Abstract

To facilitate the efficient exploration and development of coalbed methane of the Longtan Formation in the Guxu coal mining area, Sichuan, it is essential to evaluate the reservoir characteristics of the main production layers. In this study, scanning electron microscopy, low-temperature liquid nitrogen adsorption experiments, high-pressure mercury pressure experiments, and isothermal adsorption experiments were conducted to investigate the reservoir characteristics of favorable coalbed methane reservoirs. The results indicate that the main coal seams in the Longtan Formation are medium-to-high ash content anthracite with a well-developed pore–fracture system. The pore size distribution exhibits both unimodal and bimodal types, while the pore morphology includes impermeable pores closed at one end, open permeable pores, and ink bottle-shaped pores. It shows that the middle part of Longtan Formation acts as an enrichment zone for coalbed methane, which is characterized by a stronger adsorption capacity, high Langmuir volume, high gas content, and high gas saturation distribution. The pH value, mineralization degree, and hydrogen–oxygen isotope of the produced water in the main coal seams indicate that the enrichment zone is typically located in a stagnant flow zone with a reducing environment and favorable storage conditions.

1. Introduction

As an important unconventional natural gas, coalbed methane (CBM) is associated with coal seams. It is a kind of clean, high-thermal-efficiency, low-pollution, and high-quality energy, which is stored in the coal seams as adsorbed gas on the surface of coal matrix, free gas in the pores of coal matrix, free gas in the fractures (cleat system), dissolved gas in the water of the coal seams, etc. [1,2,3]. It has been commercially developed in several countries around the world, including the United States, Australia, Russia, Canada, and China. Moreover, coalbed methane mining can significantly reduce the risk of gas outbursts in coal mines, improve the safety of coal mine production, and reduce greenhouse gas emissions [4,5].

In China, the proven reserves and production capacity of CBM are mainly concentrated in several northern CBM industrial bases, such as the southern part of the Qinshui Basin and the eastern margin of the Ordos Basin [6,7], with limited reserves and a limited production capacity. Therefore, it is urgent to find a number of new strategic replacement areas for exploration and development. Following the successful development of CBM in the Qinshui Basin and the Ordos Basin in the Carboniferous–Permian period, the exploration and development of CBM in the Late Permian Longtan Formation in the southern part of the Sichuan Basin has also accelerated [8,9]. Previous studies have explored the development and distribution characteristics of coal reservoirs, macroscopic and microscopic coal-rock types, coal quality, and the surrounding rock of coal reservoirs, as well as the material basis of coal reservoirs and the relevant relationship between coal seam gas enrichment in ancient coal mine areas [9,10,11,12]. However, there have been no major breakthroughs in the exploration and development of this area, mainly due to insufficient research on the CBM reservoir characteristics, content variations, and fluid properties in this area.

In this study, the characteristics of coal-rock reservoirs in the Guxu coal mining area are characterized by means of sampling, experiments, and analysis, and the main exploration and development layers of CBM are also evaluated. Then, combined with the determination of hydrogen and oxygen isotopes of reservoir fluid characteristics, the preservation conditions of CBM are discussed, providing a geological theoretical basis for further clarifying the direction of CBM exploration and development.

2. Geological Setting

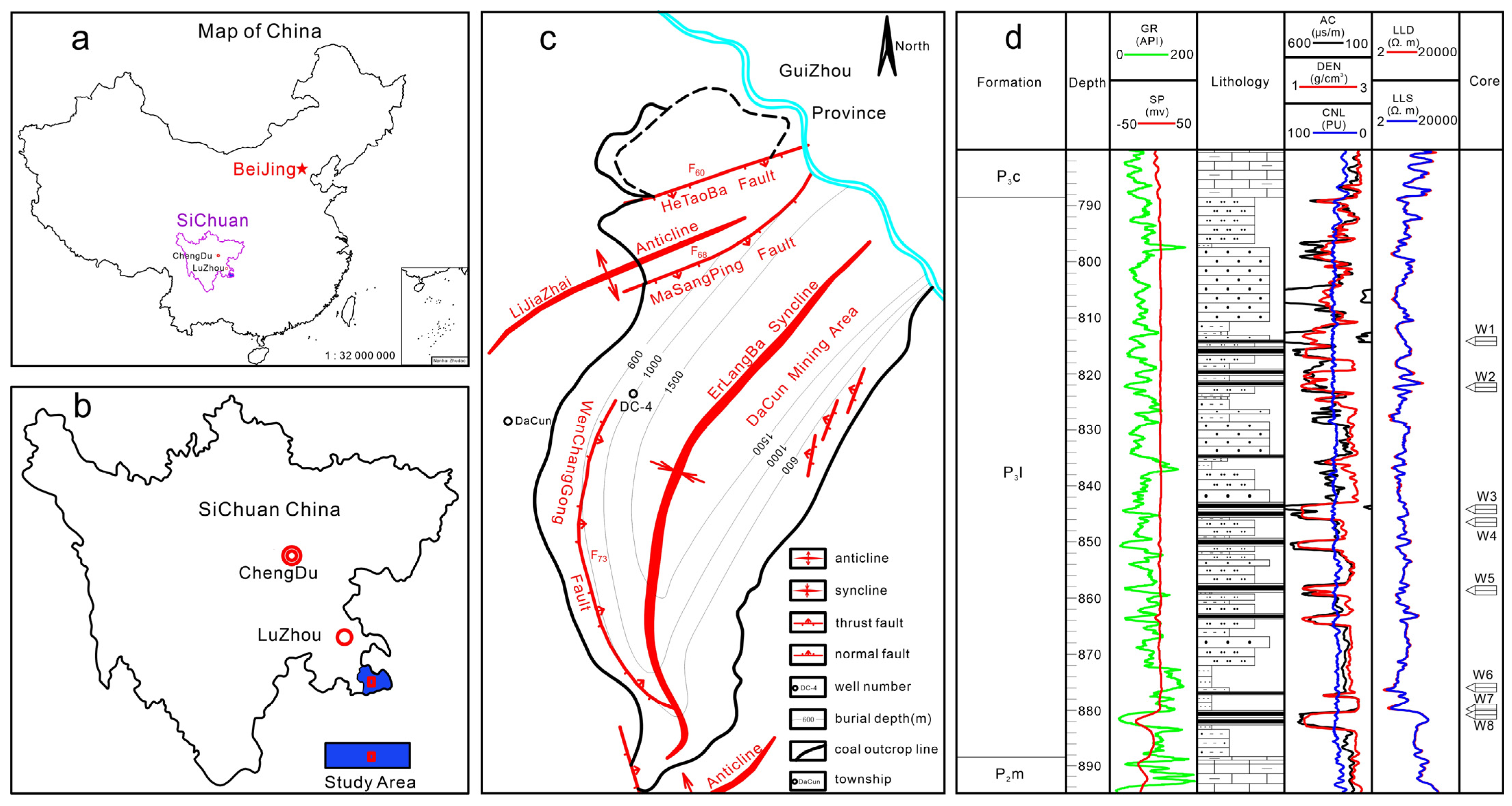

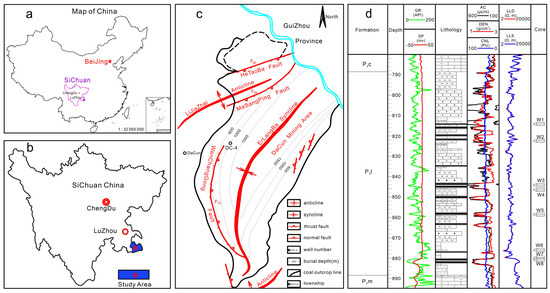

The Guxu coal mining area is located in the transition zone between the Sichuan Basin and the Yunnan–Guizhou Plateau, within the territory of Gulin and Xuyong Counties in Luzhou City, Sichuan Province. The tectonic position belongs to the eastern segment of the Gulin complex anticline, which is located in the western part of the Yangtze Plate and the southern margin of the Sichuan Basin. As shown in Figure 1a–c, the outcropping strata in the area are Silurian, Permian, Triassic, and Jurassic systems from old to new, with the latest stratum being the Middle Jurassic Upper Shaximiao Formation (J2s) and the oldest stratum being the Silurian Hanjiadian Formation (S2h). The coal-bearing stratum is the Upper Permian Longtan Formation, which belongs to marine–continental transitional facies deposition. And the total thickness of the strata is 65.60 m~118.05 m, with an average of 82.97 m.

Figure 1.

The location of the Guxu coal mining area in Sichuan, structural outline drawing, and sample collection locations of Longtan Formation. (a) Map of Sichuan province in China; (b) Map of Guxu coal mining area in Sichuan province, China; (c) Structural outline drawing of Guxu coal mining area; (d) Sample collection locations of Longtan Formation.

In the Yunnan–Guizhou–Sichuan region, the Longtan Formation contains a total of 37 coal seams that can be correlated. Within the study area, there are over 20 sets of coal seams, among which the correlatable coal seams from top to bottom are named C11 coal to C25 coal (where “11” or “25” represents the coal seam number). Throughout the region, there are two coal seams, C14 coal and C17 coal (with true thickness ≥ 0.7 m), that are fully exploitable. Additionally, partially or completely exploitable coal seams include C13 coal, C16 coal, C23 coal, C24 coal, and C25 coal, totaling five layers. The structure of the coal seam is relatively simple, with a small amount of thin-layer gangue. The average total thickness of the mineable coal seams is 9.36 m, accounting for 11.28% of the total thickness of the Longtan Formation, with high stability and good coal content.

3. Sample Collection and Experimental Methods

3.1. Sample Collection

The research area is located approximately 112 km southeast of Luzhou City, Sichuan Province (Figure 1a,b), with its tectonic position on the southern limb of the Gulin duplex anticline, and with the main structure being the Erlangba anticline (Figure 1c). The 8 samples of this study were collected from the DC-4 well in the Dacun mining section of the Guxu coal mining area (Figure 2). The strata drilled from top to bottom in this well were Quaternary, Lower Triassic Jialingjiang Formation (T1j), Feixianguan Formation (T1f), Upper Permian Changxing Formation (P3c), Longtan Formation (P3l), and Middle Permian Maokou Formation (P2m). The samples were taken from the C13 coal, C14 coal, C17 coal, C23 coal, and C25 coal of the Longtan Formation (Figure 1d and Table 1).

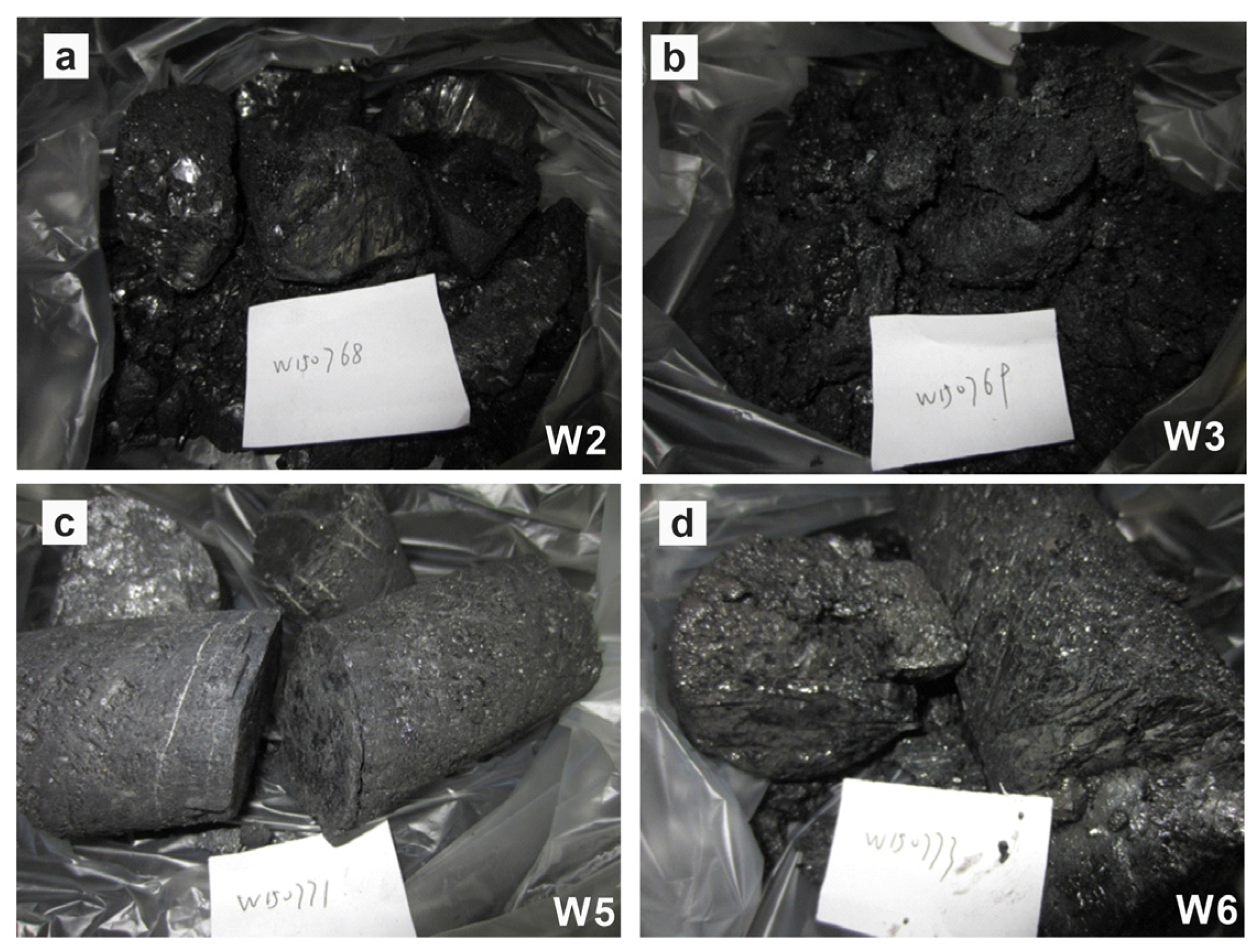

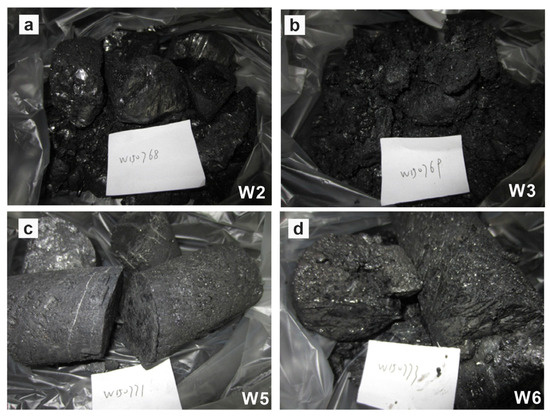

Figure 2.

