The Use of Canola for Biofuel Production in the Context of Energy Security—A Systematic Literature Review

Abstract

1. Introduction

| Method | Process | Source |

|---|---|---|

| Transesterification | Reaction of vegetable oil with alcohol in the presence of a catalyst | Gaide et al., 2024 [30] |

| Hydrothermal hydrogenation | Extraction of the biofuel from the biomass with high temperature | Demirbas, 2007 [5] |

2. Method

3. The Relation Between Energy Prices and Canola Biofuel Research

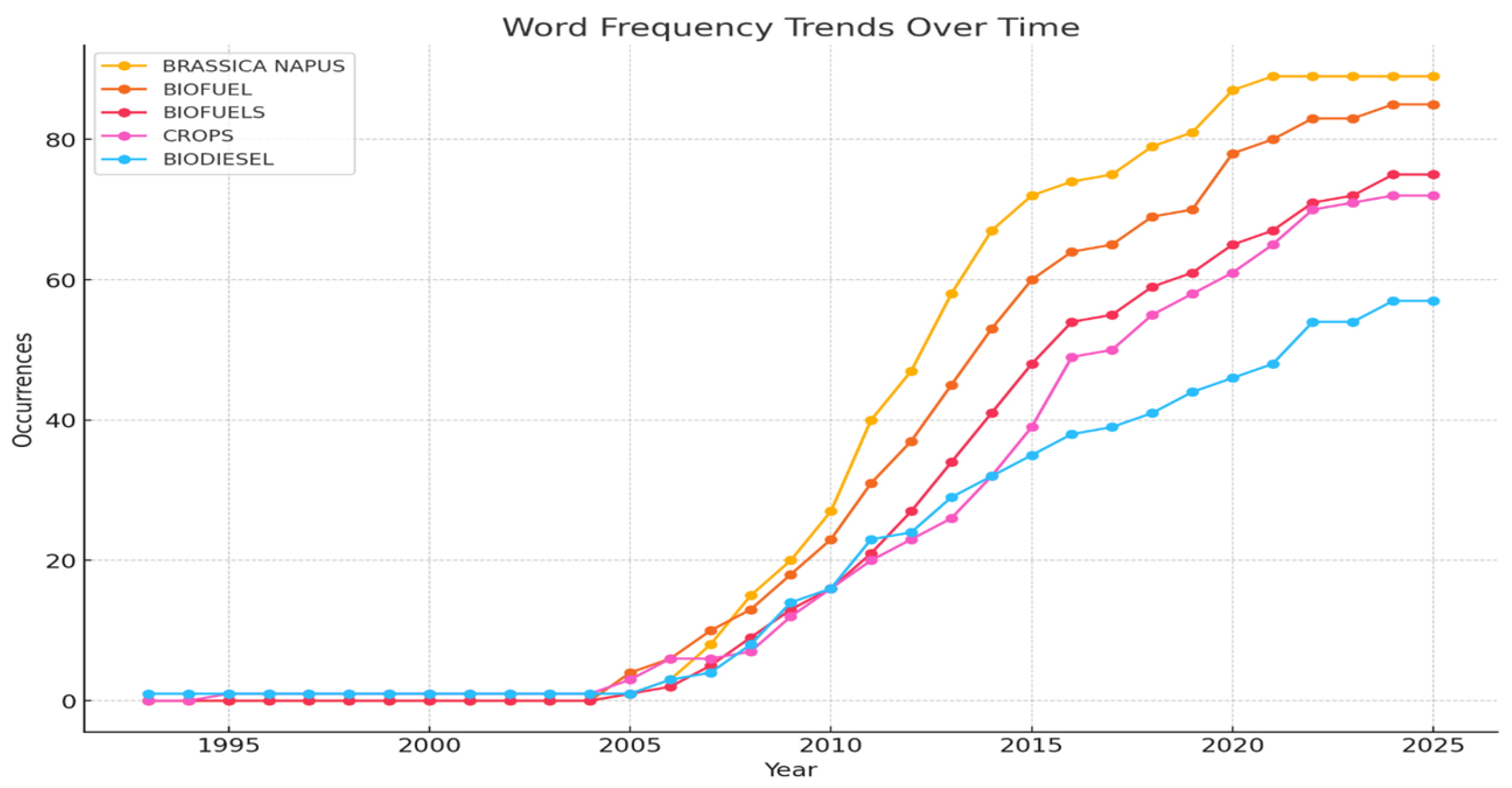

4. An Outlook on the Broad Bibliometric Outcome

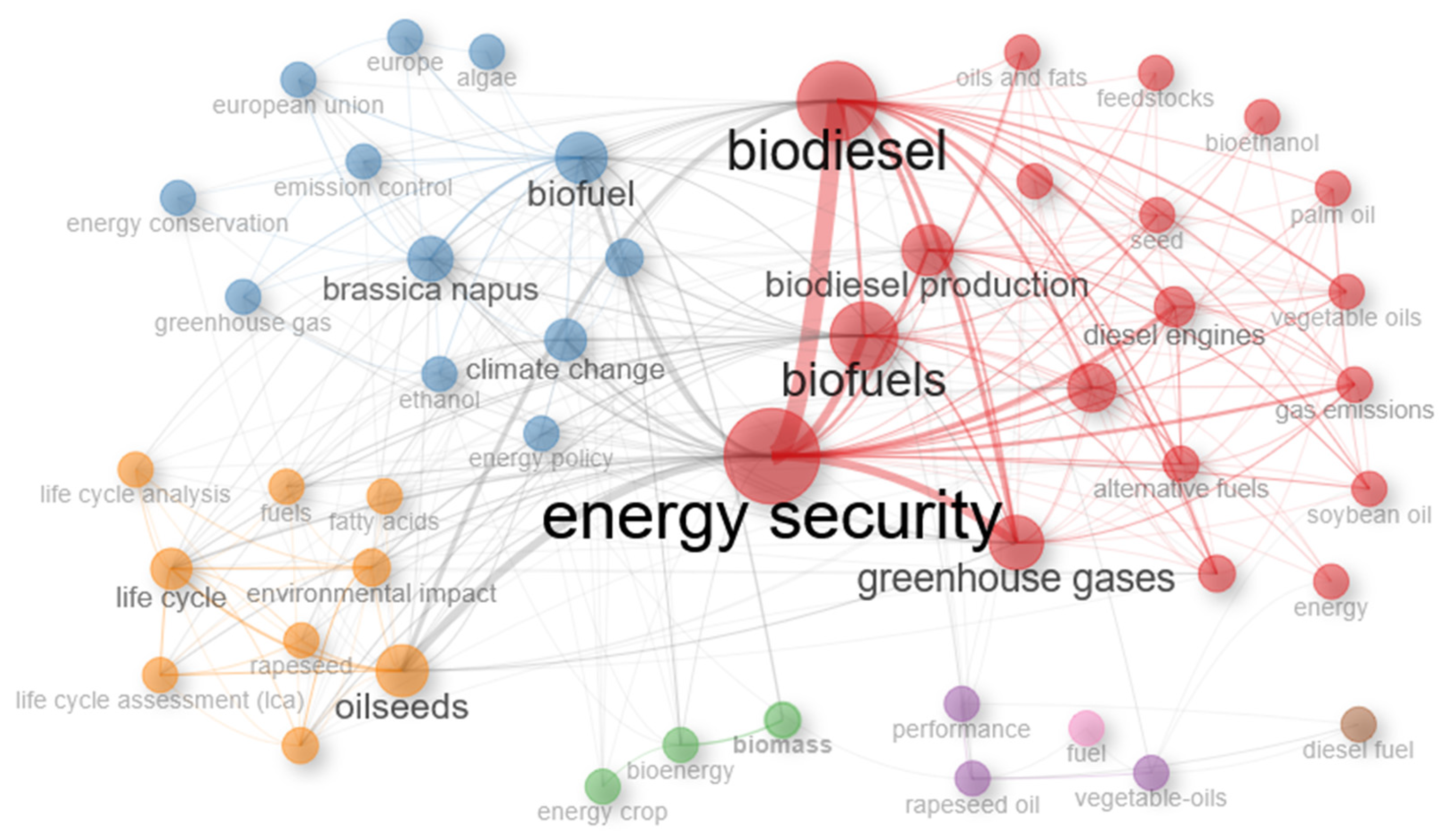

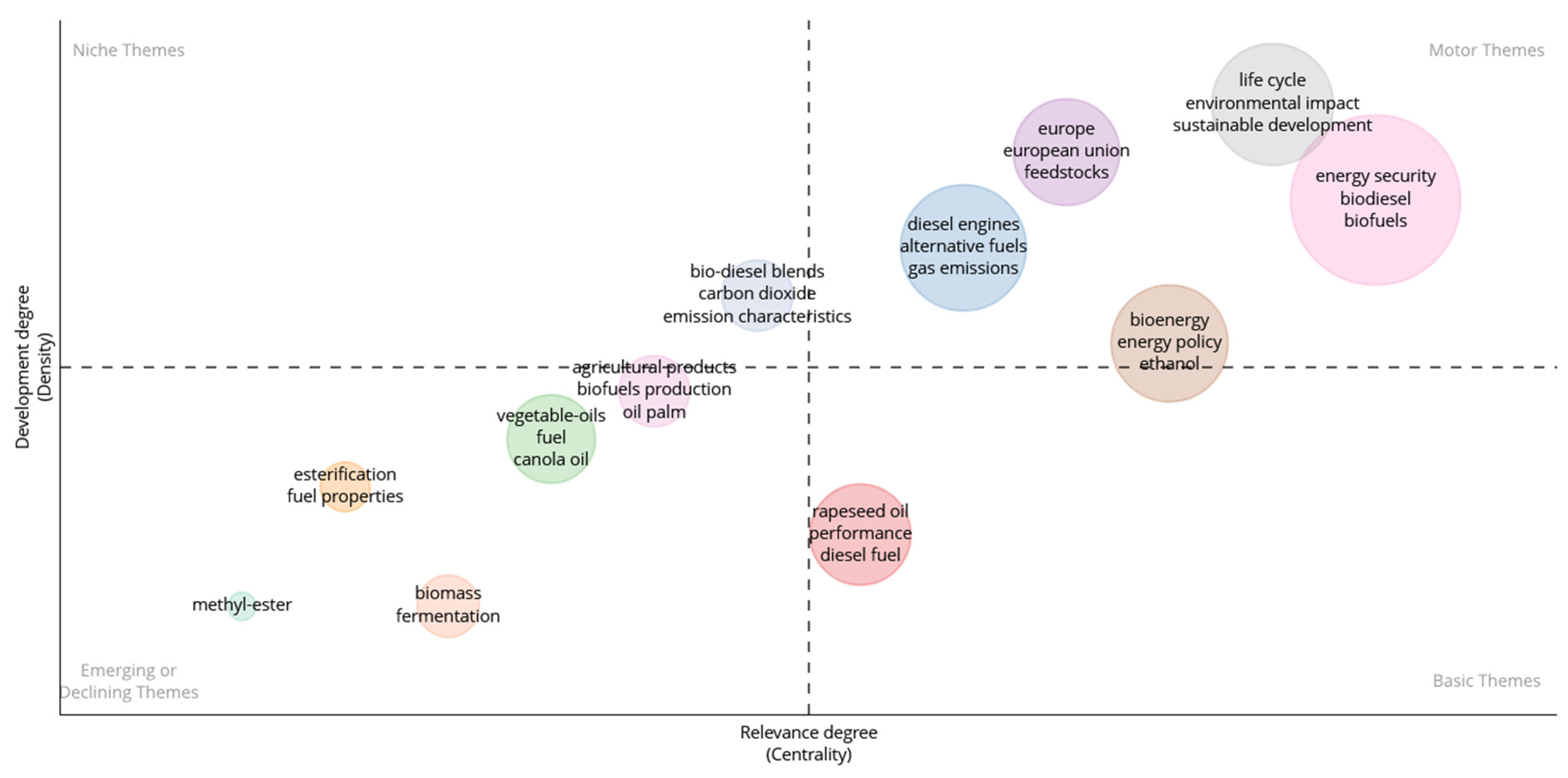

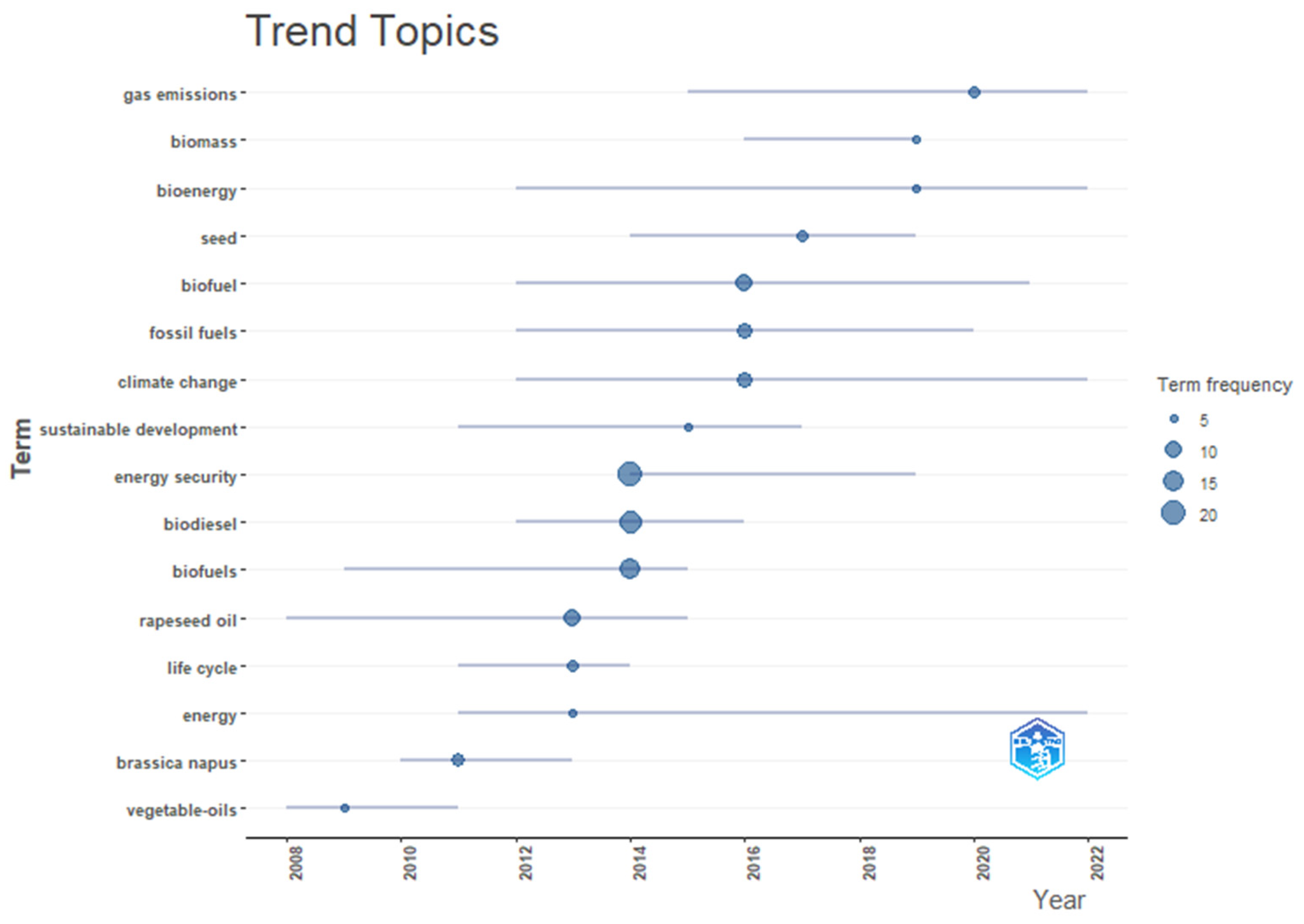

5. Second Bibliometric Attempt—Major Themes and Methods Applied

- Laboratory research: Investigates biofuel properties and optimizes production through experimental studies [44].

