Research on the Shale Porosity–TOC Maturity Relationship Based on an Improved Pore Space Characterization Method

Abstract

1. Introduction

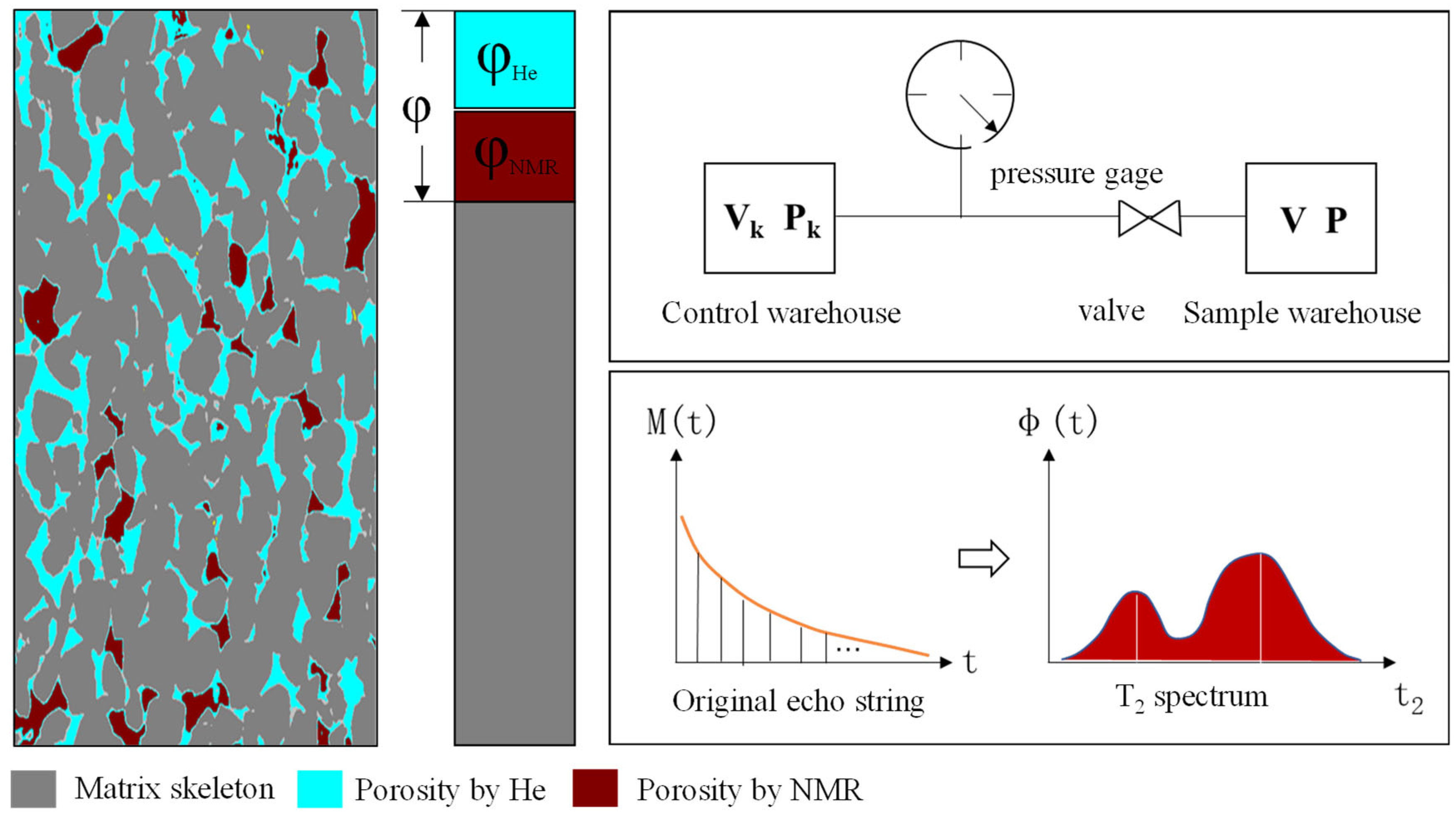

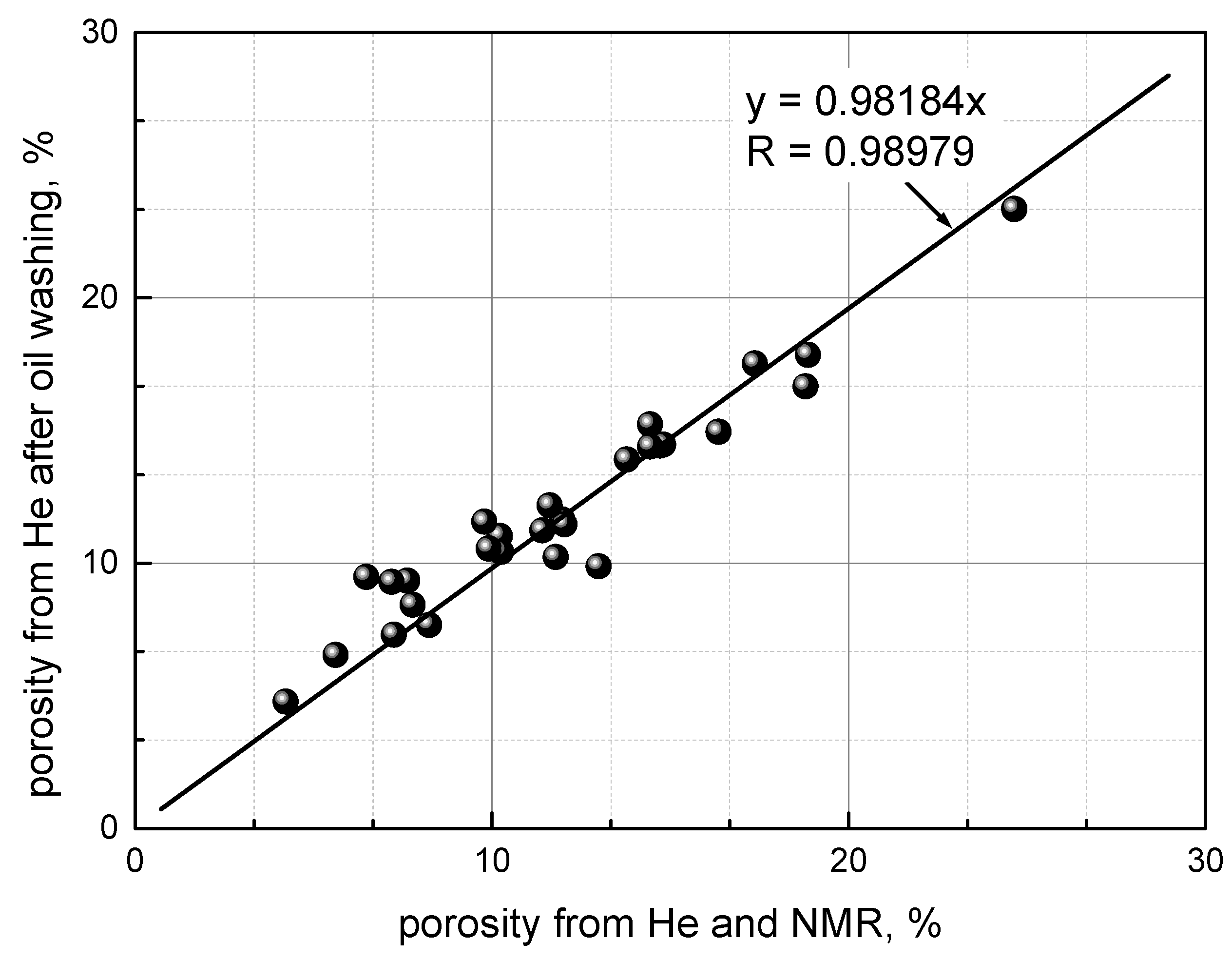

2. An Improved Pore Structure Characterization Method for Shale

- (1)

- Put shale samples into an oven with a constant temperature of 60 °C until the cores’ weight changes little (generally, core weight variance is less than 5%). Then, place dry samples into a sample warehouse. Vacuum the sample warehouse and control the warehouse to ensure that the residual gas in the pores of the shale sample is evacuated.

- (2)

- Fill the control warehouse with helium to a certain pressure. Open the connecting valve between the sample warehouse and control warehouse to let shale samples become fully saturated with helium gas. When the pressure gauge stabilizes, the skeleton volume of shale samples () can be obtained according to Boyle’s law.

- (3)

- The total volume of shale samples () (unit: v/v) can be measured through the caliper measurement method and the Archimedes immersion method. The helium porosity can be calculated as (unit: v/v).

- (4)

- is obtained by integrating the NMR T2 spectrum, the resonance frequency is 4.52 MHz, the waiting time is 3000 ms and echo spacing is 0.35 ms, and the number of scans was 128.

- (5)

- Then, the total porosity of shale samples is (unit: v/v).