Core photographs of some main coal seams in the Longtan Formation in the Guxu region. (a) W2, the rock sample was taken from the well depth of 821.57 m–822.40 m, which belongs to semi-bright coal; (b) W3, the rock sample was taken from the well depth of 843.85 m–844.15 m, which belongs to dull coal. (c) W5, the rock sample was taken from the well depth of 858.39 m–858.67 m, which belongs to semi-bright coal; (d) W6, the rock sample was taken from the well depth of 875.85 m–875.95 m, which belongs to semi-bright coal.

Table 1.

Statistical table of Longtan Formation samples in Guxu coal mining area.

3.2. Experimental Methods

3.2.1. Mineral Components and Microscopic Observation

To determine the moisture content of coal, 25 g coal samples were heated to 101–110 °C under nitrogen in a 101 series electric blast drying oven until the weight stabilized. From the weight loss, the moisture content was calculated.

Using a KL-SWCK6 (Hebi keli measurement and control technology Co., Ltd., Hebi, China) muffle furnace, the ash and volatile yields were determined. The moisture content was deducted from the mass reduction ratio, and one gram of dried coal was heated to 850 °C for ash yield (the ratio of ash to coal mass) and to 900 °C in a covered crucible that was sealed off from the air for seven minutes for volatile yield. The fixed carbon was the remaining amount when ash and volatile materials were subtracted.

The amounts of minerals and microcomponents were identified by a polarizing microscope that operated on reflected light. Volume percentages could be calculated by accurately identifying the minerals and microcomponents.

Applying a Leica DM4P photometer microscope (Leica Microsystems, Wetzlar, Germany), the reflectance of coal macerals was determined by comparing the photovoltaic signals of the macerals in coal slides to reference values.

3.2.2. Pore Structure Characterization Experiments

Low-temperature nitrogen adsorption experiment: The American company Quantachrome NOVA-2000e (Quantachrome Instruments Corporation, Boynton Beach, FL, United States) surface area and pore size analyzer was used. Samples were crushed and sieved to 0.18–0.25 mm (60–80 mesh) and then dried (48 h at 60 °C). The experiments were conducted at low temperature (77 K), using the Micromeritics ASAP2020 (Micromeritics Instrument Corporation, Norcross, CA, United States) particle analyzer. The specific surface area and total pore volume were calculated using the BET (Brunauer–Emmett–Teller) [13] model and BJH (Barrett–Joyner–Halenda) model [14,15], respectively.

The pore structure parameters of coal samples were measured by the Micromeritics Auto Pore IV 9500 (Micromeritics Instrument Corporation, Norcross, CA, United States). Mercury volume changes are recorded with less than 0.1 μL accuracy, the pore size range is 50 Å to 360 μm, and the highest pressure is 228 MPa. Pressure was gradually increased on the sample, using a mercury intrusion porosimeter, and the mercury volume absorbed by the sample’s pores was recorded. The relationship between mercury volume and applied pressure was plotted. From these results, the sample’s pore diameter, volume, and surface area were calculated, providing insights into its pore structure [16,17].

The IS-100 high-pressure (Terratek, Inc., Salt Lake City, UT, United States) isothermal adsorption instrument was utilized to assess the adsorption equilibrium of methane volume across multiple pressure conditions at a testing temperature of 30 °C [18,19] and a maximum adsorption pressure of 10 MPa. A sample of 200 g with a particle size ranging from 0.25 mm to 0.18 mm (60–80 mesh) was selected for this purpose [20]. Employing the Langmuir adsorption theory [21], the coal’s adsorption constants (Langmuir volume and Langmuir pressure) and the isothermal adsorption curve were determined.

The FESEM S4800 (Hitachi, Ltd., Tokyo, Japan) scanning electron microscope was employed to observe the types of pores, pore sizes, micro-fractures, filling minerals, and pore distribution in coal samples. By using a polisher on the natural fracture surface of the sample to achieve fine polishing, a mirror-finished sample was obtained. This allowed for the observation of nanopores with a magnification capability exceeding 50,000 times.

3.2.3. Water Quality Analysis Experiment

Water quality component analysis involved collecting samples using Beckman tubes (Changde BKMAM BIOTECHNOLOGY Co., Ltd., Changde, China,) for ion determination. CO32− and HCO3 were titrated using 0.01 mol·L dilute hydrochloric acid; Na+, K+, Mg2+, and Ca2+ were measured using an Inductively Coupled Plasma–Optical Emission Spectrometer (ICP-OES) (Thermo Fisher Scientific, Waltham, MA, USA, ICAP PRO X, under conditions of 18 °C to 25 °C and relative humidity of 40% to 60%). Cl− and SO42− were determined using an ion chromatograph (USA, Thermo Fisher Scientific, ICS-5000+, in the same environmental conditions). The amount of carbon dioxide or oxygen consumed during decomposition was measured using a heating and oxidizing agent decomposition method.

Initially, 10 mL of water sample was filtered through a disposable filter membrane with a pore size of 0.22 µm and then sealed in plastic centrifuge tubes and frozen at −20 °C for preservation. Subsequently, the hydrogen and oxygen isotope values in the water were determined using a high-temperature pyrolysis/mass spectrometry method. The specific steps involved injecting 0.2 µL of the water sample into an elemental analyzer, where it underwent pyrolysis at 1400 °C in a high-temperature pyrolysis tube, breaking down into hydrogen and oxygen gases [22]. The oxygen from the pyrolysis tube then reacted with excess reducing carbon to produce carbon monoxide through an incomplete oxidation reaction. After separation by a chromatography column, the carbon monoxide and hydrogen gases were introduced into an isotope mass spectrometer. Finally, the oxygen isotope values in the carbon monoxide and the hydrogen isotope values in the hydrogen gas were measured, thereby determining the stable isotope values of oxygen and hydrogen elements in the water sample.

3.2.4. Coalbed Methane Content Measurement

The coalbed methane content was determined through natural desorption of the coal sample, measurement of residual gas, and calculation of lost gas. Initially, upon drilling sampling (with a coal core length of 30 cm and a diameter of 48 mm), the sample was quickly lifted to the wellhead at a speed exceeding 50 m/min. Subsequently, the sample was sealed in a desorption canister and allowed to desorb for 24 h at the reservoir temperature (30 °C), using the water displacement gas collection method to measure the volume of desorbed gas. After the completion of natural desorption, 300 g of the sample was taken out and pulverized in a ball mill, and the volume of the residual gas was then measured. The volume of gas, ambient temperature, atmospheric pressure, and desorption time were observed and recorded every 5 min. Observations continued once every 24 h after the initial 24-hour period, lasting for 7 days. Based on the recorded data, desorption corrections and calculations of the lost volume were performed following the coalbed methane content determination method.

4. Results and Analysis

4.1. Reservoir Characteristics of Coal Seams

4.1.1. Macroscopic Coal-Rock Characteristics

As shown in Figure 2, The main coal seams in the study area are black in color, with an adamantine luster predominantly and an adamantine-like luster secondarily, and may leave black streaks when rubbed. The fracture surfaces are mostly stepped or irregular, with a small amount showing a shell shape. The endogenous and exogenous fractures are mostly developed in bright coal and vitrinite, often filled with mineral veins. The macroscopic coal-rock types include semi-bright coals (e.g., C14, C17, C23, C24, and C25) and semi-dull coals (e.g., C13 and C16). Semi-bright coals are mainly composed of bright coals, followed by vitrinite, with a small number of dull coals. Vitrinite is characterized by fine–medium bands, lineation, and lens-like distributions, with a few filamentous carbon lenses. Semi-dull coal is mainly composed of dull coal, followed by bright coal, with more filamentous carbon lenses and occasional bands of vitrinite. The structure of the coal seams is predominantly banded, followed by linear structures, with small amounts of blocky, powdery, and flaky structures. Some of the coal bodies have been structurally deformed as a result of tectonic forces (Table 2).

Table 2.

Statistical table of physical properties of main coal seams in Guxu region.

4.1.2. Microscopic Characteristics

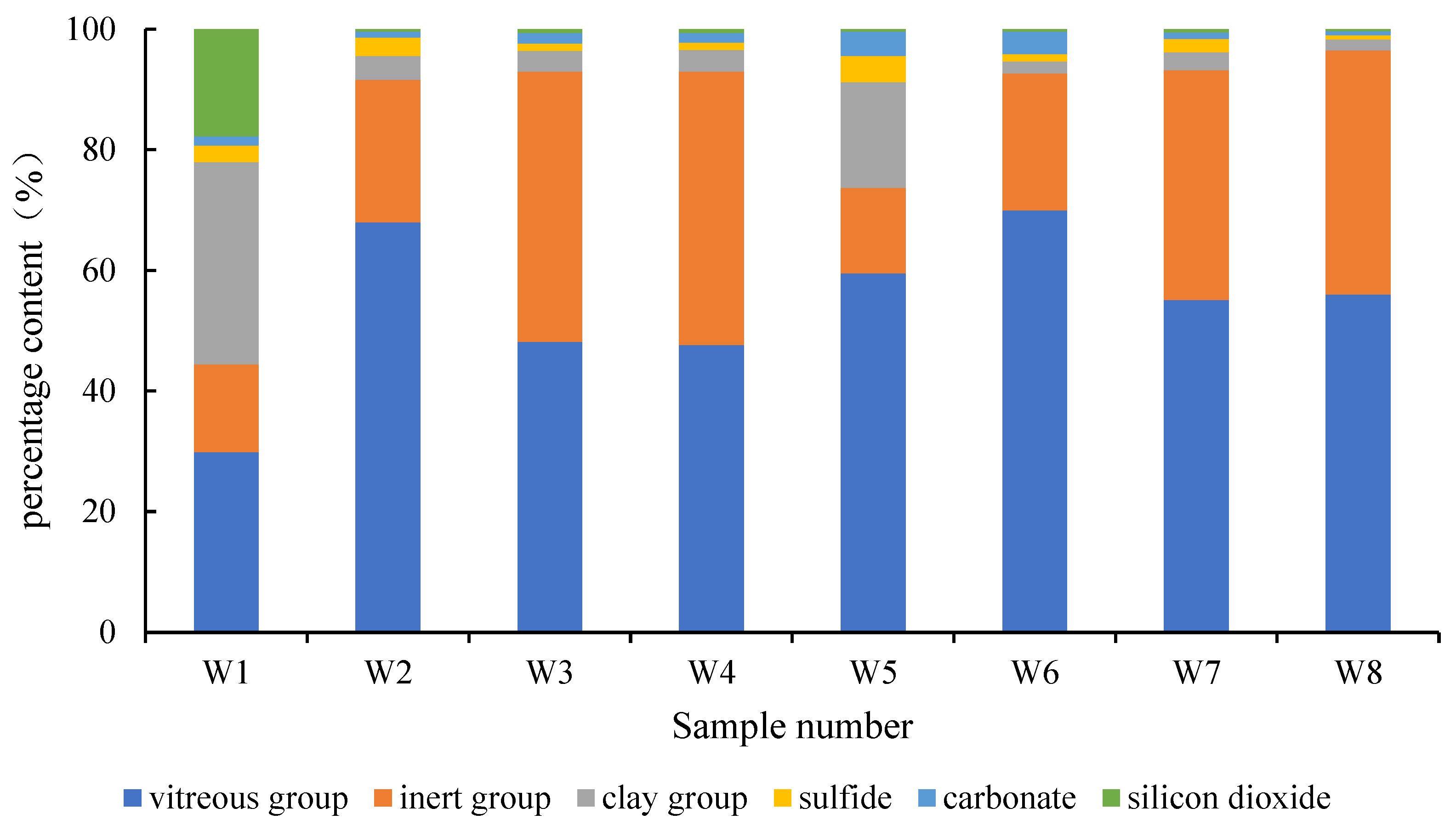

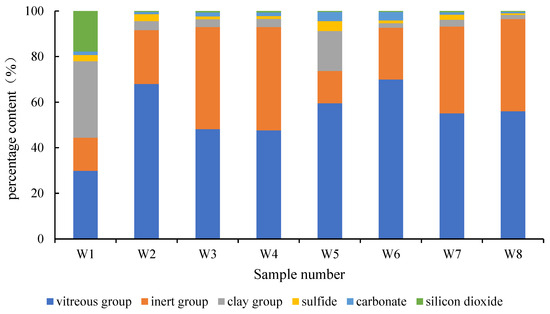

The coal-rock components of eight coal samples in the study area were observed Figure 3). The compositions of coal maceral are mainly vitrinite, followed by inertinite. The vitrinite content ranges from 29.9% to 70%, with homogeneous vitrinite and matrix vitrinite being the main types. The inertinite content ranges from 14.2% to 45.4%, with filamentous inertinite being the main type. The content of mineral components varies between 3.5% and 55.6%, dominated by clay minerals, followed by sulfide, carbonate, and silica oxide minerals. The clay minerals are star-shaped and finely dispersed, with pyrites in sparsely distributed star shapes. And carbonates appear in a small amount of fragmented calcite, while silicates are sporadically distributed in a small amount of quartz particles. The reflectance measurement of vitrinite indicates that the maximum Ro value of the main coal seam ranges from 2.5% to 3.01%, with an average value of 2.77%, which belongs to bituminous coal.

