Capacity Demand Analysis of Rural Biogas Power Generation System with Independent Operation Considering Source-Load Uncertainty

Abstract

1. Introduction

2. Source-Load Uncertainty Analysis of Rural Distribution Network

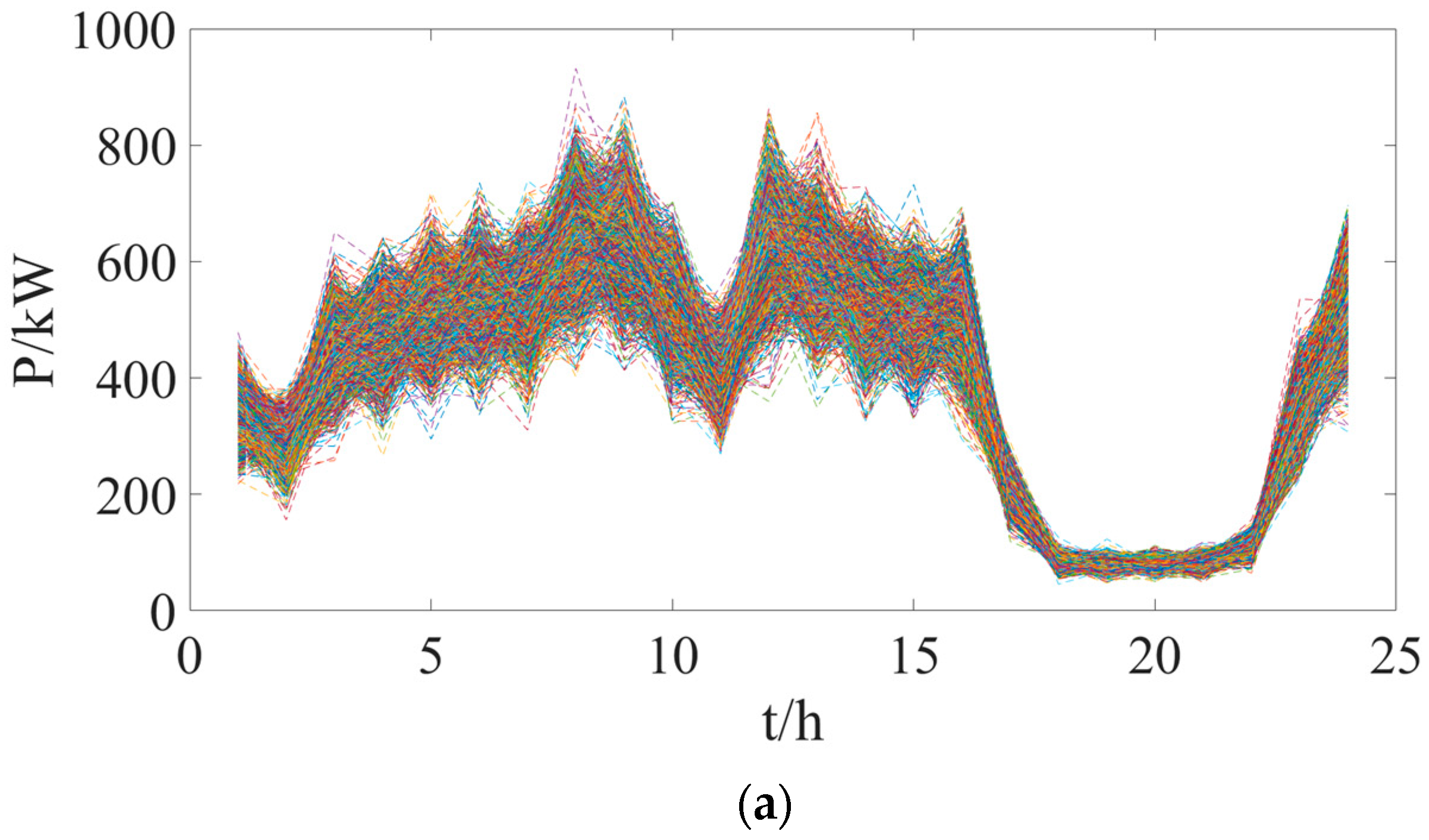

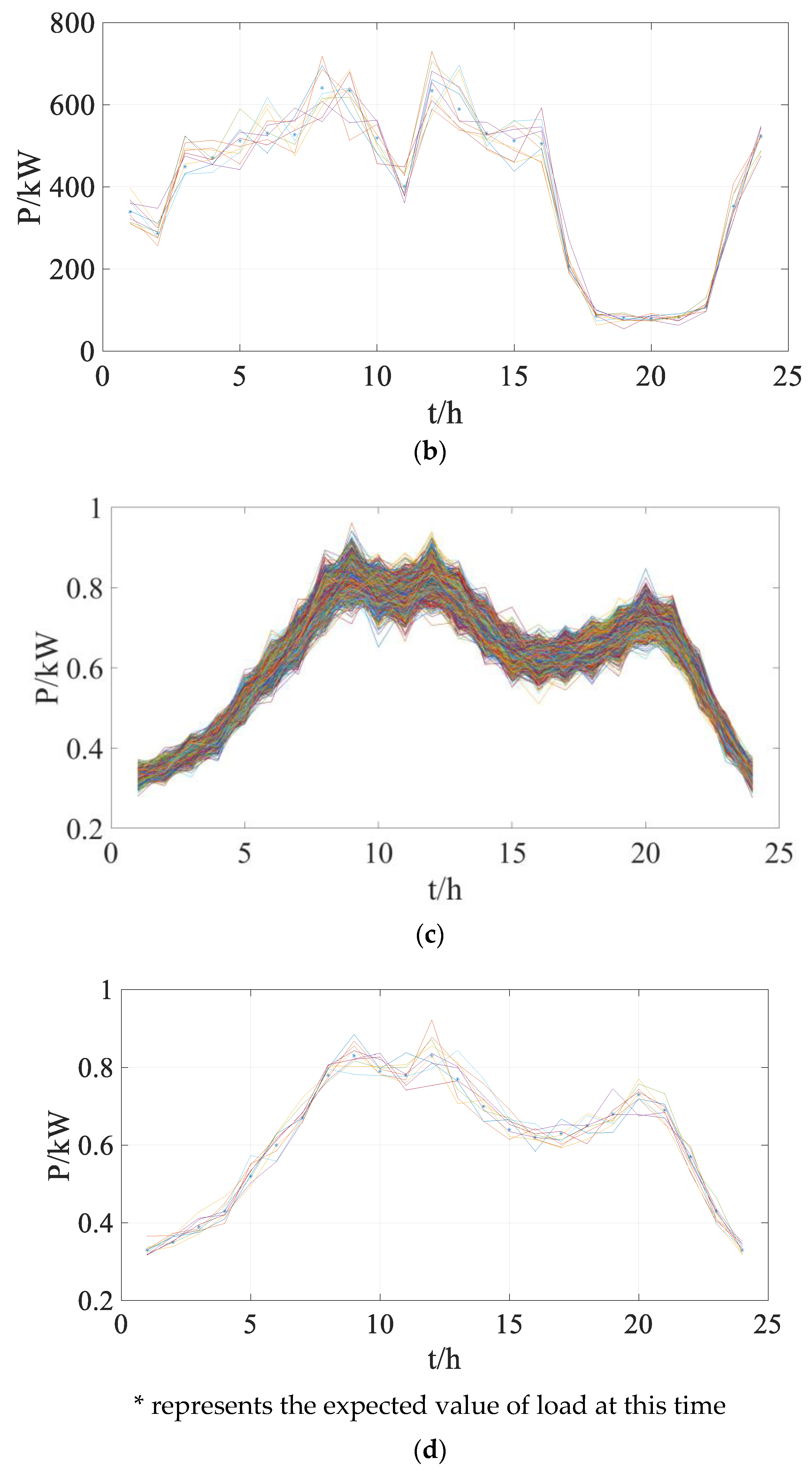

2.1. Pure Load Demand Sample Processing Based on QRA

2.2. GMM-Based Source-Load Uncertainty Clustering

2.3. System Typical Scene Generation

- (1)

- According to the QRA, the nonparametric probability prediction model is determined, and the quantile corresponding to the actual power of the historical pure load demand is obtained by interpolation calculation.

