Near-Infrared Spectroscopy Modeling of Combustion Characteristics in Chip and Ground Biomass from Fast-Growing Trees and Agricultural Residue

Abstract

1. Introduction

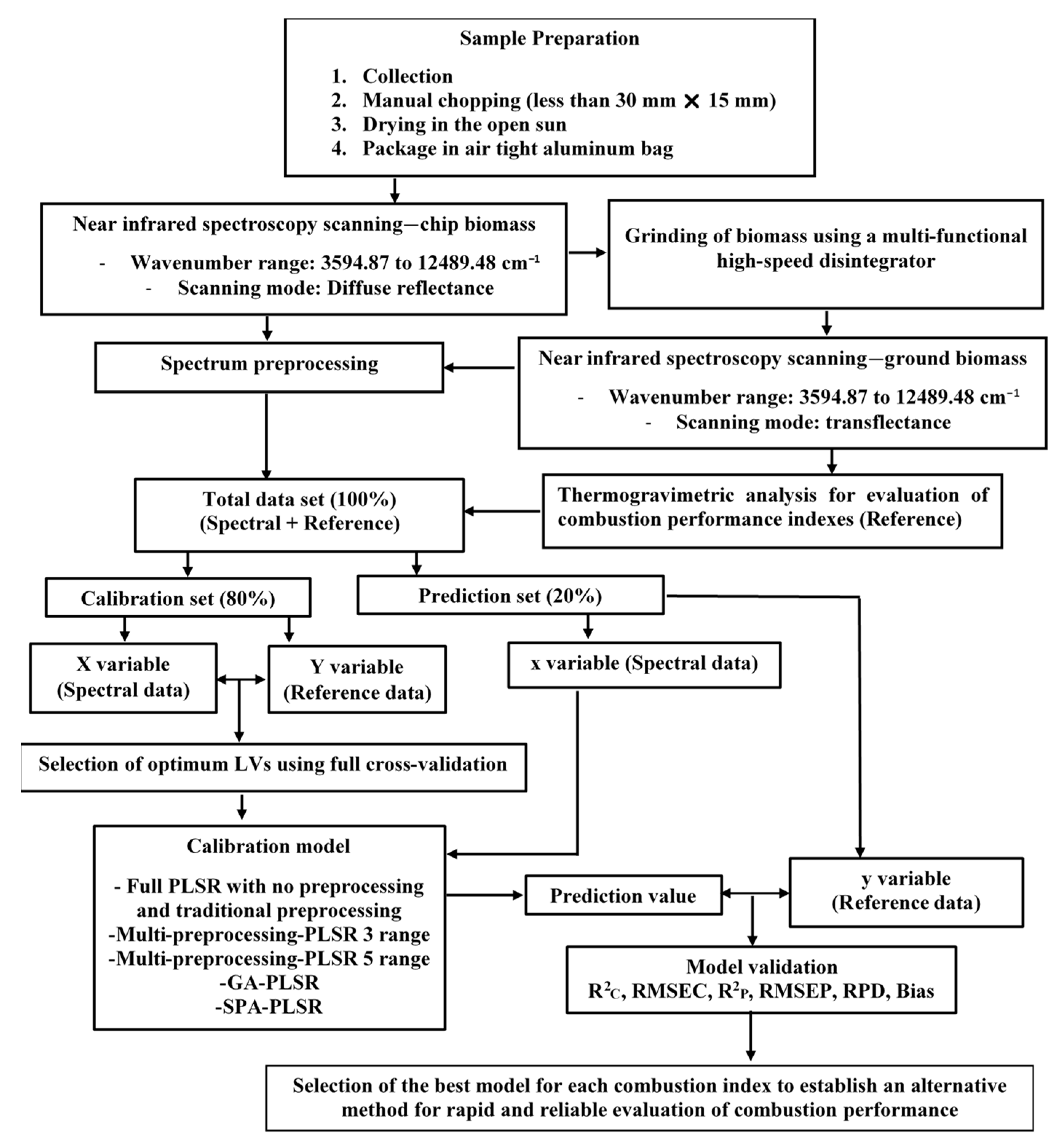

2. Materials and Methods

2.1. Sample Preparation

2.2. FT-NIRS Scanning

2.3. Thermogravimetric Analysis Experiment

2.4. Reference Data Calculation

2.5. Outlier Identification

2.6. Partial Least Squares Regression Modeling

3. Results and Discussion

3.1. NIR Spectra of Fast-Growing Trees and Agricultural Residues

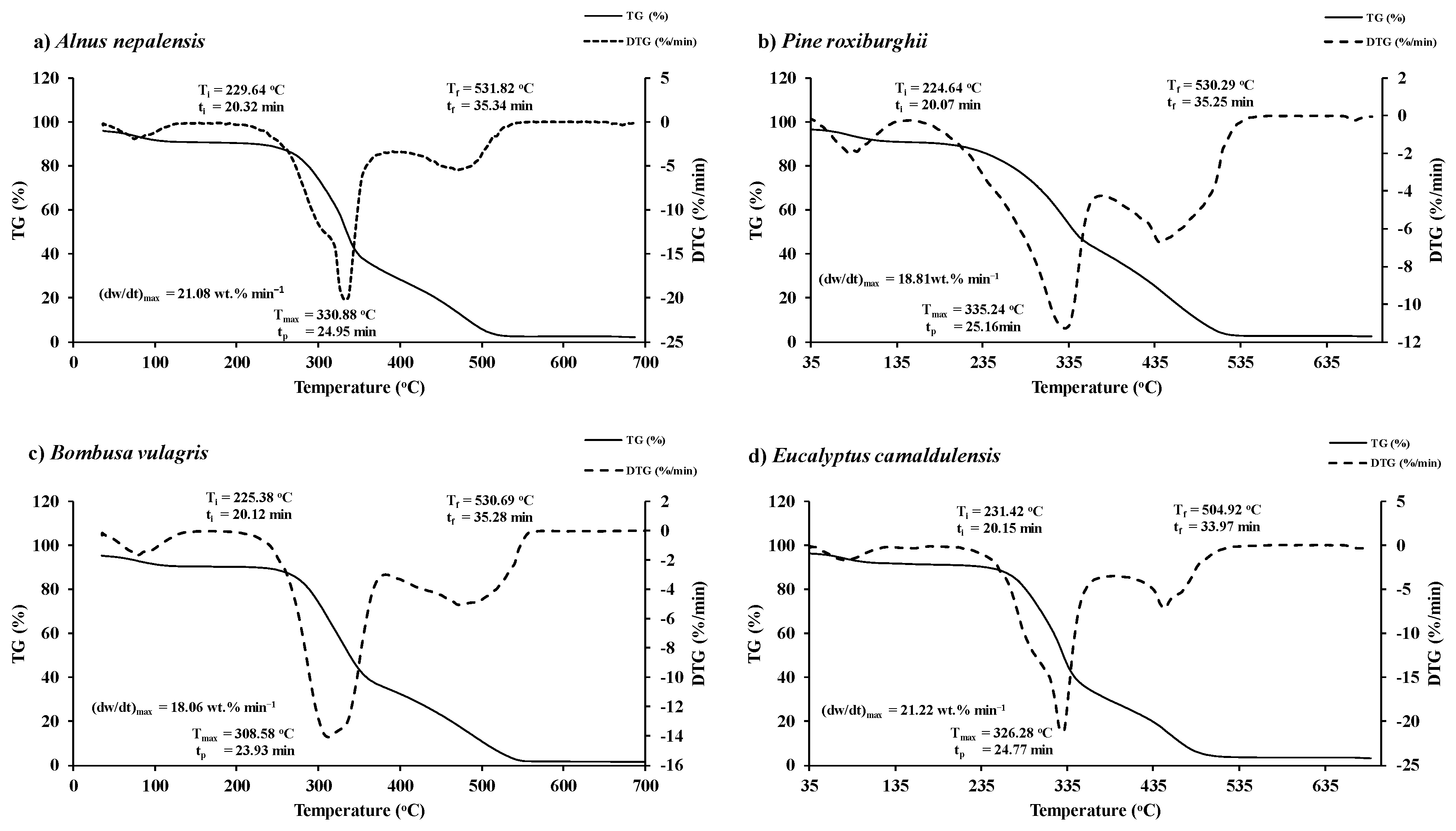

3.2. Combustion Characteristic Parameters and Combustion Performance Indices from TGA

3.3. Modeling for Combustion Performance Indices

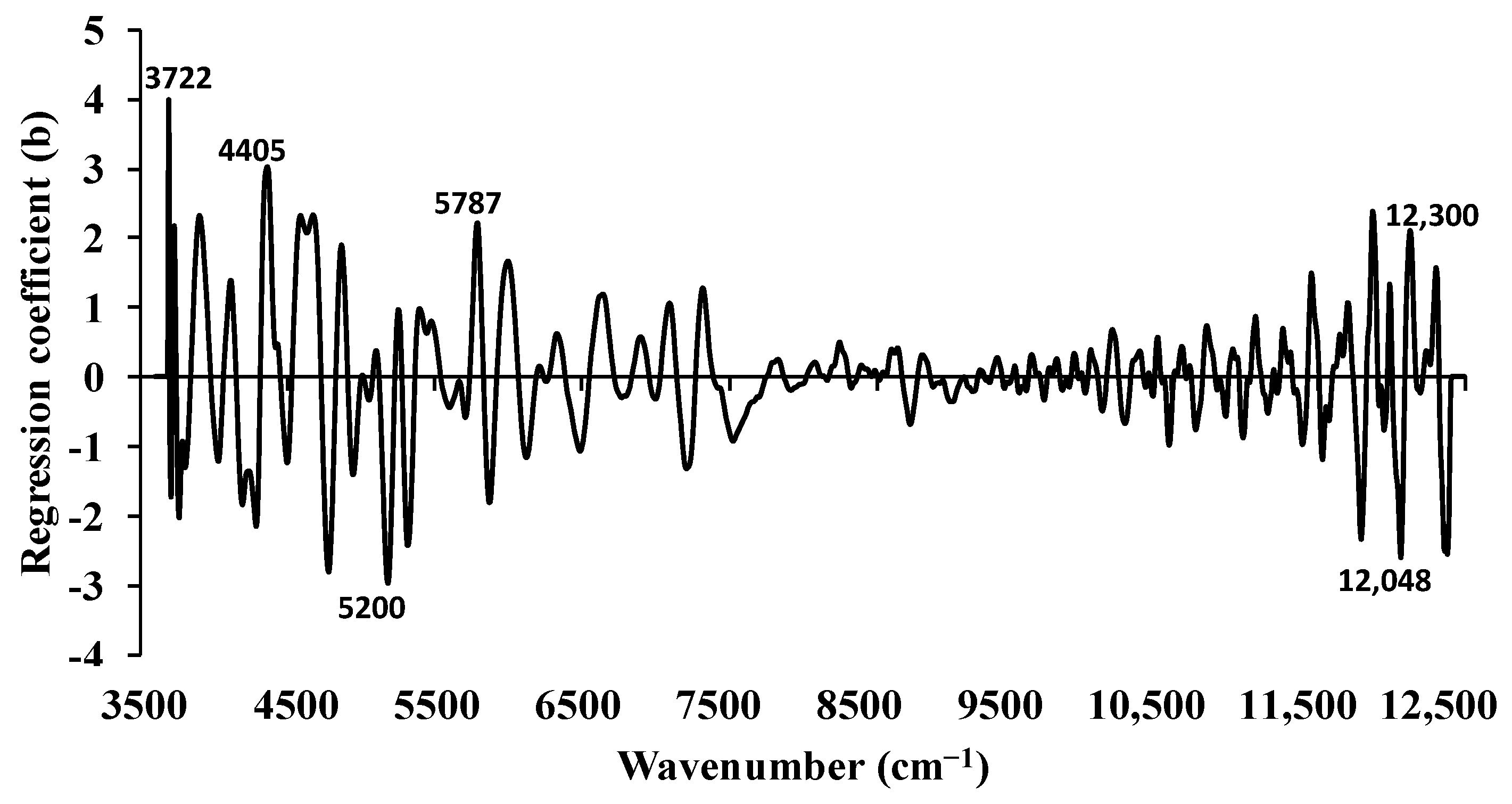

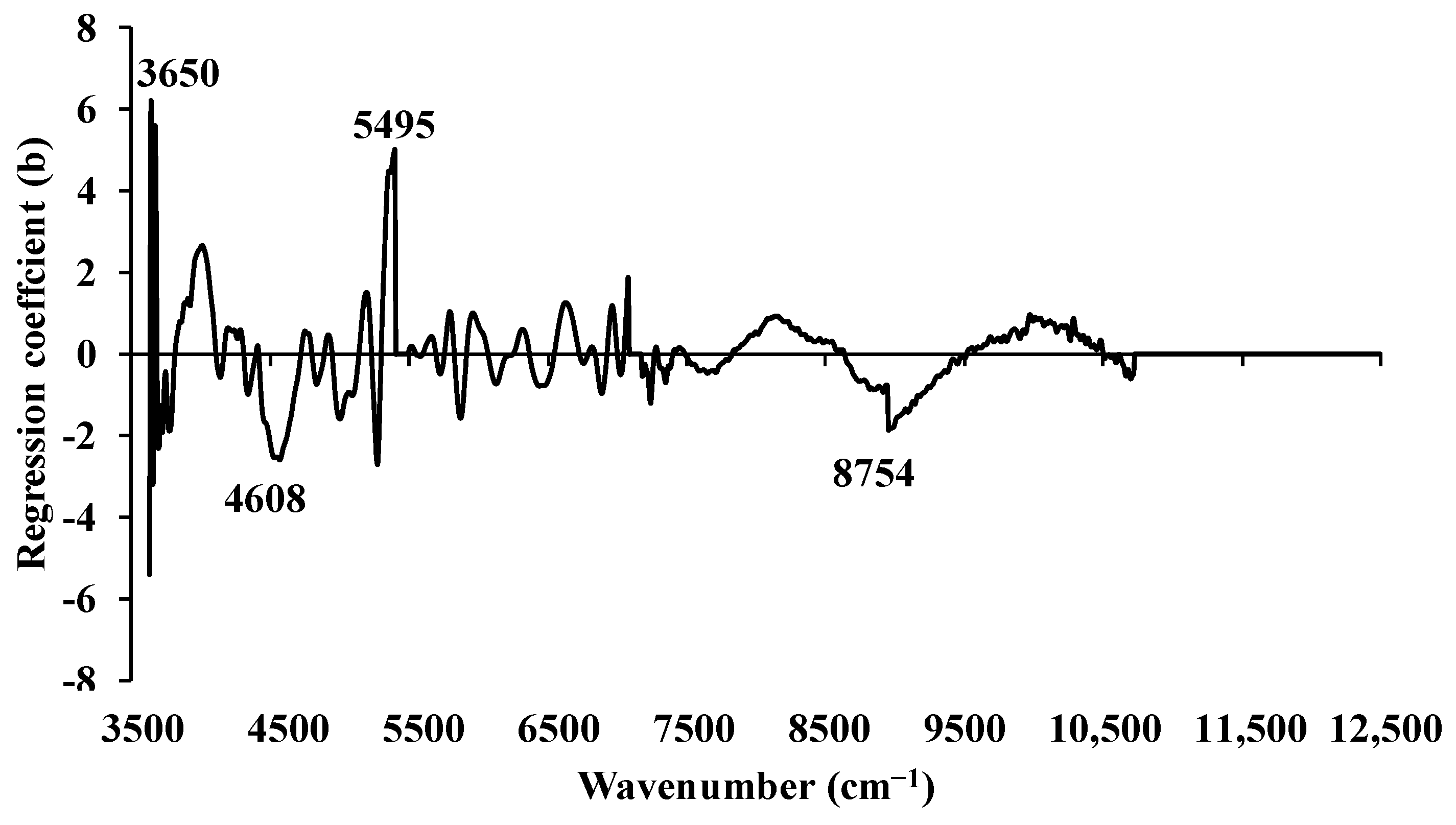

3.3.1. Ignition Index (Di)

3.3.2. Burnout Index (Df)

3.3.3. Comprehensive Combustion Index (Si)

3.3.4. Flammability Index (Ci)

3.4. Comparison with Previous Work

3.5. Benefit of Combined Agricultural Residue with Fast-Growing Trees in Model Development

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Ci | flammability index |

| D1 | first derivative |

| D2 | second derivative |

| Di | ignition index |

| Df | burnout index |

| DTG | derivative thermogravimetric |

| FT | Fourier transform |

| GA | genetic algorithm |

| LVs | number of latent variables |

| Max | maximum |

| Min | minimum |

| Mean | average |

| MSC | multiplicative scatter correction |

| MP | multi-preprocessing |

| NIRS | near-infrared spectroscopy |

| PLSR | partial least squares regression |

| R2 | coefficient of determination |

| R2C | coefficient of determination of calibration set |

| R2P | coefficient of determination of prediction set |

| RPD | ratio of prediction to deviation |

| RMSEC | root mean square error of calibration set |

| RMSEP | root mean square error of prediction set |

| Si | comprehensive combustion performance |

| SD | standard deviation |

| SEC | standard error of calibration set |

| SEP | standard error of prediction set |

| SNV | standard normal variate |

| SPA | successive projection algorithm |

| TG | thermogravimetric |

| TGA | thermogravimetric analysis |

| Ti | ignition temperature |

| Tf | burnout temperature |

| ti | ignition time |

| tf | burnout time |

References

- IEA. Greenhouse Gas Emissions from Energy Data Explorer. Available online: https://www.iea.org/data-and-statistics/data-tools/greenhouse-gas-emissions-from-energy-data-explorer (accessed on 11 August 2023).