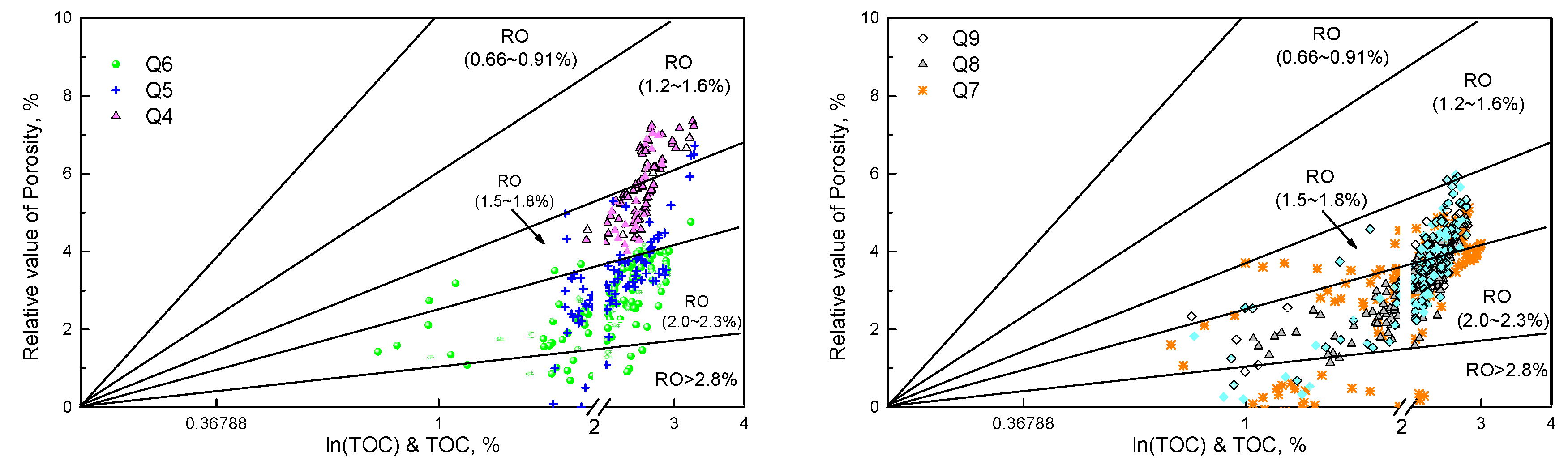

3. Shale Porosity–TOC Maturity Relationship Based on the New Pore Structure Characterization Method

3.1. Effect Factors for Shale Pore Evolution

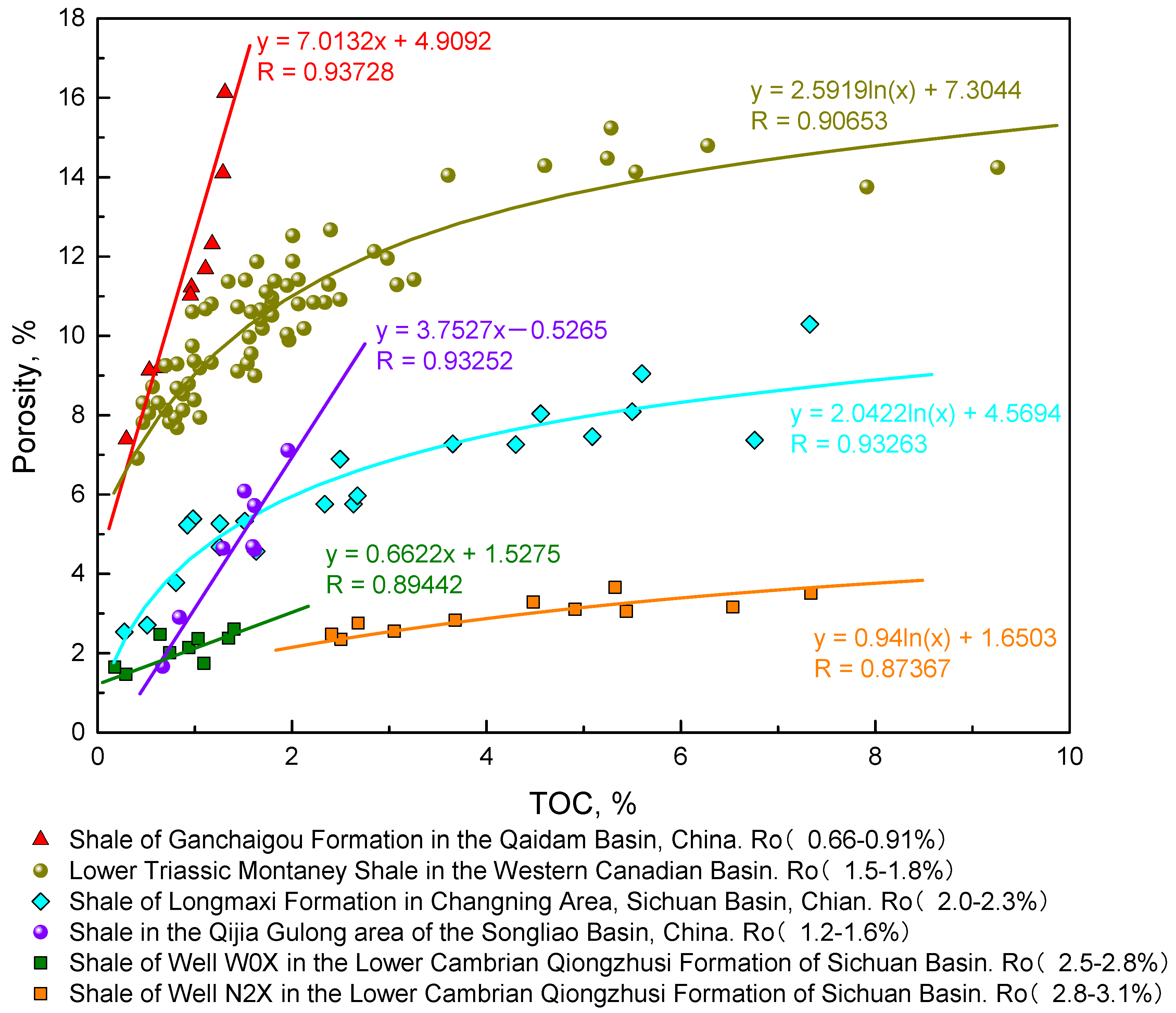

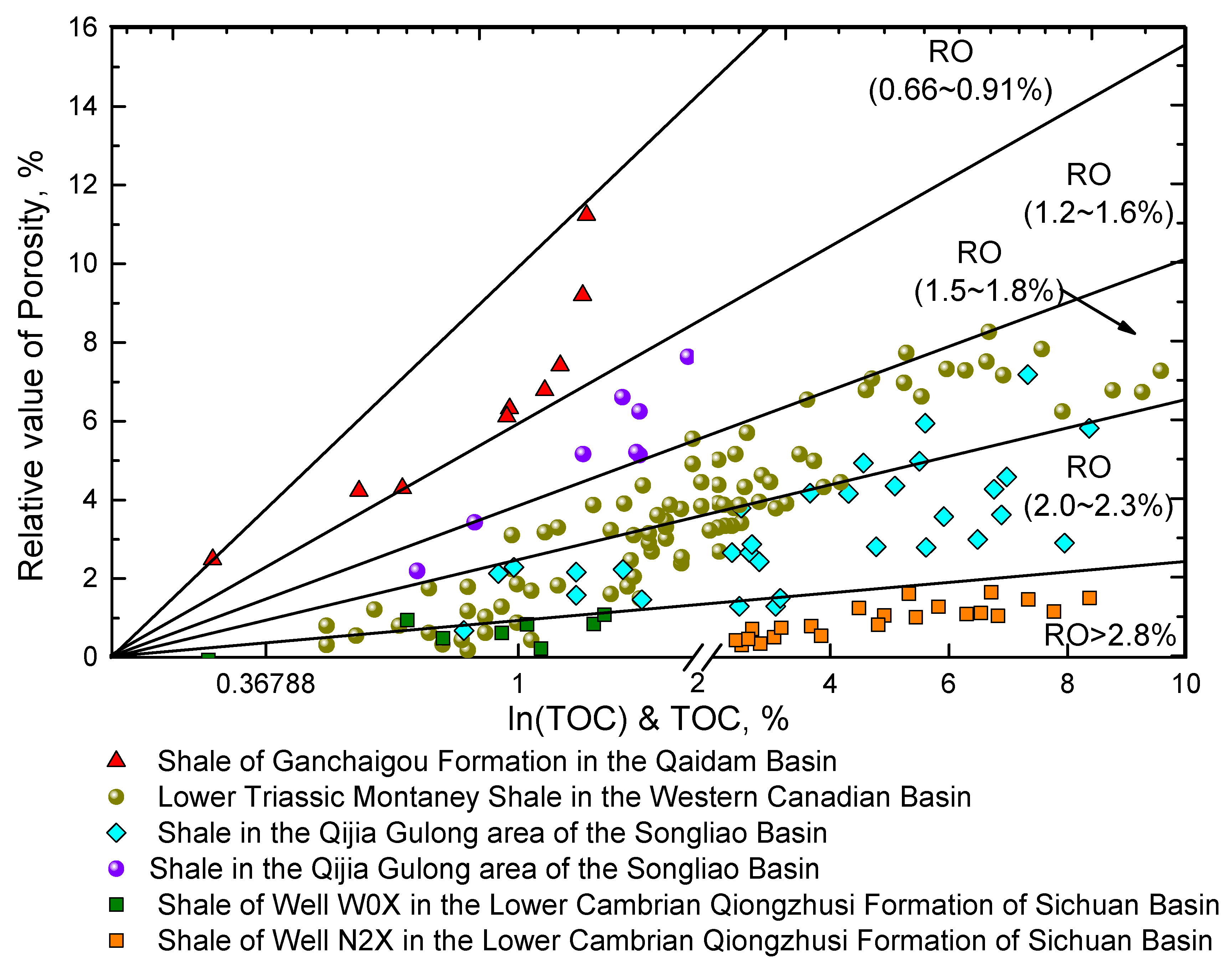

3.2. The Shale Porosity–TOC Maturity Relationship

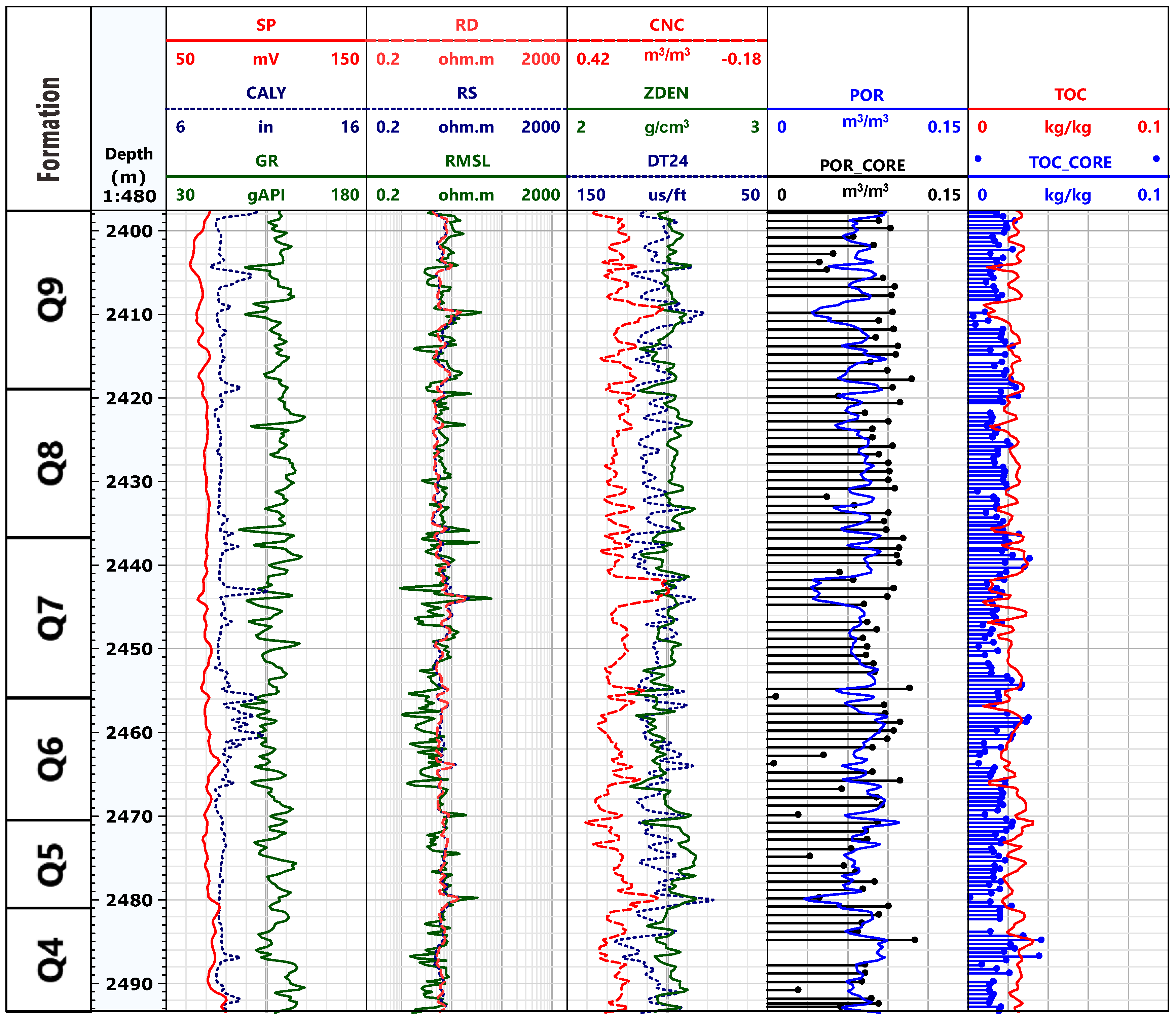

4. Application

5. Discussion and Future Work

5.1. Discussion

5.2. Future Work

- A.

- The theoretical functions of the porosity–TOC maturity relationship need to be further improved to meet the accuracy of shale reservoir evaluation [48].

- B.

- The diagenetic evolution of a specific study area can be further analyzed using the porosity–TOC maturity relationship [49].

- C.

- Shale maturity can be predicted using the porosity–TOC maturity relationship, as TOC and porosity are calculated from logging data; this will improve the understanding of shale oil-rich mechanisms and sweet spot prediction [50].

- D.

- E.

