European Green Deal: Justification of the Relationships between the Functional Indicators of Bioenergy Production Systems Using Organic Residential Waste Based on the Analysis of the State of Theory and Practice

Abstract

1. Introduction

2. Analysis of Literature Data and Problem Statement

- –

- To propose a methodology for evaluating the interrelationships between functional indicators of bioenergy production systems using the organic waste of residential areas.

- –

- Based on the use of the proposed methodology, to substantiate the dependencies between functional indicators of bioenergy production systems using the organic waste of residential areas and their mathematical models.

3. Methodology for Evaluating Relationships between Functional Indicators of Bioenergy Production Systems Using the Organic Waste of Residential Areas

- –

- electrical energy :where —volume of processing of organic raw materials, t/year.

- –

- thermal energy :

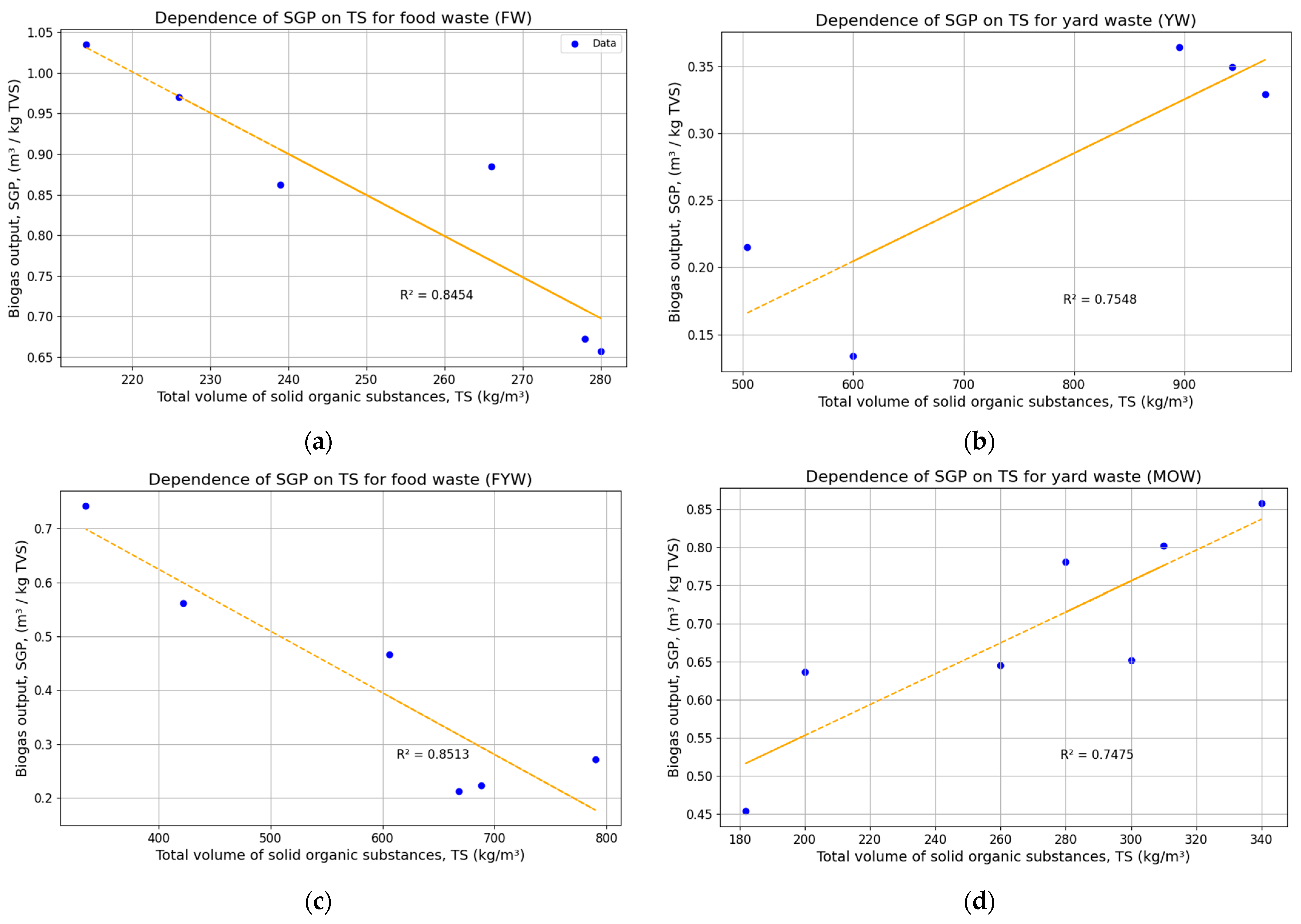

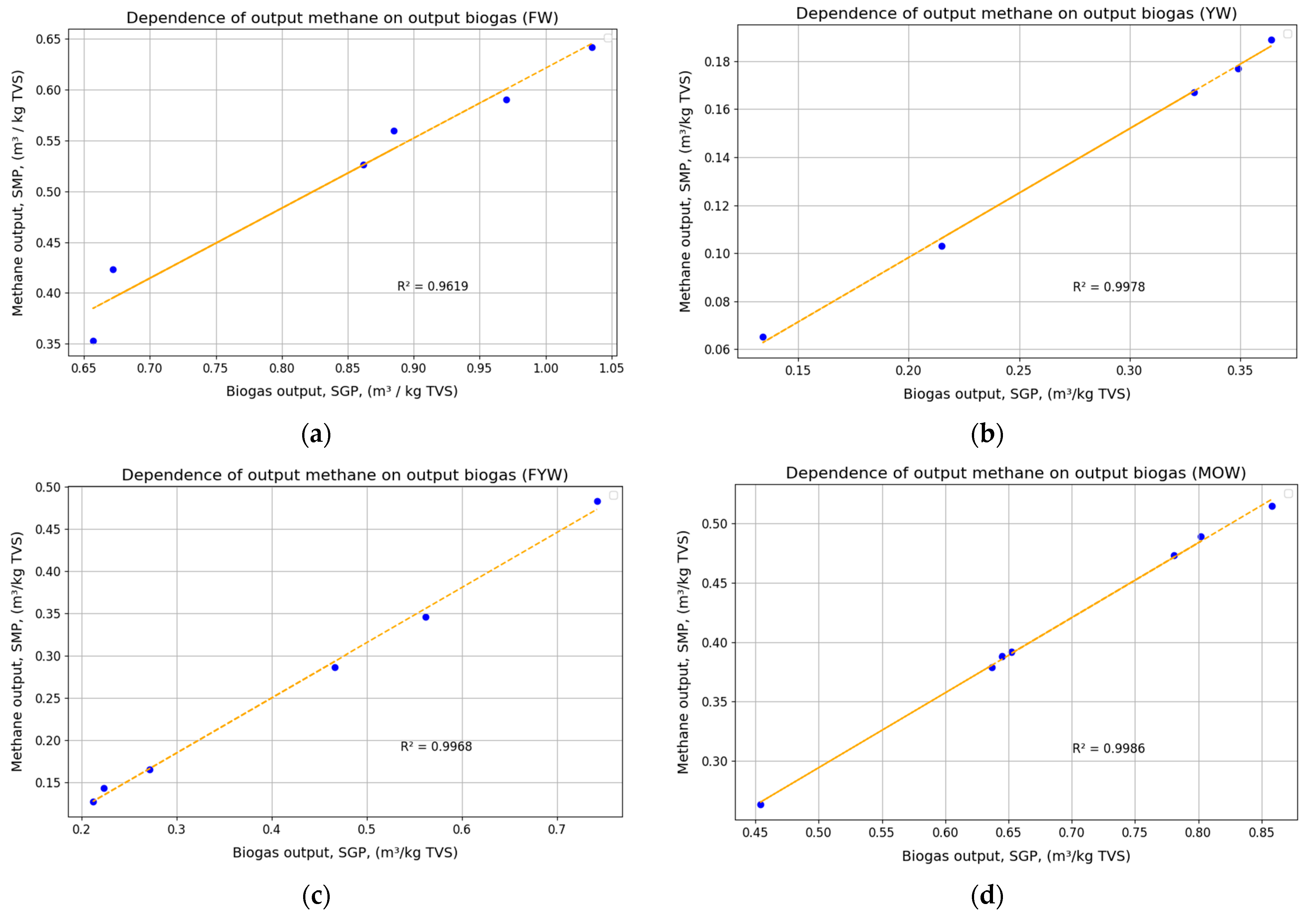

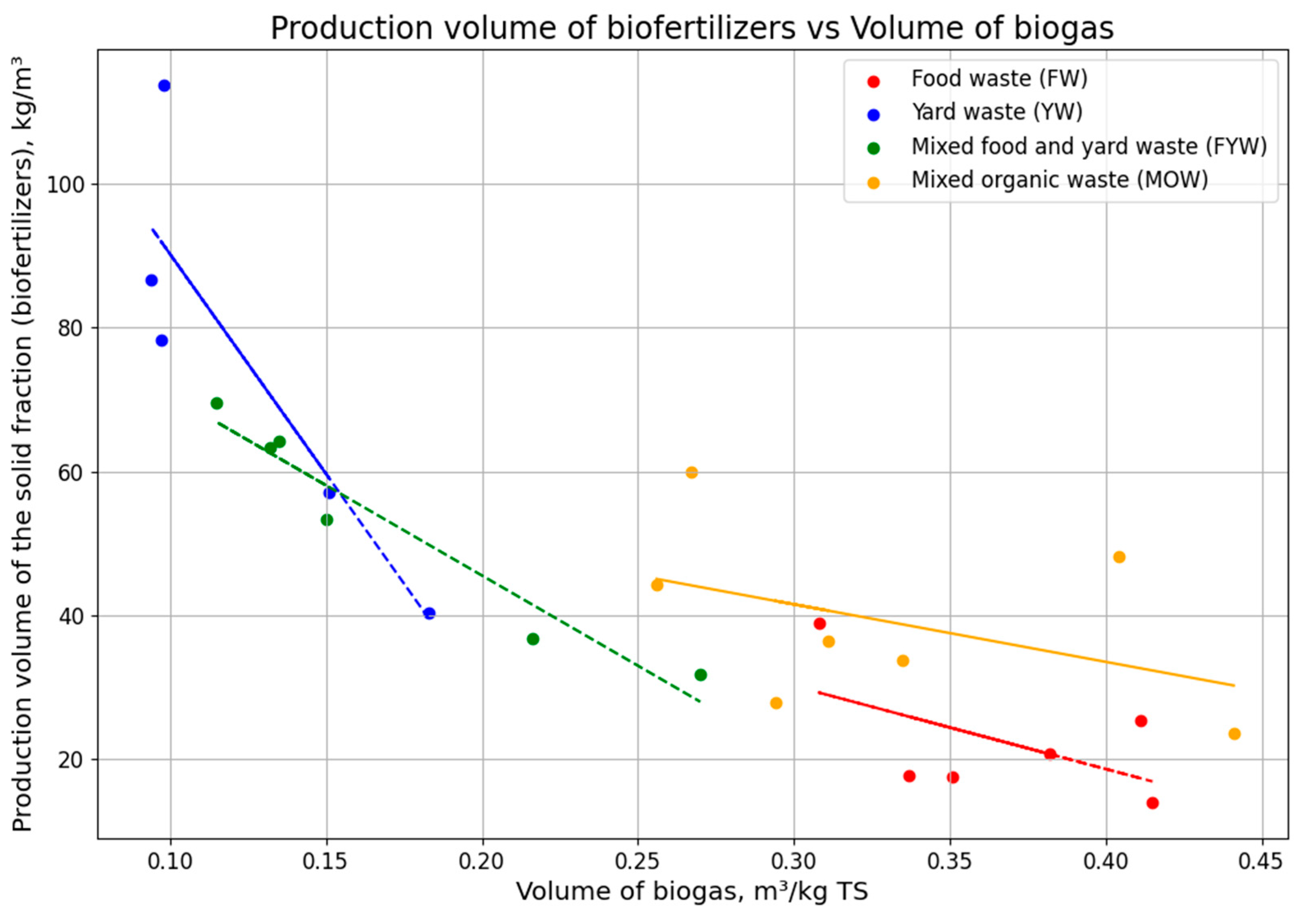

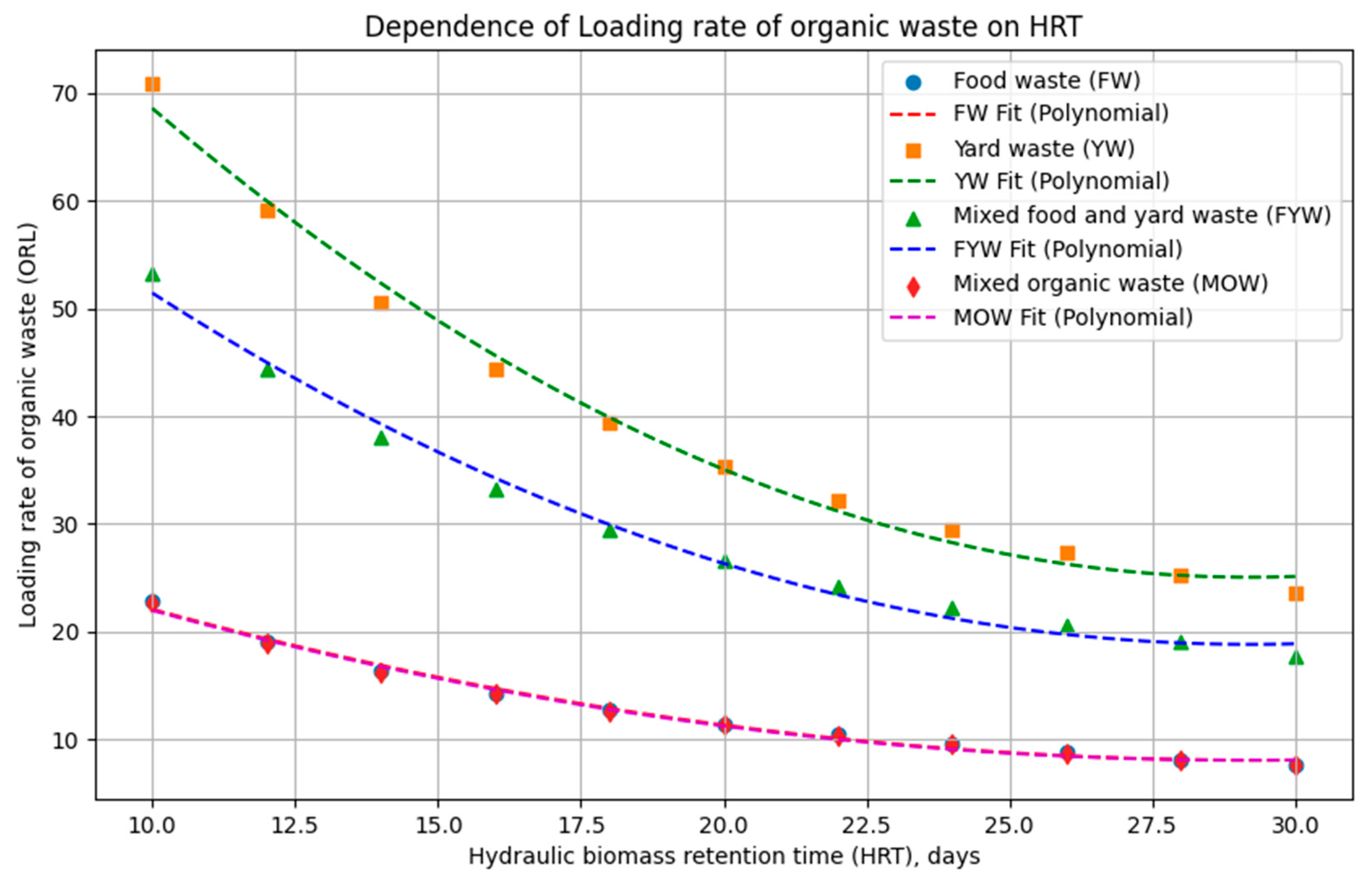

4. Results of Substantiation of Dependencies between Functional Indicators of Bioenergy Production Systems Using the Organic Waste of Residential Areas

- –

- food waste (FW)

- –

- yard waste (YW)

- –

- mixed food and yard waste (FYW)

- –

- mixed organic waste (MOW)

- –

- food waste (FW)

- –

- yard waste (YW)

- –

- mixed food and yard waste (FYW)

- –

- mixed organic waste (MOW)

- –

- food waste (FW)

- –

- yard waste (YW)

- –

- mixed food and yard waste (FYW)

- –

- mixed organic waste (MOW)

- –

- food waste (FW)

- –

- yard waste (YW)

- –

- mixed food and yard waste (FYW)

- –

- mixed organic waste (MOW)

- –

- yard waste (YW) has the highest volume of TS but a low biogas yield and share of methane production;

- –

- food waste (FW) has the highest yield of biogas and, accordingly, the highest share of methane production;

- –

- mixed organic waste (MOW) has the lowest TS volume and the lowest TVS content.

- –

- food waste (FW)

- –

- yard waste (YW)

- –

- mixed food and yard waste (FYW)

- –

- mixed organic waste (MOW)

- –

- food waste (FW)

- –

- yard waste (YW)

- –

- mixed food and yard waste (FYW)

- –

- mixed organic waste (MOW)

- –

- food waste (FW)

- –

- yard waste (YW)

- –

- mixed food and yard waste (FYW)

- –

- mixed organic waste (MOW)

5. Discussion of Research Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations Environment Programme. Global Waste Management Outlook; UNEP: Nairobi, Kenya, 2023; Available online: https://www.unep.org/resources/report/global-waste-management-outlook (accessed on 11 October 2023).

