Abstract

The electric heating process for lifting heavy oil has been widely applied. However, research on its temperature field laws mostly focuses on onshore heavy oil wells, while research offshore is limited. Therefore, based on the energy conservation equation and heat transfer theory, a transient one-dimensional wellbore temperature model coupled with the temperature and viscosity of heavy oil and considering the effect of time was developed. In order to verify the accuracy of the model, the results of the previous model were used for comparison with the present model, and the results showed that the model has good accuracy. The results show that a reasonable selection of the process parameters of electric heating can increase the production of heavy oil while saving development costs and improving the economic benefits of the oilfield. The conclusions and recommendations of this paper can provide a theoretical basis and guiding suggestions for the optimal design of process parameters for lifting heavy oil using an offshore electric heating process.

1. Introduction

With the rapid development of the world economy, the demand for oil is increasing. The rapid depletion of conventional oil resources has led to growing interest in heavy oil from countries such as Venezuela, the United States and Canada [1]. The technology for the extraction of onshore heavy oil is relatively mature after decades of development. However, due to the influence of environmental conditions, operating space and costs, the extraction of offshore heavy oil fields is much more difficult than onshore [2]. The viscosity of heavy oil is sensitive to temperature. The viscosity of the heavy oil increases considerably during the process from reservoir to surface, which makes it more difficult to extract the heavy oil. Therefore, the flowability of heavy oil can be improved by increasing the temperature [3]. The commonly used thermal recovery methods are not suitable for certain reservoirs, and electric heating technology is an effective solution for these reservoirs [4]. Currently, the electric heating process is considered to be one of the main options for offshore heavy oil heating due to its low cost, high efficiency and environmental friendliness [5,6,7].

Electric heating is more effective in lifting heavy oil, which can significantly improve the recovery rate [8]. At present, there are many field examples of using electric heating process to extract heavy oil. A suitability study of electric heating for heavy oil recovery was carried out in the Bati Raman and Camurlu fields in Turkey. The results show that the electric heating process together with the addition of iron powder to the crude oil can reduce the viscosity of the crude oil more, and the production of crude oil can be increased from the original 320 barrels to 440 barrels in the same operation time [9]. In order to increase the production of heavy oil reservoirs off the coast of Congo, electric heating technology was used to increase the reservoir temperature. This makes the viscosity in reservoir conditions drop from 1000 cp to lower values, which improves production and reservoir recovery [10]. The use of electric heating technology in a 9° API heavy oil field in Colombia has increased daily production by over 160%, avoiding the use of light oil to dilute heavy oil and saving a lot of costs [11]. The application of electric heaters in the Klamono Field resulted in a reduction in the viscosity of the crude oil from 68 cp to 46 cp and an increase in production by 4.9 bbl/d. Field data show that the additional cost of using the heater is less than the benefit it brings, so the project has a good prospect [12]. The application of downhole electric heating technology in a cold recovery heavy oil horizontal well in Alberta, Canada, shows that in the early stage of well production, the oil production of heated wells is 4–6 times higher than that of cold recovery wells, which reflects the effectiveness and superiority of downhole electric heating technology [13,14]. The Santanghu Oilfield has determined the heating depth, heating power, heating frequency and the artificial lifting system in the form of combinations of hollow sucker rods and poles. The results show that the application of hollow sucker rod electric heating oil extraction technology can effectively solve the difficulties in the extraction of heavy oil blocks in this oilfield [15].

Since the heating power, heating depth and heating time of the electric heating process all have an impact on the temperature distribution of the wellbore, it is of great significance to carry out research on the temperature field of the wellbore for the extraction of heavy oil by electric heating. Based on the equations of conservation of mass, momentum and energy, Zhu et al. [16] established a temperature–pressure coupling model by considering the mixing effect of light oil and heavy oil as well as the effect of electric heating. The calculations of the model show that the electric heating technology can reduce the amount of light oil used. Wang et al. [17] considered temperature-dependent reservoir thermophysical parameters in the heat transfer and fluctuation equations. The temperature distribution of the wellbore was calculated based on the coupling relationship between electromagnetic field and temperature field. Finally, the effects of reservoir properties and casing relative dielectric constant on the temperature distribution were analysed. Based on the theory of heat transfer and the calculation method of gas–liquid two-phase flow wellbore temperature and pressure field, Zhu et al. [18] considered the influence of temperature on the thermal properties of heavy oil and established a numerical calculation method for wellbore temperature field using continuous electric heating and electromagnetic short-section heating processes. Based on the basic theory of heat transfer, Zhou [19,20] established a relationship model between pumping unit lifting energy consumption and wellbore temperature field. According to the results, the temperature field and viscous resistance distribution of the tubing under different heating powers were analysed, and the electric heating power and depth were optimised. Ramírez et al. [21] used CFD software (STAR-CCM (+v16.06.010-R8)) to model and simulate the distribution of temperature and viscosity in a heavy oil production well using induction electric heating. The results show that downhole electric induction heating is an effective method to reduce the dynamic viscosity of heavy oil.