Figure 3.

The percentage chart of coal maceral composition.

4.1.3. Coal Quality Characteristics

A proximate analysis was carried out on eight coal samples in the study area (Table 3). The ash contents of the main coal seams varied from 8.9% to 32.63%, all of which are medium-to-high ash coal. The moisture contents of the main coal seams obtained from air-drying base varied from 1.94% to 2.53%, all of which are ultralow-moisture coal. The volatile matter contents of the main coal seams varied from 5.60% to 8.91%, all of which are low-volatile-matter, high-metamorphic anthracite. The average fixed carbon content of the main coal seams varied from 59.27% to 85.50%, which are medium-to-high fixed carbon coal.

Table 3.

Analysis results of proximate analysis (wt.%).

4.2. Coal Reservoir Characteristics

4.2.1. Development Characteristics of Micropores and Fractures

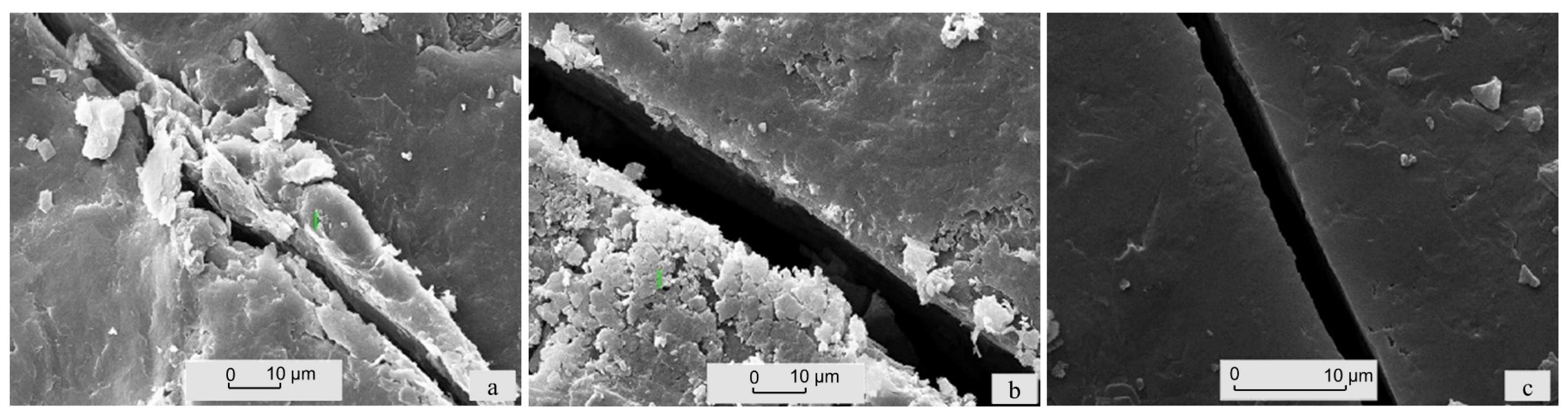

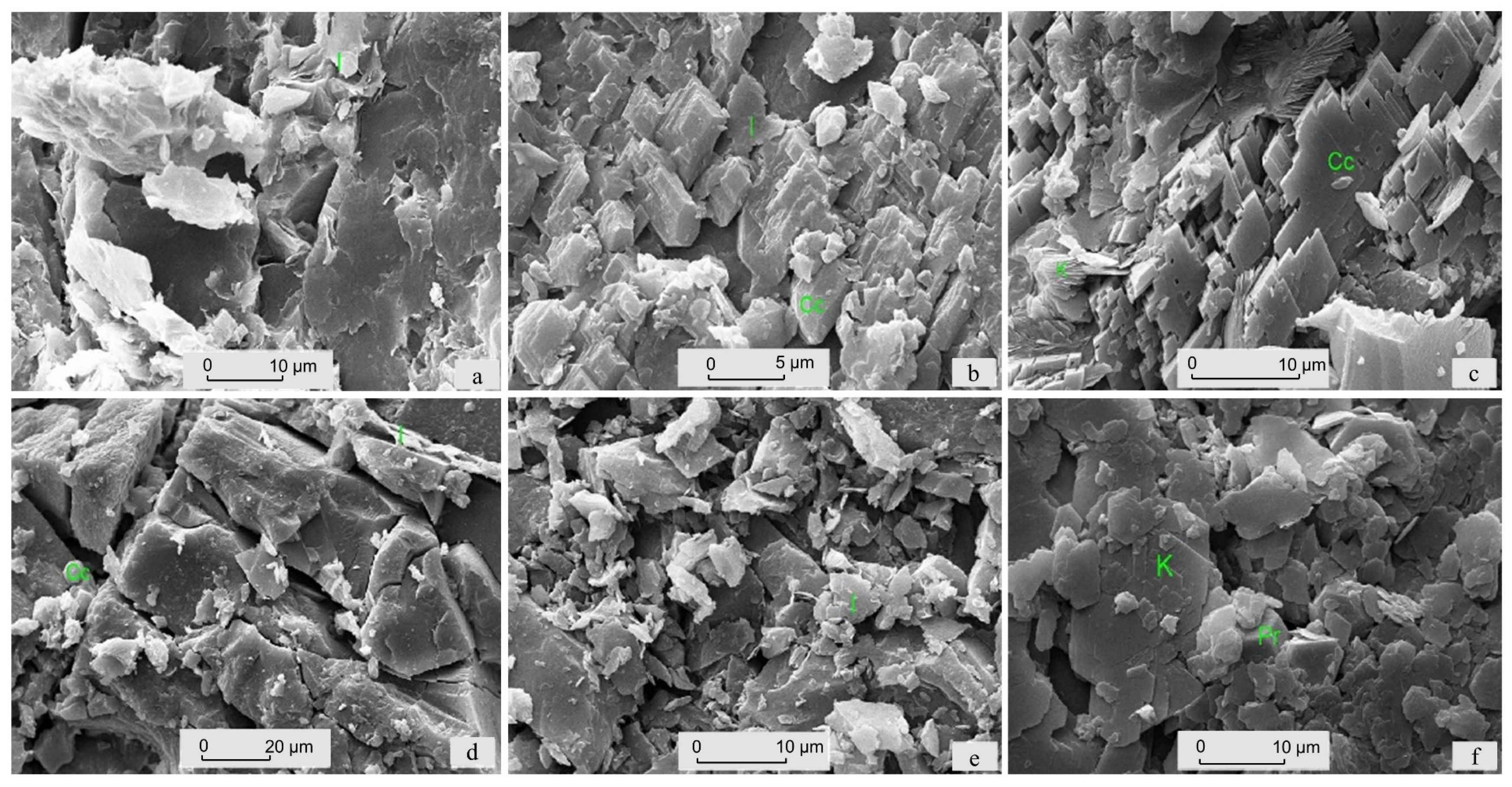

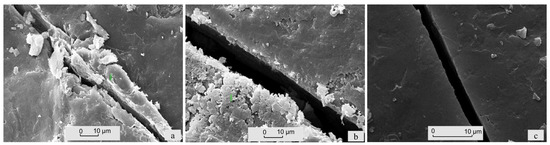

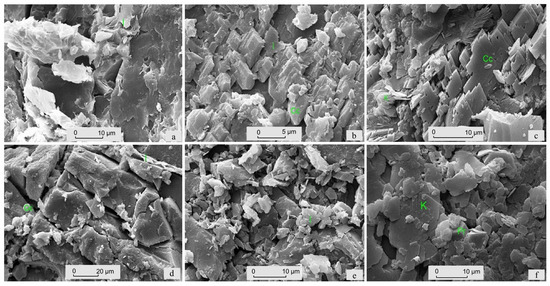

The development degree of pores and fractures in the coal reservoirs affects the adsorption, preservation, and seepage migration of coalbed methane. As an important channel for coalbed methane seepage, the morphology and closure degree of microfractures are important indicators for evaluating the connectivity of reservoirs. In this study, the development characteristics of micropores and fractures in the main coal reservoir were observed by scanning electron microscopy (Figure 4). In general, the microfractures and pores of the coal seams in the study area are well-developed, and the microscopic reservoir properties are relatively good, although some fractures are filled with clay minerals or calcite.

Figure 4.

(a) W2, filamentous illite filling organic matter fractures, surrounded by carbonaceous material; (b) W3, organic matter fractures approximately 10 µm wide, surrounded by carbonaceous material; (c) W7, organic matter fractures approximately 2–5 µm wide observed.

Some primary minerals are visible under the microscope as having been dissolved again to form secondary dissolution pores. However, it is affected by clay mineral infill or partial infill, resulting in poor connectivity. Based on the observation of pore structures in coal samples and previous studies, the pore types in this study are mainly classified into organic matter pores and mineral pores (Table 4 and Figure 5), which are formed during geological history and later modifications.

Table 4.

Coal seam pore types of Longtan Formation in Guxu coal mining area.

Figure 5.

(a) W2, filamentous illite interlayer pores and organic matter pyrolysis pores; (b) W4, lamellar illite and calcite intercrystalline pores; (c) W5, book-like kaolinite, calcite intercrystalline pores, and dissolution pores; (d) W5, development of organic matter cleat, calcite, and illite can be seen; (e) W6, filamentous illite and carbonaceous granular pores; (f) W7, kaolinite and intergranular pores of single crystal pyrite, with no organic matter observed.

4.2.2. Pore Structure Characterization

As an unconventional reservoir, the coal reservoir has a complex pore–fracture system. In order to finely characterize the pore–fracture characteristics, liquid nitrogen adsorption and high-pressure mercury experiments were carried out to characterize the pore–fracture structure of the main coal seam.

- (1)

- Low-temperature liquid nitrogen adsorption experiment

The pore classification scheme of coal seams in the study area is based on the pore size division proposed by Hodot (1966) [23], dividing them into four types: macropores (>1 μm), mesopores (0.1 μm~1 μm), transitional pores (0.01 μm~0.1 μm), and micropores (<0.01 μm). In this study, the specific surface area, pore volume, and pore structure distribution of the adsorption pores were determined by liquid nitrogen adsorption experiments. As shown in Table 5, the average pore size of the main coal seam ranged from 18.81 nm to 22.37 nm, which belongs to the transitional pores. The BET specific surface area ranged from 0.14 m2/g to 0.74 m2/g, and the BJH total pore volume ranged from 0.001 mL/g to 0.004 mL/g.

Table 5.

Low-temperature liquid nitrogen adsorption results of coal seams in the Guxu area.