- An Official Website of the European Union. A European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 12 February 2024).

- Tryhuba, I.; Hutsol, T.; Tryhuba, A.; Cieszewska, A.; Kovalenko, N.; Mudryk, K.; Glowacki, S.; Bryś, A.; Tulej, W.; Sojak, M. An Approach to Assessing the State of Organic Waste Generation in Community Households Based on Associative Learning. Sustainability 2023, 15, 15922. [Google Scholar] [CrossRef]

- Di Matteo, U.; Nastasi, B.; Albo, A.; Astiaso Garcia, D. Energy Contribution of OFMSW (Organic Fraction of Municipal Solid Waste) to Energy-Environmental Sustainability in Urban Areas at Small Scale. Energies 2017, 10, 229. [Google Scholar] [CrossRef]

- D’Aquino, C.A.; Pereira, B.A.; Sawatani, T.F.; Santos, S.C.; Sauer, I.L. Biogas Potential from Slums as a Sustainable and Resilient Route for Renewable Energy Diffusion in Urban Areas and Organic Waste Management in Vulnerable Communities in São Paulo. Sustainability 2022, 14, 7016. [Google Scholar] [CrossRef]

- Tryhuba, A.; Hutsol, T.; Tryhuba, I.; Mudryk, K.; Kukharets, V.; Głowacki, S.; Dibrova, L.; Kozak, O.; Pavlenko-Didur, K. Assessment of the Condition of the Project Environment for the Implementation of Technologically Integrated Projects of the “European Green Deal” Using Maize Waste. Energies 2022, 15, 8220. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, T.; Zhang, J.; Liu, H.; Chicaiza-Ortiz, C.; Lee, J.T.E.; He, Y.; Dai, Y.; Tong, Y.W. A machine learning assisted prediction of potential biochar and its applications in anaerobic digestion for valuable chemicals and energy recovery from organic waste. Carbon Neutrality 2024, 3, 2. [Google Scholar] [CrossRef]

- Soltanian, S.; Aghbashlo, M.; Almasi, F.; Hosseinzadeh-Bandbafha, H.; Nizami, A.-S.; Ok, Y.S.; Lam, S.S.; Tabatabaei, M. A critical review of the effects of pretreatment methods on the exergetic aspects of lignocellulosic biofuels. Energy Convers. Manag. 2020, 212, 112792. [Google Scholar] [CrossRef]

- Boyarchuk, V.; Ftoma, O.; Francik, S.; Rudynets, M. Method and Software of Planning of the Substantial Risks in the Projects of Production of raw Material for Biofuel. CEUR Workshop Proc. 2020, 2565, 11. [Google Scholar]

- Burnley, S.J.; Ellis, J.C.; Flowerdew, R.; Poll, A.J.; Prosser, H. Assessing the composition of municipal solid waste in Wales. Resour. Conserv. Recycl. 2007, 49, 264–283. [Google Scholar] [CrossRef]

- Cabbai, V.; Ballico, M.; Aneggi, E.; Goi, D. BMP tests of source selected OFMSW to evaluate anaerobic codigestion with sewage sludge. Waste Manag. 2013, 33, 1626–1632. [Google Scholar] [CrossRef] [PubMed]

- Bong, C.P.C.; Lim, L.Y.; Lee, C.T.; Klemeš, J.J.; Ho, C.S.; Ho, W.S. The characterisation and treatment of food waste for improvement of biogas production during anaerobic digestion: A review. J. Clean. Prod. 2018, 172, 1545–1558. [Google Scholar] [CrossRef]

- Davidsson, Å.; Gruvberger, C.; Christensen, T.H.; Hansen, T.L.; Jansen, J.L.C. Methane yield in source-sorted organic fraction of municipal solid waste. Waste Manag. 2007, 27, 406–414. [Google Scholar] [CrossRef] [PubMed]

- El-Mashad, H.M.; Zhang, R. Biogas production from co-digestion of dairy manure and food waste. Bioresour. Technol. 2010, 101, 4021–4028. [Google Scholar] [CrossRef]

- Mu, L.; Zhang, L.; Zhu, K.; Ma, J.; Ifran, M.; Li, A. Anaerobic co-digestion of sewage sludge, food waste and yard waste: Synergistic enhancement on process stability and biogas production. Sci. Total Environ. 2020, 704, 135429. [Google Scholar] [CrossRef] [PubMed]

- Abad, V.; Avila, R.; Vicent, T.; Font, X. Promoting circular economy in the surroundings of an organic fraction of municipal solid waste anaerobic digestion treatment plant: Biogas production impact and economic factors. Bioresour. Technol. 2019, 283, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Grosso, M.; Nava, C.; Testori, R.; Rigamonti, L.; Viganò, F. The implementation of anaerobic digestion of food waste in a highly populated urban area: An LCA evaluation. Waste Manag. Res. 2012, 30, 78–87. [Google Scholar] [CrossRef] [PubMed]

- Feasibility of Generating Green Power through Anaerobic Digestion of Garden Refuse from the Sacramento Area. Final Report. April 2005. Available online: https://nerc.org/documents/sacramento_feasibility_study.pdf (accessed on 12 February 2024).