Although there have been many applications and studies on the electric heating process in the extraction of heavy oil, most of the current researches are aimed at onshore heavy oil wells, and there is little research on the influence law of the electric heating process in offshore heavy oil wells. In this paper, the coupling of temperature and viscosity of heavy oil is used to establish the temperature field of electrically heated lifted offshore heavy oil, and unlike the conventional steady state model, the present model also introduces a time term for calculation. By modelling the transient one-dimensional wellbore temperature field of electrically heated extraction of heavy oil, the wellbore temperature distribution at any moment of an electrically heated heavy oil well can be clearly known.

In this paper, based on the in-depth study of the heat transfer mechanism of the wellbore and considering the difference between onshore and offshore heavy oil wells, a temperature field model of the offshore heavy oil wellbore with electric heating was established. The effects of heavy oil production, electric heating power, electric heating depth, electric heating time and thermal conductivity of insulation tubing on the temperature distribution of the wellbore at different moments were analysed. The results of the study can provide theoretical guidance for the design of operational parameters for lifting offshore heavy oil by electric heating process, increasing well productivity and reducing development costs. This work is of great practical importance.

2. Mathematical Model

2.1. Model Assumptions

Due to the fact that radial heat transfer is much greater than axial heat storage, axial heat storage can be ignored, so the flow of heavy oil in the wellbore can be considered as one-dimensional. The viscosity of heavy oil is temperature-sensitive, and its viscosity is high, resulting in more frictional heat generated during the flow process. Based on the above reasons, we can make the following assumptions:

- The flow of heavy oil in a tubing is one-dimensional.

- Only the radial heat transfer from the wellbore is considered, and the axial heat transfer from the wellbore is ignored.

- Heavy oil is incompressible, and its viscosity changes during production.

- Consider the thermal effects generated during the flow process of heavy oil.

2.2. Distribution Model of Wellbore Temperature Field

2.2.1. Governing Equation

The heat exchange between the wellbore and the external environment is shown in Figure 1, where a microelement segment of the wellbore is selected, a one-dimensional coordinate system is established and the opposite direction of fluid flow is positive. According to the heat transfer process shown in Figure 1, the energy conservation equation for the fluid can be written as:

Figure 1.

Schematic diagram of heat exchange process in electric heating extraction of heavy oil.

The heat exchange between the formation and the wellbore is as follows:

f(tD) is the transient heat transfer function, which is calculated as follows [22]:

where .

The heat exchange between the wellbore and the tube is [23]:

The heat exchange between the external environment and the wellbore is equal to the heat exchange between the wellbore and the tube. Equations (2) and (4) can be combined to obtain the heat transfer from the formation to the tube. The expression is

The heat exchange between seawater and the tube is

According to the energy conservation equation of the fluid, the heat transfer model of the wellbore microelement can be written as follows:

The left side of Equation (7) represents the change in heat inside the microelement, and the right side represents the heat flowing out of the microelement, the heat flowing into the microelement, the heat exchange between the external environment and the tubing, the frictional heat generated by the fluid flow and the heat generated by the electrical heating, respectively.

where, in the formation, ; in the seawater, .

The comprehensive heat transfer coefficients Uti and Usea are used to describe the series thermal resistance from the tube to the external environment. The comprehensive heat transfer coefficients of formation and seawater are represented by Equations (9) and (10), respectively.

2.2.2. Auxiliary Equation

In order to solve the equation, in addition to the basic control equation, some auxiliary equations are also needed.

- (1)

- Calculation of convective heat transfer coefficient hf.

- (2)

- Calculation of the heat transfer coefficient hr for thermal radiation in the annulus.

- (3)

- Calculation of natural conductive heat transfer coefficient [24].

- (4)

- Calculation of convective heat transfer coefficients between seawater and riser [25].

- (5)

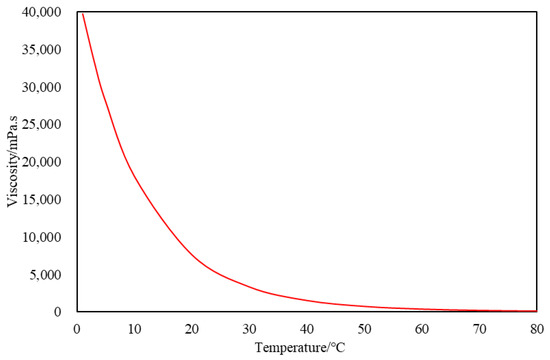

- The relationship between crude oil viscosity and temperature [26] is shown in Equation (15). The viscosity–temperature curve of crude oil is plotted based on the viscosity–temperature relationship, as shown in Figure 2. The inflection point temperature of the crude oil can be determined as 40 °C based on Figure 2. The viscosity μ of crude oil is mainly used for calculating the heat transfer coefficient hf.

Figure 2. Viscosity–temperature curve of crude oil.

Figure 2. Viscosity–temperature curve of crude oil.

2.3. Model Solving Conditions

2.3.1. Initial Conditions

The temperature of the fluid in the tubing at the initial moment is equal to the formation temperature:

2.3.2. Boundary Conditions

The temperature at the bottom of the well is always equal to the reservoir temperature:

2.4. Numerical Solution

In order to solve the model, a program was written in Python, in which the temperature calculation and the viscosity of the heavy oil were coupled and iterated with each other to make the calculation more accurate.

