Abstract

Composition regulation of zeotropic mixture working fluid for a thermodynamic cycle is an effective way to improve energy conversion efficiency, which offers the potential to construct efficient, flexible and intelligent cycles. Current research on cycle construction of zeotropic mixture composition regulation still heavily relies on construction methods using pure working fluids, where the characteristics of flexible composition variations fail to be utilized. In this paper, the research progress of cycle construction methods and composition regulated structures are comprehensively reviewed, aiming to clarify the potential for enhancing a thermodynamic cycle based on composition regulation. The characteristics of different cycle construction methods are firstly summarized and compared. Then, the composition-regulated structures of a physical-based method and chemical-based method are introduced, and the composition regulation performance are also concluded. Finally, a future outlook on the cycle design and structure design is provided. The review results show that the combination of 3D construction method and superstructure/intelligences construction method has the potential to maximize the cycle performance, where the improvement of each thermal process and the optimization of complex cycles can be considered simultaneously. The composition regulation based on a passive physical method has the advantage of being readily applicable; however, the composition regulation range is limited. In addition, the distillation and hydrate method have a wider regulation range through extra energy input, where the trade-off between energy consumption and cycle performance improvement should be considered in the future. This study greatly assists in the design of thermodynamic cycles involving zeotropic mixture composition regulation and the corresponding composition regulation structures.

1. Introduction

With the put forward of “Carbon neutrality”, increasing the utilization efficiency of energy, especially renewable energy, and reducing the use of fossil energy has become a critical pathway to reducing carbon emission. Among them, the medium- and low-grade thermal energy (temperature lower than 350 °C) plays a crucial role in the utilization of renewable energy. According to the National Bureau of Statistics of China, the total amount of medium and low grade energy that can be developed and utilized in renewable energy, including geothermal energy, solar energy, ocean energy, is estimated to be 6.37 × 1022 J [1], which is 420 times greater than the total energy consumption of China in 2021 [2], indicating enormous utilization potential. Furthermore, in industrial processes that highly rely on fossil energy, over 30% [3,4] of energy is released as medium- and low-energy-grade waste heat. Therefore, to attain low-carbon and high-efficiency energy consumption, the utilization of a medium and low energy grade can be explored through the perspective of renewable energy utilization and waste heat recovery, which is the key component in ensuring the stable transition of the energy structure and achievement of carbon neutrality.

To utilize medium- and low-grade energy, one effective way is though a thermodynamic cycle. Among them, the organic Rankine cycle (ORC) has received extensive attention in both academic and industrials fields. In the past, research on ORC mainly focused on the selection of working fluids [5], the design of key components [6] and improvements in the thermodynamic cycle structure [7]. However, due to the irreversible losses in each component, especially in terms of the heat exchange process, the system’s efficiency during applications and experimental testing remains limited. For instance, the efficiency of the first law of thermodynamics is lower than 12% [8], and the thermodynamic perfectibility is lower than 50% [9].

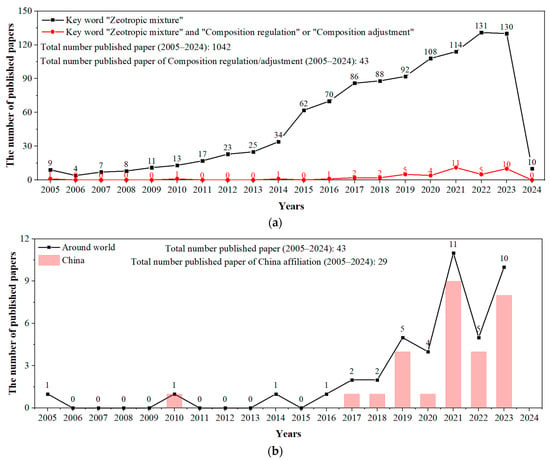

To break though the above limitation and further improve the thermal efficiency of the thermodynamic cycle, some researchers have proposed utilizing the zeotropic mixture working fluid. Using “zeotropic mixture” as a key word to retrieve in Web of science database, it can be observed that 1042 papers have been published from 2005 to 2024 around the world, as shown in Figure 1a, with a growing trend over the years. Among these papers, a significant proportion of the research is focused on the heat transfer performance, phase equilibrium or the replacement of pure working fluids with zeotropic mixture working fluid in a thermodynamic cycle. Additionally, as depicted in Figure 1b, 43 papers among these publications are related to composition regulation, whereby nearly 70% are published by Chinese authors. The regulation of mass fraction ratios in the zeotropic mixture working fluid, referred to as “composition regulation”, capitalizes on the inherent variability of physical properties. This variability facilitates in matching between working fluid properties and thermodynamic processes, notably the temperature matching during heat exchange process. As a consequence, it also further reduces the irreversible losses in the system and improve system performance [10]. Research on thermodynamic cycles with zeotropic mixture working fluid can be summarized into three types: construction of a thermodynamic cycle, key technologies of a system component, and system applications. For the previous type, the innovation of novel a thermodynamic cycle construction is based on thermodynamic theories and methods. Meanwhile, by optimizing and analyzing system performance under various system operating conditions and the system component, the maximum performance limit of the new thermodynamic cycle can be obtained. For the second type, the research mainly focuses on the key components involved in each thermodynamic process, aiming to obtain the actual performance of each component under specific operating conditions. For the last type, the integration and the experiments’ test of the novel thermodynamic cycle is mainly concerned with the objective of evaluating the performance of actual thermodynamic cycles under specific operating conditions. However, currently, the proven construction method of thermodynamic-cycle-based composition regulation have not been widely reported. The majority of construction technical pathways heavily rely on construction methods using pure working fluids, thereby failing to fully utilize the characteristics of flexible composition variations.

Figure 1.

The number of published papers around the word. Data were collected on 23 March 2024 from the Web of science database. (a) Key word “Zeotropic mixture”; (b) key word ”Zeotropic mixture” and “Composition regulation” or “Composition adjustment”.

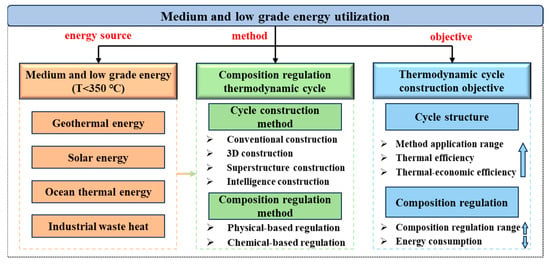

Based on the aforementioned information, to reveal the potential for enhancing thermodynamic systems based on composition regulation, this paper presents a comprehensive review of the research progress on the novel thermodynamic cycle that utilizes zeotropic mixture working fluid with composition regulation, as shown in Figure 2. The focus of the research lies primarily in the thermodynamic cycle construction and key technologies of the system component. Firstly, the conventional construction thermodynamic cycle, 3D construction thermodynamic cycle method, superstructure construction thermodynamic cycle method and intelligence construction thermodynamic cycle method are summarized and compared. Furthermore, the composition regulation technologies based on physical phase separation (T-junction, liquid-separation condenser and distillation towers) and chemical reaction regulation (hydrate-based method) is summarized. The proposed novel thermodynamic cycle construction provides valuable insights for the advanced thermal power conversion technologies. However, the application of the composition variation characteristic of the zeotropic mixture working fluid for the available method is still limited. Additionally, when applying the composition regulation technologies to the actual thermodynamic cycle, it is crucial to strike a comprehensive balance between the extra energy input and the energy output resulting from the composition regulation. This study is of great help in the construction of the zeotropic mixture composition regulation thermodynamic cycle and the design of the composition regulation structure.

Figure 2.

Schematic of review outline: energy source, method, and objective.

2. Methods of Thermodynamic Cycle Construction

The method of the thermodynamic cycle construction serves as the foundation for proposing a new thermodynamic cycle. By explicitly defining the basic principles of thermodynamic cycle construction, it can effectively guide the design of innovative cycle structures. In traditional research, the introduction of new thermodynamic cycles often relies on modifying and combining multiple conventional thermodynamic cycles using topological configurations such as repetition and parallelism, for specific thermodynamic processes. However, there is a lack of unified methods to provide guidance, resulting in complex and diverse new cycle structures that heavily depend on specific boundary conditions. Recently, some scholars have proposed various methods for thermodynamic cycle construction, including the conventional construction method, 3D construction method, superstructure method and intelligent method.