| Method | No. of Studies | Key Applications | Example Studies |

|---|---|---|---|

| LCA | 8 | Environmental impact, GHG emissions, energy balance | Stephenson et al., 2008 [38]; Stow et al., 2012 [39]; Susmozas et al., 2015 [43]; Ukaew et al., 2014 [41] |

| Experimental Testing | 7 | Engine performance, fuel properties, emissions analysis | Tesfa et al., 2014 [46]; Ali and Abuhabaya, 2012 [42]; Sales, 2011 [47] |

| Statistical and Econometric Analysis | 4 | Policy impact, market trends, economic efficiency | Chmielewski, 2022 [1]; Susmozas et al., 2015 [43]; Stow et al., 2012 [39] |

| Process Simulation (Aspen Plus, SimaPro, MATLAB) | 3 | Process modeling for hydrogen production, HRJ fuel synthesis, biofuel conversion | Susmozas et al., 2015 [43]; Ukaew et al., 2014 [41]; Taufiqurrahmi and Bhatia, 2011 [48] |

| Comparative Fuel Performance Studies | 5 | Comparing biodiesel vs. fossil fuels, hydrotreated fuels, and hydrogen energy | Tesfa et al., 2014 [46]; Ukaew et al., 2014 [41]; Sales, 2011 [47] |

| Catalytic and Chemical Process Optimization | 3 | Improving transesterification, catalytic cracking, hydroprocessing efficiency | Taufiqurrahmi and Bhatia, 2011 [48]; Suarez et al., 2009 [45] |

| Nitrogen Cycle and Fertilizer Impact Studies | 2 | Impact of canola fertilizer on N2O emissions and LCA accuracy | Ukaew et al., 2014 [41]; Susmozas et al., 2015 [43] |

6. SWOT Analysis of Canola-Based Biofuel Production—Energy Security Context

7. A Comparison of Canola with Other Biofuel Sources

- Energy crops: sunflower, soybean, and palm oil

- 2.

- Waste oil

- 3.

- Microalgae

- 4.

- Hydrotreated fuels (HRJ) and biohydrogen

| Biofuel Source | Cost (USD/L) | Key Cost Factors | Source |

|---|---|---|---|

| Corn-based Ethanol (US) | USD 0.10–0.25 | Yield, technology efficiency | Méjean and Hope, 2010 [60] |

| Sugarcane Ethanol (Brazil) | USD 0.05–0.08 | Yield, efficient land use, low input costs | Méjean and Hope, 2010 [60] |

| Canola (Farm use) | USD 0.81 | Production scale, energy input | COP AgriEnergy, 2011 [61] |

| Canola | USD 0.55–0.63 | Production scale, coproducts, capital costs | Miller et al., 2012 [57] |

| Camelina | USD 0.28–1.04 | Feedstock pricing, market demand for meal | Miller et al., 2012 [57] |

| Soybean | USD 0.40–0.60 | Capital costs, feedstock pricing, co-product credits | Fore et al., 2011 [58] |

| Cellulosic Ethanol (Corn Stover) | USD 0.28–0.48/kg biomass | Biomass cost, technology development | Becerra-Pérez et al., 2022 [62] |

| Straight Vegetable Oil (Canola) | USD 0.64–0.83 | Low refining requirements and processing cost | Fore et al., 2011 [58] |

| Soybean Biodiesel (Integrated Biorefinery) | USD 0.58 | Process integration, coproducts (meal, lecithin), reduced waste | Granjo et al., 2017 [59] |

| Soybean Biodiesel (Standalone) | USD 0.79 | Higher processing cost, standalone production, limited coproducts | Haas et al., 2006 [63] |

| Corn Ethanol (US) | USD 0.70 | Energy-intensive process, government subsidies, land-use efficiency | Patzek, 2005 [64] |

| Canola (EU) | USD 0.69 | Higher land use, higher feedstock costs | Haas et al., 2006 [63] |

| Soybean (US) | USD 0.53 | Feedstock cost, refinery infrastructure, glycerol market effects | Haas et al., 2006 [63] |

| Canola (Canada) | USD 0.81 | Feedstock cost, energy-intensive processing, smaller production scale | Granjo et al., 2017 [59] |

