1. Introduction

The European Union has set ambitious objectives aimed at significantly reducing carbon dioxide emissions. A paramount goal among these is to realize a minimum 55% reduction in greenhouse gas emissions by the year 2030, compared to the levels recorded in 1990. This commitment is articulated through their Green Deal and Climate Law initiatives [

1]. In the wake of the Russian incursion into Ukraine in 2022, fresh strategies have been devised, including the RePowerEU initiative [

2]. This initiative places predominant emphasis on attaining energy self-sufficiency, particularly by reducing dependence on Russian natural gas and accelerating the utilization of hydrogen. Notably, hydrogen has emerged as a pivotal energy carrier that holds the potential to assume a central role in the transition toward a net-zero emissions energy framework. It remains a prominent point on the European Union’s policy agenda [

3,

4]. As a demonstration of their dedication, the EU intends to substantially ramp up its manufacturing capacity for renewable hydrogen production in the upcoming years, aligning with the Fitfor55 and RePowerEU plans. A notable feature of these plans is the strategic development of hydrogen valleys [

1].

A hydrogen valley refers to a localized ecosystem or region that integrates various elements of the hydrogen supply chain. This includes hydrogen production, storage, transportation, and utilization across diverse sectors such as industry, transportation, residential, etc. The concept aims to create a self-contained and interconnected network that maximizes the use of hydrogen as an energy carrier while leveraging renewable sources for its production. Hydrogen valleys are designed to foster sustainable energy systems, promote local economic development, and contribute to the transition toward a low-carbon energy future. Commonly referred to as hydrogen hubs, these valleys often serve as recipients of substantial multi-million EUR investments with the aim of propelling economic growth within their respective geographical zones [

5]. Among the prime candidates for this transformative paradigm are inhabited islands due to the manifold challenges they confront: geographic isolation, constrained energy resources, elevated electricity costs, susceptibility to climate-induced impacts, dependency on imported fuels, energy system fragility, and the complexity of energy interconnections [

6]. The EU parliament recognizes the islands’ unique energy challenges and “Encourages the Commission and the Member States to devise specific solutions in order to ramp up hydrogen production in less connected or isolated regions such as islands, while ensuring the development of related infrastructure, including by repurposing it” [

1].

Green hydrogen, produced through electrolysis utilizing renewable power sources [

4,

7,

8], can be generated by employing either centralized or decentralized methods [

1]. In the case of centralized hydrogen production, all hydrogen production occurs within a single facility situated in proximity to or co-located with the renewable energy generation site. This approach boasts reduced production costs due not only to the proximity of electricity generation to the electrolysis plant but primarily owing to the advantages of economies of scale [

9]. Nevertheless, its drawback is that the demand or end-use locations might be geographically distant from the production facility, leading to elevated transportation expenses.

Conversely, decentralized production involves the production of hydrogen in close proximity to the consumption sites, often facilitated by smaller-scale facilities. Unlike centralized production, in the decentralized model, transportation costs are negligible, yet the production expenses tend to increase. Both alternatives are feasible, and some may be more suitable in a certain situation; for instance, decentralized production may be suitable for an industry with a high volume of hydrogen consumption [

1].

1.1. Literature Review

Decentralized electrolyzers fulfill a diverse array of roles, catering to residential [

10,

11], commercial [

12], industrial installations, universities [

13], mines [

14], telecommunication systems [

15], and even refueling stations [

16,

17]. Given that the paper’s focus revolves around optimizing a Centralized Green Hydrogen Production Facility (CGHPF) situated on the island of Crete, this literature review will concentrate solely on that topic, avoiding an extensive exploration of decentralized electrolysis.

Centralized hydrogen facilities have gained considerable attention within the literature, with noteworthy contributions shedding light on this subject. For instance, El-Emam et al. [

18] present a comprehensive survey of hydrogen production technologies in conjunction with their alignment with renewable sources. This exploration highlights nuclear and geothermal energy as standout contenders, given their competitive energy costs, rendering them potentially pivotal in facilitating cost-effective, carbon-free hydrogen production. Seyam et al. [

19] delve into an investigation involving geothermal and isobutene power plants, forming a combined electric power output of 130 MW. This endeavor revolves around supplying energy to a hydrogen liquefaction power plant, yielding an impressive daily output of approximately 330 tons of liquefied hydrogen. Fereidooni et al. [

20] investigate hydrogen production powered by solar energy in Iran. Examining the annual performance, their analysis reveals a seasonal variation. The facility averages about 48 tons of generated hydrogen each month. Different scenarios are examined, encompassing a range of operating parameters for PV systems such as tracking mechanisms. The endeavor extends to an economic analysis, ultimately highlighting a payback period of approximately 16 years.