2.4.1. Discretization of Equations

Differential equations are discretised using finite difference methods to facilitate their programming solutions.

2.4.2. Meshing

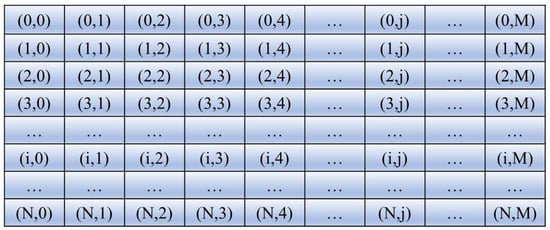

The computational model is transient and includes both temporal and spatial dimensions. The temporal and spatial grid divisions are shown in Figure 3, where i represents the spatial dimension and j represents the temporal dimension.

Figure 3.

Grid division of wellbore space and time.

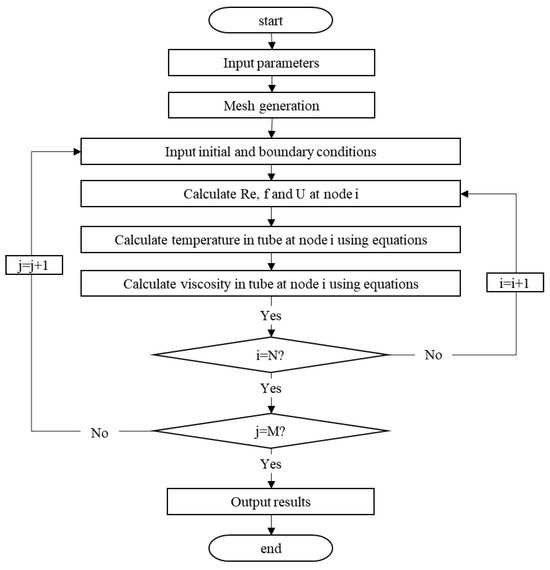

2.4.3. Solution

In order to clearly illustrate the idea of the solution, the flowchart of the calculation process of the temperature field is shown in Figure 4.

Figure 4.

Flow chart of temperature field calculation.

2.5. Model Validation

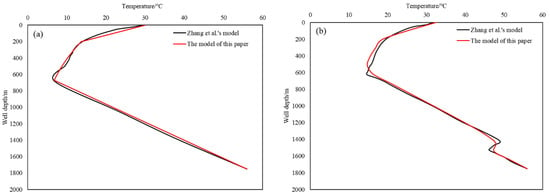

The offshore electrically heated lifted heavy oil wellbore model developed in this paper is compared with the previous models to verify the accuracy of the present model [27]. Inputting the same parameters as the previous model, the temperature distributions were verified for ambient and electrically heated conditions, as shown in Figure 5a and Figure 5b, respectively. The validation results show that the results of this model are less different from the previous results and the results are in good agreement.

Figure 5.

Comparison of the calculation results of this model and Zhang et al.’s model [27]: (a) ambient temperature; (b) electrically heated temperature.

3. Sensitivity Analysis

3.1. Basic Data

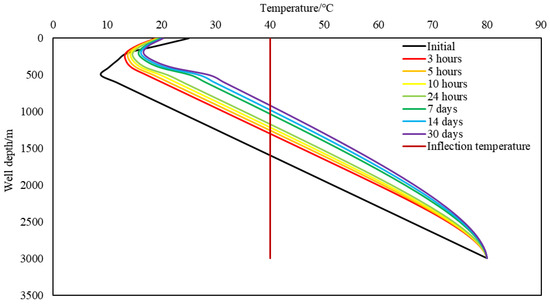

There are a number of input parameters that are fixed when using a mathematical model to calculate the temperature distribution of a heavy oil wellbore, as shown in Table 1. This paper mainly analyses the influence of parameters such as production, heating power, heating depth, heating time and thermal conductivity coefficient of insulation materials on the temperature distribution of electrically heated heavy oil wellbore. Figure 6 shows the temperature distribution of the wellbore at different times without heating when the production is 70 m3/d. From the figure, it can be seen that without using any measures, the temperature of the heavy oil in the seawater section is lower than the inflection point temperature of the crude oil, which will lead to difficulties in the flow of heavy oil in the wellbore and make it difficult to extract. Therefore, it is necessary to take electric heating measures to improve its fluidity and guarantee the normal oil recovery.

Table 1.

Basic data for wellbore temperature field calculation.

Figure 6.

Distribution of wellbore temperature at different times with a production of 70 m3/d.

