Experimental Assessment of Suitability of Darrieus and Savonius Turbines for Obtaining Wind Energy from Passing Vehicles

Abstract

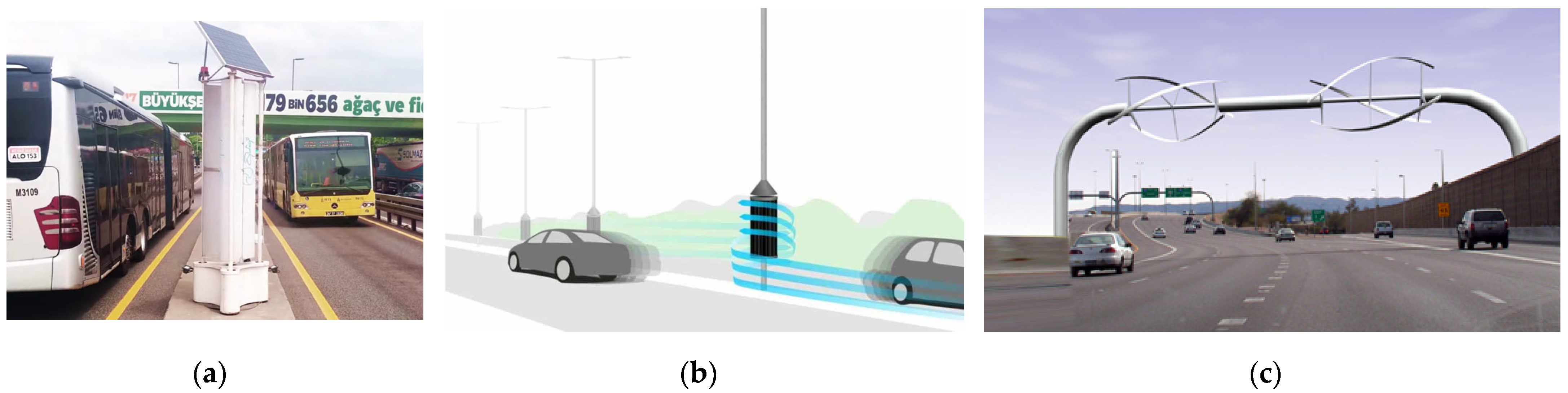

1. Introduction

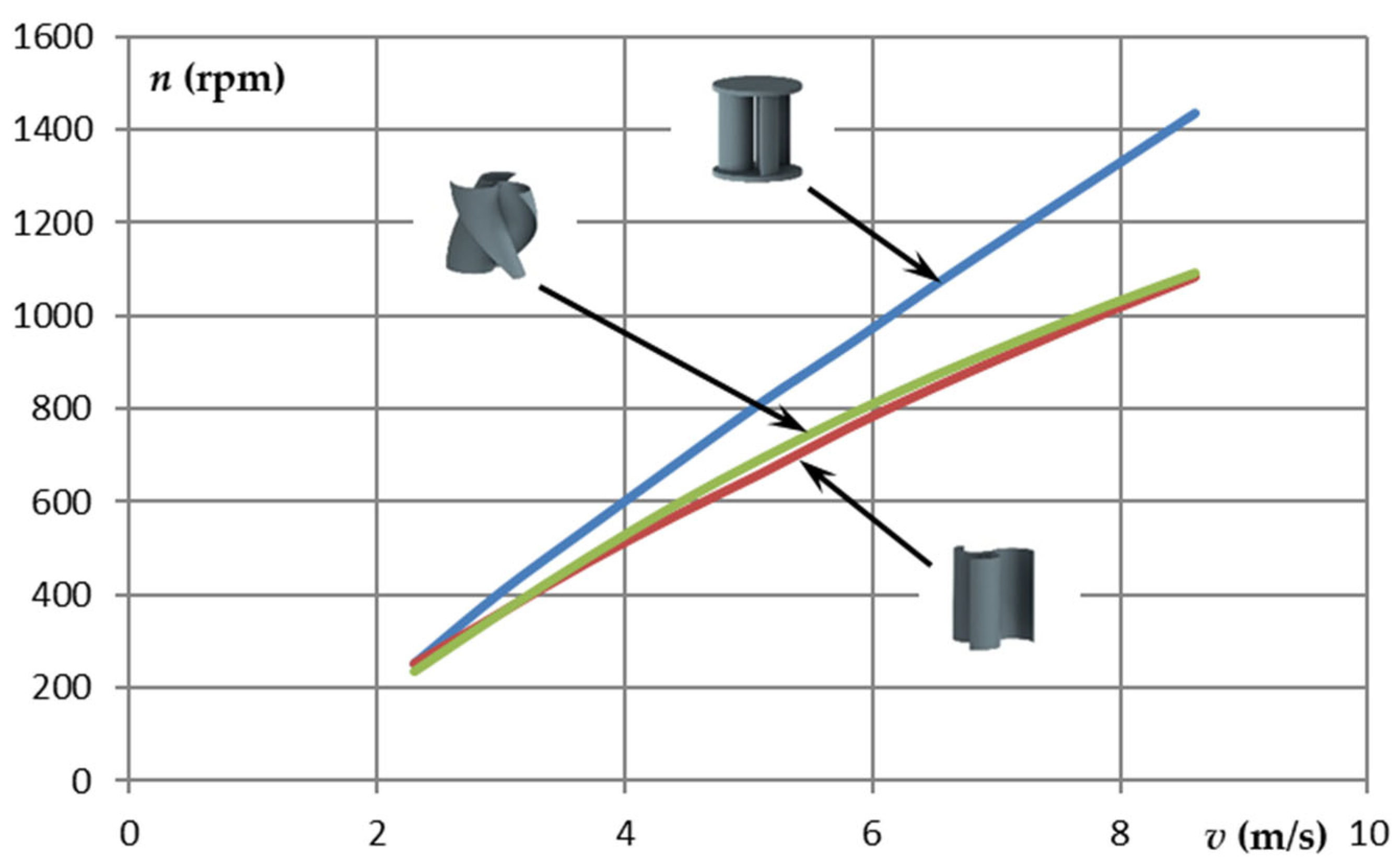

2. Materials and Methods

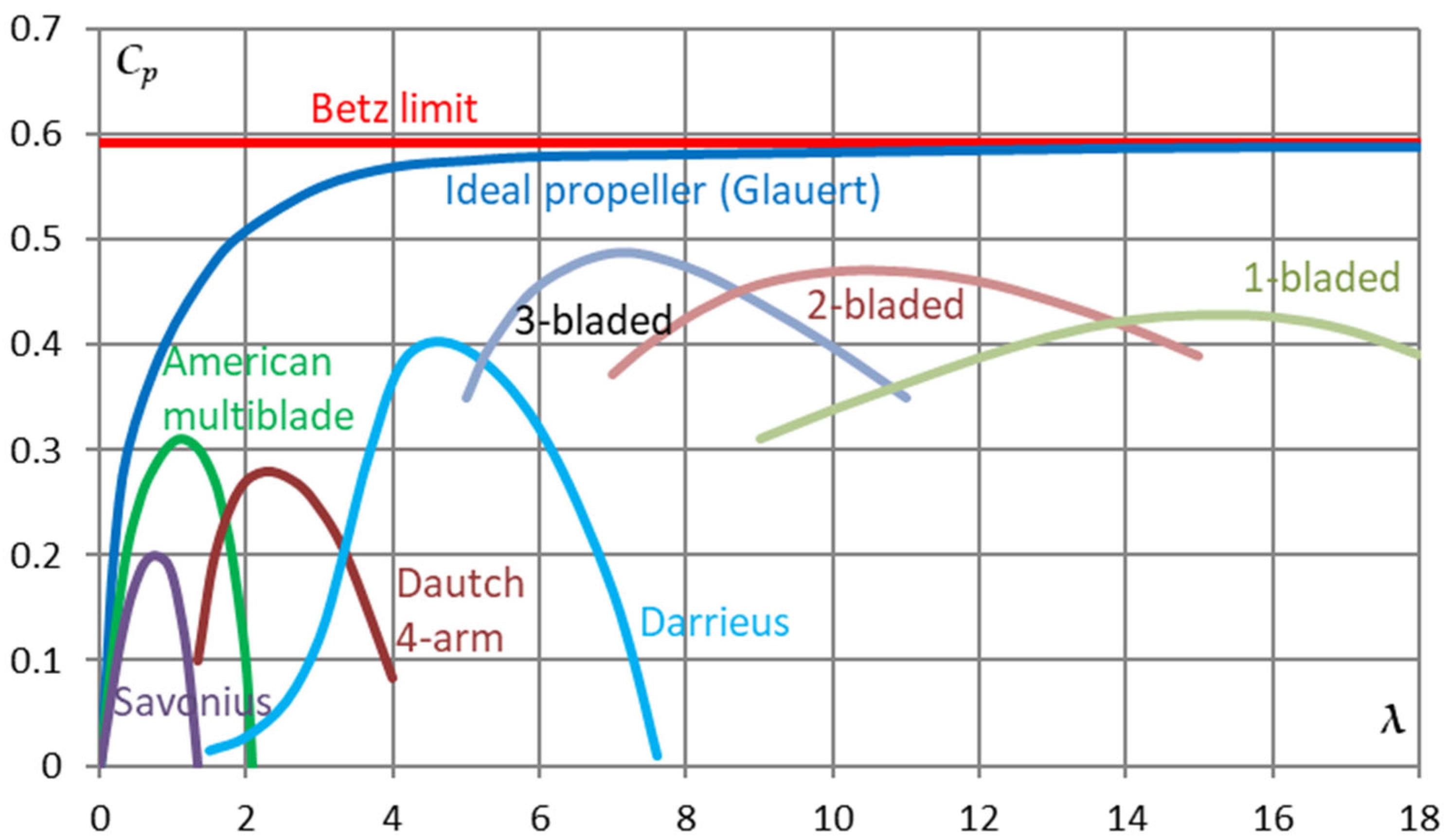

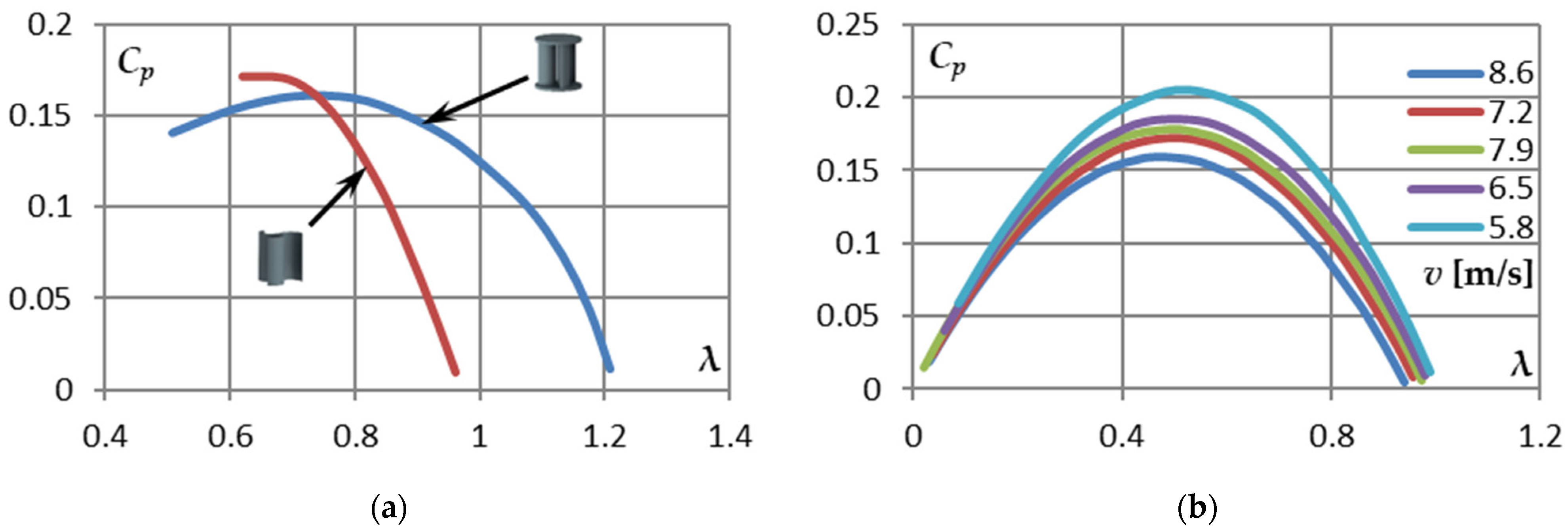

2.1. Wind Turbine Parameters

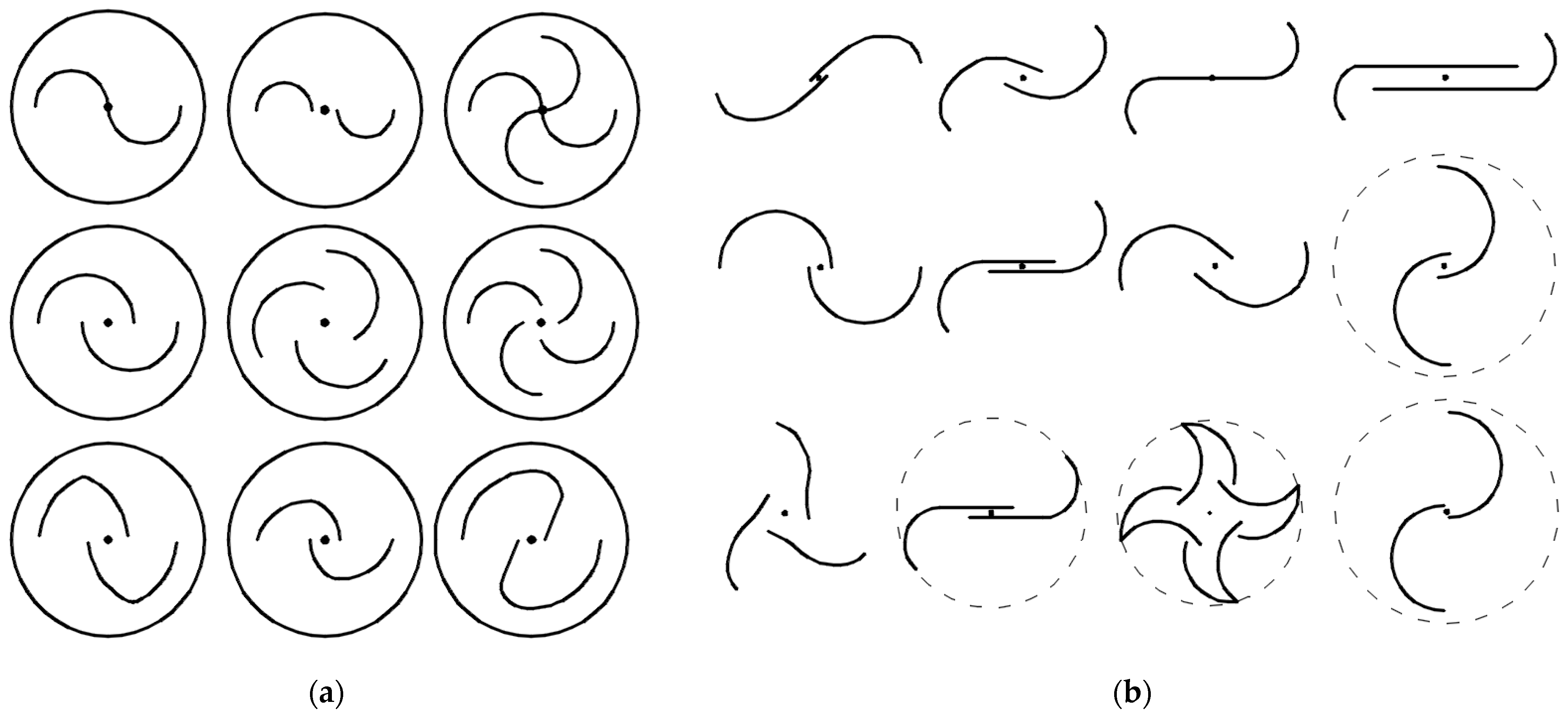

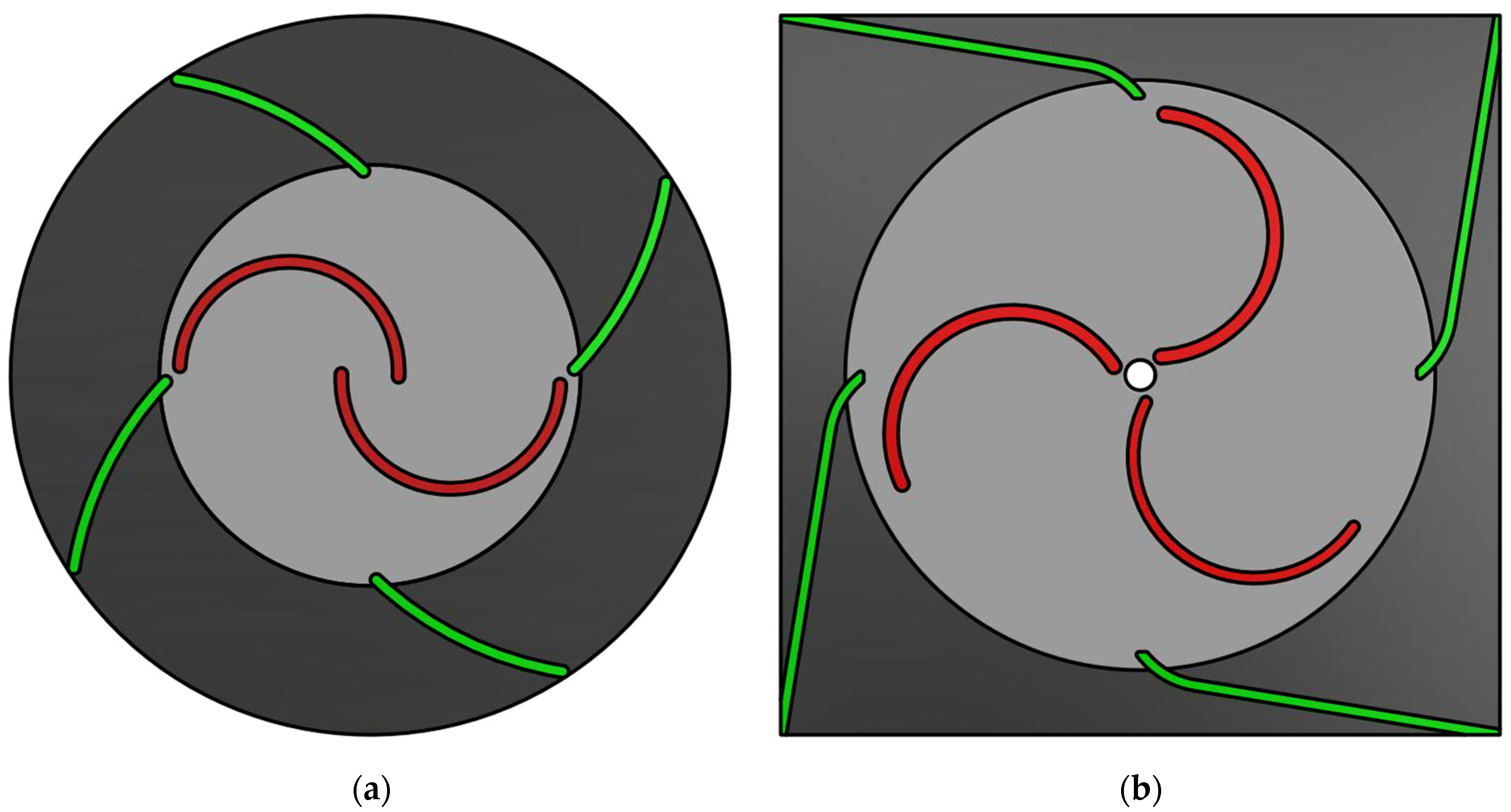

2.2. Wind Turbine Designs

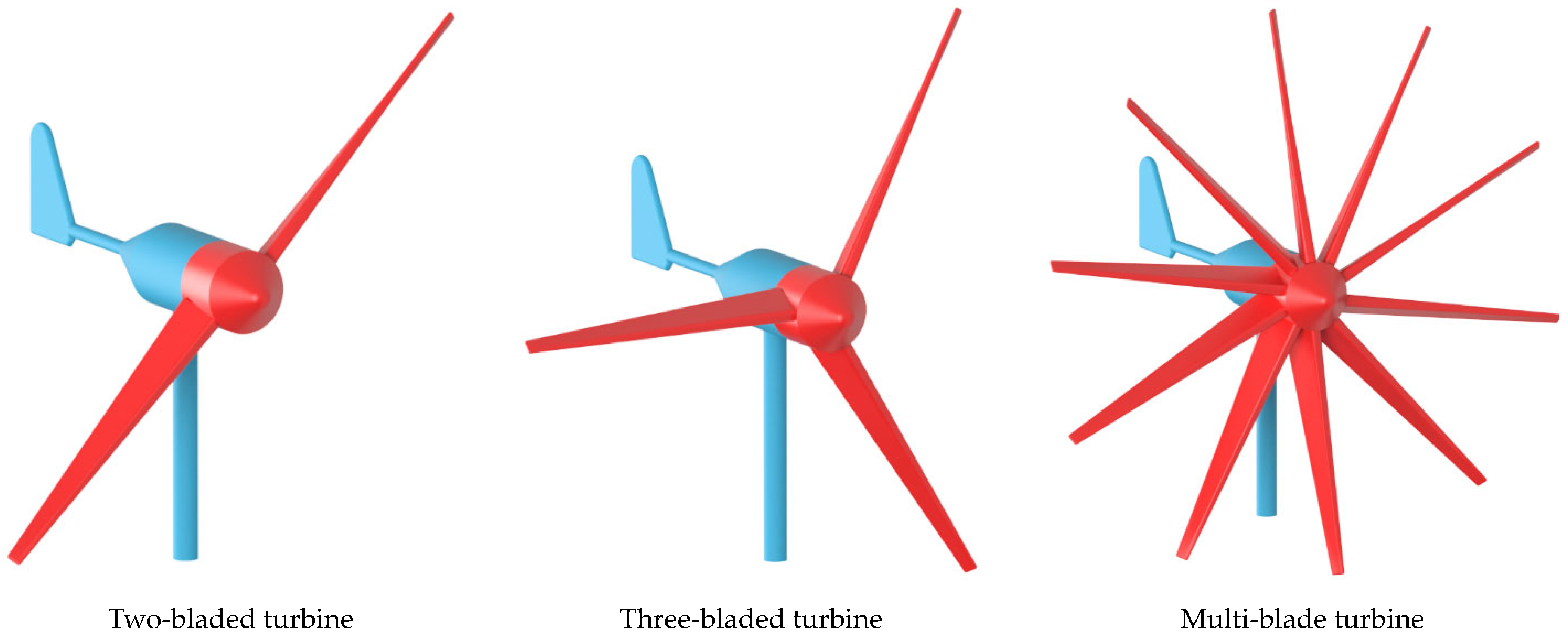