- Manić, N.; Janković, B.; Stojiljković, D.; Radojević, M.; Somoza, B.C.; Medić, L. Self-ignition potential assessment for different biomass feedstocks based on the dynamic thermal analysis. Clean. Eng. Technol. 2021, 2, 100040. [Google Scholar] [CrossRef]

- Chen, R.; Sheng, Q.; Dai, X.; Dong, B. Upgrading of sewage sludge by low temperature pyrolysis: Biochar fuel properties and combustion behavior. Fuel 2021, 300, 121007. [Google Scholar] [CrossRef]

- Yi, Q.; Qi, F.; Cheng, G.; Zhang, Y.; Xiao, B.; Hu, Z.; Liu, S.; Cai, H.; Xu, S. Thermogravimetric analysis of co-combustion of biomass and biochar. J. Therm. Anal. Calorim. 2013, 112, 1475–1479. [Google Scholar] [CrossRef]

- He, Y.; Chen, X.; Tang, X.; Chen, S.; Evrendilek, F.; Chen, T.; Dai, W.; Liu, J. Co-combustion dynamics and products of textile dyeing sludge with waste rubber versus polyurethane tires of shared bikes. J. Environ. Chem. Eng. 2023, 11, 109196. [Google Scholar] [CrossRef]

- Wu, X.; Liu, J.; Wei, Z.; Chen, Z.; Evrendilek, F.; Huang, W. Oxy-fuel co-combustion dynamics of phytoremediation biomass and textile dyeing sludge: Gas-to-ash pollution abatement. Sci. Total Environ. 2022, 825, 153656. [Google Scholar] [CrossRef] [PubMed]

- Baqain, M.; Neshumayev, D.; Konist, A. TG-MS analysis and kinetic study of co-combustion of ca-rich oil shale with biomass in air and oxy-like conditions. Carbon Capture Sci. Technol. 2024, 10, 100162. [Google Scholar] [CrossRef]

- Demirbas, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Jia, Y.; Li, Z.; Wang, Y.; Wang, X.; Lou, C.; Xiao, B.; Lim, M. Visualization of combustion phases of biomass particles: Effects of fuel properties. ACS Omega 2021, 6, 27702–27710. [Google Scholar] [CrossRef] [PubMed]

- Gaba, A.; Iordache, S.F. Reduction of air pollution by combustion processes. In The Impact of Air Pollution on Health, Economy, Environment and Agricultural Sources; InTech: London, UK, 2011; pp. 119–142. [Google Scholar]

- Alves, J.L.F.; da Silva, J.C.G.; Sellin, N.; de Borba Prá, F.; Sapelini, C.; Souza, O.; Marangoni, C. Upgrading of banana leaf waste to produce solid biofuel by torrefaction: Physicochemical properties, combustion behaviors, and potential emissions. Environ. Sci. Pollut. Res. 2022, 29, 25733–25747. [Google Scholar] [CrossRef] [PubMed]

- Wnorowska, J.; Ciukaj, S.; Kalisz, S. Thermogravimetric analysis of solid biofuels with additive under air atmosphere. Energies 2021, 14, 2257. [Google Scholar] [CrossRef]

- Jia, G. Combustion characteristics and kinetic analysis of biomass pellet fuel using thermogravimetric analysis. Processes 2021, 9, 868. [Google Scholar] [CrossRef]

- Bampenrat, A.; Sukkathanyawat, H.; Seangwattana, T. Coal/Biomass Co-Combustion Investigation by Thermogravimetric Analysis, E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021; p. 01002. [Google Scholar]

- Liu, J.; Jiang, X.; Cai, H.; Gao, F. Study of combustion characteristics and kinetics of agriculture briquette using thermogravimetric analysis. ACS Omega 2021, 6, 15827–15833. [Google Scholar] [CrossRef] [PubMed]

- Idris, S.S.; Abd Rahman, N.; Ismail, K. Combustion characteristics of Malaysian oil palm biomass, sub-bituminous coal and their respective blends via thermogravimetric analysis (TGA). Bioresour. Technol. 2012, 123, 581–591. [Google Scholar] [CrossRef] [PubMed]

- Sait, H.H.; Hussain, A.; Salema, A.A.; Ani, F.N. Pyrolysis and combustion kinetics of date palm biomass using thermogravimetric analysis. Bioresour. Technol. 2012, 118, 382–389. [Google Scholar] [CrossRef] [PubMed]

- Cao, W.; Li, J.; Lue, L. Study on the ignition behavior and kinetics of combustion of biomass. Energy Procedia 2017, 142, 136–141. [Google Scholar] [CrossRef]

- Lu, J.-J.; Chen, W.-H. Investigation on the ignition and burnout temperatures of bamboo and sugarcane bagasse by thermogravimetric analysis. Appl. Energy 2015, 160, 49–57. [Google Scholar] [CrossRef]

- Arromdee, P.; Ninduangdee, P. Combustion characteristics of pelletized-biomass fuels: A thermogravimetric analysis and combustion study in a fluidized-bed combustor. Energy Ecol. Environ. 2023, 8, 69–88. [Google Scholar] [CrossRef]

- Iryani, D.A.; Rakaseri, I.; Azhar, A.; Haryanto, A.; Hidayat, W.; Hasanudin, U. Thermogravimetric assessment for combustion characteristic of torrefied pellet biomass from agricultural solid waste. IOP Conf. Ser. Earth Environ. Sci. 2023, 1187, 012019. [Google Scholar] [CrossRef]

- Luthfi, N.; Ohkoshi, T.; Tamaru, Y.; Fukushima, T.; Takisawa, K. Investigation into the combustion kinetics and spontaneous ignition of sweet sorghum as energy resource. Bioresour. Bioprocess. 2022, 9, 49. [Google Scholar] [CrossRef]

- El-Sayed, S.A.; Mostafa, M.E.; Khass, T.M.; Noseir, E.H.; Ismail, M.A. Combustion and mass loss behavior and characteristics of a single biomass pellet positioning at different orientations in a fixed bed reactor. Biomass Convers. Biorefinery 2023, 2023, 1–21. [Google Scholar] [CrossRef]

- Guo, Q.; Cheng, Z.; Chen, G.; Yan, B.; Hou, L.A.; Ronsse, F. Optimal strategy for clean and efficient biomass combustion based on ash deposition tendency and kinetic analysis. J. Clean. Prod. 2020, 271, 122529. [Google Scholar] [CrossRef]

- Yuan, Y.; He, Y.; Tan, J.; Wang, Y.; Kumar, S.; Wang, Z. Co-Combustion characteristics of typical biomass and coal blends by thermogravimetric analysis. Front. Energy Res. 2021, 9, 753622. [Google Scholar] [CrossRef]

- Chen, G.-B.; Li, J.-W.; Lin, H.-T.; Wu, F.-H.; Chao, Y.-C. A study of the production and combustion characteristics of pyrolytic oil from sewage sludge using the taguchi method. Energies 2018, 11, 2260. [Google Scholar] [CrossRef]

- Posom, J.; Shrestha, B.; Maraphum, K.; Pitak, L.; Saengprachatanarug, K.; Sirisomboon, P.; Shrestha, B.P. Near-Infrared Spectroscopy, Hyperspectral, Multispectral Imaging Principles and Applications in Energy Properties of Biomass. In A Guide to Near-Infrared Spectroscopy, 1st ed.; Garcia Martin, J.F., Ed.; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2023. [Google Scholar]

- Shrestha, B.; Posom, J.; Sirisomboon, P.; Shrestha, B.P.; Funke, A. Effect of Combined Non-Wood and Wood Spectra of Biomass Chips on Rapid Prediction of Ultimate Analysis Parameters Using near Infrared Spectroscopy. Energies 2024, 17, 439. [Google Scholar] [CrossRef]

- Reza, M.S.; Taweekun, J.; Afroze, S.; Siddique, S.A.; Islam, M.S.; Wang, C.; Azad, A.K. Investigation of Thermochemical Properties and Pyrolysis of Barley Waste as a Source for Renewable Energy. Sustainability 2023, 15, 1643. [Google Scholar] [CrossRef]

- Shrestha, B.; Posom, J.; Sirisomboon, P.; Shrestha, B.P.; Pornchaloempong, P.; Funke, A. NIR Spectroscopy as an Alternative to Thermogravimetric Analyzer for Biomass Proximate Analysis: Comparison of Chip and Ground Biomass Models. Energies 2024, 17, 800. [Google Scholar] [CrossRef]

- Yi, B.; Chen, M.; Gao, Y.; Cao, C.; Wei, Q.; Zhang, Z.; Li, L. Investigation on the co-combustion characteristics of multiple biomass and coal under O2/CO2 condition and the interaction between different biomass. J. Environ. Manag. 2023, 325, 116498. [Google Scholar] [CrossRef] [PubMed]

- Vamvuka, D.; Loukakou, E.; Avgoustidis, C.; Stratakis, A.; Pavloudakis, F.; Sfakiotakis, S. Co-combustion characteristics of lignite/woody biomass blends. Reactivity and fusibility assessment. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 3916–3930. [Google Scholar] [CrossRef]

- Shrestha, B.; Posom, J.; Sirisomboon, P.; Shrestha, B.P. Comprehensive Assessment of Biomass Properties for Energy Usage Using Near-Infrared Spectroscopy and Spectral Multi-Preprocessing Techniques. Energies 2023, 16, 5351. [Google Scholar] [CrossRef]

- Stolov, A.A.; Simoff, D.A.; Li, J. Thermal stability of specialty optical fibers. J. Light. Technol. 2008, 26, 3443–3451. [Google Scholar] [CrossRef]

- Shrestha, B.; Shrestha, Z.; Posom, J.; Sirisomboon, P.; Shrestha, B.P. Evaluating limit of detection and quantification for higher heating value and ultimate analysis of fast-growing trees and agricultural residues biomass using NIRS. Eng. Appl. Sci. Res. 2023, 50, 612–618. [Google Scholar]

- Maraphum, K.; Ounkaew, A.; Kasemsiri, P.; Hiziroglu, S.; Posom, J. Wavelengths selection based on genetic algorithm (GA) and successive projections algorithms (SPA) combine with PLS regression for determination the soluble solids content in Nam-DokMai mangoes based on near infrared spectroscopy. Eng. Appl. Sci. Res. 2022, 49, 119–126. Available online: https://ph01.tci-thaijo.org/index.php/easr/article/view/245217 (accessed on 28 December 2023).