Fasihi et al. [

21] conducted a thorough analysis spanning from 2020 to 2050, examining hydrogen production across various global regions. The focal points of investigation encompassed the renewable baseload electricity level derived from solar and wind sources, coupled with the corresponding baseload hydrogen level. The outcomes of this study reveal a worldwide trend toward reduced baseload levels by 2050. The electricity baseload presents a drop to 33 EUR/MW, while the hydrogen baseload aligns with a value of 35 EUR/MW. In a similar vein, Nematollahi et al. [

22] undertook a comprehensive evaluation centered on hydrogen production from wind and solar sources within two Iranian provinces. By developing a mathematical model, the authors examined the system from both technical and economic perspectives. The study employed geographic information system maps to support the envisioned hydrogen economy and facilitate renewable energy integration within the studied regions. The potential applications of wind and solar energy could yield up to 40 tons/year of hydrogen within a single site. Tlili et al. [

23] explored an energy scenario in France for 2035 that focuses on hydrogen as the essential decarbonizing energy vector driven by surplus renewable energy. In their examination, the authors identified strategic regional sites for the installation of electrolyzers. Simulations indicated that the anticipated energy landscape in France for 2035 may not suffice for hydrogen production, solely relying on excess renewable energy. As a potential solution, integration with nuclear power could potentially yield dual benefits, lowering hydrogen costs and significantly enhancing system flexibility.

Khosravi et al. [

24] delved into a sophisticated energy system configuration, combining PV energy and ocean thermal energy for power generation, coupled with hydrogen production and storage, achieving an overall efficiency of 3.3%. The authors additionally conducted an economic assessment, revealing a payback period of 8 years. Hassan et al. [

25] undertook a study centered on electrifying the Australian island Thursday through the utilization of green hydrogen produced in a centralized manner on the neighboring island Horn. The cost of energy production varies between 0.37 AUD/kWh and 1.08 AUD/kWh, depending on the degree of hydrogen penetration. Hou et al. [

26] highlighted the advantages and prospects of hydrogen production through water electrolysis powered by wind turbines. The authors prioritized enhancing return on investment for these systems, indicating the most favorable approach as direct selling of the generated hydrogen to end users rather than employing it solely for electricity production. Specifically, their analysis concluded that selling hydrogen at 2 EUR/kg, 5 EUR/kg, and 9 EUR/kg corresponds to payback periods of 24.4 years, 5.5 years, and 2.6 years, respectively.

Kim et al. [

27] introduced an optimization model that employs mixed-integer linear programming (MILP) to design and evaluate a wind–hydrogen system. This comprehensive approach encompasses technical considerations for wind turbine (WT) selection, wind farm classification (onshore or offshore), and the development of the hydrogen supply network. Notably, onshore installations are favored due to their lower capital costs despite yielding less energy compared to offshore counterparts. An economic advantage is attributed to the utilization of a centralized electrolyzer, driven by economies of scale, with the hydrogen cost ranging between 7.8 EUR/kg H

2 and 11.5 EUR/kg H

2.

Finally, Apostolou et al. [

27] have reviewed several systems based on wind technology linked with hydrogen production via water electrolysis. The authors have identified three categories for wind/hydrogen applications, namely grid-connected systems, autonomous applications, and systems to support mobility. Their analysis of these applications yielded a levelized cost of hydrogen ranging from a notably optimistic 0.3 EUR/kg up to nearly 27 EUR/kg (refer to [

27]). Nevertheless, 0.3 EUR/kg is too optimistic and prerequisites an extremely low or even negative electricity price. Most of the studies demonstrate a mean cost of hydrogen of approximately 6 EUR/kg.