- (2)

- Let , the probit function, be used to transform which obeys uniform distribution in I, and this obeys J-dimensional Gaussian distribution (, Σ are parameters of multivariate Gaussian distribution), and the maximum likelihood estimation is the sample mean vector and the sample covariance matrix S.

- (3)

- Based on the GMM clustering method, I pure load demand scenarios are reduced to k typical pure load demand scenarios, and their distribution probability is obtained.

- (4)

- The probit inverse function is used to transform k vectors obeying the J-dimensional Gaussian distribution into k vectors obeying the uniform distribution , where . are the quantiles of the jth sampling point of the typical pure load demand scenario s.

- (5)

- The non-parametric model is used to obtain the quantile matrix of the known pure load demand forecasting power. Then, the matrix composed of k quantile vectors is linearly interpolated according to , to obtain k pure load demand typical scenario sets corresponding to the pure load demand forecasting power sequence, as shown in (7).

3. Optimized Operation Model of Rural Microgrid Based on Source-Load Uncertainty

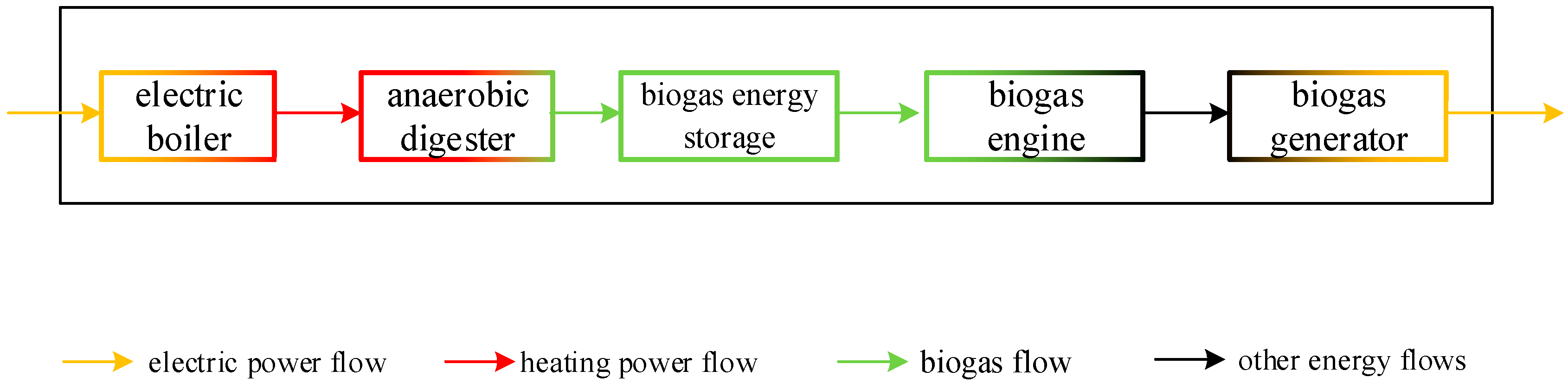

3.1. Rural Biogas Power Generation System Model

3.1.1. Biogas Fermentation Kinetic Model

3.1.2. Biogas Power Generation Model

3.2. Objective Function

3.3. Constraint Conditions

3.3.1. System Balance Constraints

3.3.2. System Equipment Constraints

- (1)

- Controllable device constraints

- (1)

- Constraints of biogas power generation system

- (2)

- EB equipment

- (2)

- Wind power and photovoltaic constraints

- (3)

- Load constraints

4. Capacity Demand Correction Method of Rural Biogas Power Generation System

4.1. Construction of GAD and CGR Indicators

4.1.1. GAD Indicator

4.1.2. CGR Indicator

4.2. Method for Determining the Capacity of Biogas Generator Set

4.2.1. Energy Storage Operating Power Correction Model

4.2.2. Energy Storage Demand Power and Capacity

4.3. Capacity Demand Analysis Flow

5. Case Study

5.1. Case Data Sources and Parameters

5.2. Typical Scene Set Generation Results

5.3. Determination of Energy Storage Demand Capacity

6. Conclusions and Foresight

6.1. Conclusions

- (1)

- A method is proposed to describe the uncertainty of the pure load demand of a high permeability system of new energy. In the traditional power system dispatching operation method, the calculation is only carried out through a single new energy and load forecasting, which greatly increases the impact of source-load uncertainty. In the method proposed in this paper, on the premise of obtaining typical scenarios, the probability of each scenario can also be calculated, which reduces the impact of pure load demand uncertainty on system scheduling operation.

