Extended Pantograph–Catenary Arc Modeling and an Analysis of the Vehicular-Grounding Electromagnetic Transients of Electric Multiple Units

Abstract

1. Introduction

- (1)

- The calculation of the dynamic characteristics of the arc length has not been examined by the chain arc model.

- (2)

- The dynamic characteristics of the actual arc length have not been taken into account, and the arc length is equivalent to the PC detachment distance in the former black-box arc models. However, the detachment distance is not able to fully characterize the arc length, and the over-voltages corresponding to different arc lengths are different.

- (3)

- The features of quenching and reigniting arcs have not been examined in depth. Their actions on the vehicular-grounding electromagnetic transients and the mutual influences of TB over-voltages of multiple arcs in a short time have not been studied.

- (1)

- The relationship between arc length and detachment distance is deduced, and an arc modeling scheme is proposed to study the influence of PC arcing on the TB over-voltages by taking into account the dynamic characteristics of arc length.

- (2)

- The characteristics of both arc extinguishing and arc ignition are thoroughly analyzed and their roles in the TB transient electromagnetic voltages are investigated, considering different influencing factors such as phase angle, excitation inductance, and vehicular protective grounding parameters.

- (3)

- The mutual effects of over-voltages of different detachments in a short time are methodically examined.

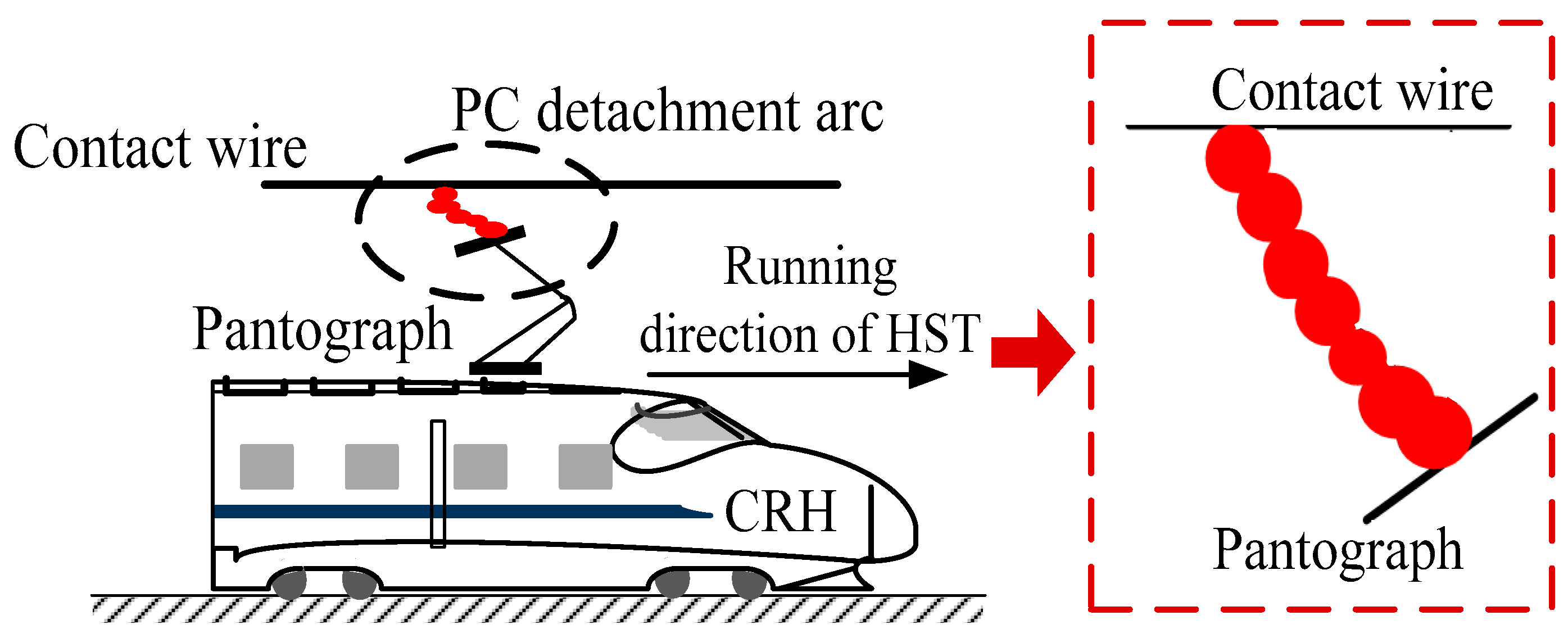

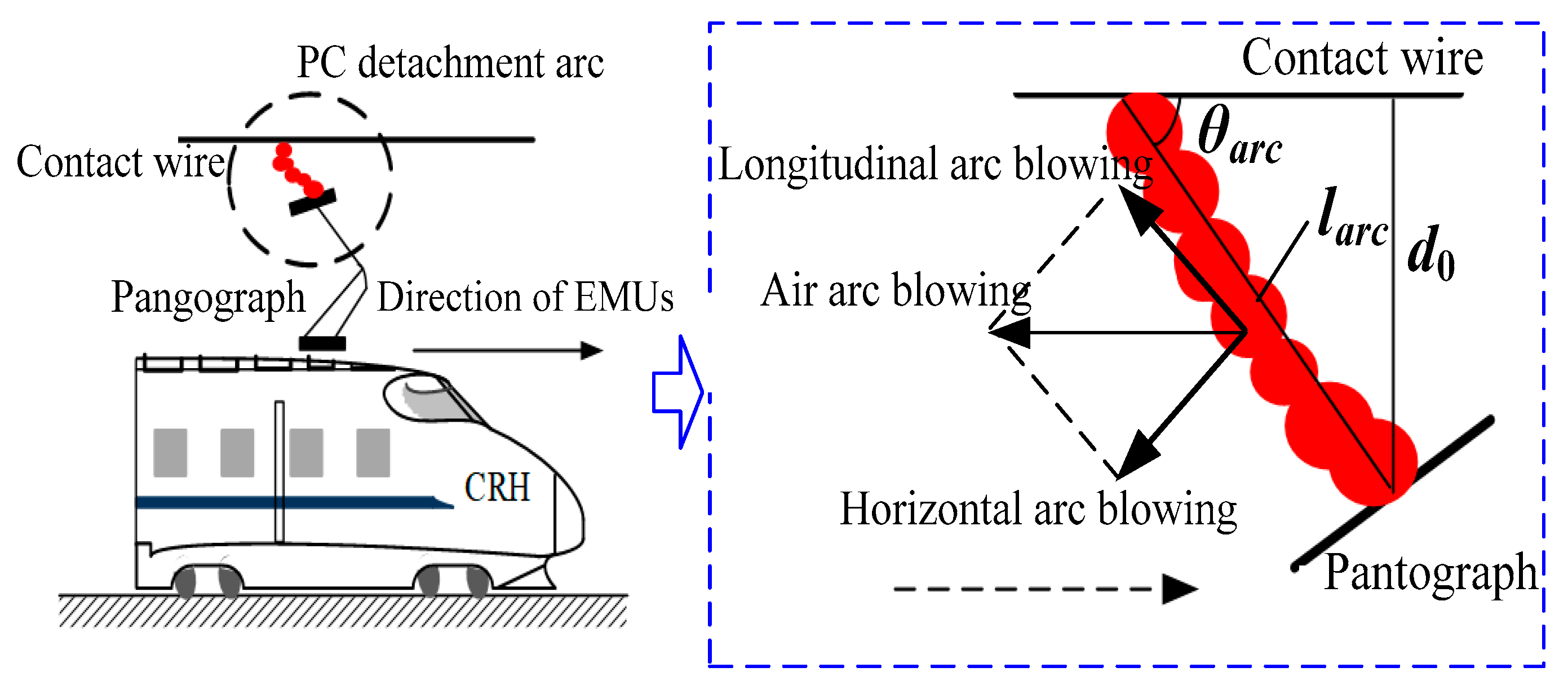

2. Modeling and Calculation of PC Detachment Arc Length Dynamic Characteristics

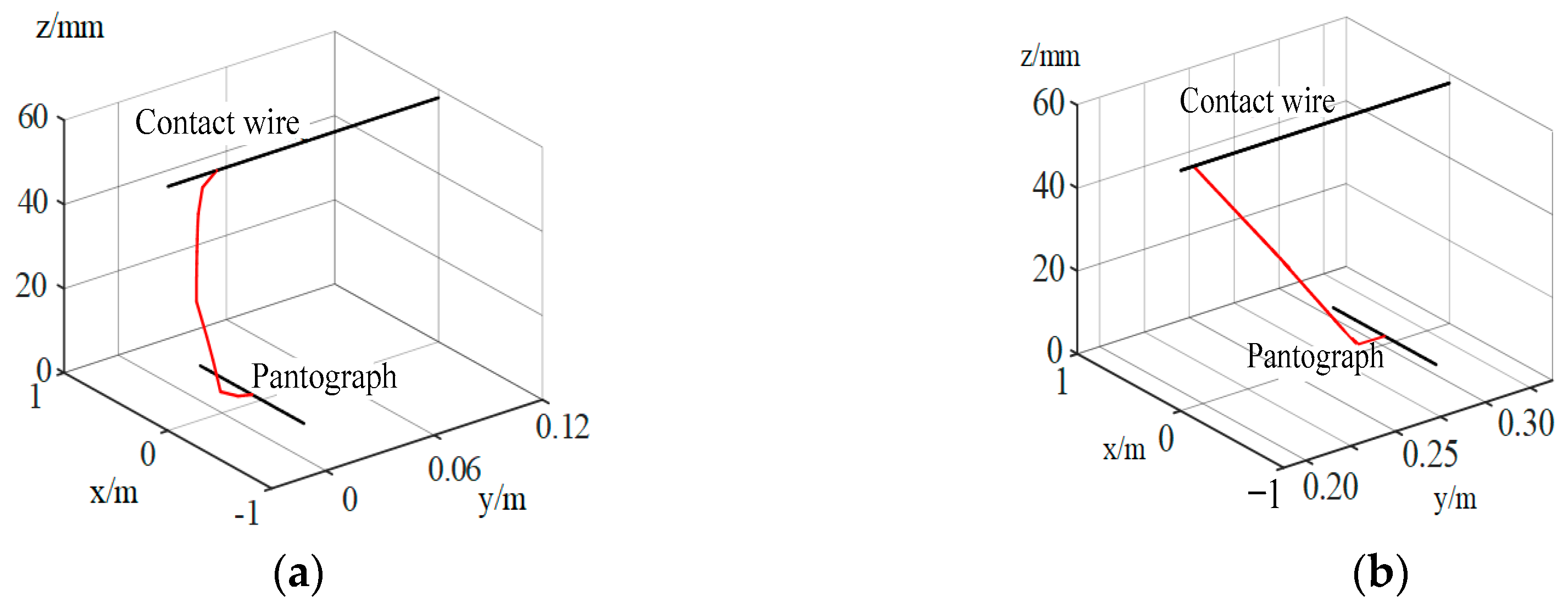

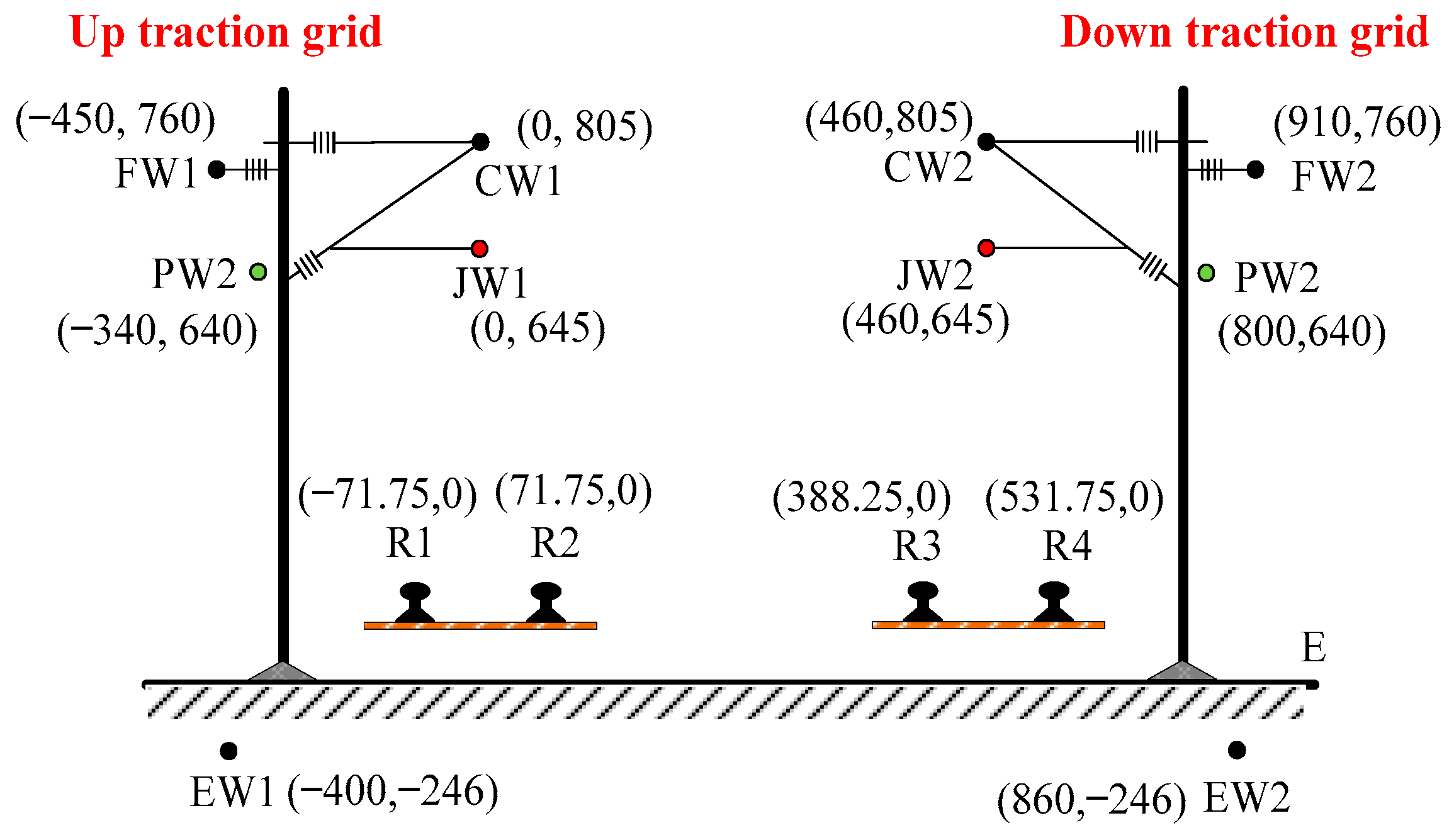

2.1. Calculation of PC Detachment Trajectory

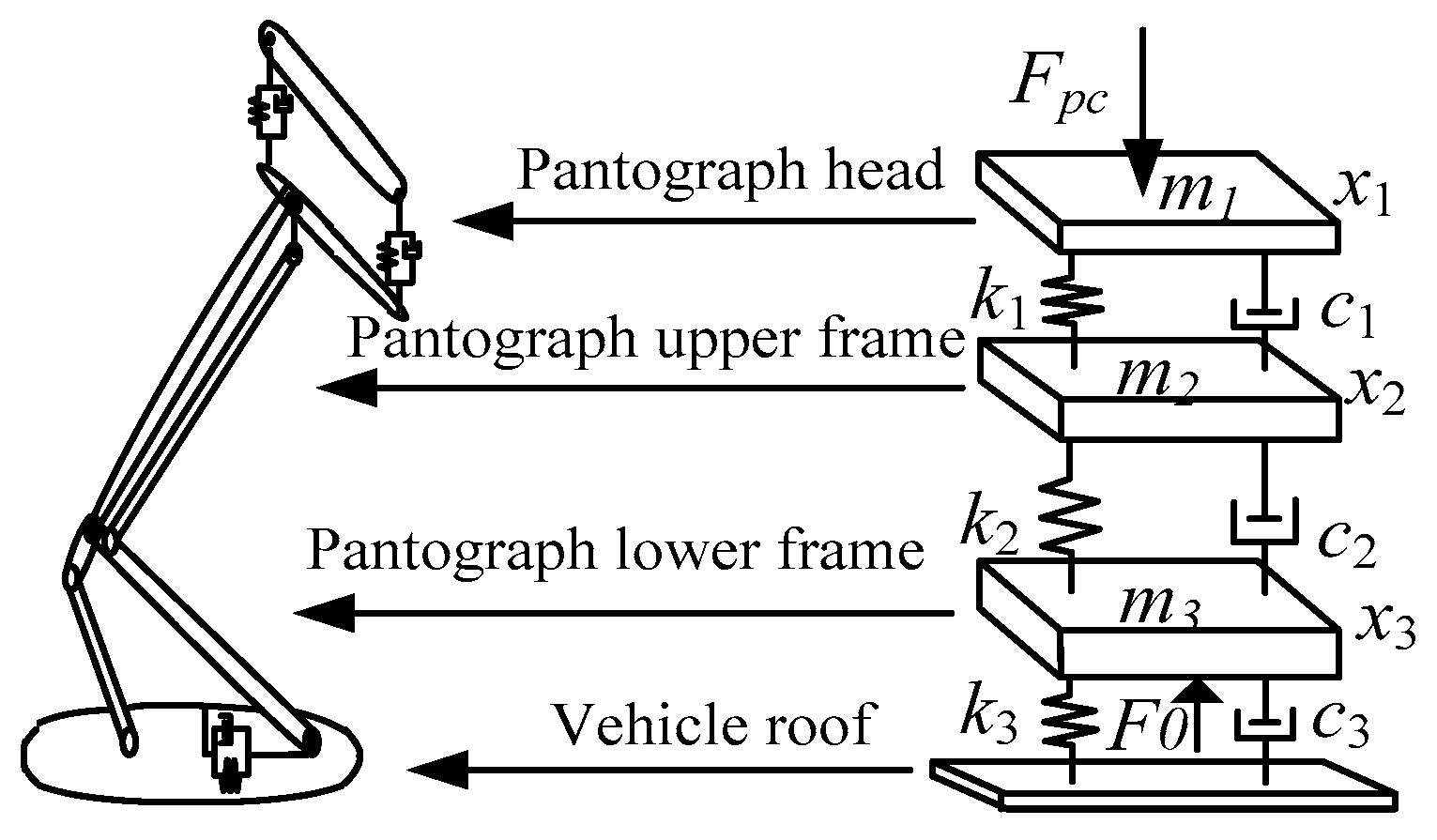

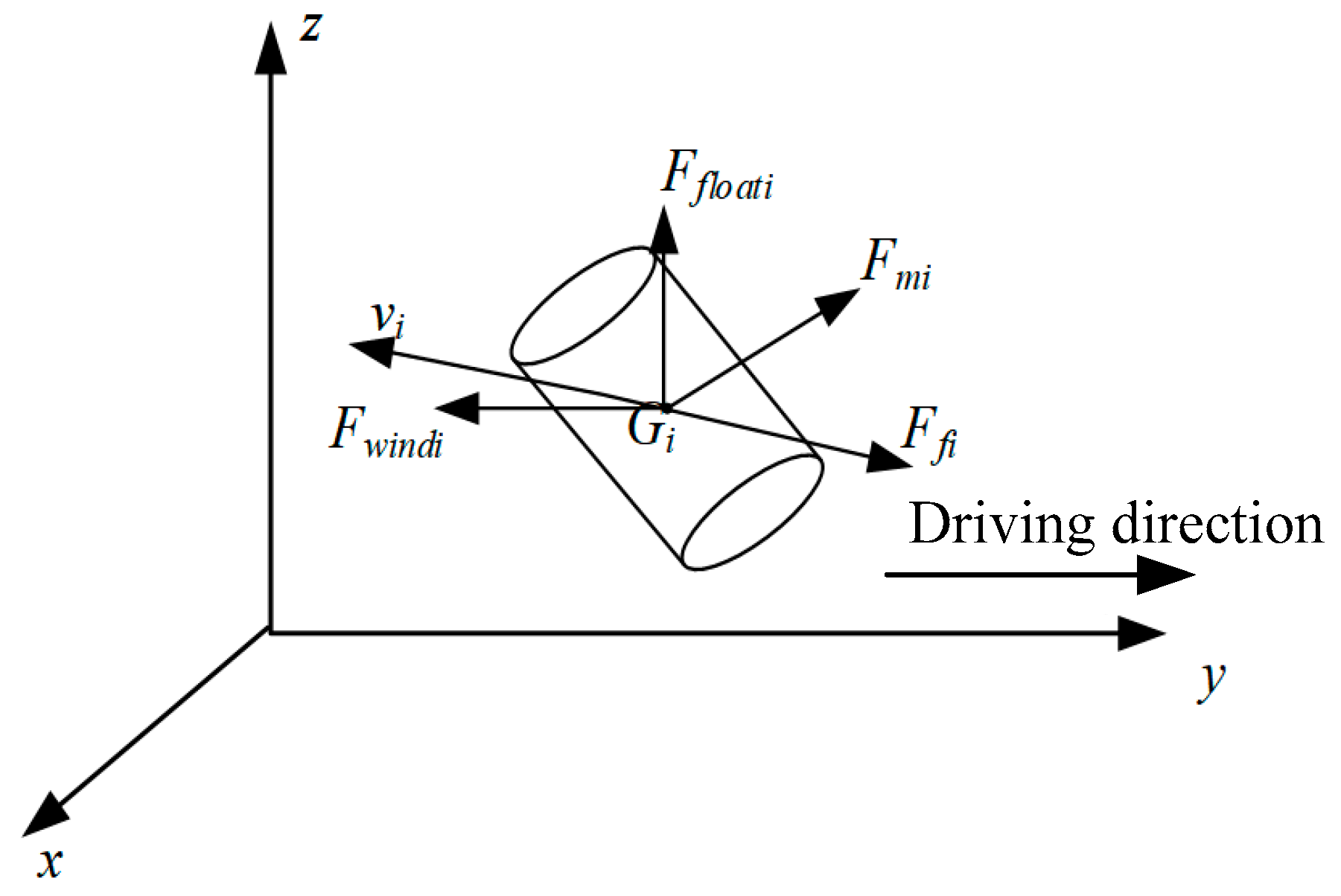

2.2. Chain Arc Modeling and Deduction

- (1)

- The bending or deformation of the arc exist, but it is not significant compared to the overall shape of the arc;

- (2)

- The influence of wind on the arc shape is mainly reflected in the overall arc shape;

- (3)

- The arc may be penetrated in some special cases, but its influence on the arc electrical characteristics and corresponding over-voltages is similar to the arc extinction.