- Li, C.; Champagne, P.; Anderson, B.C. Evaluating and modeling biogas production from municipal fat, oil, and grease and synthetic kitchen waste in anaerobic co-digestions. Bioresour. Technol. 2011, 102, 9471–9480. [Google Scholar] [CrossRef]

- Panigrahi, S.; Sharma, H.B.; Dubey, B.K. Anaerobic co-digestion of food waste with pretreated yard waste: A comparative study of methane production, kinetic modeling and energy balance. J. Clean. Prod. 2020, 243, 118480. [Google Scholar] [CrossRef]

- Brown, D.; Li, Y. Solid state anaerobic co-digestion of yard waste and food waste for biogas production. Bioresour. Technol. 2013, 127, 275–280. [Google Scholar] [CrossRef]

- Kovalyshyn, O.; Pendzey, L.; Tretiak, N.; Kulikovska, O.; Kangalov, P.; Shchur, T.; Kocira, S. Methodic Approach to Assessment of the Types of Balanced Land Use of Rural Areas. Agric. Eng. 2022, 26, 215–229. [Google Scholar] [CrossRef]

- Bongoni, R.; Sciubba, E.; Bonoli, A. Food waste management in European households: A critical review of practices and policy. J. Clean. Prod. 2020, 279, 123703. [Google Scholar] [CrossRef]

- Tryhuba, A.; Komarnitskyi, S.; Tryhuba, I.; Hutsol, T.; Yermakov, S.; Muzychenko, A.; Muzychenko, T.; Horetska, I. Planning and risk analysis in projects of procurement of agricultural raw materials for the production of environmentally friendly fuel. Int. J. Renew. Energy Dev. 2022, 11, 569–580. [Google Scholar] [CrossRef]

- Tryhuba, A.; Hutsol, T.; Kuboń, M.; Tryhuba, I.; Komarnitskyi, S.; Tabor, S.; Tomaszewska-Górecka, W. Taxonomy and Stakeholder Risk Management in Integrated Projects of the European Green Deal. Energies 2022, 15, 2015. [Google Scholar] [CrossRef]

- Tryhuba, A.; Hutsol, T.; Tryhuba, I.; Pokotylska, N.; Kovalenko, N.; Tabor, S.; Kwasniewski, D. Risk Assessment of Investments in Projects of Production of Raw Materials for Bioethanol. Processes 2021, 9, 12. [Google Scholar] [CrossRef]

- Tryhuba, A.; Bashynsky, O.; Garasymchuk, I.; Gorbovy, O.; Vilchinska, D.; Dubik, V. Research of the variable natural potential of the wind and energy energy in the northern strip of the ukrainian carpathians. E3S Web Conf. 2020, 154, 06002. [Google Scholar] [CrossRef]

- Batyuk, B.; Dyndyn, M. Coordination of Configurations of Complex Organizational and Technical Systems for Development of Agricultural Sector Branches. J. Autom. Inf. Sci. 2020, 52, 63–76. [Google Scholar]

- Boyarchuk, V.; Ftoma, O.; Padyuka, R.; Rudynets, M. Forecasting the risk of the resource demand for dairy farms basing on machine learning (MoMLeT&DS-2020). CEUR Workshop Proc. 2020, 2631, 327–340. [Google Scholar]

- Pardo, G.; Moral, R.; Bustamante, M.A. Biogas production from household food waste: The effects of particle size and bulking agents. Sci. Total Environ. 2021, 766, 142575. [Google Scholar] [CrossRef]

- Zimbabwe, L.M.; Rithy, K.; Warangkana, J.; Kua-anan, T. Suitability of municipal solid waste in African cities for thermochemical wasteto-energy conversion: The case of Harare Metropolitan City. Waste Manag. Res. 2019, 37, 83–94. [Google Scholar]

- Ratushnyi, R.; Bashynsky, O.; Ptashnyk, V. Development and Usage of a Computer Model of Evaluating the Scenarios of Projects for the Creation of Fire Fighting Systems of Rural Communities. In Proceedings of the Xl-th International Scientific and Practical Conference on Electronics and Information Technologies (ELIT), Lviv, Ukraine, 16–18 September 2019; pp. 34–39. [Google Scholar]

- Boyarchuk, V.; Tryhuba, I.; Tymochko, V.; Bondarchuk, S. Model of assessment of the risk of investing in the projects of production of biofuel raw materials. In Proceedings of the 15th International Scientific and Technical Conference on Computer Sciences and Information Technologies (CSIT), Zbarazh, Ukraine, 23–26 September 2020; Volume 2, pp. 151–154. [Google Scholar]

- Padyuka, R.; Tymochko, V.; Lub, P. Mathematical model for forecasting product losses in crop production projects. CEUR Workshop Proc. 2022, 3109, 25–31. [Google Scholar]

- Zhai, Y.; Liu, L.; Yin, X.; Cao, J.; Bai, X. Comparative study on the performance of various organic waste-to-energy technologies. Renew. Sustain. Energy Rev. 2020, 127, 109874. [Google Scholar]

- Romanowska-Duda, Z.; Piotrowski, K.; Szufa, S.; Sklodowska, M.; Naliwajski, M.; Emmanouil, C.; Kungolos, A.; Zorpas, A.A. Valorization of Spirodela polyrrhiza biomass for the production of biofuels for distributed energy. Sci. Rep. 2023, 13, 16533. [Google Scholar] [CrossRef]

- Koirala, K.; Gruening, C.; Brunner, P.H. Composting of food waste from households: An overview of challenges and potentials. J. Environ. Manag. 2020, 257, 110021. [Google Scholar] [CrossRef]

- Tryhuba, A.; Mudryk, K.; Tryhuba, I.; Hutsol, T.; Glowacki, S.; Faichuk, O.; Kovalenko, N.; Shevtsova, A.; Ratajski, A.; Janaszek-Mankowska, M. Coordination of Configurations of Technologically Integrated “European Green Deal” Projects. Processes 2022, 10, 1768. [Google Scholar] [CrossRef]

- Bashynsky, O. Conceptual model of management of technologically integrated industry development projects. In Proceedings of the 15th International Scientific and Technical Conference on Computer Sciences and Information Technologies (CSIT), Zbarazh, Ukraine, 23–26 September 2020; pp. 155–158. [Google Scholar]