2.2.1. Horizontal Axis Wind Turbines

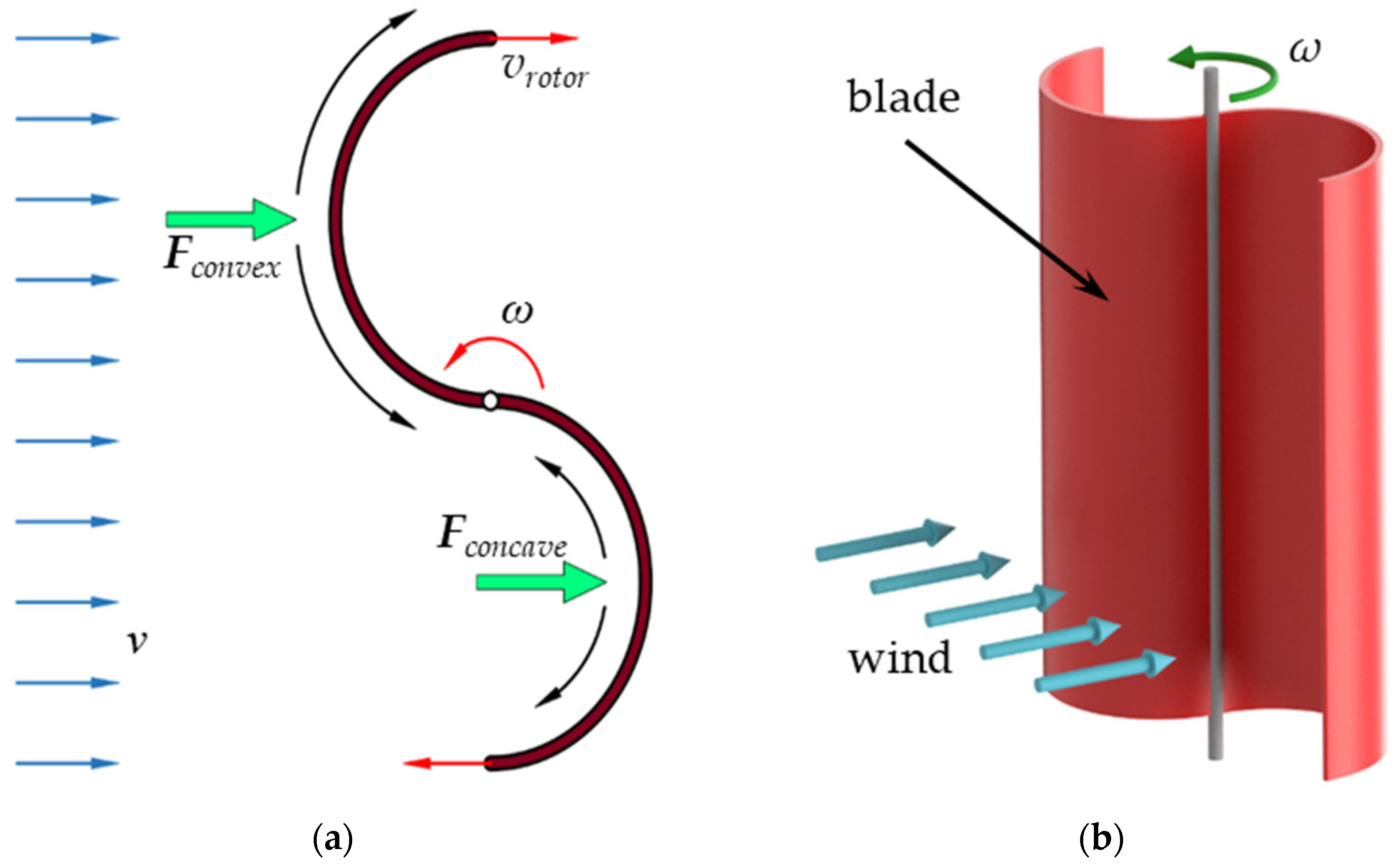

2.2.2. Vertical Axis Wind Turbines

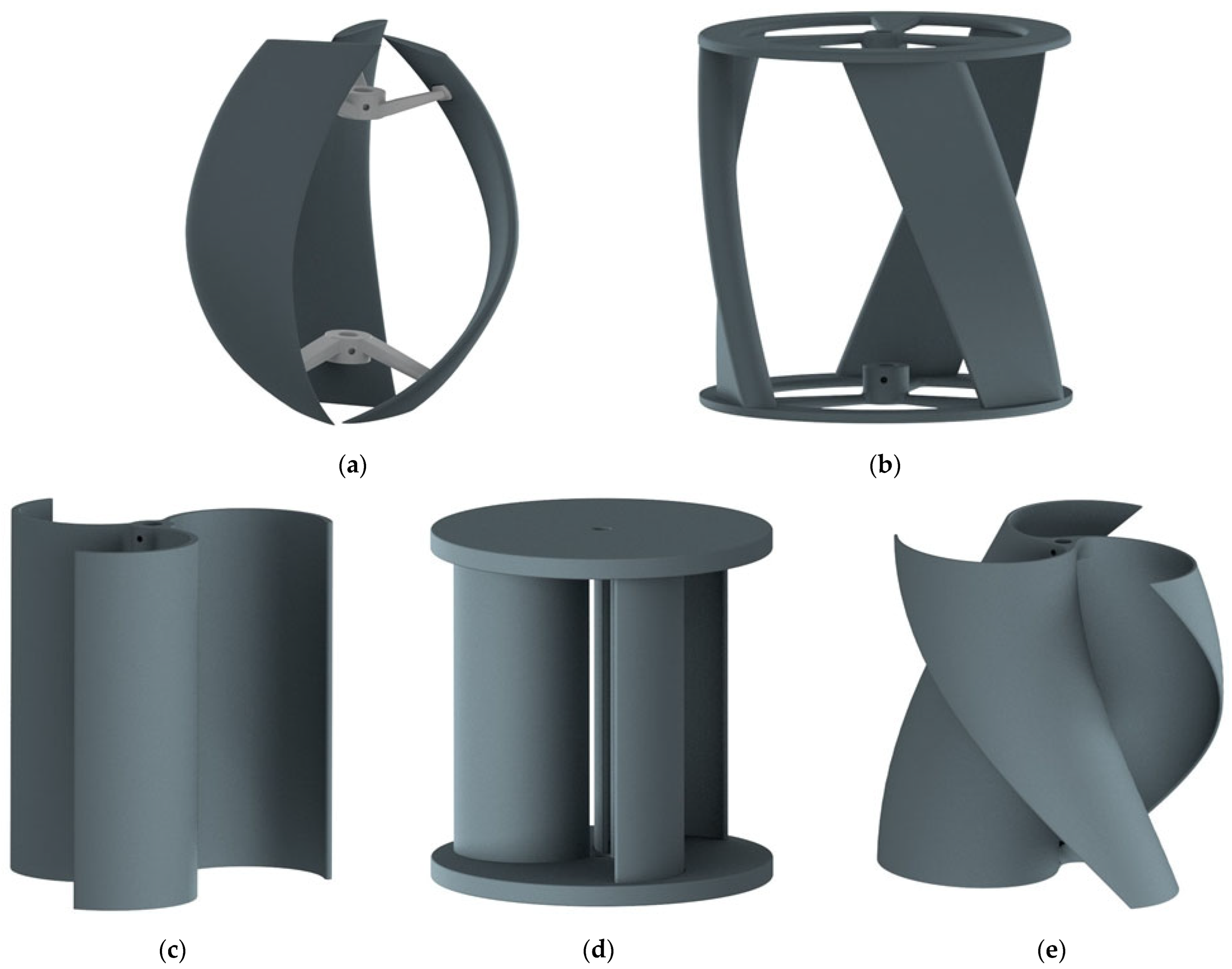

2.3. Turbine Designs Considered in Investigations

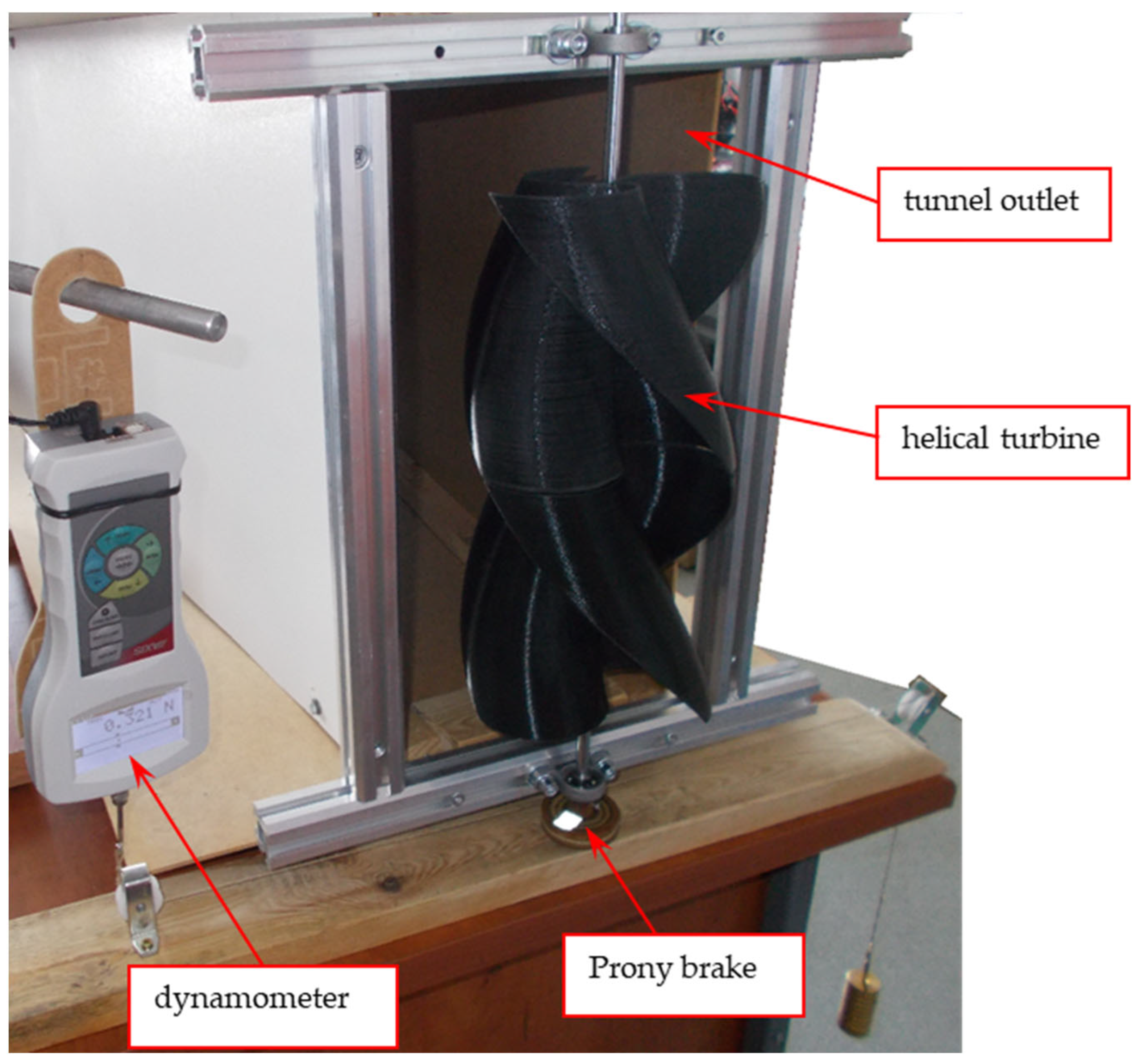

2.4. Test Stand Used in Investigations

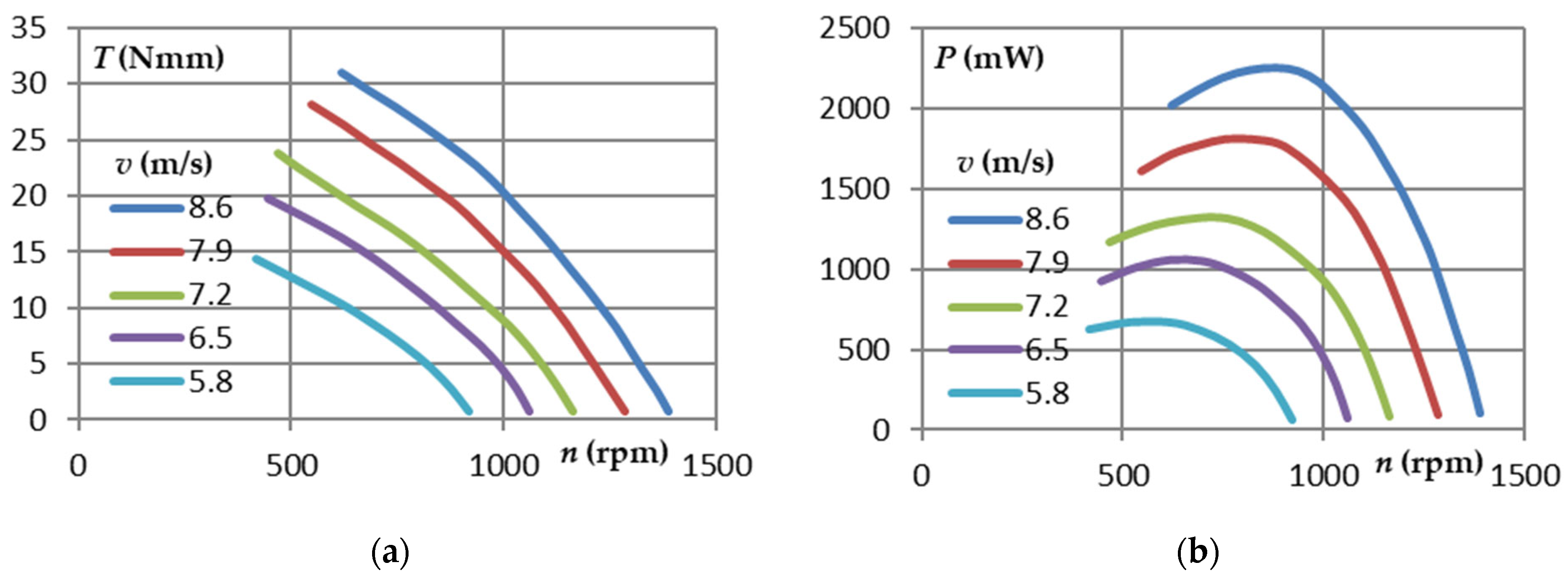

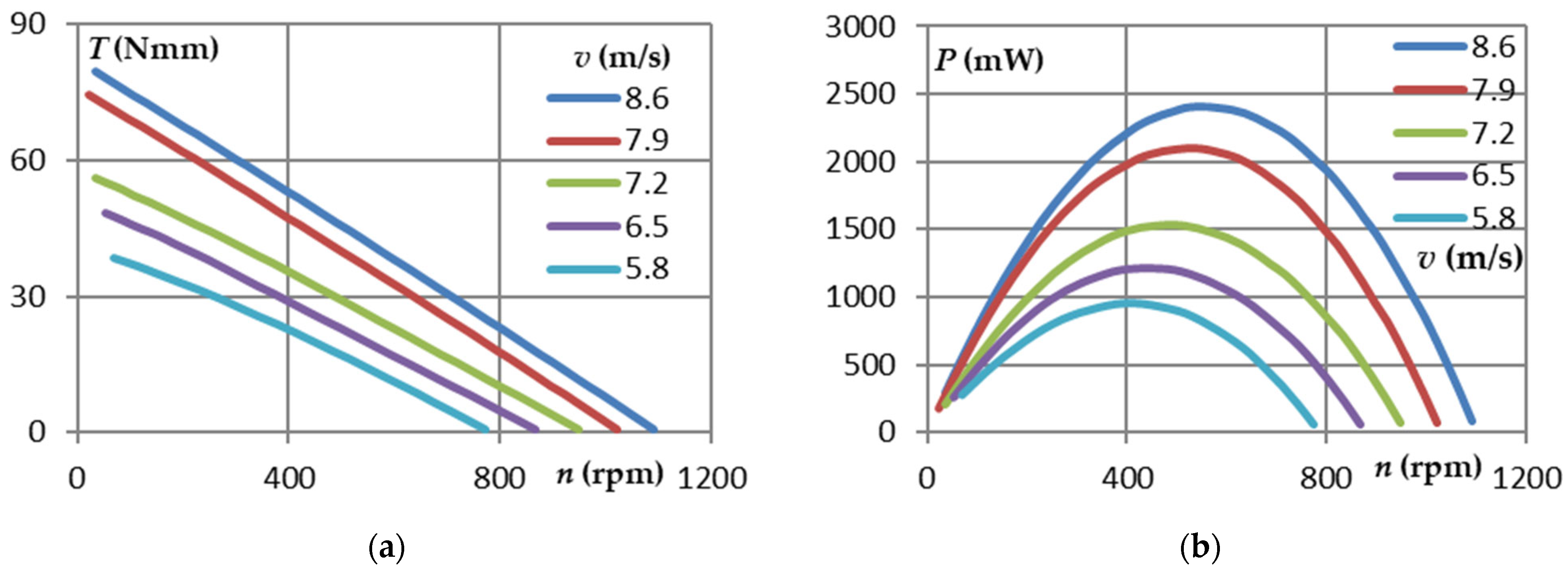

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kamoji, M.A.; Kedare, S.B.; Prabhu, S.V. Performance Tests on Helical Savonius Rotors. Renew. Energy 2009, 34, 521–529. [Google Scholar] [CrossRef]