1.2. Scope and Contribution of the Paper

The existing literature underlines the substantial variability observed in the levelized cost of hydrogen, underscoring the profound influence of regional renewable resource availability on hydrogen production economics. This variability becomes evident in studies such as that of Genç et al. [

28], which spans different regions within Turkey and reveals how the cost of hydrogen can fluctuate significantly, ranging from 5.5 AUD/kg to 46.17 AUD/kg (refer to Table 5 of [

28]), even for identical wind–hydrogen setups. This variability is a direct consequence of the distinct wind potential across different regions. Drawing inspiration from this observation, the present study carries out an economic viability assessment of a Centralized Green Hydrogen Production Facility (CGHPF). This facility integrates hybrid wind–solar generators and an electrolyzer, operating within the context of the island of Crete, Greece. Crete boasts an extraordinary wind energy potential, both in winter and summer seasons, attributed to the renowned “meltemia” winds. These winds, stemming from the northwest, are driven by the interaction of hot air masses from the Sahara and colder air currents over the Balkan Peninsula, guaranteeing a consistent wind direction (northwest) marked by minimal turbulence and fluctuations, rendering it a premium energy source [

29]. This remarkable local wind dynamic, in tandem with Crete’s exceptional solar potential—characterized by an annual global horizontal solar irradiation exceeding 1900 kWh/m

2—positions the island as an ideal site for green hydrogen production investments. It establishes Crete as a prime candidate for creating hydrogen valleys, epitomizing the island’s potential for comprehensive green hydrogen initiatives.

To optimize the installation of a CGHPF, we present a mixed-integer linear programming (MILP) framework that takes as inputs several crucial factors. These factors encompass the available land area, hourly wind and solar potential data spanning an entire year, renewable and electrolyzer costs, and electrolyzer efficiency. The proposed MILP framework ultimately yields the optimal installed capacities for wind, solar, and electrolyzer, thus maximizing the profit of the candidate investors. Its distinct feature is that it always ensures the global optimal solution to the examined optimization problem [

30]. In the context of CGHPF, two distinct market strategies were examined: The first strategy revolves around the complete autonomy of the facility, with no provision for injecting any portion of the generated renewable power into the grid. Here, the entirety of the renewable power is solely dedicated to hydrogen production. In contrast, the second strategy offers a degree of flexibility to the CGHPF. This strategy permits a portion, up to a predetermined maximum percentage, of the generated renewable power to be directly injected into the grid. This approach recognizes that not all of the generated renewable power is exclusively allocated to hydrogen production, thereby minimizing the potential for renewable power curtailment during periods of elevated renewable energy generation.

