A Diagnostic Curve for Online Fault Detection in AC Drives

Abstract

1. Introduction

2. Materials and Methods

- id, iq—currents consumed by asynchronous motor (AM) in the 2-phase rotating coordinate system dq;

- iA, iB, iC—currents consumed by asynchronous motor (AM) in the 3-phase rotating system ABC.

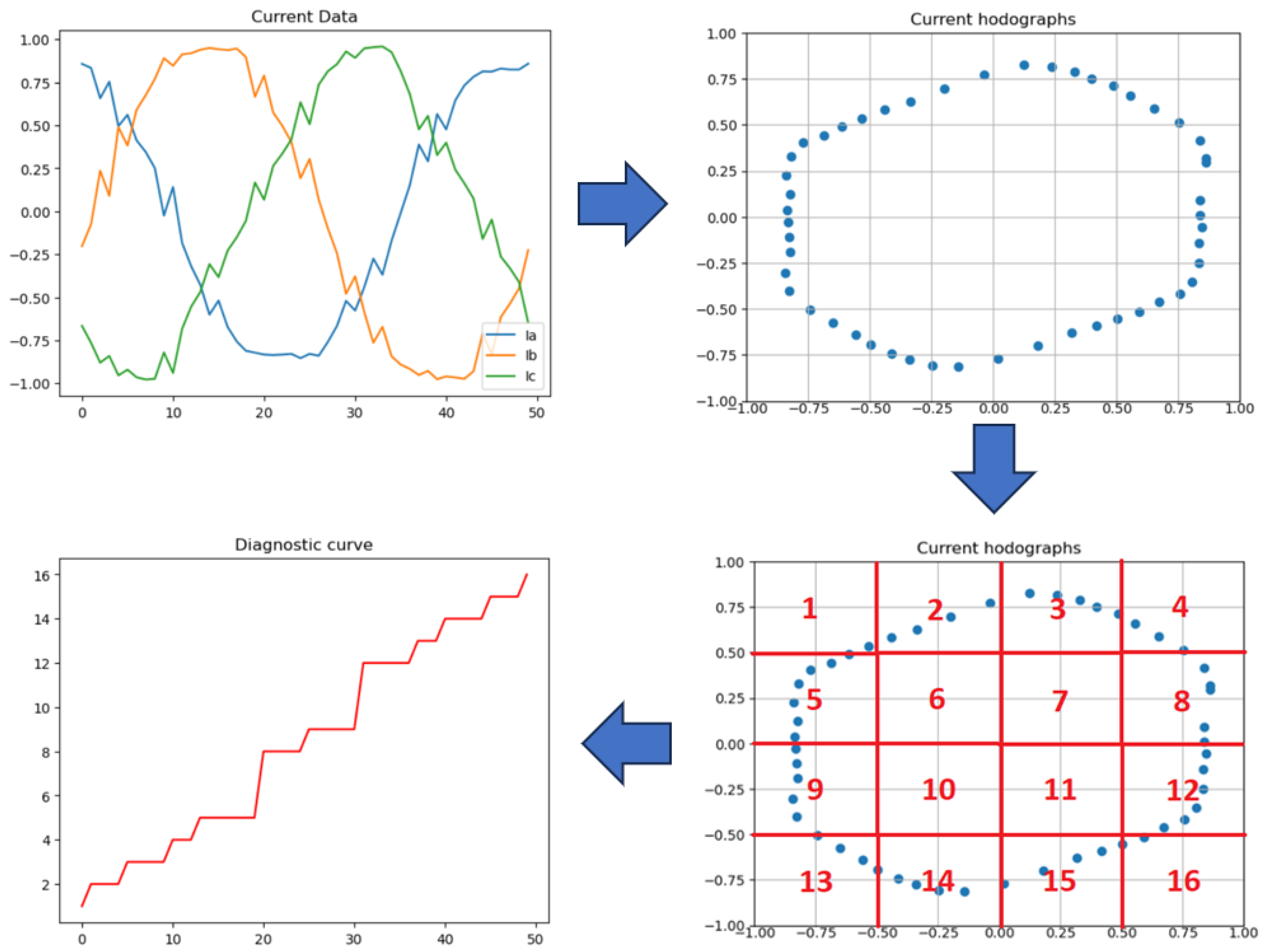

- Data scaling is performed (it is reasonable to use the maximum acceptable current sensor measurement limits as scaling coefficients). This way, the diagnostic curve does not exceed the specified range in any case;

- The number of points per period is identified;

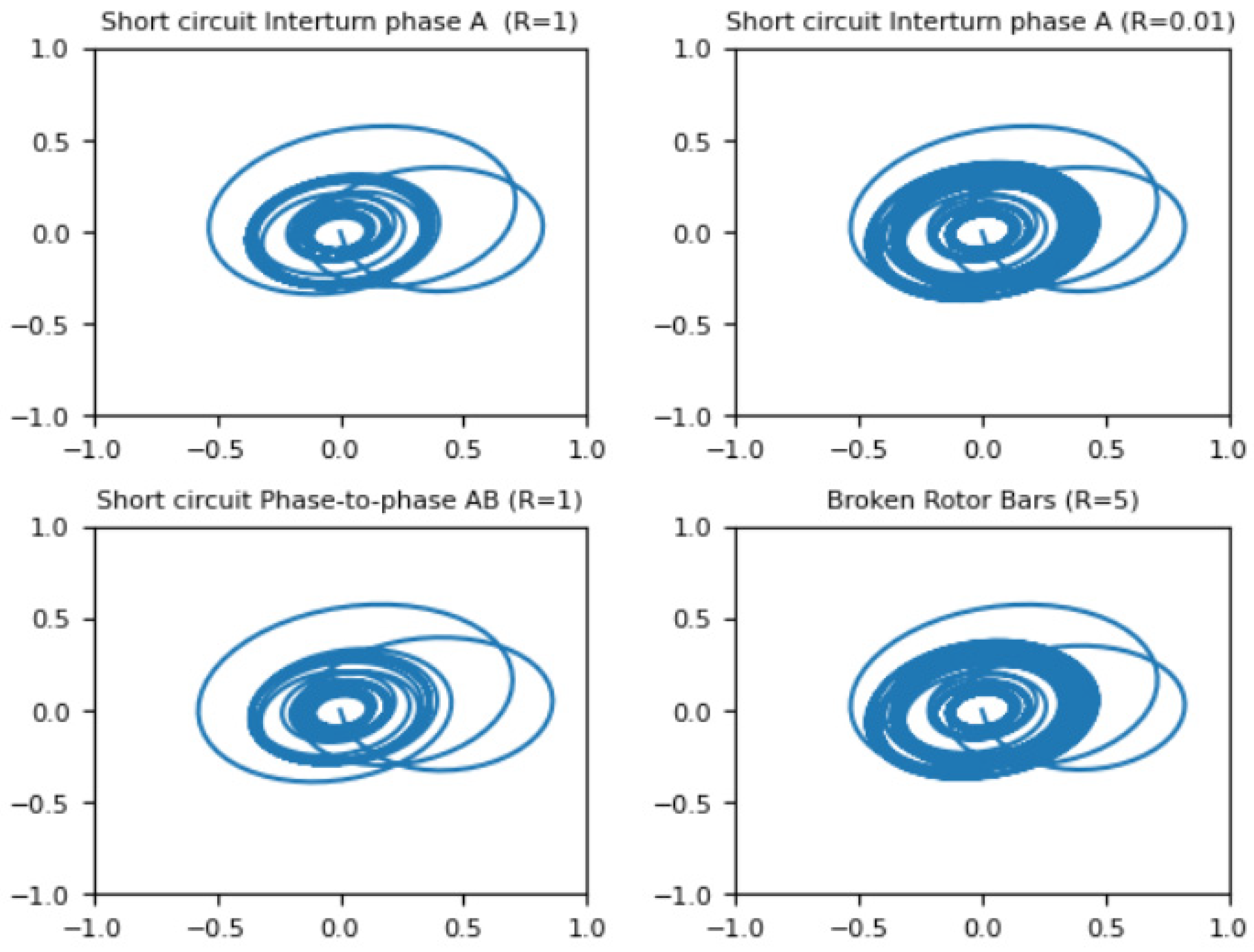

- Park’s hodograph is plotted (since the data are pre-scaled, the hodograph will always lie in the plane Re [−1;1] and Im [−1;1]);