- Ricci, R.; Romagnoli, R.; Montelpare, S.; Vitali, D. Experimental Study on a Savonius Wind Rotor for Street Lighting Systems. Appl. Energy 2016, 161, 143–152. [Google Scholar] [CrossRef]

- Sundaram, A.; Almobasher, L. Implementation of a Highway Wind Power Generation Using Vertical Axis Wind Turbine to Automatically Power a Street Lamp. Wind. Eng. 2020, 45, 1176–1192. [Google Scholar] [CrossRef]

- ENLIL Vertical Axis Wind Turbine|Smart City. Available online: http://okosvaros.lechnerkozpont.hu/en/node/703 (accessed on 2 February 2024).

- Wind Turbines Attached to Lamp Posts Generate Electricity via Traffic. Available online: https://www.intelligentliving.co/wind-turbines-lamp-posts/ (accessed on 2 February 2024).

- Student Design Turns Highways into Wind Farms. Available online: https://inhabitat.com/student-designs-highway-power/ (accessed on 2 February 2024).

- Tian, W.; Mao, Z.; Li, Y. Numerical Simulations of a VAWT in the Wake of a Moving Car. Energies 2017, 10, 478. [Google Scholar] [CrossRef]

- Lapointe, C.; Gopalan, H. Numerical Investigation of Mini Wind Turbines Near Highways. J. Sol. Energy Eng. 2016, 138, 024503. [Google Scholar] [CrossRef]

- Hegde, S.S.; Thamban, A.; Bhai, S.P.M.; Ahmed, A.; Upadhyay, M.; Joishy, A.; Mahalingam, A. Highway Mounted Horizontal Axial Flow Turbines For Wind Energy Harvesting From Cruising Vehicles. In Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 14 November 2016; pp. 1–9. [Google Scholar]

- Tian, W.; Mao, Z.; An, X.; Zhang, B.; Wen, H. Numerical Study of Energy Recovery from the Wakes of Moving Vehicles on Highways by Using a Vertical Axis Wind Turbine. Energy 2017, 141, 715–728. [Google Scholar] [CrossRef]

- Lee, O.; Baby, D. Optimising Highway Energy Harvesting: A Numerical Simulation Study on Factors Influencing the Performance of Vertical-Axis Wind Turbines. Energies 2023, 16, 7245. [Google Scholar] [CrossRef]

- Bani-Hani, E.H.; Sedaghat, A.; AL-Shemmary, M.; Hussain, A.; Alshaieb, A.; Kakoli, H. Feasibility of Highway Energy Harvesting Using a Vertical Axis Wind Turbine. Energy Eng. 2018, 115, 61–74. [Google Scholar] [CrossRef]