- Shale pore controlling factors and evolution vary significantly among regions, and the most suitable porosity measurements need to be tested for a specific region. The full-scale pore structure characterization method, combining multiple experimental methods, is a worthy study area for shale resource evaluation [53].

6. Conclusions

- (1)

- Based on measurement advantages analysis, a new method combining helium and NMR is proposed: the new method does not need to wash oil and salt, it does no damage to shale core samples, and experimental data of 28 rock samples has verified that the new method has higher accuracy.

- (2)

- Sorting out the pore evolution of organic and inorganic matter during geological periods, the organic matter content and maturity are key factors for total porosity development.

- (3)

- The shale porosity–TOC maturity relationship chart is developed based on shale samples from six formations, and the application of the new chart in Well X in the Gulong field of the Songliao Basin demonstrates that the method can be used in the evaluation of shale reservoirs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, G. Challenges and countermeasures of log evaluation in unconventional petroleum exploration and development. Pet. Explor. Dev. Online 2021, 48, 1033–1047. [Google Scholar] [CrossRef]

- Liu, G.; Liu, R.; Du, J.; Zhang, K.; Yu, J.; Liu, Q.; He, X. Study on Pore Structure and Fractal Characterization during Thermal Evolution of Oil Shale Experiments. ACS Omega 2022, 7, 12922–12936. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Wu, S.; Zhai, X.; Pan, S.; Lin, S. Micro/Nanopore Systems in Lacustrine Tight Oil Reservoirs, China. J. Nanosci. Nanotechnol. 2021, 21, 599–607. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Wang, M.; Wang, X.; Meng, Q.; Wu, Y.; Lin, T.; Li, J.; Zhang, J. Pore Structure Characteristics and Affecting Factors of Shale in the First Member of the Qingshankou Formation in the Gulong Sag, Songliao Basin. ACS Omega 2022, 7, 35755–35773. [Google Scholar] [CrossRef]

- HUO, J.; ZHI, D.; ZHENG, M.; Tang, Y.; Wang, X.; Chang, Q.; GAO, Y. Characteristics and main controls of shale oil reservoirs in Lucaogou Formation, Jimsar Sag, Junggar Basin. Pet. Geol. Exp. 2020, 42, 506–512. [Google Scholar]

- Wang, M.; Li, M.; Li, J.B.; Xu, L.; Zhang, J.X. The key parameter of shale oil resource evaluation: Oil content. Pet. Sci. 2022, 19, 1443–1459. [Google Scholar] [CrossRef]

- Garum, M.; Glover, P.W.; Lorinczi, P.; Drummond-Brydson, R.; Hassanpour, A. Micro-and nano-scale pore structure in gas shale using Xμ-CT and FIB-SEM techniques. Energy Fuels 2020, 34, 12340–12353. [Google Scholar] [CrossRef]

- Yang, L.; Dou, N.; Lu, X.; Zhang, X.; Chen, X.; Gao, J.; Wang, Y. Advances in understanding imbibition characteristics of shale using an NMR technique: A comparative study of marine and continental shale. J. Geophys. Eng. 2018, 15, 1363–1375. [Google Scholar] [CrossRef]

- Odusina, E.; Sigal, R.F. Laboratory NMR measurements on methane saturated Barnett Shale samples. Petrophysics 2011, 52, 32–49. [Google Scholar]

- Harris-Lowe, R.F.; Smee, K.A. Thermal expansion of liquid helium ii. Phys. Rev. A 1970, 2, 158. [Google Scholar] [CrossRef]

- Yuan, Y.; Rezaee, R. Comparative porosity and pore structure assessment in shales: Measurement techniques, influencing factors and implications for reservoir characterization. Energies 2019, 12, 2094. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Solano, N.; Bustin, R.M.; Bustin, A.M.M.; Chalmers, G.R.; He, L.; Melnichenko, Y.B.; Radliński, A.P.; Blach, T.P. Pore structure characterization of North American shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 2013, 103, 606–616. [Google Scholar] [CrossRef]

- Kuila, U.; McCarty, D.K.; Derkowski, A.; Fischer, T.B.; Prasad, M. Total porosity measurement in gas shales by the water immersion porosimetry (WIP) method. Fuel 2014, 117, 1115–1129. [Google Scholar] [CrossRef]

- Yuan, Y.; Rezaee, R.; Verrall, M.; Hu, S.Y.; Zou, J.; Testmanti, N. Pore characterization and clay bound water assessment in shale with a combination of NMR and low-pressure nitrogen gas adsorption. Int. J. Coal Geol. 2018, 194, 11–21. [Google Scholar] [CrossRef]

- Lizhi, X. Nuclear Magnetic Resonance Imaging Logging and Rock NMR and Its Application; Science Press: Beijing, China, 2011. [Google Scholar]

- Xie, W.; Yin, Q.; Wang, G.; Yu, Z. Variable dimension fractal-based conversion method between the nuclear magnetic resonance T2 spectrum and capillary pressure curve. Energy Fuels 2020, 35, 351–357. [Google Scholar] [CrossRef]

- Brumberger, H. (Ed.) Modern Aspects of Small-Angle Scattering; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 451. [Google Scholar]

- Bahadur, J.; Ruppert, L.F.; Pipich, V.; Sakurovs, R.; Melnichenko, Y.B. Porosity of the Marcellus Shale: A contrast matching small-angle neutron scattering study. Int. J. Coal Geol. 2018, 188, 156–164. [Google Scholar] [CrossRef]

- Seiler, H. Secondary electron emission in the scanning electron microscope. J. Appl. Phys. 1983, 54, R1–R18. [Google Scholar] [CrossRef]

- Sarker, M.R.H.; Siddiqui, S. Advances in micro-CT based evaluation of reservoir rocks. In Proceedings of the SPE Saudi Arabia Section Technical Symposium, Al-Khobar, Saudi Arabia, 9–11 May 2009; p. SPE-126039. [Google Scholar]

- Wang, F.; Guo, S. Influential factors and model of shale pore evolution: A case study of a continental shale from the Ordos Basin. Mar. Pet. Geol. 2019, 102, 271–282. [Google Scholar] [CrossRef]