- Williams, P.; Manley, M.; Antoniszyn, J. Near Infrared Technology: Getting the Best out of Light; African Sun Media: Stellenbosch, South Africa, 2019. [Google Scholar]

- Zornoza, R.; Guerrero, C.; Mataix-Solera, J.; Scow, K.M.; Arcenegui, V.; Mataix-Beneyto, J. Near infrared spectroscopy for determination of various physical, chemical and biochemical properties in Mediterranean soils. Soil Biol. Biochem. 2008, 40, 1923–1930. [Google Scholar] [CrossRef] [PubMed]

- Xue, J.; Yang, Z.; Han, L.; Chen, L. Study of the influence of NIRS acquisition parameters on the spectral repeatability for on-line measurement of crop straw fuel properties. Fuel 2014, 117, 1027–1033. [Google Scholar] [CrossRef]

- Madhu, P.; Dhanalakshmi, C.S.; Mathew, M. Multi-criteria decision-making in the selection of a suitable biomass material for maximum bio-oil yield during pyrolysis. Fuel 2020, 277, 118109. [Google Scholar] [CrossRef]

- Cardarelli, A.; Pinzi, S.; Barbanera, M. Effect of torrefaction temperature on spent coffee grounds thermal behaviour and kinetics. Renew. Energy 2022, 185, 704–716. [Google Scholar] [CrossRef]

- Brassard, P.; Palacios, J.H.; Godbout, S.; Bussières, D.; Lagacé, R.; Larouche, J.-P.; Pelletier, F. Comparison of the gaseous and particulate matter emissions from the combustion of agricultural and forest biomasses. Bioresour. Technol. 2014, 155, 300–306. [Google Scholar] [CrossRef]

- Mansora, A.M.; Lima, J.S.; Anib, F.N.; Hashima, H.; Hoa, W.S. Characteristics of cellulose, hemicellulose and lignin of MD2 pineapple biomass. Chem. Eng. 2019, 72, 79–84. [Google Scholar]

- Workman, J., Jr.; Weyer, L. Practical Guide to Interpretive Near-Infrared Spectroscopy; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Shrestha, A.; Saechua, W.; Sirisomboon, P. Some physical and combustion characteristic of Leucaena Leucocephala pellet. In Proceedings of the 16th TSAE National Conference and 8th TSAE International Conference, Agricultural and Food Engineering Outlook on Sustainable Future, ET-08, Bangkok International Trade & Exhibition Centre, Bangkok, Thailand, 17–19 March 2015; pp. 127–132. [Google Scholar]

- Shrestha, A. Feasibility Study on Near Infrared Spectroscopy for Evaluation of Combustion Performance Parameters and Moisture Content of Bamboo Chips (Dendrocalamus Sericeus cl. Phamon); King Mongkut’s Institute of Technology: Ladkrabang, Thailand, 2016. [Google Scholar]

| Combustion Parameters | Combustion Performance Indices | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Category | Biomass Sample | (dw/dt)max | (dw/dt)mean | Ti | Tf | Tmax | ti | tf | tp | Δt1/2 | Di (10−2) | Df (10−3) | Si (10−6) | Ci (10−4) |

| (wt.% min−1) | (wt.% min−1) | (°C) | (°C) | (°C) | (min) | (min) | (min) | (min) | wt.%.min−3 | wt.%.min−4 | wt.%2.min−2.C−3 | wt.%min−1.°C−2 | ||

| Fast-growing trees | Alnus nepalensis | 21.08 | 2.83 | 229.64 | 531.82 | 330.88 | 20.32 | 35.34 | 24.95 | 5.19 | 4.15 | 4.79 | 2.54 | 3.99 |

| Pinus roxiburghii | 18.81 | 2.85 | 224.64 | 530.29 | 335.24 | 20.07 | 35.25 | 25.16 | 5.04 | 3.71 | 4.43 | 2.71 | 3.71 | |

| Bombusa vulagris | 18.06 | 2.67 | 225.38 | 530.69 | 308.58 | 20.12 | 35.28 | 23.93 | 5.68 | 3.76 | 4.60 | 2.41 | 3.60 | |

| Eucalyptus camaldulensis | 21.22 | 2.77 | 231.42 | 504.92 | 326.28 | 20.43 | 33.97 | 24.77 | 4.60 | 4.20 | 5.09 | 2.54 | 3.96 | |

| Bombax ceiba | 21.90 | 2.65 | 226.45 | 508.18 | 303.74 | 20.15 | 34.15 | 23.65 | 5.25 | 4.61 | 6.05 | 2.41 | 4.30 | |

| Agricultural residues | Zea mays (cob) | 21.16 | 2.80 | 225.85 | 511.08 | 291.40 | 20.15 | 34.27 | 23.15 | 5.56 | 4.54 | 6.18 | 2.49 | 4.15 |

| Zea mays (shell) | 21.92 | 2.78 | 227.18 | 506.18 | 289.13 | 20.19 | 34.03 | 23.05 | 28.54 | 4.71 | 1.25 | 2.46 | 4.25 | |

| Zea mays (stover) | 17.22 | 2.48 | 203.27 | 507.00 | 299.44 | 19.10 | 34.06 | 23.53 | 5.27 | 3.84 | 4.26 | 2.87 | 4.30 | |

| Oryza sativa | 15.34 | 2.49 | 240.60 | 552.40 | 316.75 | 20.84 | 36.37 | 24.25 | 6.06 | 3.04 | 3.88 | 1.89 | 2.65 | |

| Saccharum officinarum | 19.56 | 2.82 | 195.33 | 500.89 | 328.38 | 18.77 | 33.72 | 24.93 | 4.39 | 4.18 | 4.31 | 3.75 | 5.20 | |

| Biomass | Parameter (Ground) | Units | NT | Calibration Set | Validation Set | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nc | Max | Min | Mean | SD | Np | Max | Min | Mean | SD | ||||

| Ground | Ignition index Di (10−2) | wt.%.min−3 | 103 | 82 | 5.3496 | 2.4171 | 4.0699 | 0.6510 | 21 | 5.0998 | 2.8155 | 3.8740 | 0.7008 |

| Burnout index Df (10−3) | wt.%.min−4 | 87 | 70 | 6.7591 | 1.0380 | 4.2231 | 1.3066 | 17 | 6.5259 | 1.2071 | 4.2180 | 1.2905 | |

| Comprehensive combustion index Si (10−6) | wt.%2.min−2.°C−3 | 107 | 86 | 4.0363 | 1.6140 | 2.5704 | 0.4551 | 21 | 4.0296 | 1.7917 | 2.5502 | 0.4649 | |

| Flammability index Ci (10−4) | wt.%.min−1.°C−2 | 114 | 91 | 6.5187 | 2.3349 | 3.9879 | 0.8590 | 23 | 5.3362 | 2.4757 | 3.8578 | 0.6980 | |

| Chip | Ignition index Di (10−2) | wt.%.min−3 | 102 | 82 | 5.3500 | 2.7000 | 4.0532 | 0.6295 | 20 | 5.1000 | 2.8200 | 3.8975 | 0.7098 |

| Burnout index Df (10−3) | wt.%.min−4 | 94 | 75 | 7.1715 | 1.0380 | 4.4178 | 1.3070 | 19 | 6.9777 | 1.1030 | 4.5240 | 1.4880 | |

| Comprehensive combustion index Si (10−6) | wt.%2.min−2.°C−3 | 102 | 82 | 4.0363 | 1.7584 | 2.5577 | 0.4478 | 20 | 4.0296 | 1.7917 | 2.5325 | 0.4697 | |

| Flammability index Ci (10−4) | wt.%.min−1.°C−2 | 112 | 90 | 6.2216 | 2.3349 | 3.9384 | 0.7779 | 22 | 5.3362 | 2.4757 | 3.8255 | 0.6966 | |