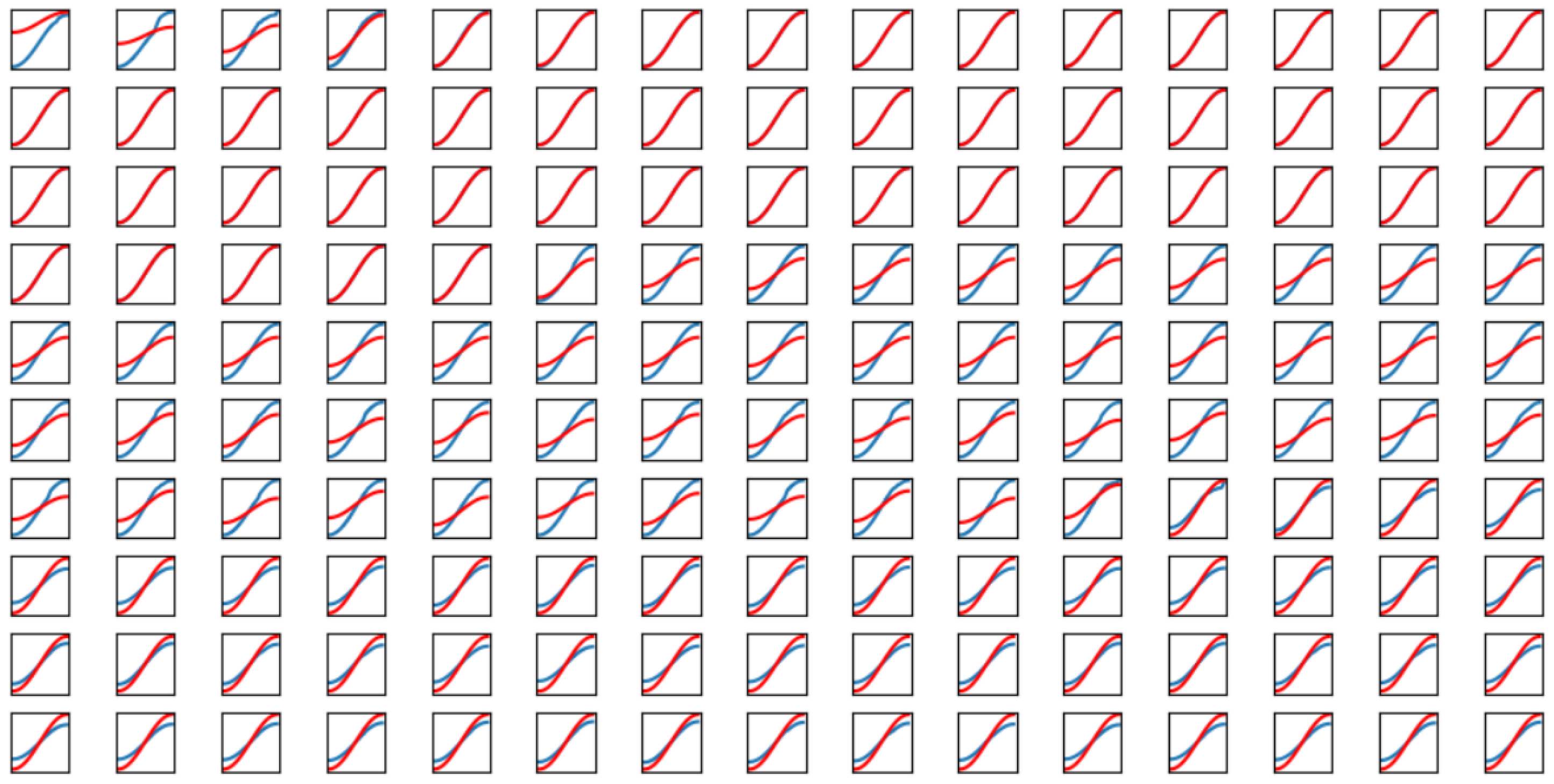

- The amount of segments is determined. The segments will define the sensitivity of the obtained curve to various changes in the electric motor;

- Segments are numbered sequentially from left to right, from top to bottom;

- For each point in a period peak, the segment is defined, and the points array is formed from the segment numbers;

- The resulting array is then sorted from the minimum to the maximum;

- The obtained data points are represented on the graph.

