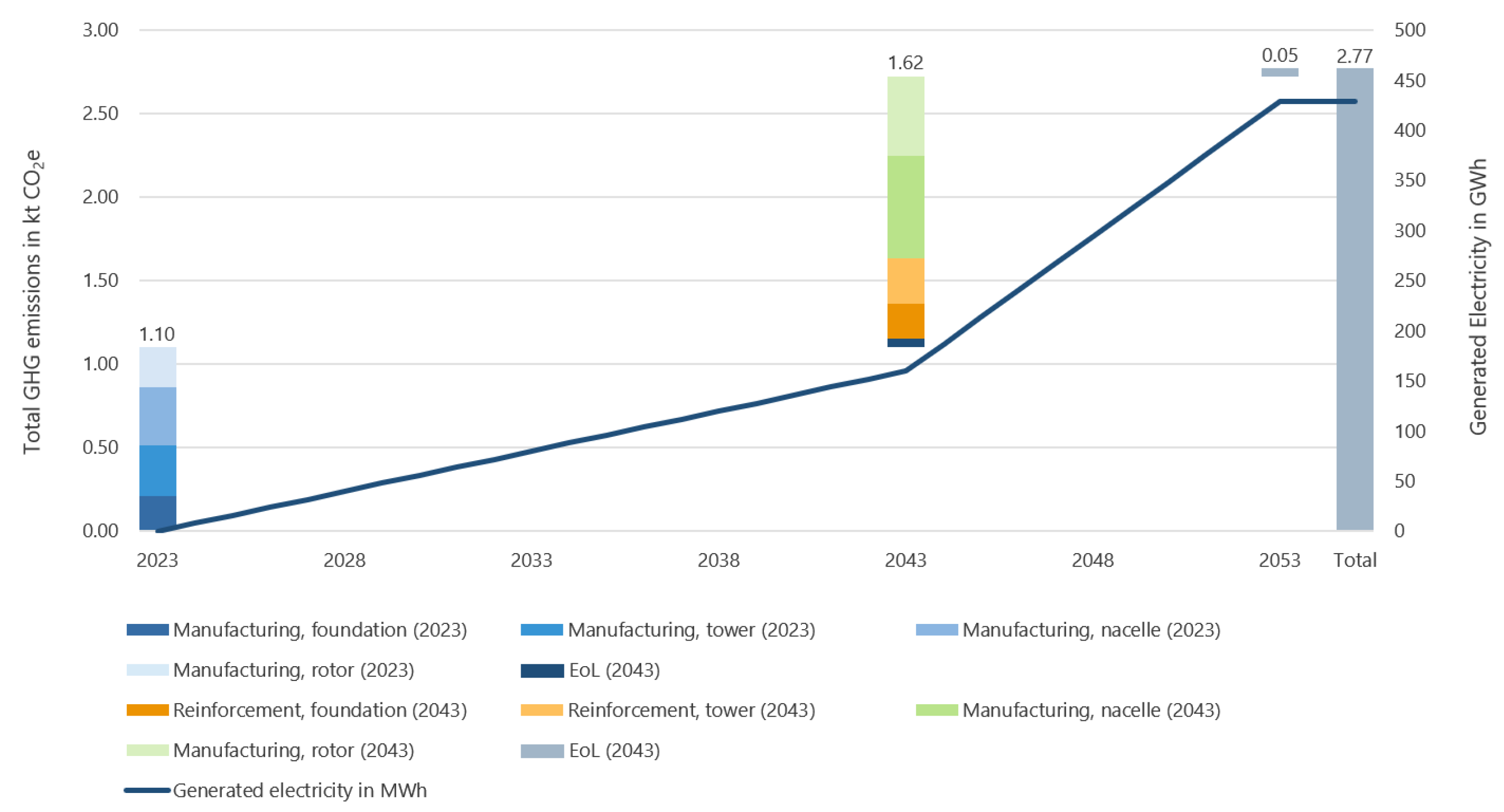

3.3. Life Cycle Impact Assessment and Interpretation

3.3.1. Total GHG Emissions and Total Electricity Produced

3.3.2. Global Warming Potential

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cozzi, L.; Gül, T.; Fernández, A.; Spencer, T.; Bouckaert, S.; McGlade, C.; Remme, U.; Wanner, B.; D’Ambrosio, D.e.a. Net Zero Roadmap: A Global Pathway to Keep the 1.5 °C Goal in Reach: 2023 Update. 2023. Available online: https://iea.blob.core.windows.net/assets/9a698da4-4002-4e53-8ef3-631d8971bf84/NetZeroRoadmap_AGlobalPathwaytoKeepthe1.5CGoalinReach-2023Update.pdf (accessed on 27 September 2024).