- (2)

- The GAD and CGR indexes are introduced to address both the utilization rate of energy storage and operating costs. Subsequently, a modified model integrating these indexes is formulated to determine the demand capacity. The example results demonstrate that the proposed model substantially mitigates gas storage construction costs and charging/discharging imbalances, with a maximum increase in system operating costs of only 2.07%.

6.2. Foresight

- (1)

- The results of this paper can provide some theoretical guidance for the energy storage configuration in the future new energy, high-permeability system, but the relationship between the new energy consumption level and the energy storage capacity demand is not studied, and the related research work will be carried out in the future.

- (2)

- In this paper, only the number of scenes is reduced to 10, without demonstrating whether it is reasonable to choose 10 typical scenes. In the follow-up study, the number of scenes should be reduced as much as possible under the premise of ensuring the calculation accuracy. The research on clustering error can be carried out to make the selection of the number of typical scenes more reasonable.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, G.; Cheng, H.; Ma, Z.; Fan, S. Overview of ESS planning methods for alleviating peak-shaving pressure of grid. Electr. Power Autom. Equip. 2017, 37, 3–11. [Google Scholar]

- Frazier, A.W.; Cole, W.; Denholm, P.; Greer, D.; Gagnon, P. Assessing the potential of battery storage as a peaking capacity resource in the United States. Appl. Energy 2020, 275, 115385. [Google Scholar] [CrossRef]

- Li, J.; Yue, P.; Li, C.; Zhang, Z.; Wang, R. Control strategy of energy storage system in wind farm group to improve wind energy utilization level. Electr. Power Autom. Equip. 2021, 41, 162–169. [Google Scholar]

- Zhu, Y.; Qin, L.; Yan, Q.; Zhang, X. Wind-storage combined frequency regulation strategy and optimal configuration method of energy storage system considering process of frequency response. Electr. Power Autom. Equip. 2021, 41, 28–35. [Google Scholar]

- Chen, H.; Liu, C.; Xu, Y.; Yue, F.; Liu, W.; Yu, Z.H. The strategic position and role of energy storage under the goal of carbon peak and carbon neutrality. Energy Storage Sci. Technol. 2021, 10, 1477–1485. [Google Scholar]

- Sun, W.; Pei, L.; Xiang, W.; Sang, B.; Li, G.; Xi, P. Evaluation method of system value for energy storage in power system. Autom. Electr. Power Syst. 2019, 43, 47–55. [Google Scholar]

- Huang, H.; Zhou, M.; Zhang, L.; Li, G.; Sun, Y. Joint generation and reserve scheduling of wind-solar-pumped storage power systems under multiple uncertainties. Int. Trans. Electr. Energy Syst. 2019, 29, e12003. [Google Scholar] [CrossRef]

- Zhang, B.; Sun, Y.; Zhang, S. Second-order cone programming based probabilistic optimal energy flow of day-ahead dispatch for integrated energy system. Autom. Electr. Power Syst. 2019, 43, 25–33. [Google Scholar]

- Xu, C.; Xu, X.; Yan, Z.; Li, H. Distributionally robust optimal dispatch method considering mining of wind power statistical characteristics. Autom. Electr. Power Syst. 2022, 46, 33–42. [Google Scholar]

- Zhang, J.; Cheng, C.; Shen, J.; Li, G.; Li, X.; Zhao, Z. Short-term joint optimal operation method for high proportion renewable energy grid considering wind-solar uncertainty. Proc. CSEE 2020, 40, 5921–5932. [Google Scholar]

