The Impact of Biochar Additives and Fat-Emulsifying Substances on the Efficiency of the Slaughterhouse Waste Biogasing Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrate, Inoculum, and Media

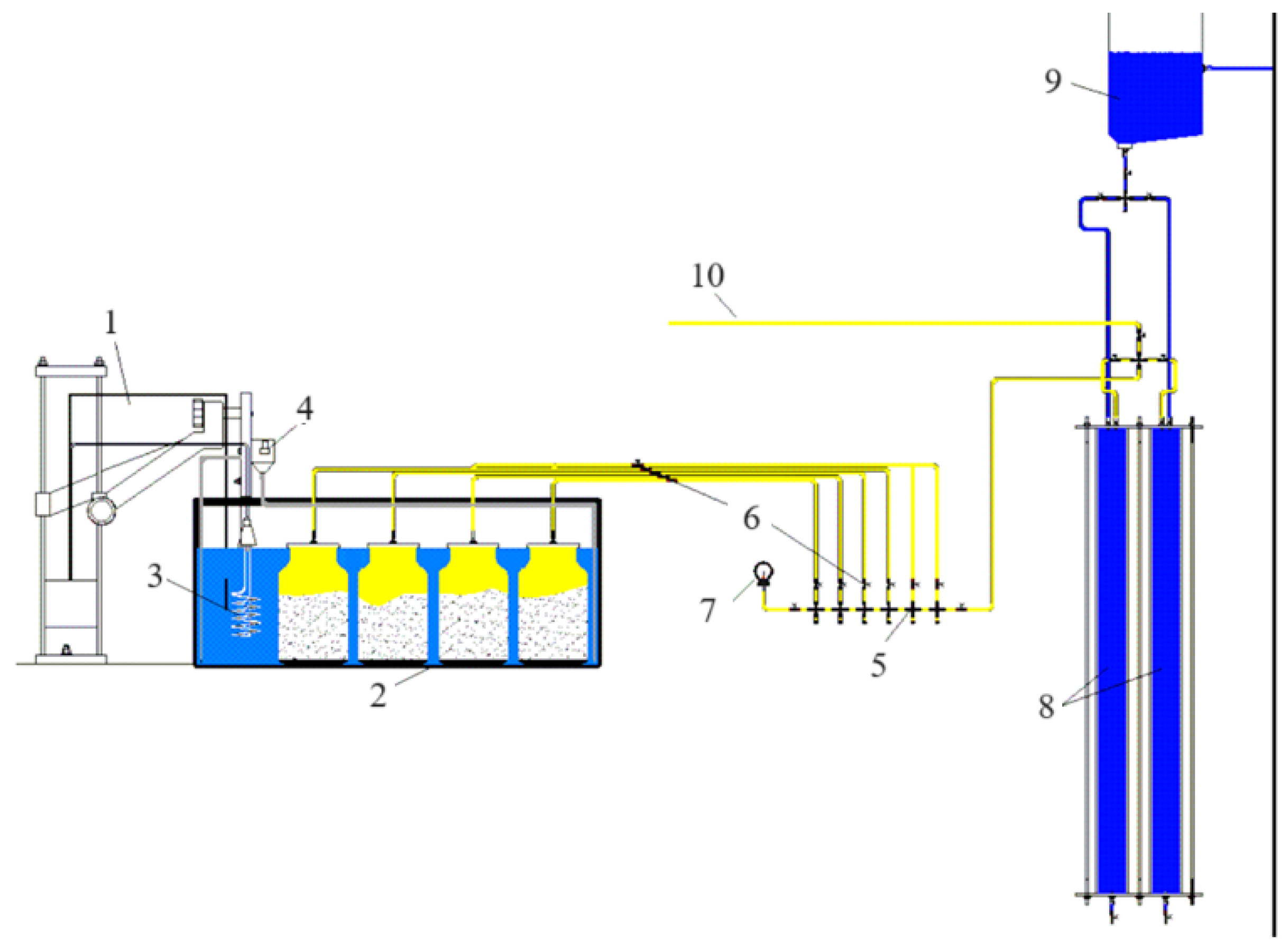

2.2. Experimental Set-up

- -

- Process duration;

- -

- Total biogas yield per kg of dry weight of waste;

- -

- Total methane yield per kg of dry weight of waste;

- -

- Total carbon dioxide emission per kg of dry weight of waste;