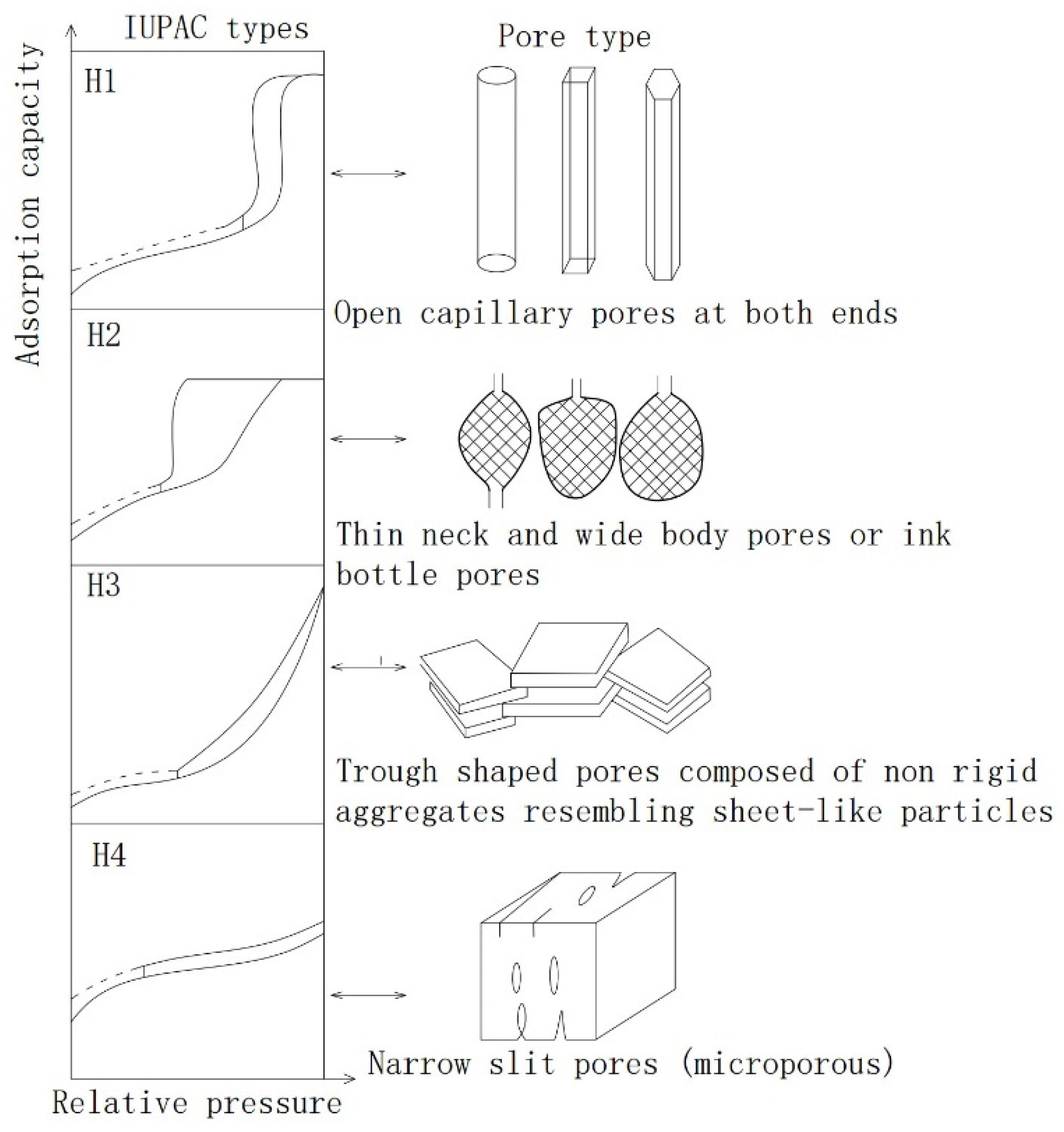

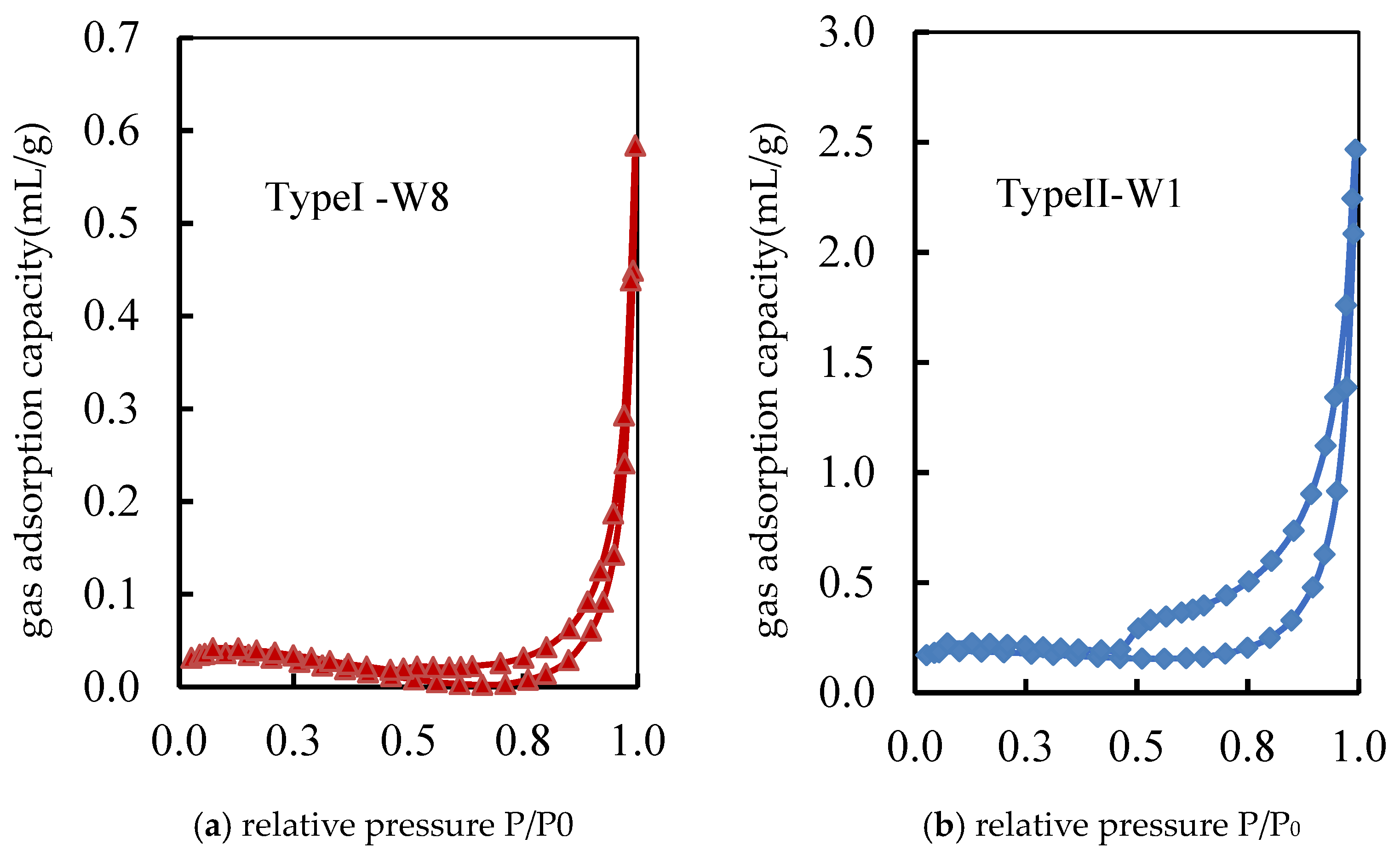

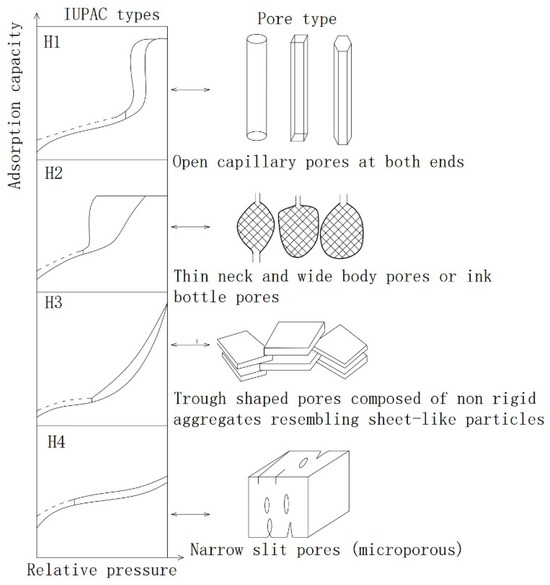

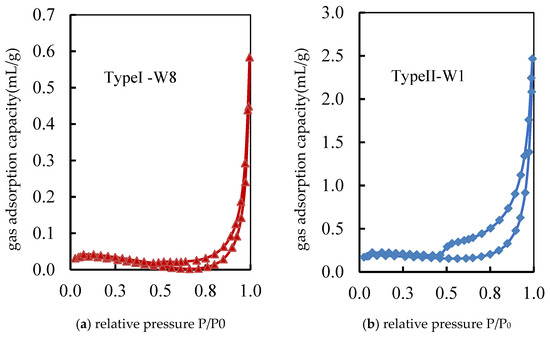

According to the IUPAC isotherm classification (Figure 6), there are two main distribution forms of the low-temperature liquid nitrogen adsorption and desorption curve of the main coal seam in this study, which is shown in Figure 7.

Figure 6.

IUPAC adsorption hysteresis classification and pore types.

Figure 7.

Adsorption and desorption curves of Longtan Formation coal in the Guxu area.

Type I: The adsorption–desorption curve represented by W8 is similar to the H4 type in Figure 6. It can be seen from Figure 8a that the desorption hysteresis loop is generated in the adsorption and desorption curve of W8, without an obvious inflection point, G. Nitrogen adsorption rises slowly at the relative pressures of 0 to 0.9, and nitrogen molecules are adsorbed in monolayers on larger pore walls. At the lower relative pressure (P/P0 < 0.5), the adsorption and desorption curves coincide, indicating that the pore morphology in the smaller pore size range is mostly one-end-closed impermeable pores. At higher relative pressures (P/P0 > 0.5), a certain lag in the desorption hysteresis loop occurs, indicating that the pore structure is dominated by semi-closed pores, and this is not conducive to the desorption and diffusion of coalbed methane.

