Depolymerization of PMMA-Based Dental Resin Scraps on Different Production Scales

Abstract

1. Introduction

2. Materials and Methods

3. Results

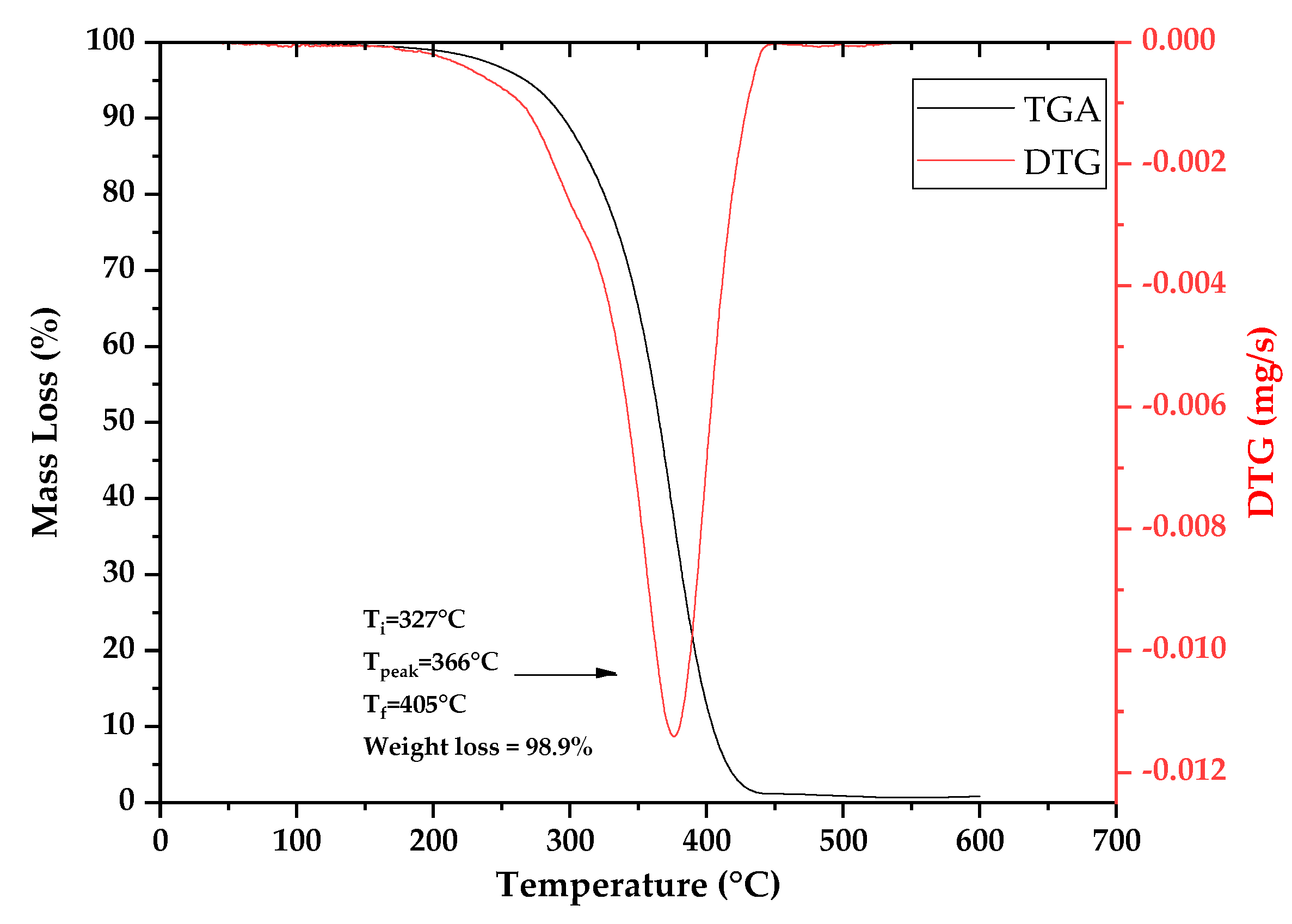

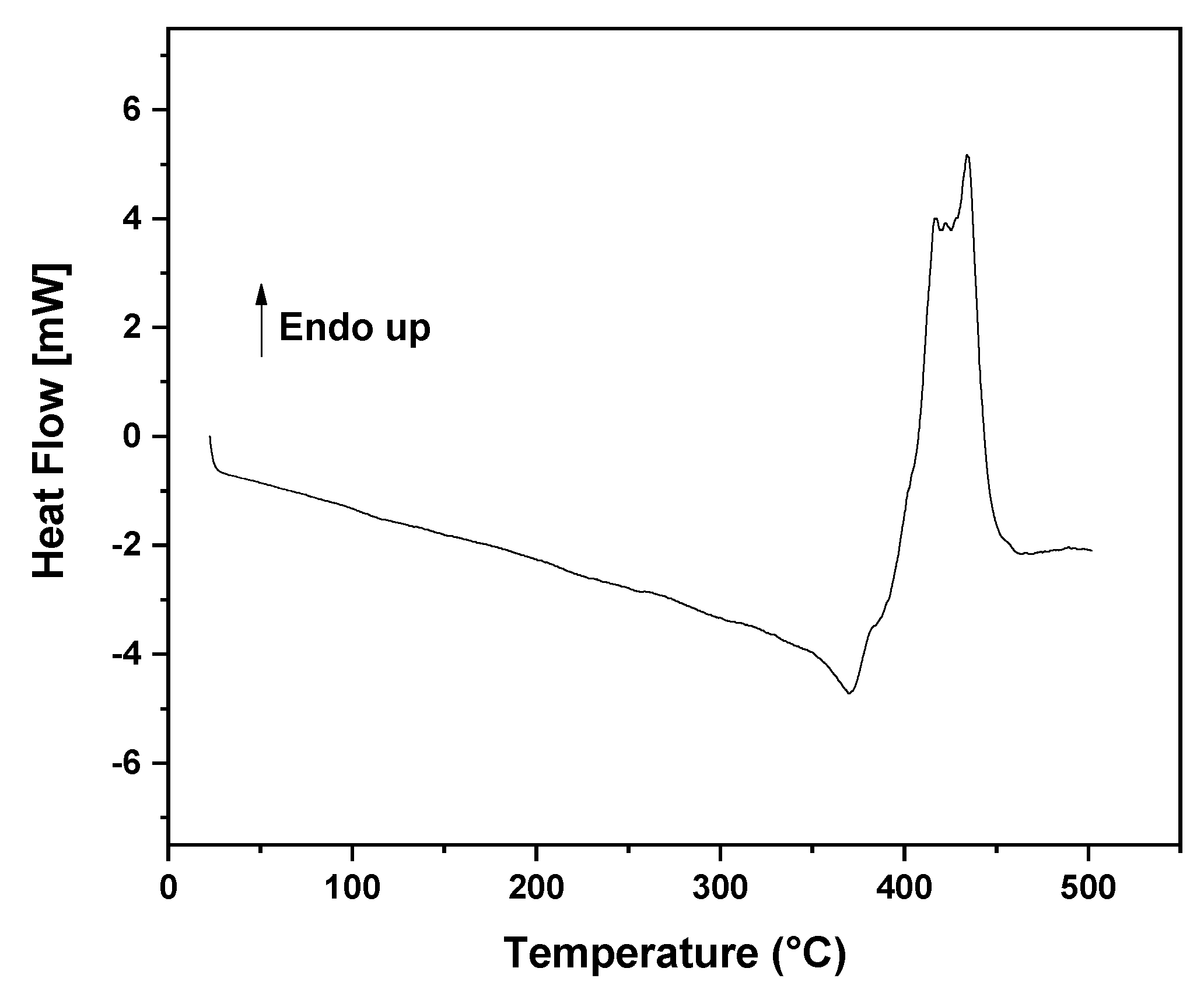

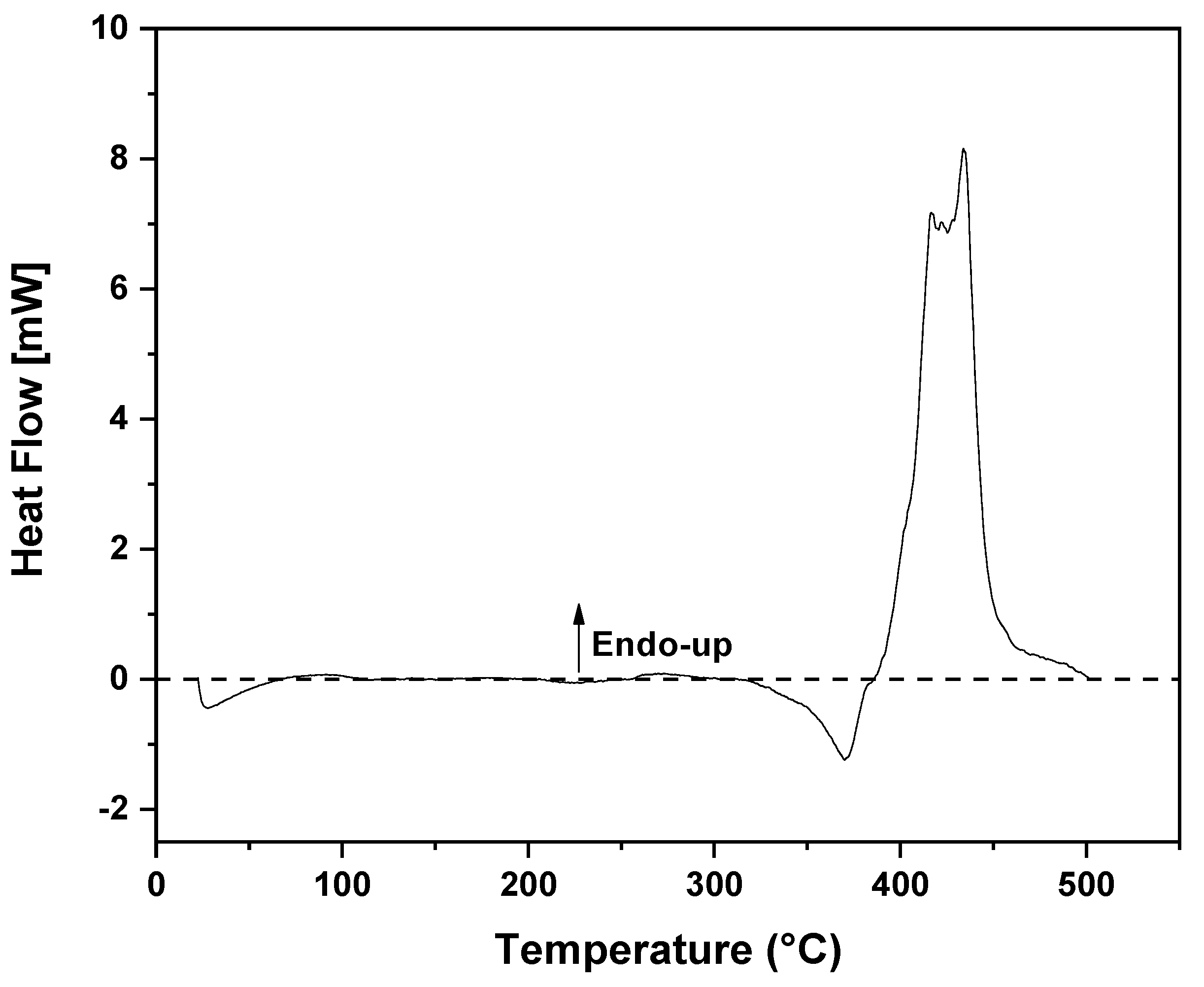

3.1. Thermal Decomposition and Characterization of PMMA Dental Scraps (PMMAW)

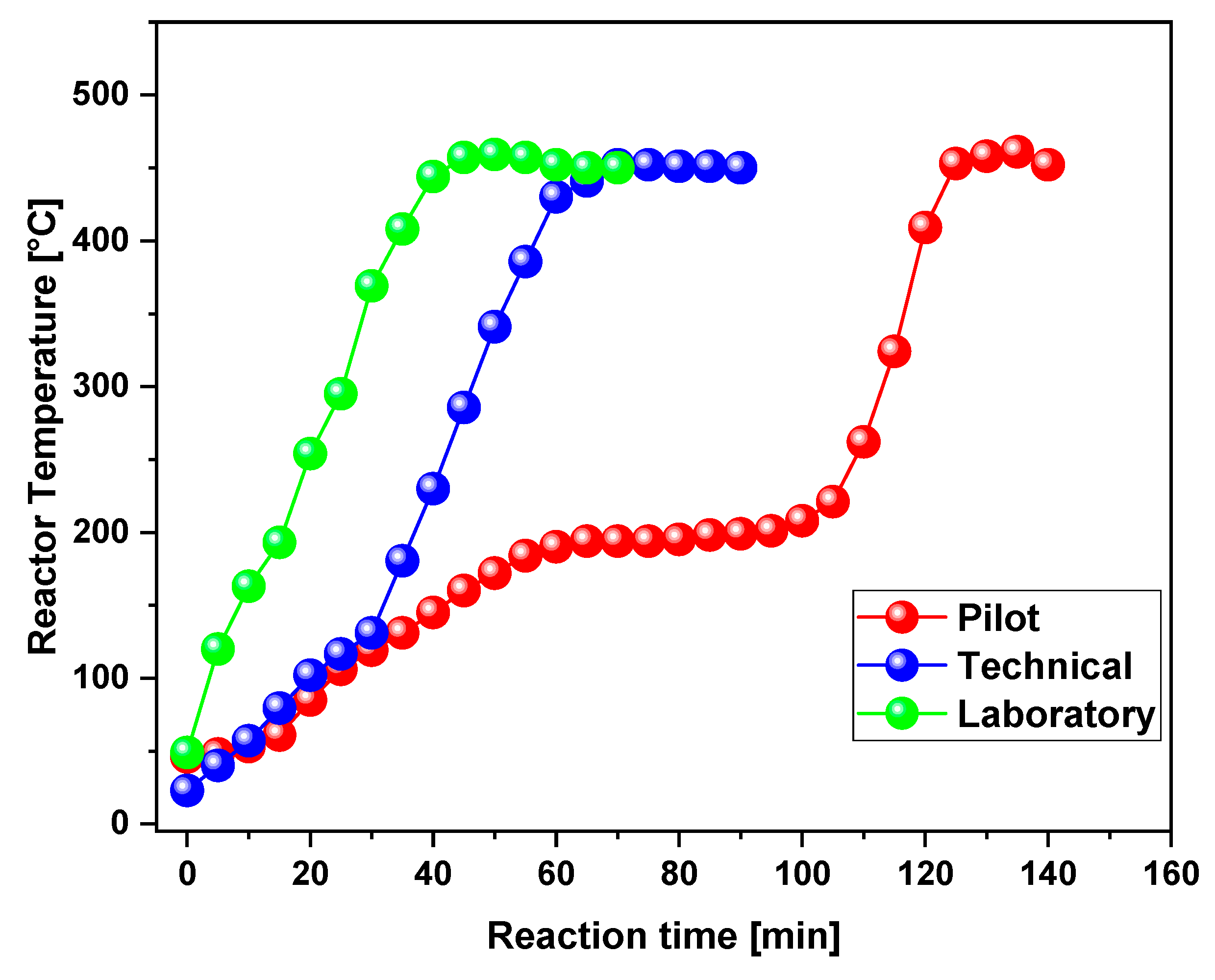

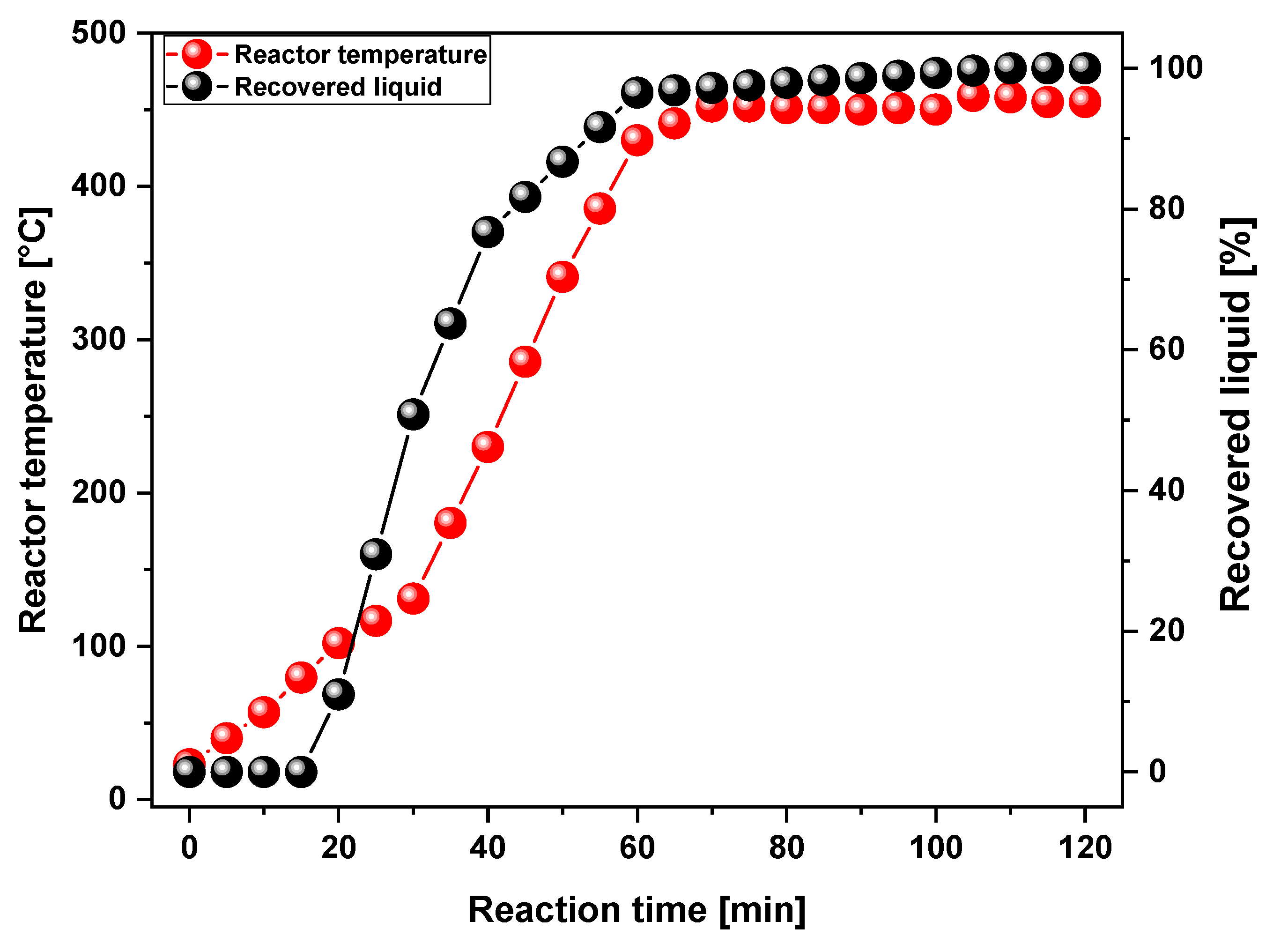

3.2. Process Analysis

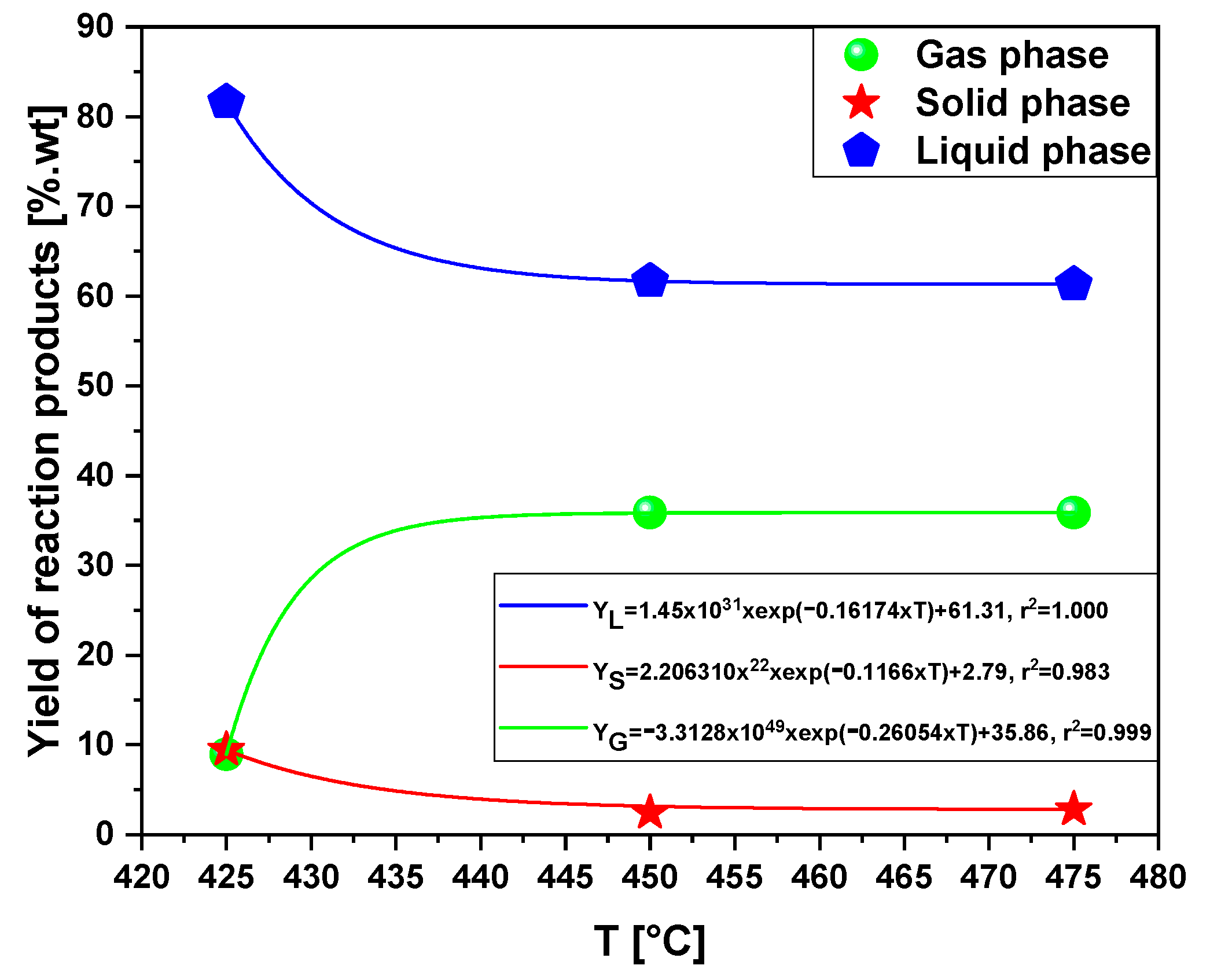

3.2.1. Scaling-Up Effect on the Yield of Products

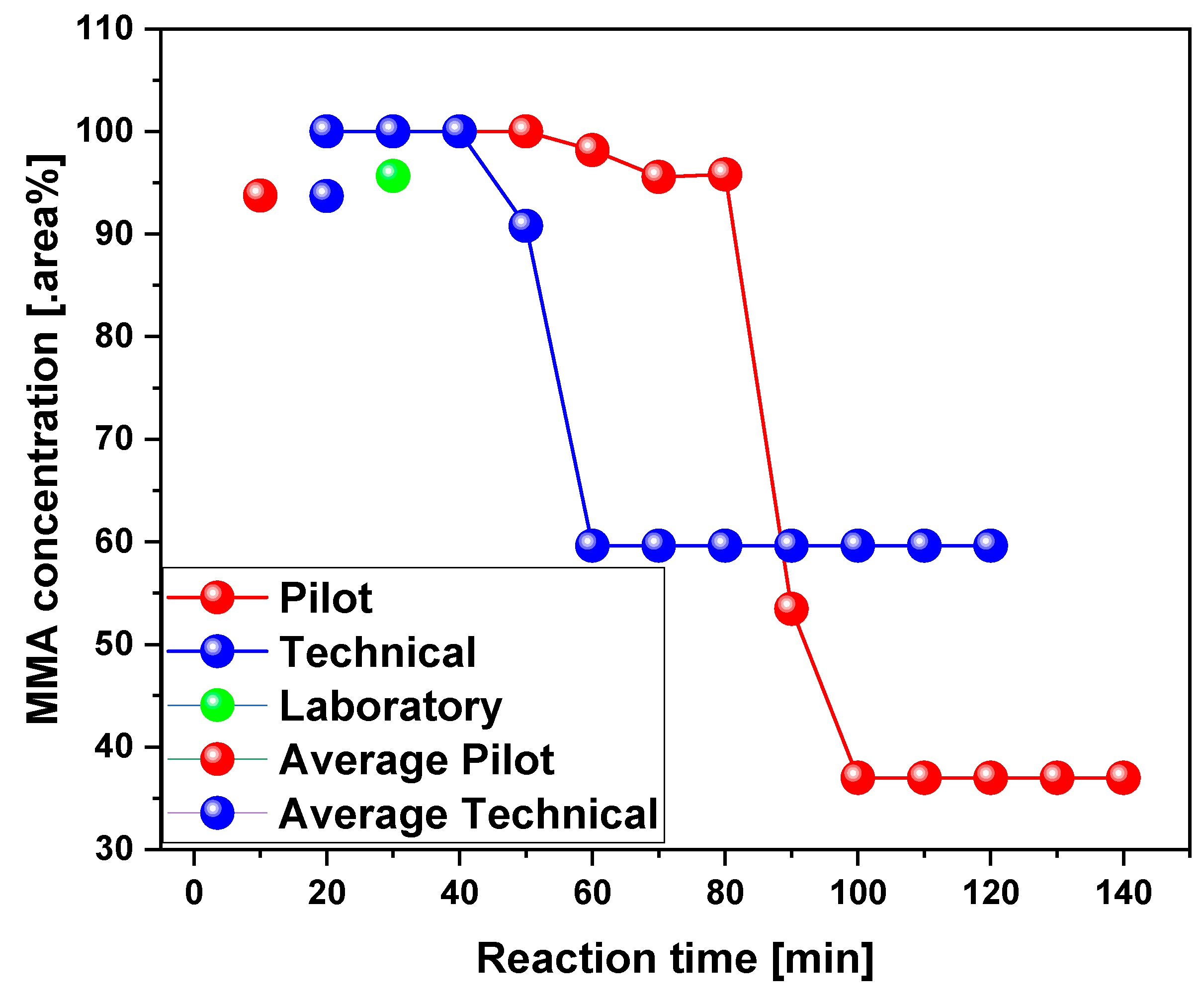

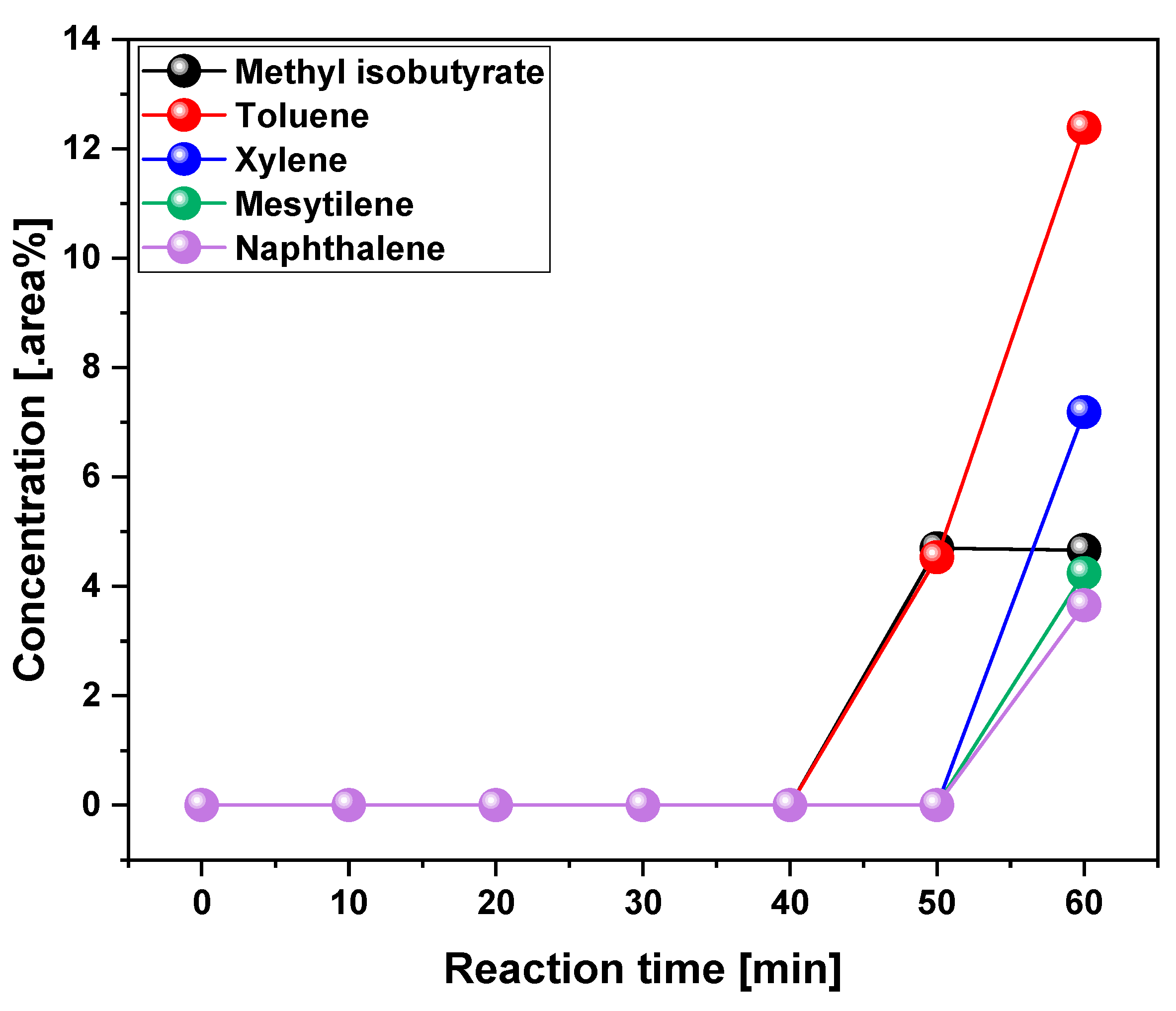

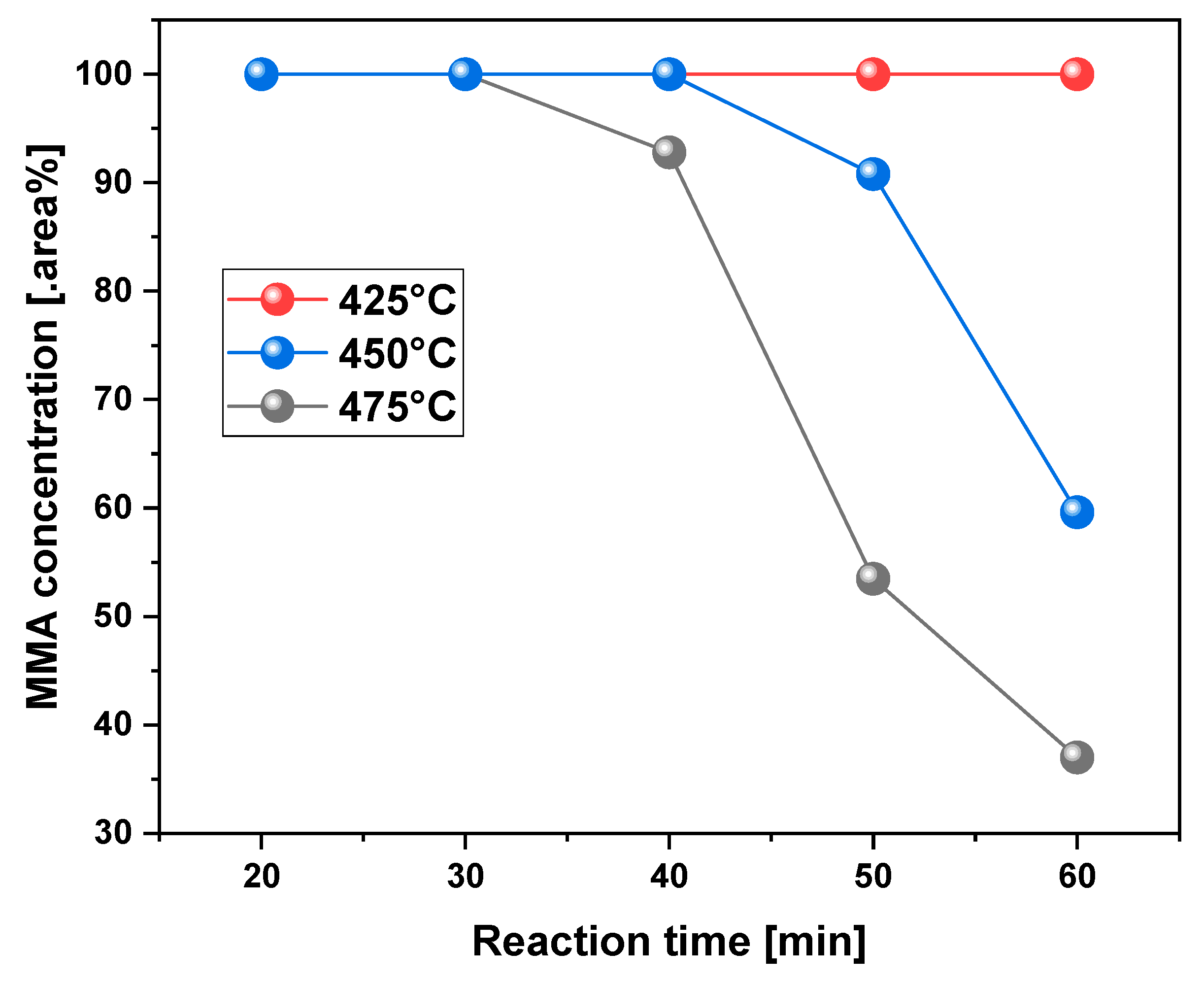

3.2.2. Scaling-Up Effect on the Chemical Composition of the Liquid Phase

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dai, L.; Zhou, N.; Lv, Y.; Cheng, Y.; Wang, Y.; Liu, Y.; Cobb, K.; Chen, P.; Lei, H.; Ruan, R. Pyrolysis Technology for Plastic Waste Recycling: A State-of-the-Art Review. Prog. Energy Combust. Sci. 2022, 93, 101021. [Google Scholar] [CrossRef]

- Ali, U.; Karim, K.J.B.A.; Buang, N.A. A Review of the Properties and Applications of Poly (Methyl Methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Frazer, R.Q.; Byron, R.T.; Osborne, P.B.; West, K.P. PMMA: An Essential Material in Medicine and Dentistry. J. Long-Term Eff. Med. Implant. 2005, 15, 629–639. [Google Scholar] [CrossRef] [PubMed]