- -

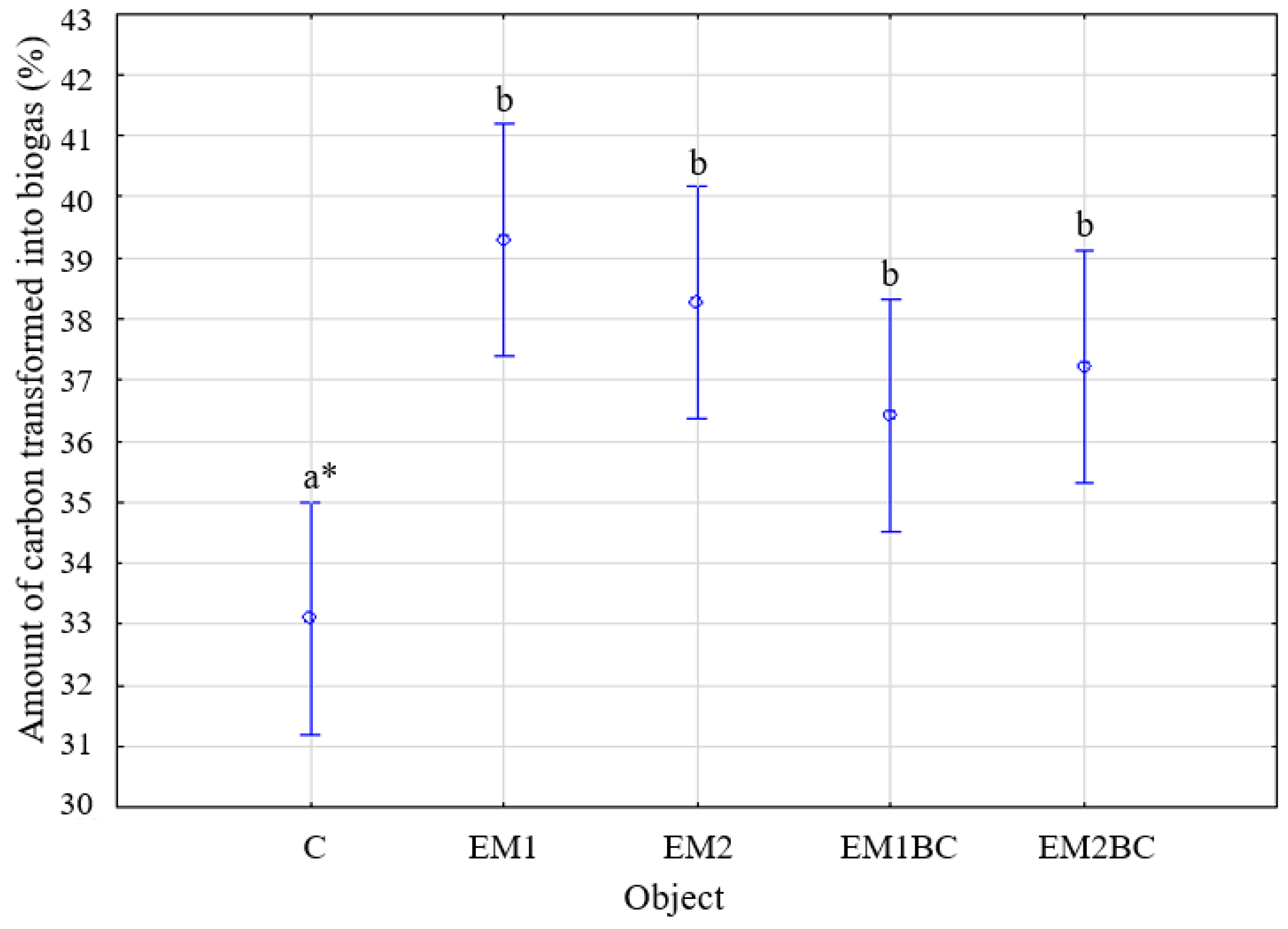

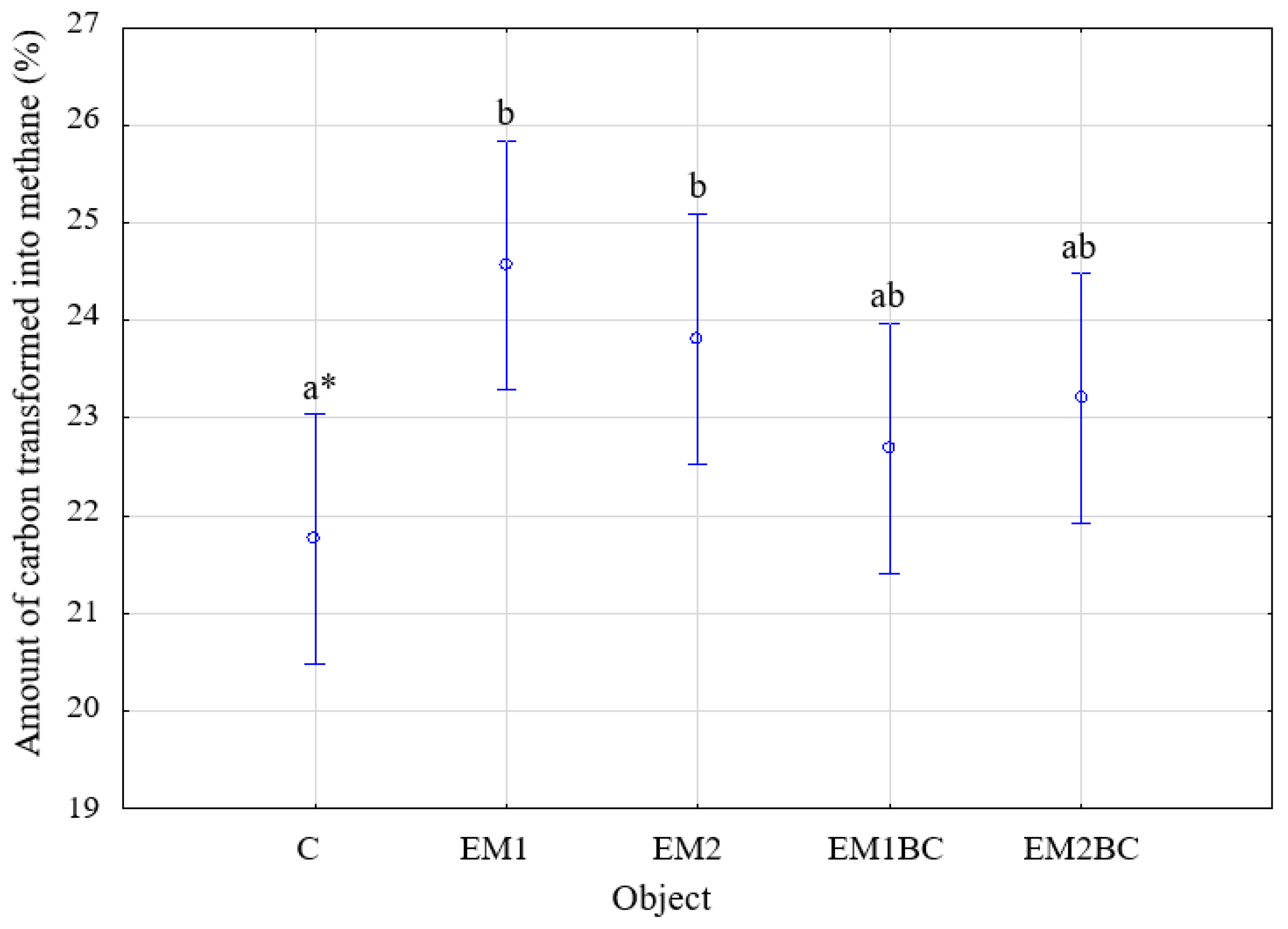

- The amount of carbon transformed into methane as a result of the process.

2.3. Analytical Methods

- The dry matter content was determined gravimetrically.

- The ash content was determined gravimetrically after annealing.

- The organic carbon and total nitrogen contents were determined using the elemental analysis method in the Vario Max Cube apparatus by Elementar.

- The fat content was determined according to the ISO 1443:1973 standard [46].

- The protein content was determined using the Bradford method.

- COD and CODD values were determined by the dichromate method in accordance with the PN-ISO 6060:2006 standard [47].

- Static methane fermentation was carried out according to the methodology of DIN-38414/S8 [45].