2.1. Conventional Construction Method of Thermodynamic Cycle

Conventional construction method primarily involves the optimization of specific thermodynamic processes (such as multiple evaporation, heat recovery, reheat, composition regulation, etc.) to tackle the challenges encountered in the existing thermodynamic cycle. In the refrigeration thermodynamic cycle, to increase the evaporation pressure and reduce the compression work, a greater amount of low-boiling point refrigerant should be applied in the evaporator. Yan et al. [11] proposed a vapor-compression refrigeration cycle with separation condensation. By regulating the composition of zeotropic mixture working fluid, the system performance (COP, volumetric refrigeration capacity, total exergy destruction and energetic efficiency) can be improved. Yang et al. [12] proposed a new combined power and ejector cycle with composition regulation, aiming at reducing the exergy loss of each component. The results show that the exergy efficiency and the thermal efficiency reach 10.29% and 10.77%, respectively. Similarly, Yaïci et al. [13] focus on the utilization of low-grade heat source utilization and the low-GWP and near zero-ODP working fluids, which proposed combined cooling, heat, and power generation systems. The results demonstrate that the heating efficiency and COP can be increased. However, it is important to note that there is a significant reduction in the net power output and power efficiency. Feili et al. [14] analyze the bi-evaporator ejector refrigeration cycle (BE-ERC) with the objective of improving exergy efficiency. The results show that the exergy efficiency of the BE-ERC system can reach 20.95%. By implementing a liquid-separation condenser in ORC with zeotropic mixture, Luo et al. [15] demonstrated an increase in the heat transfer coefficient, thereby alleviating the need for a corresponding increase in the heat transfer area. The results indicate a power output increase of 13.05–26.18%. Lu et al. [16,17] designed an ORC and a Carnot battery system using a zeotropic mixture with composition regulation. The performance of systems under off-design operating conditions can be increased. The results show that the ORC system achieves a 21.43% lower average electricity production cost, while the Carnot battery system achieves a 22.40% higher round-trip efficiency.

To sum up, the use of the conventional construction method effectively addresses the concerns and exhibits an improved thermodynamic performance and economic performance. However, it has limitations, as the design of the new systems relies primarily on experience and may not represent the optimal design for the system. It is more suitable as a prototype thermodynamic system, and in later stages, the assistance of intelligent algorithms is still required to aid in system construction.

2.2. 3D Construction Method of Thermodynamic Cycle

Zeotropic mixture working fluid exhibits both temperature glide and composition variation of each phase during the phase change process. Currently, the application of the zeotropic mixture working fluid primarily follows the research methodology of pure working fluid. It is applied directly in the traditional organic Rankine cycle (ORC) without any modification to the system construction. Only the characteristic of temperature glide of the zeotropic mixture working fluid is utilized during phase change process to achieve better temperature matching between the working fluid and the heat (cold) source. Although the irreversibility in the heat transfer process can be decreased, the improvement of the performance of the zeotropic mixture working fluid systems is still limited, and their thermo-economic performance might be lower compared to the ORC with pure working fluid. There is still a lack of comprehensive exploration regarding the impact of composition variation of zeotropic mixture working fluid on system performance. In fact, the main difference between zeotropic mixture working fluid and the pure working fluid lies in the composition variation in the phase change process. If zeotropic mixture working fluids are directly applied to the conventional cycle structures, they are, indeed, confined to a single cycle composition, restricting the potential for system performance improvement that could be attained through composition variations. How to overcome the limitations of the pure working fluid in the thermodynamic cycles and exploring avenues to enhance thermal cycle efficiency by effectively utilizing the characteristics of zeotropic mixture working fluid composition variations has become a pressing issue in cycle construction that needs to be addressed.

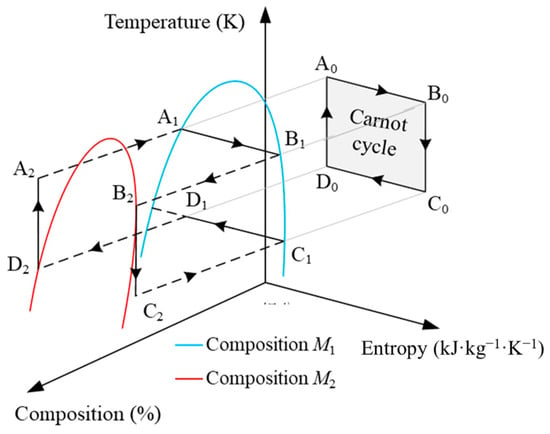

In view of this, Xu et al. [18] proposed a 3D construction method of the thermodynamic cycle based on the “temperature-entropy-composition of working fluid” coordinate system, as shown in Figure 3. In this method, the variations of working fluid composition is the core concept, where the thermodynamic process of composition separation and mixing is added to the conventional thermodynamic cycle. Therefore, the composition of zeotropic mixture in each thermodynamic process can be regulated, allowing each thermodynamic process to progress under difference working fluid composition. The 3D construction method of the thermodynamic cycle is taking full advantage of composition variations under different thermodynamic processes, achieving overall cycle performance improvement by synergistically considering the performance of all thermodynamic processes.

Figure 3.

Schematic diagram of 3D construction of thermodynamic cycle (modified from Ref. [18]).

The foundation of applying the 3D construction method of the thermodynamic cycle reveals the correlation between the thermophysical properties of the working fluid and the performance of each thermodynamic process, as well as determining the selection criteria and the optimal working fluid of each specific thermodynamic process. The typical studies on the selection of working fluids for various thermodynamic processes in ORC are summarized in Table 1. Zheng et al. [19] presented a statistical parameter σ for selecting the optimal zeotropic working fluid for the heat transfer process by analyzing the irreversibility of this process. Stijepovic et al. [20] proposed a correlation between the molar volume of the saturated liquid working fluid and the performance of the compression process. The results indicate that the performance of compression process is inversely proportional to the saturated liquid working fluid. The combined parameter based on the compressibility factor, density and specific heat capacity under constant pressure, which is utilized in the optimal working fluid selection for the compression process, was introduced by Xu et al. [21] through experiment research. Moreover, despite the investigation of the correlation between the expansion process and the thermophysical properties of the working fluid in references [20,22,23,24,25], a unified conclusion has not been reached.

Table 1.

Studies on the working fluid selection for thermodynamic process in ORC.

Based on the 3D construction method of the thermodynamic cycle, the construction of the new cycle requires determining the functional features of the cycle firstly according to the boundary conditions of the heat source and heat sink, as well as the demand of the cycle. Subsequently, the optimal working fluid of each thermodynamic process is defined based on the operating characteristics. Then, the cycle is combined with various thermodynamic processes through composition regulation, and the mixture working fluid of the cycle is determined. This method offers a new approach to cycle construction based on the zeotropic mixture working fluid, which breaks through the limitation imposed by a single working fluid in conventional thermodynamic cycles, allowing for improved cycle performance. However, the application of this method also relies on the selection criteria of the working fluid in each thermodynamic process. Currently, there is still a lack of extension research on the working fluid selection aimed at each thermodynamic process. Meanwhile, due to the differences in the assumptions among various studies, the results in the available research lack universality. Therefore, further extensive and in-depth research is urgently needed.

2.3. Superstructure Method of Thermodynamic Cycle

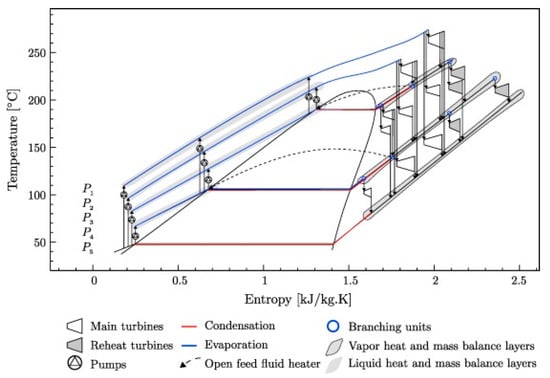

In the superstructure method of the thermodynamic cycle, the superstructure is a set of all possible alternative options in the thermodynamic cycle design [26]. It should be collected firstly while constructing a new thermodynamic cycle, including various thermodynamic process (superheated process, heat recovery process, etc.) and interconnection methods of these processes. Then, the optimal parameters such as cycle structure, working fluid and operating conditions are obtained from superstructure optimization based on the application scenarios and boundary conditions. Kermani et al. [27] presented an ORC superstructure that includes five pressure levels based on the superstructure construction method. The schematic of the temperature entropy diagram is shown in Figure 4.

