1. Introduction

Morphing wings are intelligent wing structures and their concept is far from new, but the development of smart materials in the 21st Century allowed researchers to excavate them from the dust of times. There are many camber-morphing ideas: some of them have superior aerodynamic improvements, and some have minor ones [

1]; however, the fact is that camber-morphing is an aerodynamic improvement, just as nature has shown from the beginning. Observing the smooth and gentle way birds of pray sail through the air using their wing-morphing abilities has inspired researchers of all times to create visionary aerodynamic concepts [

2,

3,

4]. The dynamic development of intelligent shape-changing materials in the 21st Century empowered the scientific world to excavate these concepts and adjust them to the economic needs of the current era of aviation [

5,

6,

7].

Over the years, there have been numerous projects and research works conducted regarding camber-morphing airfoil concepts for commercial and micro UAV aircraft [

1,

8,

9]. Nguyen et al. [

10] presented the Variable Camber Continuous Trailing Edge Flap (VCCTEF) concept for commercial aircraft application, which has been developed by NASA for a few years. The conclusion demonstrated significant drag reduction via the application of the morphing airfoil concept and great potential for fuel and energy savings by the adaptive change of airfoil during flight. Ting et al. [

11] further researched the VCCTEF concept. Using numerical simulations, they analysed the aerodynamic loads and hinge moments acting on the Generic Transport Model (GTM) morphing wing aircraft, finding that the increase in the hinge moment is proportional to the stiffness decrease. A consecutive step in developing the VCCTEF concept was an optimisation study conducted by a similar team of researchers as in the previously recalled work. They revealed that a three-segment morphing trailing edge has the potential to be the most optimal for drag reduction for transport aircraft [

12]. Jo et al. [

13] compared the NACA8410 and NACA2410 airfoils and then created wings with a variably camber-morphing along the span direction. Using CFD simulations, they discovered that the NACA8410 has a significantly higher lift force coefficient and a better pressure distribution in the examined cases than the NACA2410.

As for publications considering bio-inspired morphing wings at very low Reynolds numbers [

14], they usually refer to micro Unmanned Aerial Vehicles (UAVs) (see

Figure 1). Anoyoji et al. [

15] studied owl-like airfoils for low Reynolds number flights of Micro Air Vehicles (MAVs). The NACA0012 airfoil was compared with a smooth owl-like airfoil for

. The authors found that a strong under-camberfor morphing airfoils causes a higher lift force coefficient compared to the NACA0012 airfoil. Another bio-inspired structure for MAVs was researched by Bardera et al. [

16]. They conducted three-dimensional studies using the PIV and CFD methods for a stingray-like MAV. Three different morphing stages were examined, and it was concluded that semi-deformation demonstrated the best aerodynamic improvement. Tamai et al. [

17] proposed a flexible-membrane airfoil for an MAV. It could change the shape of the wing in flight to adapt to the current conditions like natural flyers do. They investigated the created membrane airfoil using PIV. Majid and Jo [

14] investigated morphing wings at a low Reynolds number. They examined nine cases in CFD simulations, achieving an

increase in the lift-to-drag ratio for the morphing geometry compared to the conventional airfoil. Bardera et al. [

6] established morphing geometries that could prevent flow from separation, significantly enhance the lift force coefficient, and reduce turbulence. A technical approach to UAV morphing wings was presented by Dhileep et al. [

18]. They investigated a single corrugated variable camber concept and demonstrated that the morphing airfoils exhibited increased the performance compared to the traditional ones. The potential existence of the optimal deflection angle to provide the maximum lift-to-drag ratio for every angle of attack was another important conclusion of this work.

There are also publications considering extremely low Reynolds numbers. Zhu et al. [

19] conducted research on a rectangular cylinder for

200–400. They studied the flutter phenomenon of a canonical rectangular cylinder model. Their final conclusion was that studying the behaviour of the vortices is crucial to understanding the flutter phenomenon and that even simple low Reynolds number simulations contain important data that can be utilised for future research on higher Reynolds numbers. Another research work on low Reynolds number was conducted by Liu et al. [

20]. They created a model of two cylinders in tandem and studied the fluid forces acting on the model for

75–200. The authors demonstrated the reduction of vortex shedding, as well as the decrease of the fluid forces compared to the extensively researched single-cylinder model.

The airfoil morphing concept went beyond only aviation applications a long time ago. Currently, this is a promising solution raised in every field that uses airfoils or hydrofoils as more energy efficient and having higher aerodynamic performance. Fatiha et al. [

21] presented a morphing hydrofoil for ship propeller blades. They established that the hydrofoil shape has a significant impact on hydrodynamic forces, and with morphing, the hydrofoil cavitation phenomenon can be controlled. Remaining in heavy load variations, there is one important subject to consider—wind gusts. For example, waves create hydrokinetic loads on tidal turbines, and strong wind gusts may create potentially dangerous aerodynamic loads on wind turbines. An example of such a treacherous condition is a downburst, in aviation considered very risky during the landing of aircraft and for UAVs. Frant et al. [

22] created an aerodynamic state-of-the-art CFD method to model gusts, allowing modelling any speed and direction or time-varying direction of a gust. They conducted aerodynamic wind tunnel tests to validate the numerical model. The results showed that a 10 m/s gust can significantly change the aerodynamic forces and moments acting on the wing. Another numerical model was proposed by Zhou et al. [

23]. The authors created a surrogate model for wind turbine wake prediction. The potential of this model enables predicting fluctuating wake structures’ dynamics in hazardous terrain and extreme weather conditions.

Wind turbines are the main objective of current green energy solutions. The aim is to harvest more energy with the lowest possible costs. Thus, the number of wind turbines is growing drastically. Longer blades and higher pylons allow exploiting faster breezes at greater altitudes. This causes higher loads on turbine blades and generates potential construction difficulties. Passive adaptive blades have proven their ability to reduce loads on wind turbine blades in varying weather conditions. Changes in aerodynamic coefficients created by trailing-edge deflection present a linear relation to wind speed [

24]. Experimental and numerical approaches to passive adaptive wind turbine blades were presented in Murray’s work [

25]. The research revealed a significant reduction of loads for adaptive flexible airfoils compared to rigid blades. Beyene and Peffley [

26] conducted wind tests confirming that flexible blades decrease loads to even

compared to rigid ones. They concluded that flexible blades adapt better to different load conditions with zero additional costs for harvested energy. The innovative response to the growing problem of high loads on turbine blades could be morphing airfoils. They could also be utilised to support wind turbine rotor braking in a variety of situations. With the development of smart materials and the continuously appearing new technical approaches to morphing airfoils, these active flexible structures could adapt more efficiently to varying weather conditions or hazardous situations and improve efficiency with their tested load reduction and aerodynamic efficiency improvement [

27].

Following green energy solutions, morphing airfoils have found their place in tidal turbine applications. Oceanic currents are an unexploited source of green energy with great potential and could seriously strengthen energy security. Hoerner et al. [

28] experimented with hydrokinetic vertical-axis or cross-flow tidal turbine (CFTT) morphing blades. They concluded that the flexibility of the camber-morphing airfoil has a significant impact on the wake structure and allows less accidental wake changes over time. A passive–adaptive geometry of airfoils was presented by Castorrini et al. [

29]. The authors conducted 2D and 3D FSI simulations of three small rotor geometries, also for fluctuating water flow conditions. The study revealed the computational fluid–structure interaction to have great possibilities for modelling tidal turbine rotors. Present tidal turbines encounter several inconveniences such as current fluctuations caused by waves, large hydrokinetic loads’ inconstancy, or interaction with turbine supports. In their theoretical study, Pisetta et al. [

30] discussed morphing blades with such flexibility, for which the load increase from current fluctuations can be reduced by even

without affecting the amount of energy harvested.