- (1)

- The arc element is a rigid body, the external forces only affect the overall arc shape, and the arc element does not bend or deform;

- (2)

- The wind load is a static force that acts uniformly on the surface of the element;

- (3)

- When the arc element moves, it is an impenetrable object.

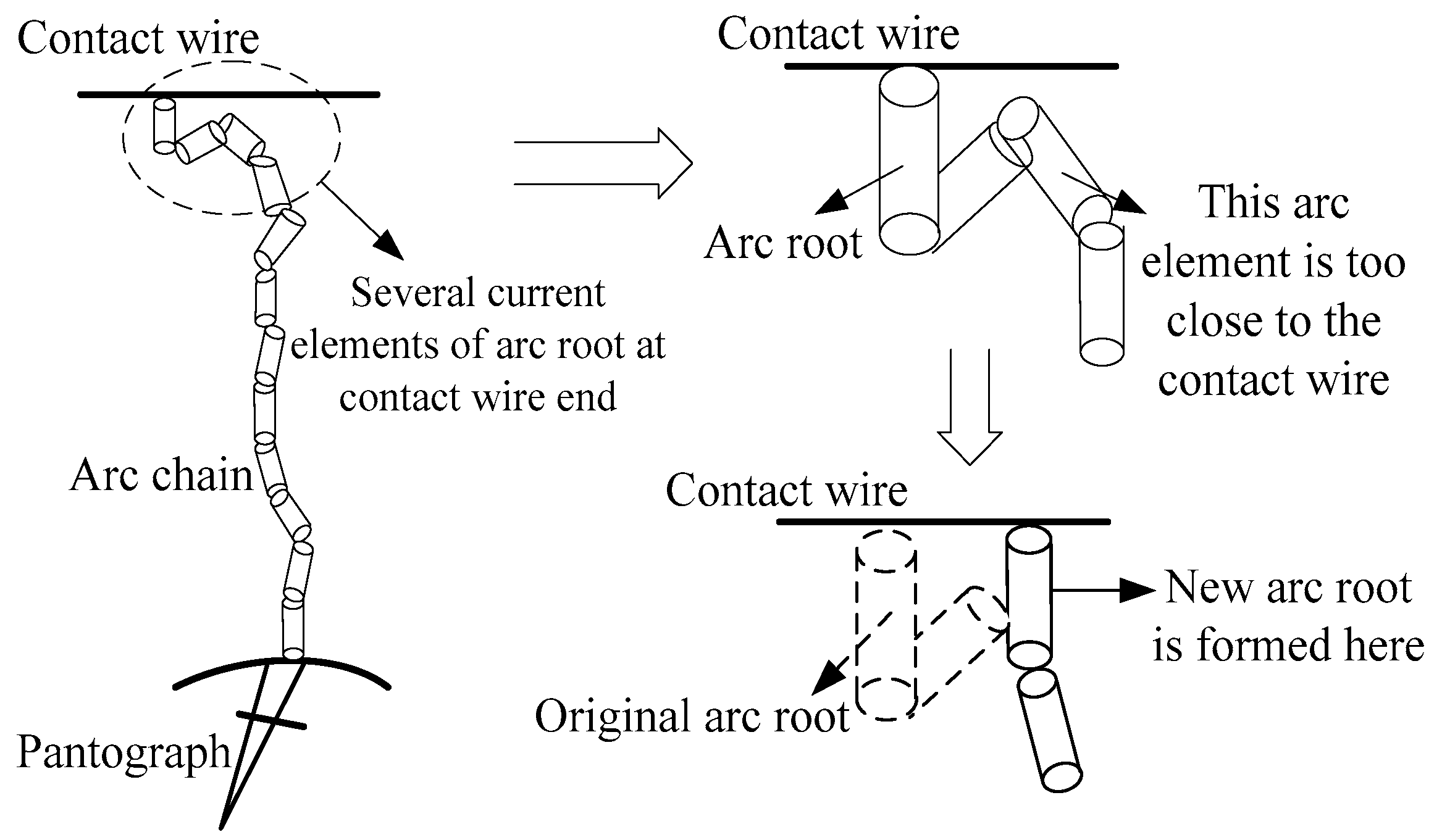

- (1)

- Arc column dynamic adjustment

- (2)