Figure 4.

Schematic diagram of ORC superstructure with five pressure levels [27].

The available research on the construction of medium- and low-temperature thermodynamic cycles by using the superstructure method is summarized in Table 2. In 2017, the superstructure method is innovatively used in the construction of ORC by Elsido [27,28], Lee [29] and Yu [30]. Heat recovery process, superheated process, vapor extraction process, multistage compression process, multistage expansion process and other thermodynamic processes were applied in the construction of the ORC superstructure. Subsequently, the superstructure method has been widely used in the design and optimization of the new ORC structure, such as liquefied natural gas (LNG) cold thermal energy recovery [31,32], industrial waste heat recovery [33,34], geothermal power generation [35] and solar power generation [36,37]. Lee et al. [29] applied a ternary zeotropic mixture working fluid n-C5H12/CF4/CHF3 (0.09/0.33/0.58) in the superstructure optimization study containing 1024 types of cycle structures. Result shows that the thermal efficiency of the new cycle structure is 26.2% higher than conventional ORC. Yuan et al. [32] designed a new ORC structure that comprehensively considers both power generation performance and system thermal economy using the binary zeotropic mixture R32/C2H4 (0.45/0.55). Furthermore, the superstructure method has also been used in the construction and optimization of the heat pump cycle [38,39] and supercritical CO2 Brayton cycles [40,41].

Table 2.

Studies on the superstructure method of thermodynamic cycle.

The superstructure method of the thermodynamic cycle is a “top-down” method to thermodynamic cycle construction. The upper-level superstructure is established, which contains all cycle structures, and the specific lower-level cycle structure is determined based on the boundary conditions. The computational consumption of cycle construction is reduced through the implementation of the superstructure method, particularly for thermodynamic cycles with multiple processes. With the superstructure method, the time-consuming process of individually calculating and comparing the performance of each cycle can be bypassed. Instead, complex cycle optimization can be achieved through computer optimization algorithms. However, there also exist limitations to the superstructure method. The proposed superstructure heavily relies on the thermodynamic theory and research experience of the designer, resulting in variations in the form of the superstructure among individuals and inevitably introducing impractical or suboptimal structure form. To sum up, determining an appropriate superstructure is the key point to the superstructure method of the thermodynamic cycle. Additionally, only a few studies have been conducted on zeotropic mixture working fluid, with the majority of studies primarily focusing on pure working fluids. The superstructure for utilizing zeotropic mixture working fluid, in contrast to the one using pure working fluids, involves not only mass flow rate regulation but also composition regulation. Therefore, the introduction of zeotropic mixture working fluid to the thermodynamic cycle superstructure construction has the potential to expand the diversity of new cycle structures.

2.4. Intelligent Construction of Thermodynamic Cycle

The superstructure-free construction of the thermodynamic cycle, which is proposed to breakthrough the limitation of the superstructure design in the upper-level of the superstructure method of the thermodynamic cycle, has the characteristic of a “down-top” construction cycle method. By definition, the basic element structure (single thermodynamic process or combination method of multi-thermodynamic process) of the thermodynamic cycle construction is firstly at a lower level. Then, the synthesis rules of each basic element structure are determined to obtain the new thermodynamic cycle at the upper level.

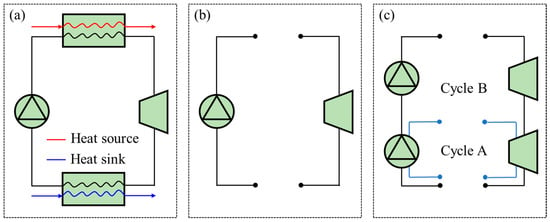

The basic element structure in the superstructure-free method is obtained through the HEATSEP method, where the heat transfer processes are separated from the entire cycle, forming a hot (cold) end. Taking the conventional ORC structure in Figure 5a as an example, the basic element structure is obtained using the HEATSEP method (Figure 5b). Then, the compression process and the expansion process are retained in the cycle and the evaporation process, and the condensation process are replaced by hot end or cold end. Ultimately, the thermophysical properties of the working fluid is transmitted through both ends of the hot (cold) end. Based on the principles of thermodynamic process sharing, the new thermodynamic cycle is constructed using various intelligent cycle construction methods based on the basic element structure. The thermodynamic process sharing represents those two thermodynamic cycles undergoing the same thermodynamic process. As shown in Figure 5c, it can be seen that Cycle A and Cycle B undergo the compression process simultaneously, indicating that the compression process of Cycle A is a shared thermodynamic process.

Figure 5.

Schematic diagram of superstructure-free construction of thermodynamic cycle: (a) Conventional ORC; (b) HEATSEP; (c) Thermodynamic process sharing.

To sum up, the superstructure-free construction of the thermodynamic cycle consists of two steps. The first step is determining the basic element structure based on the HEATSEP method and obtaining the new cycle structure using an intelligent algorithm based on the principle of shared thermodynamic process. The second step is optimizing the heat exchanger network based on the split thermal process and the boundary conditions of the heat source (sink).

The available research of the thermodynamic cycle construction based on the superstructure-free construction method is summarized in Table 3. This method was first proposed by Toffolo et al. [42] in 2014, which determined the basic principle of the HEATSEP method and the thermodynamic process sharing. Subsequently, it has been applied to the design of the ORC structure [43,44,45]. Lin et al. [46] also employed the superstructure-free construction method to design optimal cycle structures using both pure fluid and mixture fluid, respectively. Liang et al. [47] constructed a dual-evaporation ORC structure using a binary zeotropic mixture working fluid n-pentane/n-heptane (0.9/0.1) through the superstructure-free construction method. Moreover, the superstructure-free construction method also has been widely applied to design the advanced thermodynamic cycle such as absorption refrigeration cycle [48,49], absorption power cycle [50] and supercritical CO2 Brayton cycle [51,52].

Table 3.

Studies on the intelligent construction of thermodynamic cycle.

The characteristics of each cycle construction method is summarized in Table 4. Compared to the superstructure construction method, the superstructure-free construction method does not predetermine the search domain of the cycle structure. Instead, through a proper combination of thermodynamic processes, any possible thermodynamic cycle structure can be constructed theoretically. Meanwhile, in the superstructure-free construction method, the cycle construction does not rely on previous experiences but is optimized by intelligent algorithms based on combination principles. Therefore, it is also categorized as an intelligent construction of the thermodynamic cycle. However, though any possible thermodynamic cycle structure can be constructed through a superstructure-free construction method, the characteristic and the advantage of the zeotropic mixture working fluid on composition regulation has not been explored deeply, similar to the superstructure construction method. The application of active composition regulation of zeotropic mixture working fluid between different thermodynamic processes in the superstructure-free construction method has the potential to further improve the thermal performance of new cycles.

Table 4.

Comparation of different construction methods.

3. Methods of Zeotropic Mixture Composition Regulation

In the construction of an advanced thermodynamic cycle using zeotropic mixture, a key parameter is the composition regulation technology. In the section, the composition regulation technologies are comprehensively reviewed, including both physical phase separation methods and chemical phase separation methods.

3.1. Composition Regulation Based on Phase Separation

3.1.1. T-junction

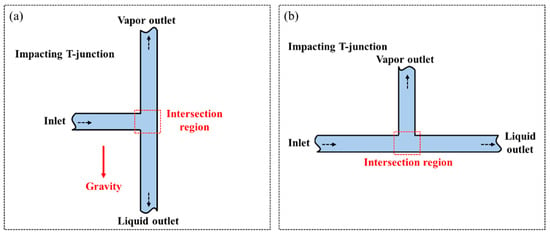

T-junction is a phase separation device with a simple structure, low cost, and easy integration with existing systems, which has been widely applied in petroleum exploitation engineering, chemical industry, nuclear power plant and so on. It can be categorized into two types, namely “Impacting T-junction” [53] and “Branching T-junction” [54], as shown in Figure 6. When the two-phase fluid flows into the intersection region of the T-junction, the trajectory of the vapor phase and the liquid phase deviates due to the differential of the inertia force in each phase, resulting in phase separation.

Figure 6.

Schematic of T-junction: (a) impacting type; (b) branching type.