Another interesting application of morphing airfoil structures is the automotive industry. Flexible structures can create additional passively developed forces for increased grip and enlarged stability in corners. Mishra et al. [

31] conducted research on Flexi Wings for Formula 1 race car application. This concept can provide more precise air flow direction adjustment, which enhances manoeuvrability and optimises steering control. The interaction between components can significantly increase or decrease race car performance. Cravero et al. [

32] conducted a numerical analysis of the aerodynamic interaction between the front wing and front wheel in a Formula 1 race car. The research revealed that the rotating wheel enhances the aerodynamic performance of the race car’s front section and that swirling flow over the front wing lowers the pressure before the air intake, generating increased air intake efficiency. This phenomenon could be strengthened by the application of a morphing wing structure. Active aerodynamic morphing structures and their ability to change aerodynamic performance could enhance safety during the Brake-In-Turn manoeuvre. Broniszewski and Piechna [

33] created an algorithm combining a CFD solver with a car dynamics’ solver. The authors proposed an aerodynamic solution for in-turn braking enhancement by creating additional downforce on the rear wheels and enabling active prevention of control loss during corner braking.

Camber-morphing airfoils are a multidisciplinary subject with an emphasis on aviation. The recognition of the turbulence around morphing structures, as well as creating new camber-morphing airfoils and comparing them to conventional ones are crucial for creating optimal aerodynamic morphing airfoils for aviation [