- Gao, Z.; Fan, Y.; Xuan, Q.; Zheng, G. A review of shale pore structure evolution characteristics with increasing thermal maturities. Adv. Geo-Energy Res. 2020, 4, 247–259. [Google Scholar] [CrossRef]

- Liang, M.; Wang, Z.; Gao, L.; Li, C.; Li, H. Evolution of pore structure in gas shale related to structural deformation. Fuel 2017, 197, 310–319. [Google Scholar] [CrossRef]

- Modica, C.J.; Lapierre, S.G. Estimation of kerogen porosity in source rocks as a function of thermal transformation: Example from the Mowry Shale in the Powder River Basin of Wyoming. AAPG Bull. 2012, 96, 87–108. [Google Scholar] [CrossRef]

- Yu, H.; Wang, Z.; Rezaee, R.; Zhang, Y.; Han, T.; Arif, M.; Johnson, L. Porosity estimation in kerogen-bearing shale gas reservoirs. J. Nat. Gas Sci. Eng. 2018, 52, 575–581. [Google Scholar] [CrossRef]

- Curtis, M.E.; Cardott, B.J.; Sondergeld, C.H.; Rai, C.S. The development of organic porosity in the Woodford Shale related to thermal maturity. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012; p. SPE-160158. [Google Scholar]

- Xu, H.; Yu, H.; Fan, J.; Xia, J.; Liu, H.; Wu, H. Formation mechanism and structural characteristic of pore-networks in shale kerogen during in-situ conversion process. Energy 2022, 242, 122992. [Google Scholar] [CrossRef]

- Tan, M.; Mao, K.; Song, X.; Yang, X.; Xu, J. NMR petrophysical interpretation method of gas shale based on core NMR experiment. J. Pet. Sci. Eng. 2015, 136, 100–111. [Google Scholar] [CrossRef]

- Iqbal, M.A.; Rezaee, R. Porosity and Water Saturation Estimation for Shale Reservoirs: An Example from Goldwyer Formation Shale, Canning Basin, Western Australia. Energies 2020, 13, 6294. [Google Scholar] [CrossRef]

- Chen, Z.; Jiang, C. A revised method for organic porosity estimation in shale reservoirs using Rock-Eval data: Example from Duvernay Formation in the Western Canada Sedimentary Basin. AAPG Bull. 2016, 100, 405–422. [Google Scholar] [CrossRef]

- Xie, W.; Yin, Q.; Guan, W.; Wang, G.; Lai, J. Estimating the relative permeability from the electrical parameters of sandstone with a complex pore structure. Energy Fuels 2020, 34, 14124–14131. [Google Scholar] [CrossRef]

- Xie, W.; Yin, Q.; Wu, L.; Yang, F.; Zhao, J.; Wang, G. A new nuclear magnetic resonance-based permeability model based on two pore structure characterization methods for complex pore structure rocks: Permeability assessment in Nanpu Sag, China. Geophysics 2024, 89, MR43–MR51. [Google Scholar] [CrossRef]

- Sun, L.; Tuo, J.; Zhang, M.; Wu, C.; Chai, S. Pore structures and fractal characteristics of nano-pores in shale of Lucaogou formation from Junggar Basin during water pressure-controlled artificial pyrolysis. J. Anal. Appl. Pyrolysis 2019, 140, 404–412. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Haghshenas, B.; Ghanizadeh, A.; Qanbari, F.; Williams-Kovacs, J.D.; Riazi, N.; Debuhr, C.; Deglint, H.J. Nanopores to megafractures: Current challenges and methods for shale gas reservoir and hydraulic fracture characterization. J. Nat. Gas Sci. Eng. 2016, 31, 612–657. [Google Scholar] [CrossRef]

- Ross, D.J.K.; Bustin, R.M. The importance of shale composition and pore structure upon gas storage potential of shale gas reservoirs. Mar. Pet. Geol. 2009, 26, 916–927. [Google Scholar] [CrossRef]

- Ji, L.; Zhang, T.; Milliken, K.L.; Qu, J.; Zhang, X. Experimental investigation of main controls to methane adsorption in clay-rich rocks. Appl. Geochem. 2012, 27, 2533–2545. [Google Scholar] [CrossRef]

- Liu, B.; Schiieber, J.; Mastalerz, M. Combined SEM and reflected light petrography of organic matter in the New Albany Shale in the Illinois Basin: A perspective on organic pore development with thermal maturation. Int. J. Coal Geol. 2017, 184, 57–72. [Google Scholar] [CrossRef]

- Curtis, M.E.; Ambrose, R.J.; Sondergeld, C.H.; Rai, C.S. Investigation of the relationship between organic porosity and thermal maturity in the Marcellus Shale. In Proceedings of the North American Unconventional Gas Conference and Exhibition, The Woodlands, TX, USA, 14–16 June 2011. [Google Scholar]

- Jennings, D.S.; Antia, J. Petrographic characterization of the Eagle Ford Shale, south Texas: Mineralogy, common constituens, and distribution of nanometer-scal pore types. In Electron Microscopy of Shale Hydrocarbon Reservoirs: AAPG Memoir; Camp, W., Diaz, E., Wawak, B., Eds.; American Association of Petroleum Geologists: Tulsa, OK, USA, 2013; Volume 102, pp. 101–113. [Google Scholar]

- Zargari, S.; Wilkinson, T.M.; Packard, C.E.; Prasad, M. Effect of thermal maturity on elastic properties of kerogen. Geophysics 2016, 81, M1–M6. [Google Scholar] [CrossRef]

- Xi, Z.; Tang, S.; Zhang, S.; Sun, K. Pore structure characteristics of marine–continental transitional shale: A case study in the Qinshui Basin, China. Energy Fuels 2017, 31, 7854–7866. [Google Scholar] [CrossRef]