8. Technological Stagnation of the Canola Biofuels

9. Biofuel Regulations in the EU

10. Discussion

11. Conclusions and Recommendations

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

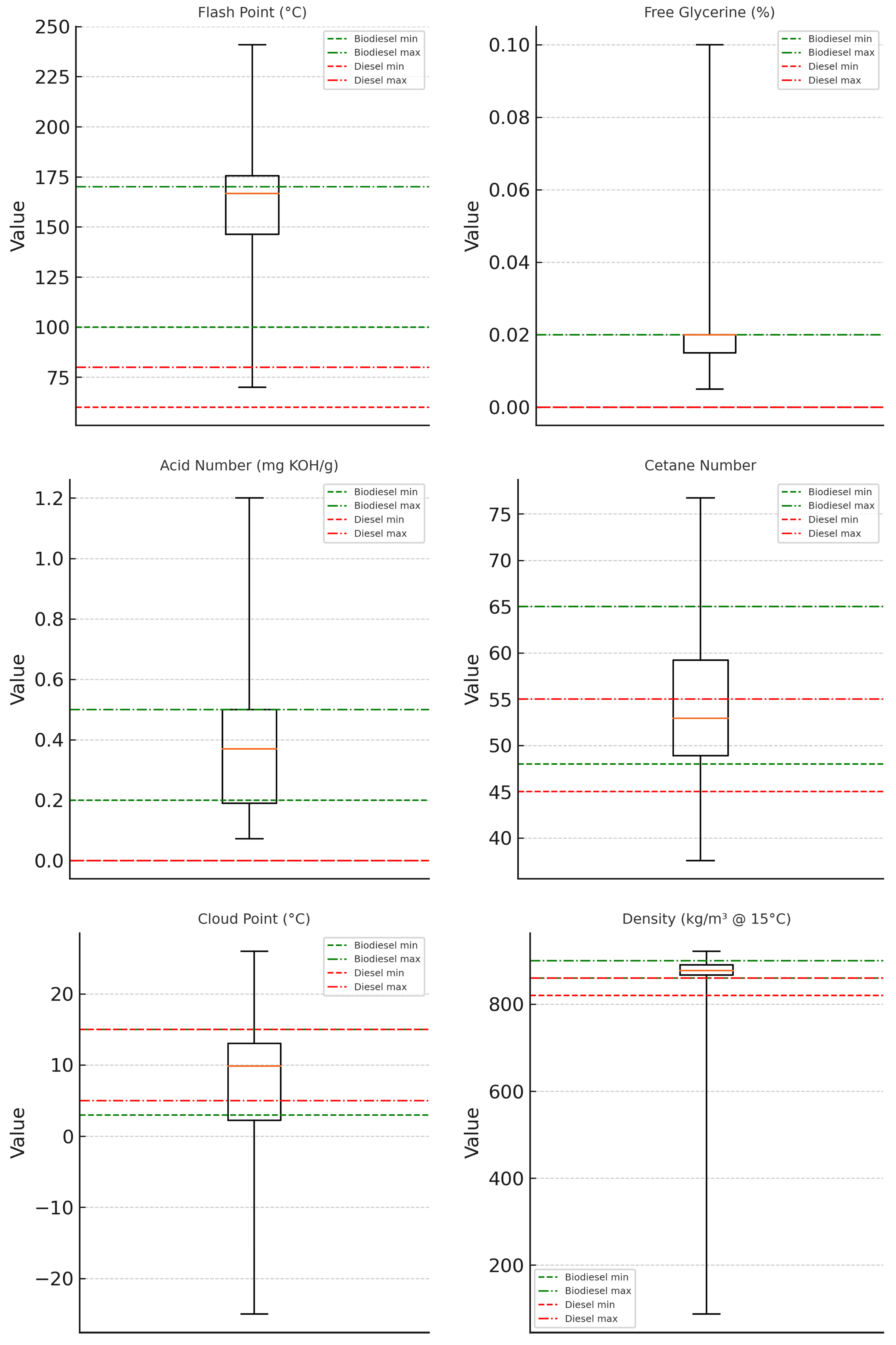

Appendix A

| Property | Min | Q1 | Median | Q3 | Max |

|---|---|---|---|---|---|

| Kinematic Viscosity (mm2/s at 40 °C) | 2.2 | 4.09 | 4.6 | 5.3 | 17.14 |

| Density (kg/m3 at 15 °C) | 87.4 | 867 | 877 | 890.02 | 922 |

| Cetane Number | 37.55 | 48.875 | 52.94 | 59.215 | 76.74 |

| Higher Heating Value (MJ/kg) | 18.33 | 26.42 | 38.6225 | 40.79 | 52.2 |

| Flash Point (°C) | 70 | 146.4 | 166.6 | 175.5 | 241 |

| Cloud Point (°C) | −25 | 2.25 | 9.835 | 13 | 26 |

| Pour Point (°C) | −28 | −2.35 | 4 | 8.06 | 18 |

| Sulfur Content (ppm) | 0 | 10 | 15 | 50 | 210 |

| Free Glycerine (%) | 0.005 | 0.015 | 0.02 | 0.02 | 0.1 |

| Acid Number (mg KOH/g) | 0.072 | 0.19 | 0.37 | 0.5 | 1.2 |

| Oxidation Stability (hours) | 0.18 | 1.5825 | 2.945 | 8.0025 | 20.7 |

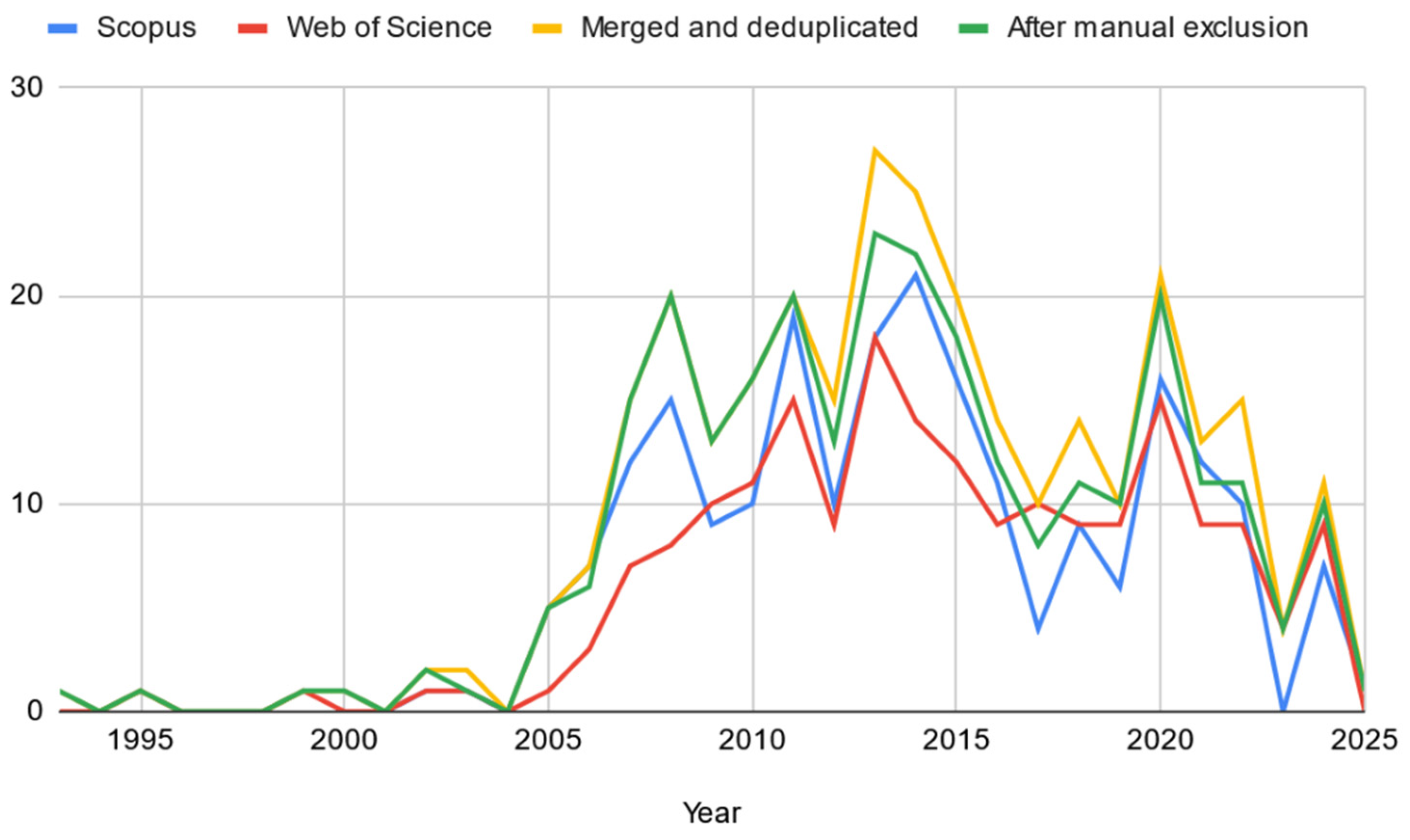

| Year | Scopus | Web of Science | Merged and Deduplicated | After Manual Exclusion | U.S. No 2 Diesel Ultra Low Sulfur (0–15 ppm) Retail Prices (Dollars per Gallon) | U.S. All Grades, All Formulations, Retail Gasoline Prices (Dollars per Gallon) |

|---|---|---|---|---|---|---|

| 2025 | 1 | 0 | 1 | 1 | N/A | N/A |

| 2024 | 7 | 9 | 11 | 10 | 3.814 | 3.424 |

| 2023 | 0 | 4 | 4 | 4 | 2.473 | 3.635 |

| 2022 | 10 | 9 | 15 | 11 | 2.993 | 4.059 |

| 2021 | 12 | 9 | 13 | 11 | 3.84 | 3.1 |

| 2020 | 16 | 15 | 21 | 20 | 3.968 | 2.258 |

| 2019 | 6 | 9 | 10 | 10 | 3.922 | 2.691 |

| 2018 | 9 | 9 | 14 | 11 | 3.825 | 2.813 |

| 2017 | 4 | 10 | 10 | 8 | 2.707 | 2.528 |

| 2016 | 11 | 9 | 14 | 12 | 2.304 | 2.25 |

| 2015 | 16 | 12 | 20 | 18 | 2.65 | 2.52 |

| 2014 | 21 | 14 | 25 | 22 | 3.178 | 3.437 |

| 2013 | 18 | 18 | 27 | 23 | 3.056 | 3.575 |

| 2012 | 10 | 9 | 15 | 13 | 2.551 | 3.68 |

| 2011 | 19 | 15 | 20 | 20 | 3.287 | 3.576 |

| 2010 | 10 | 11 | 16 | 16 | 4.989 | 2.835 |

| 2009 | 9 | 10 | 13 | 13 | 4.214 | 2.406 |

| 2008 | 15 | 8 | 20 | 20 | 3.76 | 3.299 |

| 2007 | 12 | 7 | 15 | 15 | N/A | 2.843 |

| 2006 | 7 | 3 | 7 | 6 | N/A | 2.618 |

| 2005 | 5 | 1 | 5 | 5 | N/A | 2.314 |

| 2004 | 0 | 0 | 0 | 0 | N/A | 1.895 |

| 2003 | 1 | 1 | 2 | 1 | N/A | 1.603 |

| 2002 | 1 | 1 | 2 | 2 | N/A | 1.386 |

| 2001 | 0 | 0 | 0 | 0 | N/A | 1.46 |

| 2000 | 1 | 0 | 1 | 1 | N/A | 1.523 |

| 1999 | 1 | 1 | 1 | 1 | N/A | 1.176 |

| 1998 | 0 | 0 | 0 | 0 | N/A | 1.072 |

| 1997 | 0 | 0 | 0 | 0 | N/A | 1.244 |

| 1996 | 0 | 0 | 0 | 0 | N/A | 1.245 |

| 1995 | 1 | 1 | 1 | 1 | N/A | 1.158 |

| 1994 | 0 | 0 | 0 | 0 | N/A | 1.078 |

| 1993 | 1 | 0 | 1 | 1 | N/A | N/A |

Appendix B

- https://www.webofscience.com/wos/woscc/summary/ddf43e47-7842-4d10-a0a1-d2c1263541b8-014156698e/relevance/1. (accessed on 13 January 2025)