13] as energy solutions [

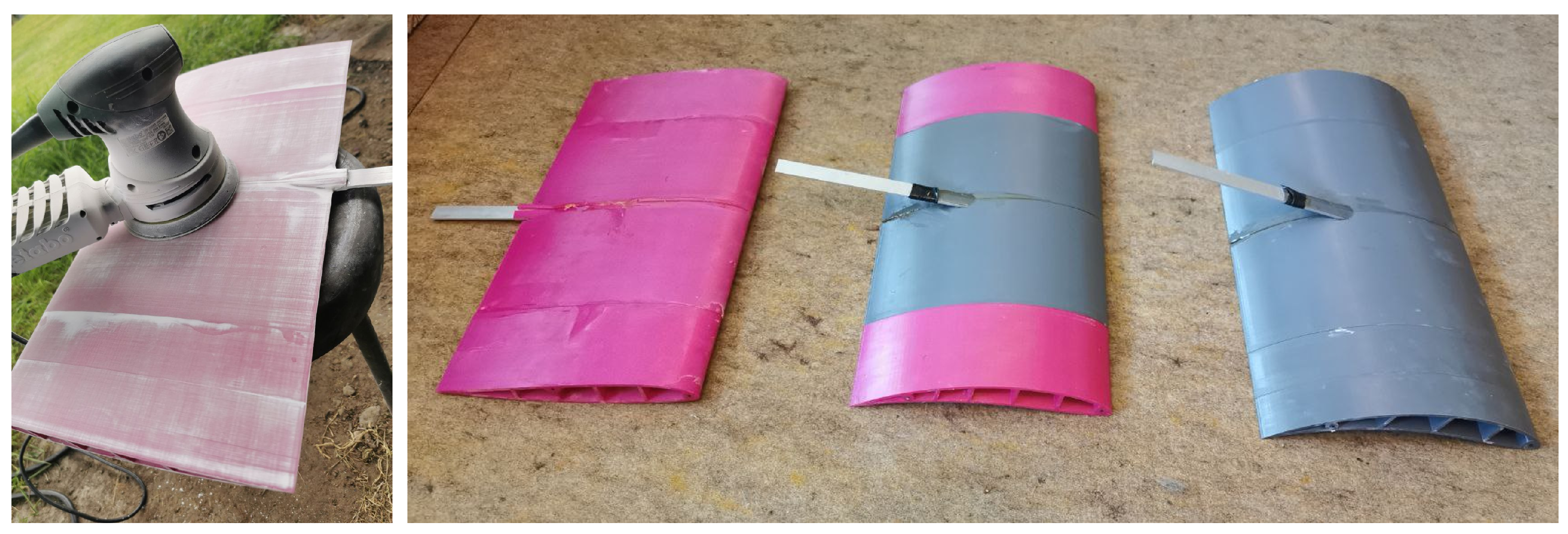

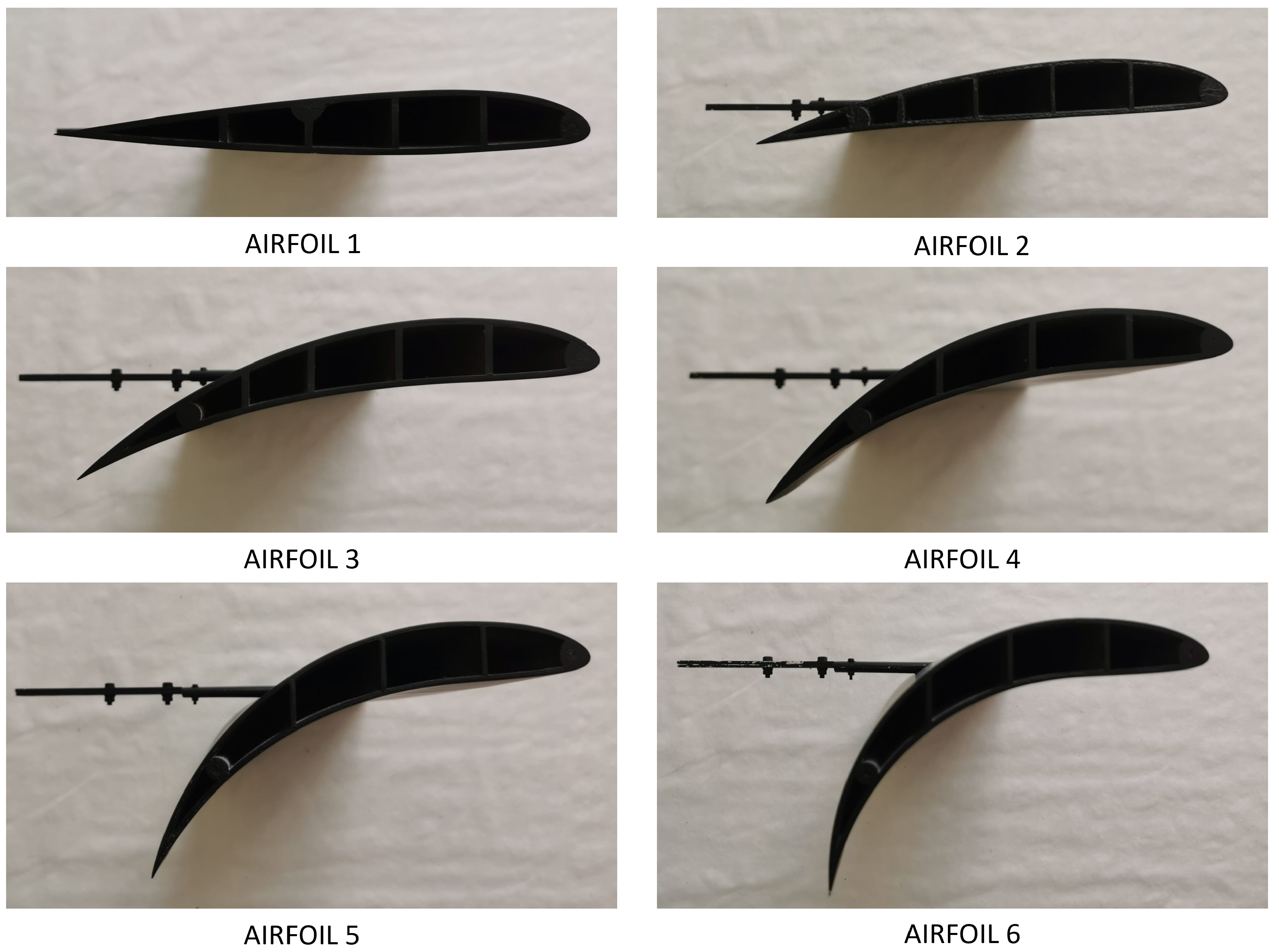

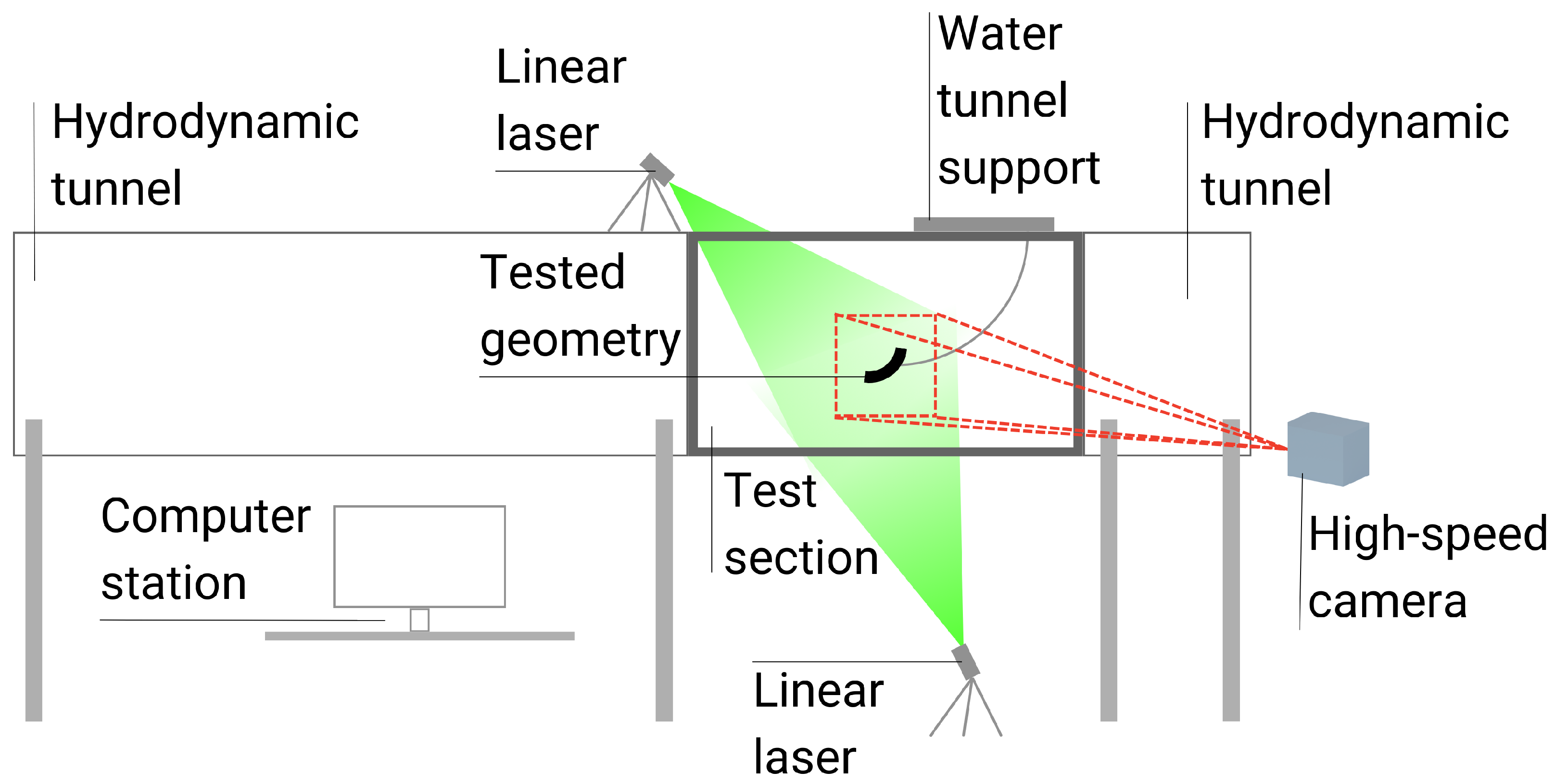

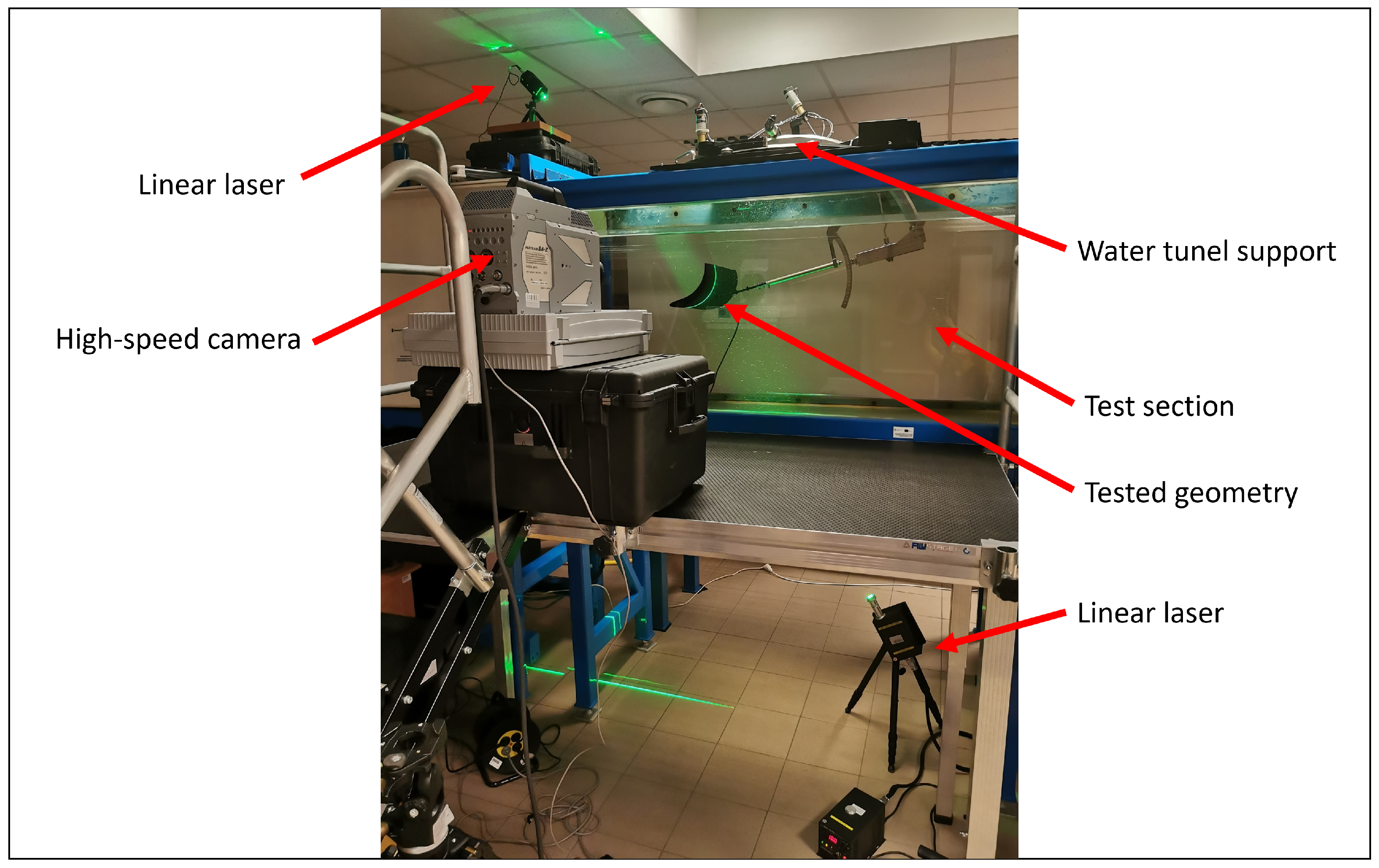

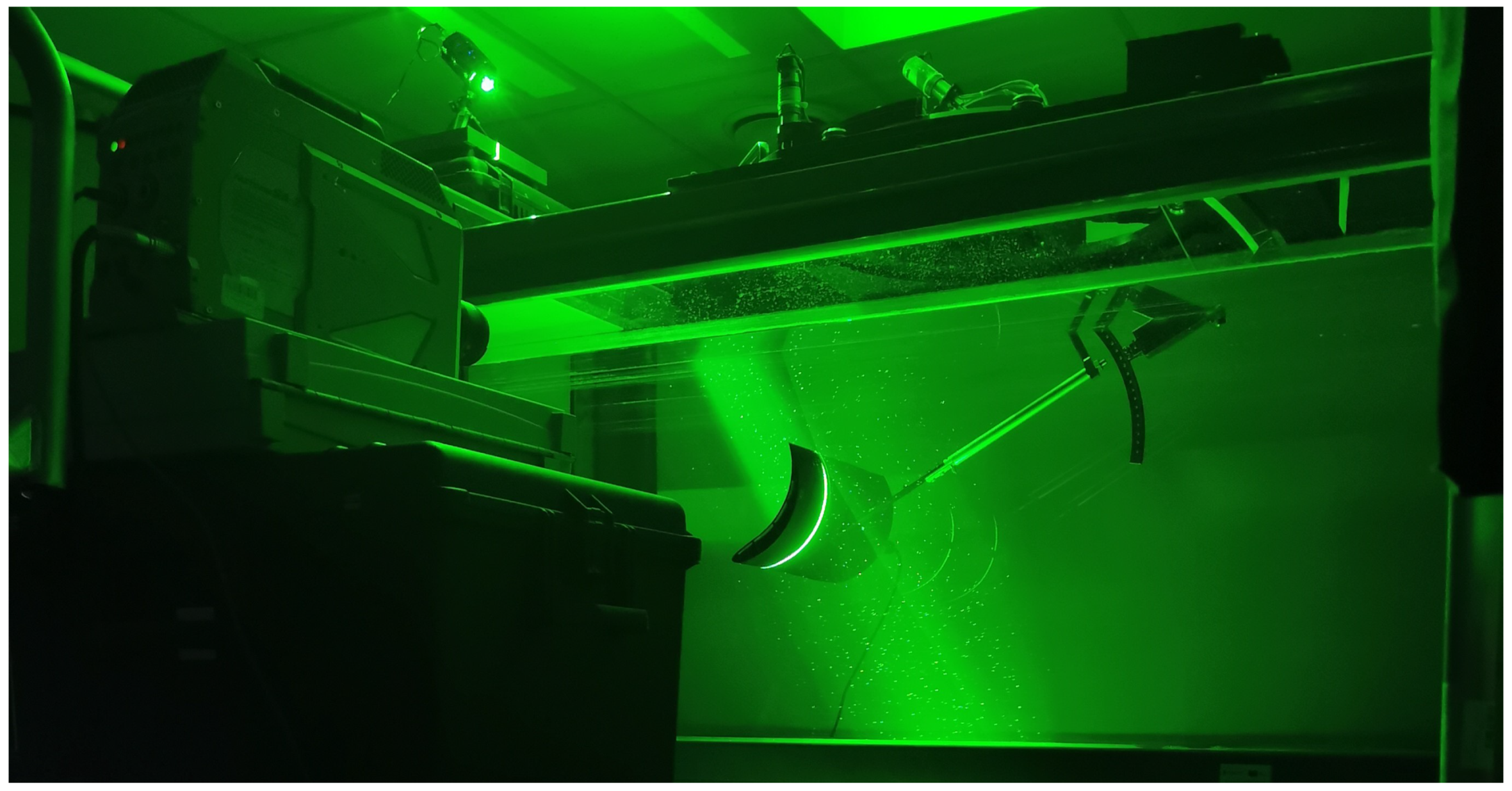

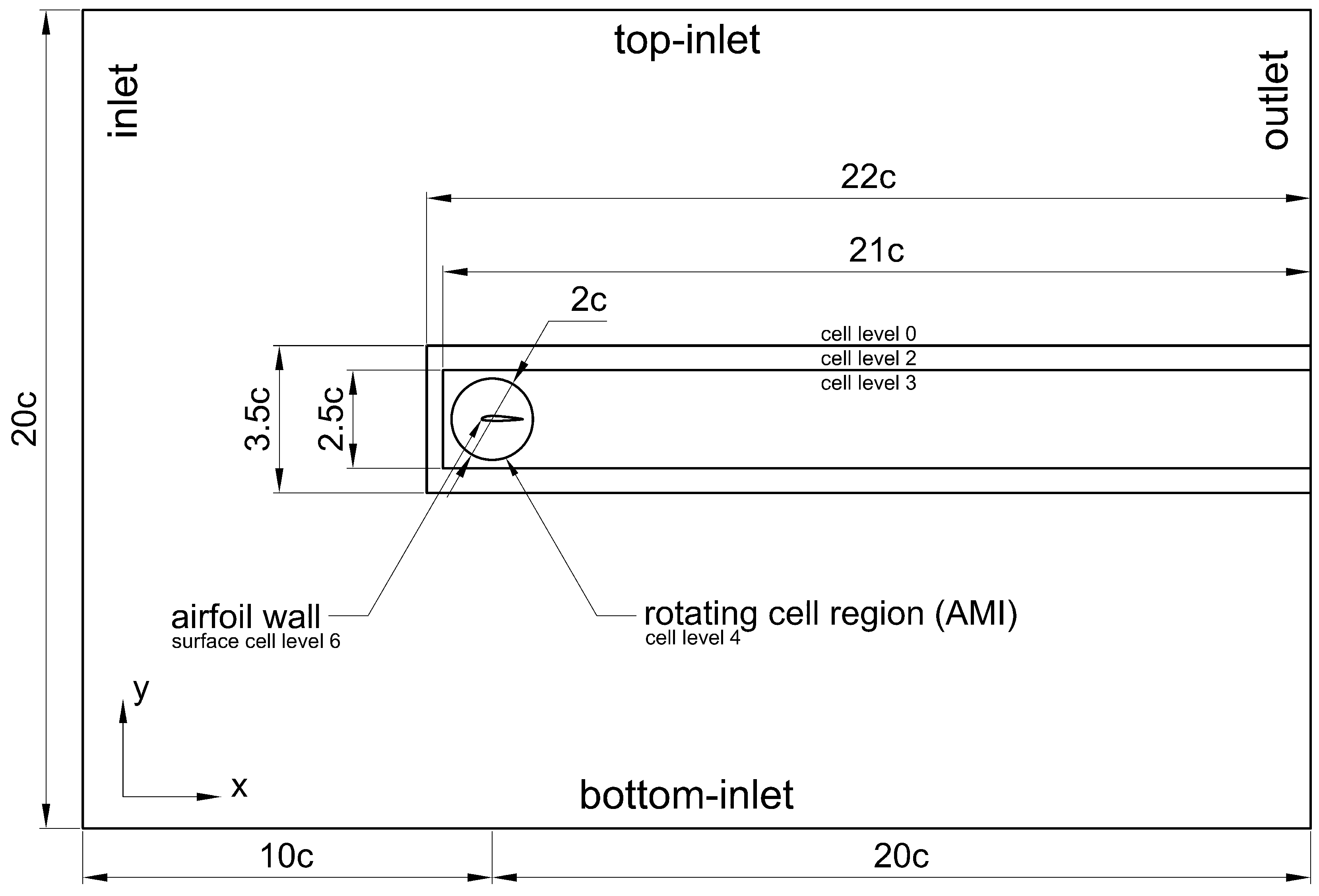

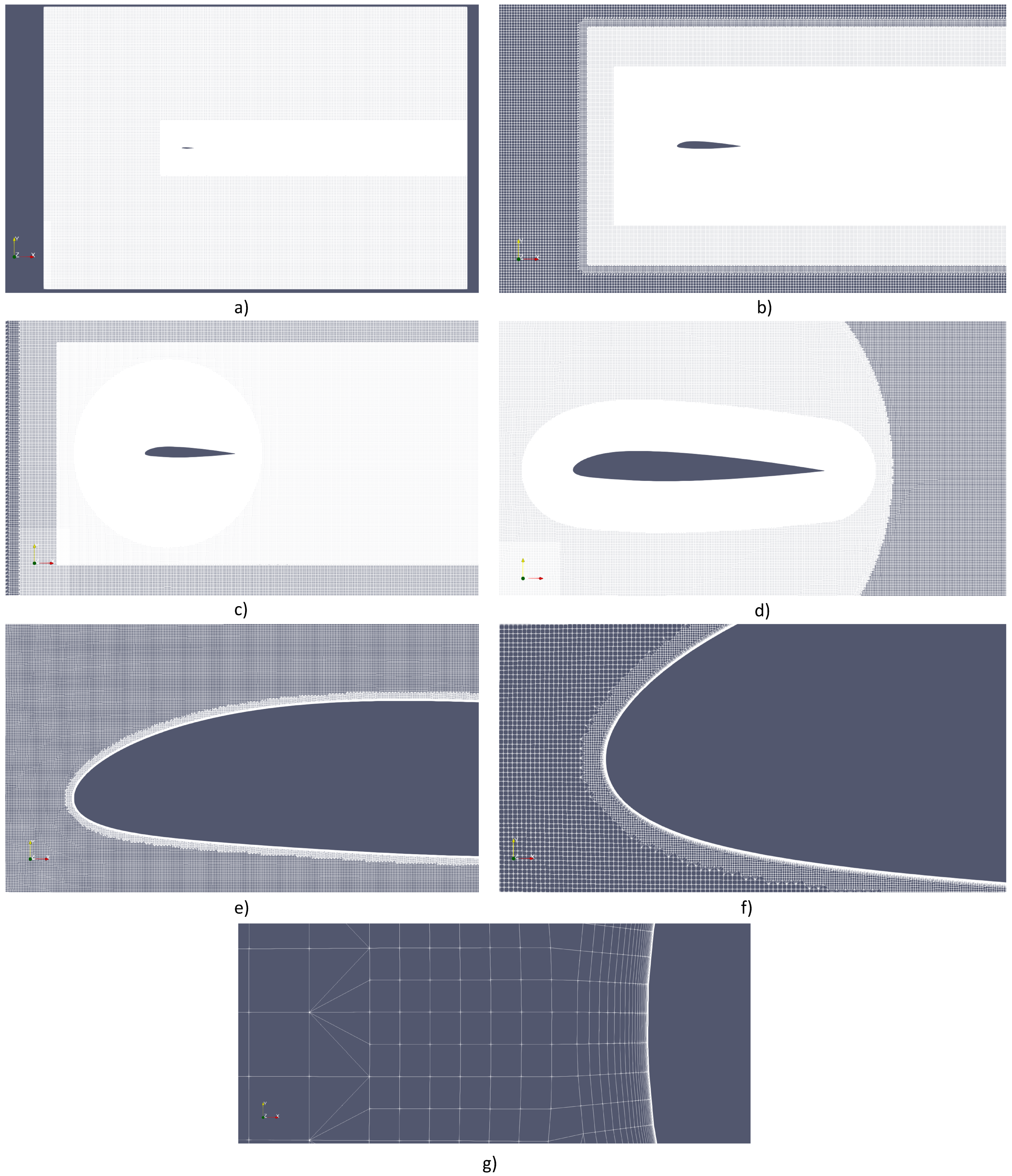

34]. Thus, this paper investigates changes in the aerodynamic efficiency of the airfoils for representative angles of attack and presents the turbulence distribution at very low Reynolds numbers. The main objective of this work is to research a variety of morphing airfoils with different camber deflections. The majority of the literature focuses on very limited camber deflections, and the authors find high cambered morphing airfoils an interesting and insufficiently researched field of aerodynamics. The research was conducted in a two-dimensional way, as for the PIV method, as for CFD simulations. Experiments were performed in a hydrodynamic tunnel using PIV for six airfoil models with various morphing stages. The CFD simulations were obtained using the

OpenFOAM software and utilising the k

-SST turbulence model. The CFD environment was a representation of an experiment conducted in an aerodynamic water tunnel. The lift force coefficients, drag coefficients, and lift-to-drag ratio characteristics are presented.