- Ebrahimian, F.; Khoshnevisan, B.; Mohammadi, A.; Karimi, K.; Birkved, M.A. Biorefinery platform to valorize organic fraction of municipal solid waste to biofuels: An early environmental sustainability guidance based on life cycle assessment. Energy Convers. Manag. 2023, 283, 116905. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Villanueva-Rey, P.; Moreira, M.T. Household food waste prevention and management in Europe: A systematic review. J. Clean. Prod. 2021, 314, 128052. [Google Scholar] [CrossRef]

- Ratushny, R.; Bashynsky, O.; Shcherbachenko, O. Identification of firefighting system configuration of rural settlements. MATEC Web Conf. 2018, 247, 35. [Google Scholar]

- Szufa, S.; Piersa, P.; Junga, R.; Błaszczuk, A.; Modlinski, N.; Marczak-Grzesik, M.; Sobek, S.; Adrian, Ł.; Dzikuc, M. Numerical modeling of the co-firing process of an in situ steam-torrefied biomass with coal in a 230 MW industrial-scale boiler. Energy 2023, 263, 125918. [Google Scholar] [CrossRef]

- Boyarchuk, V.; Boiarchuk, O.; Pavlikha, N.; Kovalchuk, N. Study of the impact of the volume of investments in agrarian projects on the risk of their value (ITPM-2021). CEUR Workshop Proc. 2021, 2851, 303–313. [Google Scholar]

- Kukharets, V.; Juočiūnienė, D.; Hutsol, T.; Sukmaniuk, O.; Čėsna, J.; Kukharets, S.; Piersa, P.; Szufa, S.; Horetska, I.; Shevtsova, A. An Algorithm for Managerial Actions on the Rational Use of Renewable Sources of Energy: Determination of the Energy Potential of Biomass in Lithuania. Energies 2023, 16, 548. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. Municipal solid waste management in India: From waste disposal to recovery of resources? J. Mater. Cycles Waste Manag. 2018, 20, 1–12. [Google Scholar]

- Koval, N.; Kondysiuk, I.; Grabovets, V.; Onyshchuk, V. Forecasting the fund of time for performance of works in hybrid projects using machine training technologies. CEUR Workshop Proc. 2021, 2917, 196–206. [Google Scholar]

- Kovalenko, N.; Kovalenko, V.; Hutsol, T.; Ievstafiieva, Y.; Polishchuk, A. Economic Efficiency and Internal Competitive Advantages of Grain Production in the Central Region of Ukraine. Agric. Eng. 2021, 25, 51–62. [Google Scholar] [CrossRef]

- Finnveden, G.; Ekvall, T.; Arushanyan, Y.; Bisaillon, M.; Henriksson, G.; Gunnarsson Östling, U.; Söderman, M.L.; Sahlin, J.; Stenmarck, Å.; Sundberg, J. Policy Instruments towards a Sustainable Waste Management. Sustainability 2013, 5, 841–881. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Cecchi, F.; Pavan, P.; Llabres, P. The Performances of Digesters Treating the Organic Fraction of Municipal Solid Wastes Differently Sorted. Biol. Wastes 1990, 33, 181–199. [Google Scholar] [CrossRef]

- Levis, J.W.; Barlaz, M.A. Anaerobic biodegradability of six biopolymers. J. Environ. Sci. Health 2011, 46, 1261–1270. [Google Scholar]

- Paemanee, C.; Tontisirin, K. Life cycle assessment of electricity generation from organic waste: A case study in Thailand. Renew. Energy 2016, 93, 228–236. [Google Scholar]

- Ftoma, O.; Boyarchuk, O. Method of quantitative evaluation of the risk of benefits for investors of fodder-producing cooperatives. In Proceedings of the 14th International Scientific and Technical Conference on Computer Sciences and Information Technologies (CSIT), Lviv, Ukraine, 17–20 September 2019; pp. 55–58. [Google Scholar]

- Mata-Alvarez, J.; Macé, S.; Llabrés, P. Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives. Bioresour. Technol. 2000, 74, 3–16. [Google Scholar] [CrossRef]

- Shahzad, K.; Ehsan, A.; Nawaz, A.; Irshad, M.; Rizwan, M.; Afzal, M. An integrated approach for energy recovery from organic waste: A review of global practices and future directions. Waste Manag. 2021, 120, 463–480. [Google Scholar] [CrossRef]

- Debono, D.; Sant, T. An assessment of the management of organic household waste in Malta. Waste Manag. 2021, 119, 310–318. [Google Scholar] [CrossRef]

- Kanellos, G.; Tremouli, A.; Kondylis, A.; Stamelou, A.; Lyberatos, G. Anaerobic Co-digestion of the Liquid Fraction of Food Waste with Waste Activated Sludge. Waste Biomass Valorization 2024, 12. [Google Scholar] [CrossRef]

- Ratushny, R.; Bashynsky, O.; Ptashnyk, V. Planning of Territorial Location of Fire-Rescue Formations in Administrative Territory Development Projects. CEUR Workshop Proc. 2020, 2565, 9. [Google Scholar]

- Mostafavi, M.; Afshari, H.; Saif, A. A robust framework for waste-to-energy technology selection: A case study in Nova Scotia, Canada. Energy Convers. Manag. 2023, 284, 116965. [Google Scholar] [CrossRef]

- Makkawi, Y.; Pour, F.H.; Elsayed, Y.; Khan, M.; Moussa, O.; Masek, O.; Badrelzaman, M.; El Tahir, W. Recycling of post-consumption food waste through pyrolysis: Feedstock characteristics, products analysis, reactor performance, and assessment of worldwide implementation potentials. Energy Convers. Manag. 2022, 272, 116348. [Google Scholar] [CrossRef]

- Unyay, H.; Piersa, P.; Zabochnicka, M.; Romanowska-Duda, Z.; Kuryło, P.; Kuligowski, K.; Kazimierski, P.; Hutsol, T.; Dyjakon, A.; Wrzesińska-Jędrusiak, E.; et al. Torrefaction of Willow in Batch Reactor and Co-Firing of Torrefied Willow with Coal. Energies 2023, 16, 8083. [Google Scholar] [CrossRef]