In impacting the T-junction, the inlet is perpendicular to the two outlets. The two-phase fluid flows into the T-junction from the inlet and impacting the wall of T-junction, then the flow trajectory of the vapor phase and the liquid phase deviates due to the differential of the gravitational force in each phase, resulting in phase separation. Ideally, in an impacting T-junction, the liquid and vapor can be fully separated, where the lower vapor quality than the inlet tube can be achieved as liquid flows out from the lower tube (i.e., liquid outlet) as well as the higher vapor quality than the inlet tube can be achieved as vapor flows out from the upper tube (i.e., vapor outlet). However, due to the intensive interaction between vapor and liquid, the phases cannot be fully separated after the fluids impact the wall of the T-junction, resulting in the phenomenon of droplet entrainment and bubble entrainment.

In the branching T-junction, the fluids flow straight forward from one of the two branches. The two-phase fluid flows into the T-junction from the inlet and then the flow trajectory of the vapor phase and the liquid phase deviates due to the differential of the inertia force in each phase, resulting in phase separation. Ideally, in a branching T-junction, the two-phase fluid can be fully separated when the inlet flow pattern is a stratified flow by controlling the outlet pressure and mass flow rate. However, the flow pattern of the two-phase fluid can also present as an intermittent flow, annular flow or mist flow and so on. The interaction between vapor and liquid is more intensive than the flow pattern in the stratified flow, which results in a decrease in phase separation efficiency.

The available research of composition regulation in the zeotropic mixture working fluid using T-junction is summarized in Table 5. It can be seen that there are still some limitations on the composition regulation in the T-junction. Zheng [55] and Su [56] conducted a series of experimental research on impacting T-junction and branching T-junction, respectively. Lu [57] and Su [58] established a numerical model of branching T-junction and explored the flow characteristic and the phase separate performance of the two-phase fluid. They point out that since the zeotropic mixture working fluid consists of R134a and R600a, the composition in the branching T-junction can be regulated from 0.44/0.56 at the inlet to 0.70/0.30 at the outlet, which achieves the maximum composition regulation ability in the available research. Although the structure parameters, working fluid and the boundary conditions differ, the composition regulation in T-junction mostly relies on the phase separation based on the available research. Moreover, the phase separation efficiency is more affected by the tube geometry, inlet mass flux, inlet vapor quality, inlet pressure, inlet working fluid and the inlet composition simultaneously. A generalized conclusion and the prediction model that are suitable for different types of T-junction are still lacking and need to be developed.

Table 5.

Studies on the composition regulation of zeotropic mixtures using T-junction.

To further improve the composition regulation performance of the T-junction, the research of active composition regulation of T-junction and the combined T-junction has been conducted. Su et al. [60] developed a numerical model of branching T-junction with different temperatures on the wall of the branch tube and run tube. Then, the composition regulation performance driven by the thermal field of the zeotropic mixture working fluid in the branching T-junction is investigated. The results showed that compared to passive composition regulation, actively adding different strengths of the thermal field at each outlet can achieve a higher composition regulation performance. Yang et al. [61] designed and fabricated a combined T-junction and further tested the phase separation performance of R134a. The results demonstrated that the combined T-junction had the capability to separate more vapor out of the liquid compared to a single T-junction. Building upon this, Bai et al. [62] developed a numerical model based on the structure of the combined T-junction and conducted research under a wide range of boundary conditions, including inlet mass flow rate, mass flow rate ratio and so on. The optimized geometry of combined T-junction is proposed. Fu et al. [59] designed a compound T-junction and conducted tests to evaluate the composition separation performance of R134a/R245fa (0.429/0.571). The results indicate that, at an inlet mass flow rate and vapor quality of 13 g/s and 0.19, respectively, the composition separation efficiency can reach 86.86%, which is 10% higher than that in the conventional branching T-junction.

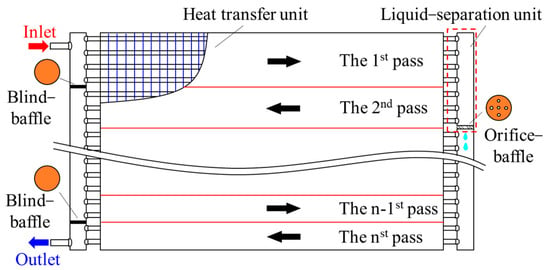

3.1.2. Liquid-Separation Condenser

The liquid-separation condenser is a component that combines heat transfer and vapor–liquid separation. As the vapor continuously converts into liquid inside the heat transfer tubes, the prompt separation of the liquid and vapor allows for the regulation of the mass flow rate ratio between the vapor and liquid within the tubes. It was initially proposed by Peng et al. [63] to enhance the heat transfer performance of heat exchangers which can be divided into three main parts: firstly, replacing a long tube with multiple short tubes for condensation; secondly, implementing vapor–liquid separation between each short tube to remove the liquid film promptly, maintaining dropwise condensation rather than film wise condensation; and thirdly, regulating the flow area of each short tube to maintain the same mass flux of the refrigerant. It is always preferable to integrate the liquid-separation unit into the condenser as a whole to make the LSC compact and effective; typical configuration of the liquid-separation condenser is shown in Figure 7 [64]. Thus, the structure of the liquid-separation unit is essential to the phase separation performance. Li [65] and Huang [64] developed numerical models of the liquid-separation unit with single tube type and multiple tube type, respectively. The two-phase flow characteristics of R134a under various inlet working conditions and structure parameter are explored. The results show that the vapor quality in the outlet tube (i.e., the heat exchange tube in the next pass) is higher than that in the inlet tube, where the phase separation occurs in the liquid-separation unit. Moreover, plenty of research findings have shown that, compared to conventional heat exchanger, the liquid-separation condenser can achieve an increase in the heat transfer coefficient while reducing the pressure drop [66]. Furthermore, the thermal performance and thermal-economic performance can also be effectively enhanced by using a liquid-separation condenser, including refrigeration systems [67], heat pump systems [68], ORC [69] as well as heat pump water heater (HPWH) [70].

Figure 7.

Schematic diagram of liquid-separation condenser [64].

The application of liquid-separation condensation technology to ORC using zeotropic mixture working fluid R600/R601a was investigated by Li et al. [10]. The results indicated improvements in system performance and thermal economy. The explanations for these improvements can be summarized as follows [71,72]: firstly, from the perspective of heat transfer, the prompt separation of the liquid and vapor effectively enhances the heat transfer coefficient in the heat exchanger, thereby reducing the heat transfer area. Secondly, from the perspective of thermodynamics, the prompt separation of the liquid and vapor also leads to regulation in composition, further improving the temperature match between the working fluid during condensation and the heat source, thereby reducing irreversibility in the heat transfer process. Additionally, through active design of the liquid-separation condenser using the zeotropic mixture working fluid, it is expected to further enhance the heat transfer coefficient and reduce irreversibility losses. Moreover, the separated liquid phase from the condenser can be supplied to other components of the system, thereby altering the composition of the components and achieving a better thermal performance. A series of research conducted by Luo et al. [15,16,73,74,75] also verified that, under appropriate zeotropic working fluids and suitable operating conditions, the liquid-separation condenser can effectively reduce the heat exchanger area, and improve the thermal performance and economic performance of ORC. Lu et al. [76] conducted an experimental study on a 1 kW ORC with composition regulation. The results show that when the working fluid is R134a/R245fa, the composition can be regulated from 0.300/0.700 to 0.172/0.828. Furthermore, compared to the composition-fixed ORC, the net power output can be increased by 4.79% to 9.71%.

Additionally, the application of liquid-separation condensation technology has also been implemented by Sun [77], Chen [78], Pang [79], and Zhu [80] in various scenarios such as combined cooling and power cycle (CCP), LNG cold energy recovery, flash cycle, and dual cooling source system (DCS). The results all demonstrated that under specific operating conditions, the liquid-separation condenser has the capability to effectively enhance system performance. A summary of the system-related research on the zeotropic mixture working fluid liquid-separation condensation is provided in Table 6.

Table 6.

Studies on ORC using zeotropic mixtures with liquid-separation condensation.

In summary, it can be observed that, at the theoretical level, the effectiveness of liquid-separation condensation technology in improving the thermal performance and the thermal-economy of ORC has been demonstrated, providing strong support for its potential widespread application. However, in actual operating systems, the variations in the system operating condition and structure lead to deviations in vapor–liquid separation performance from theoretical analysis, resulting in lower thermal performance than predicted. Therefore, further in-depth studies are still required through extensive experimental investigations. Additionally, the vapor–liquid separation mechanism and the composition separation mechanism of the liquid-separation unit, which is an essential component for achieving vapor–liquid separation, remains unclear. Further analysis of the flow characteristics of the zeotropic mixture working fluid necessitates additional experimental and simulation studies.