| Parameter (Chip) | Units | Algorithm | Preprocessing | LVs | Calibration Set | Validation Set | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| R2C | RMSEC | R2P | RMSEP | RPD | Bias | |||||

| Di | wt.%.min−3 | Full-PLSR | Second derivative | 6 | 0.6491 | 0.3706 | 0.6100 | 0.4321 | 1.6 | −0.0996 |

| SPA-PLSR | Vector normalization (SW: 130) | 9 | 0.6101 | 0.3907 | 0.5994 | 0.4379 | 1.6 | −0.0770 | ||

| GA-PLSR | Vector normalization (SW: 518) | 8 | 0.6479 | 0.3713 | 0.6073 | 0.4335 | 1.6 | −0.1094 | ||

| MP-PLSR: 5-Range | Combination set: 2,4,0,5,5 | 4 | 0.5962 | 0.3976 | 0.5929 | 0.4414 | 1.6 | −0.1071 | ||

| MP-PLSR: 3-Range | Combination set: 2,5,4 | 4 | 0.6015 | 0.3950 | 0.6008 | 0.4371 | 1.6 | −0.0764 | ||

| Df | wt.%.min−4 | Full-PLSR | Constant offset | 9 | 0.7470 | 0.6531 | 0.6920 | 0.8045 | 1.9 | 0.2043 |

| SPA-PLSR | Constant offset (SW: 717) | 8 | 0.7335 | 0.6704 | 0.6738 | 0.8279 | 1.8 | 0.2549 | ||

| GA-PLSR | Min-max normalization (SW: 64) | 10 | 0.7141 | 0.6943 | 0.7019 | 0.7914 | 1.9 | 0.1245 | ||

| MP-PLSR: 5-Range | Combination set: 6,6,4,6,0 | 9 | 0.7420 | 0.6596 | 0.6361 | 0.8744 | 1.7 | 0.1619 | ||

| MP-PLSR: 3-Range | Combination set: 1,6,6 | 10 | 0.7533 | 0.6450 | 0.6550 | 0.8515 | 1.8 | 0.2290 | ||

| Si | wt.%2.min−2.°C−3 | Full-PLSR | Raw spectra | 9 | 0.7700 | 0.2136 | 0.7699 | 0.2196 | 2.1 | 0.0372 |

| SPA-PLSR | First derivative+MSC (SW: 346) | 12 | 0.8153 | 0.1914 | 0.7484 | 0.2296 | 2.0 | −0.0122 | ||

| GA-PLSR | First derivative (SW: 18) | 11 | 0.8006 | 0.1989 | 0.7812 | 0.2141 | 2.2 | 0.0535 | ||

| MP-PLSR: 5-Range | Combination set: 3,5,3,6,0 | 9 | 0.8068 | 0.1958 | 0.7721 | 0.2185 | 2.2 | 0.0533 | ||

| MP-PLSR: 3-Range | Combination set: 6,2,4 | 3 | 0.6047 | 0.2800 | 0.5126 | 0.3196 | 1.4 | −0.0414 | ||

| Ci | wt.%min−1.°C−2 | Full-PLSR | SNV | 14 | 0.8215 | 0.3267 | 0.6119 | 0.4240 | 1.6 | 0.0523 |

| SPA-PLSR | Second derivative (SW: 213) | 11 | 0.6797 | 0.4377 | 0.6439 | 0.4061 | 1.7 | −0.0297 | ||

| GA-PLSR | Mean centering (SW: 16) | 13 | 0.5744 | 0.5045 | 0.5666 | 0.4481 | 1.5 | 0.0823 | ||

| MP-PLSR: 5-Range | Combination set: 2,2,1,6,5 | 9 | 0.6469 | 0.4595 | 0.6853 | 0.3818 | 1.8 | −0.0652 | ||

| MP-PLSR: 3-Range | Combination set: 2,5,0 | 14 | 0.6903 | 0.4304 | 0.6766 | 0.3871 | 1.8 | −0.0343 | ||

| Parameter (Ground) | Units | Algorithm | Preprocessing | LVs | Calibration Set | Validation Set | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| R2C | RMSEC | R2P | RMSEP | RPD | Bias | |||||

| Di | wt.%.min−3 | Full-PLSR | Raw spectra | 8 | 0.6533 | 0.3810 | 0.6466 | 0.4064 | 1.7 | −0.0898 |

| SPA-PLSR | Raw (SW: 1132) | 8 | 0.6542 | 0.3805 | 0.6472 | 0.4062 | 1.7 | −0.0898 | ||

| GA-PLSR | Mean centering (SW:523) | 9 | 0.6442 | 0.3859 | 0.6071 | 0.4286 | 1.6 | −0.0743 | ||

| MP-PLSR: 5-Range | Combination set: 3,5,3,1,0 | 9 | 0.7039 | 0.3521 | 0.6782 | 0.3879 | 1.8 | −0.0016 | ||

| MP-PLSR: 3-Range | Combination set: 1,4,6 | 13 | 0.7773 | 0.3053 | 0.5634 | 0.4518 | 1.5 | −0.0511 | ||

| Df | wt.%.min−4 | Full-PLSR | First derivative (g = 5, s = 5) | 11 | 0.8449 | 0.5111 | 0.8217 | 0.5286 | 2.4 | 0.0678 |

| SPA-PLSR | Second derivative(SW: 954) | 10 | 0.8139 | 0.5598 | 0.8001 | 0.5598 | 2.2 | 0.0206 | ||

| GA-PLSR | First derivative (SW:921) | 11 | 0.8417 | 0.5163 | 0.8426 | 0.4968 | 2.5 | 0.0631 | ||

| MP-PLSR: 5-Range | Combination set: 1,5,4,3,6 | 12 | 0.8151 | 0.5580 | 0.8018 | 0.5574 | 2.3 | 0.1177 | ||

| MP-PLSR: 3-Range | Combination set: 2,2,1 | 14 | 0.8240 | 0.5443 | 0.8137 | 0.5405 | 2.6 | 0.2432 | ||

| Si | wt.%2.min−2.°C−3 | Full-PLSR | MSC | 14 | 0.9028 | 0.1411 | 0.8808 | 0.1566 | 3.1 | 0.0532 |

| SPA-PLSR | MSC (SW: 626) | 13 | 0.8849 | 0.1536 | 0.8045 | 0.2005 | 3.0 | 0.1298 | ||

| GA-PLSR | MSC (SW: 60) | 10 | 0.8567 | 0.1713 | 0.8566 | 0.1717 | 2.8 | −0.0632 | ||

| MP-PLSR: 5-Range | Combination set: 4,4,5,6,4 | 12 | 0.9449 | 0.1062 | 0.8136 | 0.1958 | 2.3 | 0.0102 | ||

| MP-PLSR: 3-Range | Combination set: 4,2,1 | 13 | 0.9071 | 0.1380 | 0.8316 | 0.1861 | 2.5 | −0.0257 | ||

| Ci | wt.%min−1.°C−2 | Full-PLSR | MSC | 15 | 0.7881 | 0.3932 | 0.6914 | 0.3792 | 1.9 | −0.1361 |

| SPA-PLSR | Raw (SW: 13) | 15 | 0.7234 | 0.4492 | 0.6524 | 0.4025 | 1.8 | −0.1162 | ||

| GA-PLSR | Raw (SW: 333) | 9 | 0.5822 | 0.5520 | 0.5476 | 0.4592 | 1.5 | −0.0477 | ||

| MP-PLSR: 5-Range | Combination set: 3,2,1,1,4 | 12 | 0.7576 | 0.4205 | 0.7204 | 0.3610 | 2.0 | −0.1310 | ||

| MP-PLSR: 3-Range | Combination set: 1,2,4 | 15 | 0.7860 | 0.3951 | 0.6919 | 0.3790 | 1.9 | −0.0884 | ||

| Combustion Performance Index | Biomass Type | Peak Wavenumber (cm−1) | Functional Group | Spectra-Structure | Material Type |

|---|---|---|---|---|---|

| Di | Chip | 3722 | C−H aromatic | C−H aryl | |

| 4405 | O−H stretching and C−O stretching | cellulose | |||

| 5200 | O−H stretching and HOH deformation combination | O−H molecular water | |||

| 5787 | C−H methylene (.CH2) (asymmetric) | Hydrocarbons, aliphatic | |||

| 12,048 | C−H methylene C−H | Hydrocarbons, aliphatic | |||

| 12,300 | C−H combination | Hydrocarbons, aliphatic | |||

| Ground | 3650 | O−H from primary alcohols as (-CH-OH) | O−H (ν) | Primary alcohols | |

| 4608 | C−H stretching and C−H deformation combination | Alkenes | |||

| 5495 | O−H/C−H combination | O−H stretching and C−O stretching (3νs) combination | Cellulose | ||

| 8754 | C−H aromatic (ArCH) | C−H (3ν), aromatic C−H | Hydrocarbons, aromatic | ||