2.4. Statistical Analysis

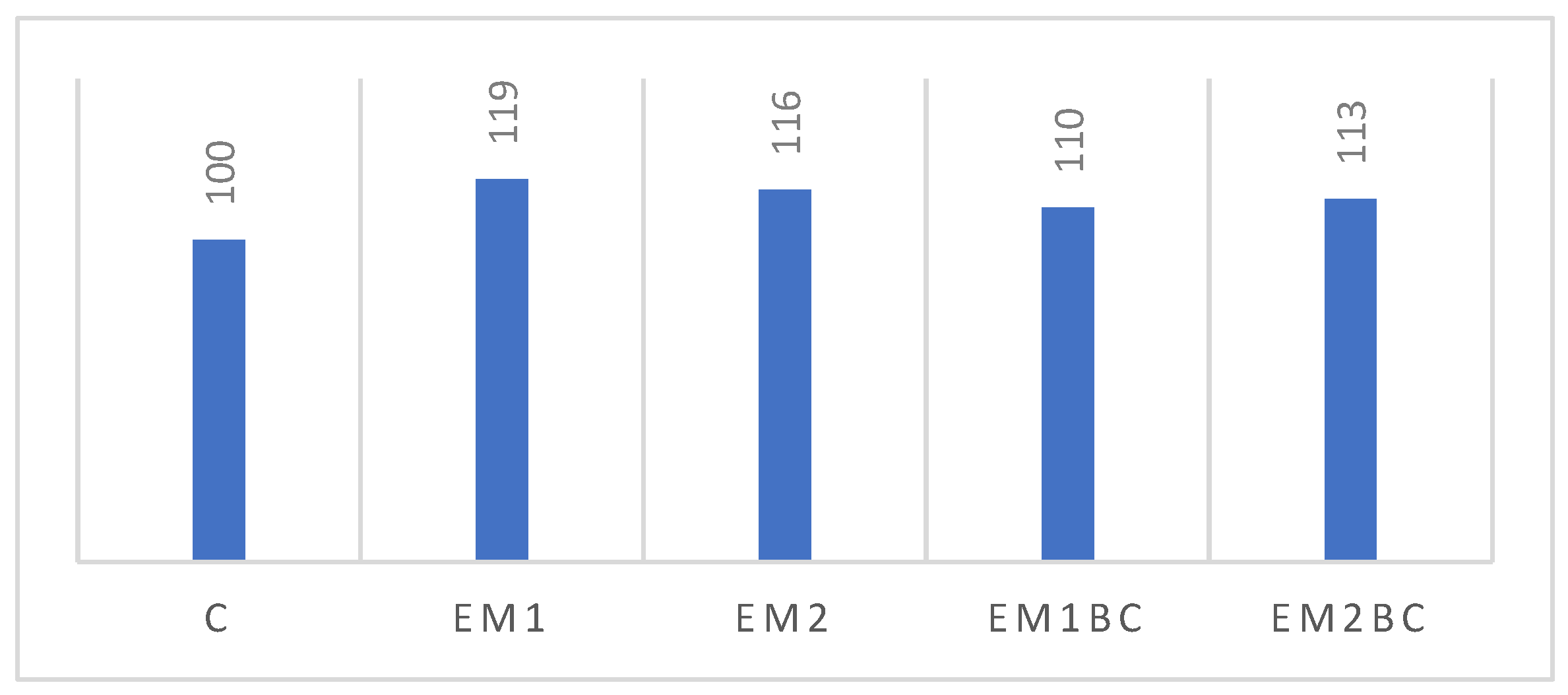

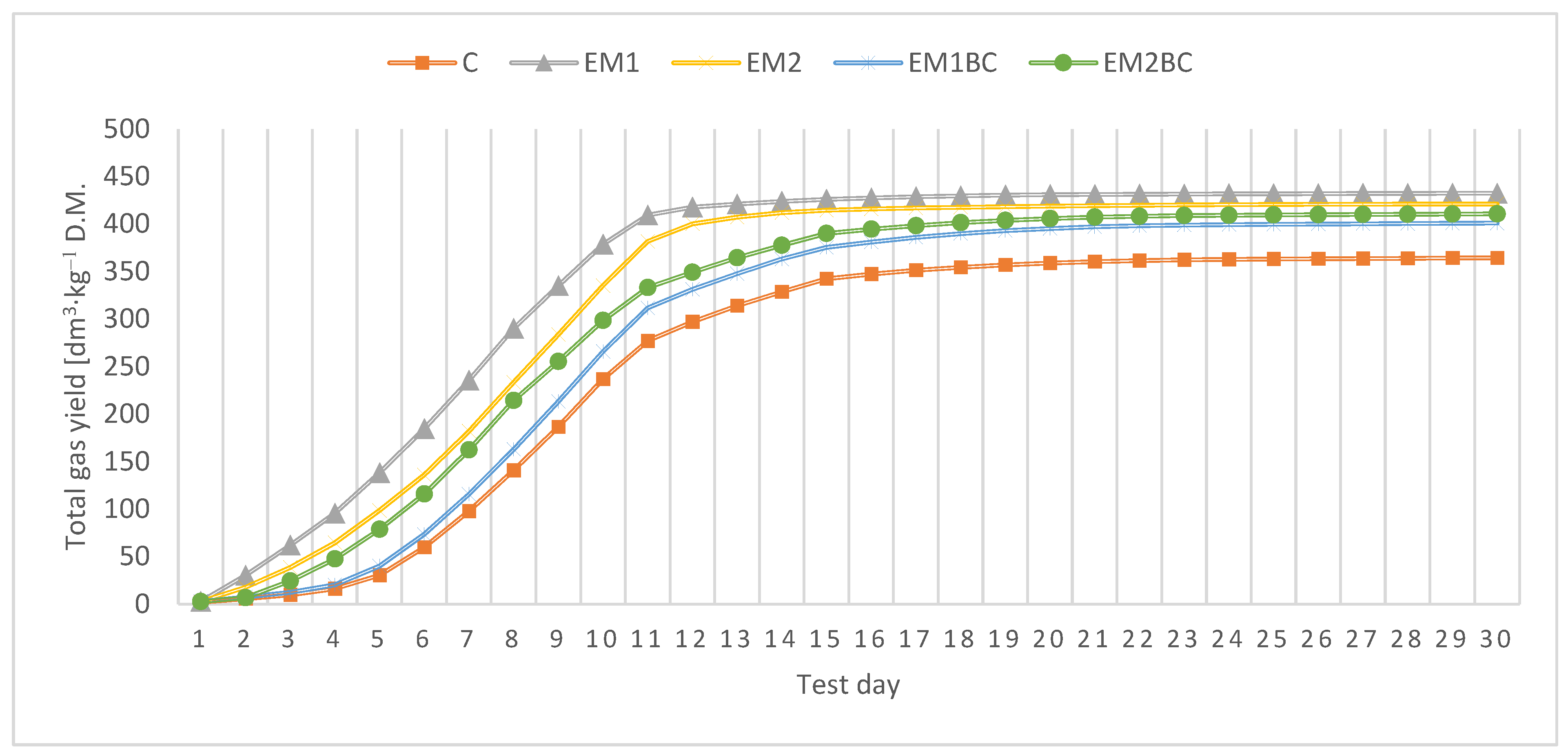

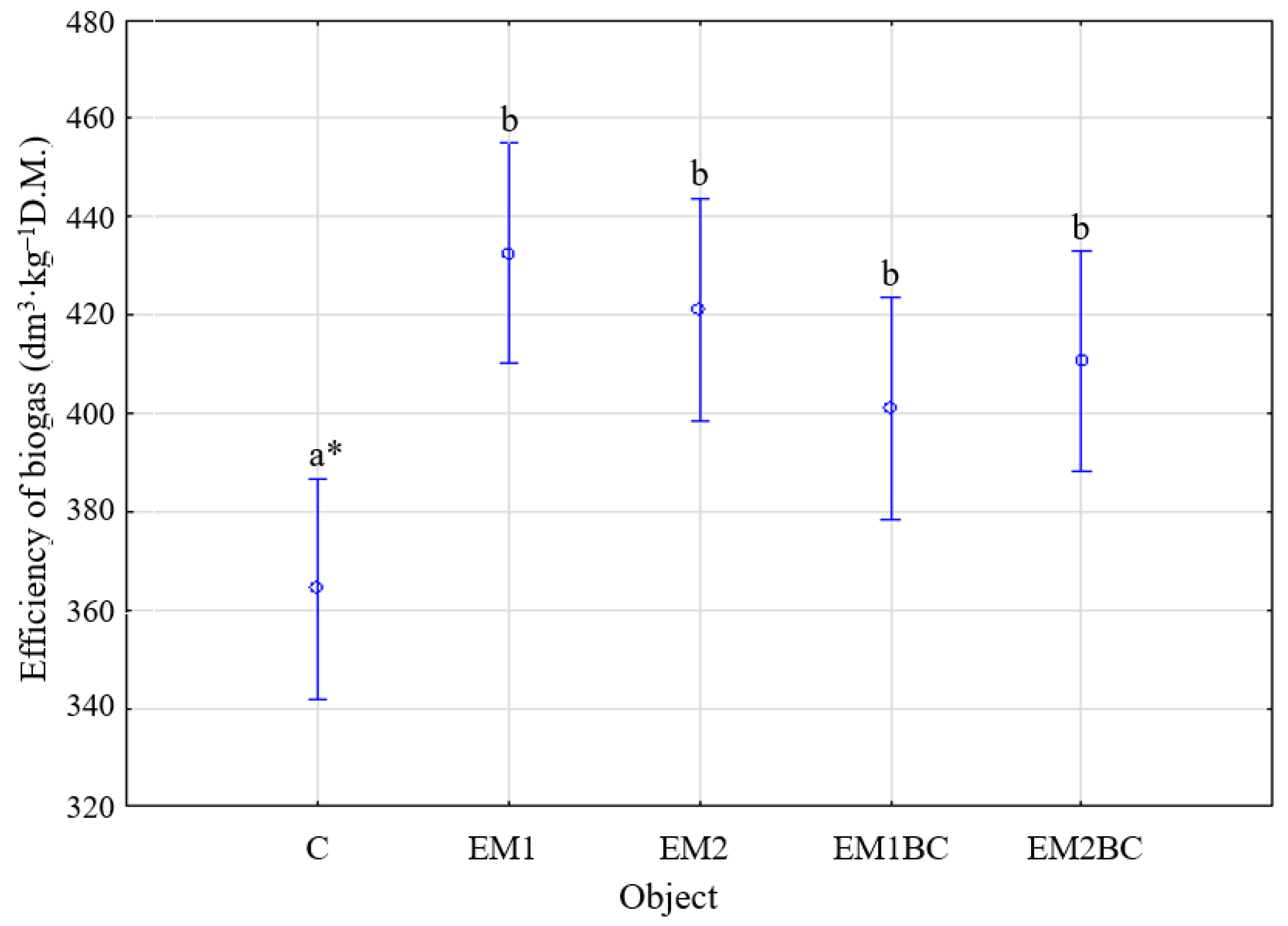

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Talebian-Kiakalaieh, A.; Amin, N.A.S.; Mazaheri, H. A Review on Novel Processes of Biodiesel Production from Waste Cooking Oil. Appl. Energy 2013, 104, 683–710. [Google Scholar] [CrossRef]

- Wan Alwi, S.R.; Klemeš, J.J.; Varbanov, P.S. Cleaner Energy Planning, Management and Technologies: Perspectives of Supply-Demand Side and End-of-Pipe Management. J. Clean. Prod. 2016, 136, 1–13. [Google Scholar] [CrossRef]

- Derehajło, S.; Tymińska, M.; Skibko, Z.; Borusiewicz, A.; Romaniuk, W.; Kuboń, M.; Olech, E.; Koszel, M. Heavy Metal Content in Substrates in Agricultural Biogas Plants. Agric. Eng. 2023, 27, 315–329. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Szeląg-Sikora, A. Evaluation of the Chemical Composition of Raw Common Duckweed (Lemna minor L.) and Pulp after Methane Fermentation. J. Elementol. 