- Gozum, N.; Safgonul Unal, E.; Altan-Yaycioglu, R.; Gucukoglu, A.; Ozgun, C. Visual Performance of Acrylic and PMMA Intraocular Lenses. Eye 2003, 17, 238–242. [Google Scholar] [CrossRef] [PubMed]

- Spasojevic, P.; Zrilic, M.; Panic, V.; Stamenkovic, D.; Seslija, S.; Velickovic, S. The Mechanical Properties of a Poly(Methyl Methacrylate) Denture Base Material Modified with Dimethyl Itaconate and Di-n-Butyl Itaconate. Int. J. Polym. Sci. 2015, 2015, 561012. [Google Scholar] [CrossRef]

- Gigault, J.; ter Halle, A.; Baudrimont, M.; Pascal, P.Y.; Gauffre, F.; Phi, T.L.; El Hadri, H.; Grassl, B.; Reynaud, S. Current Opinion: What Is a Nanoplastic? Environ. Pollut. 2018, 235, 1030–1034. [Google Scholar] [CrossRef]

- Rillig, M.C.; Lehmann, A. Microplastic in Terrestrial Ecosystems. Science (1979) 2020, 368, 1430–1431. [Google Scholar] [CrossRef] [PubMed]

- Fatih Demirbas, M. Biorefineries for Biofuel Upgrading: A Critical Review. Appl. Energy 2009, 86, S151–S161. [Google Scholar] [CrossRef]