- https://www.webofscience.com/wos/woscc/summary/a5ef517c-962a-4b36-a684-d1c642c56554-01423cb52c/relevance/1. (accessed on 20 January 2025)

References

- Chmielewski, Ł. Tendencies for Usage of Rapeseed Oil and Maize for Biocomponent Production in Poland Between 2015 and 2020. Zagadnienia Ekon. Rolnej/Probl. Agric. Econ. 2022, 372, 85–107. [Google Scholar] [CrossRef]

- Lee, A.F.; Wilson, K. Recent Developments in Heterogeneous Catalysis for the Sustainable Production of Biodiesel. Catal. Today 2015, 242, 3–18. [Google Scholar] [CrossRef]

- Baka, J.; Roland-Holst, D. Food or Fuel? What European Farmers Can Contribute to Europe’s Transport Energy Requirements and the Doha Round. Energy Policy 2009, 37, 2505–2513. [Google Scholar] [CrossRef]

- Arbab, M.I.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Imtenan, S.; Sajjad, H. Fuel Properties, Engine Performance and Emission Characteristics of Common Biodiesels as a Renewable and Sustainable Source of Fuel. Renew. Sustain. Energy Rev. 2013, 22, 133–147. [Google Scholar] [CrossRef]

- Demirbas, A. Progress and Recent Trends in Biofuels. Prog. Energy Combust. Sci. 2007, 33, 1–18. [Google Scholar] [CrossRef]

- Binhweel, F.; Bahadi, M.; Elgamouz, A. A Comparative Review of Some Physicochemical Properties of Biodiesels Synthesized from Different Generations of Vegetative Oils. Mater. Today Proc. 2021, 47, 2217–2224. [Google Scholar] [CrossRef]

- Hilário, C.V.; Campos, J.C.C.; Siqueira, A.M.O.; Leite, M.O.; Martins, M.A.; Brito, R.F.; Abderrahmane, K. Physical-Chemical Properties of First-Generation Biofuel Aiming Application in Diesel Locomotive. Rev. Gestão Soc. Ambient. 2024, 18, e05080. [Google Scholar] [CrossRef]

- Azad, A.K. Biodiesel from Mandarin Seed Oil: A Surprising Source of Alternative Fuel. Energies 2017, 10, 1689. [Google Scholar] [CrossRef]

- Sajjadi, B.; Raman, A.A.A.; Arandiyan, H. A Comprehensive Review on Properties of Edible and Non-Edible Vegetable Oil-Based Biodiesel: Composition, Specifications and Prediction Models. Renew. Sustain. Energy Rev. 2016, 63, 62–92. [Google Scholar] [CrossRef]

- Okonkwo, C.P.; Ajiwe, V.I.E.; Ikeuba, A.I.; Emori, W.; Okwu, M.O.; Ayogu, J.I. Production and Performance Evaluation of Biodiesel from Elaeis guineensis Using Natural Snail Shell-Based Heterogeneous Catalyst: Kinetics, Modeling and Optimisation by Artificial Neural Network. RSC Adv. 2023, 13, 19495–19507. [Google Scholar] [CrossRef]

- Kandasamy, K.; Dhairiyasamy, R.; Gabiriel, D. Comparative Study of Plant-Based Antioxidants on the Stability of Soybean and Beef Tallow Biodiesels. Energy Sci. Eng. 2025, 13, 1706–1719. [Google Scholar] [CrossRef]

- Ikechukwu, C.D.; Ifijen, I.H.; Udokpoh, N.U.; Ikhuoria, E.U. Biodiesel Generation from Palm Kernel Biomass via an In-Situ Transesterification Approach. Tanzan. J. Sci. 2021, 47, 1844–1855. [Google Scholar] [CrossRef]

- Bui, H.M.; Manickam, S. Process Optimization and Environmental Analysis of Ultrasound-Assisted Biodiesel Production from Pangasius Fat Using CoFe2O4 Catalyst. ACS Omega 2023, 8, 36162–36170. [Google Scholar] [CrossRef]

- Eryılmaz, T.; Şahin, S. Investigation of Fuel Properties of Biodiesel Produced from Crude, Refined and Fried Safflower Oils. Turk. J. Agric. Nat. Sci. 2023, 10, 1121–1128. [Google Scholar] [CrossRef]

- Mamedov, İ.G.; Mamedova, G.; Azimova, N. Testing of Ethylene Glycol Ketal, Dioxane and Cyclopentanone as Components of B10, B20 Fuel Blends. Energy Environ. Storage 2022, 2, 9–12. [Google Scholar] [CrossRef]

- Shaah, M.A.; Hossain, M.S.; Allafi, F.A.; Omar, F.M.; Ahmad, M.I. Biodiesel Production from Candlenut Oil Using a Non-Catalytic Supercritical Methanol Transesterification Process: Optimization, Kinetics, and Thermodynamic Studies. RSC Adv. 2022, 12, 9845–9861. [Google Scholar] [CrossRef]

- Baig, A.; Ng, F.T. Determination of Acid Number of Biodiesel and Biodiesel Blends. J. Am. Oil Chem. Soc. 2011, 88, 243–253. [Google Scholar] [CrossRef]

- Rashid, U.; Ibrahim, M.; Yasin, S.; Yunus, R.; Taufiq-Yap, Y.H.; Knothe, G. Biodiesel from Citrus reticulata (Mandarin Orange) Seed Oil, a Potential Non-Food Feedstock. Ind. Crops Prod. 2013, 45, 355–359. [Google Scholar] [CrossRef]

- Tubino, M.; Aricetti, J.A. A Green Method for Determination of Acid Number of Biodiesel. J. Braz. Chem. Soc. 2011, 22, 1073–1081. [Google Scholar] [CrossRef]

- Rashedi, A.; Gul, N.; Hussain, M.; Hadi, R.; Khan, N.I.; Nadeem, S.G.; Kumar, V. Life Cycle Environmental Sustainability and Cumulative Energy Assessment of Biomass Pellets Biofuel Derived from Agroforest Residues. PLoS ONE 2022, 17, e0275005. [Google Scholar] [CrossRef]

- Carneiro-Junior, J.A.d.M.; de Oliveira, G.F.; Alves, C.T.; Andrade, H.M.C.; Beisl Vieira de Melo, S.A.; Torres, E.A. Valorization of Prosopis juliflora Woody Biomass in Northeast Brazilian Through Dry Torrefaction. Energies 2021, 14, 3465. [Google Scholar] [CrossRef]

- Kousalya, V.; Prasanna, K.T. Influence of Soil Sulfur Content and Other Edaphic Factors on Sulfur Levels in Calophyllum inophyllum L. Biodiesel. Int. J. Environ. Clim. Change 2024, 14, 282–295. [Google Scholar] [CrossRef]

- Ekpenkhio, J.E. Production of Bio-Kerosene from Jatropha curcas Seeds: Evaluation and Parameter Influence. Curr. J. Appl. Sci. Technol. 2024, 43, 52–60. [Google Scholar] [CrossRef]

- Fernandes, A.M.A.P.; Tega, D.U.; Jara, J.L.P.; Cunha, I.B.S.; Sá, G.F.; Daroda, R.J.; Eberlin, M.N.; Alberici, R.M. Free and Total Glycerin in Biodiesel: Accurate Quantitation by Easy Ambient Sonic-Spray Ionization Mass Spectrometry. Energy Fuels 2012, 26, 3042–3047. [Google Scholar] [CrossRef]

- Donoso, D.; Bolonio, D.; Lapuerta, M.; Canoira, L. Oxidation Stability: The Bottleneck for the Development of a Fully Renewable Biofuel from Wine Industry Waste. ACS Omega 2020, 5, 16645–16653. [Google Scholar] [CrossRef]

- Yang, Z.; Hollebone, B.P.; Wang, Z.; Yang, C.; Landriault, M. Factors Affecting Oxidation Stability of Commercially Available Biodiesel Products. Fuel Process. Technol. 2013, 106, 366–375. [Google Scholar] [CrossRef]

- Chrysikou, L.P.; Litinas, A.; Bezergianni, S. Assessment of Biodiesel Stability under Long-Term Storage and Dynamic Accelerated Oxidation: A Comparison Approach. Clean Technol. Environ. Policy 2022, 24, 2583–2593. [Google Scholar] [CrossRef]