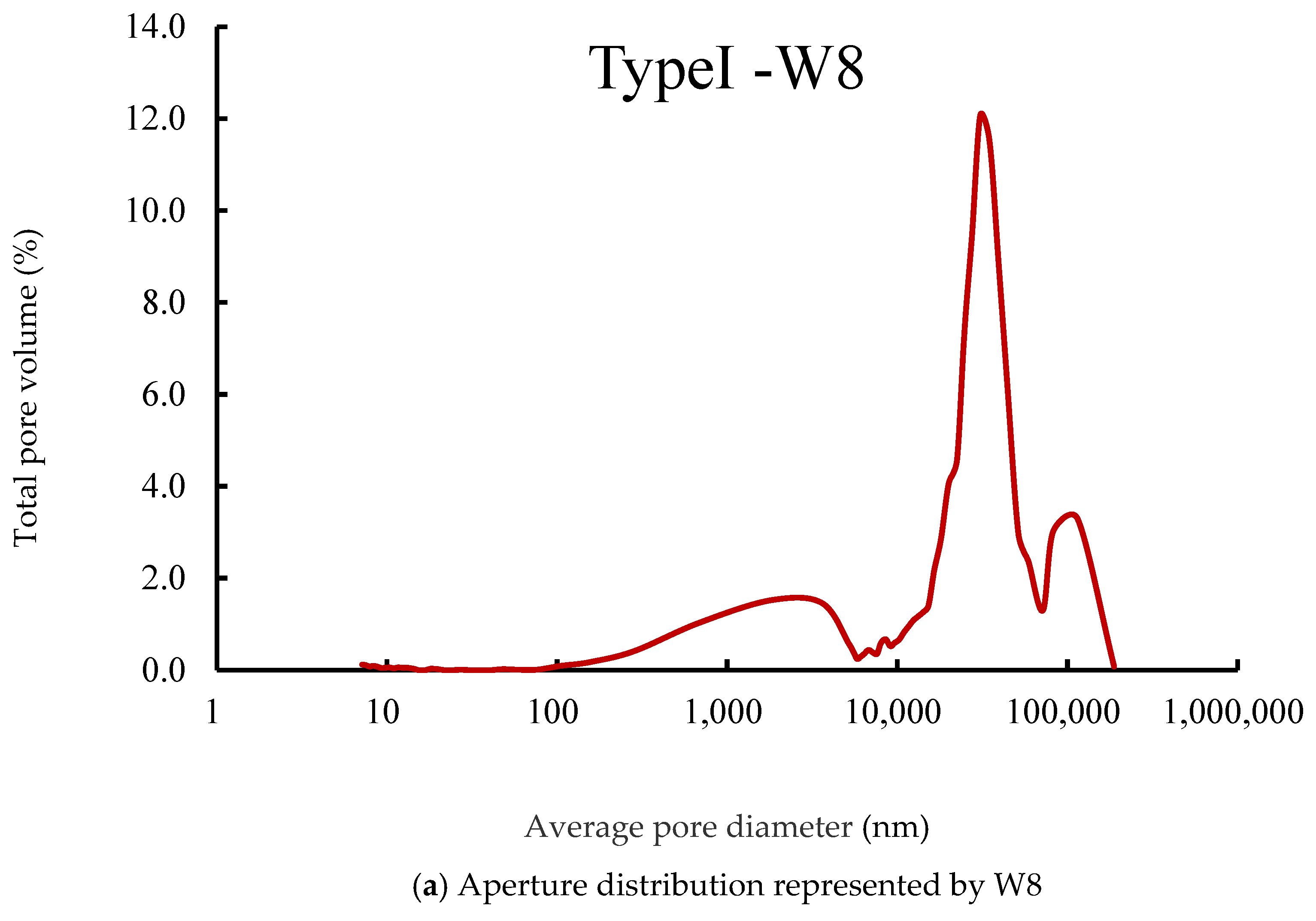

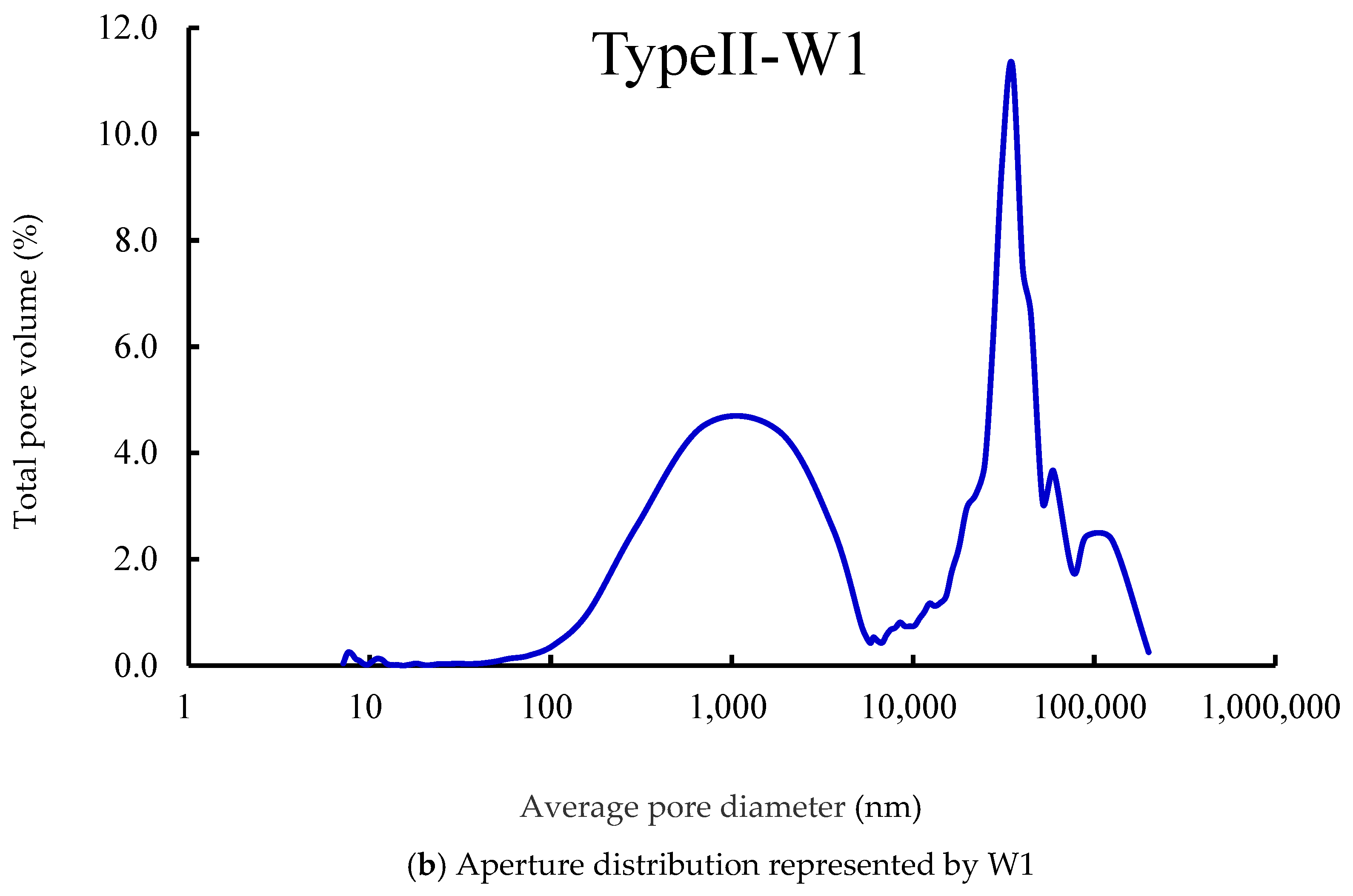

Figure 8.

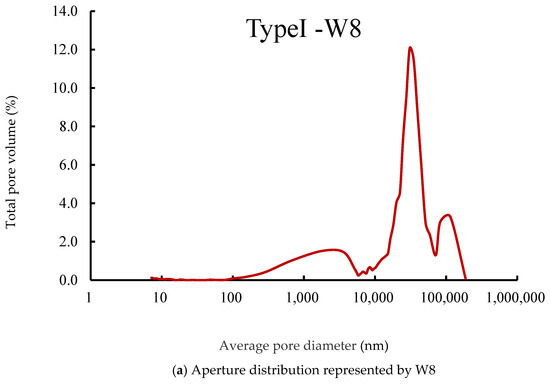

Distribution of high-pressure mercury pore size of coal samples from the Longtan Formation in the Guxu area.

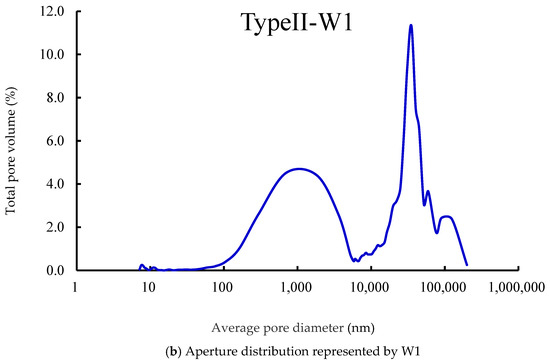

Type II: The adsorption–desorption curve represented by W1 is similar to the H3 type in Figure 6. The desorption curve in Figure 8b has a sharp decline inflection point, and the pore structure is relatively complex. At the lower relative pressure (P/P0 < 0.5), the adsorption and desorption curves overlap, indicating that there is a closed impermeable pore in the smaller pore size range. At higher relative pressures (P/P0 > 0.5), an adsorption hysteresis loop appears with a distinct inflection point, G, indicating that grooved pores are more developed in non-rigid aggregates, and there may also be open-ended tubular pores.

- (2)

- High-pressure mercury intrusion experiment

In Table 6, it can be seen that the peak pore size of the main coal seam in the study area is >1 μm, which belongs to the macropores. The average pore size is between 1.8 μm and 9.5 μm, which belongs to the mesopores. The median pore size is between 0.0311 μm and 0.04025 μm, which belongs to the micropores. And the specific surface area ranges from 0.06 m2/g to 0.072 m2/g. It shows that the pore structure of the coal seams in this area is dominated by micropores, making it favorable for adsorption.

Table 6.

Experimental results of the main coal seams of the Longtan Formation in the Guxu area.

As shown in Figure 8, the pore size distribution of the main coal seams in the study area can be roughly divided into two types: the unimodal distribution represented by W8, and the bimodal distribution represented by W1. In addition, it can be observed that both have pore size peaks in the range of 10 μm–100 μm. But the difference is that the curve represented by W1 has a second peak at about 1μm and a wider peak surface, which makes the pore structure more complex and corresponds to a larger specific surface area of W1 than that of W8.

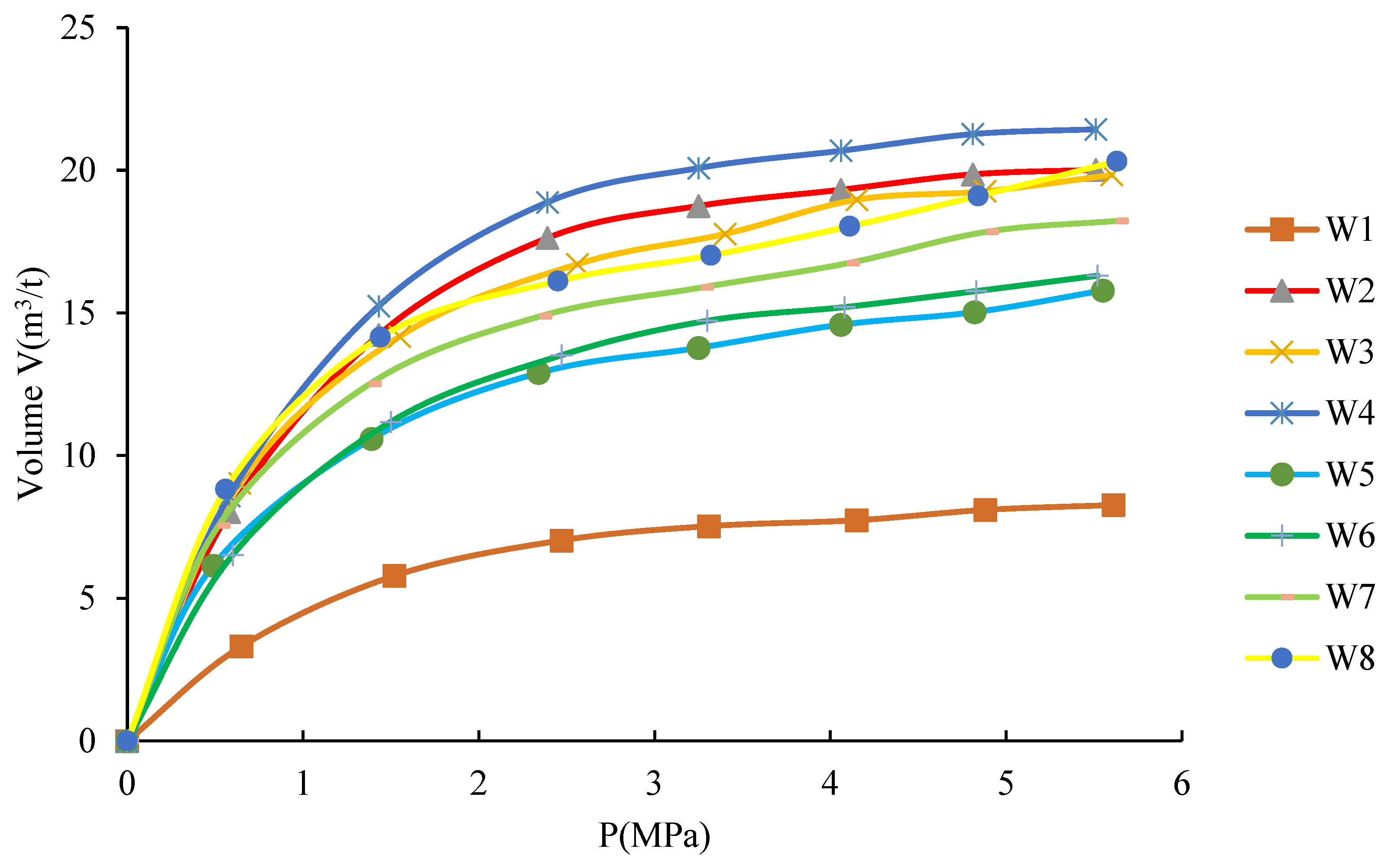

4.2.3. Isothermal Adsorption Characteristics

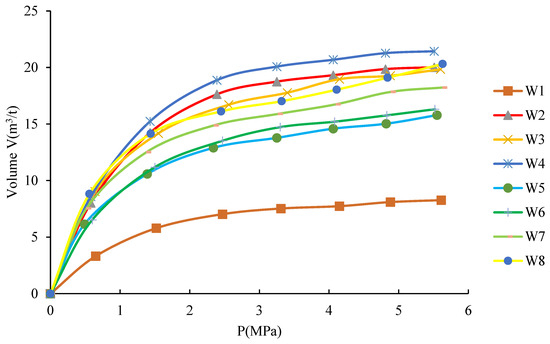

It is of great significance to study the adsorption–desorption performance of coal reservoirs for the gas-bearing characteristics of coal seams and the exploration and development of coalbed methane [24,25]. In this experiment, the isothermal adsorption tests were carried out at the temperature of 30 °C for 8 samples of 25 g each. The main results of the tests of the main coal seams were obtained, which are shown in Table 7 and Figure 9. In Table 7, it can be found that the Langmuir volume (saturated adsorption capacity of raw coal) of the main coal seams is between 10.08 and 25.75 m3/t, indicating that most of the main coal seams have strong adsorption capacity. Moreover, the adsorption capacity of the main coal seams in the upper and lower parts of the Longtan Formation is weak, while the adsorption capacity in the middle part is stronger, which is conducive to the enrichment of coalbed methane.

Table 7.

Results of isothermal adsorption on main coal seams from the Longtan Formation, Guxu area.

Figure 9.

Isothermal adsorption curves of coalbed methane in the Longtan Formation, Guxu area.