- Curtis, M.E.; Cardott, B.J.; Sondergeld, C.H.; Rai, C.S. Development of organic porosity in the Woodford Shale with increasing thermal maturity. Int. J. Coal Geol. 2012, 103, 26–31. [Google Scholar] [CrossRef]

- Zhao, J.; Jin, Z.; Jin, Z.; Hu, Q.; Hu, Z.; Du, W.; Geng, Y. Mineral types and organic matters of the Ordovician-Silurian Wufeng and Longmaxi Shale in the Sichuan Basin, China: Implications for pore systems, diagenetic pathways, and reservoir quality in fine-grained sedimentary rocks. Mar. Pet. Geol. 2017, 86, 655–674. [Google Scholar] [CrossRef]

- Wu, S.; Yang, Z.; Zhai, X.; Cui, J.; Bai, L.; Pan, S.; Cui, J. An experimental study of organic matter, minerals and porosity evolution in shales within high-temperature and high-pressure constraints. Mar. Pet. Geol. 2019, 102, 377–390. [Google Scholar] [CrossRef]

- Kamali, M.R.; Mirshady, A.A. Total organic carbon content determined from well logs using ΔLogR and Neuro Fuzzy techniques. J. Pet. Sci. Eng. 2004, 45, 141–148. [Google Scholar] [CrossRef]

- Zhao, P.; Mao, Z.; Huang, Z.; Zhang, C. A new method for estimating total organic carbon content from well logs. Aapg Bull. 2016, 100, 1311–1327. [Google Scholar] [CrossRef]

- Shi, X.; Wang, J.; Liu, G.; Yang, L.; Ge, X.; Jiang, S. Application of extreme learning machine and neural networks in total organic carbon content prediction in organic shale with wire line logs. J. Nat. Gas Sci. Eng. 2016, 33, 687–702. [Google Scholar] [CrossRef]

- Song, L.; Martin, K.; Carr, T.R.; Ghahfarokhi, P.K. Porosity and storage capacity of Middle Devonian shale: A function of thermal maturity, total organic carbon, and clay content. Fuel 2019, 241, 1036–1044. [Google Scholar] [CrossRef]

- Xie, W.; Chen, S.; Vandeginste, V.; Yu, Z.; Wang, H.; Wang, M. Review of the effect of diagenetic evolution of shale reservoir on the pore structure and adsorption capacity of clay minerals. Energy Fuels 2022, 36, 4728–4745. [Google Scholar] [CrossRef]

- Lu, Y.; Yang, F.; Bai, T.A.; Han, B.; Lu, Y.; Gao, H. Shale Oil Occurrence Mechanisms: A Comprehensive Review of the Occurrence State, Occurrence Space, and Movability of Shale Oil. Energies 2022, 15, 9485. [Google Scholar] [CrossRef]

- Craddock, P.R.; Haecker, A.; Bake, K.D.; Pomerantz, A.E. Universal curves describing the chemical and physical evolution of type II kerogen during thermal maturation. Energy Fuels 2020, 34, 15217–15233. [Google Scholar] [CrossRef]

- Shi, K.; Chen, J.; Pang, X.; Jiang, F.; Hui, S.; Zhang, S.; Pang, H.; Wang, Y.; Chen, D.; Pu, T.; et al. Average molecular structure model of shale kerogen: Experimental characterization, structural reconstruction, and pyrolysis analysis. Fuel 2024, 355, 129474. [Google Scholar] [CrossRef]

- Zhao, R.; Xue, H.; Lu, S.; Li, J.; Tian, S.; Dong, Z. Multi-scale pore structure characterization of lacustrine shale and its coupling relationship with material composition: An integrated study of multiple experiments. Mar. Pet. Geol. 2022, 140, 105648. [Google Scholar] [CrossRef]

| Method | Principle | Feature | Reference |

|---|---|---|---|

| Helium expansion measurement (He) | Accessible pores of helium are connected. | Temperature changes and pressure fluctuations lead to reduced measurement accuracy. For crushed samples, the method for determining the mesh size to ensure that helium enters the isolated pores has no unified standard. | [10,11] |

| High pressure mercury injection (MIC) | Accessible pores of mercury are connected. | The maximum mercury injection pressure is 60,000 psi, and its corresponding throat size is 3.6 nm. The range of measured pore throats is wide, and rich information of the pore structure can be obtained. For shale samples, mercury is disabled to enter micro-nano pores; also, injecting mercury usually causes microcracks, and the damage of the pore structure leads to significant deviations between the tested and actual pore structure. | [12] |

| Fluids saturation | Saturate the evacuated core with salt water, oil, or alcohol under pressurized conditions; the pores saturated with fluids are tested. | The testing result is influenced by the fluid type, pore surface wettability, saturation method, pre-treatment of rock cores and the experimental environment. | [13] |

| Low pressure gas adsorption (LPGA) | Pore structure parameters can be calculated according to theoretical models from the measured gas adsorption content on the pore surface under low temperature conditions. | Certain gases selecting according to experimental conditions, and reasonable calculation models are the key to accurately obtaining test results. | [14] |

| Nuclear magnetic resonance (NMR) testing | Pore distribution is obtained from the relaxation time of hydrogen nuclei in pore fluids. | NMR testing is non-destructive, convenient, fast, and has rich measurement information. Influential factors of quantitative pore structure characterization from NMR T2 distribution include the content and maturity of organic matter, pore surface wettability, and measurement parameters. | [15,16] |

| Small angle scattering (SAS) | Pore structure is characterized through elastic coherent scattering using X-rays or neutrons as probes. | Micro-nano pore structure can be tested, but its application in oil and gas field is rare. | [17,18] |

| Scanning electron microscope (SEM) | Pore structure is scanned by focused high-energy electron rays. | The resolution of SEM can reach nm level, but its view field is too small to represent the whole rock. | [19] |

| Micro-CT | Micro-structure of rock samples is scanned by using microfocus X-ray, without damaging the samples. | Digital core can be built to simulate physics experiments, micrometer pores can be scanned, but its application in nanoscale shale is limited. | [20] |