- Kovacevic, V.; Wesseler, J. Cost-effectiveness analysis of algae energy production in the EU. Energy Policy 2010, 38, 5749–5757. [Google Scholar] [CrossRef]

- Rasetti, M.; Finco, A.; Bentivoglio, D. GHG Balance of Biodiesel Production and Consumption in EU. Int. J. Glob. Energy Issues 2014, 37, 191–204. [Google Scholar] [CrossRef]

- Gaide, I.; Grigas, A.; Makareviciene, V.; Sendzikiene, E. Life Cycle Assessment and Biodegradability of Biodiesel Produced Using Different Alcohols and Heterogeneous Catalysts. Green Chem. Lett. Rev. 2024, 17, 2394503. [Google Scholar] [CrossRef]

- Boldrin, A.; Balzan, A.; Astrup, T. Energy and Environmental Analysis of a Rapeseed Biorefinery Conversion Process. Biomass Convers. Biorefinery 2013, 3, 127–141. [Google Scholar] [CrossRef]

- European Biodiesel Board. Statistical Report 2023. Available online: https://ebb-eu.org/wp-content/uploads/2024/03/EBB_Statistical_Report2023-Final.pdf (accessed on 15 January 2025).

- Staniszewski, J.; Matuszczak, A. Environmentally Adjusted Analysis of Agricultural Efficiency: A Systematic Literature Review of Frontier Approaches. Zagadnienia Ekon. Rolnej/Probl. Agric. Econ. 2023, 374, 20–41. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. Bibliometrix: An R-Tool for Comprehensive Science Mapping Analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- USDA. Production—Rapeseed. 2024. Available online: https://www.fas.usda.gov/data/production/commodity/2226000 (accessed on 13 January 2025).

- Hoque, N.; Biswas, W.K.; Mazhar, I.; Howard, I. LCSA Framework for Assessing Sustainability of Alternative Fuels for Transport Sector. Chem. Eng. Trans. 2019, 72, 103–108. [Google Scholar] [CrossRef]

- Shi, R.; Ukaew, S.; Archer, D.W.; Lee, J.H.; Pearlson, M.N.; Lewis, K.C.; Shonnard, D.R. Life Cycle Water Footprint Analysis for Rapeseed Derived Jet Fuel in North Dakota. ACS Sustain. Chem. Eng. 2017, 5, 3845–3854. [Google Scholar] [CrossRef]

- Stephenson, A.L.; Dennis, J.S.; Scott, S.A. Improving the sustainability of the production of biodiesel from oilseed rape in the UK. Process Saf. Environ. Prot. 2008, 86, 427–440. [Google Scholar] [CrossRef]

- Stow, M.; McManus, M.C.; Bannister, C. A Life Cycle Assessment Comparison of Rapeseed Biodiesel and Conventional Diesel. Sustain. Veh. Technol. 2012, 23–33. [Google Scholar] [CrossRef]

- Bentivoglio, D.; Finco, A.; Bacchi, M.R.P.; Spedicato, G. European Biodiesel Market and Rapeseed Oil: What Impact on Agricultural Food Prices? Int. J. Glob. Energy Issues 2014, 37, 220–235. [Google Scholar] [CrossRef]

- Ukaew, S.; Beck, E.; Meki, M.N.; Shonnard, D.R. Application of the Roundtable on Sustainable Biofuels Method to Regional Differences in Nitrous Oxide Emissions for the Rapeseed Hydrotreated Renewable Jet Life Cycle. J. Clean. Prod. 2014, 83, 220–227. [Google Scholar] [CrossRef]

- Ali, J.; Abuhabaya, A. Sunflower Biodiesel: Efficiency and Emissions. WIT Trans. Eng. Sci. 2012, 81, 25–36. [Google Scholar] [CrossRef]

- Susmozas, A.; Iribarren, D.; Dufour, J. Assessing the Life-Cycle Performance of Hydrogen Production via Biofuel Reforming in Europe. Resources 2015, 4, 398–411. [Google Scholar] [CrossRef]

- Sakuragi, K.; Li, P.; Otaka, M.; Makino, H. Recovery of Bio-Oil from Industrial Food Waste by Liquefied Dimethyl Ether for Biodiesel Production. Energies 2016, 9, 106. [Google Scholar] [CrossRef]

- Suarez, P.A.Z.; Santos, A.L.F.; Rodrigues, J.P.; Alves, M.B. Biocombustíveis a partir de óleos e gorduras: Desafios tecnológicos para viabilizá-los (Oils and fats based biofuels: Technological chalendges). Quim. Nova 2009, 32, 768–775. [Google Scholar] [CrossRef]

- Tesfa, B.; Gu, F.; Mishra, R.; Ball, A. Emission Characteristics of a CI Engine Running with a Range of Biodiesel Feedstocks. Energies 2014, 7, 334–350. [Google Scholar] [CrossRef]

- Sales, A. Production of Biodiesel from Sunflower Oil and Ethanol by Base Catalyzed Transesterification; Department of Chemical Engineering Royal Institute of Technology (KTH): Stockholm, Sweden, 2011; Available online: https://www.diva-portal.org/smash/get/diva2:443295/FULLTEXT01.pdf (accessed on 24 January 2025).

- Taufiqurrahmi, N.; Bhatia, S. Catalytic Cracking of Edible and Non-Edible Oils for the Production of Biofuels. Energy Environ. Sci. 2011, 4, 1087–1112. [Google Scholar] [CrossRef]

- Gawłowski, S.; Listowska-Gawłowska, R.; Piecuch, T. Uwarunkowania i prognoza bezpieczeństwa energetycznego Polski na lata 2010–2110 (Conditions and forecast of Poland’s energy safety for the period 2010–2110). Rocz. Ochr. Sr. 2010, 12, 127–176. Available online: https://bibliotekanauki.pl/articles/1819653 (accessed on 18 January 2025).

- Viccaro, M.; Romano, S.; Rosalia, I.; Cozzi, M. Searching for the Profitability of Energy Crops: An Agroecological–Economic Land Use Suitability (AE-landUSE) Model. Environments 2024, 11, 91. [Google Scholar] [CrossRef]

- Koizumi, T. Biofuels and Food Security. Renew. Sustain. Energy Rev. 2015, 52, 829–841. [Google Scholar] [CrossRef]

- Mittapelly, P.; Guelly, K.N.; Hussain, A.; Cárcamo, H.A.; Soroka, J.J.; Vankosky, M.A.; Hegedus, D.D.; Tansey, J.A.; Costamagna, A.C.; Gavloski, J.; et al. Flea Beetle (Phyllotreta spp.) Management in Spring-Planted Canola (Brassica napus L.) on the Northern Great Plains of North America. GCB Bioenergy 2024, 16, e13178. [Google Scholar] [CrossRef]

- Khanal, A.; Shah, A. Oilseeds to Biodiesel and Renewable Jet Fuel: An Overview of Feedstock Production, Logistics, and Conversion. Biofuels Bioprod. Biorefining 2021, 15, 913–930. [Google Scholar] [CrossRef]

- Santhakumaran, L.N. Search for Future Fuels—Pathway Points to a “Boring” Process. In Wood is Good; Pandey, K., Ramakantha, V., Chauhan, S., Arun Kumar, A., Eds.; Springer: Singapore, 2017; pp. 411–421. [Google Scholar] [CrossRef]

- Staš, M.; Vrtiška, D.; Kittel, H.; Šimáček, P. Vlastnosti a Analýza Kapalných Alternativních Paliv III: Rostlinné Oleje a Hydrogenované Rostlinné Oleje. Paliva 2023, 15, 63–69. [Google Scholar] [CrossRef]

- Jayed, M.H.; Masjuki, H.H.; Kalam, M.A.; Mahlia, T.M.I.; Husnawan, M.; Liaquat, A.M. Prospects of Dedicated Biodiesel Engine Vehicles in Malaysia and Indonesia. Renew. Sustain. Energy Rev. 2011, 15, 220–235. [Google Scholar] [CrossRef]

- Miller, P.; Sultana, A.; Kumar, A. Optimum scale of feedstock processing for renewable diesel production. Biofuels Bioprod. Biorefining 2012, 6, 188–204. [Google Scholar] [CrossRef]

- Fore, S.R.; Lazarus, W.; Porter, P.; Jordan, N. Economics of small-scale on-farm use of canola and soybean for biodiesel and straight vegetable oil biofuels. Biomass Bioenergy 2011, 35, 193–202. [Google Scholar] [CrossRef]

- Granjo, J.F.O.; Duarte, B.P.M.; Oliveira, N.M.C. Integrated production of biodiesel in a soybean biorefinery: Modelling, simulation and economical assessment. Energy 2017, 129, 273–291. [Google Scholar] [CrossRef]

- Méjean, A.; Hope, C. Modelling the costs of energy crops: A case study of US corn and Brazilian sugar cane. Energy Policy 2010, 38, 547–561. [Google Scholar] [CrossRef]

- COP AgriEnergy. Guidelines for Estimating Canola Biodiesel Production Costs—Farm Fuel. 2011. Available online: https://www.gov.mb.ca/agriculture/farm-management/cost-production/pubs/cop_agrienergy_canolabiodieselfarmfuel.pdf (accessed on 18 January 2025).