- Luo, E.; Zhang, Y.; Feng, Y.; Zhu, L.Z. The research on cours, current situation and future direction of China’s biogas industry development-Based on the typical case analysis of Luohe area, Henan. Chin. J. Agric. Resour. Reg. Plan. 2022, 43, 132–142. [Google Scholar]

- Li, J.; Li, B.; Xu, W. Analysis of the policy impact on China’s biogas industry development. China Biogas 2018, 36, 3–10. [Google Scholar]

- Wang, Z.Q.; Wang, J.; Ma, M.I.; Yang, H.; Chen, D.; Wang, L.; Li, P. Distributed event-triggered fixed-time fault-tolerant secondary control of islanded AC microgrid. J. IEEE Trans. Power Syst. 2022, 37, 4078–4093. [Google Scholar] [CrossRef]

- Xu, D.; Zhou, B.; Chan, K.W.; Li, C.; Wu, Q.; Chen, B.; Xia, S. Distributed multienergy coordination of multimicrogrids with bio-gas-solar-wind renewables. IEEE Trans. Ind. Inform. 2019, 15, 3254–3266. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, D.; Li, C.B.; Chung, C.Y.; Cao, Y.; Chan, K.W.; Wu, Q. Optimal scheduling of biogas-solar-wind renewable portfolio for multicarrier energy supplies. IEEE Trans. Power Syst. 2018, 33, 6229–6239. [Google Scholar] [CrossRef]

- Ghaem Sigarchian, S.; Paleta, R.; Malmquist, A.; Pina, A. Feasibility study of using a biogas engine as backup in a decentralized hybrid (PV/wind/battery) power generation system-Case study Kenya. Energy 2015, 90, 1830–1841. [Google Scholar] [CrossRef]

- Yang, H.; Shi, B.; Huang, W.; Samayeh, M. Day-ahead optimized operation of micro energy grid considering integrated demand response. Electr. Power Constr. 2021, 42, 11–19. [Google Scholar]

| 1 | 2 | 3 | 4 | Total | |

|---|---|---|---|---|---|

| Quantity | 1418 | 54 | 4020 | 6030 | 11,526 |

| S0 | 13,187.4 | 477.9 | 7336.5 | 27,044.55 | 48,046.35 |

| Scene Number | System Operation Cost | The Amount of Cost Increase after Correction | |

|---|---|---|---|

| Before Correction | After Correction | ||

| 1 | 1751.08 | 1774.26 | 23.18 |

| 2 | 1696.89 | 1707.26 | 10.37 |

| 3 | 1988.57 | 2007.41 | 18.84 |

| 4 | 1842.75 | 1869.02 | 26.27 |

| 5 | 2159.71 | 2183.64 | 23.93 |

| 6 | 2010.05 | 2022.43 | 12.38 |

| 7 | 1667.02 | 1681.78 | 14.73 |

| 8 | 1996.57 | 2037.85 | 41.28 |

| 9 | 1687.91 | 1713.44 | 25.53 |

| 10 | 2111.80 | 2124.36 | 12.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, M.; Liu, J.; Tang, A.; You, X. Capacity Demand Analysis of Rural Biogas Power Generation System with Independent Operation Considering Source-Load Uncertainty. Energies 2024, 17, 1880. https://doi.org/10.3390/en17081880

Zhou M, Liu J, Tang A, You X. Capacity Demand Analysis of Rural Biogas Power Generation System with Independent Operation Considering Source-Load Uncertainty. Energies. 2024; 17(8):1880. https://doi.org/10.3390/en17081880

Chicago/Turabian StyleZhou, Miao, Jun Liu, Aihong Tang, and Xinyu You. 2024. "Capacity Demand Analysis of Rural Biogas Power Generation System with Independent Operation Considering Source-Load Uncertainty" Energies 17, no. 8: 1880. https://doi.org/10.3390/en17081880

APA StyleZhou, M., Liu, J., Tang, A., & You, X. (2024). Capacity Demand Analysis of Rural Biogas Power Generation System with Independent Operation Considering Source-Load Uncertainty. Energies, 17(8), 1880. https://doi.org/10.3390/en17081880