- Dos Santos, P.B.; da Silva Ribeiro, H.J.; Ferreira, A.C.; Ferreira, C.C.; Bernar, L.P.; da Costa Assunção, F.P.; de Castro, D.A.R.; Santos, M.C.; Duvoisin, S.; Borges, L.E.P.; et al. Process Analysis of PMMA-Based Dental Resins Residues Depolymerization: Optimization of Reaction Time and Temperature. Energies 2021, 15, 91. [Google Scholar] [CrossRef]

- Kaminsky, W.; Predel, M.; Sadiki, A. Feedstock Recycling of Polymers by Pyrolysis in a Fluidised Bed. Polym. Degrad. Stab. 2004, 85, 1045–1050. [Google Scholar] [CrossRef]

- Kaminsky, W.; Franck, J. Monomer Recovery by Pyrolysis of Poly(Methyl Methacrylate) (PMMA). J. Anal. Appl. Pyrolysis 1991, 19, 311–318. [Google Scholar] [CrossRef]

- Kaminsky, W. Recycling of Polymers by Pyrolysis. J. Phys. IV 1993, 3, C7-1543–C7-1552. [Google Scholar] [CrossRef]

- Arisawa, H.; Brill, T.B. Kinetics and Mechanisms of Flash Pyrolysis of Poly(Methyl Methacrylate) (PMMA). Combust. Flame 1997, 109, 415–426. [Google Scholar] [CrossRef]

- Kaminsky, W.; Eger, C. Pyrolysis of Filled PMMA for Monomer Recovery. J. Anal. Appl. Pyrolysis 2001, 58–59, 781–787. [Google Scholar] [CrossRef]

- Smolders, K.; Baeyens, J. Thermal Degradation of PMMA in Fluidised Beds. Waste Manag. 2004, 24, 849–857. [Google Scholar] [CrossRef]