- Carrara, S.; Alves Dias, P.; Pazzotta, B.; Pavel, C. Raw Materials Demand for Wind and Solar PV Technologies in the Transition To-wards a Decarbonised Energy System, EUR 30095 EN; European Union: Luxembourg, 2020. [Google Scholar]

- European Union. Study on the Critical Raw Materials for the EU 2023: Final Report; European Union: Luxembourg, 2023. [Google Scholar]

- Charpentier Poncelet, A.; Helbig, C.; Loubet, P.; Beylot, A.; Muller, S.; Villeneuve, J.; Laratte, B.; Thorenz, A.; Tuma, A.; Sonnemann, G. Losses and lifetimes of metals in the economy. Nat. Sustain. 2022, 5, 717–726. [Google Scholar] [CrossRef]

- Buchert, M.; Bleher, D.; Bulach, W.; Knappe, F.; Muchow, N.; Reinhardt, J.; Meinshausen, I. Kartierung des Anthropogenen Lagers III (KartAL III); Abschlussbericht; UBA-Texte 47/2022; Umweltbundesamt: Dessau-Roßlau, Germany, 2022. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain: Policy Report; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017. [Google Scholar]

- Gebhardt, M.; Spieske, A.; Birkel, H. The future of the circular economy and its effect on supply chain dependencies: Empirical evidence from a Delphi study. Transp. Res. Part E Logist. Transp. Rev. 2022, 157, 102570. [Google Scholar] [CrossRef]

- Hagelücken, C.; Schmidt, M.; Schebek, L.; Liedtke, C.; Bongardt, B.; Dosch, K.; Faulstich, M.; Flamme, S.; Gast, M.; Hermann, S.; et al. Chancen und Grenzen des Recyclings im Kontext der Circular Economy: Rahmenbedingungen, Anforderungen und Handlungsempfehlungen. 2023. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/1410/publikationen/2023_uba_kom_ressourcen_bf.pdf (accessed on 3 February 2025).

- Schäfer, P. Recycling—Ein Mittel zu Welchem Zweck? Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2021; ISBN 978-3-658-32923-5. [Google Scholar]

- Reuter, M.A.; van Schaik, A.; Gutzmer, J.; Bartie, N.; Abadías-Llamas, A. Challenges of the Circular Economy: A Material, Metallurgical, and Product Design Perspective. Annu. Rev. Mater. Res. 2019, 49, 253–274. [Google Scholar] [CrossRef]

- Law for the Expansion of Renewable Energies: EEG. 2023. Available online: https://climate-laws.org/document/renewable-energy-sources-act-eeg-latest-version-eeg-2022_1b40 (accessed on 9 December 2024).

- Doukas, H.; Arsenopoulos, A.; Lazoglou, M.; Nikas, A.; Flamos, A. Wind repowering: Unveiling a hidden asset. Renew. Sustain. Energy Rev. 2022, 162, 112457. [Google Scholar] [CrossRef]

- Fuchs, C.; Kasten, J.; Vent, M. Current State and Future Prospective of Repowering Wind Turbines: An Economic Analysis. Energies 2020, 13, 3048. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Swtizerland, 2006.

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Swtizerland, 2006.

- Li, H.; Jiang, H.-D.; Dong, K.-Y.; Wei, Y.-M.; Liao, H. A comparative analysis of the life cycle environmental emissions from wind and coal power: Evidence from China. J. Clean. Prod. 2020, 248, 119192. [Google Scholar] [CrossRef]

- Danish Energy Agency. Technology Data for Transport of Energy: Data Sheets for Transport of Energy. Excel File. Available online: https://ens.dk/en/analyses-and-statistics/technology-data-transport-energy (accessed on 5 June 2024).