- Arc root current element jump correction

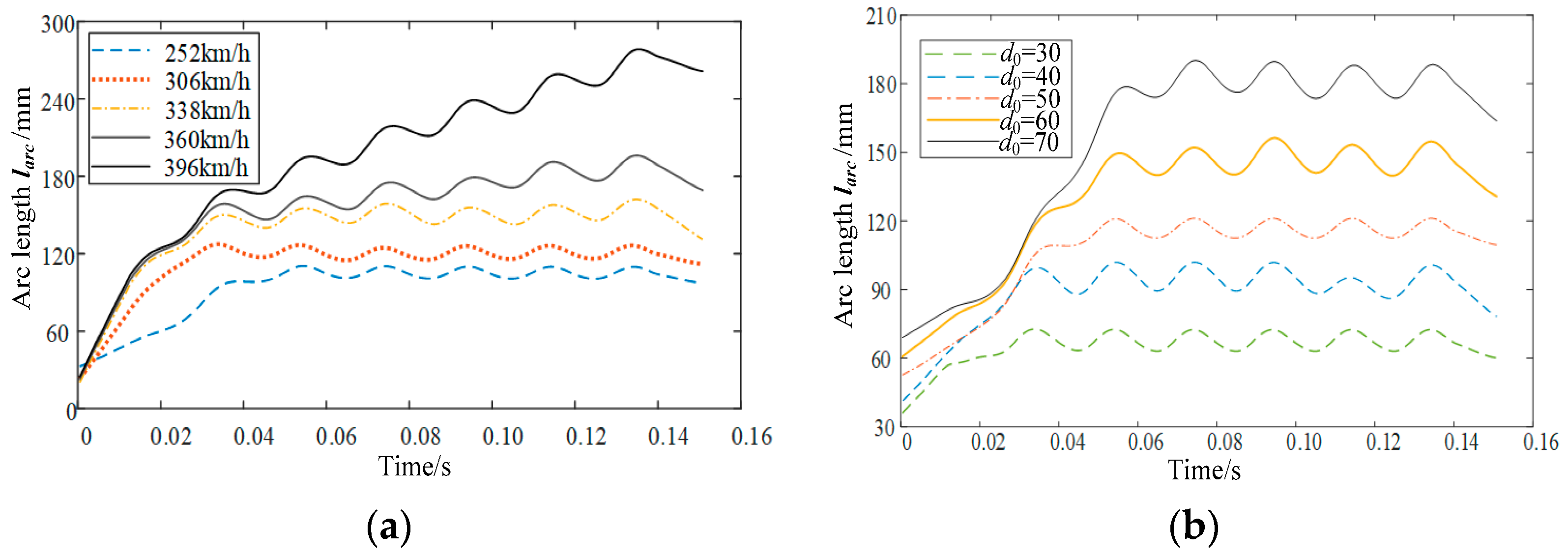

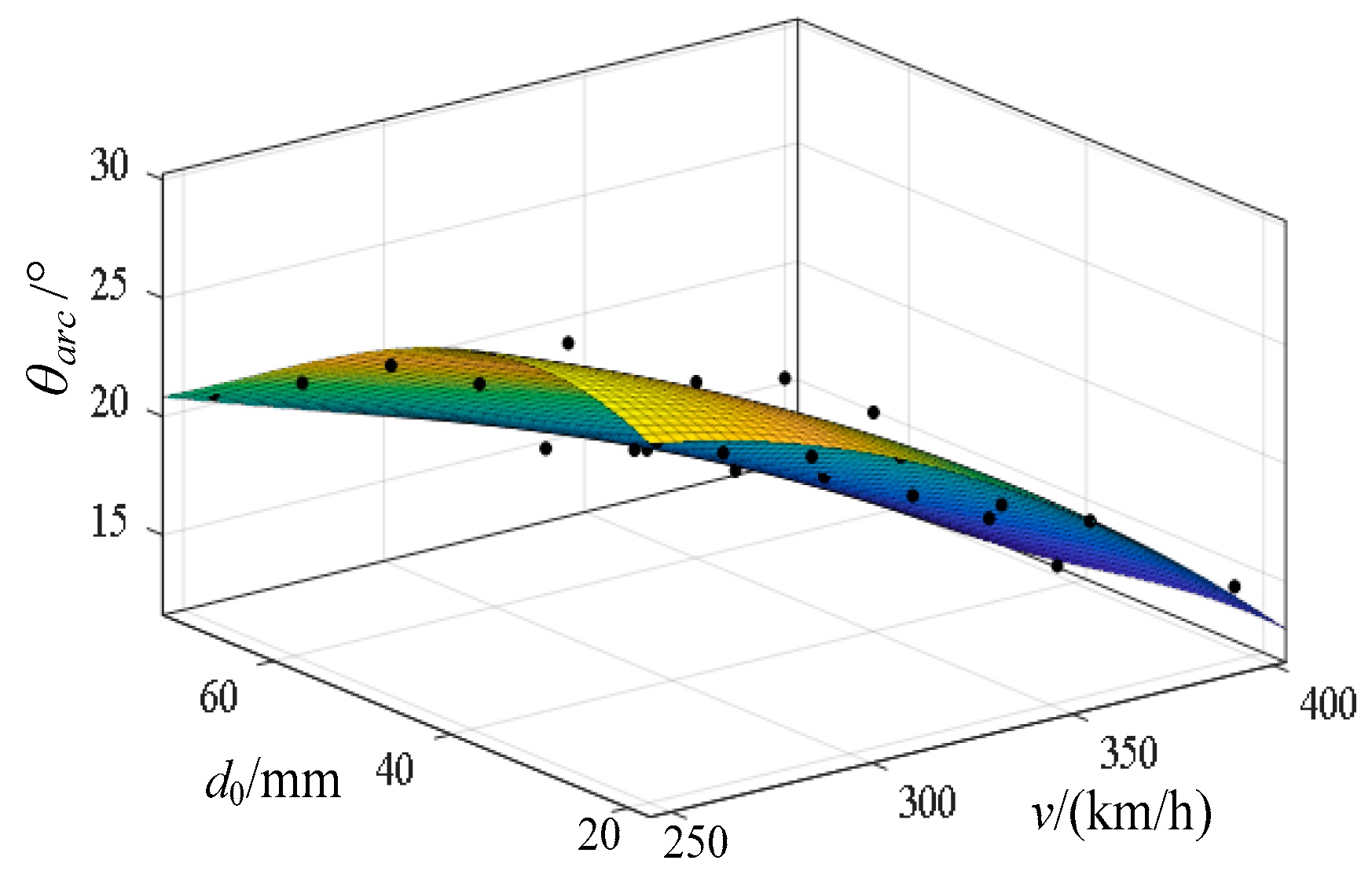

2.3. Analyses of PC Detachment Arc Motion Characteristics

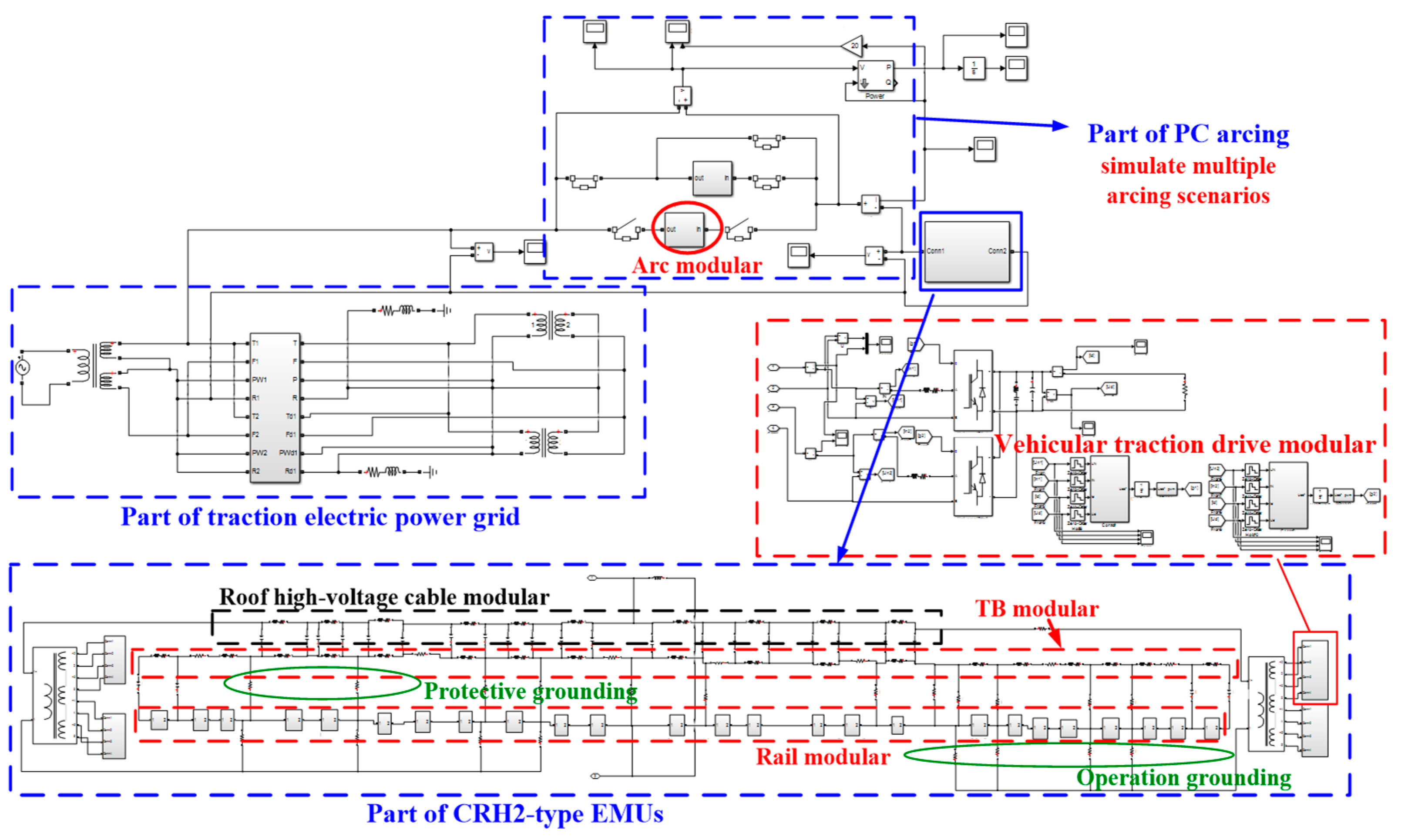

3. Modeling of Vehicle-Grid Electric Power System Considering Arc Length Dynamic Characteristics

3.1. Extended Arc Model Considering Arc Length Dynamic Characteristics

3.2. Vehicle-Grid Electric Power Model

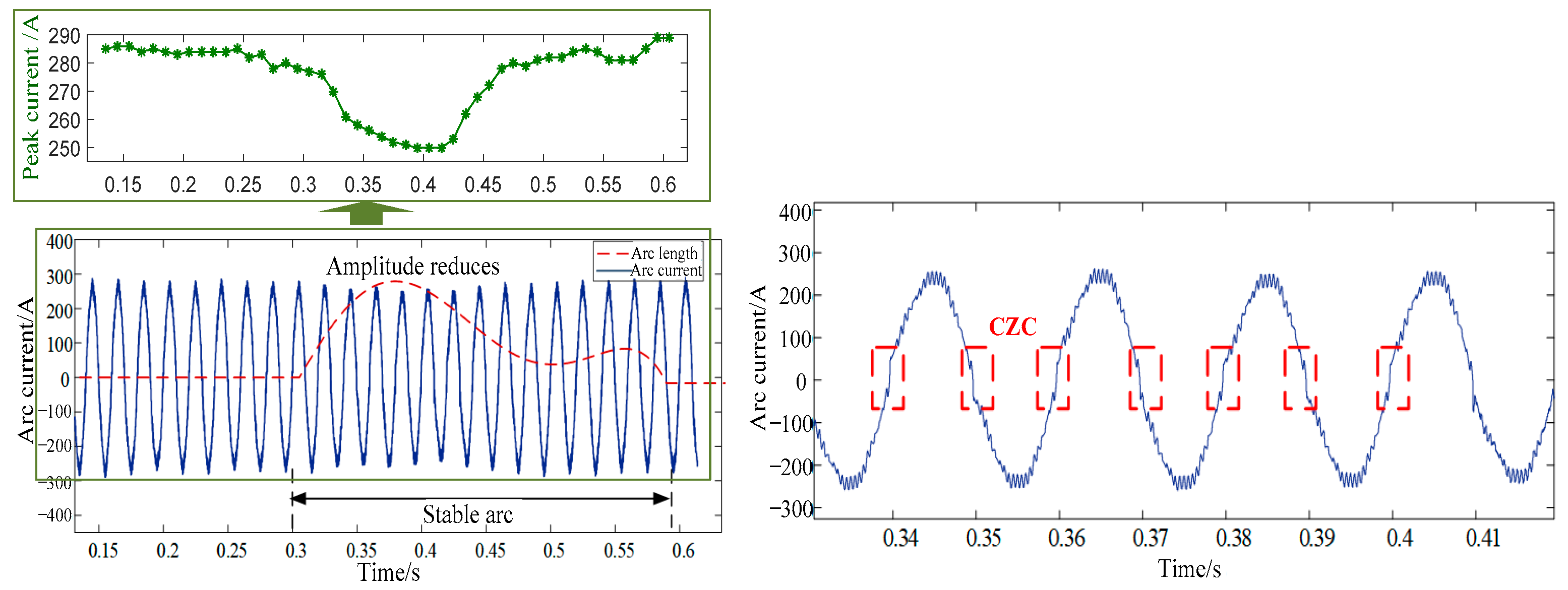

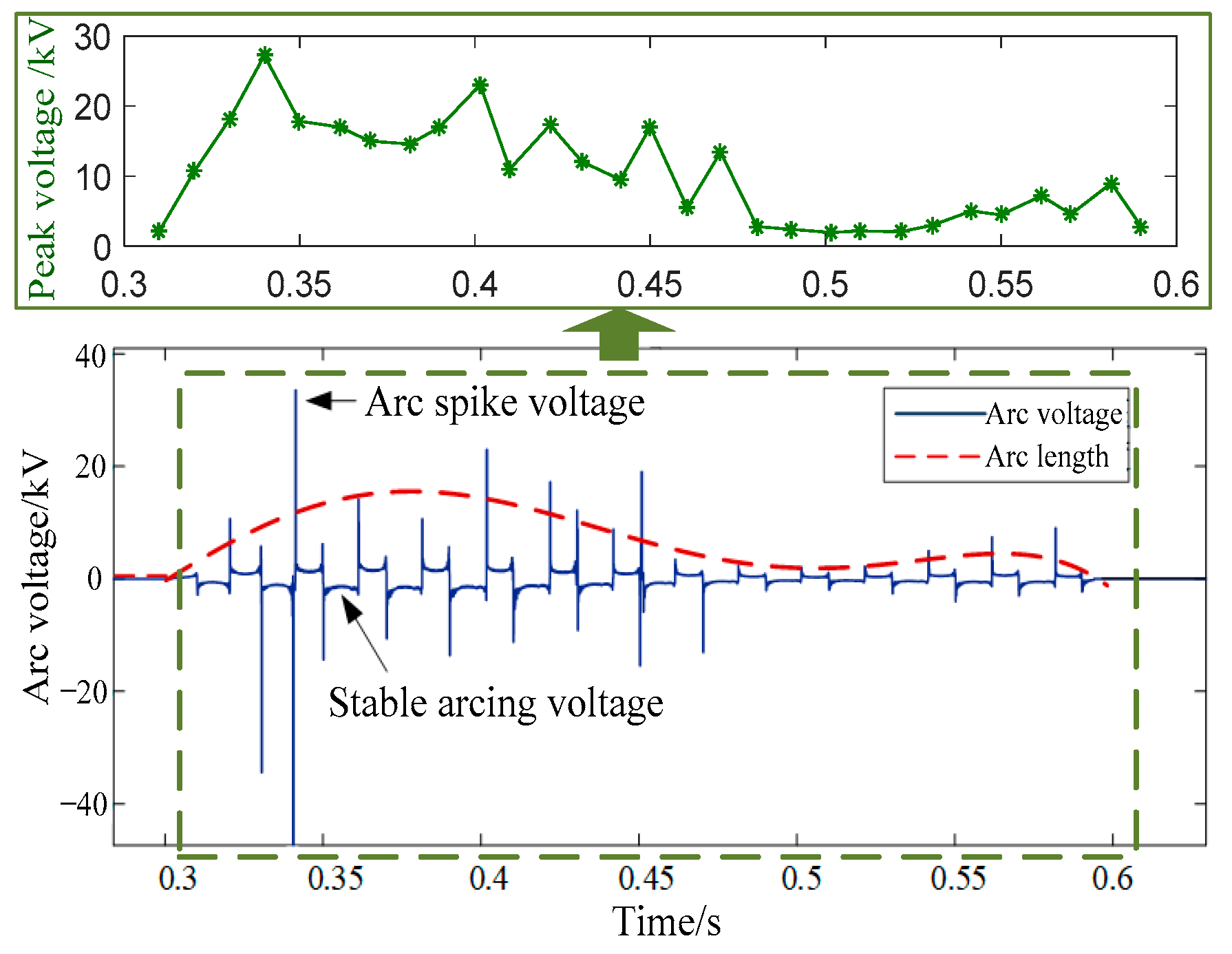

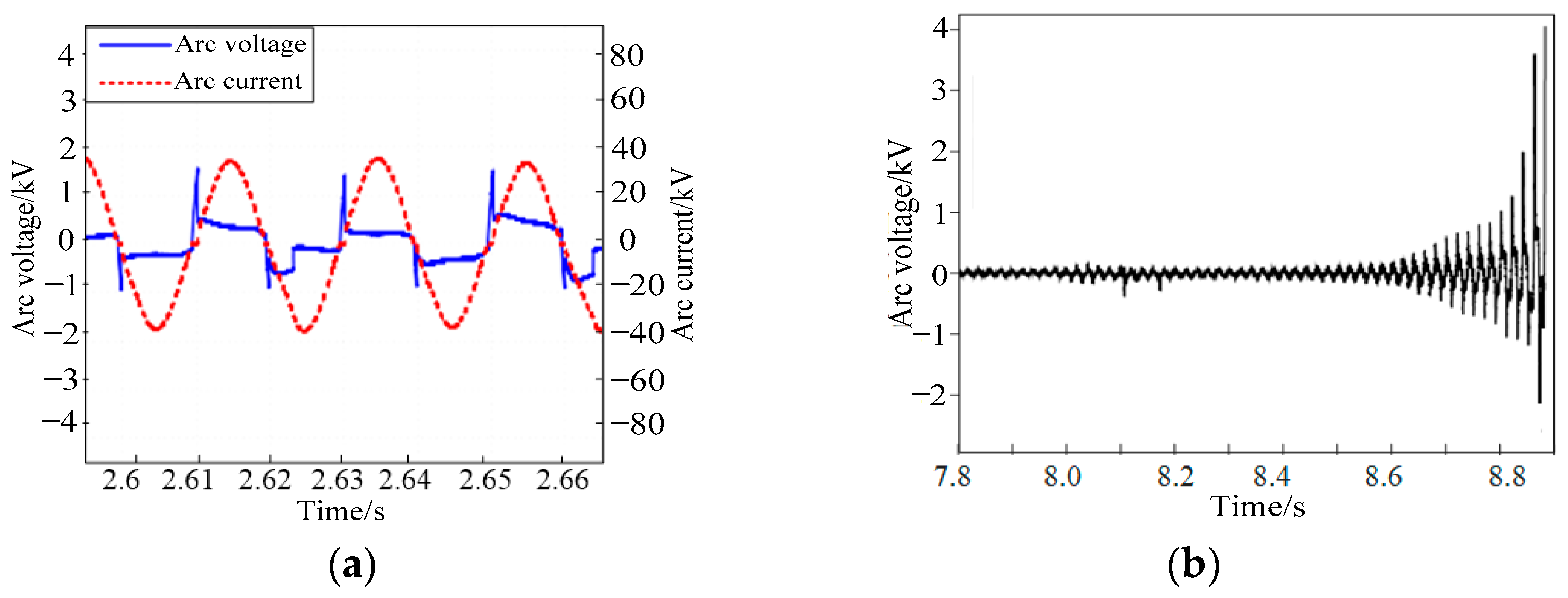

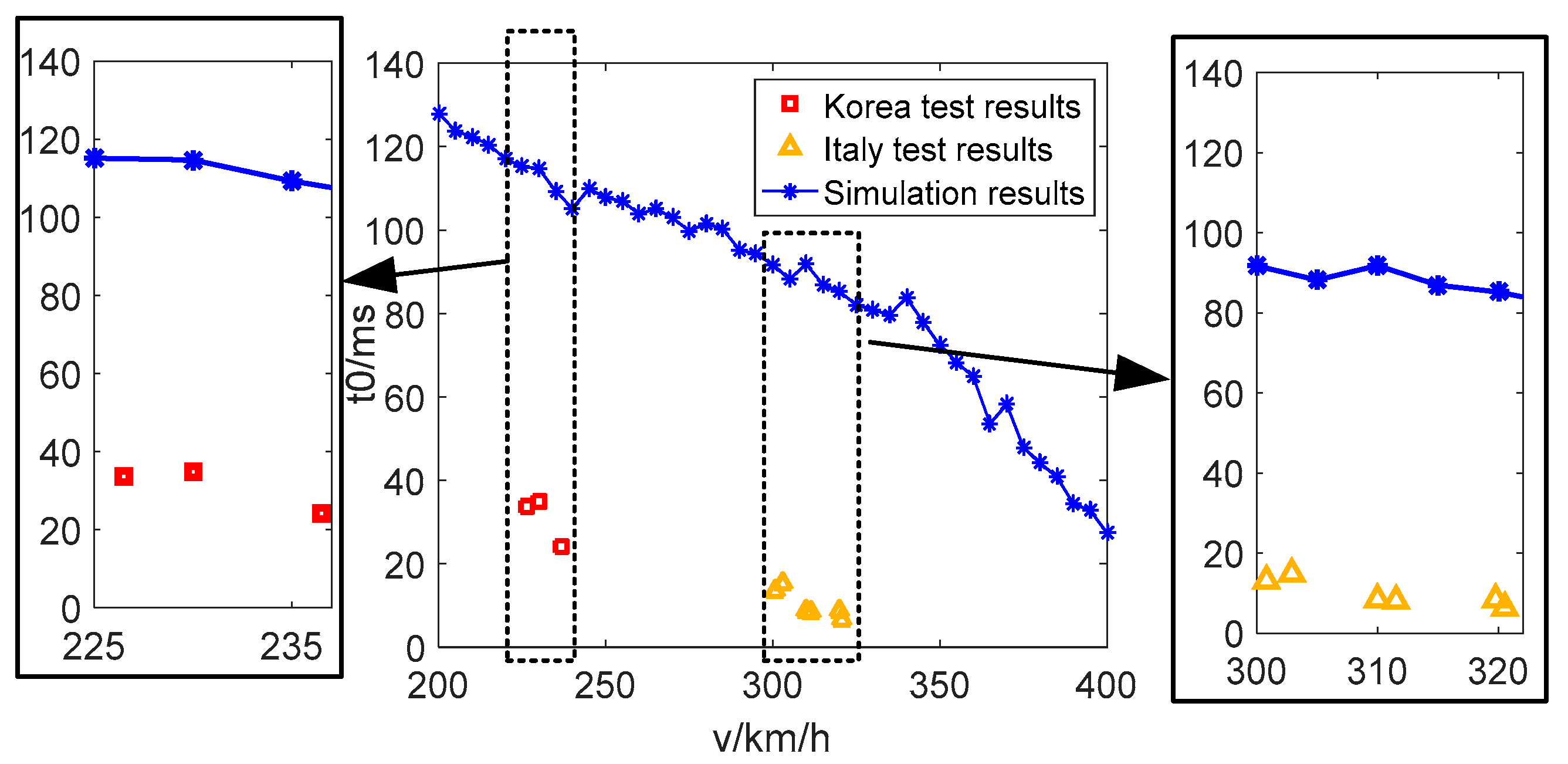

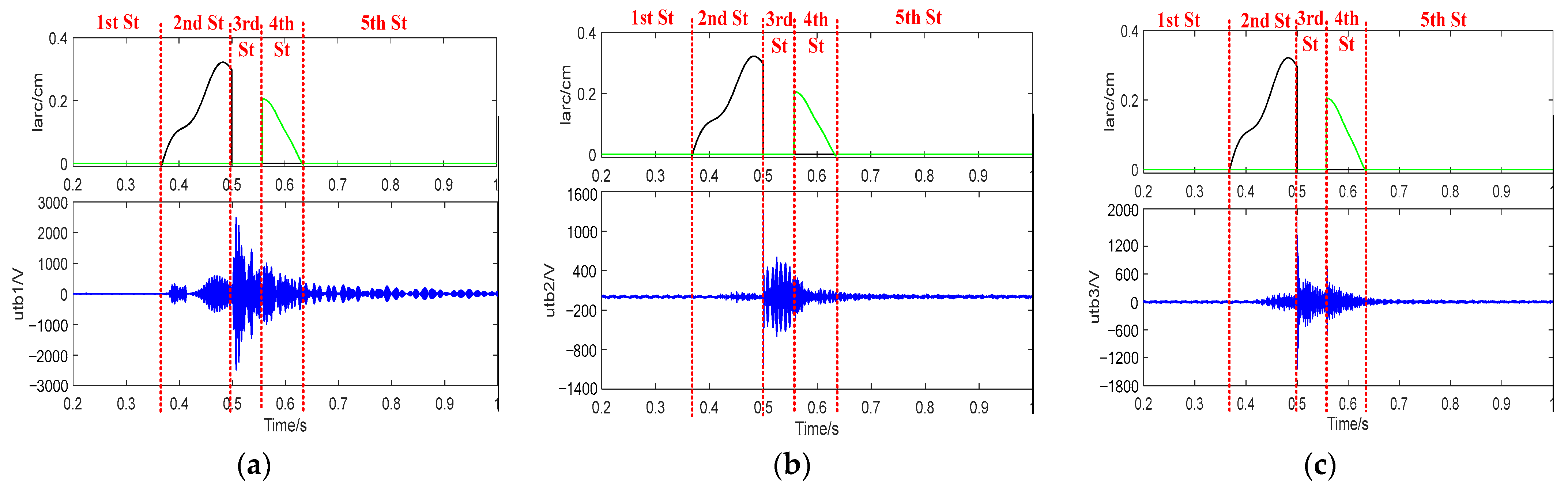

3.3. Model Validation

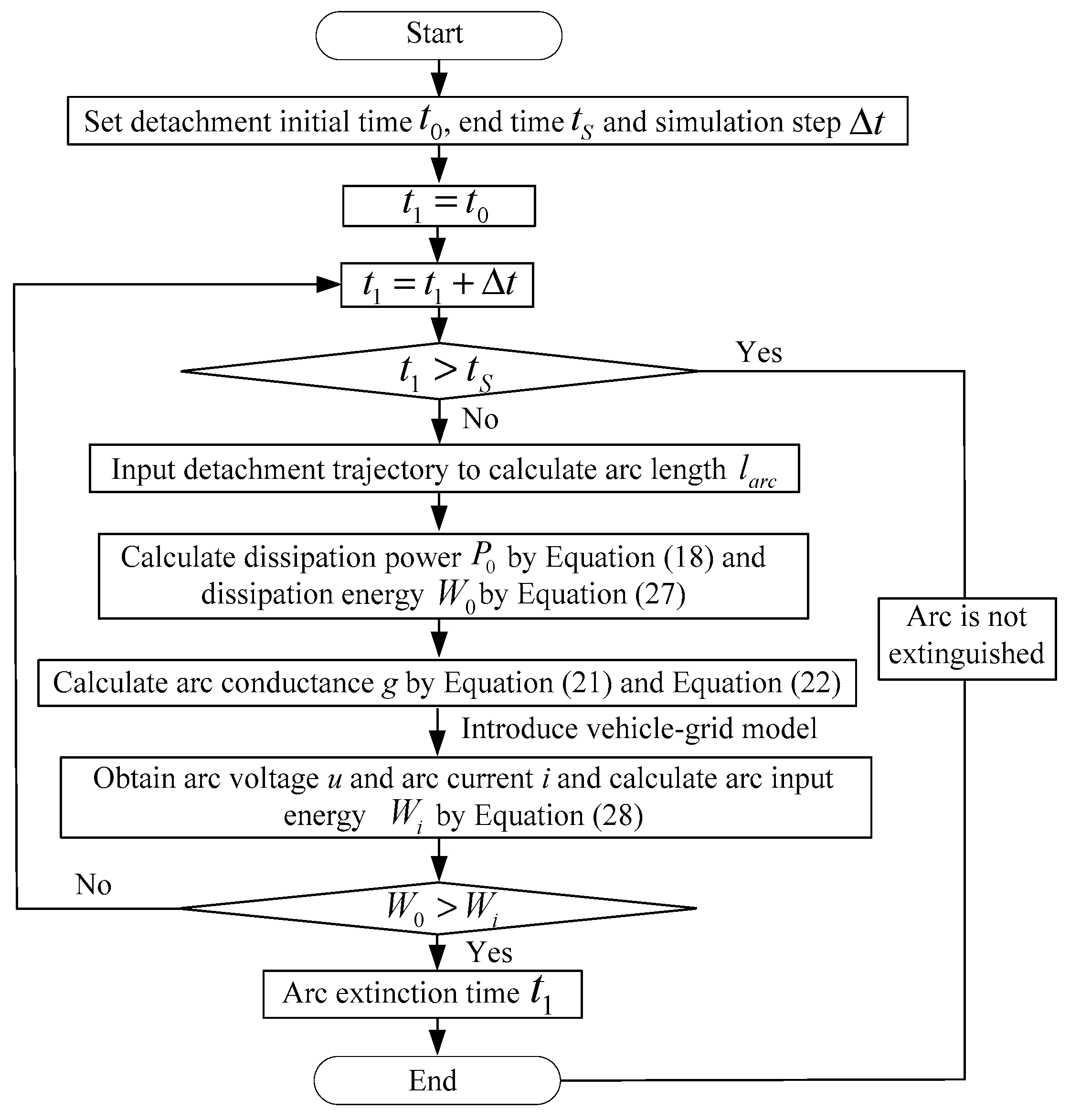

3.4. Calculations of the Arc Extinction and Arc Reignition Times

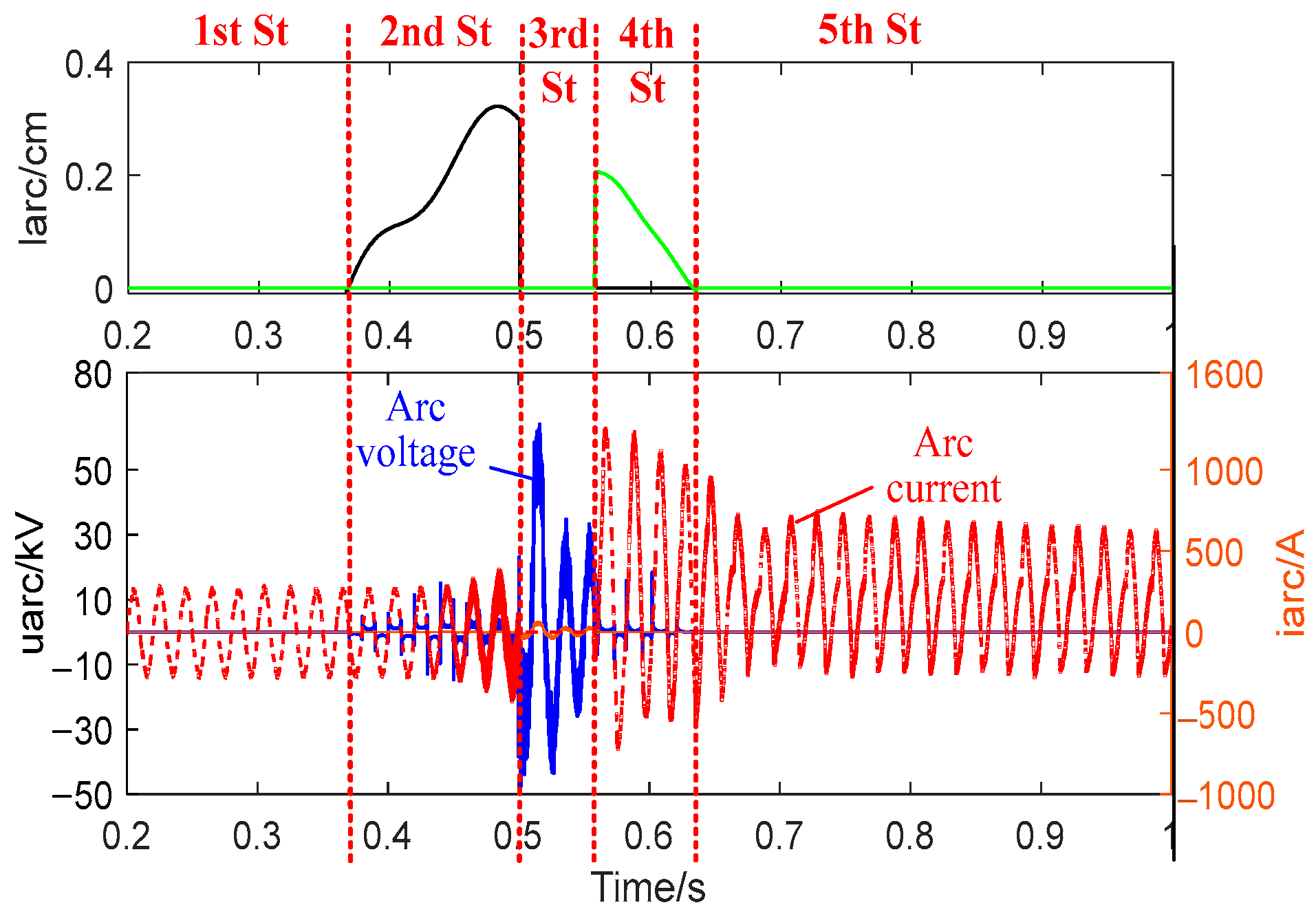

4. Vehicular-Grounding Electromagnetic Transient Analyses Considering Arc Reignition

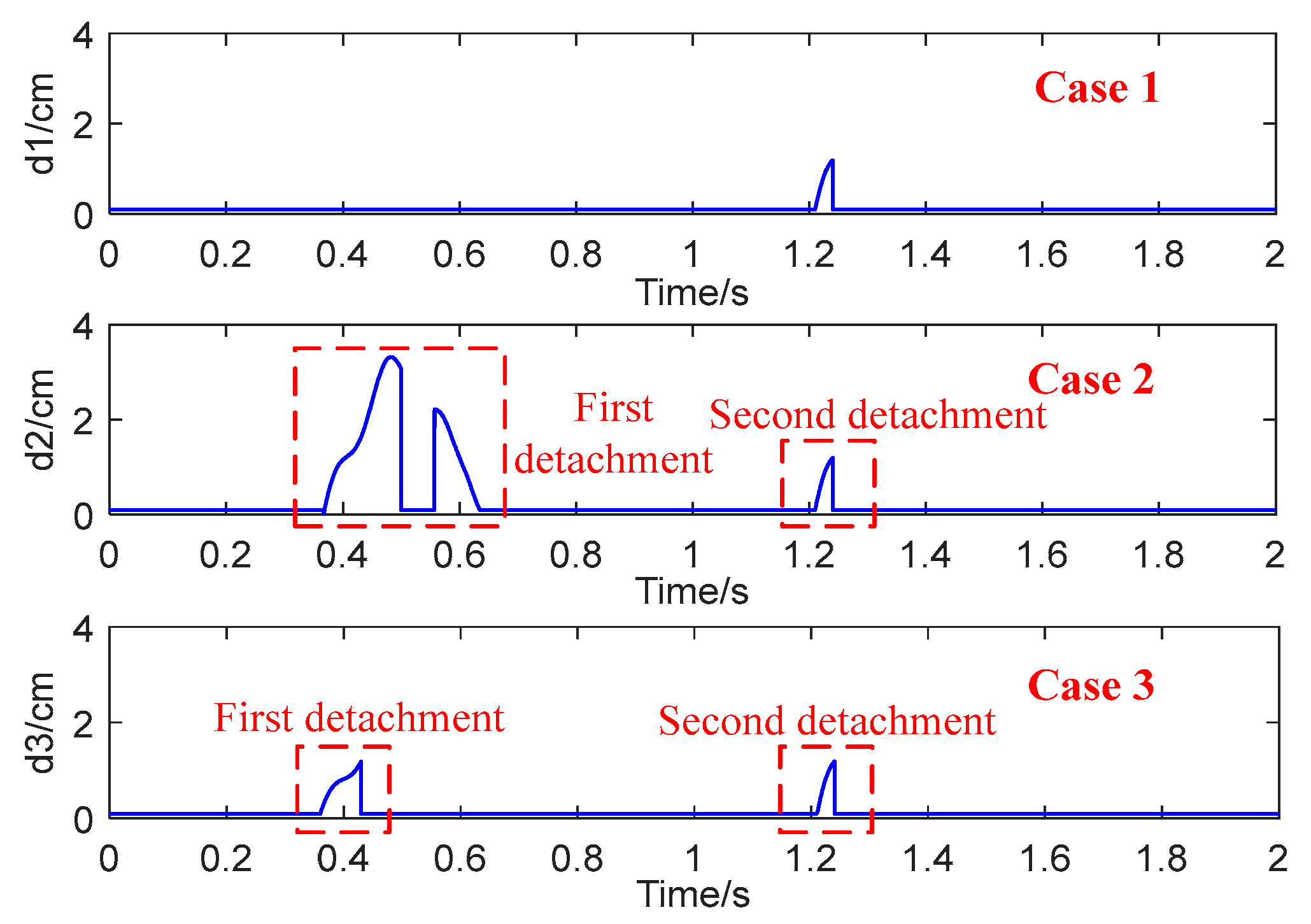