- Kang, B.S.; Kim, S.G.; Kim, J.S. Thermal Degradation of Poly(Methyl Methacrylate) Polymers: Kinetics and Recovery of Monomers Using a Fluidized Bed Reactor. J. Anal. Appl. Pyrolysis 2008, 81, 7–13. [Google Scholar] [CrossRef]

- Achilias, D.S. Chemical Recycling of Poly(Methyl Methacrylate) by Pyrolysis. Potential Use of the Liquid Fraction as a Raw Material for the Reproduction of the Polymer. Eur. Polym. J. 2007, 43, 2564–2575. [Google Scholar] [CrossRef]

- Lopez, G.; Artetxe, M.; Amutio, M.; Elordi, G.; Aguado, R.; Olazar, M.; Bilbao, J. Recycling Poly-(Methyl Methacrylate) by Pyrolysis in a Conical Spouted Bed Reactor. Chem. Eng. Process. Process Intensif. 2010, 49, 1089–1094. [Google Scholar] [CrossRef]

- Szabo, E.; Olah, M.; Ronkay, F.; Miskolczi, N.; Blazso, M. Characterization of the Liquid Product Recovered through Pyrolysis of PMMA–ABS Waste. J. Anal. Appl. Pyrolysis 2011, 92, 19–24. [Google Scholar] [CrossRef]

- Braido, R.S.; Borges, L.E.P.; Pinto, J.C. Chemical Recycling of Crosslinked Poly(Methyl Methacrylate) and Characterization of Polymers Produced with the Recycled Monomer. J. Anal. Appl. Pyrolysis 2018, 132, 47–55. [Google Scholar] [CrossRef]

- Zeng, W.R.; Li, S.F.; Chow, W.K. Review on Chemical Reactions of Burning Poly(Methyl Methacrylate) PMMA. J. Fire Sci. 2002, 20, 401–433. [Google Scholar] [CrossRef]

