Dead-Time Compensation Using ADALINE for Reduced-Order Observer-Based Sensorless SynRM Drives

Abstract

1. Introduction

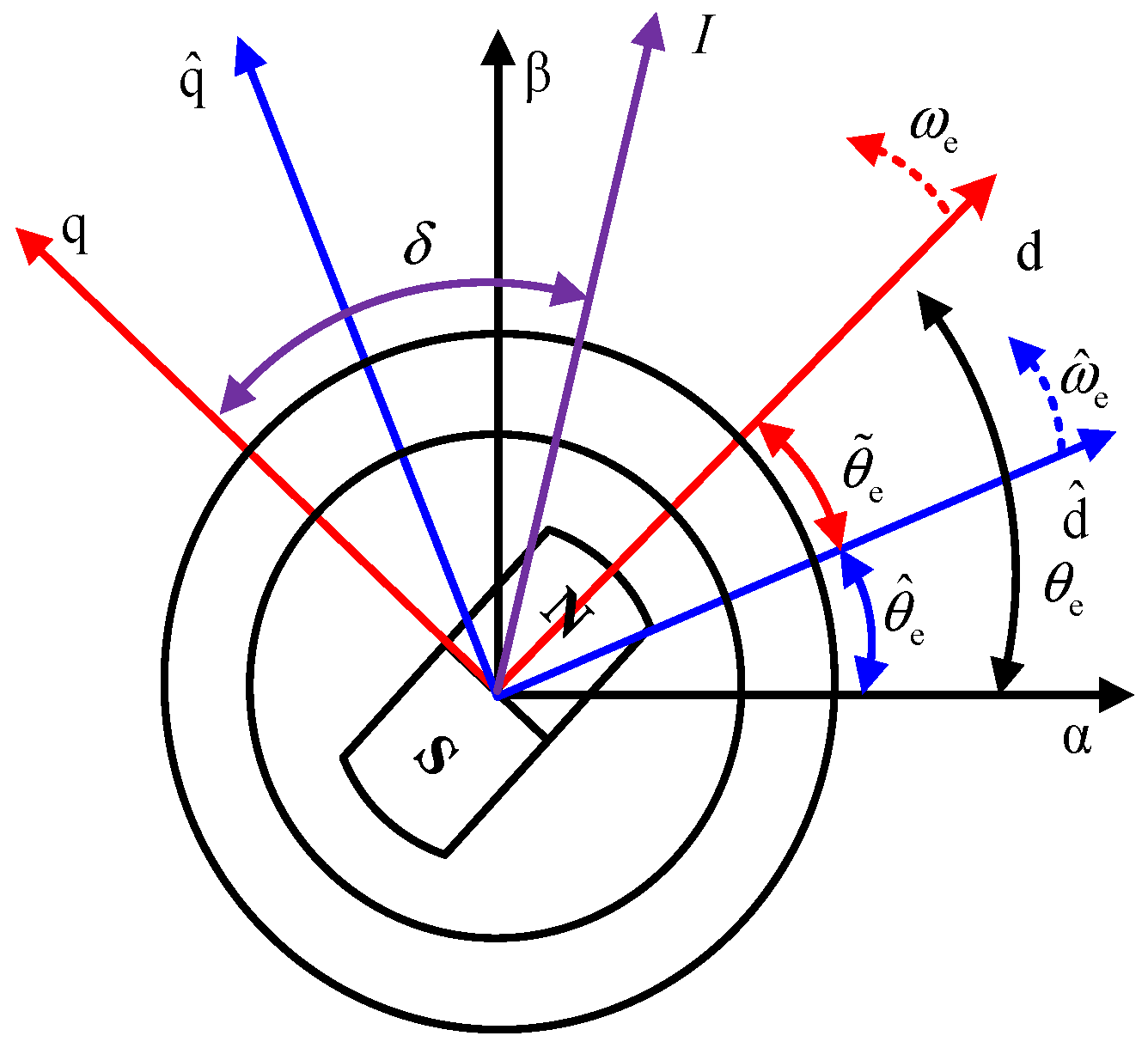

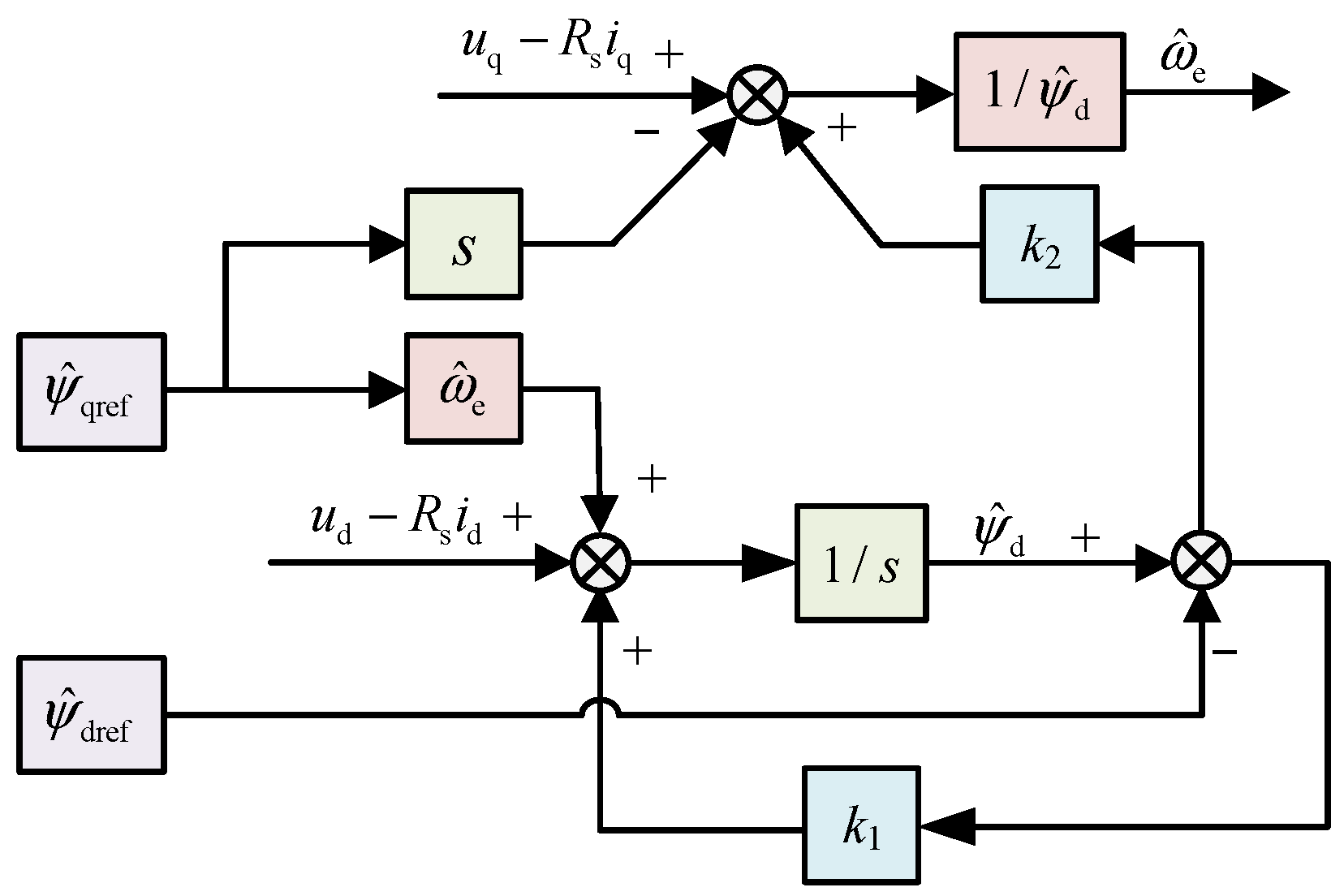

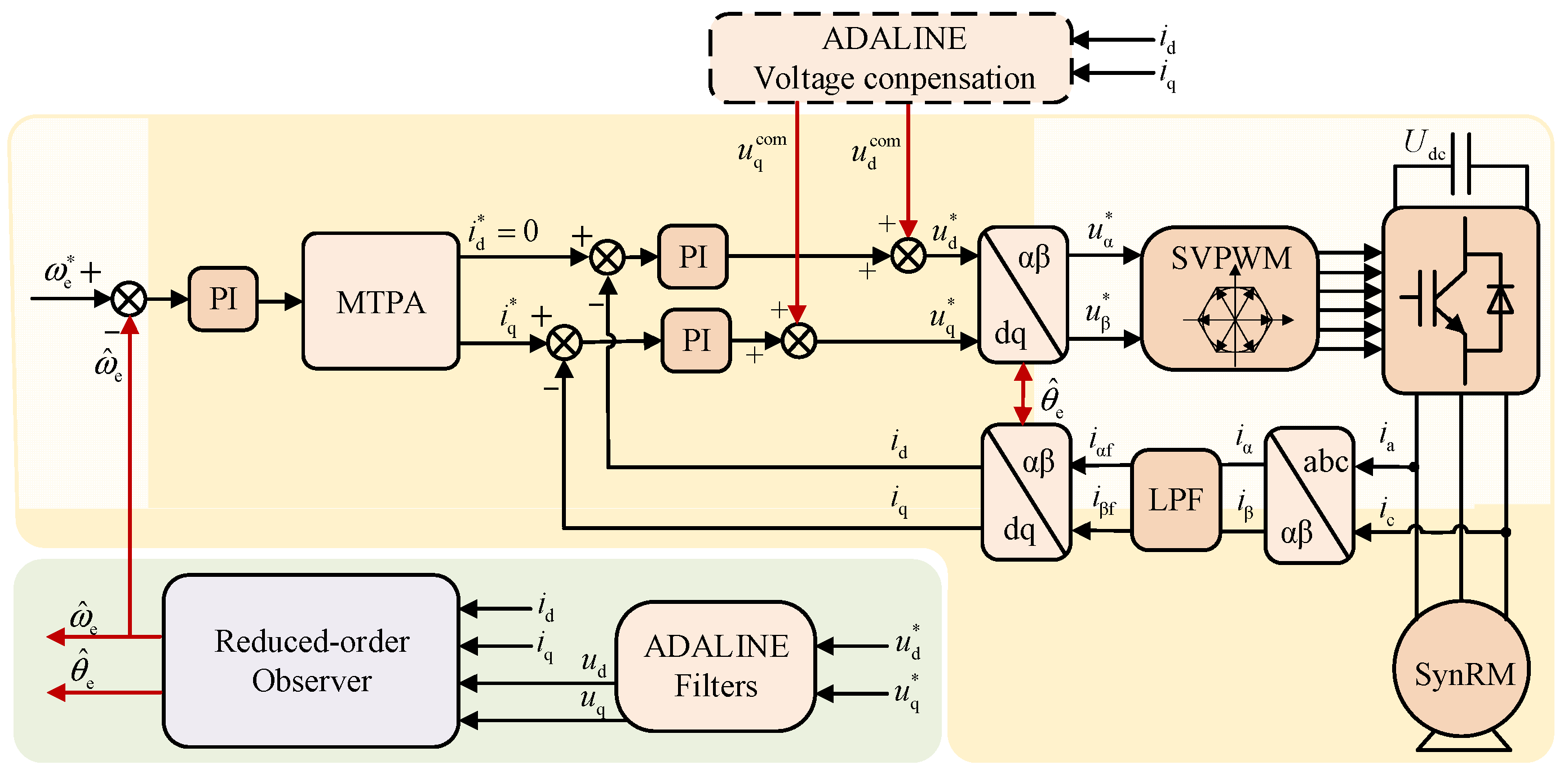

2. Reduced-Order Observer-Based Sensorless Control for SynRM Drives

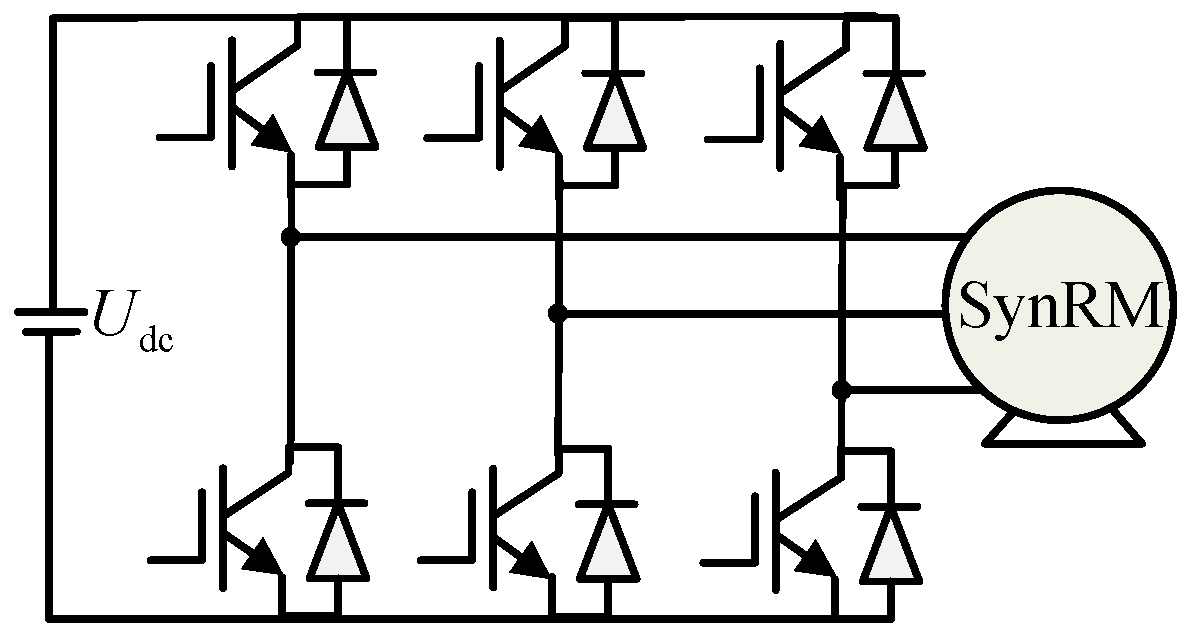

3. Proposed Sensorless Control Strategy Combined with ADALINE Dead Time Compensation

3.1. Dead Time Effect Analysis

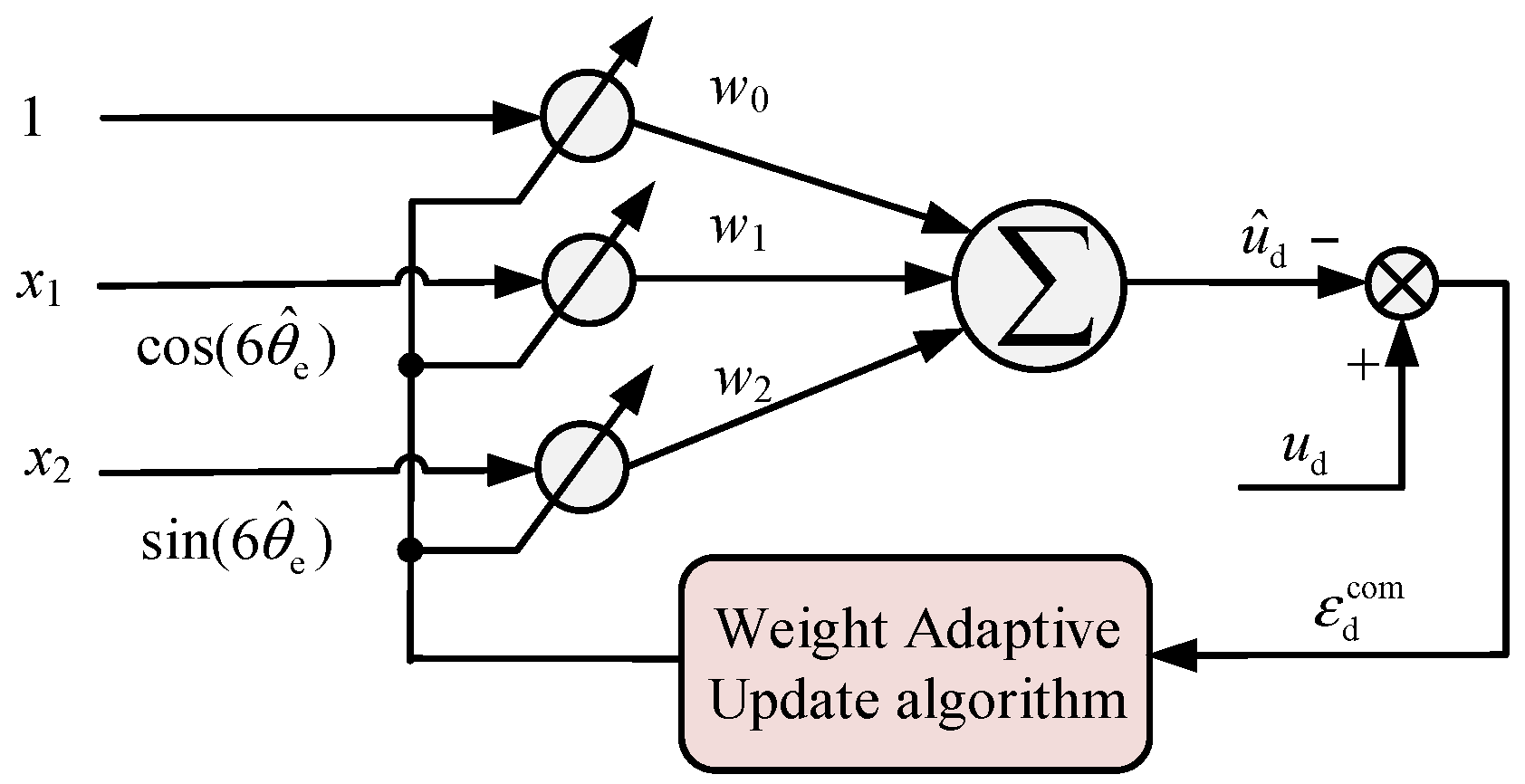

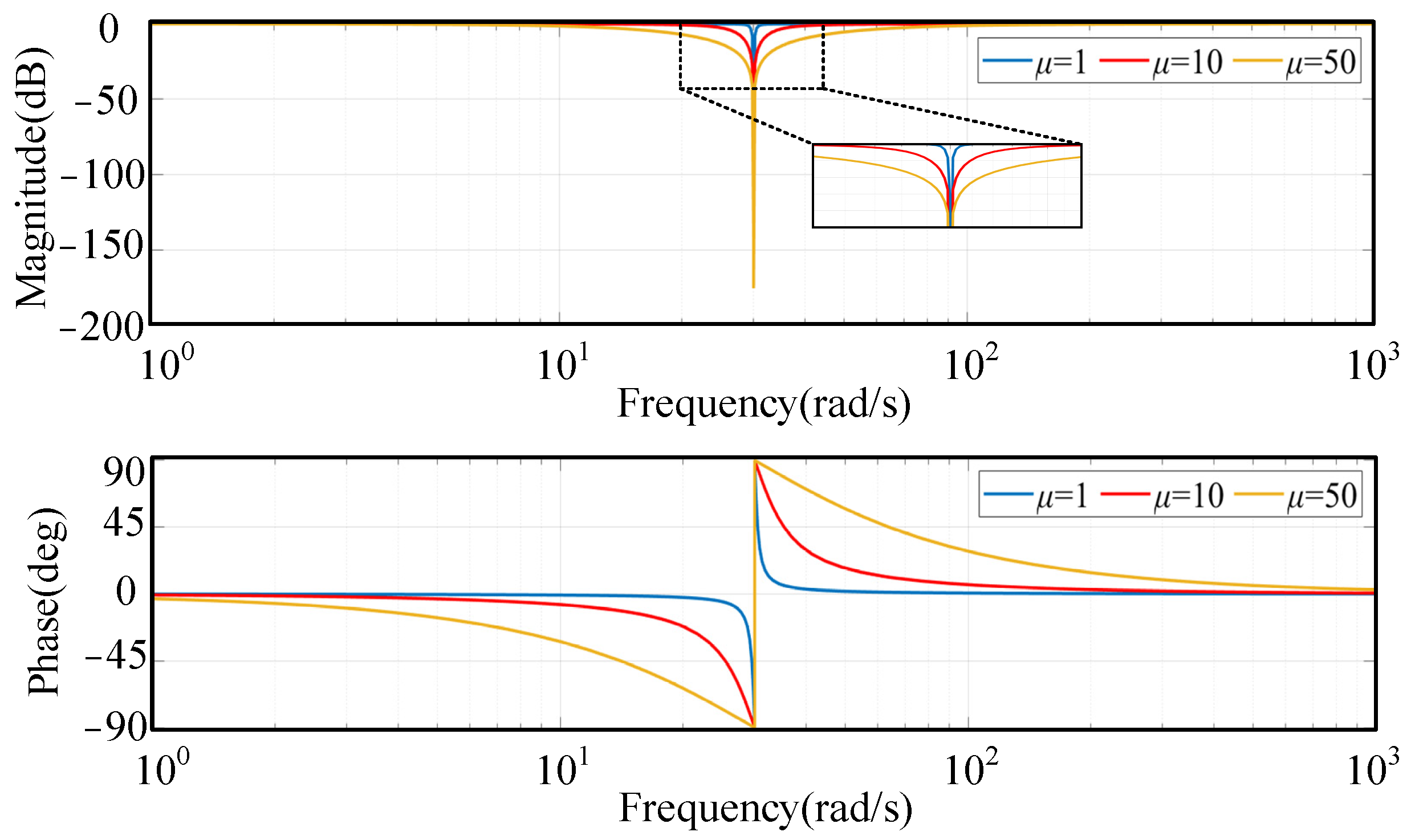

3.2. Voltage Filter Based on the ADALINE Method