4.3. Fluid Characteristics of Coal Reservoirs

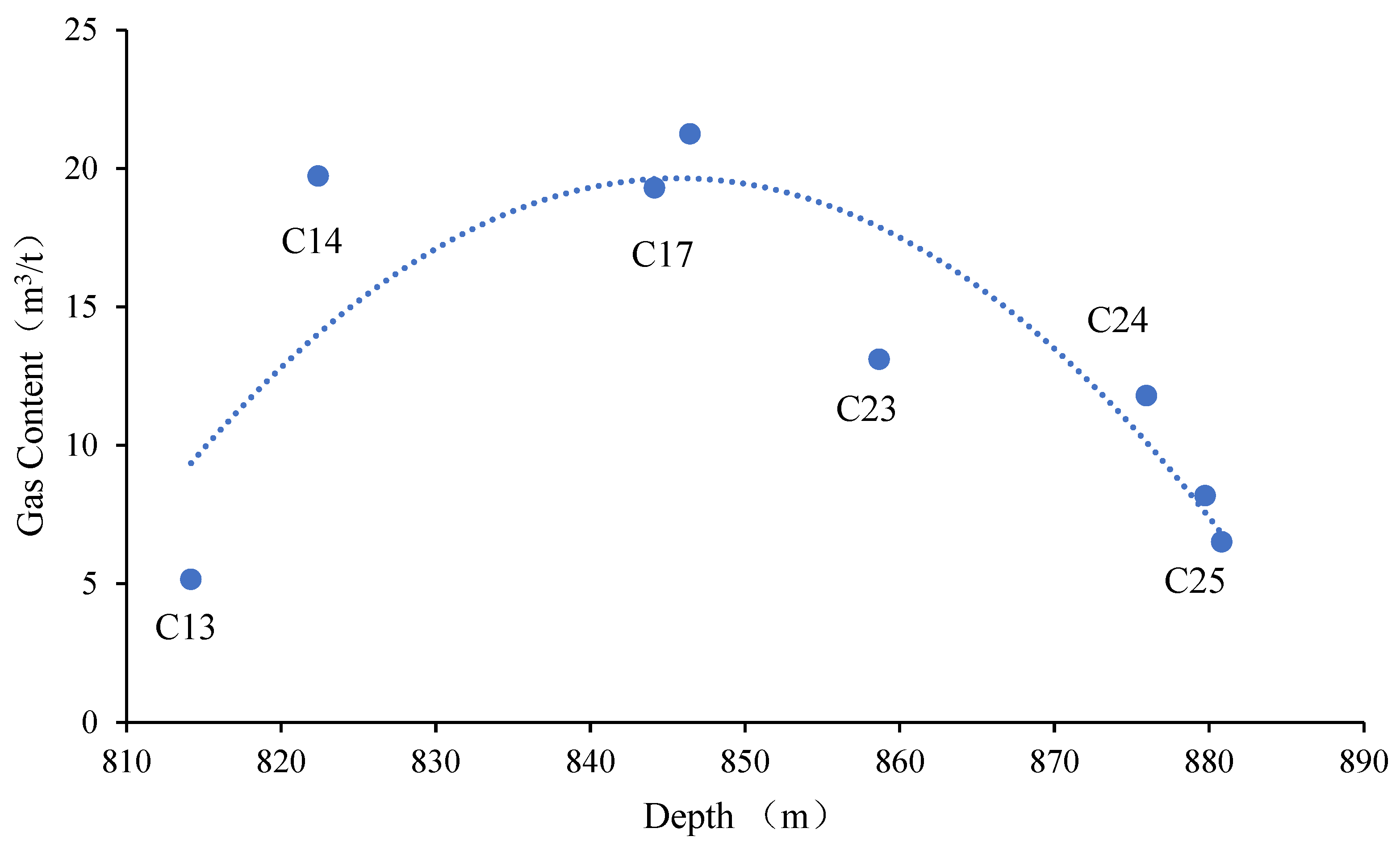

4.3.1. Gas Distribution

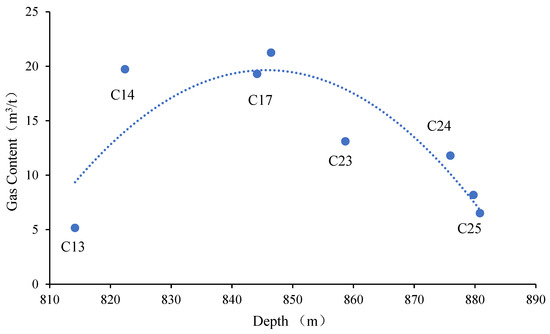

Gas content is an important geological basis for coalbed methane exploration and development, and it is a key factor in determining production capacity. Therefore, it is an essential basic work to measure gas content for coalbed methane exploration and development. The results show that the gas content of coal seams ranges from 5.16 m3/t to 21.24 m3/t, with an average of 13.12 m3/t (Table 8). Moreover, it can be concluded from Figure 10 that the main coal seam gradually increases to a peak and then gradually decreases from shallow to deep. In other words, the gas content of coal seams exhibits the characteristic of low at both ends and high in the middle, and the coal seams with the highest gas content are mainly concentrated in the middle of the Longtan Formation.

Table 8.

Results of gas content of coal (air-drying basis) in the Guxu area.

Figure 10.

Isothermal adsorption curve of coal methane in the Longtan Formation, Guxu area.

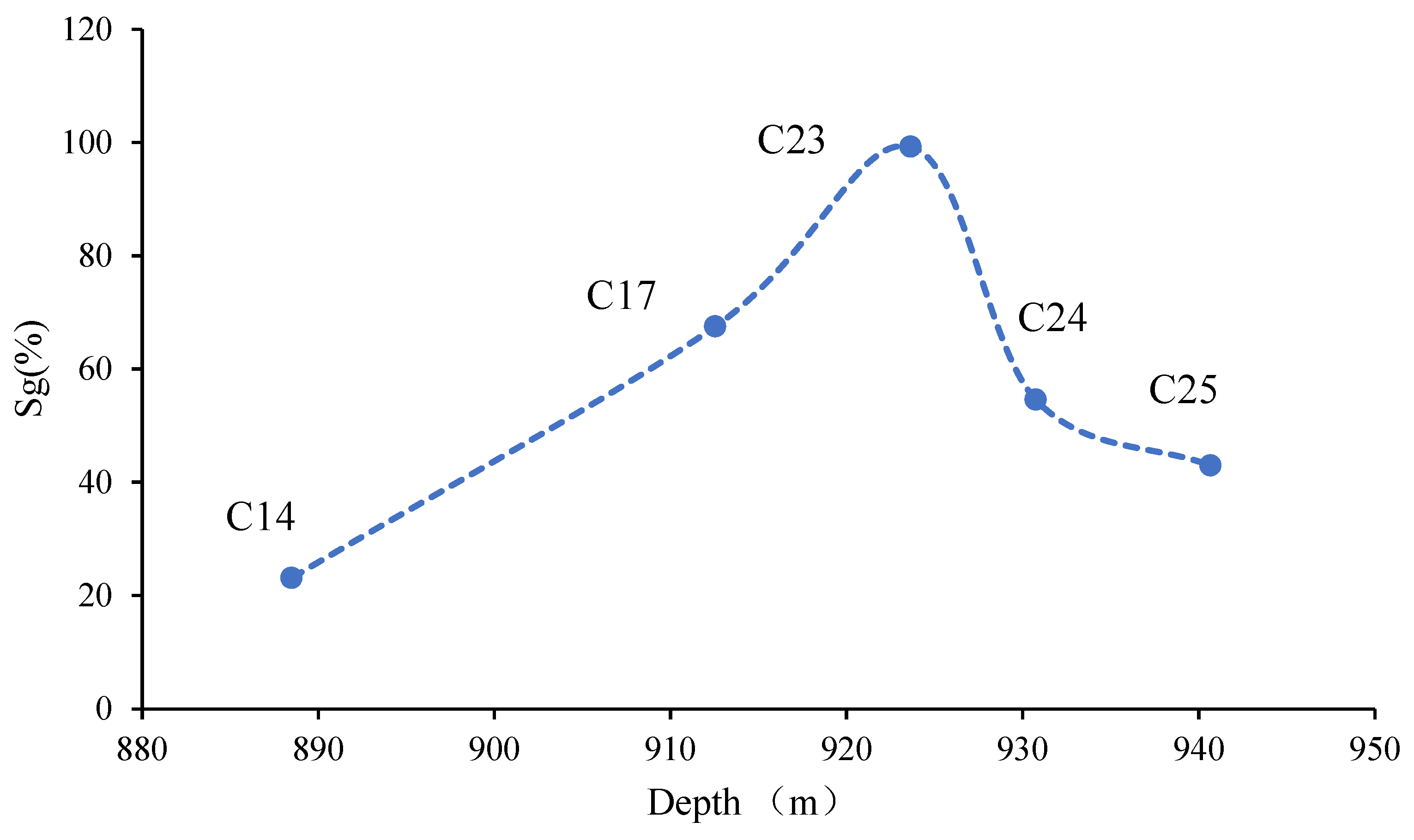

4.3.2. Gas Saturation

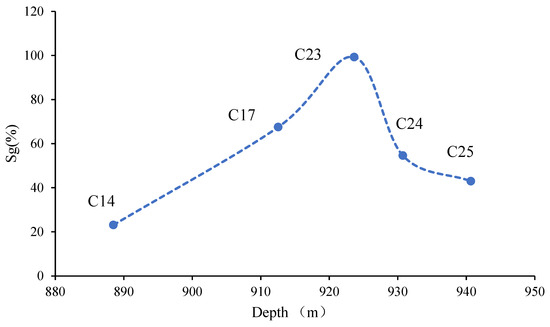

Gas saturation (Sg) refers to the degree to which the pore and fracture spaces of coal reservoirs are filled with adsorbed gas on the surface. It is obtained from the isothermal adsorption curve and is the ratio of the measured gas content to the theoretical gas content corresponding to the original reservoir pressure on the adsorption isotherm curve.

where Sg is the gas saturation of the coal seam (%), Vmeasured is the measured gas content of coal seam (m3/t), VL is the Langmuir volume (m3/t), PL is the Langmuir pressure (MPa), and P is the pressure of coal reservoir (MPa).

According to the coal exploration report of the Dacun exploration area in the Guxu mining area of the Chuannan coalfield in Gulin County, Sichuan Province, the gas saturation of the main coal seam is calculated by taking 45–172 wells as an example (Table 9), and the distribution map of gas saturation is drawn (Figure 11). The results show that the gas saturation of the main coal seam is predominantly in an undersaturated state, with an increasing and then decreasing trend from shallow to deep. Furthermore, the gas saturation in the middle part of the Longtan Formation is better than that in the shallow and deep parts, making it a promising layer for coalbed methane development, mainly concentrated in the C17 coal to C23 coal.

Table 9.

Calculation table of gas saturation in the Longtan Formation in the Guxu area.

Figure 11.

Distribution of gas saturation in the main coal seam of the Longtan Formation, Guxu area.

4.3.3. Gas Composition

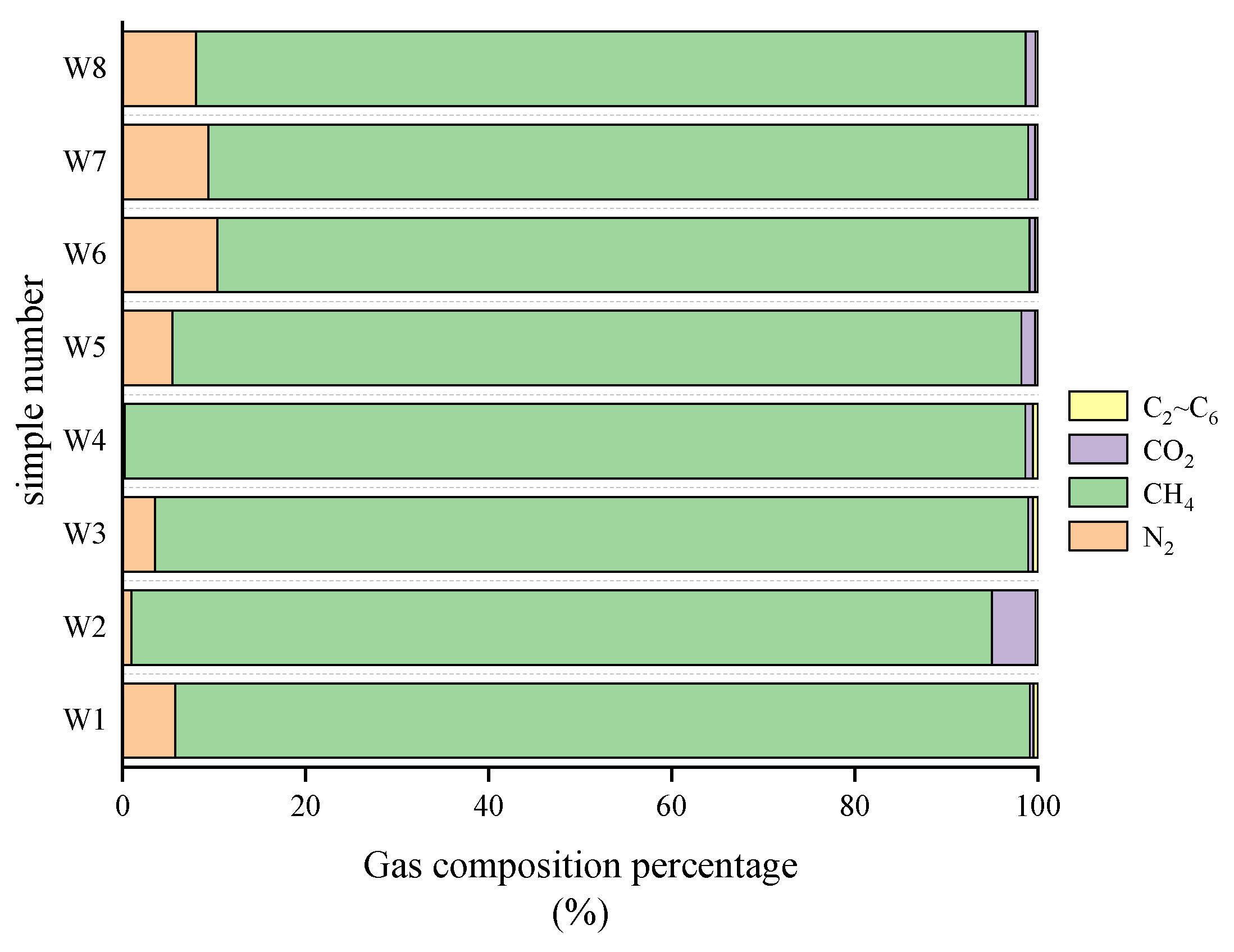

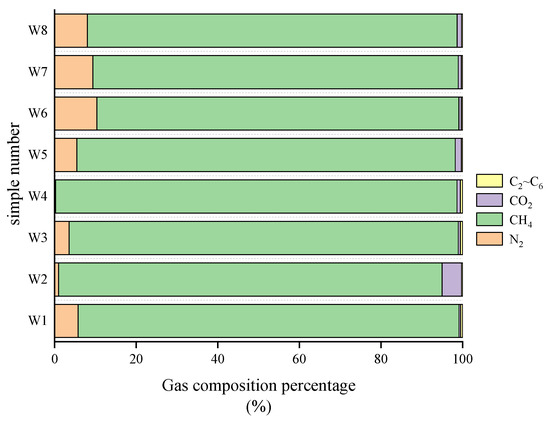

The gas composition of coalbed methane varies significantly with different regions and metamorphic degrees of coal seams. It is mainly composed of CH4, N2, CO2, and C2~C6 (heavy hydrocarbons) and sometimes contains trace amounts of H2S, CO, He, Ar, Hg, etc. In Figure 12, it can be seen that the gas composition of the main coal seam in the study area is dominated by CH4, with volume fractions ranging from 88.72 to 98.38% and averaging 92.86%, followed by N2, with the volume fraction ranging from 0.24% to 10.36% and averaging 5.45%. Meanwhile, the CO2 volume fraction ranged from 0.38% to 4.7%, with an average of 1.29%, and C2 to C6 ranged from 0.3% to 0.57%, with an average of 0.4%. As a result, the study area demonstrates distinct dry gas characteristics.