- Hirata, T.; Kashiwagi, T.; Brown, J.E. Thermal and Oxidative Degradation of Poly(Methyl Methacrylate): Weight Loss. Macromolecules 1985, 18, 1410–1418. [Google Scholar] [CrossRef]

- Manring, L.E. Thermal Degradation of Poly(Methyl Methacrylate). 2. Vinyl-Terminated Polymer. A Rev. Plast. Mod 1969, 19, 1515. [Google Scholar] [CrossRef]

- Peterson, J.D.; Vyazovkin, S.; Wight, C.A. Kinetic Study of Stabilizing Effect of Oxygen on Thermal Degradation of Poly(Methyl Methacrylate). J. Phys. Chem. B 1999, 103, 8087–8092. [Google Scholar] [CrossRef]

- Hu, Y.H.; Chen, C.Y. The Effect of End Groups on the Thermal Degradation of Poly(Methyl Methacrylate). Polym. Degrad. Stab. 2003, 82, 81–88. [Google Scholar] [CrossRef]

- Ferriol, M.; Gentilhomme, A.; Cochez, M.; Oget, N.; Mieloszynski, J.L. Thermal Degradation of Poly(Methyl Methacrylate) (PMMA): Modelling of DTG and TG Curves. Polym. Degrad. Stab. 2003, 79, 271–281. [Google Scholar] [CrossRef]

- Gao, Z.; Kaneko, T.; Hou, D.; Nakada, M. Kinetics of Thermal Degradation of Poly(Methyl Methacrylate) Studied with the Assistance of the Fractional Conversion at the Maximum Reaction Rate. Polym. Degrad. Stab. 2004, 84, 399–403. [Google Scholar] [CrossRef]