3. Results and Discussion

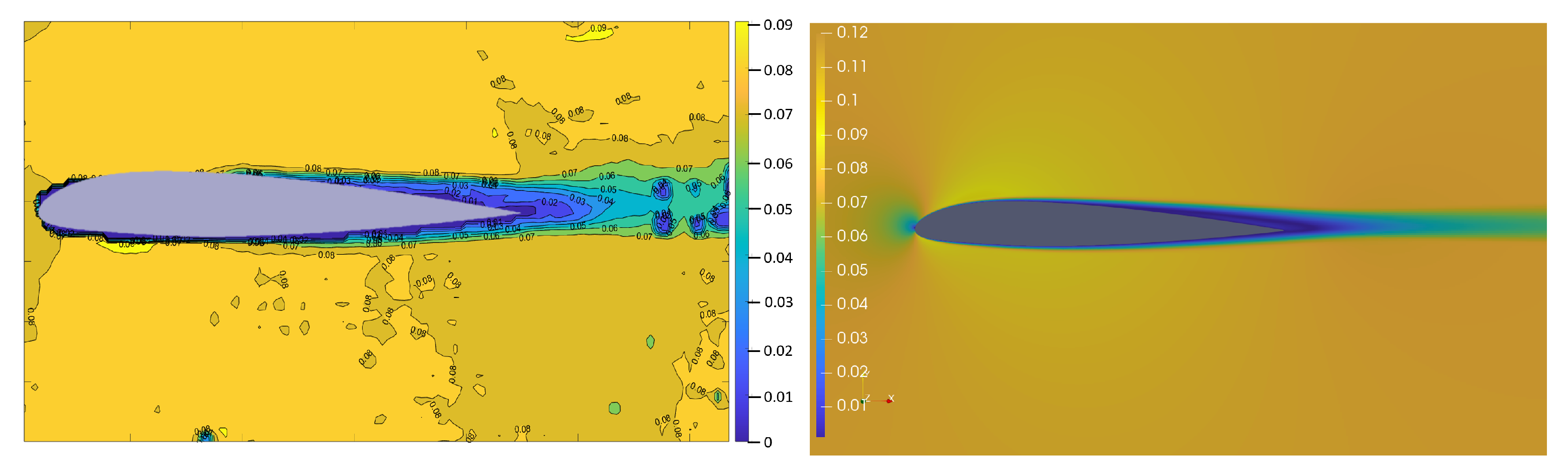

In this section, the results of the obtained experiments and simulations are discussed. As explained in

Section 2.3.5, the main focus of the study was centred on the PIV experimental approach. CFD simulations were performed to create an aerodynamic coefficient characteristics’ trend. For that reason, the medium remained water and the boundary conditions, such as velocity, remained unchanged. The validation of the numerical model was based on the velocity distribution. The obtained CFD results were of good quality and good enough to provide sufficient aerodynamic coefficient numerical results, especially for the preliminary research this work presents. Nevertheless, the authors present some insight into the differences between experimental and computational velocity distribution results.

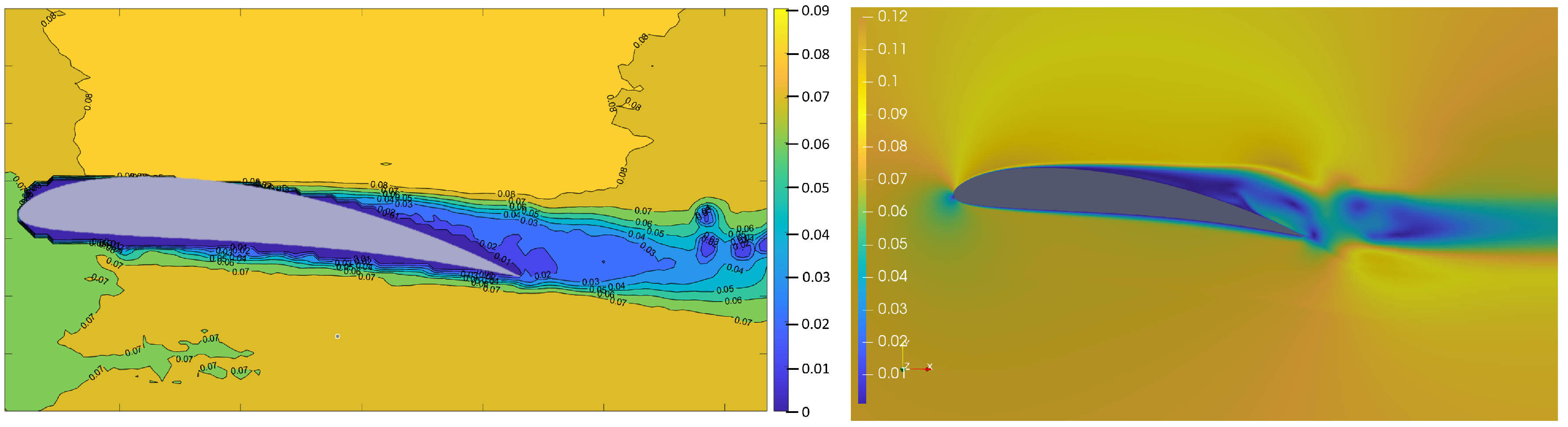

In the figures (

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16 and

Figure 17), the PIV and CFD results are presented. The shapes of the airfoils were inserted into PIV results to clarify the actual airfoil shape in every condition, as the shaded region in PIV varies and is not always identical to the tested geometry, especially in the area in front of the leading edge.

Figure 12 presents the velocity distribution for the NACA24012 airfoil, in this article, named Airfoil 1. As one can see, the velocity distribution is in the same range for both graphic results, and the laminar flow from the CFD method is less turbulent. Even for low Reynolds numbers and non-morphed airfoils, the wake structure behind the airfoil is turbulent, which is clearly visible in the discussed figure on the PIV result. The CFD results are numerical simulations taking ideal conditions and simplifying the environmental models, as the PIV method is an experimental method conducted in a real water tunnel. This simple comparison confirms the demand for an experimental approach to the turbulence study.

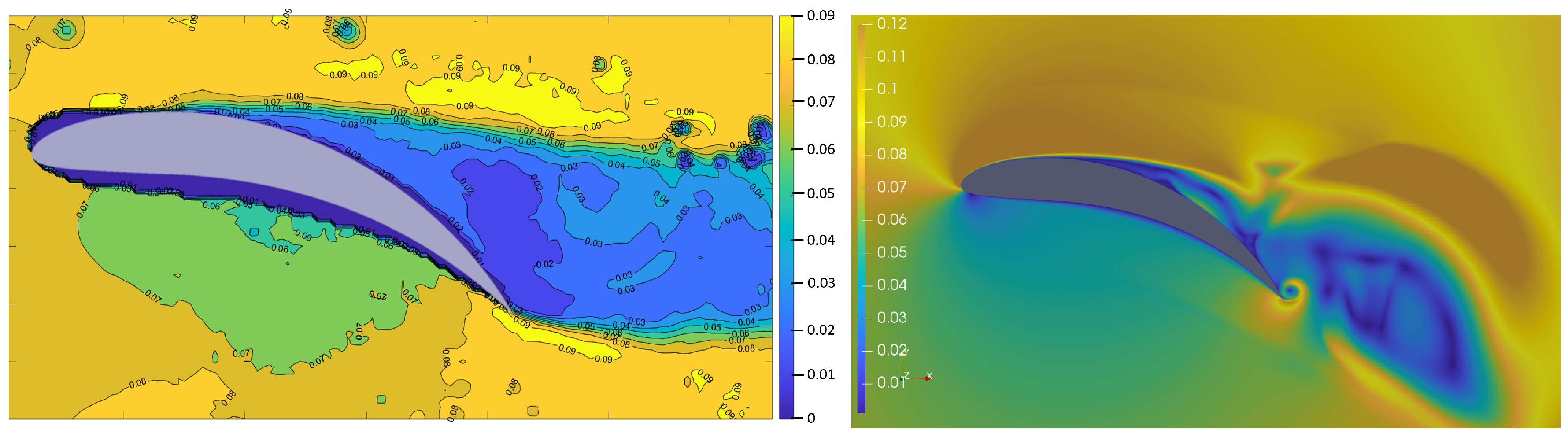

In

Figure 13 and

Figure 14, the CFD results, there are two areas of increased velocity, one above the airfoil and a second behind the trailing edge. The PIV results show a similar distribution of velocity, but in the CFD results, the velocity in this area is higher. The turbulence is comparable, taking into consideration that the PIV results are average values from 500 camera frames, and the CFD result is presented for specific iterations. Despite the clearly visible differences between the presented results, the velocity distribution and turbulence distribution are comparable, which enables the validation of the CFD results.