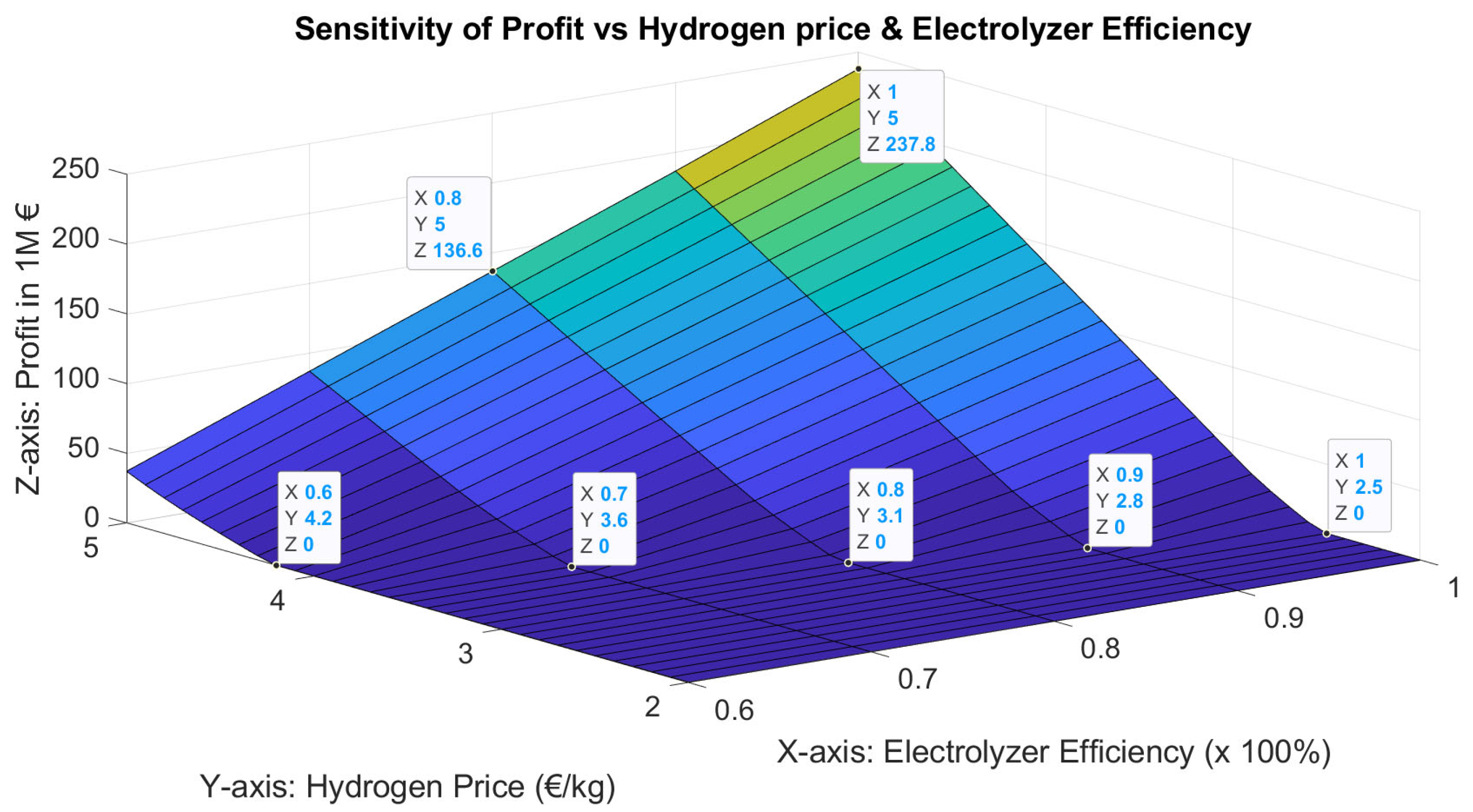

Simulation results confirm that hydrogen can be sold in Crete at prices as low as 3.5 EUR/kg. Specifically, it was found in the base scenario that, selling hydrogen at 3.5 EUR/kg, the net profit of the investment could be as high as EUR 6.19 million. It is noted that the high profitability is justified by the extraordinary renewable potential of Crete.