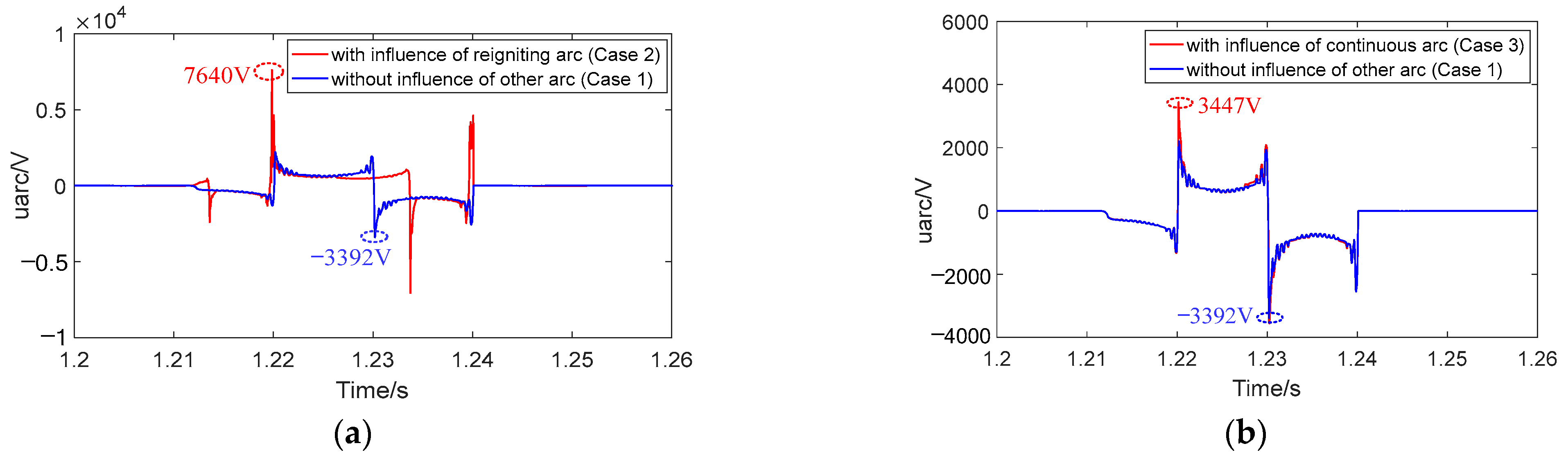

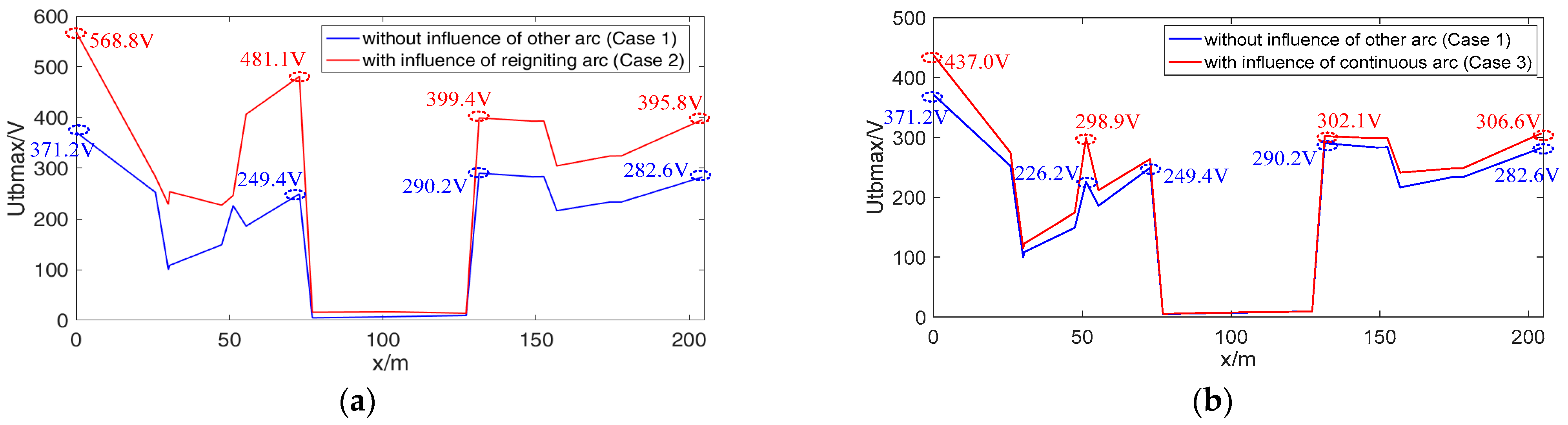

5. Vehicular-Grounding Electromagnetic Transient Analyses Considering Arc Mutual Effects of Multiple Detachments

6. Conclusions

- (1)

- The chain arc model is established to explore the arc shape changing principle under the multi-field coupling influences. The jump of the upper arc root essentially explains the reason why the arc length will not continue to increase. Additionally, the arc length grows with the increasing vehicle speed and detachment distance.

- (2)

- On the basis of deducing the dynamic relationship between the detachment distance and arc length, the arc length dynamic characteristics are introduced and an arc modeling scheme is proposed to elaborate the vehicle-grid electric power model under various detachment arcing scenarios. The rationality and correctness of the proposed modeling approach is then verified by comparing the simulated results with those of the measured results and the previous model.