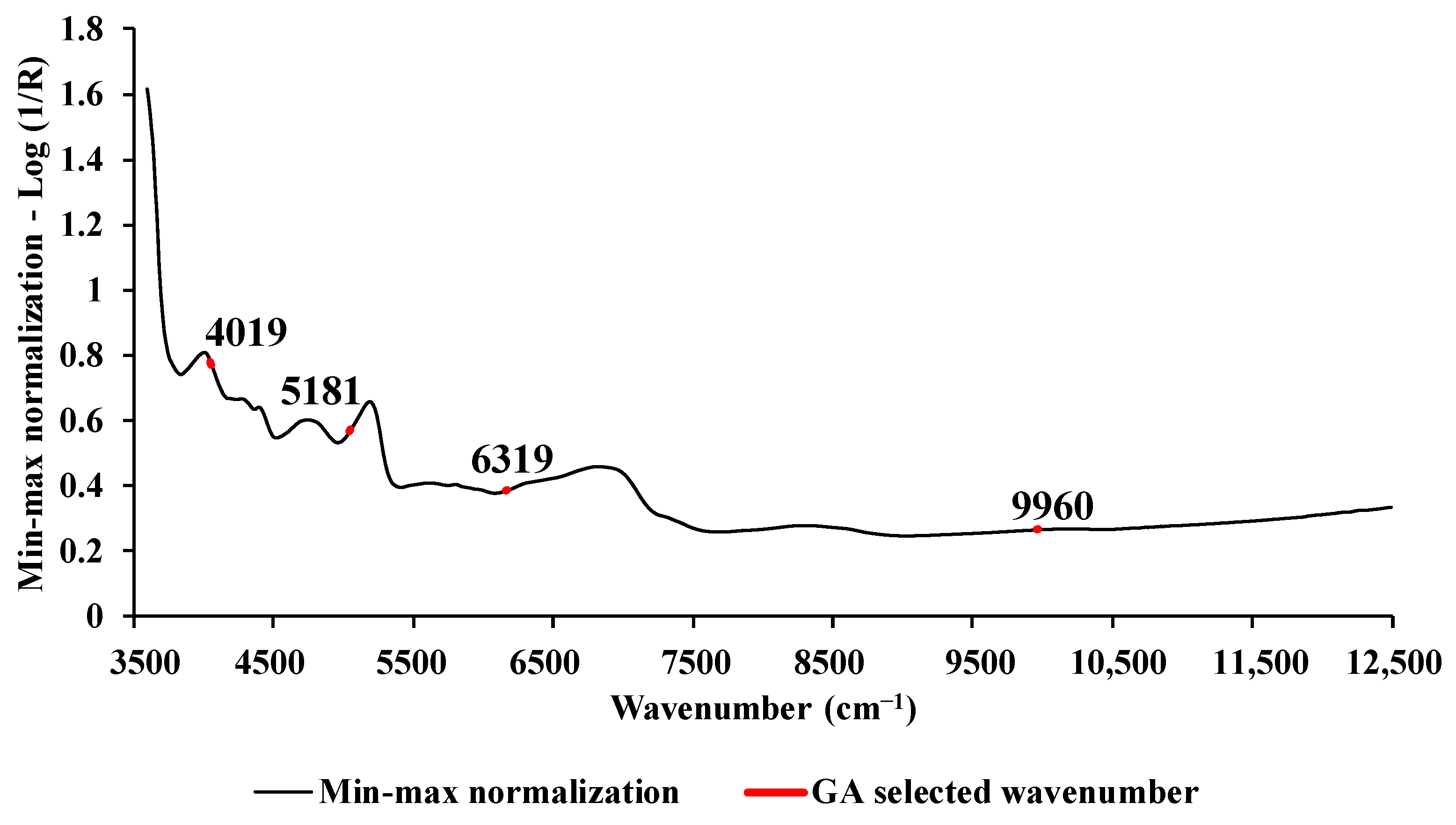

| Df | Chip | 4019 | C−H stretching and C−C stretching combination | Cellulose | |

| 5181 | O−H stretching and HOH bending combination | Polysaccharides | |||

| 6319 | O−H stretching band, alkyl alcohols or water | Alcohols or water O−H | |||

| 9960 | O−H from secondary alcohols as (−CH−OH) | O−H (3ν)(−CH−OH) | Secondary alcohols | ||

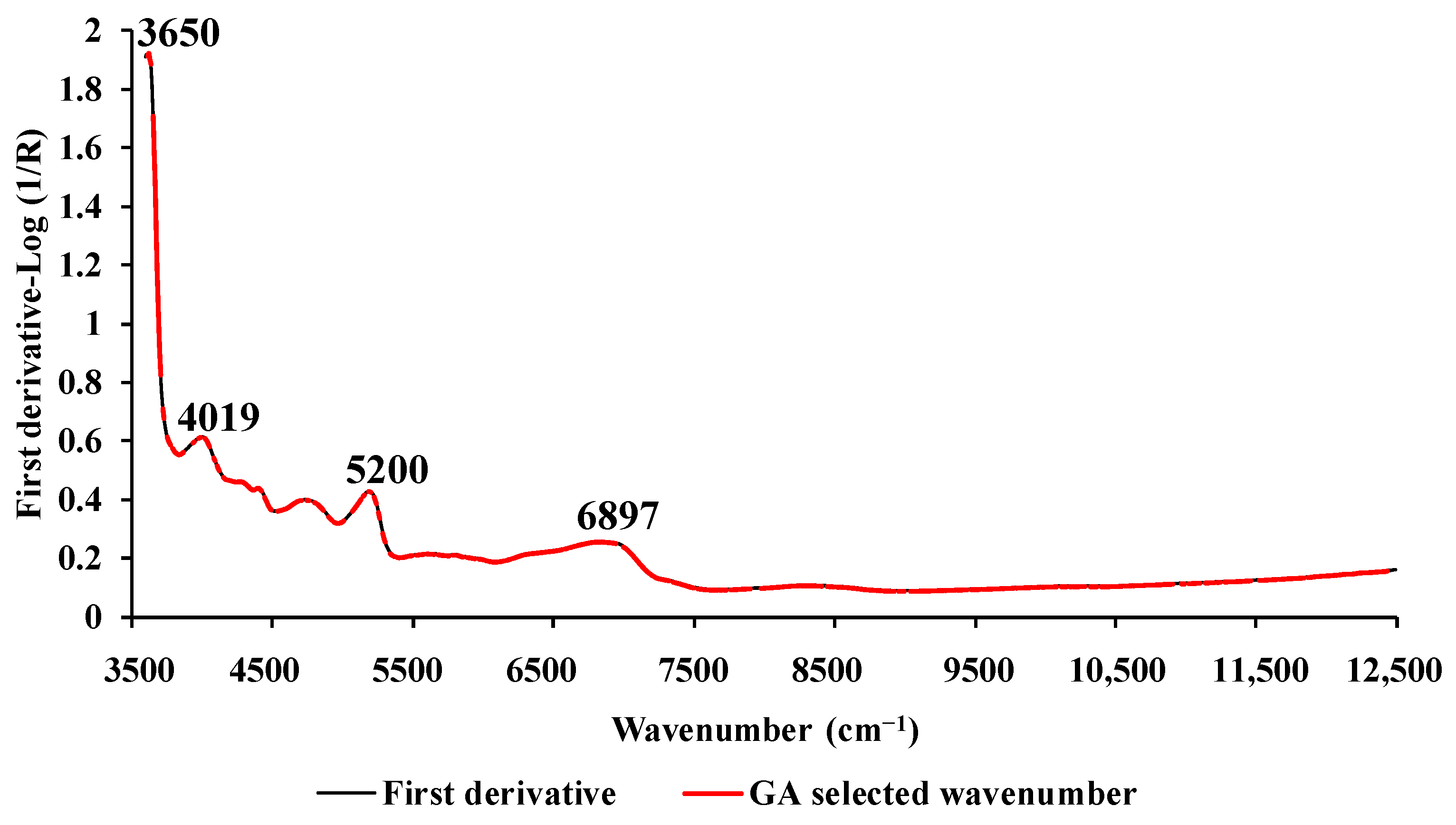

| Ground | 3650 | O−H from primary alcohols as (−CH−OH) | O−H (ν) | Primary alcohols | |

| 4019 | C−H stretching and C−C stretching combination | Cellulose | |||

| 5200 | O−H stretching and HOH deformation combination | O−H molecular water | |||