- Ajeeb, W.; Costa Neto, R.; Baptista, P. Life cycle assessment of green hydrogen production through electrolysis: A literature review. Sustain. Energy Technol. Assess. 2024, 69, 103923. [Google Scholar] [CrossRef]

- Sohn, J.; Kalbar, P.; Goldstein, B.; Birkved, M. Defining Temporally Dynamic Life Cycle Assessment: A Review. Integr. Environ. Assess. Manag. 2020, 16, 314–323. [Google Scholar] [CrossRef]

- Pehnt, M. Dynamic life cycle assessment (LCA) of renewable energy technologies. Renew. Energy 2006, 31, 55–71. [Google Scholar] [CrossRef]

- Collinge, W.O.; Landis, A.E.; Jones, A.K.; Schaefer, L.A.; Bilec, M.M. Dynamic life cycle assessment: Framework and application to an institutional building. Int. J. Life Cycle Assess. 2013, 18, 538–552. [Google Scholar] [CrossRef]

- Arvidsson, R.; Svanström, M.; Sandén, B.A.; Thonemann, N.; Steubing, B.; Cucurachi, S. Terminology for future-oriented life cycle assessment: Review and recommendations. Int. J. Life Cycle Assess. 2024, 29, 607–613. [Google Scholar] [CrossRef]

- Cucurachi, S.; van der Giesen, C.; Guinée, J. Ex-ante LCA of Emerging Technologies. Procedia CIRP 2018, 69, 463–468. [Google Scholar] [CrossRef]

- Arvidsson, R.; Tillman, A.-M.; Sandén, B.A.; Janssen, M.; Nordelöf, A.; Kushnir, D.; Molander, S. Environmental Assessment of Emerging Technologies: Recommendations for Prospective LCA. J. Ind. Ecol. 2018, 22, 1286–1294. [Google Scholar] [CrossRef]

- Bergerson, J.A.; Brandt, A.; Cresko, J.; Carbajales-Dale, M.; MacLean, H.L.; Matthews, H.; McCoy, S.; McManus, M.; Miller, S.A.; Morrow, W.R.I.; et al. Life cycle assessment of emerging technologies: Evaluation techniques at different stages of market and technical maturity. J. Ind. Ecol. 2020, 24, 11–25. [Google Scholar] [CrossRef]

- Guinée, J.B.; Cucurachi, S.; Henriksson, P.J.; Heijungs, R. Digesting the alphabet soup of LCA. Int. J. Life Cycle Assess. 2018, 23, 1507–1511. [Google Scholar] [CrossRef]

- Weyand, S.; Kawajiri, K.; Mortan, C.; Schebek, L. Scheme for generating upscaling scenarios of emerging functional materials based energy technologies in prospective LCA (UpFunMatLCA). J. Ind. Ecol. 2023, 27, 676–692. [Google Scholar] [CrossRef]

- Tsoy, N.; Steubing, B.; van der Giesen, C.; Guinée, J. Upscaling methods used in ex ante life cycle assessment of emerging technologies: A review. Int. J. Life Cycle Assess. 2020, 25, 1680–1692. [Google Scholar] [CrossRef]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. From laboratory to industrial scale: A scale-up framework for chemical processes in life cycle assessment studies. J. Clean. Prod. 2016, 135, 1085–1097. [Google Scholar] [CrossRef]

- Su, S.; Ju, J.; Ding, Y.; Yuan, J.; Cui, P. A Comprehensive Dynamic Life Cycle Assessment Model: Considering Temporally and Spatially Dependent Variations. Int. J. Environ. Res. Public Health 2022, 19, 14000. [Google Scholar] [CrossRef]

- Tiruta-Barna, L.; Pigné, Y.; Navarrete Gutiérrez, T.; Benetto, E. Framework and computational tool for the consideration of time dependency in Life Cycle Inventory: Proof of concept. J. Clean. Prod. 2016, 116, 198–206. [Google Scholar] [CrossRef]

- Cardellini, G.; Mutel, C.L.; Vial, E.; Muys, B. Temporalis, a generic method and tool for dynamic Life Cycle Assessment. Sci. Total Environ. 2018, 645, 585–595. [Google Scholar] [CrossRef]

- Levasseur, A.; Lesage, P.; Margni, M.; Deschênes, L.; Samson, R. Considering time in LCA: Dynamic LCA and its application to global warming impact assessments. Environ. Sci. Technol. 2010, 44, 3169–3174. [Google Scholar] [CrossRef]