- Toudarbari, S.; Maghrebi, M.; Hashemzadeh, A. Evaluation of Darrieus Wind Turbine for Different Highway Settings Using CFD Simulation. Sustain. Energy Technol. Assess. 2021, 45, 101077. [Google Scholar] [CrossRef]

- Tian, W.; Song, B.; Mao, Z. Numerical Investigation of Wind Turbines and Turbine Arrays on Highways. Renew. Energy 2020, 147, 384–398. [Google Scholar] [CrossRef]

- Hu, W.; E, J.; Deng, Y.; Li, L.; Han, D.; Zhao, X.; Zhang, Z.; Peng, Q. Effect Analysis on Power Coefficient Enhancement of a Convective Wind Energy Collecting Device in the Expressway. Energy Convers. Manag. 2018, 171, 249–271. [Google Scholar] [CrossRef]

- Venkatesh, P.; Babu, A.R.V.; Suresh, K. Experimental Investigations on Modified Savonius Wind Turbine with Curtain Arrangements in the Middle of the Highway. Eur. J. Electr. Eng. 2018, 20, 139–150. [Google Scholar] [CrossRef]

- Michna, M.; Blecharz, K.; Kostro, G.; Kutt, F.; Ryndzionek, R. Development and Performance Analysis of a Novel Multiphase Doubly-Fed Induction Generator. Arch. Electr. Eng. 2022, 71, 1003–1015. [Google Scholar] [CrossRef]

- Bai, C.; Song, Y.; He, G.; Yin, X.; Liu, H. A Dual-Stator Brushless Doubly-Fed Generator for Wind Power Application. Arch. Electr. Eng. 2023, 72, 1073–1087. [Google Scholar] [CrossRef]

- Jabal Laafou, A.; Abdessalam, A.M.; Addaim, A.; Moumani, Y. A Comparative Study Based on Proportional Integral and Backstepping Controllers for Doubly Fed Induction Generator Used in Wind Energy Conversion System. Arch. Electr. Eng. 2023, 72, 211–228. [Google Scholar] [CrossRef]

- Betz, A. Introduction to the Theory of Flow Machines; Pergamon Press: Oxford, UK, 1966. [Google Scholar]

- Ragheb, M.; Ragheb, A.M. Wind Turbines Theory-The Betz Equation and Optimal Rotor Tip Speed Ratio. In Fundamental and Advanced Topics in Wind Power; IntechOpen: London, UK, 2011; ISBN 978-953-307-508-2. [Google Scholar]

- Hau, E. Wind Turbines: Fundamentals, Technologies, Application, Economics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; ISBN 978-3-642-27151-9. [Google Scholar]

- Castillo, O.C.; Andrade, V.R.; Rivas, J.J.R.; González, R.O. Comparison of Power Coefficients in Wind Turbines Considering the Tip Speed Ratio and Blade Pitch Angle. Energies 2023, 16, 2774. [Google Scholar] [CrossRef]

- Manwell, J.F.; McGowan, J.G.; Rogers, A.L. Wind Energy Explained: Theory, Design and Application; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 978-0-470-68628-7. [Google Scholar]

- Eriksson, S.; Bernhoff, H.; Leijon, M. Evaluation of Different Turbine Concepts for Wind Power. Renew. Sustain. Energy Rev. 2008, 12, 1419–1434. [Google Scholar] [CrossRef]

- Schubel, P.J.; Crossley, R.J. Wind Turbine Blade Design Review. Wind. Eng. 2012, 36, 365–388. [Google Scholar] [CrossRef]

- Bazilevs, Y.; Hsu, M.-C.; Akkerman, I.; Wright, S.; Takizawa, K.; Henicke, B.; Spielman, T.; Tezduyar, T.E. 3D Simulation of Wind Turbine Rotors at Full Scale. Part I: Geometry Modeling and Aerodynamics. Int. J. Numer. Methods Fluids 2011, 65, 207–235. [Google Scholar] [CrossRef]

- Hansen, M. Aerodynamics of Wind Turbines, 3rd ed.; Routledge: London, UK, 2015; ISBN 978-1-315-76998-1. [Google Scholar]

- Spera, D.A. Wind Turbine Technology: Fundamental Concepts of Wind Turbine Engineering; ASME Press: New York, NY, USA, 2009; ISBN 978-0-7918-0260-1. [Google Scholar]

- Bertagnolio, F.; Sørensen, N.; Johansen, J.; Fuglsang, P. Wind Turbine Airfoil Catalogue; Riso National Laboratory: Roskilde, Denmark, 2001. [Google Scholar]

- Hansen, M.O.L. Aerodynamics of Wind Turbines: Rotors, Loads and Structure; James & James Ltd.: London, UK, 2000; ISBN 1-902916-06-9. [Google Scholar]

- Innovative Technology SYLWAN Company. SWT-Smart Wind Turbine. Diffuser Wind Turbine. Available online: https://docplayer.pl/6154845-Innowacyjna-technologia-zastosowanie-dyfuzora-swt-smart-wind-turbine-dyfuzorowa-turbina-wiatrowa-samoczynnie-pod-wiatr.html (accessed on 2 February 2024). (In Polish).

- Savonius, S.J. The S-Rotor and Its Applications. Mech. Eng. 1931, 53, 333–338. [Google Scholar]

- Darrieus, G.J. Turbine Having Its Rotating Shaft Transverse to the Flow of the Current. U.S. Patent 1,835,018, 8 December 1931. [Google Scholar]

- Wagner, H.-J.; Mathur, J. Introduction to Wind Energy Systems: Basics, Technology and Operation, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 978-3-642-44812-6. [Google Scholar]

- Sobczak, K.; Obidowski, D.; Reorowicz, P.; Marchewka, E. Numerical Investigations of the Savonius Turbine with Deformable Blades. Energies 2020, 13, 3717. [Google Scholar] [CrossRef]

- Damak, A.; Driss, Z.; Abid, M.S. Experimental Investigation of Helical Savonius Rotor with a Twist of 180°. Renew. Energy 2013, 52, 136–142. [Google Scholar] [CrossRef]

- Mendoza, V.; Katsidoniotaki, E.; Bernhoff, H. Numerical Study of a Novel Concept for Manufacturing Savonius Turbines with Twisted Blades. Energies 2020, 13, 1874. [Google Scholar] [CrossRef]

- Abraham, J.P.; Plourde, B.D.; Mowry, G.S.; Minkowycz, W.J.; Sparrow, E.M. Summary of Savonius Wind Turbine Development and Future Applications for Small-Scale Power Generation. J. Renew. Sustain. Energy 2012, 4, 042703. [Google Scholar] [CrossRef]

- Tian, W.; Song, B.; VanZwieten, J.H.; Pyakurel, P. Computational Fluid Dynamics Prediction of a Modified Savonius Wind Turbine with Novel Blade Shapes. Energies 2015, 8, 7915–7929. [Google Scholar] [CrossRef]

- Savonius, S.J. The Wing-Rotor in Theory and Practice; Savonius and Co.: Helsingfors, Finland, 1925. [Google Scholar]

- Zemamou, M.; Aggour, M.; Toumi, A. Review of Savonius Wind Turbine Design and Performance. Energy Procedia 2017, 141, 383–388. [Google Scholar] [CrossRef]