| 6897 | O−H (2ν) | Starch/polymeric alcohol | |||

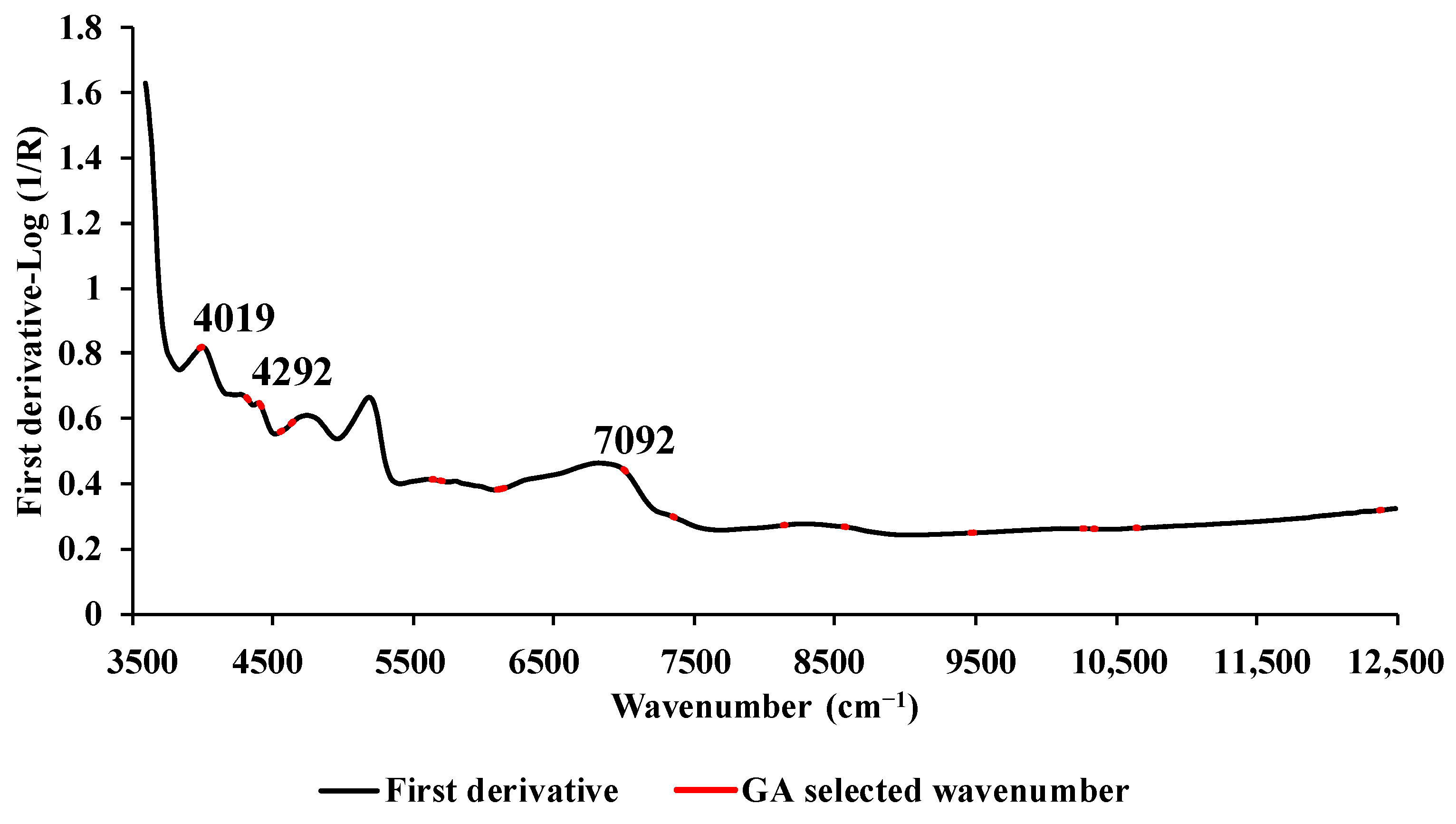

| Si | Chip | 4019 | C−H stretching and C−C stretching combination | Cellulose | |

| 4292 | C−H stretching and CH2 deformation combination | Polysaccharides | |||

| 7092 | O−H alcohol (RO−H) | O−H (2ν) | Hydrocarbons, aliphatic | ||

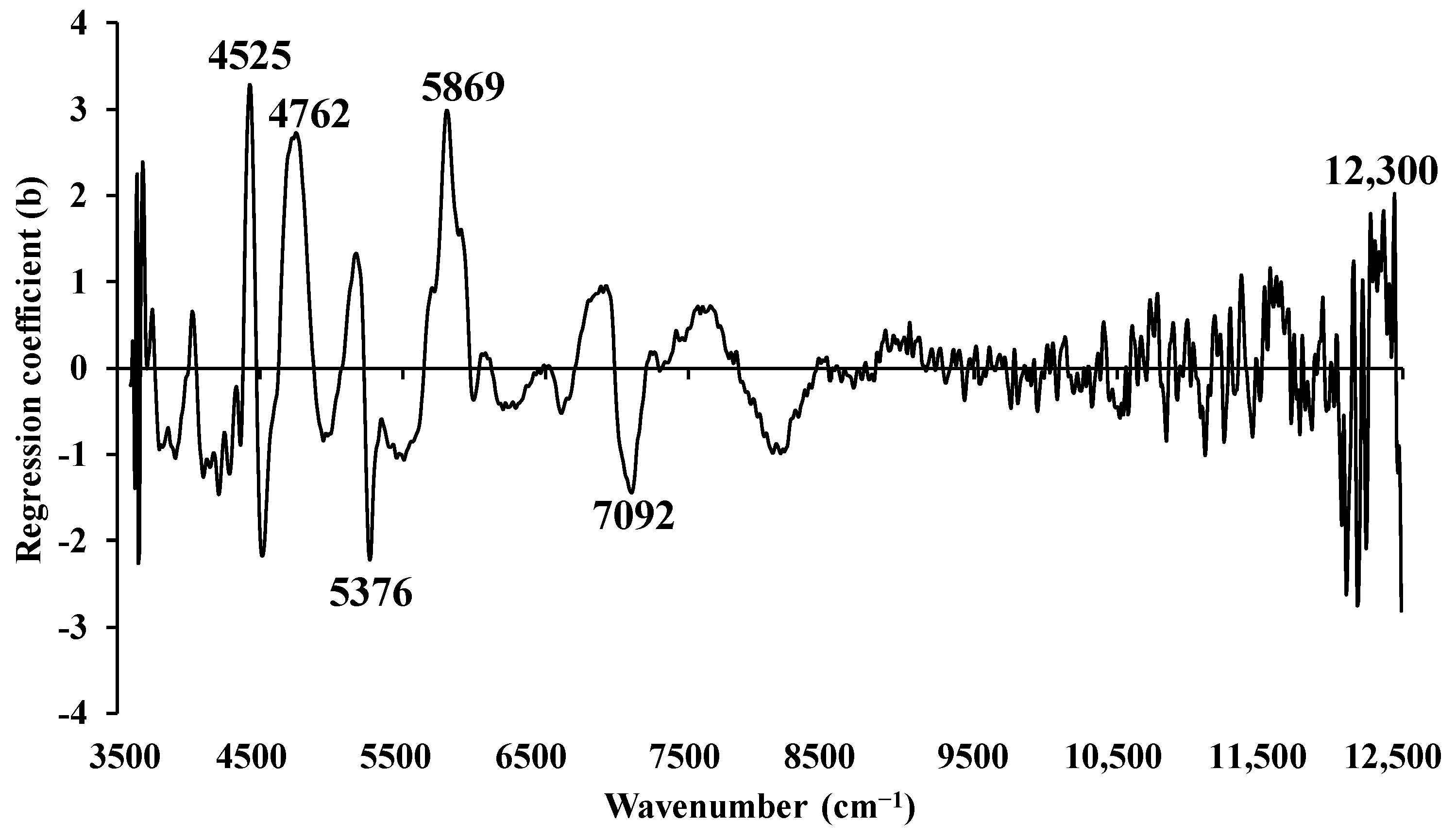

| Ground | 4525 | N−H ammonia in water | N−H (3ν) for NH3 in water | Ammonia in water | |