- Østergaard, N.; Thorsted, L.; Miraglia, S.; Birkved, M.; Rasmussen, F.N.; Birgisdóttir, H.; Kalbar, P.; Georgiadis, S. Data Driven Quantification of the Temporal Scope of Building LCAs. Procedia CIRP 2018, 69, 224–229. [Google Scholar] [CrossRef]

- Mutel, C.L.; Hellweg, S. Regionalized life cycle assessment: Computational methodology and application to inventory databases. Environ. Sci. Technol. 2009, 43, 5797–5803. [Google Scholar] [CrossRef] [PubMed]

- Thonemann, N.; Schulte, A.; Maga, D. How to Conduct Prospective Life Cycle Assessment for Emerging Technologies? A Systematic Review and Methodological Guidance. Sustainability 2020, 12, 1192. [Google Scholar] [CrossRef]

- Langkau, S.; Steubing, B.; Mutel, C.; Ajie, M.P.; Erdmann, L.; Voglhuber-Slavinsky, A.; Janssen, M. A stepwise approach for Scenario-based Inventory Modelling for Prospective LCA (SIMPL). Int. J. Life Cycle Assess. 2023, 28, 1169–1193. [Google Scholar] [CrossRef]

- Mendoza Beltran, A.; Cox, B.; Mutel, C.; Vuuren, D.P.; Font Vivanco, D.; Deetman, S.; Edelenbosch, O.Y.; Guinée, J.; Tukker, A. When the Background Matters: Using Scenarios from Integrated Assessment Models in Prospective Life Cycle Assessment. J. Ind. Ecol. 2020, 24, 64–79. [Google Scholar] [CrossRef]

- Sacchi, R.; Terlouw, T.; Siala, K.; Dirnaichner, A.; Bauer, C.; Cox, B.; Mutel, C.; Daioglou, V.; Luderer, G. PRospective EnvironMental Impact asSEment (premise): A streamlined approach to producing databases for prospective life cycle assessment using integrated assessment models. Renew. Sustain. Energy Rev. 2022, 160, 112311. [Google Scholar] [CrossRef]

- Riahi, K.; van Vuuren, D.P.; Kriegler, E.; Edmonds, J.; O’Neill, B.C.; Fujimori, S.; Bauer, N.; Calvin, K.; Dellink, R.; Fricko, O.; et al. The Shared Socioeconomic Pathways and their energy, land use, and greenhouse gas emissions implications: An overview. Glob. Environ. Chang. 2017, 42, 153–168. [Google Scholar] [CrossRef]

- Schmidt, M.; Heidak, P. Intertemporal allocation of long-lasting recycling cascades. Energies 2025, Manuscript submitted for publication. [Google Scholar]

- Issa, T.; Chang, V.; Issa, T. Sustainable business strategies and PESTEL framework. Int. J. Comput. 2010, 1, 73–80. [Google Scholar] [CrossRef]

- Erakca, M.; Baumann, M.; Helbig, C.; Weil, M. Systematic review of scale-up methods for prospective life cycle assessment of emerging technologies. J. Clean. Prod. 2024, 451, 142161. [Google Scholar] [CrossRef]

- Buyle, M.; Audenaert, A.; Billen, P.; Boonen, K.; van Passel, S. The Future of Ex-Ante LCA? Lessons Learned and Practical Recommendations. Sustainability 2019, 11, 5456. [Google Scholar] [CrossRef]

- Ecoinvent. Ecoinvent Database. Available online: https://ecoinvent.org/database/ (accessed on 9 July 2024).

- Mutel, C. Brightway: An open source framework for Life Cycle Assessment. JOSS 2017, 2, 236. [Google Scholar] [CrossRef]

- Villares, M.; Işıldar, A.; van der Giesen, C.; Guinée, J. Does ex ante application enhance the usefulness of LCA? A case study on an emerging technology for metal recovery from e-waste. Int. J. Life Cycle Assess. 2017, 22, 1618–1633. [Google Scholar] [CrossRef]

- Voglhuber-Slavinsky, A.; Zicari, A.; Smetana, S.; Moller, B.; Dönitz, E.; Vranken, L.; Zdravkovic, M.; Aganovic, K.; Bahrs, E. Setting life cycle assessment (LCA) in a future-oriented context: The combination of qualitative scenarios and LCA in the agri-food sector. Eur. J. Futures Res. 2022, 10, 15. [Google Scholar] [CrossRef]

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.O.; Wernet, G. Overview and Methodology: Data Quality Guideline for the Ecoinvent Database Version 3. Ecoinvent Report No. 1(v3), St. Gallen. 2013. Available online: https://lca-net.com/publications/show/overview-methodology-data-quality-guideline-ecoinvent-database-version-3/ (accessed on 9 December 2024).