3.1.3. Distillation Tower

The distillation tower achieves the phase separation through gravity force and is widely used in the petrochemical industry, as shown in Figure 8 [82]. To maintain optimal phase separation performance, heat sources and heat sink are typically arranged at the bottom and top of the distillation tower, respectively, enabling the evaporation and condensation of the working fluid within the tower. Additionally, various structured packings such as grid packing and corrugated packing are often added to the distillation tower to enhance the efficiency of the mass transfer.

Figure 8.

Schematic diagram of distillation tower [82].

Collings et al. [82] utilized a distillation tower to achieve the regulation of the zeotropic mixture working fluid and proposed an ORC system with regulation of composition in response to ambient temperatures. Similar composition regulation methods were also adopted by Liu and Gao [83]. By regulating the composition through the distillation tower in an ORC system, the regulation of the system performance under both design and off-design conditions is enabled. Kim et al. [84] employed a packed-type distillation tower for capacity control of the heat pump system. The results demonstrated that when using R32/R134a (0.50/0.50) as the working fluid, the composition could be regulated within the range of 0.39/0.61 to 0.65/0.35. Correspondingly, the system’s cooling capacity could be modulated between 2.64 kW and 3.38 kW.

Based on the above summary, it can be observed that the utilization of the distillation tower in thermodynamic systems allows for the regulation of composition in response to the ambient temperature and off-design operating condition. In comparison to passive separation structures based on inertia force or gravitational force in the T-junction and liquid-separation condenser, actively controlling the temperature at the bottom and top of the distillation tower enables active phase separation, which offers a wider range of composition regulation and holds significant potential for achieving precise composition regulation. However, the composition regulation through the distillation tower in the available research has only focused on system composition regulation, without considering the composition regulation of the specific thermodynamic process, which restricted the improvement of the system thermal performance.

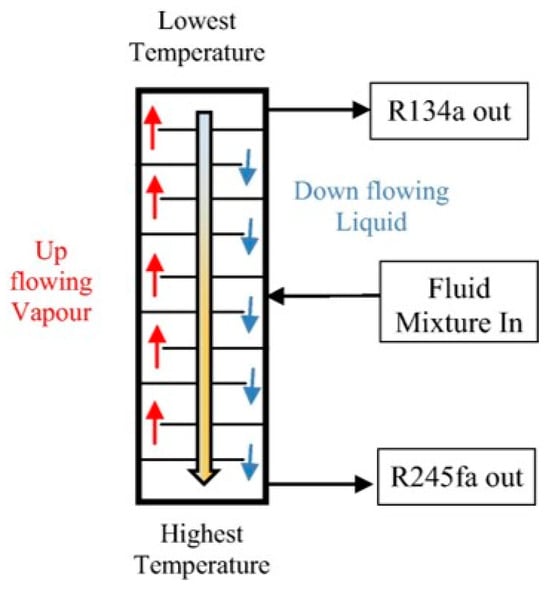

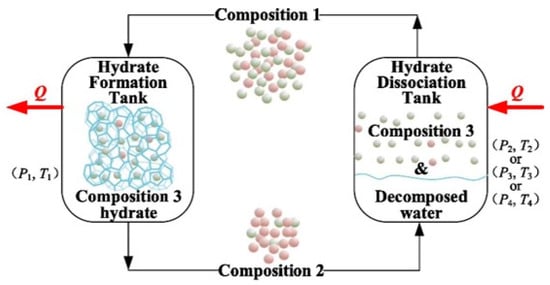

3.2. Composition Regulation Based on Chemical Reaction

Composition regulation based on chemical reactions is a method that utilizes the selective reaction of reactants through chemical reactions to achieve the composition regulation. Currently, only Zhang [85] and Lai [86] propose a composition regulation technique based on the separation characteristics of hydrates, called “hydrate-based gas separation” and conduct experimental verification [87]. Gas hydrates are crystalline compounds formed by encapsulating guest molecules within cage-like structures composed of water molecules. During formation, gas hydrates exhibit selectivity towards guest molecules, with different guest molecules requiring varying temperature and pressure for hydrate formation. Therefore, by controlling the temperature and pressure, the generation and decomposition of working fluid hydrates can be achieved, enabling active regulation of zeotropic mixture working fluid, as shown in Figure 9 [85]. Zhang et al. [87] conducted experimental research on the regulation of zeotropic hydrate composition. R125/R22 is selected as the working fluid and the effect of hydrate generation methods and temperature control methods on the regulation speed and range of composition regulation are analyzed. The results show that, through the generation and decomposition of hydrates, the maximum R125 enrichment in the gas phase could be regulated from 50 mol% to 68.67 mol%. Later, Lai et al. experimentally investigated the hydrate-based composition regulation of R32/R1234yf. The results indicate that R32 in the gas phase can change by 11.14–18.21 mol% in 90 min.

Figure 9.

Schematic diagram of hydrate-based composition separation [85].

The hydrate-based composition regulation is a novel technique of active composition regulation. The results of the experiment above has demonstrated the feasibility of this method. However, further research is needed in terms of relevant theory, simulation, and comprehensive experimental studies.

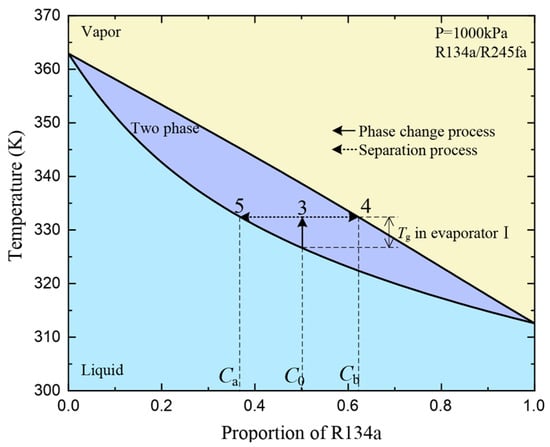

In conclusion, as shown in Table 7, composition regulation based on physical phase separation mostly can typically be achieved using simple devices. However, such devices cannot achieve arbitrary composition regulation. As shown in Figure 10, ideally, full phase separation of two-phase fluid can be achieved, resulting in the composition separation of a zeotropic mixture working fluid with an initial composition of C0 into a liquid phase with a composition of Ca and a gas phase with a composition of Cb. In these situation, Xu et al. [88] indicates that the thermal efficiency and the second law efficiency of composition regulation ORC can be increased by 1.56% and 22.89% compared to that in the conventional ORC, respectively. The hydrate-based composition regulation requires more complex chemical reaction systems. However, a wider range of composition regulations can be obtained. Through the rational design of chemical reaction systems, there is potential for further enhancement of cycle performance.

Table 7.

Comparation of different composition regulation structures.

Figure 10.

Schematic diagram of composition regulation of zeotropic mixtures in vapor and liquid phase [88].

4. Conclusions and Prospects

Thermodynamic cycle utilizing composition regulation technology of zeotropic mixture working fluid is the principal pathway to achieve energy conversion, which has the capability to break through the limitation in lower thermal performance by matching the physical properties of working fluid to each thermodynamic process. This paper presents a comprehensive review on the construction of the thermodynamic cycle with composition regulation of the zeotropic mixture working fluid. The perspectives of the cycle construction method and composition regulated structure are mainly concerned; the conclusions are as follows:

- (1)

- Using a 3D construction method can obtain maximum thermal performance for single thermodynamic process, where the working fluid pair for each process is different and highly relies on the working conditions.

- (2)

- The reliance of a non-artificial experience is the vital parameter to obtain an optimal thermodynamic cycle, with only the intelligence construction method capable of achieving this, while the conventional construction method and superstructure construction method cannot.

- (3)

- The advantages of simple structure and not requiring external energy input of T-junction and liquid-separation condenser contribute to the thermodynamic cycle. However, the range of composition regulation achieved through gravitation force and inertia force is restricted.

- (4)

- Though a wider composition regulation range can be obtained through distillation tower and a hydrate-based method, there is a comprehensive trade-off between the energy input and the improvement in cycle performance.