2018, 23, 685–695. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Kuboń, M.; Komorowska, M. The Effect of the Addition of a Fat Emulsifier on the Amount and Quality of the Obtained Biogas. Energies 2020, 13, 1825. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, A.K.; Singh, A. Bioconversion of Food Industry Waste to Value Added Products: Current Technological Trends and Prospects. Food Biosci. 2023, 55, 102935. [Google Scholar] [CrossRef]

- Luo, X.; Liu, Y.; Wang, X.; Lei, L.; Shen, J.; Zhang, Q.; Wang, Y.; Ruan, R.; Cui, X. A Co-Ensiling Strategy of Food Wastes: Peanut Shell as an Additive to Distillers’ Grains to Improve Efficiency of Energy Conversion. J. Clean. Prod. 2023, 423, 138710. [Google Scholar] [CrossRef]

- Czekała, W.; Nowak, M.; Bojarski, W. Anaerobic Digestion and Composting as Methods of Bio-Waste Management. Agric. Eng. 2023, 27, 173–186. [Google Scholar] [CrossRef]

- Pitk, P.; Kaparaju, P.; Vilu, R. Methane potential of sterilized solid slaughterhouse wastes. Bioresour. Technol. 2012, 116, 42–46. [Google Scholar] [CrossRef]

- Niemiec, M.; Sikora, J.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Komorowska, M. Assessment of the Possibilities for the Use of Selected Waste in Terms of Biogas Yield and Further Use of Its Digestate in Agriculture. Materials 2022, 15, 988. [Google Scholar] [CrossRef]

- Ragasri, S.R.; Sabumon, P.C. A Critical Review on Slaughterhouse Waste Management and Framing Sustainable Practices in Managing Slaughterhouse Waste in India. J. Environ. Manag. 2023, 327, 116823. [Google Scholar] [CrossRef] [PubMed]

- REPowerEU. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal/repowereu-affordable-secure-and-sustainable-energy-europe_pl (accessed on 29 April 2024).