2. Optimization Model

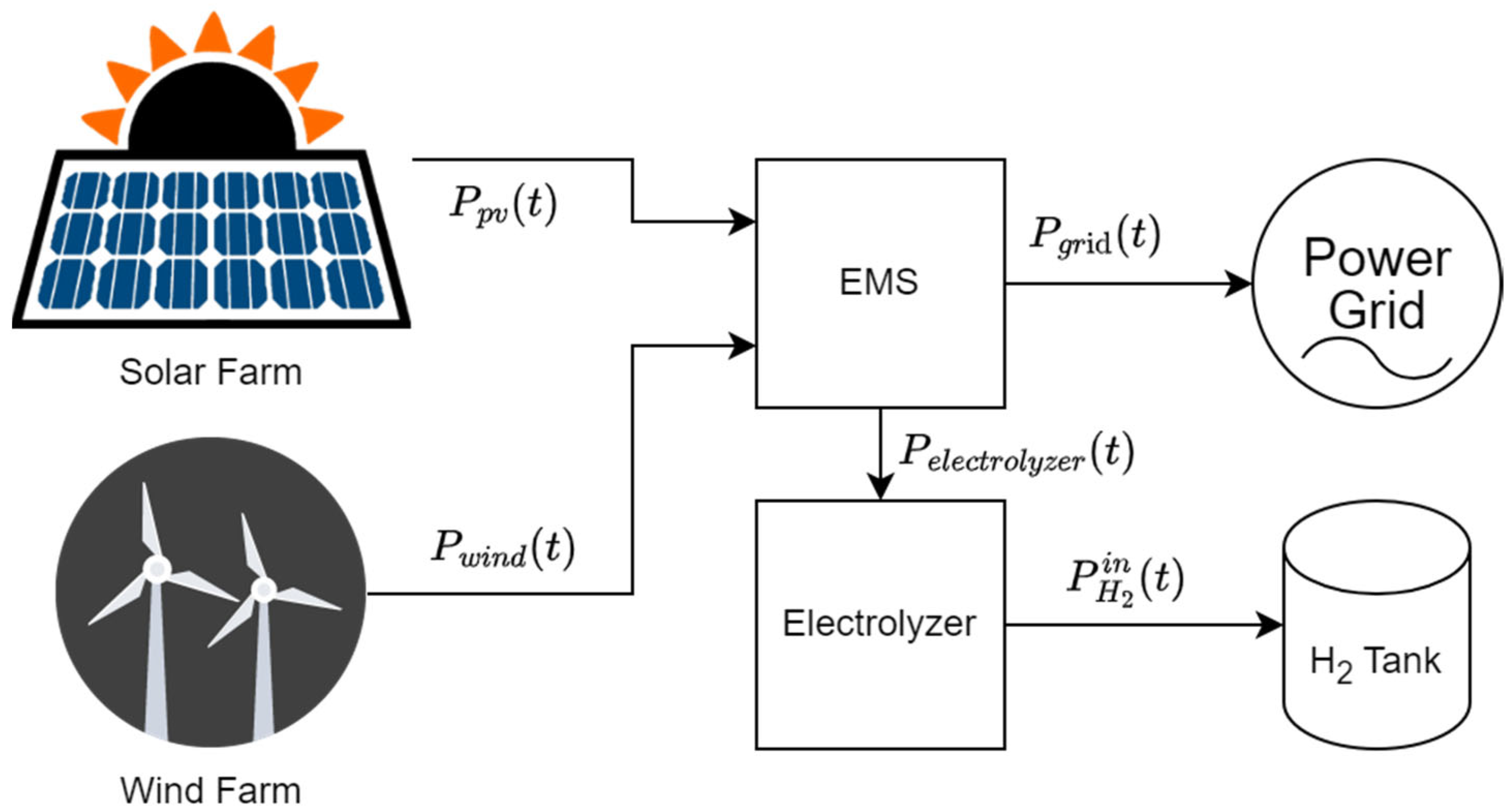

The system model is presented in

Figure 1. The Energy Management System (EMS) is responsible for sending the generated renewable energy either directly to the power grid or storing it as hydrogen in the hydrogen tank via the electrolyzer.

The optimization model is described in Equations (1)–(15). The model can constitute an important tool for optimizing the installed power of the electrolyzer, hydrogen tank, and solar and wind installed power in a CGHPF with the aim of optimizing the total installation profit over the lifetime of the project. The proposed model is a linear programming problem, simply solved using commercial solvers, e.g., CPLEX and GAMS. In this paper, we used the CPLEX solver in MATLAB. The CPLEX solver is a highly sophisticated optimization tool designed to tackle complex mathematical programming challenges. Specializing in linear programming (LP), mixed-integer programming (MIP), and quadratic programming (QP) problems, CPLEX utilizes advanced algorithms, including the branch-and-bound method and cutting-plane algorithms, to efficiently solve large-scale optimization problems. The strong advantage of our model is its ability to always compute the global optimal solution due to its linear nature as well as its simplicity.

The objective function of the proposed optimization model is given in Equation (1), while the constraints of the model are given in Equations (2)–(15).

The

and

in Equation (1) are given in Equations (2) and (3), respectively. All the variables have been defined in the nomenclature. The

denotes the total income from the investment throughout the total project lifetime, e.g., 20 years.

and

denote the selling price of hydrogen and electricity, respectively. Note that in this paper, we have assumed that the CGHPF has the capability to inject a small part (e.g., 20%) of the annual renewable production into the grid, instead of exclusively producing hydrogen. This portion is represented here as

. In this way, a degree of flexibility is provided to the investors of CGHPFs to inject the surplus of renewable energy into the grid instead of rejecting/curtailing it, thus increasing their profit and their incentive to invest in CGHPFs. The cost of the investment is given in Equation (3c), consisting of the installation costs

given in Equation (3a) and the operation and maintenance (O&M) cost is given in Equation (3b). The CAPEX is the sum of the wind farm installation cost (

), the solar farm installation cost (

), the electrolyzer installation cost (

), and the hydrogen tank cost (

). The O&M cost is considered to be 2% of the CAPEX discounted with the inflation rate

over the lifetime of the project.