Figure 12.

Bar chart of different gas component contents in main coal seams of Guxu mining area.

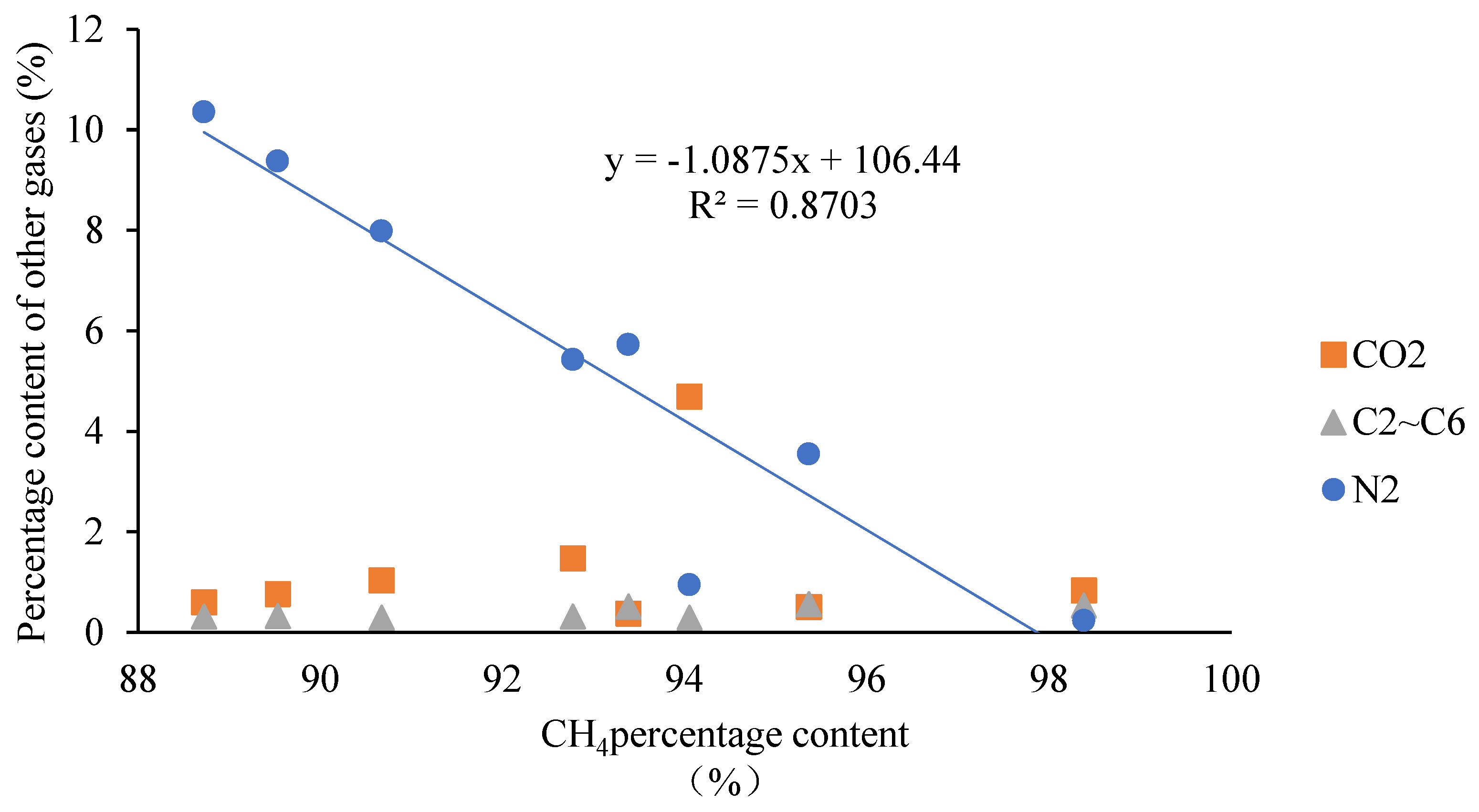

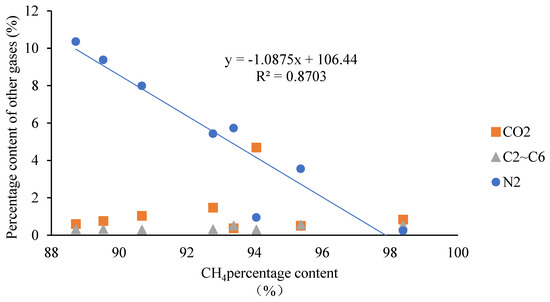

From the fitting trend of the volume fractions between N2, CO2, C2~C6, and CH4 (Figure 13), it can be seen that the N2 volume fraction and CH4 volume fraction of the main coal seam in the study area have a good negative correlation, which shows a reciprocal relationship, reflecting the transformation effect of the atmosphere in the process of coalbed methane accumulation. Also, the volume fractions of CO2 and C2~C6 are relatively small and do not change significantly with the volume fraction of CH4.

Figure 13.

Correlation chart of CH4 and other gas components in main coal seams of Guxu mining area.

Previous studies have suggested that when the volume fraction of CO2 exceeds 60%, it is mainly of an inorganic origin, while when the volume fraction of CO2 is less than 15%, it is mainly of an organic origin. In this study, the volume fraction of CO2 of the main coal seam ranges from 0.38% to 4.7%, indicating that the main coalbed methane in the study area is less affected by inorganic sources of CO2, such as mantle-source genesis and dissolution of carbonate minerals, and most of it is affected by organic genesis, such as the decarboxylation reaction of organic macromolecules and decomposition of organic matter by bacteria.

4.3.4. Coal Seam Water

Based on the water quality test results of the produced water from DC-1, DC-2, and DCMT3 wells in the study area (Table 10), and combined with the isotopic composition data of water, the source and storage of water in the underground coal seams can be determined [26].

Table 10.

Results of coal seam produced water quality from DC-1, DC-2, and DC-MT3 wells in the Guxu area.

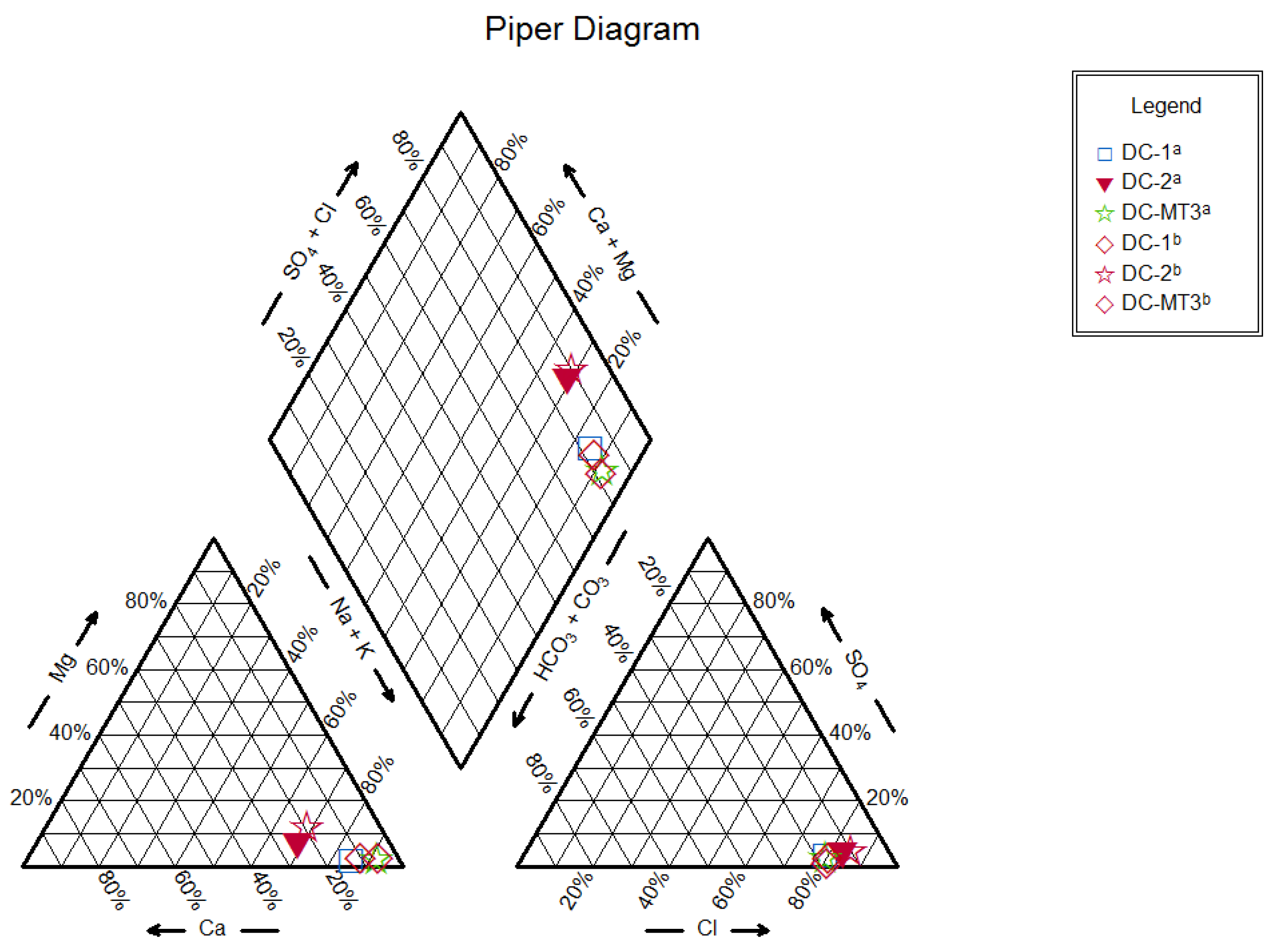

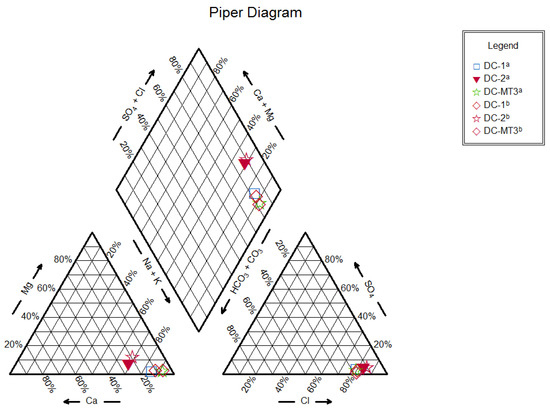

In Table 10, it is known that the pH value of the produced water in the study area is between 7.47 and 7.59, which belongs to weakly alkaline water, and the variation range of the acidity and alkalinity value (pH) is not large. Moreover, the salinity ranges from 2059.01 mg/L to 4674.75 mg/L, with an average of 2968.67 mg/L, and is classified as slightly saline or saline water. The higher salinity degree indicates that the overlying layers with better sealing properties prevent vertical infiltration and supply of groundwater, resulting in the slow flow of groundwater from the coal reservoir in the study area. And it is basically in the stagnant zone or alternating stagnant–runoff zone, which has not been severely damaged and is in a reducing environment. However, the total hardness varies greatly, ranging from 261.32 mg/L to 620.26 mg/L. The contents of alkali metal ions in water, such as Ca2+ and Mg2+, are high, mainly due to the permanent hardness formed by salts such as sulfates and chlorides containing calcium and magnesium ions. A small amount of hardness formed by bicarbonates containing calcium and magnesium ions and the temporary hardness formed by small amounts of carbonates indicate that although the coal reservoir is generally in a stagnant flow zone of the reducing environment, there is a certain degree of lateral runoff recharge.

The Piper trilinear diagram is expressed as the percentage of three major groups of anions (SO42−, Cl−, and HCO3−) and cations (Ca2+, Na+ + K+, and Mg2+) in milligram equivalents per liter, which is shown in Figure 14. Therefore, the source of coal-bearing formation water in the Longtan Formation was determined by the milliequivalent percentage of respective anions and cations. As shown in Figure 15, it can be concluded that the produced water of coal seams in the study area is of the Na-HCO3 or Na-HCO3-Cl type.

Figure 14.

Piper diagram of water quality types in the Guxu area.

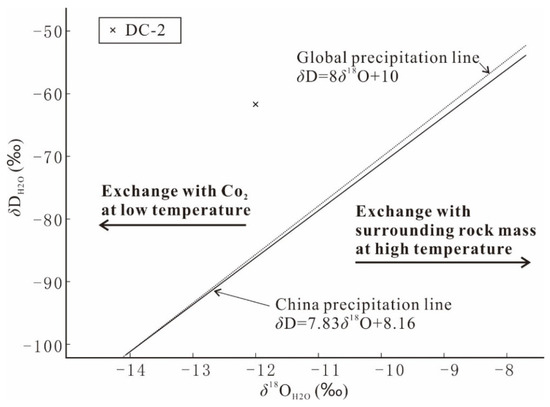

Figure 15.