3.3. Voltage Compensation Strategy Based on Current Harmonic Extraction

4. Experimental Results

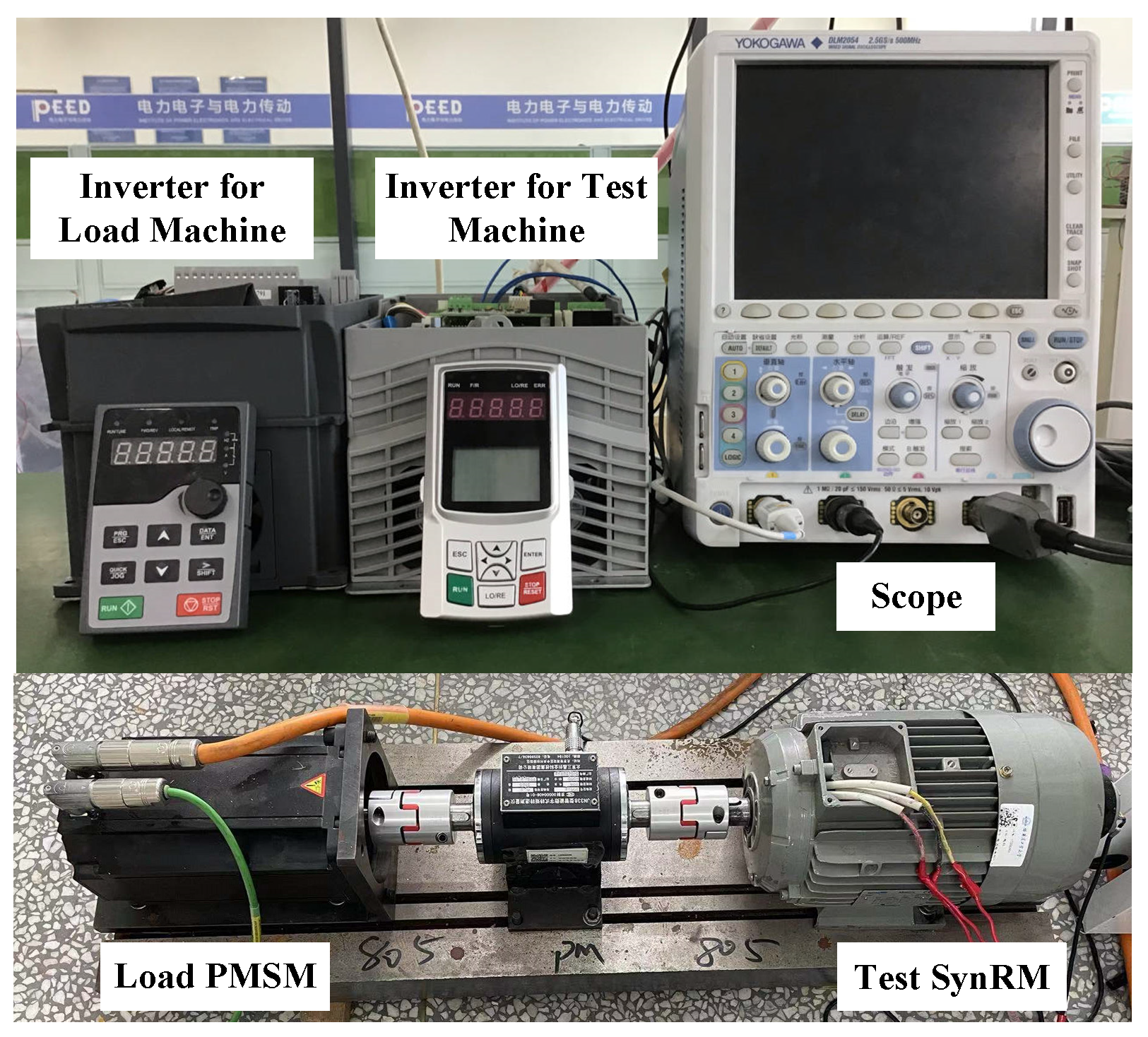

4.1. Experimental Setup

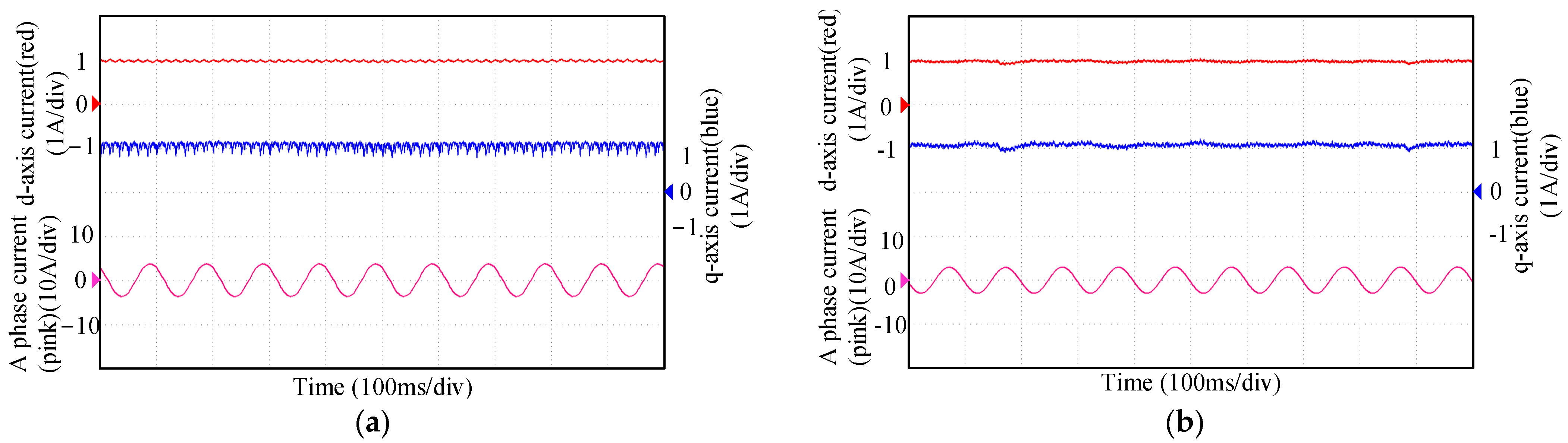

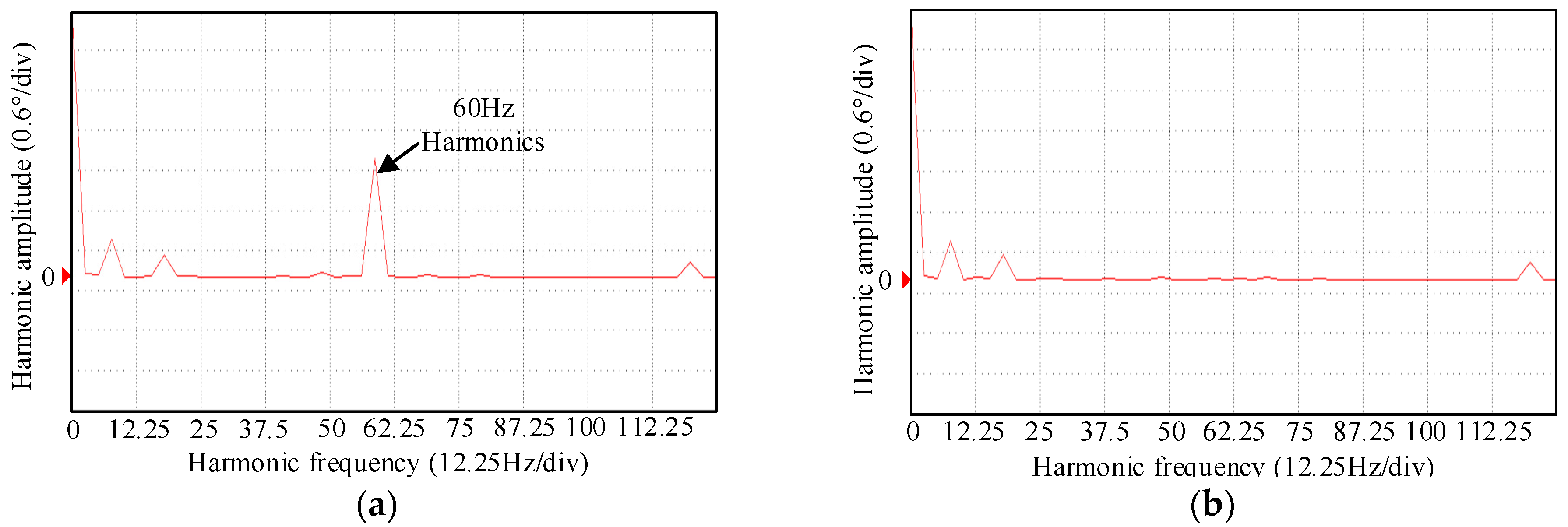

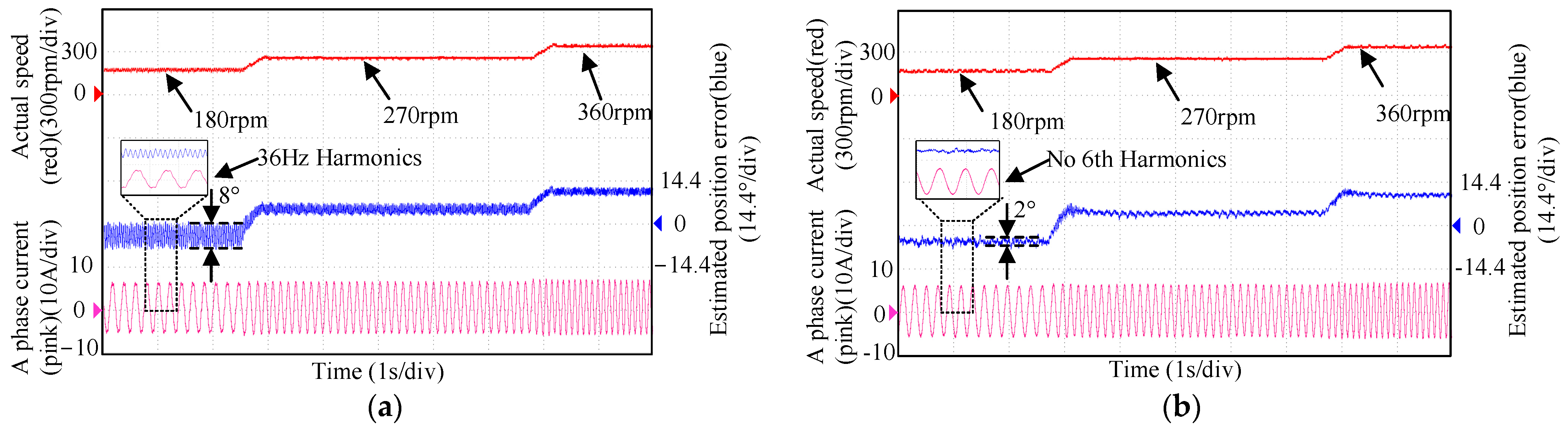

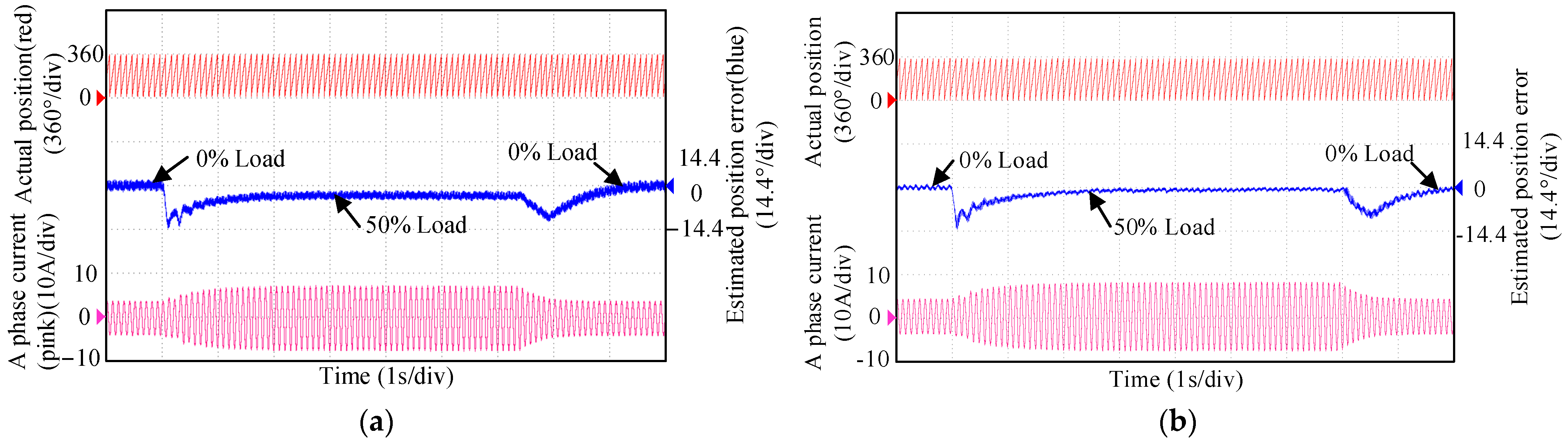

4.2. Experimental Results and Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Foti, S.; De-Caro, S.; Scimone, T.; Testa, A.; Danilo-Tornello, L.; Scelba, G.; Cacciato, M. Rotor Position Error Compensation in Sensorless Synchronous Reluctance Motor Drives. IEEE Trans. Power Electron. 2022, 37, 4442–4452. [Google Scholar] [CrossRef]