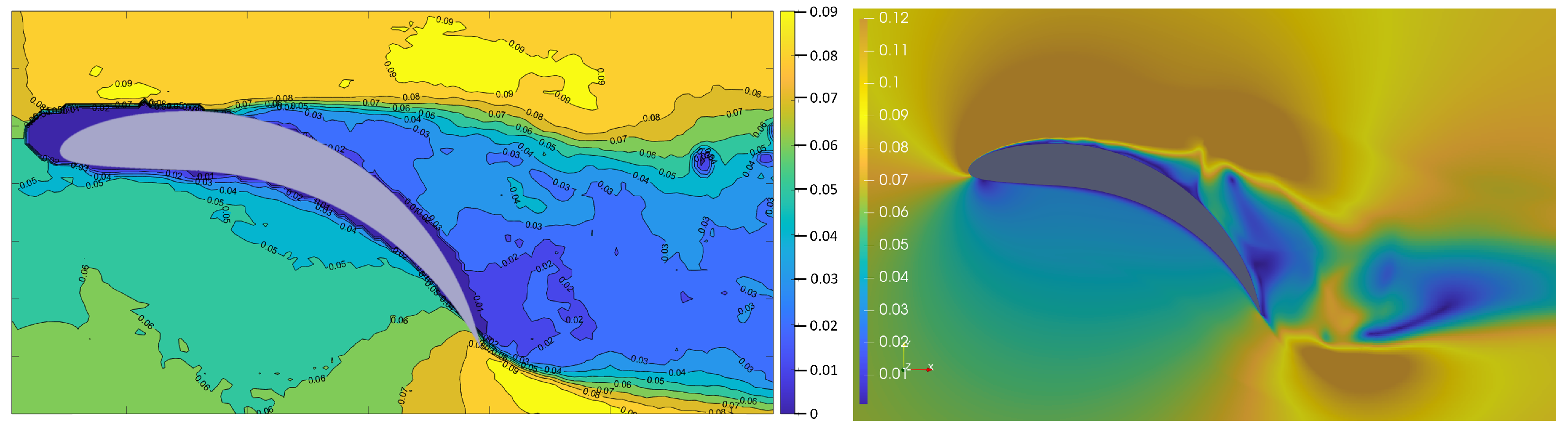

In

Figure 15, again, there is an area of increased velocity above the airfoil that spreads widely behind the airfoil geometry. This occurs for both the CFD and PIV results, and only the values of the maximum velocity differ. The wake structure is moved downwards in the CFD result, due to the increased velocity area behind the airfoil. Behind the trailing edge, in the PIV result, there is an increase in the velocity, and for the CFD results, this increase has a circular shape. As the PIV results’ values were averaged and show only the velocity distribution and not the eddy circulations, the actual flow is wrapping around the trailing edge, as shown in the CFD result.

For Airfoil 5’s graphic results (

Figure 16), they are similar to the previous areas of increased velocity. One is placed above the airfoil and other behind the trailing edge of the airfoil. The increased velocity area behind the trailing edge is longer and wider and the wake structure is greater compared to Airfoil 4’s results. On the upper side of the airfoil in both results, there is an area of increased velocity, suggesting the indication of a large eddy in this area. The upper side of the wake structure in the CFD results is slightly moved downwards compared to the PIV result.

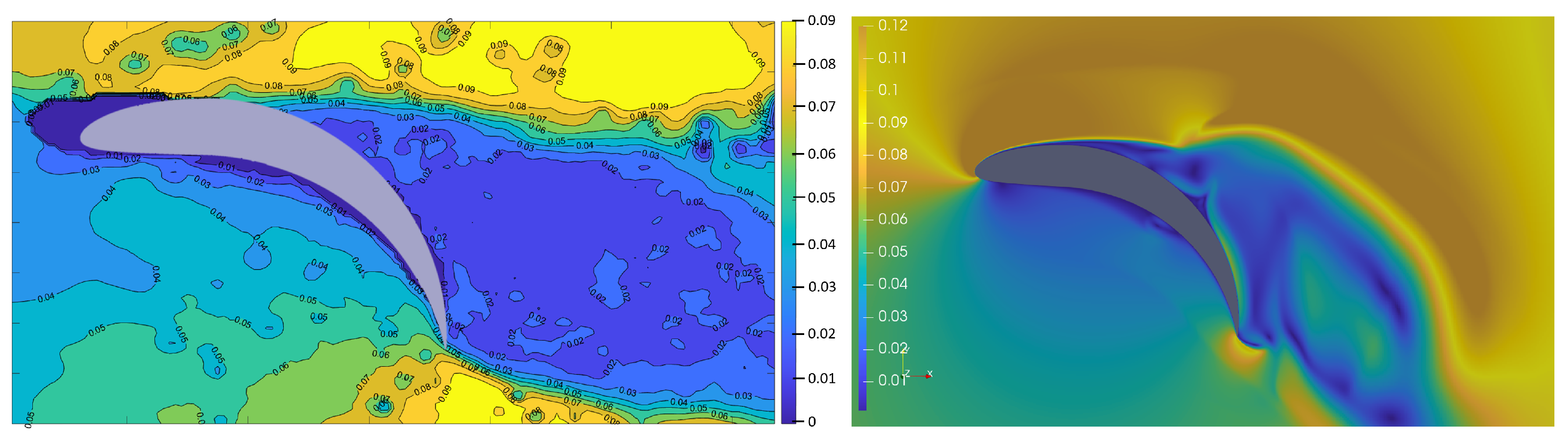

The fully morphed airfoil’s geometry results are presented in

Figure 17. The flow is fully separated, and the areas of increased velocity above the airfoil and behind the trailing edge present the maximum region. In the CFD result, the wake structure is significantly moved downwards for this specific iteration, as it fluctuates upwards and downwards in the real condition. In the middle of the airfoil’s upper surface, there is a clearly visible eddy in both graphic results.

Relating to all above-mentioned graphic results, the velocity distribution under the airfoils is highly comparable and adequate for both research methods. The wake structure has similar eddy structures for both conducted research methods. The CFD results are characterised by slightly higher maximum velocity values, but their distribution over the presented region is adequate. The wake structure is raising proportionally to the camber deflection of the airfoil. The two mean regions of increased velocity are recognised, one above the rear side of the airfoil and the other one behind the trailing edge. These regions are also rising with camber deflection. The boundary layer separation occurs at the same point for every airfoil geometry for both experiment methods. The CFD results are similar to the PIV results in the eddy distribution, though the fluctuation of the wake structure in the CFD results causes the wake structure to descend. This occurs more intensively with the increase in the camber deflection.

In the PIV results, one can notice small eddies behind the airfoil for every airfoil geometry. These structures do not appear in the CFD results, as CFD creates smoother results. During experiments, many eddies were visible in the turbulence region behind the airfoil. The CFD results are not as clearly visible due to the simplifications, by which the computational solutions are affected.