Based on the above conclusions, it can be observed that cycle construction method for composition regulation and the trade-off between energy consumption and separation performance are the main factors hindering the improvement of the zeotropic mixture composition regulation cycle. The prospects for future research are as follows:

- (1)

- The combination of 3D construction method and intelligence construction method, where the composition matching for each thermodynamic process is taken as the fundamental principle and the composition regulation process is taken as the basic element in cycle construction, is expected to be a new technical pathway of advance thermodynamic cycle construction.

- (2)

- In composition regulation units, further exploration should be investigated for active composition separation by adding external energy sources in T-junctions, while balancing the trade-off between energy consumption and system performance improvement.

- (3)

- The hydrate-based method has been proven that composition can be regulated through chemical reaction; further exploration is necessary at the theoretical, simulation and experimental level to investigate the fundamental principles and laws of composition regulation as well as the thermal performance when it is coupled within the thermodynamic cycle.

Author Contributions

Conceptualization, K.H., W.X., R.C. and L.Z.; methodology, K.H., W.X., R.C. and L.Z.; formal analysis, K.H., W.X., R.C. and L.Z.; investigation, W.X., S.D. and L.Z.; resources, W.X., S.D. and L.Z.; data curation, K.H. and W.X.; writing—original draft preparation, K.H., W.X., R.C., J.Z. and L.Z.; writing—review and editing, K.H., W.X., R.C., J.Z., S.D. and L.Z.; supervision, W.X., S.D. and L.Z.; project administration, W.X. and L.Z.; funding acquisition, W.X. and L.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by China Postdoctoral Science Foundation, grant number 2021TQ0237, and 2022M722354 and National Natural Science Foundation of China, grant number 52176017.

Data Availability Statement

Not applicable.

Conflicts of Interest

Author Jianyuan Zhang was employed by the company Xi’an Thermal Power Research Institute Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhao, J.; Li, Y.; Li, H.; Zhong, Y.; Ma, L.; Li, W. Mid-/low-temperature energy in China. Acta Energiae Solaris Sin. 2022, 43, 250–260. (In Chinese) [Google Scholar]

- National Bureau of Statistics of China. The target of sustained recovery and development of the national economy in 2021 has been achieved. Mach. Ind. Std. Qlty. 2022, 3, 9–12. (In Chinese) [Google Scholar]

- Du, K.; Calautit, J.; Eames, P.; Wu, Y. A state-of-the-art review of the application of phase change materials (PCM) in Mobilized-Thermal Energy Storage (M-TES) for recovering low-temperature industrial waste heat (IWH) for distributed heat supply. Renew. Energy 2021, 168, 1040–1057. [Google Scholar] [CrossRef]

- Firth, A.; Zhang, B.; Yang, A. Quantification of global waste heat and its environmental effects. Appl. Energy 2019, 235, 1314–1334. [Google Scholar] [CrossRef]

- Aboelwafa, O.; Fateen, S.K.; Soliman, A.; Ismail, I.M. A review on solar Rankine cycles: Working fluids, applications, and cycle modifications. Renew. Sustain. Energy Rev. 2018, 82, 868–885. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, G.; Li, L.; Yang, Q.; Tang, B.; Liu, Y. Expansion devices for organic Rankine cycle (ORC) using in low temperature heat recovery: A review. Energy Convers. Manag. 2019, 199, 111944. [Google Scholar] [CrossRef]

- Shi, L.; Shu, G.; Tian, H.; Deng, S. A review of modified Organic Rankine cycles (ORCs) for internal combustion engine waste heat recovery (ICE-WHR). Renew. Sustain. Energy Rev. 2018, 92, 95–110. [Google Scholar] [CrossRef]

- Park, B.; Usman, M.; Imran, M.; Pesyridis, A. Review of Organic Rankine Cycle experimental data trends. Energy Convers. Manag. 2018, 173, 679–691. [Google Scholar] [CrossRef]

- Landelle, A.; Tauveron, N.; Haberschill, P.; Revellin, R.; Colasson, S. Organic Rankine cycle design and performance comparison based on experimental database. Appl. Energy 2017, 204, 1172–1187. [Google Scholar] [CrossRef]

- Li, J.; Liu, Q.; Duan, Y.; Yang, Z. Performance analysis of organic Rankine cycles using R600/R601a mixtures with liquid-separated condensation. Appl. Energy 2017, 190, 376–389. [Google Scholar] [CrossRef]

- Yan, G.; Cui, C.; Yu, J. Energy and exergy analysis of zeotropic mixture R290/R600a vapor-compression refrigeration cycle with separation condensation. Int. J. Refrig. 2015, 53, 155–162. [Google Scholar] [CrossRef]

- Yang, X.; Zheng, N.; Zhao, L.; Deng, S.; Li, H.; Yu, Z. Analysis of a novel combined power and ejector-refrigeration cycle. Energy Convers. Manag. 2016, 108, 266–274. [Google Scholar] [CrossRef]

- Luo, X.; Huang, R.; Yang, Z.; Chen, J.; Chen, Y. Performance investigation of a novel zeotropic organic Rankine cycle coupling liquid separation condensation and multi-pressure evaporation. Energy Convers. Manag. 2018, 161, 112–127. [Google Scholar] [CrossRef]

- Yaïci, W.; Entchev, E.; Longo, M. Organic Rankine cycle-ejector heat pump hybrid system using low GWP zeotropic mixtures for trigeneration application. Energy Convers. Manag. 2024, 299, 117853. [Google Scholar] [CrossRef]

- Feili, M.; Rostamzadeh, H.; Ghaebi, H. A new high-efficient cooling/power cogeneration system based on a double-flash geothermal power plant and a novel zeotropic bi-evaporator ejector refrigeration cycle. Renew. Energy 2020, 162, 2126–2152. [Google Scholar] [CrossRef]

- Lu, P.; Luo, X.; Wang, J.; Chen, J.; Liang, Y.; Yang, Z.; Wang, C.; Chen, Y. Thermo-economic design, optimization, and evaluation of a novel zeotropic ORC with mixture composition adjustment during operation. Energy Convers. Manag. 2021, 230, 113771. [Google Scholar] [CrossRef]

- Lu, P.; Luo, X.; Wang, J.; Chen, J.; Liang, Y.; Yang, Z.; He, J.; Wang, C.; Chen, Y. Thermodynamic analysis and evaluation of a novel composition adjustable Carnot battery under variable operating scenarios. Energy Convers. Manag. 2022, 269, 116117. [Google Scholar] [CrossRef]

- Xu, W.; Zhao, L.; Deng, S.; Li, S. A preliminary approach to the 3D construction of thermodynamic cycle based on zeotropic working fluids. Chin. Sci. Bull. 2019, 64, 206–214. (In Chinese) [Google Scholar] [CrossRef]

- Zheng, N.; Song, W.; Zhao, L. Theoretical and experimental investigations on the changing regularity of the extreme point of the temperature difference between zeotropic mixtures and heat transfer fluid. Energy 2013, 55, 541–552. [Google Scholar] [CrossRef]

- Stijepovic, M.Z.; Linke, P.; Papadopoulos, A.I.; Grujic, A.S. On the role of working fluid properties in Organic Rankine Cycle performance. Appl. Therm. Eng. 2012, 36, 406–413. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, J.; Zhao, L.; Deng, S.; Zhang, Y. Novel experimental research on the compression process in organic Rankine cycle (ORC). Energy Convers. Manag. 2017, 137, 1–11. [Google Scholar] [CrossRef]

- Giuffrida, A. Modelling the performance of a scroll expander for small organic Rankine cycles when changing the working fluid. Appl. Therm. Eng. 2014, 70, 1040–1049. [Google Scholar] [CrossRef]

- Da Lio, L.; Manente, G.; Lazzaretto, A. Predicting the optimum design of single stage axial expanders in ORC systems: Is there a single efficiency map for different working fluids? Appl. Energy 2016, 167, 44–58. [Google Scholar] [CrossRef]

- Ma, W.; Liu, T.; Li, M. Second-law-based screening of working fluids for medium-low temperature organic Rankine cycles (ORCs): Effects of physical and chemical properties. Energy Procedia 2019, 158, 1406–1411. [Google Scholar] [CrossRef]

- Burugupally, S.P.; Weiss, L.; Depcik, C. The effect of working fluid properties on the performance of a miniature free piston expander for waste heat harvesting. Appl. Therm. Eng. 2019, 151, 431–438. [Google Scholar] [CrossRef]

- Xue, D. Study on Mass Integration for Waste Minimization. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2001. (In Chinese). [Google Scholar]