- Motaung, T.E.; Luyt, A.S.; Bondioli, F.; Messori, M.; Saladino, M.L.; Spinella, A.; Nasillo, G.; Caponetti, E. PMMA–Titania Nanocomposites: Properties and Thermal Degradation Behaviour. Polym. Degrad. Stab. 2012, 97, 1325–1333. [Google Scholar] [CrossRef]

- Fateh, T.; Richard, F.; Rogaume, T.; Joseph, P. Experimental and Modelling Studies on the Kinetics and Mechanisms of Thermal Degradation of Polymethyl Methacrylate in Nitrogen and Air. J. Anal. Appl. Pyrolysis 2016, 120, 423–433. [Google Scholar] [CrossRef]

- Bhargava, A.; Van Hees, P.; Andersson, B. Pyrolysis Modeling of PVC and PMMA Using a Distributed Reactivity Model. Polym. Degrad. Stab. 2016, 129, 199–211. [Google Scholar] [CrossRef]

- Cheng, J.; Pan, Y.; Yao, J.; Wang, X.; Pan, F.; Jiang, J. Mechanisms and Kinetics Studies on the Thermal Decomposition of Micron Poly (Methyl Methacrylate) and Polystyrene. J. Loss Prev. Process Ind. 2016, 40, 139–146. [Google Scholar] [CrossRef]

- Holland, B.J.; Hay, J.N. The Kinetics and Mechanisms of the Thermal Degradation of Poly(Methyl Methacrylate) Studied by Thermal Analysis-Fourier Transform Infrared Spectroscopy. Polymer 2001, 42, 4825–4835. [Google Scholar] [CrossRef]

- Ozlem, S.; Aslan-Gürel, E.; Rossi, R.M.; Hacaloglu, J. Thermal Degradation of Poly(Isobornyl Acrylate) and Its Copolymer with Poly(Methyl Methacrylate) via Pyrolysis Mass Spectrometry. J. Anal. Appl. Pyrolysis 2013, 100, 17–25. [Google Scholar] [CrossRef]

- Özlem-Gundogdu, S.; Gurel, E.A.; Hacaloglu, J. Pyrolysis of of Poly(Methy Methacrylate) Copolymers. J. Anal. Appl. Pyrolysis 2015, 113, 529–538. [Google Scholar] [CrossRef]

- Manring, L.E. Thermal Degradation of Poly(Methyl Methacrylate). 4. Random Side-Group Scissiont. Macromolecules 1991, 24, 3304–3309. [Google Scholar] [CrossRef]

- Godiya, C.B.; Gabrielli, S.; Materazzi, S.; Pianesi, M.S.; Stefanini, N.; Marcantoni, E. Depolymerization of Waste Poly(Methyl Methacrylate) Scraps and Purification of Depolymerized Products. J. Environ. Manag. 2019, 231, 1012–1020. [Google Scholar] [CrossRef]

- Popescu, V.; Vasile, C.; Brebu, M.; Popescu, G.L.; Moldovan, M.; Prejmerean, C.; Stǎnuleţ, L.; Trişcǎ-Rusu, C.; Cojocaru, I. The Characterization of Recycled PMMA. J. Alloys Compd. 2009, 483, 432–436. [Google Scholar] [CrossRef]

- Grause, G.; Predel, M.; Kaminsky, W. Monomer Recovery from Aluminium Hydroxide High Filled Poly(Methyl Methacrylate) in a Fluidized Bed Reactor. J. Anal. Appl. Pyrolysis 2006, 75, 236–239. [Google Scholar] [CrossRef]

- Newborough, M.; Highgate, D.; Vaughan, P. Thermal Depolymerisation of Scrap Polymers. Appl. Therm. Eng. 2002, 22, 1875–1883. [Google Scholar] [CrossRef]

- Sasaki, A.; Tsuji, T. Poly(methyl methacrylate) pyrolysis by two fluidized bed process. In Proceedings of the 5th Symposium on Feedstock and Mechanical Recycling of Polymeric Materials (ISFR 2009), Chengdu, China, 11–14 October 2009. [Google Scholar]

- Zeng, W.R.; Li, S.F.; Chow, W.K. Preliminary Studies on Burning Behavior of Polymethylmethacrylate (PMMA). J. Fire Sci. 2002, 20, 297–317. [Google Scholar] [CrossRef]

- Chen, R.; Xu, M. Kinetic and Volatile Products Study of Micron-Sized PMMA Waste Pyrolysis Using Thermogravimetry and Fourier Transform Infrared Analysis. Waste Manag. 2020, 113, 51–61. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Li, Q.; Xu, X.; Zhang, D. Pyrolysis Kinetics and Reaction Mechanism of Representative Non-Charring Polymer Waste with Micron Particle Size. Energy Convers. Manag. 2019, 198, 111923. [Google Scholar] [CrossRef]

- Jayarama Krishna, J.V.; Srivatsa Kumar, S.; Korobeinichev, O.P.; Vinu, R. Detailed Kinetic Analysis of Slow and Fast Pyrolysis of Poly(Methyl Methacrylate)-Flame Retardant Mixtures. Thermochim. Acta 2020, 687, 178545. [Google Scholar] [CrossRef]

- Özsin, G. Assessing Thermal Behaviours of Cellulose and Poly(Methyl Methacrylate) during Co-Pyrolysis Based on an Unified Thermoanalytical Study. Bioresour. Technol. 2020, 300, 122700. [Google Scholar] [CrossRef] [PubMed]

- Korobeinichev, O.P.; Paletsky, A.A.; Gonchikzhapov, M.B.; Glaznev, R.K.; Gerasimov, I.E.; Naganovsky, Y.K.; Shundrina, I.K.; Snegirev, A.Y.; Vinu, R. Kinetics of Thermal Decomposition of PMMA at Different Heating Rates and in a Wide Temperature Range. Thermochim. Acta 2019, 671, 17–25. [Google Scholar] [CrossRef]

- Da Ros, S.; Braido, R.S.; de Souza e Castro, N.L.; Brandão, A.L.T.; Schwaab, M.; Pinto, J.C. Modelling the Chemical Recycling of Crosslinked Poly (Methyl Methacrylate): Kinetics of Depolymerisation. J. Anal. Appl. Pyrolysis 2019, 144, 104706. [Google Scholar] [CrossRef]

- Poudel, J.; Lee, Y.M.; Kim, H.J.; Oh, S.C. Methyl Methacrylate (MMA) and Alumina Recovery from Waste Artificial Marble Powder Pyrolysis. J. Mater. Cycles Waste Manag. 2021, 23, 214–221. [Google Scholar] [CrossRef]

- Snegirev, A.Y.; Talalov, V.A.; Stepanov, V.V.; Korobeinichev, O.P.; Gerasimov, I.E.; Shmakov, A.G. Autocatalysis in Thermal Decomposition of Polymers. Polym. Degrad. Stab. 2017, 137, 151–161. [Google Scholar] [CrossRef]

- Handawy, M.K.; Snegirev, A.Y.; Stepanov, V.V.; Talalov, V.A. Kinetic Modeling and Analysis of Pyrolysis of Polymethyl Methacrylate Using Isoconversional Methods. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1100, 012053. [Google Scholar] [CrossRef]

- Chen, R.; Pan, R.; Li, Q. Thermal Degradation Characteristics, Kinetics and Thermodynamics of Micron-Sized PMMA in Oxygenous Atmosphere Using Thermogravimetry and Deconvolution Method Based on Gauss Function. J. Loss Prev. Process Ind. 2021, 71, 104488. [Google Scholar] [CrossRef]

- Kaminsky, W. Thermal Recycling of Polymers. J. Anal. Appl. Pyrolysis 1985, 8, 439–448. [Google Scholar] [CrossRef]

- Ding, Y.; Chen, W.; Zhang, W.; Zhang, X.; Li, C.; Zhou, R.; Miao, F. Experimental and Numerical Simulation Study of Typical Semi-Transparent Material Pyrolysis with in-Depth Radiation Based on Micro and Bench Scales. Energy 2022, 258, 124863. [Google Scholar] [CrossRef]

- Bate, D.M.; Lehrle, R.S. A New Approach for Measuring the Rate of Pyrolysis of Cross-Linked Polymers: Evaluation of Degradation Rate Constants for Cross-Linked PMMA. Polym. Degrad. Stab. 1998, 62, 67–71. [Google Scholar] [CrossRef]