3.2. The Influence of Oil Production on the Temperature Distribution of Heavy Oil Wellbore

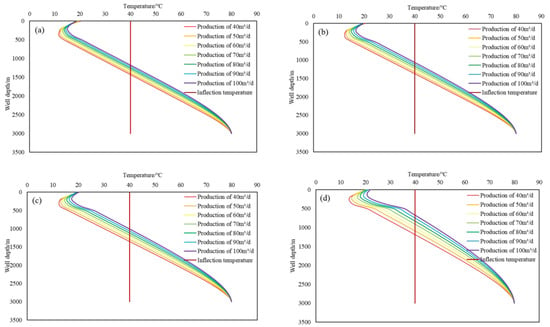

In order to investigate the effect of different production on the temperature distribution of the heavy oil wellbore, the temperature distribution of the wellbore after 3 h, 10 h, 24 h and 30 d at production of 40, 50, 60, 70, 80, 90 and 100 m3/d was investigated, as shown in Figure 7. As can be seen in Figure 7, the higher the production, the higher the wellbore temperature distribution in general. As the extraction time increases, the more obvious the distinction between the wellbore temperature distributions at different production. However, at the initial stage of extraction of heavy oil (before 10 h) and at a certain depth in the seawater section, there will be a situation where the higher the production, the lower the temperature.

Figure 7.

Influence of different production on the temperature field of the wellbore at different periods of exploitation: (a) 3 h; (b) 10 h; (c) 24 h; (d) 30 days.

It can be analysed that during the flow of crude oil from the formation to the wellhead in the formation section, the temperature of the surrounding formation is decreasing all the time. Therefore, the crude oil has to dissipate heat to the formation in the process of flowing. The larger the production, the slower the heat dissipation. Therefore, in general, the higher the production, the higher the temperature. However, when the crude oil flows into the seawater section, the heat dissipation of crude oil to seawater is accelerated, and the temperature of seawater is gradually rising during the flow of crude oil to the wellhead, so that the temperature of crude oil will be lower than the temperature of seawater at a certain depth in the seawater section. Therefore, as the crude oil continues to flow towards the wellhead, the crude oil begins to absorb heat from the seawater. The larger production absorbs heat and warms up more slowly, which results in a lower temperature in the seawater section the larger the oil production is. As the extraction time increases, the temperature of the formation becomes higher and higher, and the temperature difference between it and the crude oil becomes smaller and smaller, so the crude oil dissipates less and less heat to the surrounding formation. Similarly, the larger the production, the less the temperature decreases, so the distinction between the wellbore temperature distributions at different production levels is more obvious.

3.3. The Influence of Heating Power on the Temperature Distribution of Heavy Oil Wellbore

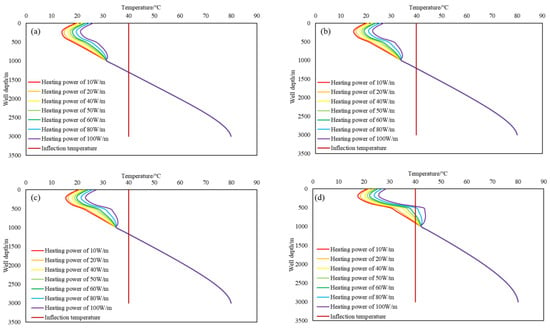

In order to study the effect of different heating power on the temperature distribution of heavy oil wellbore, the temperature distribution of wellbore after 3 h, 10 h, 24 h and 30 d at the heating power of 10, 20, 40, 50, 60, 80 and 100 W/m was investigated, as shown in Figure 8. As can be seen in Figure 8, the higher the heating power, the higher the wellbore temperature distribution. With the increase in extraction time, the distinction between the wellbore temperature distributions of the formation sections at different heating powers becomes more obvious. However, the wellbore temperature distribution in the seawater section at different heating powers is not clearly distinguished.

Figure 8.

Influence of different heating powers on the temperature field of the wellbore at different periods of exploitation: (a) 3 h; (b) 10 h; (c) 24 h; (d) 30 days.

The analysis shows that electric heating of the wellbore compensates for some of the heat lost during the flow of the heavy oil, so that the temperature of the wellbore is significantly increased after electric heating of the wellbore compared to the unheated one. The higher the heating power for the same heating time, the more heat is compensated and the higher the temperature of the heavy oil. During the process of heavy oil flowing from the bottom of the well to the wellhead, it needs to pass through two media: the formation and seawater. The heat dissipation in the formation is smaller than that in seawater. Therefore, the heat lost after heating in the formation is smaller than that in seawater. With the increase in heating time, the temperature of heavy oil under different heating power in the formation section will be distinguished more and more obviously, while when the heat dissipation in seawater is more, the heat generated by electric heating cannot be well “stored”, so the temperature of heavy oil under different heating power is not distinguishable.

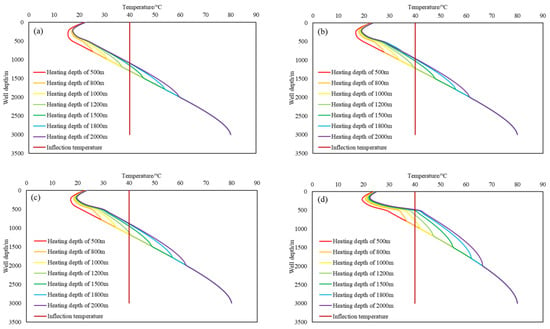

3.4. The Influence of Heating Depth on the Temperature Distribution of Heavy Oil Wellbore

In order to study the effect of different heating depth on the temperature distribution of heavy oil wellbore, the temperature distribution of the wellbore after 3 h, 10 h, 24 h and 30 d at a heating depth of 500, 800, 1000, 1200, 1500, 1800 and 2000 m was investigated, as shown in Figure 9. From Figure 9, it can be seen that the deeper the heating depth, the slower the temperature of the heavy oil in the formation section decreases during the upward flow process, but the difference in wellhead temperature after passing through the seawater section is very small. As the extraction time increases, the difference in temperature of heavy oil at different heating depths becomes more obvious.