- (3)

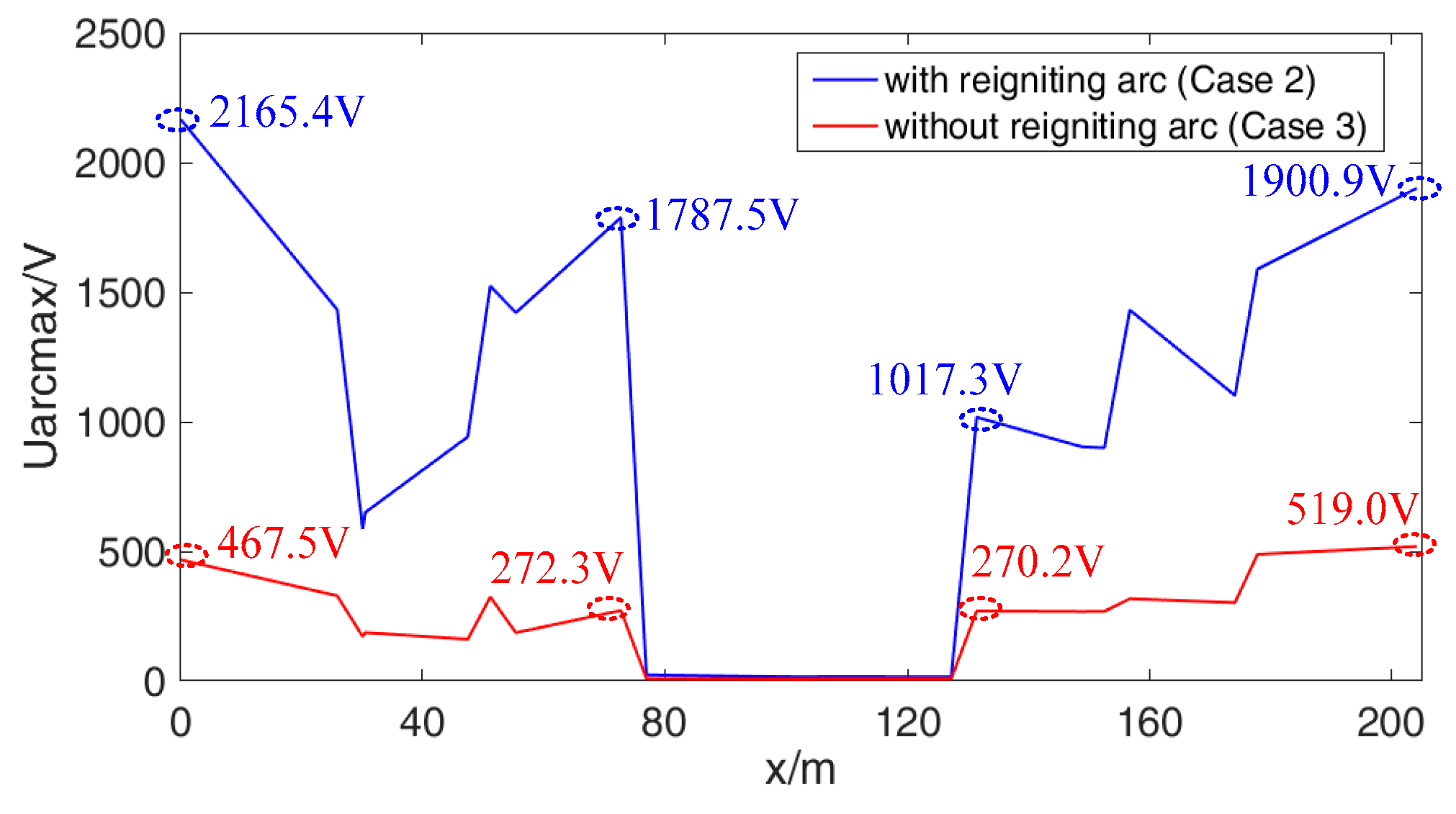

- During arc extinction and arc reignition, the inrush current results in much more severe TB over-voltages. The influence of the instantaneous PH phase is significant, covering nearly 180°. A smaller excitation inductance results in higher over-voltages due to the larger stored energy in the charging process of roof cable distribution capacitance. For the multiple detachments, the superposition of over-voltages is remarkable, where the effect of the arc reignition is much higher than that of the continuous arc.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Midya, S.; Bormann, D.; Schutte, T.; Thottappillil, R. Pantograph arcing in electrified railways-mechanism and influence of various parameters-part II: With AC traction power supply. IEEE Trans. Power Deliv. 2009, 24, 1940–1950. [Google Scholar] [CrossRef]

- Midya, S.; Bormann, D.; Schutte, T.; Thottappillil, R. DC component from pantograph arcing in AC traction system-influencing parameters, impact, and mitigation techniques. IEEE Trans. Power Deliv. 2011, 53, 18–27. [Google Scholar] [CrossRef]

- Chen, X.; Cao, B.; Liu, Y.; Gao, G.; Wu, G. Dynamic model of pantograph-catenary arc of train in high speed airflow field. High Volt. Eng. 2016, 42, 3593–3600. (In Chinese) [Google Scholar]

- Wu, J.; Xiao, S.; Zhang, C.; Luo, Y.; Rao, Y.; Gao, G.; Wu, G.; Sykulski, J.K. Multiobjective optimization of the integrated grounding system for high-speed trains by balancing train body current and overvoltage. IEEE Trans. Transp. Electrif. 2021, 7, 1712–1723. [Google Scholar] [CrossRef]

- National Standardization Administration. GB/T3805-2008Extra Low Voltage (ELV) Limit; China Standards Press: Beijing, China, 2011.