- Credo, A.; Di-Leonardo, L.; Parasiliti-Collazzo, F.; Tursini, M. The Impact of the Control Strategy in Flux Observer Based Sensorless Control of Synchronous Reluctance Motors. IEEE Access 2021, 9, 156380–156391. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, B.; Xiao, Y.; Shi, J.; Li, X.; Li, L. Rotor Design and Optimization of a Three-Phase Line-Start Synchronous Reluctance Motor. IEEE Trans. Ind. Appl. 2021, 57, 1365–1374. [Google Scholar] [CrossRef]

- Mirazimi, M.S.; Kiyoumarsi, A. Magnetic field analysis of SynReland PMASynRel machines with hyperbolic flux barriers using conformalmapping. IEEE Trans. Transp. Electrif. 2020, 6, 52–61. [Google Scholar] [CrossRef]

- Burkhart, B.; Klein-Hessling, A.; Ralev, I.; Weiss, C.P.; De Doncker, R.W. Technology research and applications of switched reluctance drives. CPSS Trans. Power Electron. Appl. 2017, 2, 12–27. [Google Scholar] [CrossRef]

- Mu, J.; Ge, X.; Chang, Y.; Liang, G. Speed-Sensorless Control of Induction Motor Drives with a FCS-Based Estimation Scheme. CPSS Trans. Power Electron. Appl. 2023, 8, 278–289. [Google Scholar] [CrossRef]