Figure 9.

Influence of different heating depths on the temperature field of the wellbore at different periods of exploitation: (a) 3 h; (b) 10 h; (c) 24 h; (d) 30 days.

The analysis shows that in the early stage of electric heating, the electric heating compensates less heat to the heavy oil due to the shorter heating time. Therefore, the heavy oil with different heating depths soon converge to the same in the upward flow process. As the heating time increases, the more the electric heating compensates for the heat of the heavy oil. In the formation section where the heavy oil flows, the deeper the heating depth, the slower the temperature of the heavy oil decreases. For the seawater section, since its heat dissipation capacity is larger than that of the formation section, a large part of the compensatory heat generated by electric heating is also dissipated in the seawater section. Therefore, after the heat dissipation in the seawater section, the temperature of heavy oil after electric heating at different depths does not differ much at the wellhead. Thus, for lifting heavy oil by offshore electric heating, the heating cables do not have to be lowered to a very deep depth.

3.5. The Influence of Heating Time on the Temperature Distribution of Heavy Oil Wellbore

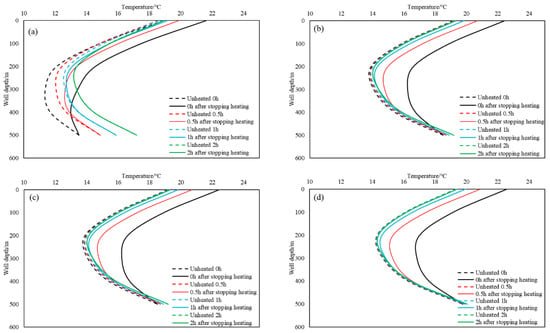

In order to study the effect of different heating time on the temperature distribution of heavy oil wellbore, the temperature distribution of wellbore without heating measures and with electric heating from 500 m (seawater depth) were studied separately. In this paper, the temperature distribution of the wellbore during the two hours when the heating was stopped after 1, 3, 5 and 10 h of heating was investigated, respectively, in comparison with the temperature distribution of the wellbore at the same moment without heating, as shown in Figure 10. As can be seen in Figure 10, regardless of the length of the heating time, the temperature profile of the heated wellbore almost overlaps with the unheated one for 2 h after the heating is stopped. This indicates that the length of the heating time is independent of the cooling time of the wellbore temperature. The temperature drops fastest in the early moments of heating cessation, and as the time of heating cessation increases, the wellbore temperature decreases from a rapid drop at the beginning to a slower drop later on.

Figure 10.

Temperature field two hours after stopping heating at different heating times compared with the temperature field of the wellbore at the same time without heating: (a) 1 h; (b) 3 h; (c) 5 h; (d) 10 h.

The analysis shows that the heat generated during electrical heating can “compensate” for some of the heat lost from the wellbore to the outside, but it is not well “stored” in the wellbore. Therefore, long-term heating needs to maintain a balance between heating and heat dissipation. When heating is stopped, regardless of the length of previous heating time, the temperature will quickly decrease to the same level as the unheated wellbore. In the early stages of the cessation of heating, the temperature of the wellbore differs considerably from what it should have been when the wellbore was not heated, so the temperature drops more rapidly. As the temperature drops, the temperature difference becomes smaller and the drop is slower, finally dropping to the same temperature as the unheated wellbore. Based on the law that the temperature is affected by the heating time, it is possible to obtain a reasonable heating method for electric heating according to the site conditions. For example, using intermittent heating can save more electricity resources and thus save costs while ensuring the fluidity of heavy oil.

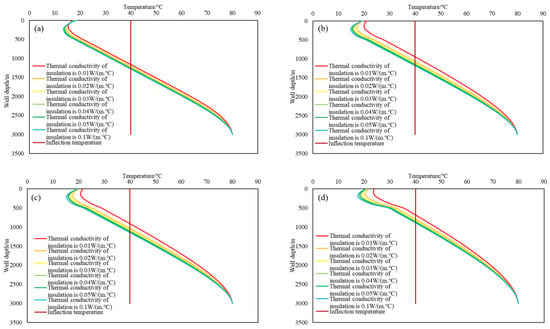

3.6. The Influence of Thermal Conductivity of Insulation Materials on the Temperature Distribution of Heavy Oil Wellbore

In order to study the effect of different thermal conductivity of insulation material on the temperature distribution of heavy oil wellbore, the temperature distribution of the wellbore after 3 h, 10 h, 24 h and 30 d at thermal conductivities of 0.01, 0.02, 0.03, 0.04, 0.05 and 0.1 W/(m·°C) of the insulation layer was investigated, respectively, as shown in Figure 11. It can be seen from Figure 11 that the smaller the thermal conductivity of the insulation layer, the higher the temperature distribution of the wellbore in general. However, in the initial stage of extracting heavy oil (before 3 h), at a certain depth in the seawater section, there will be a situation where the smaller the thermal conductivity of the insulation layer, the lower the temperature will be.