- Kazimierski, P.; Kosmela, P.; Piersa, P.; Szufa, S. Pyrolysis and Torrefaction—Thermal Treatment of Creosote-Impregnated Railroad Ties as a Method of Utilization. Materials 2023, 16, 2704. [Google Scholar] [CrossRef] [PubMed]

- Sikora, J.; Niemiec, M.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Kuboń, M.; Komorowska, M. The Effect of the Addition of a Fat Emulsifier on the Amount and Quality of the Obtained Biogas. Energies 2020, 13, 1825. [Google Scholar] [CrossRef]

- Lisowska, A.; Filipek-Mazur, B.; Komorowska, M.; Niemiec, M.; Bar-Michalczyk, D.; Kuboń, M.; Tabor, S.; Gródek-Szostak, Z.; Szeląg-Sikora, A.; Sikora, J.; et al. Environmental and Production Aspects of Using Fertilizers Based on Waste Elemental Sulfur and Organic Materials. Materials 2022, 15, 3387. [Google Scholar] [CrossRef] [PubMed]

- Kuboń, M.; Sikora, J.; Olech, E.; Szeląg-Sikora, A. Energy Islands as a Potential Source of Securing the Energy Supply of Bio-Feedstock for Biogas Plants. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer Proceedings in Energy; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Czekała, W.; Nowak, M.; Bojarski, W. Anaerobic Digestion and Composting as Methods of Bio-Waste Management. Agric. Eng. 2023, 27, 173–186. [Google Scholar] [CrossRef]

- Unyay, H.; Piersa, P.; Perendeci, N.A.; Wielgosinski, G.; Szufa, S. Valorization of Anaerobic Digestate: Innovative Approaches for Sustainable Resource Management and Energy Production—Case Studies from Turkey and Poland. Int. J. Green Energy 2023, 1–16. [Google Scholar] [CrossRef]

- Slezak, R.; Unyay, H.; Szufa, S.; Ledakowicz, S. An Extensive Review and Comparison of Modern Biomass Reactors Torrefaction vs. Biomass Pyrolizers—Part 2. Energies 2023, 16, 2212. [Google Scholar] [CrossRef]

| Option | Description/Literary Source | Total Volume of Solid Organic Substances, TS (kg/m3) | The Content of Volatile Organic Substances, TVS (% from TS) | Biogas Output, SGP, (m3/kg TVS) | Methane Output, SMP, (m3/kg TVS) | Kinetic Constant of Methane Production, km |

|---|---|---|---|---|---|---|

| Food waste (FW) | ||||||

| VFW1 | Kitchen waste/[12] | 214.1 | 88.1 | 1.035 | 0.642 | 1.611 |

| VFW2 | Household waste/[13] | 280.0 | 86.1 | 0.657 | 0.353 | 1.857 |

| VFW3 | Food waste/[14] | 266.0 | 93.4 | 0.885 | 0.560 | 1.580 |

| VFW4 | Food waste/[15] | 239.0 | 91.3 | 0.862 | 0.526 | 1.637 |

| VFW5 | Food waste/[19] | 278.0 | 93.6 | 0.672 | 0.375 | 1.788 |

| VFW6 | Food waste/[20] | 226.0 | 93.8 | 0.970 | 0.590 | 1.644 |

| Average | 250.5 | 91.1 | 0.847 | 0.508 | 1.686 | |

| Yard waste (YW) | ||||||

| VYW1 | Yard waste/[12] | 504.0 | 92.0 | 0.215 | 0.103 | 2.087 |

| VYW2 | Yard waste/[15] | 973.0 | 91.1 | 0.329 | 0.167 | 1.970 |

| VYW3 | Yard waste/[18] | 600.0 | 90.5 | 0.134 | 0.065 | 2.062 |

| VYW4 | Yard waste/[20] | 895.0 | 87.3 | 0.364 | 0.189 | 1.926 |

| VYW5 | Yard waste/[21] | 943.0 | 91.7 | 0.349 | 0.177 | 1.972 |

| Average | 783.0 | 90.5 | 0.278 | 0.140 | 2.003 | |

| Mixed food and yard waste (FYW) | ||||||

| VFYW1 | FW + YW (1:1)/[15] | 606.0 | 91.2 | 0.466 | 0.286 | 1.629 |

| VFYW2 | FW + YW (1:3)/[15] | 790.0 | 91.2 | 0.271 | 0.165 | 1.642 |

| VFYW3 | FW + YW (1:5)/[21] | 688.0 | 90.8 | 0.223 | 0.143 | 1.559 |

| VFYW4 | FW + YW (1:10)/[21] | 668.0 | 90.4 | 0.212 | 0.127 | 1.669 |

| VFYW5 | FW + YW (3:1)/[15] | 422.0 | 91.3 | 0.562 | 0.346 | 1.624 |

| VFYW6 | FW + YW (5:1)/[17] | 335.0 | 90.5 | 0.742 | 0.483 | 1.536 |

| Average | 585.0 | 90.9 | 0.413 | 0.258 | 1.606 | |

| Mixed organic waste (MOW) | ||||||

| VMOW1 | Sorted from house/[10] | 200.0 | 88.2 | 0.637 | 0.379 | 1.680 |

| VMOW2 | Sorted from house/[11] | 181.9 | 73.5 | 0.454 | 0.263 | 1.726 |

| VMOW3 | Sorted from house/[16] | 260.0 | 87.0 | 0.645 | 0.388 | 1.668 |

| VMOW4 | Sorted from house/[16] | 310.0 | 91.0 | 0.802 | 0.489 | 1.640 |

| VMOW5 | Sorted from house/[16] | 280.0 | 87.0 | 0.781 | 0.473 | 1.650 |

| VMOW6 | Sorted from house/[16] | 300.0 | 80.0 | 0.652 | 0.392 | 1.660 |

| VMOW7 | Sorted from house/[16] | 340.0 | 87.0 | 0.858 | 0.515 | 1.666 |

| Average | 267.0 | 85.0 | 0.690 | 0.414 | 1.670 | |

| Option | Volume of Biogas, , m3/kg TS | Methane Content G in Biogas, % | Volume of Methane Produced, , m3 | Volume of Electricity Production, E, kWh | Volume of Thermal Energy Production, Q, kWh | Production Volume of the Solid Fraction (Biofertilizers), F, kg/m3 |