The power balance equation is constrained in Equation (4), equating the power produced by the renewables (

), the power injected into the grid (

), and the power delivered to the electrolyzer (

).

Equations (5) and (6) constrain the power produced by the solar and wind generators, respectively, to be lower than the maximum available power based on the installation capacity (

). Note that

and

are the normalized (

) powers of the renewables denoting the power produced per 1 MW of installed renewable power at time

t. The annual waveforms of these parameters are obtained by historical data or measurements in the candidate location of the CGHPF.

In Equation (7), the electrolyzer input power

is constrained between the maximum

and minimum

power of the electrolyzer.

In Equation (8), the surplus renewable power, which exceeds the maximum electrolyzer power, is injected into the power grid, offering additional income to the investor instead of being curtailed. Note that

H(∙) is the Heaviside function, which introduces a non-linearity into the proposed model; however, Equation (8) is linearized in the

Appendix A to allow the solution of the formulation using MILP solvers.

Equation (9) ensures that the annual input energy of electrolyzer is higher than

% of the total annual renewable production. For example, assuming that

, the cumulative annual input energy of the electrolyzer is restricted to be higher than 80% of the total annual renewable generation. This restriction serves to legitimize the predominant use of the CGHPF as a green hydrogen facility. Simultaneously, it permits a limited portion of renewable energy sources (under 20%) to be directly fed into the grid. This approach mitigates the curtailment of renewables when their output surpasses the maximum capacity of the electrolyzers. Furthermore, allowing up to 20% direct penetration of renewables into the grid does not notably strain the electrical network, especially in Greek islands where solar peak coincides with the load peak due to summer tourism.

Equation (10) computes the production rate of hydrogen

as a function of the input power of the electrolyzer and the electrolyzer efficiency (

ε).

Equation (11) is the energy balance equation of the hydrogen tank, relating the stored hydrogen into the hydrogen tank at hour

(

) and

(

) with the input

and output

power of the hydrogen tank. The output power

has been defined in (12) as the mean input power during the year. In fact, Equation (12) guarantees a consistent hydrogen supply from the facility all year round at a constant rate, ensuring the seamless fulfillment of the island’s hydrogen requirements.

Equation (13) constrains the stored hydrogen energy

to be within the maximum

and minimum (0) limits of the hydrogen tank. In Equation (14), we assume that there is an available hydrogen tank that can store hydrogen produced by the electrolyzer at its maximum power for at least 48 h. This is an arbitrary assumption that ensures that the installation has a safety margin for providing hydrogen despite the intermittency of renewables.

Finally, the installed wind and solar power

are restricted in (15) based on the total available land area in the region

. Note that

and

denote, respectively, the density of wind and solar installations, e.g., occupied land per installed MW, while typical values are shown in

Table 1.

3. Optimization Results

In the formulated optimization, a base case scenario is outlined, specifically tailored to Crete, Greece. This scenario adopts standard values for various model parameters, as detailed in

Table 1. It assumes a total area of 2,000,000 m

2 available for renewable energy installations. The hydrogen selling price is set at 3.5 EUR/kg, equivalent to approximately 105 EUR/MWh. The base case scenario’s timeframe spans 20 years, with an inflation rate of 3% (as of December 2023, the inflation rate in the Eurozone is 2.9%, and the European Union is 3.4% [

32]. Therefore, an acceptable inflation rate of 3% has been assumed for the purpose of the study). Employing the proposed optimization algorithm and leveraging the parameters from

Table 1, the optimal capacity for renewable energy sources and the electrolyzer is determined. Additionally, the maximum potential profit over the project’s lifetime in Crete is calculated.