- Virtuelles Institut Strom zu Gas und Wärme NRW. Abschlusszentrum Kompetenzzentrum Virtuelles Institut Strom zu Gas und Wärme: Band 2—Lebenszyklusorientierte Analysen und Kritikalitätsanalyse von Power-to-X-Optionen. 2022. Available online: https://strom-zu-gas-und-waerme.de/wp-content/uploads/2022/07/KoVI-SGW-Abschlussbericht-Band-II-M%C3%A4rz-2022-final.pdf (accessed on 7 October 2024).

- Harpprecht, C.; Naegler, T.; Steubing, B.; Tukker, A.; Simon, S. Decarbonization scenarios for the iron and steel industry in context of a sectoral carbon budget: Germany as a case study. J. Clean. Prod. 2022, 380, 134846. [Google Scholar] [CrossRef]

- Van der Meide, M.; Harpprecht, C.; Northey, S.; Yang, Y.; Steubing, B. Effects of the energy transition on environmental impacts of cobalt supply: A prospective life cycle assessment study on future supply of cobalt. J. Ind. Ecol. 2022, 26, 1631–1645. [Google Scholar] [CrossRef]

- Scrucca, F.; Baldassarri, C.; Baldinelli, G.; Bonamente, E.; Rinaldi, S.; Rotili, A.; Barbanera, M. Uncertainty in LCA: An estimation of practitioner-related effects. J. Clean. Prod. 2020, 268, 122304. [Google Scholar] [CrossRef]

- Heijungs, R.; Suh, S. The Computational Structure of LCA; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Sonderegger, T.; Stoikou, N. Implementation of Life Cycle Impact Assessment Methods in the Ecoinvent Database v3.9; Ecoinvent: Zurich, Switzerland, 2022. [Google Scholar]

- Federal Ministry for the Environment, Nature Conservation, Building and Nuclear Safety. Klimaschutzplan 2050: Klimaschutzpolitische Grundsätze und Ziele der Bundesregierung; Federal Ministry for the Environment, Nature Conservation, Building and Nuclear Safety: Berlin, Germany, 2016. [Google Scholar]

- Kigle, S.; Ebner, M.; Guminski, A. Greenhouse Gas Abatement in EUROPE—A Scenario-Based, Bottom-Up Analysis Showing the Effect of Deep Emission Mitigation on the European Energy System. Energies 2022, 15, 1334. [Google Scholar] [CrossRef]

- Siemens Gamesa. Spares and Repairs for Wind Turbines: Flexible Solutions to Support Performance and Reduce Downtime. Available online: https://www.siemensgamesa.com/global/en/home/products-and-services/service-wind/spares-and-repairs.html (accessed on 12 December 2024).

- Schreiber, A.; Marx, J.; Zapp, P. Comparative life cycle assessment of electricity generation by different wind turbine types. J. Clean. Prod. 2019, 233, 561–572. [Google Scholar] [CrossRef]

- Borrmann, R.; Rehfeldt, K.; Kruse, D. Volllaststunden von Windenergieanlagen an Land—Entwicklung, Einflüsse, Auswirkungen, Varel. 2020. Available online: https://www.windguard.de/veroeffentlichungen.html?file=files/cto_layout/img/unternehmen/veroeffentlichungen/2020/Volllaststunden%20von%20Windenergieanlagen%20an%20Land%202020.pdf (accessed on 7 October 2024).