Figure 11.

Influence of different thermal conductivities of insulation on the temperature field of the wellbore at different periods of exploitation: (a) 3 h; (b) 10 h; (c) 24 h; (d) 30 days.

The analysis shows that the heat can be better “stored” by using insulated pipes in the extraction of heavy oil. The smaller the thermal conductivity of the insulation layer, the greater the thermal resistance of the heavy oil to heat dissipation. Therefore, when the “stored” capacity in the flow process is stronger, the heavy oil temperature will be higher. However, in the initial stage of exploitation, when the heavy oil is transported to the seawater section, the temperature of the seawater is higher than that of the heavy oil, and due to the thermal conductivity of the insulation layer being small and its thermal resistance being large, the heat of the seawater is transferred less to the heavy oil. Therefore, there will be a situation where the lower the thermal conductivity of the insulation, the lower the temperature at a certain depth in the seawater section.

4. Conclusions

- (1)

- The higher the production, the higher the wellbore temperature distribution. With the increase in extraction time, the more obvious the distinction between the wellbore temperature distribution with different production. However, at the initial stage of heavy oil extraction, at a certain depth in the seawater section, the higher the production, the lower the temperature.

- (2)

- The higher the heating power and heating depth, the higher the wellbore temperature distribution. With the increase in extraction time, the distinction between the wellbore temperature distribution in the formation section under different heating power becomes more obvious, but the seawater section is not very obvious. The heating depth has some limitations, and the increase in heavy oil temperature is not obvious after the lowering depth reaches a certain value.

- (3)

- By adopting intermittent heating measures, more power resources can be saved while ensuring that the temperature of the heavy oil is higher than the inflection point temperature. When intermittent heating processes are adopted, the intermittent time needs to be optimised according to the actual situation.

- (4)

- The smaller the thermal conductivity of the insulation material, the higher the temperature distribution of the wellbore in general, but in the initial stage of the extraction of heavy oil, at a certain depth in the seawater section, there will be a situation in which the smaller the thermal conductivity of the insulation layer, the lower the temperature.

- (5)

- The electric heating process can “compensate” for the heat lost during the flow of heavy oil, and the use of insulation materials can better “store” the heat, and the combination of the two can maintain the wellbore temperature distribution at a high level.

- (6)

- The overall temperature of the wellbore will increase with the increase in the extraction time, so the use of electric heating process and insulation materials can be reduced according to the actual situation after extracting the heavy oil for a period of time.

- (7)

- Through the influence of electric heating power, heating depth, heating time and thermal conductivity of insulation materials on wellbore temperature, the optimal process parameters of offshore electric heating for lifting heavy oil can be selected according to the actual situation on site.

Author Contributions

Conceptualization, S.S. and K.G.; methodology, K.G., X.Z. and B.S.; software, H.Y. and Y.G.; validation, Q.Z. and B.S.; formal analysis, G.C.; investigation, Q.Z. and L.T.; resources, Q.Z. and L.T.; data curation, X.Z., G.C. and B.S.; writing—original draft, S.S. and K.G.; writing—review & editing, S.S., X.Z., H.Y. and Y.G.; visualization, L.T. and H.Y.; supervision, Y.G.; project administration, Q.Z.; funding acquisition, S.S., K.G., X.Z. and G.C. All authors have read and agreed to the published version of the manuscript.

Funding

The author is very grateful for the support from the CNOOC Science and Technology Project (KJGG2022-0406) and the National Natural Science Foundation of China (No. U21B2065, No. 52274022). The funding sponsors had no role in the design of the study; in the collection, analyses or interpretation of data; in the writing of the manuscript; and in the decision to publish the results.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Author Suogui Shang, Kechao Gao, Xinghua Zhang and Guangfeng Chen were employed by the company Tianjin Branch of CNOOC (China), Limited, Author Qibin Zhao was employed by the company CNOOC (China) Ltd., Author Bin Song was employed by the company COSL-EXPRO Testing Services (Tianjin) Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Nomenclature

| A | cross-sectional area of tubing, m2; |

| API | API (American Petroleum Institute) gravity, °API; |

| ce | specific heat capacity of the formation, J/(kg·°C); |

| cf | specific heat capacity of heavy oil, J/(kg·°C); |

| hc | natural convection heat transfer coefficient, W/(m2·°C); |

| hf | convective heat transfer coefficient of heavy oil, W/(m2·°C); |

| hr | annular radiation heat transfer coefficient, W/(m2·°C); |

| hsea | convective heat transfer coefficient of seawater crossing the riser, W/(m2·°C); |