- Loganath, R.; Senophiyah-Mary, J. Critical Review on the Necessity of Bioelectricity Generation from Slaughterhouse Industry Waste and Wastewater Using Different Anaerobic Digestion Reactors. Renew. Sustain. Energy Rev. 2020, 134, 110360. [Google Scholar] [CrossRef]

- Ashayerizadeh, O.; Dastar, B.; Samadi, F.; Khomeiri, M.; Yamchi, A.; Zerehdaran, S. Study on the Chemical and Microbial Composition and Probiotic Characteristics of Dominant Lactic Acid Bacteria in Fermented Poultry Slaughterhouse Waste. Waste Manag. 2017, 65, 178–185. [Google Scholar] [CrossRef] [PubMed]

- Azarmanesh, R.; Zarghami, M.; Zonoozi, M.; Ghiasinejad, H.; Zhang, Y. Anaerobic Co-Digestion of Sewage Sludge with Other Organic Wastes: A Comprehensive Review Focusing on Selection Criteria, Operational Conditions, and Microbiology. Chem. Eng. J. Adv. 2023, 14, 100453. [Google Scholar] [CrossRef]

- Prasanna Kumar, D.J.; Mishra, R.K.; Chinnam, S.; Binnal, P.; Dwivedi, N. A Comprehensive Study on Anaerobic Digestion of Organic Solid Waste: A Review on Configurations, Operating Parameters, Techno-Economic Analysis and Current Trends. Biotechnol. Notes 2024, 5, 33–49. [Google Scholar] [CrossRef]

- Adhikari, B.B.; Chae, M.; Bressler, D.C. Utilization of Slaughterhouse Waste in Value-Added Applications: Recent Advances in the Development of Wood Adhesives. Polymers 2018, 10, 176. [Google Scholar] [CrossRef] [PubMed]

- Mozhiarasi, V.; Natarajan, T.S. Slaughterhouse and Poultry Wastes: Management Practices, Feedstocks for Renewable Energy Production, and Recovery of Value Added Products. Biomass Convers. Biorefin. 2022, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Franke-Whittle, I.H.; Insam, H. Treatment Alternatives of Slaughterhouse Wastes, and Their Effect on the Inactivation of Different Pathogens: A Review. Crit. Rev. Microbiol. 2013, 39, 139–151. [Google Scholar] [CrossRef] [PubMed]

- Santagata, R.; Viglia, S.; Fiorentino, G.; Liu, G.; Ripa, M. Power Generation from Slaughterhouse Waste Materials. An Emergy Accounting Assessment. J. Clean. Prod. 2019, 223, 536–552. [Google Scholar] [CrossRef]

- Ungureanu, N.; Vladut, V.; Biris, S.-S.; Dincă, M.; Gheorghiță, N. Management of By-Products and Waste from Poultry Meat Industry. In Proceedings of the International Symposium ISB-INMATEH—Agricultural and Mechanical Engineering, Bucharest, Romania, 7 October 2022. [Google Scholar]

- Lorenz, H.; Fischer, P.; Schumacher, B.; Adler, P. Current EU-27 Technical Potential of Organic Waste Streams for Biogas and Energy Production. Waste Manag. 2013, 33, 2434–2448. [Google Scholar] [CrossRef]

- Batista, M.; Goyannes, R.G.C.; Quelhas, O.L.G.; Lima, G.B.A.; Filho, W.L.; Yparraguirre, I.T.R. A Framework for Sustainable and Integrated Municipal Solid Waste Management: Barriers and Critical Factors to Developing Countries. J. Clean. Prod. 2021, 312, 127516. [Google Scholar] [CrossRef]

- Borek, K.; Romaniuk, W.; Roman, K.; Roman, M.; Kuboń, M. The Analysis of a Prototype Installation for Biogas Production from Chosen Agricultural Substrates. Energies 2021, 14, 2132. [Google Scholar] [CrossRef]

- Li, P.; Zhao, H.; Cheng, C.; Hou, T.; Shen, D.; Jiao, Y. A review on anaerobic co-digestion of sewage sludge with other organic wastes for methane production: Mechanism, process, improvement and industrial application. Biomass Bioenergy 2024, 185, 107241. [Google Scholar] [CrossRef]

- Uludag-Demirer, S.; Demirer, G.N. Post-Anaerobic Treatability and Residual Biogas Potential of Digestate. Biomass Convers. Biorefin. 2022, 12, 1695–1702. [Google Scholar] [CrossRef]

- McKendry, P. Energy Production from Biomass (Part 2): Conversion Technologies. Bioresour. Technol. 2002, 83, 47–54. [Google Scholar] [CrossRef]