|---|---|---|---|---|---|---|

| Food waste (FW) | ||||||

| VFW1 | 0.411 | 0.620 | 0.255 | 5.666 | 5.932 | 25.478 |

| VFW2 | 0.308 | 0.537 | 0.165 | 3.668 | 3.262 | 38.920 |

| VFW3 | 0.351 | 0.633 | 0.222 | 4.932 | 5.174 | 17.556 |

| VFW4 | 0.382 | 0.610 | 0.233 | 5.175 | 4.860 | 20.793 |

| VFW5 | 0.337 | 0.558 | 0.188 | 4.171 | 3.465 | 17.792 |

| VFW6 | 0.415 | 0.608 | 0.252 | 5.604 | 5.452 | 14.012 |

| Average | 0.363 | 0.600 | 0.218 | 4.840 | 4.694 | 22.420 |

| Yard waste (YW) | ||||||

| VYW1 | 0.183 | 0.479 | 0.087 | 1.941 | 0.952 | 40.320 |

| VYW2 | 0.094 | 0.508 | 0.048 | 1.055 | 1.543 | 86.597 |

| VYW3 | 0.151 | 0.485 | 0.073 | 1.624 | 0.601 | 57.000 |

| VYW4 | 0.098 | 0.519 | 0.051 | 1.124 | 1.746 | 113.665 |

| VYW5 | 0.097 | 0.507 | 0.049 | 1.095 | 1.635 | 78.269 |

| Average | 0.116 | 0.504 | 0.058 | 1.292 | 1.294 | 74.385 |

| Mixed food and yard waste (FYW) | ||||||

| VFYW1 | 0.150 | 0.614 | 0.092 | 2.050 | 2.643 | 53.328 |

| VFYW2 | 0.115 | 0.609 | 0.070 | 1.560 | 1.525 | 69.520 |

| VFYW3 | 0.132 | 0.641 | 0.085 | 1.879 | 1.321 | 63.296 |

| VFYW4 | 0.135 | 0.599 | 0.081 | 1.800 | 1.173 | 64.128 |

| VFYW5 | 0.216 | 0.616 | 0.133 | 2.957 | 3.197 | 36.714 |

| VFYW6 | 0.270 | 0.651 | 0.176 | 3.904 | 4.463 | 31.825 |

| Average | 0.155 | 0.625 | 0.097 | 2.155 | 2.384 | 53.235 |

| Mixed organic waste (MOW) | ||||||

| VMOW1 | 0.441 | 0.595 | 0.262 | 5.825 | 3.502 | 23.600 |

| VMOW2 | 0.404 | 0.579 | 0.234 | 5.196 | 2.430 | 48.204 |

| VMOW3 | 0.335 | 0.602 | 0.201 | 4.469 | 3.585 | 33.800 |

| VMOW4 | 0.294 | 0.610 | 0.179 | 3.973 | 4.518 | 27.900 |

| VMOW5 | 0.311 | 0.606 | 0.188 | 4.178 | 4.371 | 36.400 |

| VMOW6 | 0.267 | 0.601 | 0.160 | 3.559 | 3.622 | 60.000 |

| VMOW7 | 0.256 | 0.600 | 0.154 | 3.410 | 4.759 | 44.200 |

| Average | 0.318 | 0.600 | 0.191 | 4.240 | 3.825 | 40.050 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tryhuba, I.; Tryhuba, A.; Hutsol, T.; Lopushniak, V.; Cieszewska, A.; Andrushkiv, O.; Barabasz, W.; Pikulicka, A.; Kowalczyk, Z.; Vasyuk, V. European Green Deal: Justification of the Relationships between the Functional Indicators of Bioenergy Production Systems Using Organic Residential Waste Based on the Analysis of the State of Theory and Practice. Energies 2024, 17, 1461. https://doi.org/10.3390/en17061461

Tryhuba I, Tryhuba A, Hutsol T, Lopushniak V, Cieszewska A, Andrushkiv O, Barabasz W, Pikulicka A, Kowalczyk Z, Vasyuk V. European Green Deal: Justification of the Relationships between the Functional Indicators of Bioenergy Production Systems Using Organic Residential Waste Based on the Analysis of the State of Theory and Practice. Energies. 2024; 17(6):1461. https://doi.org/10.3390/en17061461

Chicago/Turabian StyleTryhuba, Inna, Anatoliy Tryhuba, Taras Hutsol, Vasyl Lopushniak, Agata Cieszewska, Oleh Andrushkiv, Wiesław Barabasz, Anna Pikulicka, Zbigniew Kowalczyk, and Vyacheslav Vasyuk. 2024. "European Green Deal: Justification of the Relationships between the Functional Indicators of Bioenergy Production Systems Using Organic Residential Waste Based on the Analysis of the State of Theory and Practice" Energies 17, no. 6: 1461. https://doi.org/10.3390/en17061461

APA StyleTryhuba, I., Tryhuba, A., Hutsol, T., Lopushniak, V., Cieszewska, A., Andrushkiv, O., Barabasz, W., Pikulicka, A., Kowalczyk, Z., & Vasyuk, V. (2024). European Green Deal: Justification of the Relationships between the Functional Indicators of Bioenergy Production Systems Using Organic Residential Waste Based on the Analysis of the State of Theory and Practice. Energies, 17(6), 1461. https://doi.org/10.3390/en17061461