- Xu, C.; Chen, Z.; Cheng, E.; Wang, X.; Ho, H.F. A supercapacitor-based method to mitigate overvoltage and recycle the energy of pantograph arcing in the high speed railway. Energies 2019, 12, 1214. [Google Scholar] [CrossRef]

- Habedank, U. On the mathematical description of arc behaviour in the vicinity of current zero. Etz Arch. 1988, 11, 339–343. [Google Scholar]

- Mayr, O. Contribution to the theory of static and dynamic arcs. Arch. Elektrotech. 1943, 37, 589–608. [Google Scholar]

- Guardado, J.L.; Maximov, S.G.; Melgoza, E.; Naredo, J.L.; Moreno, P. An improved arc model before current zero based on the combined Mayr and Cassie arc models. IEEE Trans. Power Deliv. 2005, 20, 138–142. [Google Scholar] [CrossRef]

- Liu, Y.; Chang, G.W.; Huang, H.M. Mayr’s equation-based model for pantograph arc of high-speed railway traction system. IEEE Trans. Power Deliv. 2010, 25, 2025–2027. [Google Scholar] [CrossRef]

- Ma, L.; Wen, Y.; Marvin, A.; Karadimou, E.; Armstrong, R.; Cao, H. A novel method for calculating the radiated disturbance from pantograph arcing in high-speed railway. IEEE Trans. Veh. Technol. 2017, 66, 8734–8745. [Google Scholar] [CrossRef]

- Yang, Y.; Cao, H.; Zhang, M.; Su, Z.; Hu, M.; Jin, M.; Liu, S. Research on the influence of pantograph catenary contact loss arcs and zero-crossing stage on electromagnetic disturbance in high-speed railway. Energies 2024, 17, 138. [Google Scholar] [CrossRef]

- Khakpour, A.; Franke, S.; Gortschakow, S.; Uhrlandt, D.; Methling, R.; Weltmann, K.D. An improved arc model based on the arc diameter. IEEE Trans. Power Deliv. 2016, 31, 1335–1341. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Z.; Mu, X.; Huang, K.; Wang, H.; Gao, S. An extended Habedank’s equation-based EMTP model of pantograph arcing considering pantograph-catenary interactions and train speeds. IEEE Trans. Power Deliv. 2016, 31, 1186–1194. [Google Scholar] [CrossRef]

- Wang, W. Study of Dynamic Characteristic for High Speed Railway Pantograph Arcing. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2013. [Google Scholar]

- Liu, Z.; Zhou, H.; Huang, K.; Song, Y.; Zheng, Z.; Cheng, Y. Extended black-Box model of pantograph-catenary detachment arc considering pantograph-catenary dynamics in electrified railway. IEEE Trans. Ind. Appl. 2019, 55, 776–785. [Google Scholar] [CrossRef]

- Xu, Z.; Song, Y.; Liu, Z. Effective measures to improve current collection quality for double pantographs and catenary based on wave propagation analysis. IEEE Trans. Veh. Technol. 2020, 69, 6299–6309. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, W.; Zhang, Z. Study on characteristics location of pantograph-catenary contact force signal based on wavelet transform. IEEE Trans. Instrum. Meas. 2018, 68, 402–411. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Z.; Gao, S. Dynamic calculations of high-speed EMU rising and dropping pantograph arc considering effect of wind load. Proc. CSU-EPSA 2016, 28, 5–9, 23. (In Chinese) [Google Scholar]

- Huang, K.; Lin, G.; Liu, Z.; Yang, Y. Research on transient over-voltages of high-speed train passing articulated split-section insulator. IEEE Trans. Transp. Electrif. 2023, 9, 1664–1682. [Google Scholar] [CrossRef]

- Huang, K.; Liu, Z.; Zhu, F.; Deng, Y. Grounding behavior and optimization analysis of electric multiple units. IEEE Trans. Transp. Electrif. 2021, 7, 240–255. [Google Scholar] [CrossRef]

- Mariscotti, A. The electrical behaviour of railway pantograph arcs. Energies 2023, 16, 1465. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, Z.; Xiong, J.; Duan, F. Characteristic analysis of pantograph-catenary detachment arc based on double- pantograph-catenary dynamics in electrified railways. IET Electr. Syst. Transp. 2022, 12, 238–250. [Google Scholar] [CrossRef]

- EN50318-2002; Railway Application-Current Collection Systems-Validation of Simulation of The Dynamic Interaction between Pantograph and Overhead Contact Line. British Standards Institute: London, UK, 2002.

- Lu, X.; Liu, Z.; Song, Y.; Wang, H.; Zhang, J.; Wang, Y. Estimator-based multiobjective robust control strategy for an active pantograph in high-speed railways. Proc. Inst. Mech. Eng. Part F-J. Rail Rapid Transit 2017, 232, 1064–1077. [Google Scholar] [CrossRef]

- Song, Y.; Liu, Z.; Wang, H.; Lu, X.; Zhang, J. Nonlinear modelling of high-speed catenary based on analytical expressions of cable and truss elements. Veh. Syst. Dyn. 2015, 53, 1455–1479. [Google Scholar] [CrossRef]

- Anghel, S.R.; Miklos, C.; Averseng, J.; Tirian, G.O. Control system for catenary-pantograph dynamic interaction force. In Proceedings of the International Joint Conference on Computational Cybernetics and Technical Informatics, Timisoara, Romania, 27–29 May 2010; pp. 181–186. [Google Scholar]

- Sima, W.; Tan, W.; Yang, Q.; Luo, B.; Li, L. Long AC arc movement model for parallel gap lighting protection device with consideration of thermal buoyancy and magnetic force. Proc. CSEE 2011, 31, 138–145. (In Chinese) [Google Scholar]

- Ji, L.; Chen, D.; Liu, Y.; Li, X.; Niu, C. Simulation of the interruption process of low voltage circuit breaker using dynamic mathematic arc model. Proc. CSEE 2009, 29, 107–113. (In Chinese) [Google Scholar]

- Xing, J.; Li, Q.; Cong, H.; Li, J.; Chen, Q. Physical mechanism and simulation method of the arc root jumping and arc length variation of the secondary arcs with long-distance transmission lines. Trans. China Electrotech. Soc. 2016, 31, 90–98. [Google Scholar]

- Buhrkall, L. DC components due to ice on the overhead contact wire of AC electrified railways. Electrische Bahnen 2005, 103, 380–389. [Google Scholar]

- Ohtaka, T.; Kertesz, V. Novel black-box arc model validated by highvoltage circuit breaker testing. IEEE Trans. Power Deliv. 2017, 33, 1835–1844. [Google Scholar] [CrossRef]

- Swierczynski, B.; Gonzalez, J.J.; Teulet, P.; Freton, P.; Gleizes, A. Advances in low-voltage circuit breaker modelling. J. Phys. D Appl. Phys. 2004, 37, 595–609. [Google Scholar] [CrossRef]

- Carson, J.R. Wave propagation in overhead wires with ground return. Bell Syst. Tech. J. 1926, 5, 339–359. [Google Scholar] [CrossRef]

- Wei, W.; Zhang, T.; Gao, G.; Wu, G. Influences of pantograph-catenary arc on electrical characteristics of a traction drive system. High Volt. Eng. 2018, 44, 1589–1597. (In Chinese) [Google Scholar]

- Wei, W.; Wu, J.; Gao, G.; Gu, Z.; Liu, X.; Zhu, G.; Wu, G. Study on pantograph arcing in a laboratory simulation system by high-speed photography. IEEE Trans. Plasma Sci. 2016, 44, 2438–2445. [Google Scholar] [CrossRef]

- Bruno, O.; Landi, A.; Papi, M. Phototube sensor for monitoring the quality of current collection on overhead electrified railways. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2001, 3, 231–241. [Google Scholar] [CrossRef]

- Park, Y.; Lee, K.; Kwon, S. Analysis of percentage of arcing between pantograph and overhead contact line as a function of duration of arc. Trans. Korean Inst. Electr. Eng. 2014, 6, 855–859. [Google Scholar] [CrossRef][Green Version]

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| Equivalent resistance of high-voltage cable | 0.014 mΩ/m | Equivalent inductance of high-voltage cable | 0.00013 mH/m | Equivalent capacitance of high-voltage cable | 0.000412 μF/m |

| TB equivalent resistance | 0.41 mΩ | TB equivalent inductance | 0.0011 mH/m | TB equivalent capacitance | 0.0000102 μF/m |

| Contact resistance between adjacent TBs | 6.4 mΩ | Vehicle roof cable capacitance to ground | 0.048 μF | Carbon brush resistance | 0.05 Ω |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, K.; Su, D. Extended Pantograph–Catenary Arc Modeling and an Analysis of the Vehicular-Grounding Electromagnetic Transients of Electric Multiple Units. Energies 2024, 17, 1512. https://doi.org/10.3390/en17071512

Huang K, Su D. Extended Pantograph–Catenary Arc Modeling and an Analysis of the Vehicular-Grounding Electromagnetic Transients of Electric Multiple Units. Energies. 2024; 17(7):1512. https://doi.org/10.3390/en17071512

Chicago/Turabian StyleHuang, Ke, and Dongdong Su. 2024. "Extended Pantograph–Catenary Arc Modeling and an Analysis of the Vehicular-Grounding Electromagnetic Transients of Electric Multiple Units" Energies 17, no. 7: 1512. https://doi.org/10.3390/en17071512

APA StyleHuang, K., & Su, D. (2024). Extended Pantograph–Catenary Arc Modeling and an Analysis of the Vehicular-Grounding Electromagnetic Transients of Electric Multiple Units. Energies, 17(7), 1512. https://doi.org/10.3390/en17071512