- de Freitas Costa, A.F.; Ferreira, C.C.; da Paz, S.P.A.; Santos, M.C.; Moreira, L.G.S.; Mendonça, N.M.; da Costa Assunção, F.P.; de Freitas, A.C.G.d.A.; Costa, R.M.R.; de Sousa Brandão, I.W.; et al. Catalytic Upgrading of Plastic Waste of Electric and Electronic Equipment (WEEE) Pyrolysis Vapors over Si–Al Ash Pellets in a Two-Stage Reactor. Energies 2023, 16, 541. [Google Scholar] [CrossRef]

- Ferreira, C.C.; Bernar, L.P.; de Freitas Costa, A.F.; da Silva Ribeiro, H.J.; Santos, M.C.; Moraes, N.L.; Costa, Y.S.; Baia, A.C.F.; Mendonça, N.M.; da Mota, S.A.P.; et al. Improving Fuel Properties and Hydrocarbon Content from Residual Fat Pyrolysis Vapors over Activated Red Mud Pellets in Two-Stage Reactor: Optimization of Reaction Time and Catalyst Content. Energies 2022, 15, 5595. [Google Scholar] [CrossRef]

- Pinto Bernar, L.; Campos Ferreira, C.; Fernando de Freitas Costa, A.; Jorge da Silva Ribeiro, H.; Gomes dos Santos, W.; Martins Pereira, L.; Mathias Pereira, A.; Lobato Moraes, N.; Paula da Costa Assunção, F.; Alex Pereira da Mota, S.; et al. Catalytic Upgrading of Residual Fat Pyrolysis Vapors over Activated Carbon Pellets into Hydrocarbons-like Fuels in a Two-Stage Reactor: Analysis of Hydrocarbons Composition and Physical-Chemistry Properties. Energies 2022, 15, 4587. [Google Scholar] [CrossRef]

- da Mota, S.A.P.; Mancio, A.A.; Lhamas, D.E.L.; de Abreu, D.H.; da Silva, M.S.; dos Santos, W.G.; de Castro, D.A.R.; de Oliveira, R.M.; Araújo, M.E.; Borges, L.E.P.; et al. Production of Green Diesel by Thermal Catalytic Cracking of Crude Palm Oil (Elaeis Guineensis Jacq) in a Pilot Plant. J. Anal. Appl. Pyrolysis 2014, 110, 1–11. [Google Scholar] [CrossRef]

- Daniel Valdez, G.; Valois, F.; Bremer, S.; Bezerra, K.; Hamoy Guerreiro, L.; Santos, M.; Bernar, L.; Feio, W.; Moreira, L.; Mendonça, N.; et al. Improving the Bio-Oil Quality of Residual Biomass Pyrolysis by Chemical Activation: Effect of Alkalis and Acid Pre-Treatment. Energies 2023, 16, 3162. [Google Scholar] [CrossRef]

- Rocha de Castro, D.; da Silva Ribeiro, H.; Hamoy Guerreiro, L.; Pinto Bernar, L.; Jonatan Bremer, S.; Costa Santo, M.; da Silva Almeida, H.; Duvoisin, S.; Pizarro Borges, L.; Teixeira Machado, N. Production of Fuel-Like Fractions by Fractional Distillation of Bio-Oil from Açaí (Euterpe Oleracea Mart.) Seeds Pyrolysis. Energies 2021, 14, 3713. [Google Scholar] [CrossRef]

- da Silva Almeida, H.; Corrêa, O.A.; Eid, J.G.; Ribeiro, H.J.; de Castro, D.A.R.; Pereira, M.S.; Pereira, L.M.; de Andrade Mâncio, A.; Santos, M.C.; da Silva Souza, J.A.; et al. Production of Biofuels by Thermal Catalytic Cracking of Scum from Grease Traps in Pilot Scale. J. Anal. Appl. Pyrolysis 2016, 118, 20–33. [Google Scholar] [CrossRef]

- da Silva Almeida, H.; Corrêa, O.A.; Ferreira, C.C.; Ribeiro, H.J.; de Castro, D.A.R.; Pereira, M.S.; de Andrade Mâncio, A.; Santos, M.C.; da Mota, S.A.P.; da Silva Souza, J.A.; et al. Diesel-like Hydrocarbon Fuels by Catalytic Cracking of Fat, Oils, and Grease (FOG) from Grease Traps. J. Energy Inst. 2017, 90, 337–354. [Google Scholar] [CrossRef]

- Santos, M.C.; Lourenço, R.M.; de Abreu, D.H.; Pereira, A.M.; de Castro, D.A.R.; Pereira, M.S.; Almeida, H.S.; Mâncio, A.A.; Lhamas, D.E.L.; da Mota, S.A.P.; et al. Gasoline-like Hydrocarbons by Catalytic Cracking of Soap Phase Residue of Neutralization Process of Palm Oil (Elaeis Guineensis Jacq). J. Taiwan Inst. Chem. Eng. 2017, 71, 106–119. [Google Scholar] [CrossRef]

- Available online: www.astm.org/Standards/D4052.htm (accessed on 6 February 2024).

- Available online: https://www.astm.org/d0446-12r17.html (accessed on 6 February 2024).

- American Oil Chemists’ Society. Official Methods and Recommended Practices, 4th ed.; AOCS: Champaign, IL, USA, 1993; Volume 3. [Google Scholar]

- Barlow, A.; Lehrle, R.S.; Robb, J.C.; Sunderland, D. Polymethylmethacrylate Degradation—Kinetics and Mechanisms in the Temperature Range 340° to 460 °C. Polymer 1967, 8, 537–545. [Google Scholar] [CrossRef]

- Kumar, M.; Arun, S.; Upadhyaya, P.; Pugazhenthi, G. Properties of PMMA/Clay Nanocomposites Prepared Using Various Compatibilizers. Int. J. Mech. Mater. Eng. 2015, 10, 7. [Google Scholar] [CrossRef]

- Chen, Q.; Yang, R.; Zhao, B.; Li, Y.; Wang, S.; Wu, H.; Zhuo, Y.; Chen, C. Investigation of Heat of Biomass Pyrolysis and Secondary Reactions by Simultaneous Thermogravimetry and Differential Scanning Calorimetry. Fuel 2014, 134, 467–476. [Google Scholar] [CrossRef]

- Ghanbari, E.; Picken, S.J.; van Esch, J.H. Analysis of Differential Scanning Calorimetry (DSC): Determining the Transition Temperatures, and Enthalpy and Heat Capacity Changes in Multicomponent Systems by Analytical Model Fitting. J. Therm. Anal. Calorim. 2023, 148, 12393–12409. [Google Scholar] [CrossRef]

- Haseli, Y.; van Oijen, J.A.; de Goey, L.P.H. Modeling Biomass Particle Pyrolysis with Temperature-Dependent Heat of Reactions. J. Anal. Appl. Pyrolysis 2011, 90, 140–154. [Google Scholar] [CrossRef]

- Karlou, K.; Schneider, H.A. DSC and P-V-T Study of PVC/PMMA Blends. J. Therm. Anal. Calorim. 2000, 59, 59–69. [Google Scholar] [CrossRef]

- Poomalai, P.; Varghese, T.O. Thermomechanical Behaviour of Poly(Methyl Methacrylate)/Copoly(Ether-Ester) Blends. ISRN Mater. Sci. 2011, 2011, 1–5. [Google Scholar] [CrossRef][Green Version]

- Saxena, P.; Shukla, P.; Gaur, M. Thermal Analysis of Polymer Blends and Double Layer by DSC. Polym. Polym. Compos. 2021, 29, S11–S18. [Google Scholar] [CrossRef]

- Hajduk, B.; Bednarski, H.; Jarka, P.; Janeczek, H.; Godzierz, M.; Tański, T. Thermal and Optical Properties of PMMA Films Reinforced with Nb2O5 Nanoparticles. Sci. Rep. 2021, 11, 22531. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Ouyang, Q.; He, L.; Huang, Q. Optical and Thermal Properties of Polymethyl Methacrylate (PMMA) Bearing Phenyl and Adamantyl Substituents. Colloids Surf. A Physicochem. Eng. Asp. 2022, 653, 130018. [Google Scholar] [CrossRef]

- Li, Y.; Guo, H. Crosslinked Poly(Methyl Methacrylate) with Perfluorocyclobutyl Aryl Ether Moiety as Crosslinking Unit: Thermally Stable Polymer with High Glass Transition Temperature. RSC Adv. 2020, 10, 1981–1988. [Google Scholar] [CrossRef]