| Algorithm 1. Diagnostic curve | |

| INPUT | |

| 1 | Get Ia,Ib,Ic from current sensor |

| 2 | Set Kcur scaling coefficient |

| 3 | Set Npoint number of points in period |

| 4 | Set Nsegm number of segments |

| MAIN PROGRAM | |

| 5 | (IaSc,IbSc,IcSc) Scale current sensor values (using Kcur) |

| 6 | (ParkRes) Get Park vector (using IaSc,IbSc,IcSc, Npoint) |

| 7 | (SegmMtrx) Get Segment Matrix (using Nsegm) |

| 8 | (PSegm) For each Npoint in ParkRes find segment number (using SegmMtrx) |

| 9 | (SortPSegm) Sorting PSegm |

| OUTPUT | |

| 10 | Plotting the diagnostic curve (SortPSegm) |

3. Experiments and Results

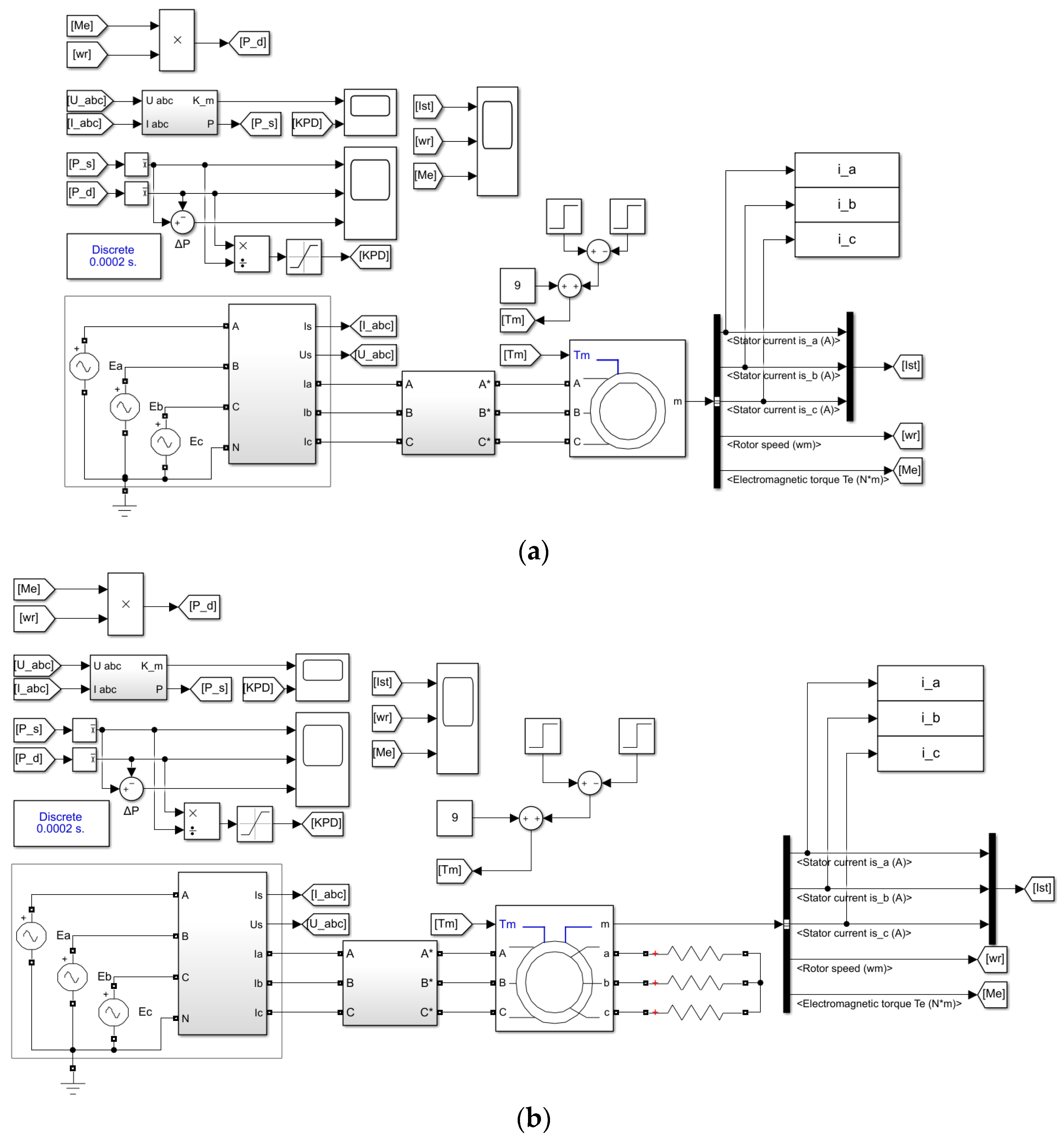

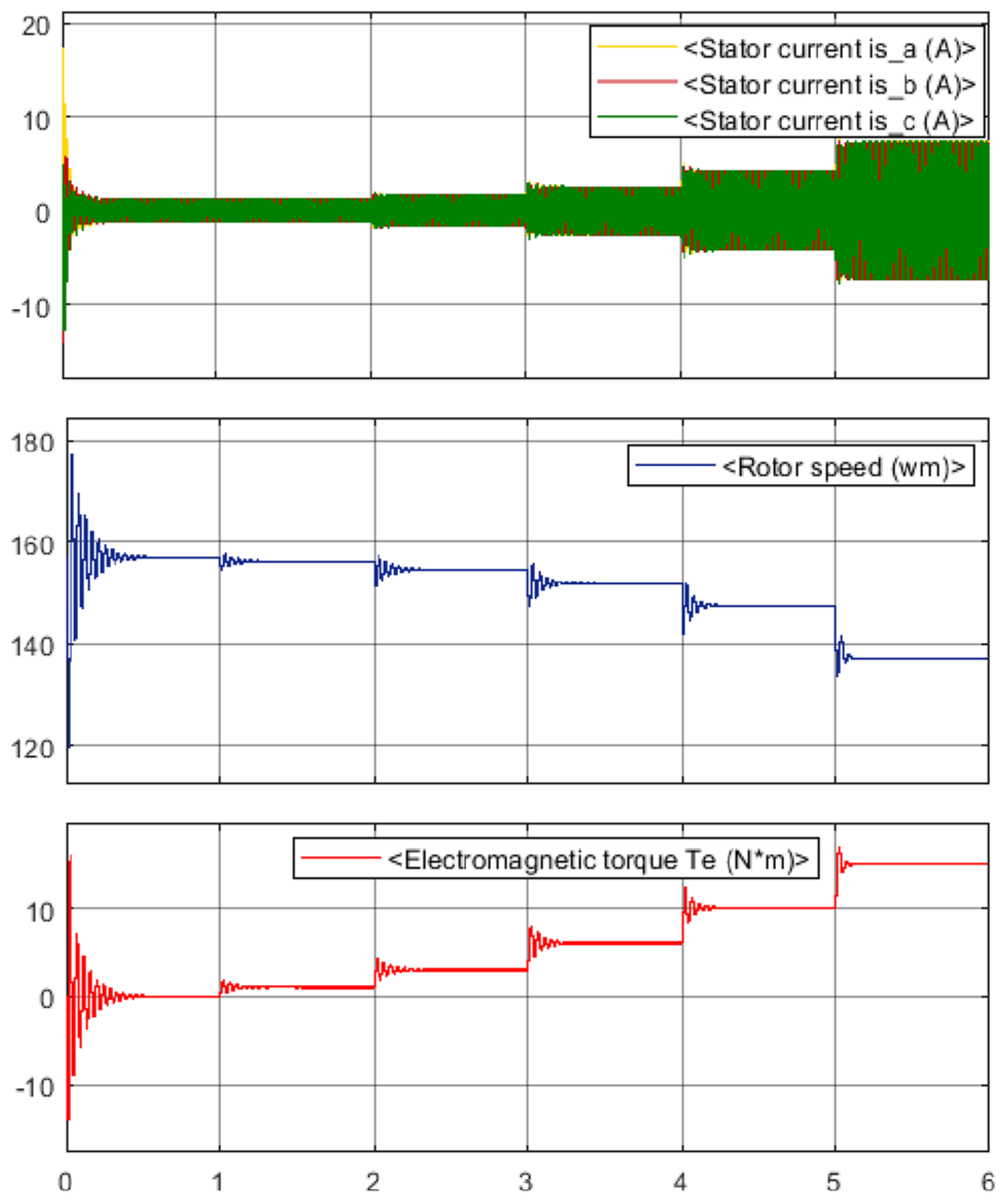

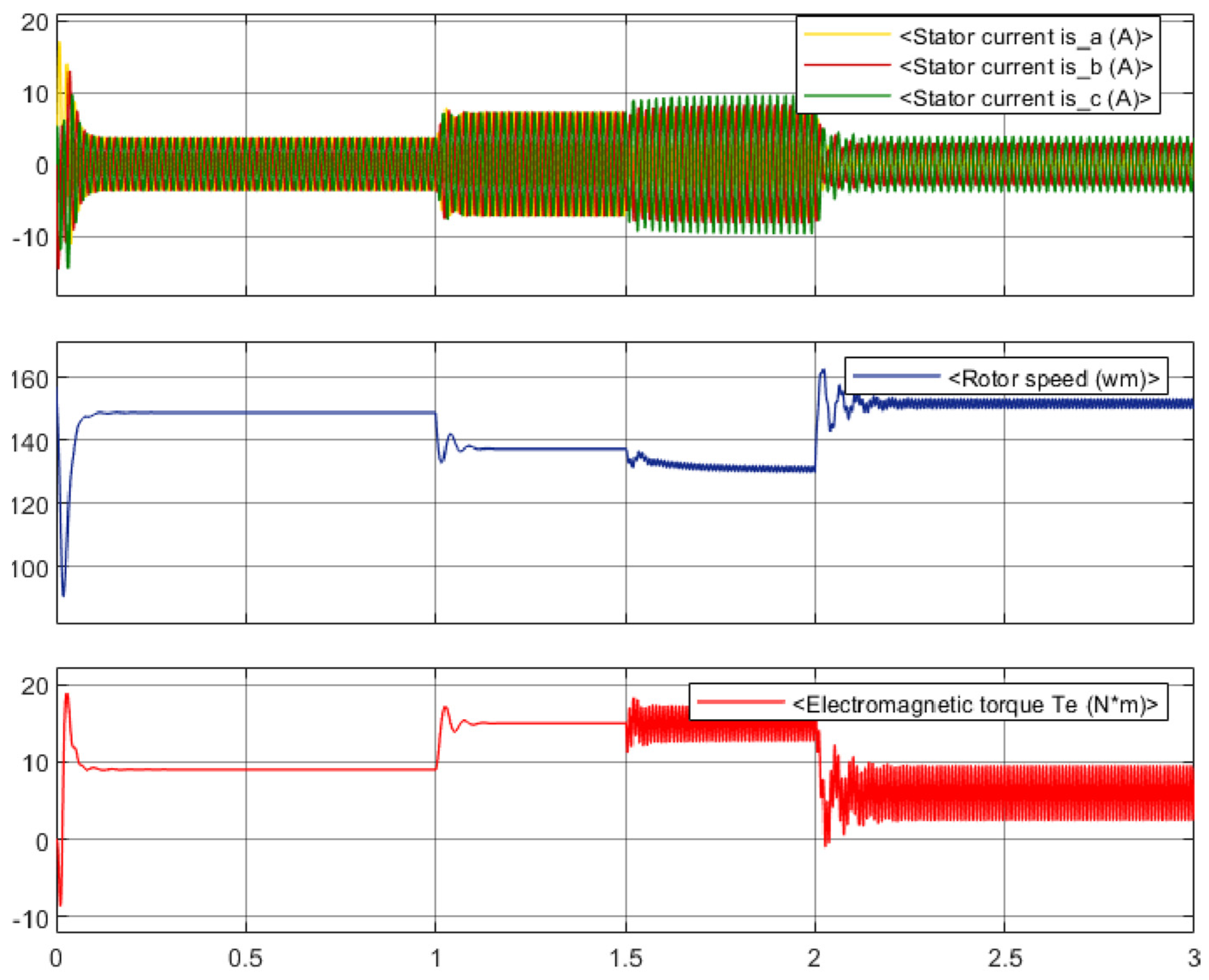

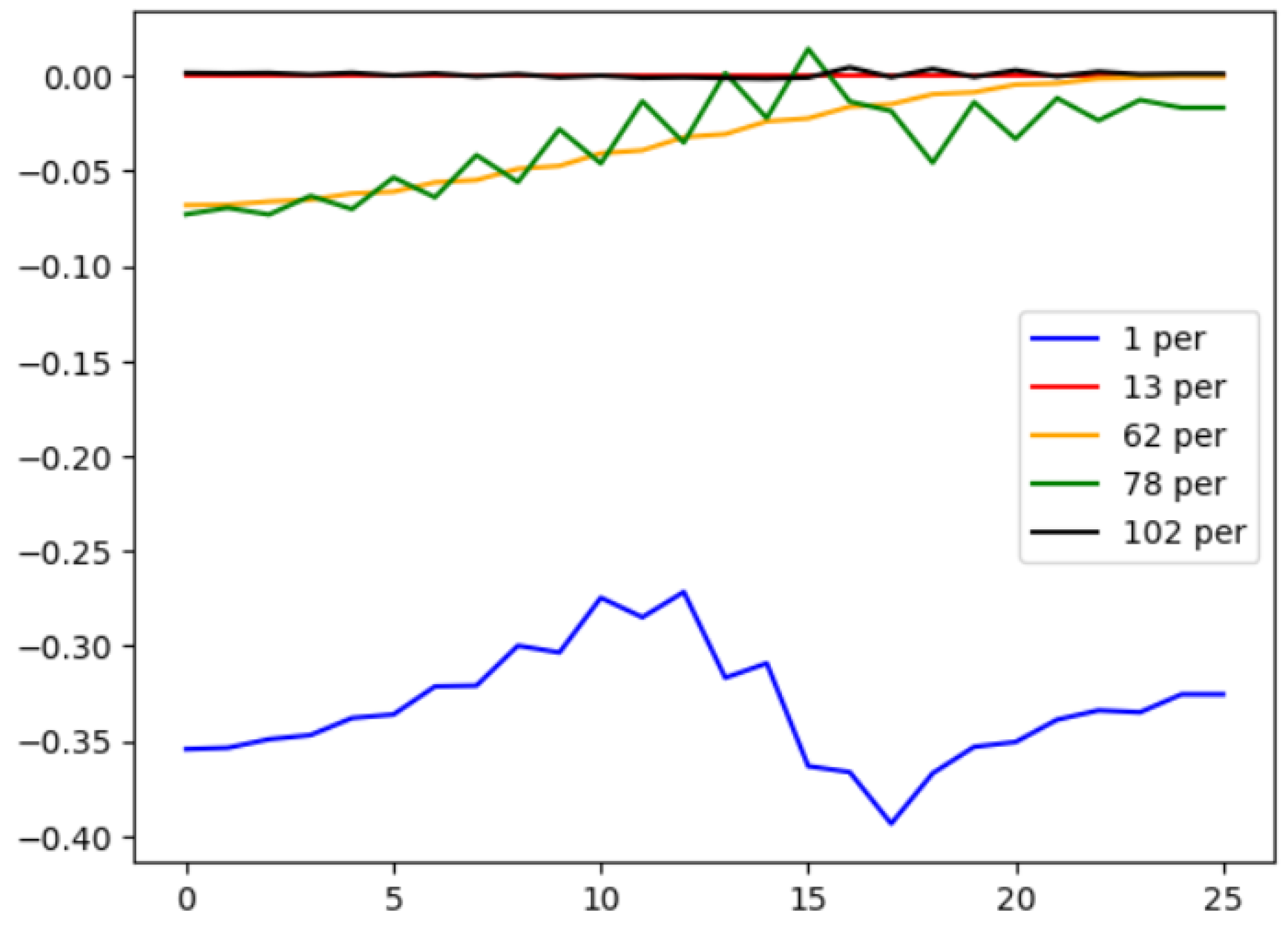

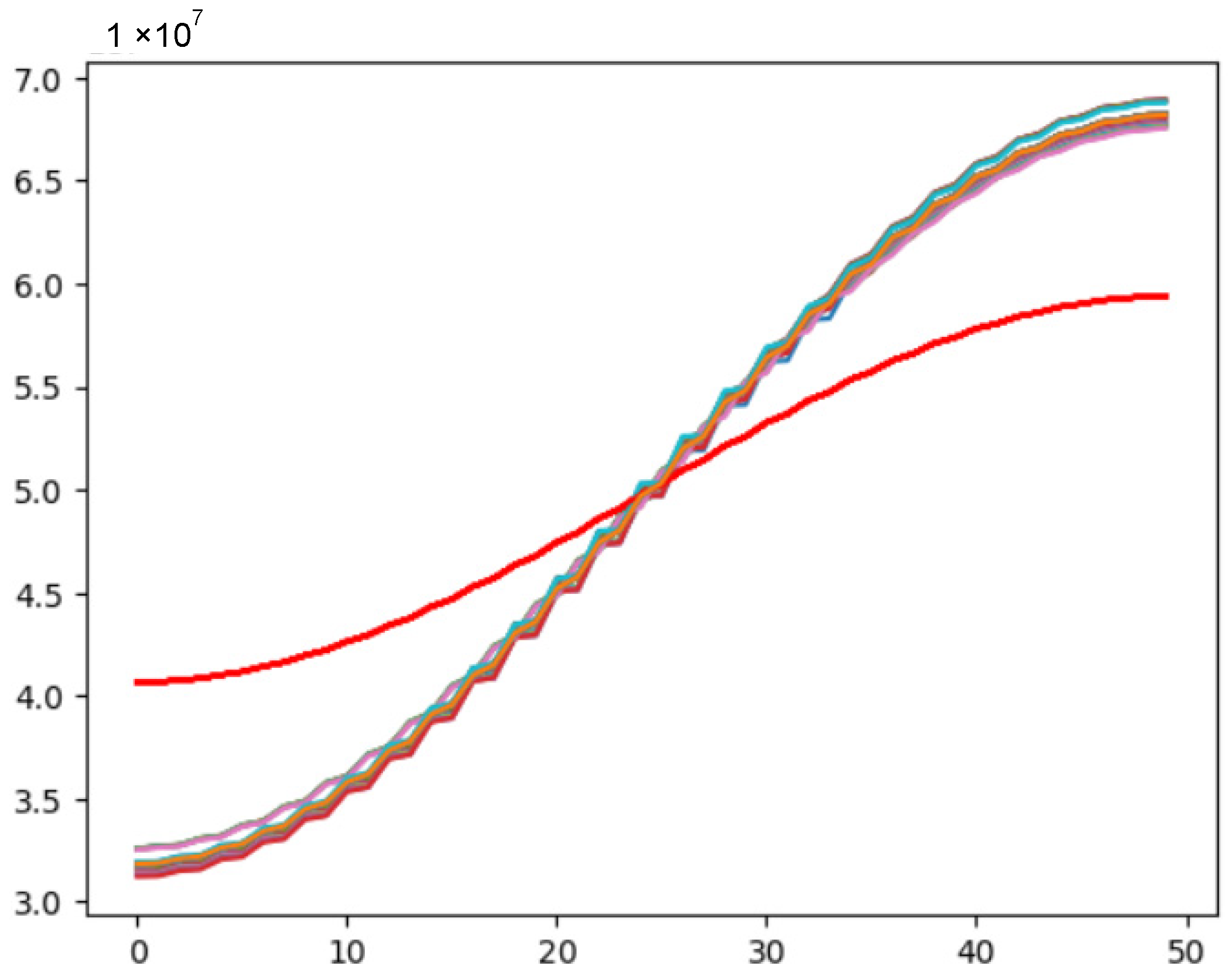

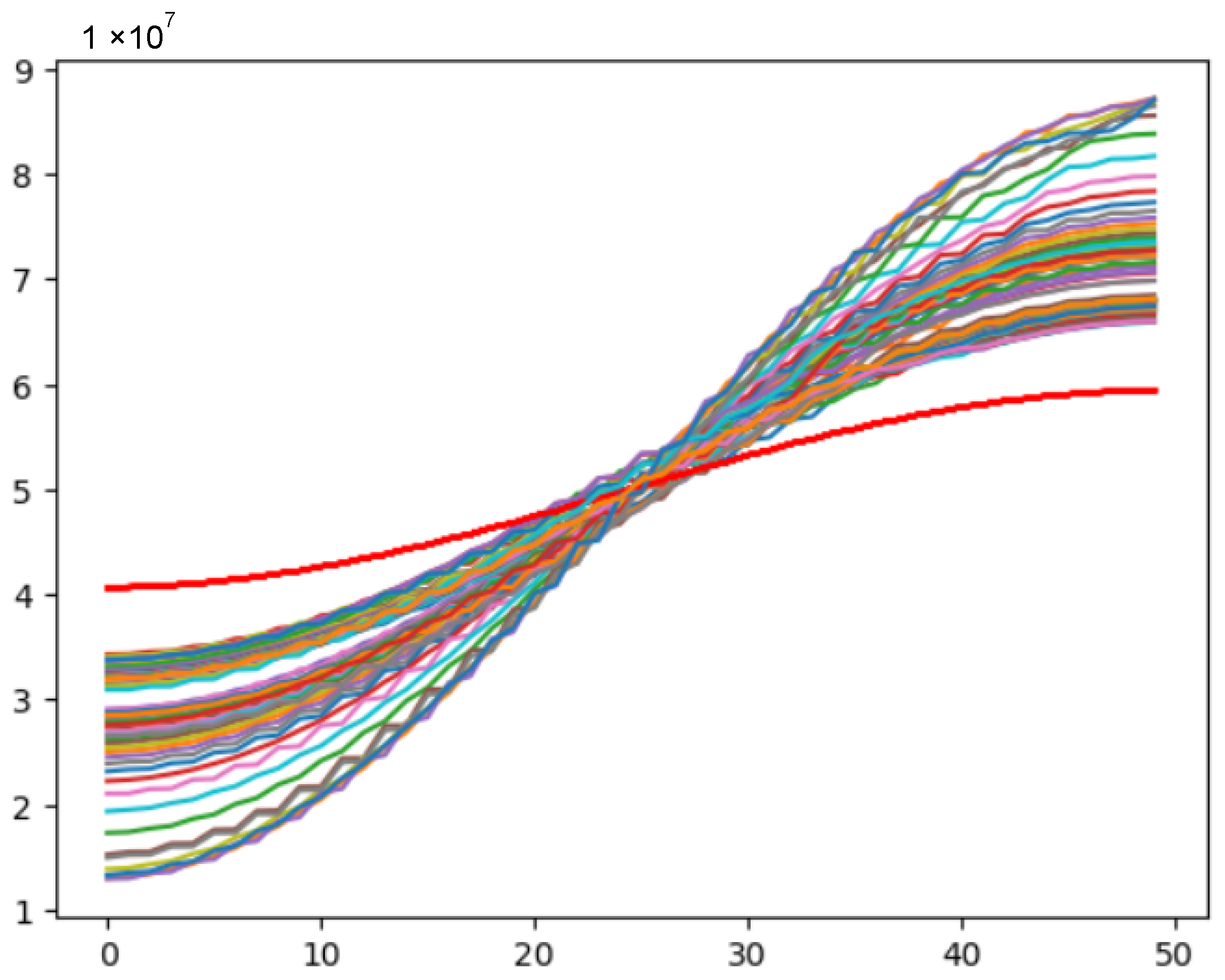

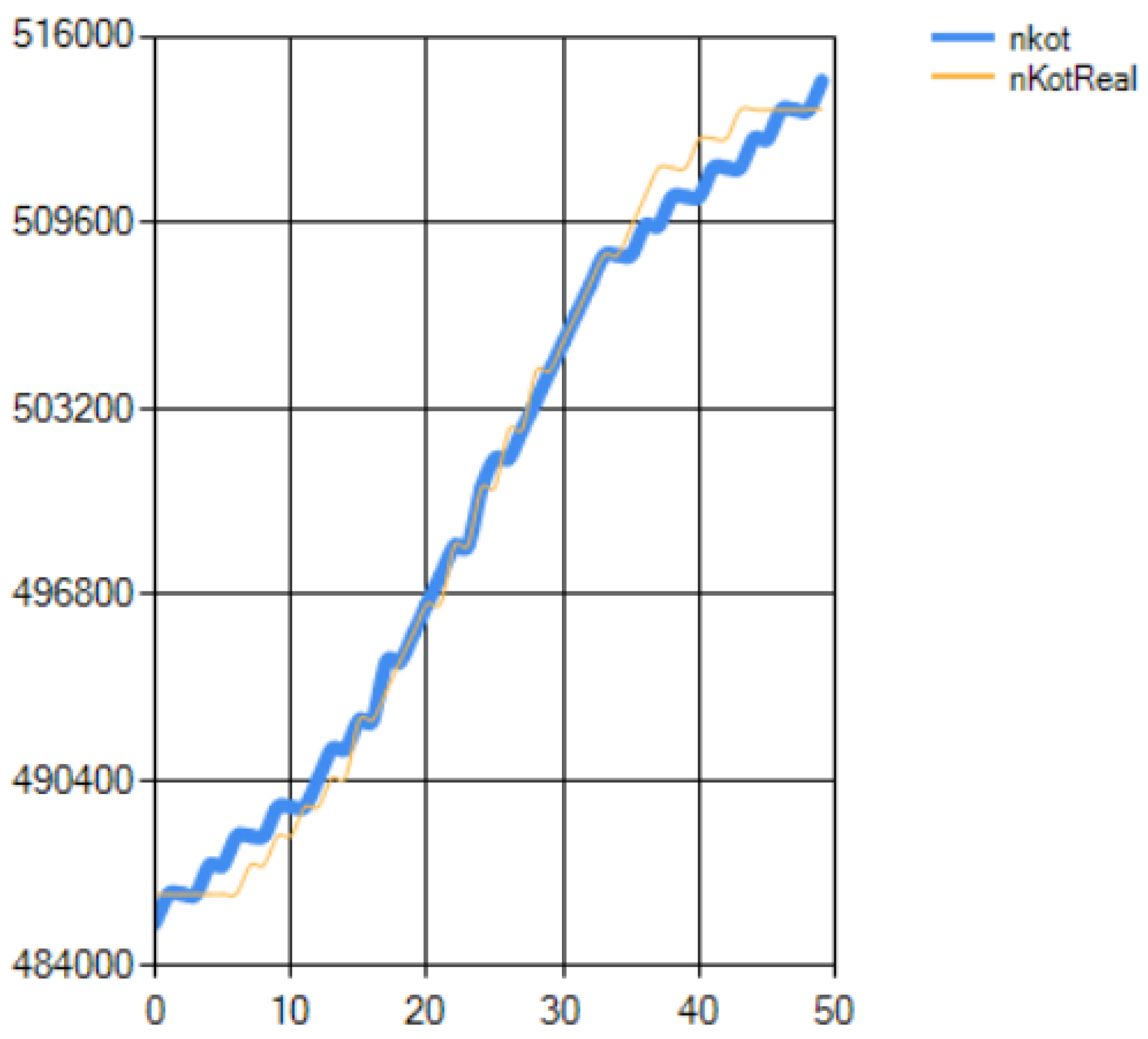