- Becerra-Pérez, L.A.; Rincón, L.; Posada-Duque, J.A. Logistics and Costs of Agricultural Residues for Cellulosic Ethanol Production. Energies 2022, 15, 4480. [Google Scholar] [CrossRef]

- Haas, M.J.; McAloon, A.J.; Yee, W.C.; Foglia, T.A. A process model to estimate biodiesel production costs. Bioresour. Technol. 2006, 97, 671–678. [Google Scholar] [CrossRef]

- Patzek, T.W.; Anti, S.-M.; Campos, R.; Ha, K.W.; Lee, J.; Li, B.; Padnick, J.; Yee, S.-A. Ethanol from Corn: Clean Renewable Fuel for the Future, or Drain on Our Resources and Pockets? Environ. Dev. Sustain. 2005, 7, 319–336. [Google Scholar] [CrossRef]

- Kohli, H.; Ali, A. Biofuel revolution: Advancements in sustainable energy solutions. In Futuristic Trends in Biotechnology; IIP Series: Chikkamagaluru, India, 2024; Volume 3, Book 23, pp. 191–210. [Google Scholar] [CrossRef]

- Patel, S.; Dixit, S.; Suneja, K.G.; Tipan, N. Second-generation biofuel—An alternative clean fuel. Smart Moves J. Ijoscience 2021, 7, 13–21. [Google Scholar] [CrossRef]

- Sadaqat, B.; Dar, M.A.; Xie, R.; Jianzhong, S. Drawbacks of first-generation biofuels: Challenges and paradigm shifts in technology for second- and third-generation biofuels. In Biofuels and Sustainability. Life Cycle Assessments, System Biology, Policies, and Emerging Technologies; A volume in Woodhead Series in Bioenergy; Zhu, D., Dar, M.A., Shahnawaz, M., Eds.; Elsevier Science Ltd.: Amsterdam, The Netherlands, 2024; pp. 33–47. [Google Scholar] [CrossRef]

- Pimentel, D.; Burgess, M. Biofuel production using food. Environ. Dev. Sustain. 2014, 16, 1–3. [Google Scholar] [CrossRef]

- Çalık, A. Exploring the efficiency and emission characteristics of hydroxy-boosted canola biodiesel in comparison to traditional diesel fuels. Front. Energy Res. 2024, 12, 1386440. [Google Scholar] [CrossRef]

- Demafelis, R.; Cases, M.; Sombilla, J.; Migo, V.; Matanguihan, A.; Landoy, R. Fast biodiesel production via potassium ferrate catalysis at room temperature using used cooking oil and refined canola oil. IOP Conf. Ser. Mater. Sci. Eng. 2024, 1318, 012009. [Google Scholar] [CrossRef]

- Stephy, G.M.; Surendarnath, S.; Flora, G.; Amesho, K.T.T. Microalgae for sustainable biofuel generation: Innovations, bottlenecks, and future directions. Environ. Qual. Manag. 2025, 34, e70019. [Google Scholar] [CrossRef]

- Behera, S.; Singh, R.; Arora, R.; Sharma, N.K.; Shukla, M.; Kumar, S. Scope of algae as third-generation biofuels. Front. Bioeng. Biotechnol. 2015, 2, 90. [Google Scholar] [CrossRef]

- Akram, F.; Shoaib, E.; Fatima, T.; Shabbir, I.; Haq, I. Evolution of biofuels: Unraveling diverse applications and emerging horizons. Energy Explor. Exploit. 2024, 43, 834–864. [Google Scholar] [CrossRef]

- Bórawski, P.; Wyszomierski, R.; Bełdycka-Bórawska, A.; Mickiewicz, B.; Kalinowska, B.; Dunn, J.W.; Rokicki, T. Development of renewable energy sources in the European Union in the context of sustainable development policy. Energies 2022, 15, 1545. [Google Scholar] [CrossRef]

- Frank, S.; Böttcher, H.; Havlík, P.; Valin, H.; Mosnier, A.; Obersteiner, M.; Schmid, E.; Elbersen, B. How effective are the sustainability criteria accompanying the European Union 2020 biofuel targets? GCB Bioenergy 2013, 5, 306–314. [Google Scholar] [CrossRef]

- Dusser, P. The European energy policy for 2020–2030: RED II—What future for vegetable oil as a source of bioenergy? OCL 2019, 26, 51. [Google Scholar] [CrossRef]

- Garvie, L.C.; Brown, M.; Lee, D.J.; Kulišić, B. Projecting investment potential of an emerging forest bioeconomy market: An EU–Australian benchmarking study. GCB Bioenergy 2024, 16, e13176. [Google Scholar] [CrossRef]

- Zhou, W. Application and development prospects of rapeseed oil in biodiesel production. J. Energy Biosci. 2024, 15, 74–86. [Google Scholar] [CrossRef]

- González-García, S.; García-Rey, D.; Hospido, A. Environmental life cycle assessment for rapeseed-derived biodiesel. Int. J. Life Cycle Assess. 2013, 18, 61–76. [Google Scholar] [CrossRef]

- Lovasz, A.; Sabău, N.C.; Borza, I.; Brejea, R. Production and Quality of Biodiesel under the Influence of a Rapeseed Fertilization System. Energies 2023, 16, 3728. [Google Scholar] [CrossRef]

- Anantha Raman, L.; Deepanraj, B.; Rajakumar, S.; Sivasubramanian, V. Experimental investigation on performance, combustion and emission analysis of a direct injection diesel engine fuelled with rapeseed oil biodiesel. Fuel 2019, 246, 69–74. [Google Scholar] [CrossRef]

- Santaraite, M.; Sendžikienė, E.; Makarevičienė, V.; Kazancev, K. Biodiesel Production by Lipase-Catalyzed in Situ Transesterification of Rapeseed Oil Containing a High Free Fatty Acid Content with Ethanol in Diesel Fuel Media. Energies 2020, 13, 2588. [Google Scholar] [CrossRef]

- Moioli, E.; Salvati, F.; Chiesa, M.; Siecha, R.T.; Manenti, F.; Laio, F.; Rulli, M.C. Analysis of the current world biofuel production under a water–food–energy nexus perspective. Adv. Water Resour. 2018, 121, 22–31. [Google Scholar] [CrossRef]

- Pulighe, G.; Bonati, G.; Colangeli, M.; Morese, M.M.; Traverso, L.; Lupia, F.; Khawaja, C.; Janssen, R.; Fava, F. Ongoing and emerging issues for sustainable bioenergy production on marginal lands in the Mediterranean regions. Renew. Sustain. Energy Rev. 2019, 103, 58–70. [Google Scholar] [CrossRef]

- Rodriguez, R.G.; Scanlon, B.R.; King, C.W.; Scarpare, F.V.; Xavier, A.C.; Pruski, F.F. Biofuel-water-land nexus in the last agricultural frontier region of the Brazilian Cerrado. Appl. Energy 2018, 231, 1330–1345. [Google Scholar] [CrossRef]

- Silalertruksa, T.; Gheewala, S.H. Land-water-energy nexus of sugarcane production in Thailand. J. Clean. Prod. 2018, 182, 521–528. [Google Scholar] [CrossRef]