| 4762 | O−H bending and C−O stretching combination | Polysaccharides | |||

| 5376 | C−Cl (7ν) | Chlorinated hydrocarbons | |||

| 5869 | C−H (2ν), methyl C−H (symmetric) | Hydrocarbons, aliphatic | |||

| 7092 | O−H alcohol (RO−H) | O−H (2ν) | Hydrocarbons, aliphatic | ||

| 12,300 | C−H combination | Hydrocarbons, aliphatic | |||

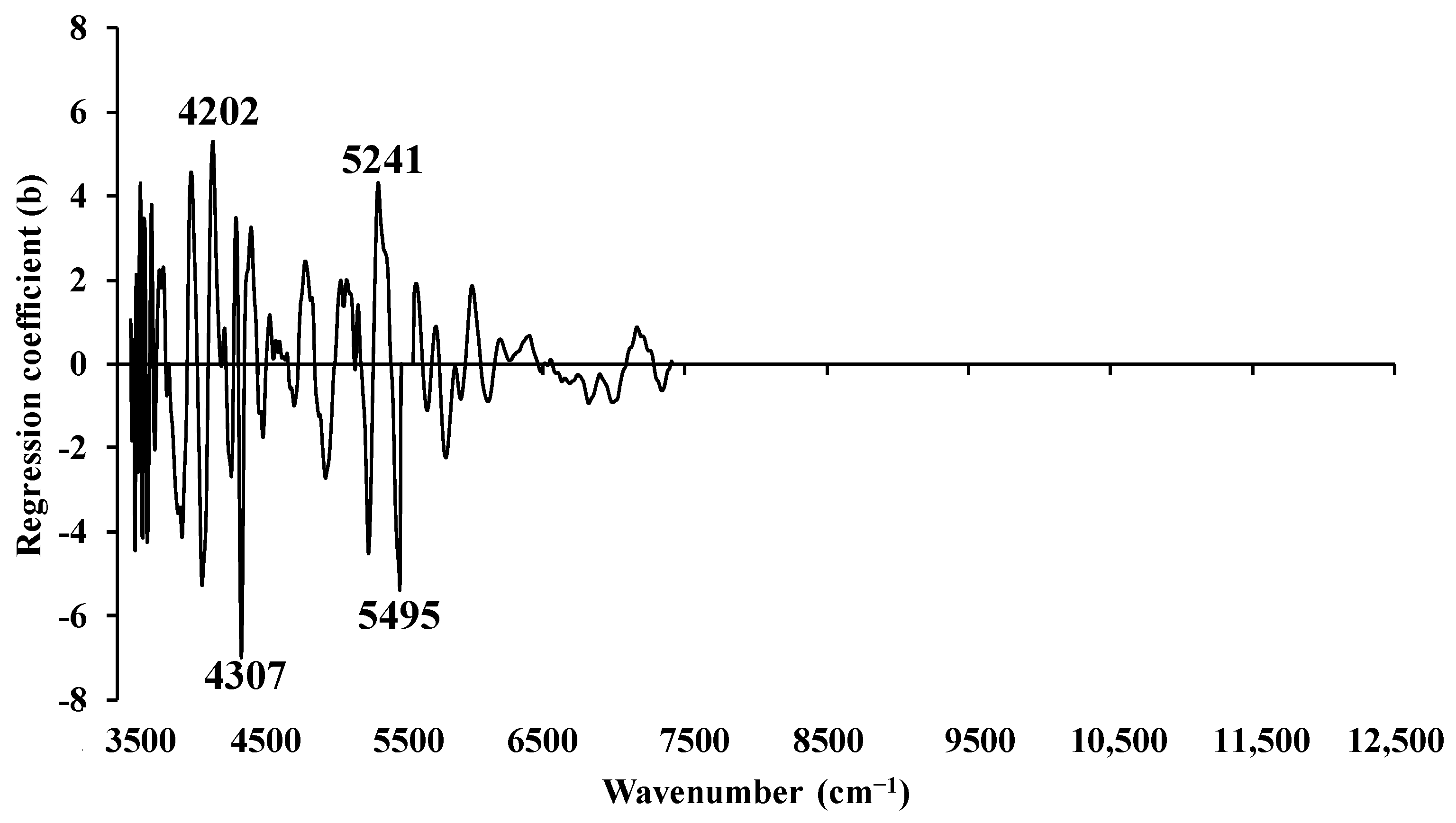

| Ci | Chip | 4202 | C−H stretching and C−C stretching combination | Lipids | |

| 4307 | C−H stretching and CH2 deformation combination | Polysaccharides | |||

| 5241 | P−OH phosphate (.P-OH) | O−H (2ν) | Phosphate | ||

| 5495 | O−H/C−H combination | O−H stretching and C−O stretching (3νs) combination | Cellulose | ||

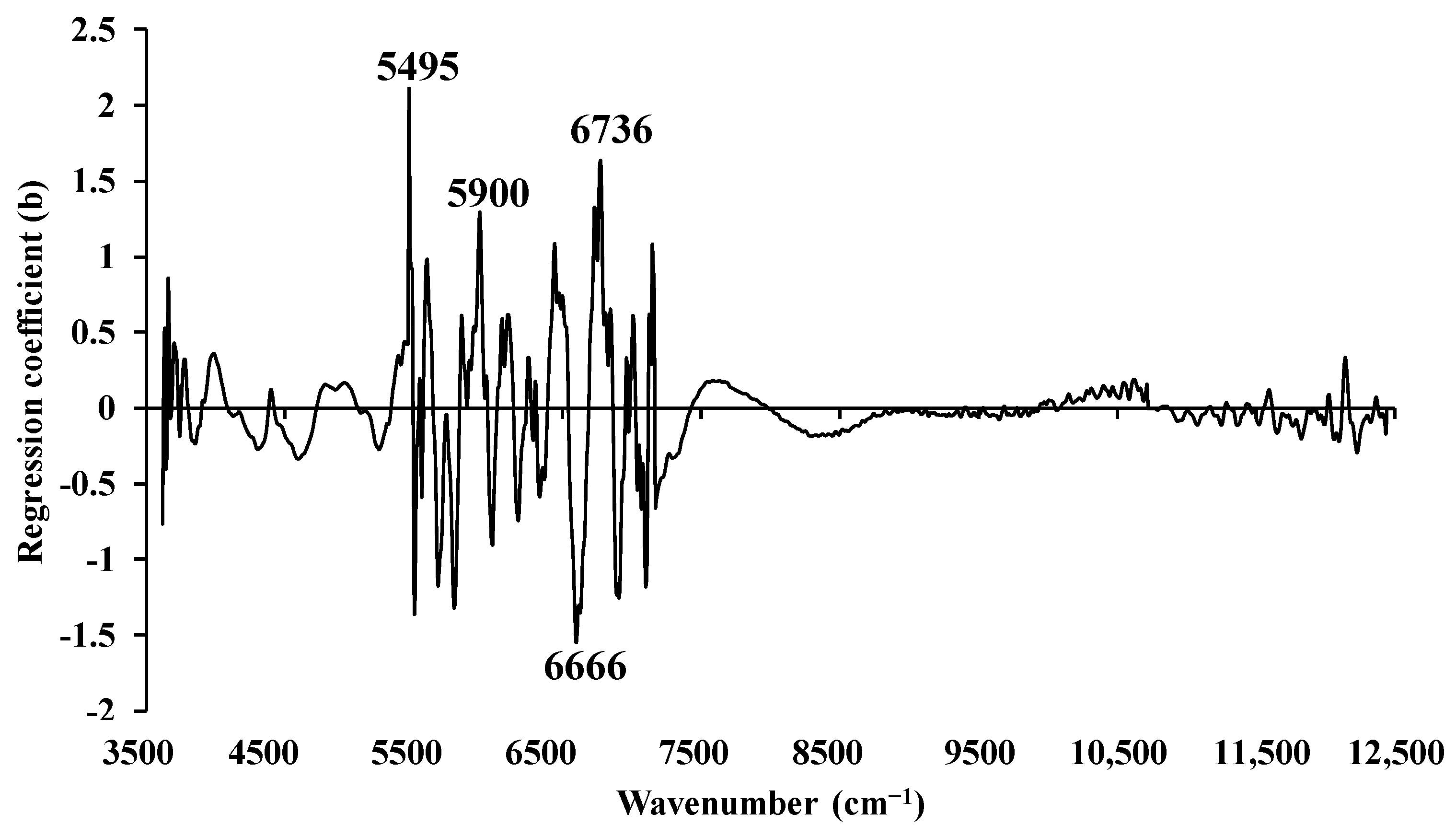

| Ground | 5495 | O−H/C−H combination | O−H stretching and C−O stretching (3νs) combination | Cellulose | |

| 5900 | C−H methyl (.CH3) | C−H (2ν), .CH3 | Hydrocarbons, methyl | ||

| 6666 | N−H combination band from urea (NH2−C=O−NH2) | N−H from urea | |||

| 6736 | N−H band from urea (NH2−C=O−NH2) | N-H (2ν) symmetric stretching from urea | Urea |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shrestha, B.; Posom, J.; Pornchaloempong, P.; Sirisomboon, P.; Shrestha, B.P.; Ariffin, H. Near-Infrared Spectroscopy Modeling of Combustion Characteristics in Chip and Ground Biomass from Fast-Growing Trees and Agricultural Residue. Energies 2024, 17, 1338. https://doi.org/10.3390/en17061338

Shrestha B, Posom J, Pornchaloempong P, Sirisomboon P, Shrestha BP, Ariffin H. Near-Infrared Spectroscopy Modeling of Combustion Characteristics in Chip and Ground Biomass from Fast-Growing Trees and Agricultural Residue. Energies. 2024; 17(6):1338. https://doi.org/10.3390/en17061338

Chicago/Turabian StyleShrestha, Bijendra, Jetsada Posom, Pimpen Pornchaloempong, Panmanas Sirisomboon, Bim Prasad Shrestha, and Hidayah Ariffin. 2024. "Near-Infrared Spectroscopy Modeling of Combustion Characteristics in Chip and Ground Biomass from Fast-Growing Trees and Agricultural Residue" Energies 17, no. 6: 1338. https://doi.org/10.3390/en17061338

APA StyleShrestha, B., Posom, J., Pornchaloempong, P., Sirisomboon, P., Shrestha, B. P., & Ariffin, H. (2024). Near-Infrared Spectroscopy Modeling of Combustion Characteristics in Chip and Ground Biomass from Fast-Growing Trees and Agricultural Residue. Energies, 17(6), 1338. https://doi.org/10.3390/en17061338