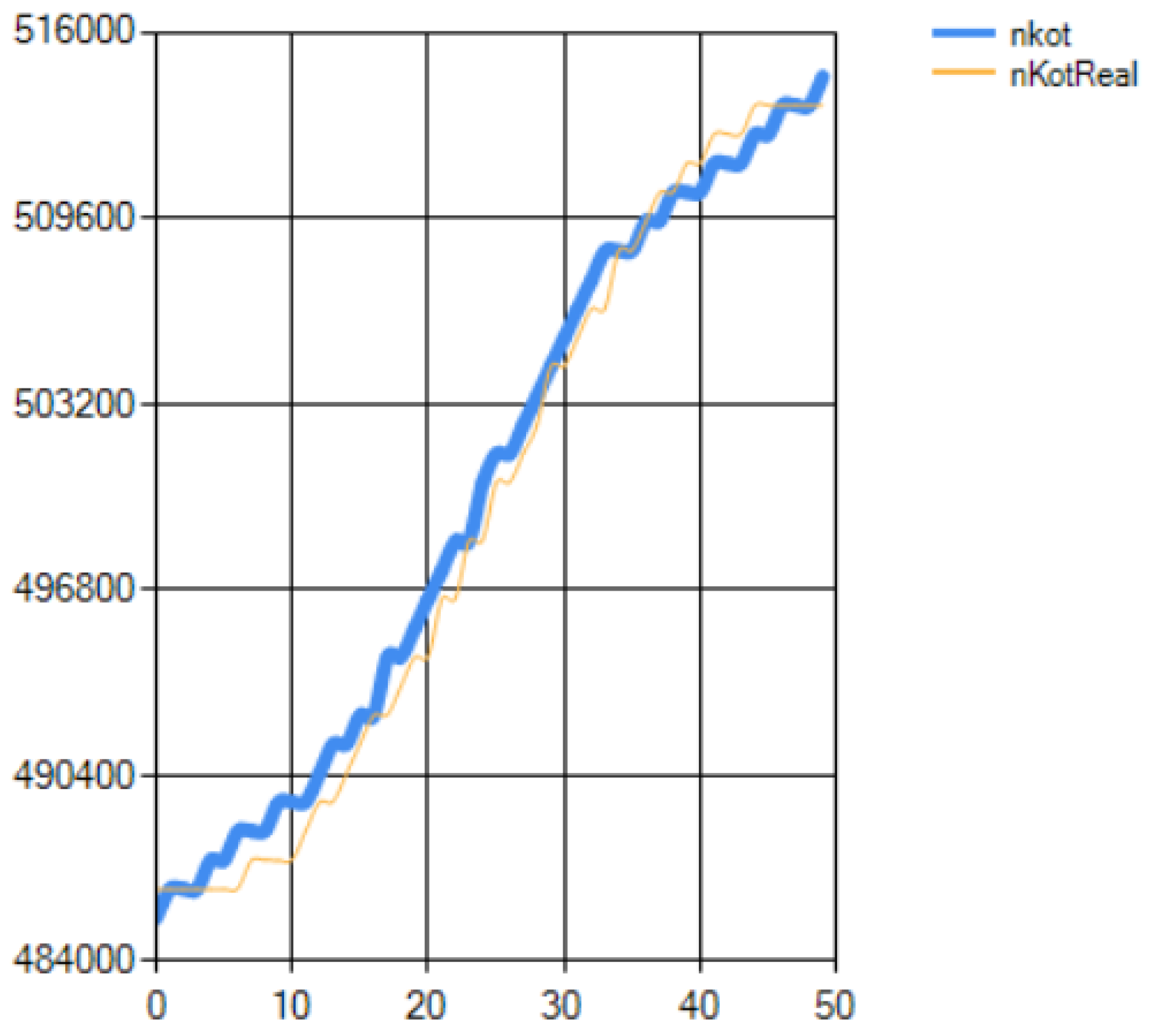

3.1. Model Experiments

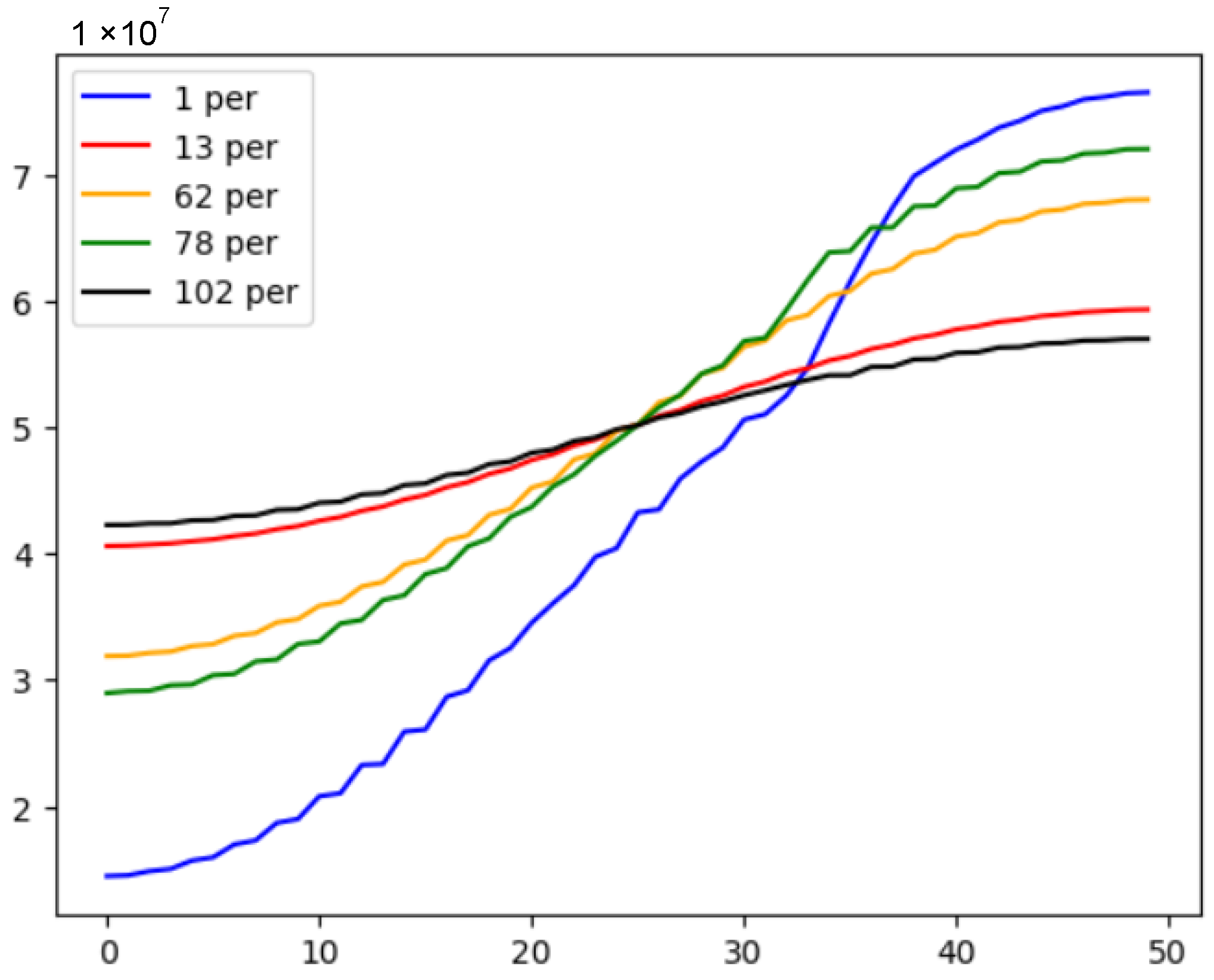

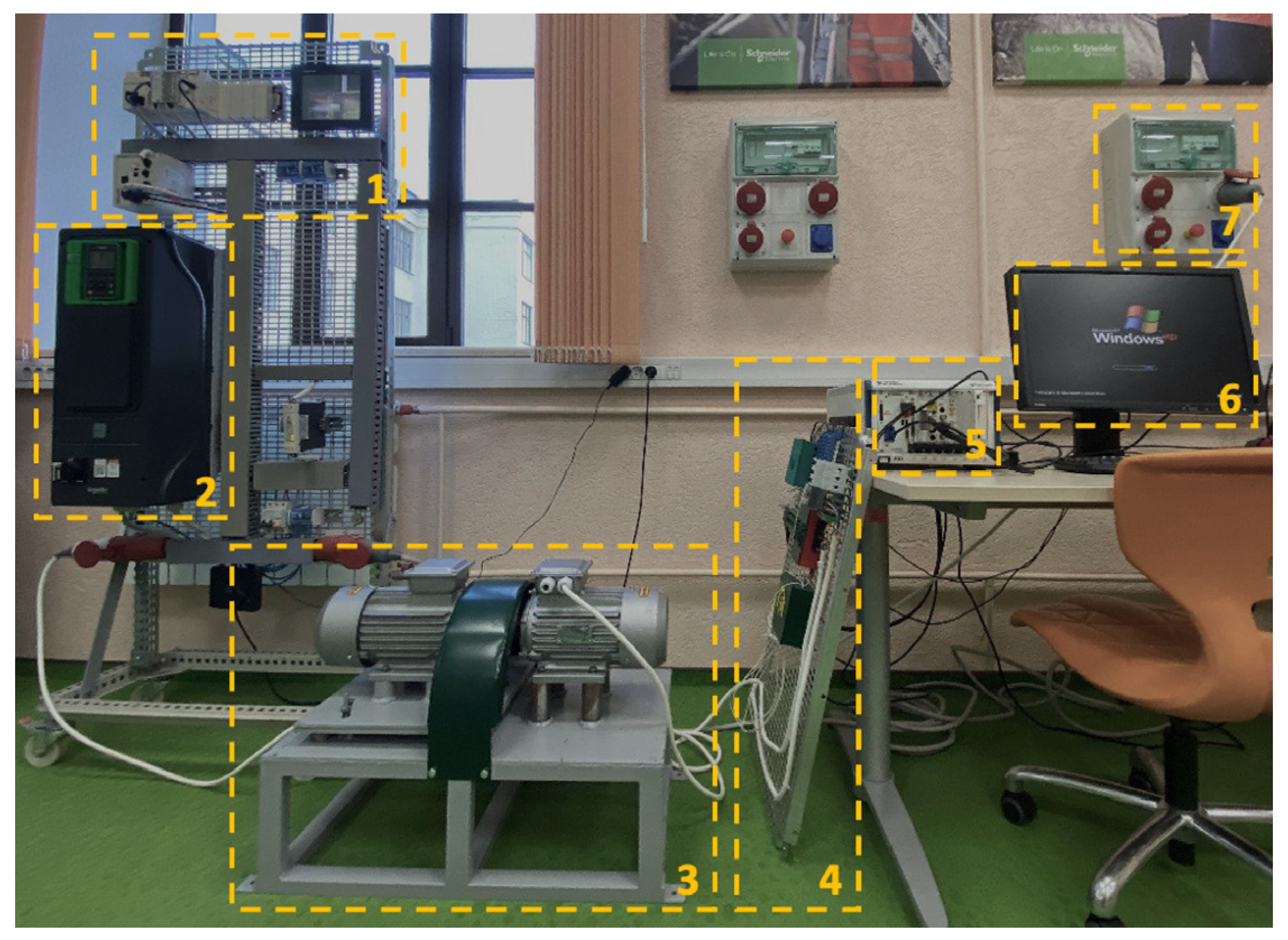

3.2. Full-Scale Experiments

4. Conclusions

- The diagnostic curve changes in real time and distorts the status of the drive for only the period of sensor polling;