- Kermani, M.; Wallerand, A.S.; Kantor, I.D.; Maréchal, F. Generic superstructure synthesis of organic Rankine cycles for waste heat recovery in industrial processes. Appl. Energy 2018, 212, 1203–1225. [Google Scholar] [CrossRef]

- Elsido, C.; Mian, A.; Martelli, E. A systematic methodology for the techno-economic optimization of Organic Rankine Cycles. Energy Procedia 2017, 129, 26–33. [Google Scholar] [CrossRef]

- Lee, U.; Jeon, J.; Han, C.; Lim, Y. Superstructure based techno-economic optimization of the organic rankine cycle using LNG cryogenic energy. Energy 2017, 137, 83–94. [Google Scholar] [CrossRef]

- Yu, H.; Eason, J.; Biegler, L.T.; Feng, X. Process integration and superstructure optimization of Organic Rankine Cycles (ORCs) with heat exchanger network synthesis. Comput. Chem. Eng. 2017, 107, 257–270. [Google Scholar] [CrossRef]

- Bao, J.; Zhang, R.; Lin, Y.; Zhang, N.; Zhang, X.; He, G. Simultaneous optimization of system structure and working fluid for the three-stage condensation Rankine cycle utilizing LNG cold energy. Appl. Therm. Eng. 2018, 140, 120–130. [Google Scholar] [CrossRef]

- Yuan, T.; Song, C.; Zhang, R.; Zhang, X.; Zhang, N.; Bao, J. Energy and Economic Optimization of the Multistage Condensation Rankine Cycle That Utilizes LNG Cold Energy: Considerations on Working Fluids and Cycle Configurations. ACS Sustain. Chem. Eng. 2019, 7, 13505–13516. [Google Scholar] [CrossRef]

- Schilling, J.; Horend, C.; Bardow, A. Integrating superstructure-based design of molecules, processes, and flowsheets. AIChE J. 2020, 66, e16903. [Google Scholar] [CrossRef]

- Elsido, C.; Martelli, E.; Grossmann, I.E. Multiperiod optimization of heat exchanger networks with integrated thermodynamic cycles and thermal storages. Comput. Chem. Eng. 2021, 149, 107293. [Google Scholar] [CrossRef]

- Watanapanich, S.; Li, S.; Lee, J. Optimal integration of organic Rankine cycles into process heat exchanger networks: A simultaneous approach. Energy Convers. Manag. 2022, 260, 115604. [Google Scholar] [CrossRef]

- Huster, W.R.; Schweidtmann, A.M.; Lüthje, J.T.; Mitsos, A. Deterministic global superstructure-based optimization of an organic Rankine cycle. Comput. Chem. Eng. 2020, 141, 106996. [Google Scholar] [CrossRef]

- Liang, Z.; Liang, Y.; Luo, X.; Chen, J.; Yang, Z.; Wang, C.; Chen, Y. Superstructure-based mixed-integer nonlinear programming framework for hybrid heat sources driven organic Rankine cycle optimization. Appl. Energy 2022, 307, 118277. [Google Scholar] [CrossRef]

- Wallerand, A.S.; Kermani, M.; Kantor, I.; Maréchal, F. General Superstructure Synthesis and Bi-level Solution Strategy for Industrial Heat Pumping. In Proceedings of the 27th European Symposium on Computer Aided Process Engineering, Barcelona, Spain, 1–5 October 2017. [Google Scholar]

- Wallerand, A.S.; Kermani, M.; Kantor, I.; Maréchal, F. Optimal heat pump integration in industrial processes. Appl. Energy 2018, 219, 68–92. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, X.; Zhang, N.; He, G.; Bao, J. How to identify trade-off of thermodynamic and economic performance of the S-CO2 cycle caused by the cycle structures? Energy Convers. Manag. 2022, 266, 115817. [Google Scholar] [CrossRef]

- Yang, C.; Deng, Y.; Zhang, N.; Zhang, X.; He, G.; Bao, J. Optimal structure design of supercritical CO2 power cycle for gas turbine waste heat recovery: A superstructure method. Appl. Therm. Eng. 2021, 198, 117515. [Google Scholar] [CrossRef]

- Toffolo, A. A synthesis/design optimization algorithm for Rankine cycle based energy systems. Energy 2014, 66, 115–127. [Google Scholar] [CrossRef]

- Toffolo, A.; Rech, S.; Lazzaretto, A. Combination of elementary process to form a general energy system configuration. In Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition IMECE2017, Tampa, FL, USA, 3–9 November 2017. [Google Scholar]

- Lazzaretto, A.; Manente, G.; Toffolo, A. A general methodology for the synthesis of energy system configurations beyond superstructures. Energy 2018, 147, 924–949. [Google Scholar] [CrossRef]

- Toffolo, A.; Rech, S.; Lazzaretto, A. Generation of Complex Energy Systems by Combination of Elementary Processes. J. Energy Resour. Technol. 2018, 140, 112005. [Google Scholar] [CrossRef]

- Lin, S.; Zhao, L.; Deng, S.; Zhao, D.; Wang, W.; Chen, M. Intelligent collaborative attainment of structure configuration and fluid selection for the Organic Rankine cycle. Appl. Energy 2020, 264, 114743. [Google Scholar] [CrossRef]

- Liang, Z.; Liang, Y.; Luo, X.; Chen, J.; Yang, Z.; Wang, C.; Chen, Y. Synthesis and simultaneous optimization of multi-heat source multi-pressure evaporation organic Rankine cycle with mixed working fluid. Energy Convers. Manag. 2022, 251, 114930. [Google Scholar] [CrossRef]

- Seki, K.; Takeshita, K.; Amano, Y. Development of Complex Energy Systems with Absorption Technology by Combining Elementary Processes. Energies 2019, 12, 495. [Google Scholar] [CrossRef]

- Volpato, G.; Rech, S.; Lazzaretto, A.; Roumpedakis, T.C.; Karellas, S.; Frangopoulos, C.A. Conceptual development and optimization of the main absorption systems configurations. Renew. Energy 2022, 182, 685–701. [Google Scholar] [CrossRef]

- Ito, W.; Takeshita, K.; Amano, Y. Demonstration of the revised procedure to explore configurations for an arbitrary absorption cycle based on the cycle simplicity index. Energy 2021, 235, 121172. [Google Scholar] [CrossRef]

- Carraro, G.; Danieli, P.; Lazzaretto, A.; Boatto, T. A common thread in the evolution of the configurations of supercritical CO2 power systems for waste heat recovery. Energy Convers. Manag. 2021, 237, 114031. [Google Scholar] [CrossRef]

- Liang, Y.; Hui, C.W.; Luo, X.; Chen, J.; Yang, Z.; Chen, Y. A general mixed-integer programming framework for efficient modeling, integration and optimization of thermodynamic cycle-based energy systems. Energy Convers. Manag. 2021, 250, 114905. [Google Scholar] [CrossRef]

- Yang, B.; Su, W.; Deng, S.; Zhao, L.; Lu, P. State-of-art of impacting T-junction: Phase separation, constituent separation and applications. Int. J. Heat Mass Transf. 2020, 148, 119067. [Google Scholar] [CrossRef]

- Yang, B.; Su, W.; Deng, S.; Zhao, L.; Lu, P. State-of-art of branching T-junction: Experiments, modeling, developing prospects and applications. Exp. Therm. Fluid. Sci. 2019, 109, 109895. [Google Scholar] [CrossRef]

- Zheng, N.; Hwang, Y.; Zhao, L.; Deng, S. Experimental study on the distribution of constituents of binary zeotropic mixtures in vertical impacting T-junction. Int. J. Heat Mass Transf. 2016, 97, 242–252. [Google Scholar] [CrossRef]

- Su, W.; Hwang, Y.; Zheng, N.; Deng, S.; Zhao, L. Experimental study on the constituent separation performance of binary zeotropic mixtures in horizontal branch T-junctions. Int. J. Heat Mass Transf. 2018, 127, 76–87. [Google Scholar] [CrossRef]

- Lu, P.; Deng, S.; Yang, B.; Zhao, L. Numerical simulation on constituents separation of R134a/R600a in a horizontal T-junction. Int. J. Refrig. 2020, 115, 148–157. [Google Scholar] [CrossRef]

- Su, D.; Zhao, L.; Zhao, R.; Bai, M.; Wang, Q.; Zhu, Y. Numerical simulation on constituent separation and mass transfer of binary zeotropic mixtures in a branching T-junction. Int. J. Refrig. 2022, 135, 198–207. [Google Scholar] [CrossRef]