| ke | thermal conductivity of the formation, W/(m·°C); |

| Nu | Nusselt number, dimensionless; |

| Qe | heat generated by electric heating, W; |

| QF | heat generated by the flow of heavy oil, W; |

| Qf | heat transfer between the formation (seawater) and the wellbore, W; |

| Qp(z) | heat flow into the microelement, W; |

| Qp(z + dz) | heat flowing out of the microelement, W; |

| Qt | the change in heat in microelements, W; |

| Qw | the heat exchange between the formation and the wellbore, W; |

| Qwf | the heat exchange between the wellbore and the tube, W; |

| qe | power of heating rod, W/m; |

| rcem | radius of cement, m; |

| rci | inner radius of casing, m; |

| rco | outer radius of casing, m; |

| rri | inner radius of riser, m; |

| rro | outer radius of riser, m; |

| rti | inner radius of tube, m; |

| rto | outer radius of tube, m; |

| rw | radius of the wellbore, m; |

| T | temperature, °C; |

| Tci | inner wall temperature of casing, °C; |

| Te | temperature of the formation, °C; |

| formation temperature at node i, °C; | |

| Tf | temperature of heavy oil, °C; |

| temperature of heavy oil at node i at time 0, °C; | |

| temperature of heavy oil at node 0 at time j, °C; | |

| temperature of heavy oil at node i at time j, °C; | |

| temperature of heavy oil at node i at time j + 1, °C; | |

| temperature of heavy oil at node i + 1 at time j, °C; | |

| reservoir temperature, °C; | |

| Tto | outer wall temperature of tube, °C; |

| Twb | temperature of the well wall, °C; |

| t | time, s; |

| Usea | total heat transfer coefficient from tube to seawater, W/(m2·°C); |

| Uti | total heat transfer coefficient from tube to formation, W/(m2·°C); |

| v | flow rate of heavy oil, m/s; |

| w | mass flow rate of heavy oil, kg/s; |

| Δt | time step, s; |

| Δz | well depth step, m; |

| ε | surface emissivity of the pipe wall, dimensionless; |

| μ | viscosity of heavy oil, mPa.s; |

| λ | thermal conductivity of heavy oil, W/(m·°C); |

| λc | thermal conductivity of air, W/(m·°C); |

| λcas | thermal conductivity of casing, W/(m·°C); |

| λcem | thermal conductivity of cement, W/(m·°C); |

| λm | friction coefficient of pipe wall, dimensionless; |

| λr | thermal conductivity coefficient of riser, W/(m·°C); |

| λsea | thermal conductivity coefficient of seawater, W/(m·°C); |

| λtub | thermal conductivity coefficient of tube, W/(m·°C); |

| ρ | density, kg/m3; |

| ρe | density of the formation, kg/m3; |

| σ | Stefan–Boltzmann constant, W/(m2·°C4). |

References

- Wang, Z.; Gao, D.; Diao, B.; Tan, L.; Zhang, W.; Liu, K. Comparative performance of electric heater vs. RF heating for heavy oil recovery. Appl. Therm. Eng. 2019, 160, 114105. [Google Scholar] [CrossRef]

- Weichao, L.; Tao, Q.; Hongxiang, G.; Jifei, Y.; Xianfu, S. Research and Application of Wellbore Temperature Field Models forThermal Recovery Well in Offshore Heavy Oilfield. J. Southwest Pet. Univ. 2012, 34, 105. [Google Scholar]

- Jin, F.; Jiang, T.; Yuan, C.; Varfolomeev, M.A.; Wan, F.; Zheng, Y.; Li, X. An improved viscosity prediction model of extra heavy oil for high temperature and high pressure. Fuel 2022, 319, 123852. [Google Scholar] [CrossRef]

- Mukhametshina, A.; Martynova, E. Electromagnetic heating of heavy oil and bitumen: A review of experimental studies and field applications. J. Pet. Eng. 2013, 2013, 476519. [Google Scholar] [CrossRef]

- Bera, A.; Babadagli, T. Status of electromagnetic heating for enhanced heavy oil/bitumen recovery and future prospects: A review—ScienceDirect. Appl. Energy 2015, 151, 206–226. [Google Scholar] [CrossRef]

- Hasibuan, M.Y.; Regina, S.; Wahyu, R.; Situmorang, D.; Azmi, F.; Syahputra, R.; Batubara, L.P.Y.; Prabowo, F.; Setiawan, A.; Afin, M.F. Electrical heating for heavy oil: Past, current, and future prospect. Preprints 2020. [Google Scholar] [CrossRef]

- Kovaleva, L.; Davletbaev, A.; Babadagli, T.; Stepanova, Z. Effects of electrical and radio-frequency electromagnetic heating on the mass-transfer process during miscible injection for heavy-oil recovery. Energy Fuels 2011, 25, 482–486. [Google Scholar] [CrossRef]

- Rangel-German, E.; Schembre, J.; Sandberg, C.; Kovscek, A. Electrical-heating-assisted recovery for heavy oil. J. Pet. Sci. Eng. 2004, 45, 213–231. [Google Scholar] [CrossRef]