- The computing power is insufficient, so it can be displayed locally on a dashboard and provide a visual inspection tool for service engineers to monitor the drive condition;

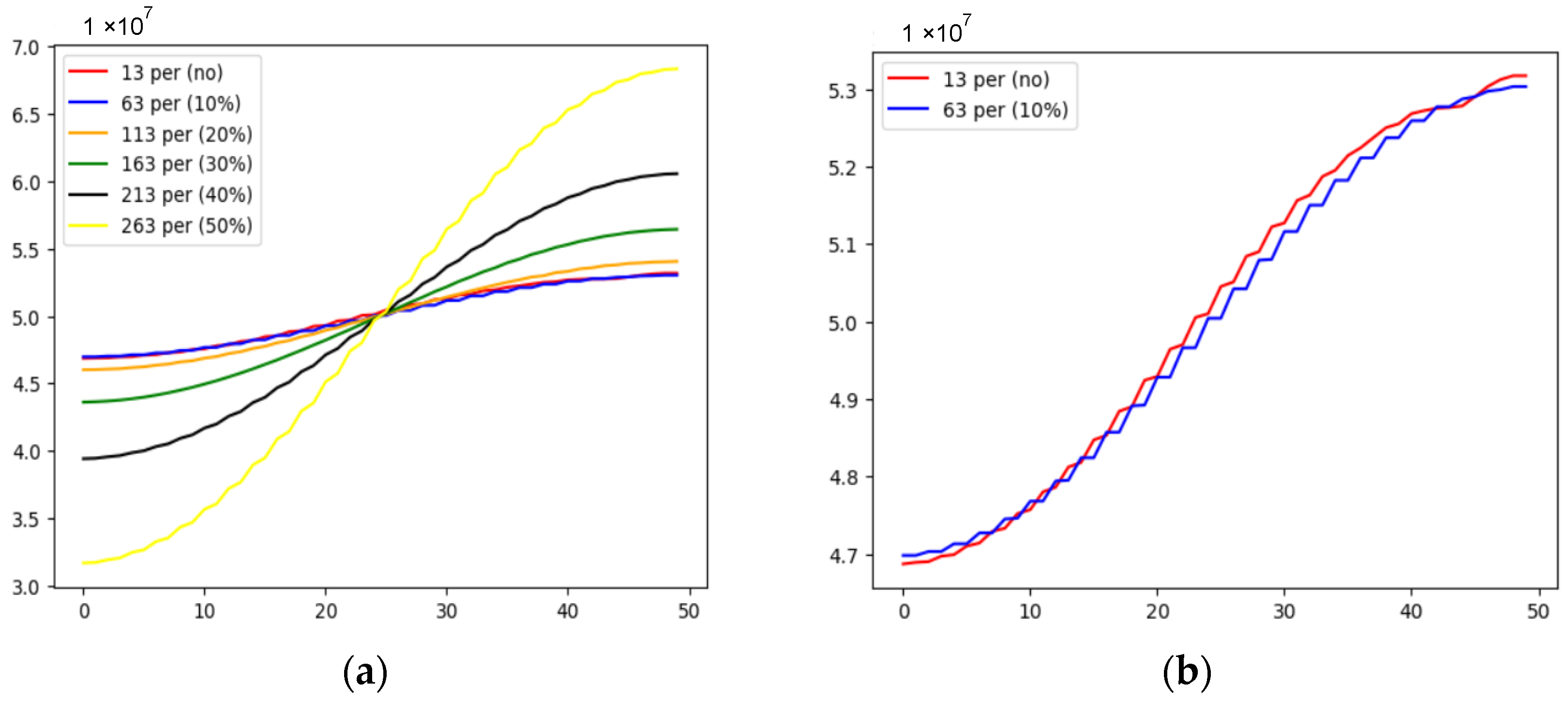

- The accuracy of the diagnostic curve is variable and depends on the number of segments dividing the Park vector space on which it is based;

- The diagnostic curve always has an equal number of points, depending on the frequency of data collection and therefore on the current sensors used in the electric drive and its monitoring system;

- Additionally, a graph evaluating the symmetry of the curve can be presented. In some cases, for full data symmetry it is acceptable to keep just half of the experimental data, which will significantly reduce the load on the system. However, this issue requires additional research;

- The diagnostic curve could be useful as an independent means of diagnostics in visual inspection methods and as input data for more complex mathematical methods of diagnostics (e.g., neural networks independently or as an algorithm of feature generation), in electric motor control systems (algorithms and methods setting that allow to bring the existing diagnostic curve to the ideal one), etc.;

- The diagnostic curve is convertible and, if needed, can be back-transformed to the Park vector hodograph and to sinus with insignificant distortions;

- The diagnostic curve is a universal method of diagnostics and detection of the system deviations. It does not require any preliminary processing and labeling data and events, such as classification of defects, tuning to specific equipment modes, etc. The diagnostic curve can be applied to all types of AC motors under all operating conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dolzhikov, V.V.; Ryadinsky, D.E.; Yakovlev, A.A. Influence of deceleration intervals on the amplitudes of stress waves during the explosion of a system of borehole charges. MIAB Min. Inf. Anal. Bull. 2022, 6, 18–32. [Google Scholar] [CrossRef]

- Khokhlov, S.; Abiev, Z.; Makkoev, V. The Choice of Optical Flame Detectors for Automatic Explosion Containment Systems Based on the Results of Explosion Radiation Analysis of Methane- and Dust-Air Mixtures. Appl. Sci. 2022, 12, 1515. [Google Scholar] [CrossRef]

- Romashev, A.O.; Nikolaeva, N.V.; Gatiatullin, B.L. Adaptive Approach Formation Using Machine Vision Technology to Determine the Parameters of Enrichment Products Deposition. J. Min. Inst. 2022, 256, 677–685. [Google Scholar] [CrossRef]

- Yemelyanov, V.; Chernyi, S.; Yemelyanova, N.; Varadarajan, V. Application of neural networks to forecast changes in the technical condition of critical production facilities. Comput. Electr. Eng. 2021, 93, 107225. [Google Scholar] [CrossRef]

- Gizatullin, R.; Dvoynikov, M.; Romanova, N.; Nikitin, V. Drilling in Gas Hydrates: Managing Gas Appearance Risks. Energies 2023, 16, 2387. [Google Scholar] [CrossRef]

- Smirnov, N.I.; Drozdov, A.N.; Smirnov, N.N. Tribodynamic aspects of the resource of electric submersible vane pumps for oil production. J. Min. Inst. 2023, 264, 962–970. [Google Scholar]

- Litvinenko, V.S. Digital Economy as a Factor in the Technological Development of the Mineral Sector. Nat. Resour. Res. 2020, 29, 1521–15411. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Zhao, C. From riches to digitalization: The role of AMC in overcoming challenges of digital transformation in resource-rich regions. Technol. Forecast. Soc. Change 2024, 200, 123153. [Google Scholar] [CrossRef]

- Cherepovitsyn, A.E.; Tretyakov, N.A. Development of New System for Assessing the Applicability of Digital Projects in the Oil and Gas Sector. J. Min. Inst. 2023, 262, 628–642. [Google Scholar]

- Fomin, S.I.; Govorov, A.S. Validation of the chosen cutoff grade value in open pit mine design. MIAB Mining Inf. Anal. Bull. 2023, 12, 169–181. [Google Scholar] [CrossRef]

- Simakov, A.S.; Trifonova, M.E.; Gorlenkov, D.V. Virtual Analyzer of the Voltage and Current Spectrum of the Electric Arc in Electric Arc Furnaces. Russ. Metall. 2021, 2021, 713–719. [Google Scholar] [CrossRef]

- Khokhlov, S.; Safina, E.; Vasiliev, V. Risk-oriented approach implementation in departments ranking and teaching staff motivation. Int. J. Qual. Res. 2018, 12, 501–516. [Google Scholar] [CrossRef]

- Braut, S.; Sikanen, E.; Nerg, J.; Sopanen, J.; Božić, Ž. Fatigue life prediction of Electric Race About (ERA) traction motor rotor. Procedia Struct. Integr. 2021, 31, 45–50. [Google Scholar] [CrossRef]