Table 2 presents the outcomes of the optimization for the base scenario, utilizing the parameters specified in

Table 1. The results reveal optimal capacities for solar and wind installations at 23.51 MW and 52.97 MW, respectively, while the electrolyzer’s optimal capacity is determined to be 25.85 MW. The total O&M cost is found to constitute approximately 30% of the CAPEX over the project’s 20-year lifespan. The net profit, as defined by the objective function in Equation (1), is projected to be EUR 6.19 million during the lifetime. These findings underscore Crete’s significant potential in renewable energy: hydrogen production and sale are not only feasible but also potentially lucrative, even at a relatively low selling price of 3.5 EUR/kg H

2. This suggests that investing in centralized hydrogen facilities in Crete could yield profitable returns even under low selling prices.

5. Conclusions and Discussion

This manuscript presents an economic viability assessment for a Centralized Green Hydrogen Production Facility (CGHPF) in Crete, Greece, leveraging the island’s exceptional wind and solar potential. It introduces a mixed-integer linear programming (MILP) framework to optimize the installation of the CGHPF, considering factors such as land area, wind and solar potential, and costs. This study underscores Crete’s potential as a prime candidate for comprehensive green hydrogen initiatives, utilizing its unique wind and solar resources.

The optimization model provided serves as a crucial tool for determining the optimal installation of various components in a CGHPF, including the electrolyzer, hydrogen tank, solar, and wind installations. Formulated as a linear programming problem, the optimization is implemented using the CPLEX solver in MATLAB, aiming to maximize the total installation profit over the project’s lifetime.

Simulation results validate the feasibility of selling hydrogen in Crete at competitive prices, with estimates as low as 3.5 EUR/kg of H

2. Specifically, under the base scenario, it was determined that selling hydrogen at this price could yield a substantial net profit of EUR 6.19 million. This profitability stems from Crete’s exceptional renewable energy potential. To highlight,

Table 3 depicts the optimized profit for green hydrogen facilities in different regions around the world using the proposed optimization model under uniform assumptions, such as land availability and selling price of hydrogen, based on the data of

Table 1. Notably, Crete’s substantial renewable energy potential makes it a particularly promising site for hydrogen investment.

A significant finding from the simulations is that even a modest direct injection of renewable power into the grid (instead of being injected to the electrolyzer) significantly encourages the expansion of electrolyzer capacity. With a hydrogen selling price of 4 EUR/kg, allowing an annual 20% direct renewable penetration into the grid increases electrolyzer capacity from 0 to 39.99 MW, resulting in a surge in investment profit from EUR 0 to 37 million, as illustrated in

Figure 8. Therefore, a policy recommendation to allow at least 20% direct penetration of renewable sources of green hydrogen facilities into the grid is suggested to encourage and accelerate the green hydrogen expansion.

The establishment of centralized hydrogen facilities goes beyond mere economic returns for investors. It has transformative benefits to both Transmission System Operators (TSOs) and Distribution System Operators (DSOs). By producing, storing, and utilizing energy locally, it significantly reduces the strain on existing grid infrastructures. This local energy management approach mitigates the need for extensive system upgrades, presenting a more effective and sustainable method of renewable energy expansion. Moreover, hydrogen facilities empower islands to have greater control over their energy future. Islands become active participants in the transition to cleaner and more sustainable energy systems, acquiring a sense of ownership and responsibility for energy production and consumption. These projects also create new economic opportunities and new jobs in hydrogen production, distribution, and maintenance while attracting sustainable tourism centered around eco-friendly energy practices. Additionally, as islands often face the burden of climate change impacts, the availability of locally produced hydrogen enhances community resilience by providing a reliable energy source during extreme weather events and reducing electricity interruptions. The growth of hydrogen-based energy systems into islands will also contribute to national economic prosperity and counteract “brain drain” by attracting scientific and technical talent. Environmentally, it contributes to a marked decrease in carbon dioxide emissions, aligning with global efforts to tackle climate change. Finally, the seamless availability of cheap green hydrogen could forward hydrogen mobility, introducing more affordable and cleaner transportation options. This shift away from traditional fuels also lessens the reliance on imported fossil fuels, further promoting economic stability and environmental conservation. This combination of energy security, economic growth, and climate resilience has a profound and positive social impact, elevating the quality of life for island residents and inspiring similar initiatives in regions around the world.