- Zhang, G.; Xiang, R.; Wang, G.; Li, C.; Bi, G.; Zhao, N.; Xu, D. Hybrid Pseudorandom Signal Injection for Position Sensorless SynRM Drives With Acoustic Noise Reduction. IEEE Trans. Transp. Electrif. 2022, 8, 1313–1325. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, G.; Yuan, B.; Liu, R.; Xu, D. Active disturbancerejection control strategy for signal injection-based sensorless IPMSMdrives. IEEE Trans. Transport. Electrif. 2018, 4, 330–339. [Google Scholar] [CrossRef]

- Xiao, D.; Nalakath, S.; Rotilli-Filho, S.; Fang, G.; Dong, A.; Sun, Y. Universal Full-Speed Sensorless Control Scheme for Interior Permanent Magnet Synchronous Motors. IEEE Trans. Power Electron. 2021, 36, 4723–4737. [Google Scholar] [CrossRef]

- Bolognani, S.; Ortombina, L.; Tinazzi, F.; Zigliotto, F. Model sensitivity of fundamental-frequency-based position estimators for sensorless pm and reluctance synchronous motor drives. IEEE Trans. Ind. Electron. 2018, 65, 77–85. [Google Scholar] [CrossRef]

- Gao, F.; Yin, Z.; Bai, C.; Yuan, D.; Liu, J. A Lag Compensation-Enhanced Adaptive Quasi-Fading Kalman Filter for Sensorless Control of Synchronous Reluctance Motor. IEEE Trans. Power Electron. 2022, 37, 15322–15337. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, G.; Wang, Q.; Ding, D.; Bi, G.; Li, B.; Wang, G.; Xu, D. Torque Disturbance Compensation Method Based on Adaptive Fourier-Transform for Permanent Magnet Compressor Drives. IEEE Trans. Power Electron. 2023, 38, 3612–3623. [Google Scholar] [CrossRef]

- Pasqualotto, D.; Rigon, S.; Zigliotto, M. Sensorless Speed Control of Synchronous Reluctance Motor Drives Based on Extended Kalman Filter and Neural Magnetic Model. IEEE Trans. Ind. Electron. 2023, 70, 1321–1330. [Google Scholar] [CrossRef]

- Zhang, Z. Sensorless Back EMF Based Control of Synchronous PM and Reluctance Motor Drives—A Review. IEEE Trans. Power Electron. 2022, 37, 10290–10305. [Google Scholar] [CrossRef]