- Chiesura, G.; Stecher, H.; Pagh Jensen, J. Blade materials selection influence on sustainability: A case study through LCA. IOP Conf. Ser. Mater. Sci. Eng. 2020, 942, 12011. [Google Scholar] [CrossRef]

- Caduff, M.; Huijbregts, M.A.J.; Althaus, H.-J.; Koehler, A.; Stefanie, H. Wind power electricity: The bigger the turbine, the greener the electricity? Environ. Sci. Technol. 2012, 46, 4725–4733. [Google Scholar] [CrossRef]

- Kilb, J.; Haas, S. Analyzing the influence of implementing dynamic prospective research data in energy industry life cycle assessment based on a case study of a power transformer. Energies 2025, Manuscript submitted for publication. [Google Scholar]

- Luderer, G.; Leimbach, M.; Bauer, N.; Kriegler, E.; Baumstark, L.; Bertram, C.; Giannousakis, A.; Hilaire, J.; Klein, D.; Levesque, A.; et al. Description of the REMIND Model (Version 1.6). SSRN J. 2015. [Google Scholar] [CrossRef]

- German Federal Government. So Läuft der Ausbau der Erneuerbaren Energien in Deutschland. Available online: https://www.bundesregierung.de/breg-de/aktuelles/ausbau-erneuerbare-energien-2225808 (accessed on 20 February 2025).

- Pompeo, M.R. On the U.S. Withdrawal from the Paris Agreement. 2019. Available online: https://2017-2021.state.gov/on-the-u-s-withdrawal-from-the-paris-agreement/ (accessed on 20 February 2025).

- UNEP. Emissions Gap Report 2023: Broken Record—Temperatures Hit New Highs, Yet World Fails to Cut Emissions (Again), Nairobi. 2023. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/43923/EGR2023_ESEN.pdf?sequence=10 (accessed on 9 December 2024).

- Umweltbundesamt. Treibhausgasminderungsziele Deutschlands. Available online: https://www.umweltbundesamt.de/daten/klima/treibhausgasminderungsziele-deutschlands#internationale-vereinbarungen-weisen-den-weg (accessed on 20 February 2020).

- De Bortoli, A. Strenghts, Limitations, and Perspectives of coupling IAMs and LCA to study feasible and desirable societal pathways. Seville, 7 May 2024.

- Life-Cycle Impact Assessment: Striving Towards Best Practice; Haes, U., Helias, A., Eds.; SETAC Press: Pensacola, FL, USA, 2002; ISBN 9781880611548. [Google Scholar]

- Zhang, Y. Taking the Time Characteristic into Account of Life Cycle Assessment: Method and Application for Buildings. Sustainability 2017, 9, 922. [Google Scholar] [CrossRef]

- Pigné, Y.; Gutiérrez, T.N.; Gibon, T.; Schaubroeck, T.; Popovici, E.; Shimako, A.H.; Benetto, E.; Tiruta-Barna, L. A tool to operationalize dynamic LCA, including time differentiation on the complete background database. Int. J. Life Cycle Assess. 2020, 25, 267–279. [Google Scholar] [CrossRef]

- Diepers, T.; Müller, A.; Jakobs, A. bw_timex: v0.3.1. Available online: https://docs.brightway.dev/projects/bw-timex/en/latest/ (accessed on 21 April 2025).

- Kasah, T. LCA of a newsprint paper machine: A case study of capital equipment. Int. J. Life Cycle Assess. 2014, 19, 417–428. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heidak, P.; Isbert, A.-M.; Haas, S.; Schmidt, M. Integration of Recent Prospective LCA Developments into Dynamic LCA of Circular Economy Strategies for Wind Turbines. Energies 2025, 18, 2509. https://doi.org/10.3390/en18102509

Heidak P, Isbert A-M, Haas S, Schmidt M. Integration of Recent Prospective LCA Developments into Dynamic LCA of Circular Economy Strategies for Wind Turbines. Energies. 2025; 18(10):2509. https://doi.org/10.3390/en18102509

Chicago/Turabian StyleHeidak, Pia, Anne-Marie Isbert, Sofia Haas, and Mario Schmidt. 2025. "Integration of Recent Prospective LCA Developments into Dynamic LCA of Circular Economy Strategies for Wind Turbines" Energies 18, no. 10: 2509. https://doi.org/10.3390/en18102509

APA StyleHeidak, P., Isbert, A.-M., Haas, S., & Schmidt, M. (2025). Integration of Recent Prospective LCA Developments into Dynamic LCA of Circular Economy Strategies for Wind Turbines. Energies, 18(10), 2509. https://doi.org/10.3390/en18102509