| Section | Ro/% | |

|---|---|---|

| Min–Max | Min−Max | |

| Average | Average | |

| Q4 | 4.7–7.3 | 1.2~1.6 |

| 6.04 | 1.56 | |

| Q5 | 0.3–6.4 | 1.5~1.8 |

| 3.95 | 1.77 | |

| Q6 | 0.8–4.7 | 1.6~2.8 |

| 3.37 | 1.84 | |

| Q7 | 0.2–4.9 | 1.2~1.9 |

| 4.06 | 1.81 | |

| Q8 | 1.1–5.2 | 1.2~1.9 |

| 4.08 | 1.85 | |

| Q9 | 0.2–5.9 | 1.2~2.0 |

| 4.55 | 1.87 |

| No. | Lith | Depth (m) | Length (mm) | Diameter (mm) | φHe (%) | φNMR (%) | φ (%) | φt (%) | No. | Lith | Depth (m) | Length (mm) | Diameter (mm) | φHe (%) | φNMR (%) | φ (%) | φt (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | shale | 4872.21 | 49.11 | 24.65 | 4.01 | 1.61 | 5.62 | 6.53 | 15 | shale | 4872.82 | 42.84 | 24.78 | 8.85 | 10.01 | 18.86 | 17.85 |

| 2 | shale | 4872.22 | 49.77 | 24.49 | 5.85 | 18.79 | 24.64 | 23.35 | 16 | shale | 4872.83 | 51.65 | 24.62 | 3.31 | 11.12 | 14.43 | 15.22 |

| 3 | shale | 4872.38 | 50.60 | 24.69 | 3.11 | 8.86 | 11.97 | 11.65 | 17 | shale | 4872.9 | 49.90 | 24.15 | 1.53 | 5.72 | 7.25 | 7.30 |

| 4 | shale | 4872.47 | 47.63 | 24.51 | 3.48 | 4.30 | 7.78 | 8.43 | 18 | shale | 4873.04 | 50.87 | 24.75 | 1.70 | 6.54 | 8.24 | 7.66 |

| 5 | shale | 4872.49 | 44.69 | 24.52 | 5.47 | 6.56 | 12.03 | 11.46 | 19 | shale | 4873.11 | 50.59 | 24.91 | 1.26 | 13.17 | 14.43 | 14.40 |

| 6 | shale | 4872.52 | 47.81 | 24.54 | 3.53 | 8.09 | 11.62 | 12.17 | 20 | shale | 4873.14 | 51.91 | 25.14 | 3.05 | 7.17 | 10.22 | 11.02 |

| 7 | shale | 4872.55 | 49.13 | 24.55 | 2.48 | 8.93 | 11.41 | 11.23 | 21 | shale | 4873.16 | 51.48 | 24.41 | 3.15 | 7.11 | 10.26 | 10.42 |

| 8 | shale | 4872.59 | 54.18 | 24.52 | 2.46 | 1.76 | 4.22 | 4.78 | 22 | shale | 4873.16 | 51.70 | 24.53 | 5.82 | 5.97 | 11.79 | 10.23 |

| 9 | shale | 4872.63 | 48.18 | 24.56 | 7.75 | 8.60 | 16.35 | 14.95 | 23 | shale | 4873.16 | 61.13 | 24.54 | 0.40 | 7.23 | 7.63 | 9.34 |

| 10 | shale | 4872.7 | 48.51 | 24.66 | 6.13 | 12.66 | 18.79 | 16.66 | 24 | shale | 4873.18 | 60.19 | 24.48 | 4.71 | 8.28 | 12.99 | 9.88 |

| 11 | shale | 4872.72 | 48.27 | 24.66 | 2.15 | 12.55 | 14.70 | 14.43 | 25 | shale | 4873.18 | 49.07 | 24.57 | 6.80 | 0.39 | 7.19 | 9.30 |

| 12 | shale | 4872.73 | 50.61 | 24.63 | 7.18 | 10.19 | 17.37 | 17.52 | 26 | shale | 4873.21 | 34.11 | 24.80 | 2.14 | 7.77 | 9.91 | 10.55 |

| 13 | shale | 4872.73 | 48.19 | 24.60 | 2.84 | 11.96 | 14.80 | 14.47 | 27 | shale | 4873.26 | 58.93 | 24.83 | 2.64 | 7.15 | 9.79 | 11.56 |

| 14 | shale | 4872.73 | 50.82 | 24.94 | 2.61 | 3.87 | 6.48 | 9.48 | 28 | shale | 4873.28 | 52.43 | 24.68 | 4.09 | 9.69 | 13.78 | 13.90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Ke, S.; Xie, W.; Zhang, Z.; Wei, B.; Wan, J.; Cheng, D.; Li, Z.; Fang, C. Research on the Shale Porosity–TOC Maturity Relationship Based on an Improved Pore Space Characterization Method. Energies 2024, 17, 997. https://doi.org/10.3390/en17050997

Zhao J, Ke S, Xie W, Zhang Z, Wei B, Wan J, Cheng D, Li Z, Fang C. Research on the Shale Porosity–TOC Maturity Relationship Based on an Improved Pore Space Characterization Method. Energies. 2024; 17(5):997. https://doi.org/10.3390/en17050997

Chicago/Turabian StyleZhao, Jianbin, Shizhen Ke, Weibiao Xie, Zhehao Zhang, Bo Wei, Jinbin Wan, Daojie Cheng, Zhenlin Li, and Chaoqiang Fang. 2024. "Research on the Shale Porosity–TOC Maturity Relationship Based on an Improved Pore Space Characterization Method" Energies 17, no. 5: 997. https://doi.org/10.3390/en17050997

APA StyleZhao, J., Ke, S., Xie, W., Zhang, Z., Wei, B., Wan, J., Cheng, D., Li, Z., & Fang, C. (2024). Research on the Shale Porosity–TOC Maturity Relationship Based on an Improved Pore Space Characterization Method. Energies, 17(5), 997. https://doi.org/10.3390/en17050997