- Cherubini, F.; Bird, N.D.; Cowie, A.; Jungmeier, G.; Schlamadinger, B.; Woess-Gallasch, S. Energy- and greenhouse gas-based LCA of biofuel and bioenergy systems: Key issues, ranges and recommendations. Resour. Conserv. Recycl. 2009, 53, 434–447. [Google Scholar] [CrossRef]

- Firrisa, M.T.; van Duren, I.; Voinov, A. Energy efficiency for rapeseed biodiesel production in different farming systems. Energy Effic. 2014, 7, 79–95. [Google Scholar] [CrossRef]

- Börjesson, P. Good or bad bioethanol from a greenhouse gas perspective—What determines this? Appl. Energy 2009, 86, 589–594. [Google Scholar] [CrossRef]

- Srivastava, A.; Sunder, S.; Tse, S. Timely Loss Recognition and Termination of Unprofitable Projects. China J. Account. Res. 2015, 8, 147–167. [Google Scholar] [CrossRef]

- Chen, H.F.; Bazzoli, G.J.; Hsieh, H.M. Hospital Financial Conditions and the Provision of Unprofitable Services. Atl. Econ. J. 2009, 37, 259–277. [Google Scholar] [CrossRef]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material Efficiency: Providing Material Services with Less Material Production. Philos. Trans. R. Soc. A. Math. Phys. Eng. Sci. 2013, 371, 20120496. [Google Scholar] [CrossRef]

- Aidt, T.; Jia, L.; Low, H. Are Prices Enough? The Economics of Material Demand Reduction. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2017, 375, 20160370. [Google Scholar] [CrossRef]

| Category | Total Papers | Included Papers | Inclusion Rate (%) | Rejection Rate (%) |

|---|---|---|---|---|

| Agricultural Practices and Biomass Utilization | 174 | 160 | 91.95 | 8.05 |

| Bioenergy and Biogas Production | 72 | 65 | 90.28 | 9.72 |

| Other/Unclassified | 26 | 21 | 80.77 | 19.23 |

| Environmental Impact and Sustainability | 15 | 15 | 100.00 | 0.00 |

| Climate Change and Renewable Energy Policies | 10 | 10 | 100.00 | 0.00 |

| Case Studies and Regional Studies | 6 | 4 | 66.67 | 33.33 |

| Biotechnological Innovation in Bioenergy | 1 | 1 | 100.00 | 0.00 |

| SUM | 304 | 276 | 90.79 | 70.33 |

| Stage | Scopus Search Term | Web of Science Search Term |

|---|---|---|

| 1 | (TITLE-ABS-KEY (“biodiesel” OR “biofuel *”) AND TITLE-ABS-KEY (“rape” OR “rapeseed” OR “canola”) AND TITLE-ABS-KEY (“farm *” OR “holding *” OR “agroholding *”)) | (TITLE-ABS-KEY (“biodiesel” OR “biofuel *”) AND TITLE-ABS-KEY (“rape” OR “rapeseed” OR “canola”) AND TITLE-ABS-KEY (“farm *” OR “holding *” OR “agroholding *”)) |

| 2 | (TITLE-ABS-KEY (“biodiesel” OR “biofuel *”) AND TITLE-ABS-KEY (“rape” OR “rapeseed” OR “canola”) AND TITLE-ABS-KEY (“security”)) | “biodiesel” OR “biofuel *” (Topic) and “rape” OR “rapeseed” OR “canola” (Topic) and “security” (Topic) |

| Data Source | Scopus | WoS | Merged | After Manual Exclusion |

|---|---|---|---|---|

| Diesel | 0.05 | 0.11 | 0.06 | 0.17 |

| Retail gas | 0.71 | 0.75 | 0.77 | 0.75 |

| Average nominal crude | 0.76 | 0.76 | 0.81 | 0.80 |

| Average real crude | 0.76 | 0.74 | 0.80 | 0.80 |

| Data Source | Scopus | WoS | Merged and Deduplicated | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Corellations | Baseline | Lag 1 | Lag 2 | Baseline | Lag 1 | Lag 2 | Baseline | Lag 1 | Lag 2 |

| Crude_Nominal | 0.2861 | 0.1408 | 0.3230 | ||||||

| Crude_Nominal_Lag 1 | 0.0705 | 0.0705 | 0.2186 | 0.2186 | 0.0823 | 0.0823 | |||

| Crude_Nominal_Lag 2 | 0.1083 | 0.1083 | −0.0857 | −0.0857 | −0.2110 | −0.2110 | |||

| Crude_Real | 0.3283 | 0.1720 | 0.3781 | ||||||

| Diesel_Price | 0.0534 | 0.1097 | 0.0570 | ||||||

| Diesel_Price_Lag 1 | −0.4459 | −0.4459 | −0.2574 | −0.2574 | −0.3377 | −0.3377 | |||

| Diesel_Price_Lag 2 | −0.4549 | −0.4549 | −0.5984 | −0.5984 | −0.4067 | −0.4067 | |||

| Gasoline_Price | 0.0783 | −0.0556 | 0.0937 | ||||||

| Lag | p-Value (Scopus) | p-Value (Web of Science) | p-Value (Merged) |

|---|---|---|---|

| 1 | 0.8377 | 0.5898 | 0.8200 |

| 2 | 0.8142 | 0.3892 | 0.3774 |

| University | Michigan Technological University | Selcuk University | University Malaya | Vytautas Magnus University |

|---|---|---|---|---|

| Country | USA | Türkiye | Malesia | Lithuania |

| Number of publications | 5 | 4 | 4 | 4 |

| Country | Malaysia | UK | Italy | USA | Poland | India | Lithuania | Turkey | Australia | Brazil |

|---|---|---|---|---|---|---|---|---|---|---|

| Number of studies | 10 | 10 | 6 | 6 | 5 | 4 | 4 | 4 | 3 | 3 |

| Node | Cluster | Betweenness | Closeness | Page Rank |

|---|---|---|---|---|

| Energy security | 1 | 291.69 | 0.0178 | 0.092 |

| Biodiesel | 1 | 161.22 | 0.0169 | 0.070 |

| Biofuels | 1 | 94.55 | 0.0153 | 0.054 |

| Evaluation Criterion | Canola Biodiesel Performance | Better Alternative |

|---|---|---|

| Biofuel Yield (L/ha) | Moderate (1190 L/ha) | Palm oil (5950 L/ha), Microalgae (136,900 L/ha) |

| GHG Emissions | Lower than fossil fuels (2.415 g CO2-eq/MJ) | Biohydrogen (3.79 g CO2-eq/MJ) |

| N2O Emissions | Moderate (0.73 kg N2O/Mg) | Waste-based biofuels have lower emissions |

| Calorific Value | Lower than diesel (37.5 MJ/kg) | HRJ fuel (43.0 MJ/kg), Palm oil biodiesel (39.5 MJ/kg) |

| NOx Emissions | Higher than diesel (+10%) | Hydrotreated biofuels have lower NOx |

| Fuel Production Cost | Mid-range (USD 0.75–0.95/L) | Waste oil biodiesel (USD 0.40–0.60/L) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szczepaniak, I.; Olech, I.; Szymańska, E.J. The Use of Canola for Biofuel Production in the Context of Energy Security—A Systematic Literature Review. Energies 2025, 18, 2410. https://doi.org/10.3390/en18102410

Szczepaniak I, Olech I, Szymańska EJ. The Use of Canola for Biofuel Production in the Context of Energy Security—A Systematic Literature Review. Energies. 2025; 18(10):2410. https://doi.org/10.3390/en18102410

Chicago/Turabian StyleSzczepaniak, Iwona, Igor Olech, and Elżbieta Jadwiga Szymańska. 2025. "The Use of Canola for Biofuel Production in the Context of Energy Security—A Systematic Literature Review" Energies 18, no. 10: 2410. https://doi.org/10.3390/en18102410

APA StyleSzczepaniak, I., Olech, I., & Szymańska, E. J. (2025). The Use of Canola for Biofuel Production in the Context of Energy Security—A Systematic Literature Review. Energies, 18(10), 2410. https://doi.org/10.3390/en18102410