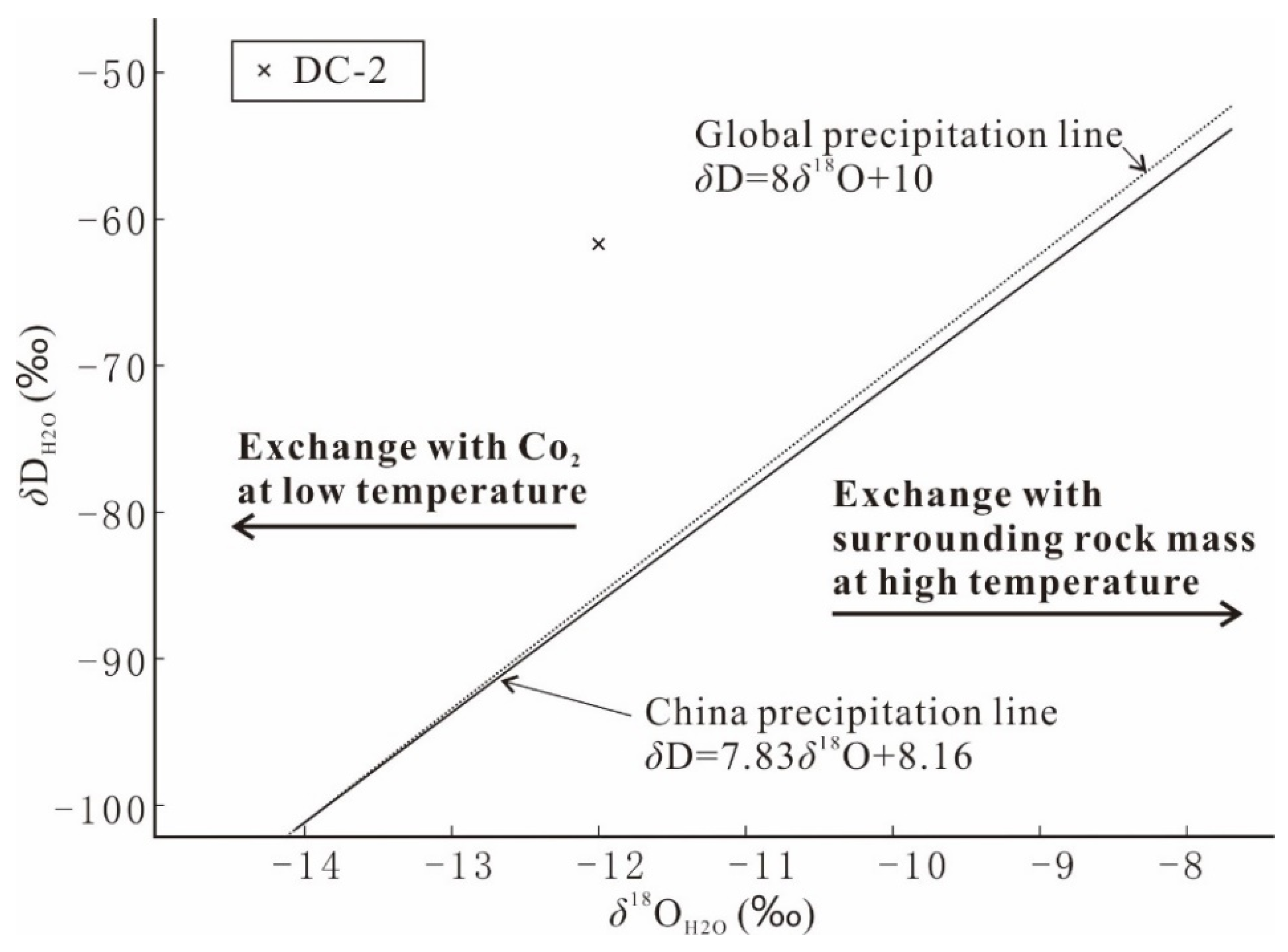

δD and δ18O relationship diagram (modified from Clark and Fritz, 1997 [27]).

The hydrogen and oxygen isotope δD and δ18O of produced water in DC-2 well are −61.6‰ and −12.0‰, respectively. Based on the global precipitation line (δD = 8δ18O + 10) obtained by Clark and Fritz in 1997 [27] and the precipitation line equation for China (δD = 7.83δ18O + 8.16), the obtained data from DC-2 well were projected onto two curves, as shown in Figure 15. It can be concluded that the produced water of the coal seam in DC-2 well is not derived from atmospheric precipitation, but is ancient-formation water. Therefore, it is basically consistent with the results of the produced water quality analysis above, indicating that the study area is generally in a stagnant flow zone, but with some degree of runoff recharge.

5. Conclusions

In this study, the reservoir development characteristics and physical properties of the main coal seams in the Guxu mining area of the Southern Sichuan coalfield were described in detail, and the origin of coalbed methane was also analyzed. The following conclusions are drawn:

- (1)

- Based on the high-pressure mercury intrusion experiment and low-temperature liquid nitrogen experiments, the results reveal that two types of pore structures are developed in the reservoir. One type mainly consists of semi-sealed impermeable pores, while the other type is dominated by open slot-like pores with cylindrical pores opening at both ends. Moreover, the second type of reservoir pore structure is preferable to the desorption and diffusion of coalbed methane.

- (2)

- The Langmuir volume of the main coal seams ranges from 10.08 m3/t to 25.75 m3/t, and the Langmuir pressure ranges from 0.99 MPa to 1.59 MPa. Overall, the main coal seams have a strong adsorption capacity, and the strongest adsorption capacity is mainly concentrated in the middle part of the Longtan Formation, which is a favorable stratum for coalbed methane.

- (3)

- The gas content of the main coal seams gradually increases from shallow to deep, reaches a peak, and then gradually decreases. The coal seams with the highest gas content are mainly concentrated in the middle part of the Longtan Formation. Meanwhile, the gas saturation is mainly in the undersaturated state, which shows the process of increasing and then decreasing from shallow to deep, and the central part is an advantageous layer for coalbed methane development.

- (4)

- The pH value of produced water in the study area ranges from 7.47 to 7.59, and the salinity ranges from 2059.01 mg/L to 4674.75 mg/L, belonging to the type of Na-HCO3 or Na-HCO3-Cl. And the hydrogen and oxygen isotopes δD is −61.6‰ and δ18O is −12.0‰, indicating that the study area is generally in a stagnant zone, with local recharge and good storage conditions [1].

Author Contributions

Conceptualization, Y.Z. (Yinde Zhang) and W.Z.; data curation, Y.Z. (Yinde Zhang) and J.H.; formal analysis, Y.Z. (Yufa Zhang); methodology, Y.Z. (Yufa Zhang) and J.H.; project administration, Y.Z. (Yinde Zhang); resources, Y.Z. (Yinde Zhang); validation, Y.Z. (Yufa Zhang), Y.Z. (Yinde Zhang) and J.H.; writing—original draft, Y.Z. (Yufa Zhang); writing—review and editing, Y.Z. (Yinde Zhang). All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Qin, Y. Progress on geological research of deep coalbed methane in China. Acta Pet. Sin. 2023, 44, 1791–1811. [Google Scholar]

- Kędzior, S. Distribution of methane contents and coal rank in the profiles of deep boreholes in the Upper Silesian Coal Basin, Poland. Int. J. Coal Geol. 2019, 202, 190–208. [Google Scholar] [CrossRef]

- Fu, X.; Zhang, X.; Wei, C. Review of research on testing, simulation and prediction of coalbed methane content. J. China Univ. Min. Technol. 2021, 50, 13–31. [Google Scholar]

- Liu, D.; Jia, Q.; Cai, Y. Research progress on coalbed methane reservoir geology and characterization technology in China. Coal Sci. Technol. 2022, 50, 196–203. [Google Scholar]

- Bi, C.; Hu, Z.; Tang, D.; Tao, S.; Zhang, J.; Tang, S.; Huang, H.; Tang, Y.; Yuan, Y.; Xu, Y.; et al. Research progress of coal measure gas and some important scientific problems. Geol. China 2021, 48, 402–423. [Google Scholar]

- Xu, F.; Nie, Z.; Sun, W.; Wang, L.; Zhang, Q.; Li, J. Efficient development theory and technology system of deep coalbed methane in Daning-Jixian block. J. China Coal Soc. 2023, in press. [Google Scholar]

- Qin, Y.; Shen, J.; Li, X. Control degree and reliability of CBM resources in China. Nat. Gas Ind. 2022, 42, 19–32. [Google Scholar]

- Yin, Z.; Zhang, G.; Liu, J.; Gu, Z.; Ye, H. Coal-measure gas reservoir characteristics and geophysical exploration method of Longtan formation in south Sichuan area. Geophys. Prospect. Pet. 2023, 62, 56. [Google Scholar]

- Bao, Y.; An, C.; Ju, Y.; Yin, Z.; Xiong, J.; Wang, W. Constraints of methane absorbability in the Upper Permian Longtan Formation of Well DC-5 in Guxu mine area of southern Sichuan Coalfield. Nat. Gas Geosci. 2020, 31, 93–99. [Google Scholar]

- Zhao, W.; Yin, Z.; Xiao, J.; Li, Y.; Huang, J.; Xiong, J. Research and application of favorable area evaluation methods for multi-coalbed coalbed methane. China Coalbed Methane 2018, 15, 8–13. [Google Scholar]

- Tang, S.; Tang, J.; Shi, Y.; Lv, D. Thermal maturation-hydrocarbon generation history and gas genesis of Longtan Formation coal seams in Guxu mining area, southern Sichuan Coalfield. J. Xi’an Univ. Sci. Technol. 2021, 41, 298–306. [Google Scholar]

- Zhang, Y.; Ran, M.; Li, D.; Li, M.; Shao, L. Evaluation of Coal Reservoir Characteristics in Chajiaotan Wellfield, Guxu Mining Area, Southern Sichuan Coalfield. In Proceedings of the 7th National Conference on Youth Technical Innovation in Coal Industry Production Frontline, Shou Zhou, China, 22 October 2012. [Google Scholar]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Barrett, E.P.; Joyner, L.G.; Halenda, P.P. The Determination of Pore Volume and Area Distributions in Porous Substances. I. Computations from Nitrogen Isotherms. J. Am. Chem. Soc. 1951, 73, 373–380. [Google Scholar] [CrossRef]

- Joyner, L.G.; Barrett, E.P.; Skold, R. The Determination of Pore Volume and Area Distributions in Porous Substances. II. Comparison between Nitrogen Isotherm and Mercury Porosimeter Methods. J. Am. Chem. Soc. 1951, 73, 3155–3158. [Google Scholar] [CrossRef]

- Yang, F.; Ning, Z.; Kong, D.; Liu, H. Pore Structure of Shales from High Pressure Mercury Injection and Nitrogen Adsorption Method. Nat. Gas Geosci. 2013, 24, 450–455. [Google Scholar]

- Tian, H.; Zhang, S.; Liu, S.; Zhang, H. Determination of organic-rich shale pore features by mercury injection and gas adsorption methods. Acta Pet. Sin. 2012, 33, 419–427. [Google Scholar]

- Qin, L.; Lin, H.; Lan, S.; Zhao, P.; Yan, M. Experimental study on coal gas adsorption characteristics under action of low temperature liquid nitrogen. Coal Sci. Technol. 2020, 48, 105–112. [Google Scholar]

- Zeng, P.; Zhang, D.; Yan, X.; Song, L.; Wang, X. Study on gas adsorption and diffusion characteristics of intact coal and tectonic coal. Min. Saf. Environ. Prot. 2023, 50, 36–41. [Google Scholar]

- Ma, X.; Wang, Z.; Haoyang, R.E.N. Response Characteristics of coal adsorbing CH4 capability under variation of temperature and pressure. Saf. Coal Mines 2016, 47, 8–11. [Google Scholar]

- Langmuir, I. the constitution and fundamental properties of solids and liquids. II. liquids.1. J. Am. Chem. Soc. 1917, 39, 1848–1906. [Google Scholar] [CrossRef]

- Hao, X.; Han, S.; Yang, L.; Dai, Y.; Huang, L.; Wang, J. Effect of Organic Matter in Water Samples on the Hydrogen Stable Isotope Ratio Determination by Thermal Conversion/Elemental Analysis-Isotope Ratio Mass Spectrometry. Rock Miner. Anal. 2019, 38, 503–509. [Google Scholar]

- Hodot, B. Outburst of Coal and Coalbed Gas (Chinese Translation); China Coal Industry Press: Beijing, China, 1966; p. 318. [Google Scholar]

- Yu, Y.; Wang, Y.; Yang, Q.; Liu, D.; Hu, B.; Huang, W.; Che, Y. Adsorption characteristics of low-rank coal reservoirs and coalbed methane development potential, Junggar Basin. Pet. Explor. Dev. 2008, 35, 410–416. [Google Scholar]

- Liu, B.; Huang, W.; Ao, W.; Zhang, S.; Wu, J.; Xu, Q.; Teng, J. Adsorption capacity of high-rank coal and its influencing factors:taking Shizhuang block of Qinshui Basin as an example. J. Xi’an Shiyou Univ. 2014, 29, 31–37. [Google Scholar]

- Yang, Z.; Wu, C.; Zhu, J.; Li, Y.; Qin, Z. Research progress on produced water geochemical from CBM wells in China. Coal Sci. Technol. 2019, 47, 110–117. [Google Scholar]

- Clark, I.; Fritz, P. Environmental Isotopes in Hydrogeology Lewis. Available online: https://www.researchgate.net/publication/201169434_Environmental_Isotopes_in_Hydrogeology_Lewis (accessed on 26 March 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).