- Hascakir, B.; Babadagli, T.; Akin, S. Experimental and Numerical Modeling of Heavy-Oil Recovery by Electrical Heating. In Proceedings of the International Thermal Operations and Heavy Oil Symposium, Calgary, AB, Canada, 20–23 October 2008; OnePetro: Richardson, TX, USA, 2008. [Google Scholar]

- Vielma, W.; Congo, E.; Misenta, M.; Ponticiello, I.; Secco, G. Downhole electrical heating system: Feasibility of heavy oil implementation in offshore Congo. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 1–4 November 2010; OnePetro: Richardson, TX, USA, 2010. [Google Scholar]

- Escobar-Remolina, J.; Barrios, W.; Ecopetrol, S.; Silva, B. Production Increase with Electric Heating Production Line Technology in an Extra-Heavy Oil Field in Colombia: Successful Case of Flow Assurance. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012; OnePetro: Richardson, TX, USA, 2012. [Google Scholar]

- Hakiki, F.; Aditya, A.; Ulitha, D.; Shidqi, M.; Adi, W.; Wibowo, K.; Barus, M. Well and inflow performance relationship for heavy oil reservoir under heating treatment. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Jakarta, Indonesia, 17–19 October 2017; OnePetro: Richardson, TX, USA, 2017. [Google Scholar]

- Karanikas, J.; Pastor, G.; Penny, S.; Ciencia, T.Y.F. Downhole electric heating of heavy-oil wells. CT 2020, 10, 61–72. [Google Scholar] [CrossRef]

- Penny, S.; Karanikas, J.M.; Barnett, J.; Harley, G.; Hartwell, C.; Waddell, T. Field case studies of downhole electric heating in two horizontal Alberta heavy oil wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 30 September–2 October 2019; OnePetro: Richardson, TX, USA, 2019. [Google Scholar]

- Pengju, Z.; Hongjun, X.; Peiyu, Z.; Songlin, R.; Zhichao, C.; Xiaolong, W.; Fugang, L. Application of Hollow Sucker Rod Electrical Heating Production Technology in Santanghu Oilfield. Drill. Prod. Technol. 2020, 43, 114. [Google Scholar]

- Zhu, M.; Zhong, H.; Li, Y.; Zeng, C.; Gao, Y. Research on viscosity-reduction technology by electric heating and blending light oil in ultra-deep heavy oil wells. J. Pet. Explor. Prod. Technol. 2015, 5, 233–239. [Google Scholar] [CrossRef][Green Version]

- Wang, Z.; Gao, D.; Fang, J. Numerical simulation of RF heating heavy oil reservoir based on the coupling between electromagnetic and temperature field. Fuel 2018, 220, 14–24. [Google Scholar] [CrossRef]

- Guanghai, Z.; Zhangcong, L.; Xudong, X.; Xuncheng, S.; Junheng, W.; Bo, W. Numerical calculation method of the wellbore temperature field for electric heating heavy oil thermal recovery. Pet. Drill. Tech. 2019, 47, 110–115. [Google Scholar]

- Zhou, H. The Optimization and Application for Heating Power in Electrical Heating Oil Tube Well. In Proceedings of the International Field Exploration and Development Conference 2019, Chengdu, China, 16–18 October 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 2813–2823. [Google Scholar]

- Zhou, H. The Study and Application for Heating Depth Optimization of Electrical Heating Tubing. In Proceedings of the International Field Exploration and Development Conference 2021, Qingdao, China, 20–22 October 2021; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1916–1922. [Google Scholar]

- Ramírez, J.; Zambrano, A.; Ratkovich, N. Prediction of Temperature and Viscosity Profiles in Heavy-Oil Producer Wells Implementing a Downhole Induction Heater. Processes 2023, 11, 631. [Google Scholar] [CrossRef]

- Hasan, A.R.; Kabir, C. Aspects of wellbore heat transfer during two-phase flow. SPE Prod. Facil. 1994, 9, 211–216. [Google Scholar] [CrossRef]

- Hasan, A.; Kabir, C. Wellbore heat-transfer modeling and applications. J. Pet. Sci. Eng. 2012, 86, 127–136. [Google Scholar] [CrossRef]

- Zhong, H.; Zhu, S.; Zeng, W.; Wang, X.; Zhang, F. Research on heavy oil gas lift assisted with light oil injected from the annulus. J. Pet. Explor. Prod. Technol. 2018, 8, 1465–1471. [Google Scholar] [CrossRef]

- Romero, J.; Touboul, E. Temperature prediction for deepwater wells: A field validated methodology. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, Louisiana, 27–30 September 1998; OnePetro: Richardson, TX, USA, 1998. [Google Scholar]

- Alomair, O.; Elsharkawy, A.; Alkandari, H. A viscosity prediction model for Kuwaiti heavy crude oils at elevated temperatures. J. Pet. Sci. Eng. 2014, 120, 102–110. [Google Scholar] [CrossRef]

- Zhang, J.; Duan, Y.; Chen, F.; Li, Z. Application of Test Simulation Technique in Deepwater Heavy Oil Reservoir. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 22–25 March 2016; OnePetro: Richardson, TX, USA, 2016. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).