- Yin, W.; Xie, Z.; Yin, Y.; Yi, J.; Liu, X.; Wu, H.; Wang, S.; Xie, Y.; Yang, Y. Aging Behavior and Lifetime Prediction of PMMA under Tensile Stress and Liquid Scintillator Conditions. Adv. Ind. Eng. Polym. Res. 2019, 2, 82–87. [Google Scholar] [CrossRef]

- Chat, K.; Tu, W.; Beena Unni, A.; Adrjanowicz, K. Influence of Tacticity on the Glass-Transition Dynamics of Poly(Methyl Methacrylate) (PMMA) under Elevated Pressure and Geometrical Nanoconfinement. Macromolecules 2021, 54, 8526–8537. [Google Scholar] [CrossRef]

- Andreozzi, L.; Faetti, M.; Giordano, M.; Palazzuoli, D. Enthalpy Recovery in Low Molecular Weight PMMA. J. Non-Cryst. Solids 2003, 332, 229–241. [Google Scholar] [CrossRef]

- Fiola, G.J.; Chaudhari, D.M.; Stoliarov, S.I. Comparison of Pyrolysis Properties of Extruded and Cast Poly(Methyl Methacrylate). Fire Saf. J. 2021, 120, 103083. [Google Scholar] [CrossRef]

- Alonso, A.; Lázaro, D.; Lázaro, M.; Alvear, D. Self-Heating Evaluation on Thermal Analysis of Polymethyl Methacrylate (PMMA) and Linear Low-Density Polyethylene (LLDPE). J. Therm. Anal. Calorim. 2022, 147, 10067–10081. [Google Scholar] [CrossRef]

- Wang, W.-H.; Su, W.; Hu, S.-Y.; Huang, Y.; Pan, Y.; Chang, S.-C.; Shu, C.-M. Pyrolysis Characteristics and Kinetics of Polymethylmethacrylate-Based Polymer Electrolytes for Lithium-Ion Battery. J. Therm. Anal. Calorim. 2022, 147, 12019–12032. [Google Scholar] [CrossRef]

- Ren, X.-Y.; Feng, X.-B.; Cao, J.-P.; Tang, W.; Wang, Z.-H.; Yang, Z.; Zhao, J.-P.; Zhang, L.-Y.; Wang, Y.-J.; Zhao, X.-Y. Catalytic Conversion of Coal and Biomass Volatiles: A Review. Energy Fuels 2020, 34, 10307–10363. [Google Scholar] [CrossRef]

- Chang, C.-C.; Wan, S.-W. China’s Motor Fuels from Tung Oil. Ind. Eng. Chem. 1947, 39, 1543–1548. [Google Scholar] [CrossRef]

| References | PMMA Type | Temp. (°C) | YLP (%) | %MMA (wt.%) | Reactor Type | Process Scale |

|---|---|---|---|---|---|---|

| [9] | PMMA waste | 345–420 | 48.2–55.5 | 83–98 | Fixed bed | Pilot (143 L) |

| [10] | Filled PMMA | 450 | 82.4 | 57.9 | Fluidized bed | Lab (3 kg/h) |

| [11] | PMMA waste | 490 | 92.1 | 91 | Fluidized bed | Lab (3 kg/h) |

| [12] | PMMA waste | 450 | 98.6 | 97.2 | Fluidized bed | Lab (3 kg/h) |

| [14] | Filled and pure PMMA | 450–480 | 94.7–96.2 (filled); 97.5–99.2 (pure) | 86.6–90.5 (filled); 93.7–98.4 (pure) | Fluidized bed | Lab (3 kg/h) |

| [14] | Filled and pure PMMA | 450 | 92.9 (filled); 98.3 (pure) | 83.5 (filled); 96.7 (pure) | Fluidized bed | Pilot (16–34 kg/h) |

| [15] | Pure PMMA | 450–590 | 57.3–98.5 | 95.8–98.7 | Fluidized bed | Lab (2 g) |

| [16] | Pure and waste PMMA | 440–500 | 98.1–99.3 (pure); 96.8–98.4 (waste) | 96.3–97.4 (pure); 95.6–97.3 (waste) | Fluidized bed | Lab (1 kg/h) |

| [17] | Pure and commercial PMMA | 450 | 99.3 (pure); 98.1 (commercial) | 99.0 (pure); 96.8 (commercial) | Fixed bed | Lab (1.5 g) |

| [18] | Commercial PMMA | 400–550 | 90.8–99.1 | 77.9–86.5 | Conical spouted bed | Lab (1.5 g/min) |

| [20] | Pure and waste PMMA | 250–450 | 9.0–85.0 | 82.2–99.9 | Fixed bed | Lab (30 g) |

| [20] | Waste PMMA | 400 | 66.3 | 76.4 | Fixed bed | Lab (2 L) |

| [37] | Pure and waste PMMA | 450 | 90–97 | 90.0–94.8 | Fixed bed | Lab (20 g) |

| [38] | Filled PMMA | 400–450 | 18–33 | 53–80 | Fluidized bed | Lab (3 kg/h) |

| [40] | Pure PMMA | 400 | 95 | 95 | Fluidized bed | Pilot (14.4 kg/h) |

| [40] | Pure PMMA | 400 | 95 | 94 | Fluidized bed | Industrial (300 kg/h) |

| [48] | Filled PMMA | 300–500 | 35–97 | 5–88 | Fixed bed | Lab (50 g) |

| Reactor | i.d. (mm) | h (mm) | Volume (L) |

|---|---|---|---|

| Borosilicate glass | 30 | 150 | 0.1 |

| Technical | 85 | 355 | 2.0 |

| Pilot | 300 | 1800 | 143 |

| Process Condition | Temperature [°C] | ||

|---|---|---|---|

| 450 | |||

| Laboratory | Semi-Pilot | Pilot | |

| Mass of feed [g] | 40.00 | 625.00 | 20,000 |

| Reactor volume [L] | 0.1 | 2.0 | 143 |

| Reactor load [kg/L] | 0.40 | 0.31 | 0.14 |

| Power load [W/kg] | 20,000 | 5600 | 290–1740 |

| Reaction time [min] | 60 | 100 | 130 |

| Temperature of liquid condensation [°C] | 230 | 109 | 113 |

| Final temperature [°C] | 450 | 455 | 458 |

| Mass of coke [g] | 0.29 | 15.11 | 1700 |

| Mass of liquid [g] | 38.31 | 384.70 | 11,836.3 |

| Mass of gas [g] | 1.46 | 223.94 | 6463.7 |

| Yield of liquid [%] | 95.63 | 61.67 | 59.18 |

| Yield of coke [%] | 3.64 | 2.43 | 8.50 |

| Yield of gas [%] | 0.73 | 35.90 | 32.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ribeiro, H.J.d.S.; Ferreira, A.C.; Ferreira, C.C.; Pereira, L.M.; Santos, M.C.; Guerreiro, L.H.H.; Assunção, F.P.d.C.; da Mota, S.A.P.; Castro, D.A.R.d.; Duvoisin, S., Jr.; et al. Depolymerization of PMMA-Based Dental Resin Scraps on Different Production Scales. Energies 2024, 17, 1196. https://doi.org/10.3390/en17051196

Ribeiro HJdS, Ferreira AC, Ferreira CC, Pereira LM, Santos MC, Guerreiro LHH, Assunção FPdC, da Mota SAP, Castro DARd, Duvoisin S Jr., et al. Depolymerization of PMMA-Based Dental Resin Scraps on Different Production Scales. Energies. 2024; 17(5):1196. https://doi.org/10.3390/en17051196

Chicago/Turabian StyleRibeiro, Haroldo Jorge da Silva, Armando Costa Ferreira, Caio Campos Ferreira, Lia Martins Pereira, Marcelo Costa Santos, Lauro Henrique Hamoy Guerreiro, Fernanda Paula da Costa Assunção, Sílvio Alex Pereira da Mota, Douglas Alberto Rocha de Castro, Sergio Duvoisin, Jr., and et al. 2024. "Depolymerization of PMMA-Based Dental Resin Scraps on Different Production Scales" Energies 17, no. 5: 1196. https://doi.org/10.3390/en17051196

APA StyleRibeiro, H. J. d. S., Ferreira, A. C., Ferreira, C. C., Pereira, L. M., Santos, M. C., Guerreiro, L. H. H., Assunção, F. P. d. C., da Mota, S. A. P., Castro, D. A. R. d., Duvoisin, S., Jr., Borges, L. E. P., Machado, N. T., & Bernar, L. P. (2024). Depolymerization of PMMA-Based Dental Resin Scraps on Different Production Scales. Energies, 17(5), 1196. https://doi.org/10.3390/en17051196