- Accordini, D.; Cagno, E.; Trianni, A. Identification and characterization of decision-making factors over industrial energy efficiency measures in electric motor systems. Renew. Sustain. Energy Rev. 2021, 149, 111354. [Google Scholar] [CrossRef]

- Gultekin, M.A.; Bazzi, A. Review of Fault Detection and Diagnosis Techniques for AC Motor Drives. Energies 2023, 16, 5602. [Google Scholar] [CrossRef]

- Mian, Z.; Deng, X.; Dong, X.; Tian, Y.; Cao, T.; Chen, K.; Al Jaber, T. A literature review of fault diagnosis based on ensemble learning. Eng. Appl. Artif. Intell. 2024, 127, 107357. [Google Scholar] [CrossRef]

- Kohtz, S.; Zhao, J.; Renteria, A.; Lalwani, A.; Xu, Y.; Zhang, X. Kiruba Sivasubramaniam Haran, Debbie Senesky, Pingfeng Wang, Optimal sensor placement for permanent magnet synchronous motor condition monitoring using a digital twin-assisted fault diagnosis approach. Reliab. Eng. Syst. Saf. 2024, 242, 109714. [Google Scholar] [CrossRef]

- Yang, X.; Liu, M.; Song, H.; Zhu, S.; Wu, Y. Vibration resistance FBG temperature sensor fabrication and its application in the motor for hydraulic pump. Measurement 2022, 205, 112141. [Google Scholar] [CrossRef]

- D’Urso, D.; Chiacchio, F.; Borrometi, D.; Costa, A.; Compagno, L. Dynamic failure rate model of an electric motor comparing the Military Standard and Svenska Kullagerfabriken (SKF) methods. Procedia Comput. Sci. 2021, 180, 456–465. [Google Scholar] [CrossRef]

- He, H.; Han, M.; Liu, W.; Cao, J.; Shi, M.; Zhou, N. MPC-based longitudinal control strategy considering energy consumption for a dual-motor electric vehicle. Energy 2022, 253, 124004. [Google Scholar] [CrossRef]

- AlShorman, O.; Irfan, M.; Abdelrahman, R.B.; Masadeh, M.; Alshorman, A.; Sheikh, M.A.; Saad, N.; Rahman, S. Advancements in condition monitoring and fault diagnosis of rotating machinery: A comprehensive review of image-based intelligent techniques for induction motors. Eng. Appl. Artif. Intell. 2024, 130, 107724. [Google Scholar] [CrossRef]

- Aizpurua, J.I.; Knutsen, K.E.; Heimdal, M.; Vanem, E. Integrated machine learning and probabilistic degradation approach for vessel electric motor prognostics. Ocean Eng. 2023, 275, 114153. [Google Scholar] [CrossRef]

- Gao, Y.; Cheong, B.; Bozhko, S.; Wheeler, P.; Gerada, C.; Yang, T. Surrogate role of machine learning in motor-drive optimization for more-electric aircraft applications. Chin. J. Aeronaut. 2023, 36, 213–228. [Google Scholar] [CrossRef]

- Zhukovskiy, Y.; Buldysko, A.; Revin, I. Induction Motor Bearing Fault Diagnosis Based on Singular Value Decomposition of the Stator Current. Energies 2023, 16, 3303. [Google Scholar] [CrossRef]

- Gómez, J.R.; Sousa, V.; Eras, J.J.C.; Gutiérrez, A.S.; Viego, P.R.; Quispe, E.C.; de León, G. Assessment criteria of the feasibility of replacement standard efficiency electric motors with high-efficiency motors. Energy 2022, 239, 121877. [Google Scholar] [CrossRef]

- Errigo, A.; Choi, J.-K.; Kissock, K. Techno-economic-environmental impacts of industrial energy assessment: Sustainable industrial motor systems of small and medium-sized enterprises. Sustain. Energy Technol. Assess. 2022, 49, 101694. [Google Scholar] [CrossRef]

- Abramik, S.; Sleszynski, W.; Nieznanski, J.; Piquet, H. A diagnostic method for on-line fault detection and localization in VSI-fed AC drives. In Proceedings of the 10th European Conferenceon Power Electronicsand Applications, EPE’2003, Toulouse, France, 2–4 September 2003. [Google Scholar]

- Junior, R.F.R.; Areias, I.A.D.S.; Campos, M.M.; Teixeira, C.E.; da Silva, L.E.B.; Gomes, G.F. Fault detection and diagnosis in electric motors using 1d convolutional neural networks with multi-channel vibration signals. Measurement 2022, 190, 110759. [Google Scholar] [CrossRef]

- Duda, A.; Drozdowski, P. Induction Motor Fault Diagnosis Based on Zero-Sequence Current Analysis. Energies 2020, 13, 6528. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, D.; Xu, Y.; Zhen, D.; Gu, F.; Andrew; Ball, D. Early rolling bearing fault diagnosis in induction motors based on on-rotor sensing vibrations. Measurement 2023, 222, 113614. [Google Scholar] [CrossRef]

- Yakhni, M.F.; Cauet, S.; Sakout, A.; Assoum, H.; Etien, E.; Rambault, L.; El-Gohary, M. Variable speed induction motors’ fault detection based on transient motor current signatures analysis: A review. Mech. Syst. Signal Process. 2023, 184, 109737. [Google Scholar] [CrossRef]

- Gu, F.; Shao, Y.; Hu, N.; Naid, A.; Ball, A.D. Electrical motor current signal analysis using a modified bispectrum for fault diagnosis of downstream mechanical equipment. Mech. Syst. Signal Process. 2011, 25, 360–372. [Google Scholar] [CrossRef]

- Suti, A.; Di Rito, G. Diagnosis of Power Switch Faults in Three-Phase Permanent Magnet Synchronous Motors via Current-Signature Technique. Actuators 2024, 13, 25. [Google Scholar] [CrossRef]

- Mendes, A.M.S.; Cardoso, A.J.M. Voltage source inverter fault diagnosis in variable speed AC drives, by the average current Park’s vector approach. In Proceedings of the IEEE International Electric Machines and Drives Conference, Seattle, WA, USA, 9–12 May 1999; Volume 6314016, pp. 704–706. [Google Scholar] [CrossRef]

- Muñoz-Aguilar, R.-S.; Rodríguez, P.; Dòria-Cerezo, A.; Candela, I.; Luna, A. A sensor-less sliding mode control scheme for a stand-alone wound rotor synchronous generator under unbalanced load conditions. Int. J. Electr. Power Energy Syst. 2014, 60, 275–282. [Google Scholar] [CrossRef]

- Cornell, E.P.; Lipo, T.A. Modeling and design of controlled current induction motor drive systems. IEEE Trans. Ind. Appl. 1977, 4, 321–330. [Google Scholar] [CrossRef]

- Thomson, W.T.; Fenger, M. Current signature analysis to detect induction motor faults. IEEE Ind. Appl. Mag. 2001, 7, 26–34. [Google Scholar] [CrossRef]

- Thomson, W.T.; Fenger, M.; Lloyd, B. Development of a tool to detect faults in induction motors via current signature analysis. In Proceedings of the Cement Industry Technical Conference, 2003, Conference Record, IEEE-IAS/PCA, Dallas, TX, USA, 4–9 May 2003; pp. 37–46. [Google Scholar] [CrossRef]

| Power P, W | Voltage Source Un, B | Rotor Speed n, rpm | Number of Pole Pairs z | Moment of Inertia J, kg*m2 | η | cosφ, | Km | Kp | Ki, |

|---|---|---|---|---|---|---|---|---|---|

| 1500 | 380 | 1390 | 2 | 0.0034 | 0.9 | 0.79 | 2.3 | 2.3 | 6.2 |

| Ls, H | Lr, H | Lm, H | Rs, Ohm | Rr, Ohm |

|---|---|---|---|---|

| 0.8535 | 0.8636 | 0.8236 | 4.843 | 4.168 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koteleva, N.; Korolev, N. A Diagnostic Curve for Online Fault Detection in AC Drives. Energies 2024, 17, 1234. https://doi.org/10.3390/en17051234

Koteleva N, Korolev N. A Diagnostic Curve for Online Fault Detection in AC Drives. Energies. 2024; 17(5):1234. https://doi.org/10.3390/en17051234

Chicago/Turabian StyleKoteleva, Natalia, and Nikolai Korolev. 2024. "A Diagnostic Curve for Online Fault Detection in AC Drives" Energies 17, no. 5: 1234. https://doi.org/10.3390/en17051234

APA StyleKoteleva, N., & Korolev, N. (2024). A Diagnostic Curve for Online Fault Detection in AC Drives. Energies, 17(5), 1234. https://doi.org/10.3390/en17051234