- Mahmoud, N.H.; El-Haroun, A.A.; Wahba, E.; Nasef, M.H. An Experimental Study on Improvement of Savonius Rotor Performance. Alex. Eng. J. 2012, 51, 19–25. [Google Scholar] [CrossRef]

- Norouztabar, R.; Mousavi Ajarostaghi, S.S.; Mousavi, S.S.; Nejat, P.; Rahimian Koloor, S.S.; Eldessouki, M. On the Performance of a Modified Triple Stack Blade Savonius Wind Turbine as a Function of Geometrical Parameters. Sustainability 2022, 14, 9816. [Google Scholar] [CrossRef]

- Alom, N.; Saha, U.K. Four Decades of Research Into the Augmentation Techniques of Savonius Wind Turbine Rotor. J. Energy Resour. Technol. 2018, 140, 050801. [Google Scholar] [CrossRef]

- Anwar, K.; Himran, S.; Sule, L.; Azis, N. Numerical Investigation of Modified Savonius Wind Turbine with Various Straight Blade Angle. J. Mech. Eng. Res. Dev. 2018, 41, 38–42. [Google Scholar] [CrossRef]

- Scheaua, F.; Goanta, A.; Dragan, N. Review of Specific Performance Parameters of Vertical Wind Turbine Rotors Based on the SAVONIUS Type. Energies 2021, 14, 1962. [Google Scholar] [CrossRef]

- Kacprzak, K.; Liskiewicz, G.; Sobczak, K. Numerical Investigation of Conventional and Modified Savonius Wind Turbines. Renew. Energy 2013, 60, 578–585. [Google Scholar] [CrossRef]

- Rahai, H.; Beach, L. Development of Optimum Design Configuration and Performance for Vertical Axis Wind Turbine; California State University: Long Beach, CA, USA, 2005. [Google Scholar]

- Tian, W.; Ni, X.; Mao, Z.; Wang, Y.-F. Study on the Performance of a New VAWT with Overlapped Side-by-Side Savonius Rotors. Energy Convers. Manag. 2022, 264, 115746. [Google Scholar] [CrossRef]

- Pallotta, A.; Pietrogiacomi, D.; Romano, G.P. HYBRI—A Combined Savonius-Darrieus Wind Turbine: Performances and Flow Fields. Energy 2020, 191, 116433. [Google Scholar] [CrossRef]

- Anjum, Z.; Najmi, L.A.; Fahad, A.; Ashraf, R.; Ehsan, S.; Aslam, W. Common Vertical Axis Savonius-Darrieus Wind Turbines for Low Wind Speed Highway Applications. Tech. J. Univ. Eng. Technol. (UET) Taxila Pak. 2016, 21, 85–90. [Google Scholar]

- Zamani, M.; Maghrebi, M.J.; Varedi, S.R. Starting Torque Improvement Using J-Shaped Straight-Bladed Darrieus Vertical Axis Wind Turbine by Means of Numerical Simulation. Renew. Energy 2016, 95, 109–126. [Google Scholar] [CrossRef]

- Mohan Kumar, P.; Sivalingam, K.; Lim, T.-C.; Ramakrishna, S.; Wei, H. Strategies for Enhancing the Low Wind Speed Performance of H-Darrieus Wind Turbine—Part 1. Clean Technol. 2019, 1, 185–204. [Google Scholar] [CrossRef]

- Kumar, P.M.; Sivalingam, K.; Narasimalu, S.; Lim, T.-C.; Ramakrishna, S.; Wei, H. A Review on the Evolution of Darrieus Vertical Axis Wind Turbine: Small Wind Turbines. J. Power Energy Eng. 2019, 7, 27–44. [Google Scholar] [CrossRef]

- Gipe, P. Wind Energy Basics: A Guide to Home and Community-Scale Wind-Energy Systems, 2nd ed.; Chelsea Green Publishing: Chelsea, VT, USA, 2009; ISBN 978-1-60358-227-8. [Google Scholar]

- Anweiler, S.; Fedak, W.; Gancarski, W.; Ulbrich, R. Power Spectrum Analysis for Determination of the Number of Vertical Axis Wind Turbine Blades. J. Mech. Energy Eng. 2017, 41, 153–162. [Google Scholar]

- Santhakumar, S.; Palanivel, I.; Venkatasubramanian, K. A Study on the Rotational Behaviour of a Savonius Wind Turbine in Low Rise Highways during Different Monsoons. Energy Sustain. Dev. 2017, 40, 1–10. [Google Scholar] [CrossRef]

- Sayais, S.Y.; Salunkhe, G.P.; Patil, P.G.; Khatik, M.F. Power Generation on Highway by Using Vertical Axis Wind Turbine & Solar System. Int. Res. J. Eng. Technol. 2018, 5, 2133–2137. [Google Scholar]

- Lipiao, J.A.C.; Divina, N.M.M.; Santiago, R.V.M.; Hortinela, C.C. Hybrid J-Type Darrieus and Savonius Vertical Axis Wind Turbine Capable of Harvesting Roadside Wind Energy. In Proceedings of the 11th International Conference on Renewable Energy Research and Application (ICRERA), Istanbul, Turkey, 18 September 2022; pp. 1–6. [Google Scholar]

- Matias, I.J.T.; Danao, L.A.M.; Abuan, B.E. Numerical Investigation on the Effects of Varying the Arc Length of a Windshield on the Performance of a Highway Installed Banki Wind Turbine. Fluids 2021, 6, 285. [Google Scholar] [CrossRef]

- Ismaeel, T.; Aljabair, S.; Abdulrazzaq, O.; Abood, Y. Energy Recovery of Moving Vehicles’ Wakes in Highways by Vertical Axis Wind Turbines. FME Trans. 2020, 48, 557–565. [Google Scholar] [CrossRef]

- Pawlak, Z. Compact Double-Stage Fluid Flow Turbine. PL Patent No. 208206, 18 August 2010. (In Polish). [Google Scholar]

| Vehicle Type | Wind Speed (m/s) |

|---|---|

| buses and trucks | 4.5–8.9 |

| delivery cars | 3.2–6.7 |

| cars | 2.1–4.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Łyskawiński, W.; Kowalski, K.; Wojciechowski, R.M. Experimental Assessment of Suitability of Darrieus and Savonius Turbines for Obtaining Wind Energy from Passing Vehicles. Energies 2024, 17, 1558. https://doi.org/10.3390/en17071558

Łyskawiński W, Kowalski K, Wojciechowski RM. Experimental Assessment of Suitability of Darrieus and Savonius Turbines for Obtaining Wind Energy from Passing Vehicles. Energies. 2024; 17(7):1558. https://doi.org/10.3390/en17071558

Chicago/Turabian StyleŁyskawiński, Wiesław, Krzysztof Kowalski, and Rafał M. Wojciechowski. 2024. "Experimental Assessment of Suitability of Darrieus and Savonius Turbines for Obtaining Wind Energy from Passing Vehicles" Energies 17, no. 7: 1558. https://doi.org/10.3390/en17071558

APA StyleŁyskawiński, W., Kowalski, K., & Wojciechowski, R. M. (2024). Experimental Assessment of Suitability of Darrieus and Savonius Turbines for Obtaining Wind Energy from Passing Vehicles. Energies, 17(7), 1558. https://doi.org/10.3390/en17071558