- Gao, F.; Yin, Z.; Bai, C.; Yuan, D.; Liu, J. Speed Sensorless Control Method of Synchronous Reluctance Motor Based on Resonant Kalman Filter. IEEE Trans. Ind. Electron. 2023, 70, 7627–7641. [Google Scholar] [CrossRef]

- Yousefi-Talouki, A.; Pescetto, P.; Pellegrino, G.; Boldea, I. Combined active flux and high-frequency injection methods for sensorless direct-flux vector control of synchronous reluctance machines. IEEE Trans. Power Electron. 2018, 33, 2447–2457. [Google Scholar] [CrossRef]

- Varatharajan, A.; Pellegrino, G. Sensorless Synchronous Reluctance Motor Drives: A General Adaptive Projection Vector Approach for Position Estimation. IEEE Trans. Ind. Appl. 2020, 56, 1495–1504. [Google Scholar] [CrossRef]

- Tuovinen, T.; Hinkkanen, M.; Luomi, J. Analysis and Design of a Position Observer With Resistance Adaptation for Synchronous Reluctance Motor Drives. IEEE Trans. Ind. Appl. 2013, 49, 66–73. [Google Scholar] [CrossRef]

- Tang, Z.; Akin, B. Suppression of Dead time Distortion Through Revised Repetitive Controller in PMSM Drives. IEEE Trans. Energy Convers. 2017, 32, 918–930. [Google Scholar] [CrossRef]

- Wang, G.; Yang, R.; Xu, D. DSP-Based Control of Sensorless IPMSM Drives for Wide-Speed-Range Operation. IEEE Trans. Ind. Electron. 2013, 60, 720–727. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, S.; Zhang, G.; Ding, D.; Li, B.; Wang, G.; Xu, D. Zero-Sequence Voltage Error Elimination Based Offline VSI Nonlinearity Identification for PMSM Drives. IEEE Trans. Transp. Electrif. 2023, 10, 55–66. [Google Scholar] [CrossRef]

- Qiu, T.; Wen, X.; Zhao, F. Adaptive-Linear-Neuron-Based Dead time Effects Compensation Scheme for PMSM Drives. IEEE Trans. Power Electron. 2016, 31, 2530–2538. [Google Scholar] [CrossRef]

- Yong-Kai, L.; Yen-Shin, L. Dead-time Elimination of PWM-Controlled Inverter/Converter Without Separate Power Sources for Current Polarity Detection Circuit. IEEE Trans. Ind. Electron. 2009, 56, 2121–2127. [Google Scholar] [CrossRef]

- Chen, L.; Peng, F.Z. Dead-time elimination for voltage source inverters. IEEE Trans. Power Electron. 2008, 23, 574–580. [Google Scholar] [CrossRef]

- Liu, K.; Zhu, Z.Q. Online Estimation of the Rotor Flux Linkage and Voltage-Source Inverter Nonlinearity in Permanent Magnet Synchronous Machine Drives. IEEE Trans. Power Electron. 2014, 29, 418–427. [Google Scholar] [CrossRef]

- Sam-Young, K.; Wootaik, L.; Min-Sik, R.; Seung-Yub, P. Effective Dead time Compensation Using a Simple Vectorial Disturbance Estimator in PMSM Drives. IEEE Trans. Ind. Electron. 2010, 57, 1609–1614. [Google Scholar] [CrossRef]

- Kim, S.-Y. Compensation of Dead-Time Effects Based on Adaptive Harmonic Filtering in the Vector-Controlled AC Motor Drives. IEEE Trans. Ind. Electron. 2007, 54, 1768–1777. [Google Scholar] [CrossRef]

- Tuovinen, T.; Hinkkanen, M.; Harnefors, L.; Luomi, J. Comparison of a Reduced-Order Observer and a Full-Order Observer for Sensorless Synchronous Motor Drives. IEEE Trans. Ind. Appl. 2012, 48, 1959–1967. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, Z.Q.; Bin, H.; Gong, L.M. Current Harmonics Suppression Strategy for PMSM With Nonsinusoidal Back-EMF Based on Adaptive Linear Neuron Method. IEEE Trans. Ind. Electron. 2020, 67, 9164–9173. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Rated power (kW) | 3 |

| Rated current (A) | 7.6 |

| Rated voltage (V) | 360 |

| Paris of poles | 2 |

| Rated speed (r/min) | 3000 |

| Phase resistance (Ω) | 0.524 |

| d-axis inductance (mH) | 51 |

| q-axis inductance (mH) | 19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, L.; Wang, Z.; Zhao, X.; Guo, R.; Wang, J.; Wang, G.; Li, S. Dead-Time Compensation Using ADALINE for Reduced-Order Observer-Based Sensorless SynRM Drives. Energies 2024, 17, 1693. https://doi.org/10.3390/en17071693

Lv L, Wang Z, Zhao X, Guo R, Wang J, Wang G, Li S. Dead-Time Compensation Using ADALINE for Reduced-Order Observer-Based Sensorless SynRM Drives. Energies. 2024; 17(7):1693. https://doi.org/10.3390/en17071693

Chicago/Turabian StyleLv, Liangnian, Ziyuan Wang, Xinru Zhao, Rui Guo, Jinpeng Wang, Gaolin Wang, and Shulin Li. 2024. "Dead-Time Compensation Using ADALINE for Reduced-Order Observer-Based Sensorless SynRM Drives" Energies 17, no. 7: 1693. https://doi.org/10.3390/en17071693

APA StyleLv, L., Wang, Z., Zhao, X., Guo, R., Wang, J., Wang, G., & Li, S. (2024). Dead-Time Compensation Using ADALINE for Reduced-Order Observer-Based Sensorless SynRM Drives. Energies, 17(7), 1693. https://doi.org/10.3390/en17071693