- Fu, J.; Liu, Z.; Yang, X.; Jin, S.; Ye, J. Experimental research on the separation performance of a compound T-junction for two-phase zeotropic mixtures. Exp. Therm. Fluid Sci. 2023, 147, 110951. [Google Scholar] [CrossRef]

- Su, D.; Zhao, R.; Zhao, L.; Wang, Q.; Bai, M.; Deng, S. Separation mechanism of T-junction in thermodynamic systems: A review and case verification. Appl. Therm. Eng. 2022, 217, 119267. [Google Scholar] [CrossRef]

- Yang, B.; Deng, S.; Su, W.; Zhao, L.; Wang, D. Experimental investigation on phase separation comparison between single and double T-junctions. Exp. Therm. Fluid Sci. 2020, 118, 110171. [Google Scholar] [CrossRef]

- Bai, M.J.; Zhao, R.K.; Lu, P.; Yang, B.; Li, Z.; Zhang, Y. Simulation study on phase separation and pressure distribution of refrigerant in horizontal double T-junctions. Int. J. Refrig. 2021, 126, 88–98. [Google Scholar] [CrossRef]

- Peng, X.; Wu, D.; Zhang, Y. Applications and principle of high performance condensers. Chem. Ind. Eng. Prog. 2007, 26, 97–104. (In Chinese) [Google Scholar]

- Huang, K.; Li, J.; Chen, J.; Chen, Y.; Luo, X.; Liang, Y.; He, J.; Yang, Z. Explorations of multi-pass-orifice header in the liquid-separation condenser by using CFD simulation. Int. J. Heat Mass Transf. 2023, 200, 123482. [Google Scholar] [CrossRef]

- Li, Y.; Luo, X.; Wang, Z.; Yang, Z.; Chen, J.; Liang, Y.; Wang, C.; Chen, Y. Numerical simulation on the header-orifice structure-based liquid-vapor separator used in liquid-separation condenser. Chem. Eng. Sci. 2021, 235, 116475. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Y.; Deng, L.; Mo, S.; Zhang, H. Experimental verification of a condenser with liquid-vapor separation in an air conditioning system. Appl. Therm. Eng. 2013, 51, 48–54. [Google Scholar] [CrossRef]

- Chen, J.; Ding, R.; Li, Y.; Lin, X.; Chen, Y.; Luo, X.; Yang, Z. Application of a vapor-liquid separation heat exchanger to the air conditioning system at cooling and heating modes. Int. J. Refrig. 2019, 100, 27–36. [Google Scholar] [CrossRef]

- Li, Y.; Chen, J.; Lin, X.; Yang, Z.; Chen, Y.; Luo, X. Quantification on the Effects of Liquid-Vapor Separation in Air-Conditioning System by using Advanced Exergy Analysis. J. Therm. Sci. 2020, 29, 597–608. [Google Scholar] [CrossRef]

- Luo, X.; Yi, Z.; Zhang, B.; Mo, S.; Wang, C.; Song, M.; Chen, Y. Mathematical modelling and optimization of the liquid separation condenser used in organic Rankine cycle. Appl. Energy 2017, 185, 1309–1323. [Google Scholar] [CrossRef]

- Chen, J.; Chen, L.; Lin, X.; Chen, Y.; Luo, X.; Yang, Z.; Liang, Y. Performance of heat pump water heater (HPWH) with and without liquid-separation: Detailed experimental comparisons. Appl. Therm. Eng. 2020, 179, 115713. [Google Scholar] [CrossRef]

- Li, J.; Liu, Q.; Ge, Z.; Duan, Y.; Yang, Z.; Di, J. Optimized liquid-separated thermodynamic states for working fluids of organic Rankine cycles with liquid-separated condensation. Energy 2017, 141, 652–660. [Google Scholar] [CrossRef]

- Li, J.; Yang, Z.; Hu, S.; Yang, F.; Duan, Y. Thermo-economic performance improvement of butane/isopentane mixtures in organic Rankine cycles by liquid-separated condensation method. Appl. Therm. Eng. 2020, 181, 115941. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, J.; Chen, Y.; Luo, X.; Liang, Y.; He, J.; Yang, Z. Performance explorations of an organic Rankine cycle featured with separating and mixing composition of zeotropic mixture. Energy 2022, 257, 124535. [Google Scholar] [CrossRef]

- Chen, C.; Huang, R.; Luo, X.; Chen, J.; Yang, Z.; Chen, Y. Conceptual design and thermodynamic optimization of a novel composition tunable zeotropic organic Rankine cycle. Energy Procedia 2019, 158, 2019–2024. [Google Scholar] [CrossRef]

- Luo, X.; Liang, Z.; Guo, G.; Wang, C.; Chen, Y.; Ponce-Ortega, J.M.; El-Halwagi, M.M. Thermo-economic analysis and optimization of a zoetropic fluid organic Rankine cycle with liquid-vapor separation during condensation. Energy Convers. Manag. 2017, 148, 517–532. [Google Scholar] [CrossRef]

- Lu, P.; Wang, J.; Lin, Y.; Luo, X.; Liang, Y.; Chen, J.; Yang, Z.; Chen, Y. Experimental investigation of a zeotropic organic Rankine cycle system with liquid-separation condensation for composition adjustment. Energy Convers. Manag. 2023, 293, 117540. [Google Scholar] [CrossRef]

- Sun, X.; Shi, L.; Tian, H.; Wang, X.; Zhang, Y.; Shu, G. A novel composition tunable combined cooling and power cycle using CO2-based binary zeotropic mixture. Energy Convers. Manag. 2021, 244, 114419. [Google Scholar] [CrossRef]

- Chen, C.; Li, N.; Mu, H.; Song, Y.; Zhao, X. Thermodynamic Optimization of a Composition-Tunable ZeotropicORC Using LNG Cold Energy as a Heat Sink. ACS Sustain. Chem. Eng. 2022, 10, 4980–4993. [Google Scholar] [CrossRef]

- Pang, X.; Ge, Z.; Xie, Z.; Xu, J.; Xie, J.; Wang, Y.; Tang, C.; Zhao, W.; Wang, K. Performance analysis of organic flash cycle using R600a/R601a mixtures with liquid-separation condensation. Proc. CSEE 2022, 42, 2615–2623. [Google Scholar]

- Zhu, Y.; Yin, Y. Multi-criteria refrigerant screening and performance optimization comparison of a basic and composition-adjustable dual cooling source system. Appl. Therm. Eng. 2024, 239, 122154. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, Y.; Yin, Y. Performance analysis of a double cooling source system featured by composition-tuning of zeotropic mixture R32/R236fa. Appl. Therm. Eng. 2023, 224, 120097. [Google Scholar] [CrossRef]

- Collings, P.; Yu, Z.; Wang, E. A dynamic organic Rankine cycle using a zeotropic mixture as the working fluid with composition tuning to match changing ambient conditions. Appl. Energy 2016, 171, 581–591. [Google Scholar] [CrossRef]

- Liu, C.; Gao, T. Off-design performance analysis of basic ORC, ORC using zeotropic mixtures and composition-adjustable ORC under optimal control strategy. Energy 2019, 171, 95–108. [Google Scholar] [CrossRef]

- Kim, M.; Kim, M.S.; Kim, Y. Experimental study on the performance of a heat pump system with refrigerant mixtures’ composition change. Energy 2004, 29, 1053–1068. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, S.; Zhao, L.; Nie, X.; Xu, W.; He, J. Exploring a potential application of hydrate separation for composition adjustable combined cooling and power system. Appl. Energy 2020, 268, 115064. [Google Scholar] [CrossRef]

- Lai, X.; Zhao, L.; Nie, X.; Zhang, Y.; Zhang, Q. Hydrate-based composition separation of R32/R1234yf mixed working fluids applied in composition-adjustable organic Rankine cycle. Energy 2023, 284, 129259. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, R.; Nie, X.; Deng, S.; Xu, W.; Zhu, Y.; Zhao, L. Hydrate-based gas separation for working fluid mixtures: Application to composition-adjustable organic Rankine cycle. Chem. Eng. J. 2022, 434, 134626. [Google Scholar] [CrossRef]

- Xu, W.; Deng, S.; Zhao, L.; Zhang, Y.; Li, S. Performance analysis on novel thermodynamic cycle under the guidance of 3D construction method. Appl. Energy 2019, 250, 478–492. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).