The differences between the PIV and CFD results described above are a representation of the demand for an experimental approach to flow research. Nevertheless, the similarities of both methods are clearly visible and precisely described to ensure the validation of the numerical model. The CFD numerical results were obtained and are presented in

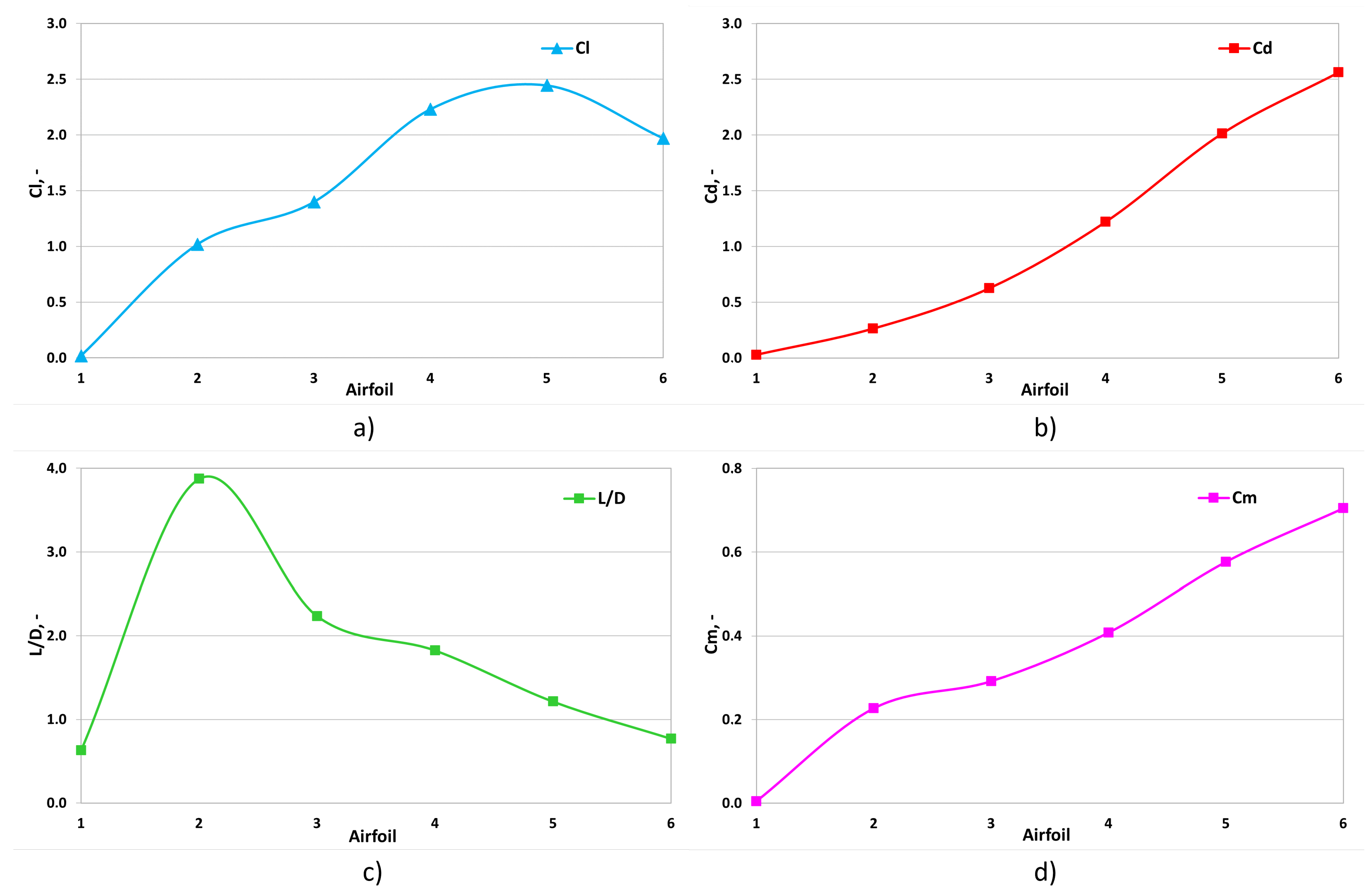

Table 6. A graphic representation of the results is presented in

Figure 18.

Figure 18a shows the lift force coefficient characteristics for all geometries. The increase in the lift force coefficient occurs for Airfoils 1 to 5, then it slightly descends for Airfoil 6.

The drag coefficient (

Figure 18b) increases with the increase in camber deflection for all geometries. As demonstrated above, the wake structure behind the airfoil rises with camber deflection, and greater turbulence implies higher drag.

The lift-to-drag ratio is a very useful value; it is the relation between the lift force coefficient and drag coefficient. It reveals the maximum amount of aerodynamic energy an airfoil is capable of generating. For an aircraft, it would be the distance the aircraft is capable of flying from 1000 m in standard atmosphere ideal conditions. Camber-morphing airfoils with slight camber deflection are usually characterised by better aerodynamic characteristics.

Figure 18c shows that the highest lift-to-drag ratio appears for Airfoil 2, a slightly cambered one, as the generated drag is still low and even marginal camber deflection generates high values of lift. Behind Airfoil 2, this characteristic drops significantly due to a lower difference in the increase in the lift force coefficient than for Airfoil 2 and an increase in the drag coefficient. For Airfoils 3 to 6, the lift-to-drag ratio descends linearly as the turbulence region and drag enhance drastically.

Every camber deflection provokes the pitching moment to increase. Aircraft pilots experience this phenomenon when the flaps are extended during every approach to landing. The pitching moment coefficient value for every geometry is presented in

Figure 18d. The pitching moment increases nearly linearly with the camber deflection of an airfoil.

4. Conclusions

In this paper, the authors presented and discuss substantial camber-morphing airfoil geometry experiments. The research was conducted with two methods: experimental in the water tunnel using the PIV method for velocity distribution representation and computational using CFD software for obtaining the coefficients and graphic velocity distribution representation.

This work presents preliminary research with the main objective to study a variety of camber-morphing airfoils with a wide range of camber deflections.

The CFD and PIV velocity distribution results exhibited significant similarities, which enables the validation of the numerical model. The aerodynamic coefficients were consistent with the predictions’ trends. It can be stated that Airfoil 2 had the best aerodynamic performance. Most research pursues creating the optimal airfoil with the highest lift force coefficient and lowest drag coefficient. It was demonstrated that camber-morphing airfoils can create drastic amounts of drag, retaining smooth and continuous surfaces. This could be a solution for micro UAV aircraft to reduce landing speed, without the necessity of installing wing mechanisation, which disturbs the airflow over the wing surface. Highly cambered airfoils can significantly reduce the landing distance, as they create massive amounts of drag, maintaining high lift.

However, airfoils with higher camber deflections can be utilised in various environments. This could be advantageous for wind turbines or tidal turbine engineers struggling with load reduction in hazardous atmospheric conditions. As highly cambered morphing airfoils create substantial drag, they could be utilised for rotor braking.

The CFD results were comparable, but they were not identical to the experimental results. As the simulations were performed in the exact environment as the experiments in the water tunnel, the simulations provided accurate and comparable results, but the differences were visible. This is a confirmation of the persisting need for an experimental approach to wake structures and turbulence research in the era of numerical simulations.

The next step of this preliminary research will be conducting experiments and numerical simulations on a wider range of angles of attack. The authors would like to obtain the full aerodynamic characteristics of the presented camber-morphing airfoils and to perform calculations correlating high amounts of produced drag with loads acting on turbine rotors and aircraft wings.

Substantial camber-morphing airfoils may be implemented in various applications from diverse fields. Though their applications are limited due to the limited abilities of current mechanical features, there remains demand for conducting aerodynamic research and for verifying different aerodynamic solutions for future use. The authors pushed the morphing airfoil concept a step further, creating a geometry that produces drag instead of decreasing it while maintaining a continuous surface. It is a solution with great potential and perspectives for further investigation.