- Silvestre, G.; Fernández, B.; Bonmatí, A. Significance of Anaerobic Digestion as a Source of Clean Energy in Wastewater Treatment Plants. Energy Convers. Manag. 2015, 101, 255–262. [Google Scholar] [CrossRef]

- Bianco, I.; Panepinto, D.; Zanetti, M. Environmental Impacts of Electricity from Incineration and Gasification: How the LCA Approach Can Affect the Results. Sustainability 2022, 14, 92. [Google Scholar] [CrossRef]

- Malinauskaite, J.; Jouhara, H.; Czajczyńska, D.; Stanchev, P.; Katsou, E.; Rostkowski, P.; Thorne, R.J.; Colón, J.; Ponsá, S.; Al-Mansour, F.; et al. Municipal Solid Waste Management and Waste-to-Energy in the Context of a Circular Economy and Energy Recycling in Europe. Energy 2017, 141, 2013–2044. [Google Scholar] [CrossRef]

- Sharma, R.; Sharma, M.; Sharma, R.; Sharma, V. The Impact of Incinerators on Human Health and Environment. Rev. Environ. Health 2013, 28, 67–72. [Google Scholar] [CrossRef]

- Allsopp, M.; Costner, P.; Johnston, P. Incineration and Human Health. State of Knowledge of the Impacts of Waste Incinerators on Human Health. Environ. Sci. Pollut. Res. Int. 2001, 8, 141–145. [Google Scholar] [CrossRef]

- Kabeyi, M.; Olanrewaju, O. Slaughterhouse Waste to Energy in the Energy Transition with Performance Analysis and Design of Slaughterhouse Biodigestor. J. Energy Manag. Technol. 2022, 6, 188–208. [Google Scholar] [CrossRef]

- Romaniuk, W.; Mazur, K.; Borek, K.; Borusiewicz, A.; Wardal, W.J.; Tabor, S.; Kuboń, M. Biomass Energy Technologies from Innovative Dairy Farming Systems. Processes 2021, 9, 335. [Google Scholar] [CrossRef]

- Nyang’au, J.O.; Møller, H.B.; Sørensen, P. Nitrogen Dynamics and Carbon Sequestration in Soil Following Application of Digestates from One- and Two-Step Anaerobic Digestion. Sci. Total Environ. 2022, 851, 158177. [Google Scholar] [CrossRef]

- Guo, Z.; Usman, M.; Alsareii, S.A.; Harraz, F.A.; Al-Assiri, M.S.; Jalalah, M.; Li, X.; Salama, E.-S. Synergistic Ammonia and Fatty Acids Inhibition of Microbial Communities during Slaughterhouse Waste Digestion for Biogas Production. Bioresour. Technol. 2021, 337, 125383. [Google Scholar] [CrossRef]

- Borowski, S.; Boniecki, P.; Kubacki, P.; Czyżowska, A. Food Waste Co-Digestion with Slaughterhouse Waste and Sewage Sludge: Digestate Conditioning and Supernatant Quality. Waste Manag. 2018, 74, 158–167. [Google Scholar] [CrossRef] [PubMed]

- Reyes, I.P.; Díaz, J.P.; Horváth, I.S. Anaerobic Biodegradation of Solid Substrates from Agroindustrial Activities—Slaughterhouse Wastes and Agrowastes. In Biodegradation and Bioremediation of Polluted Systems—New Advances and Technologies; Chamy, R., Rosenkranz, F., Soler, L., Eds.; IntechOpen: London, UK, 2015; ISBN 978-953-51-2238-8. [Google Scholar]

- Philipp, M.; Ackermann, H.; Barbana, N.; Pluschke, J.; Geißen, S.U. Possibilities for Anaerobic Digestion of Slaughter Waste and Flotates for Biomethane Production. Water 2023, 15, 1818. [Google Scholar] [CrossRef]

- Pagés-Díaz, J.; Pereda-Reyes, I.; Taherzadeh, M.J.; Sárvári-Horváth, I.; Lundin, M. Anaerobic Co-Digestion of Solid Slaughterhouse Wastes with Agro-Residues: Synergistic and Antagonistic Interactions Determined in Batch Digestion Assays. Chem. Eng. J. 2014, 245, 89–98. [Google Scholar] [CrossRef]

- Ning, Z.; Zhang, H.; Li, W.; Zhang, R.; Liu, G.; Chen, C. Anaerobic Digestion of Lipid-Rich Swine Slaughterhouse Waste: Methane Production Performance, Long-Chain Fatty Acids Profile and Predominant Microorganisms. Bioresour. Technol. 2018, 269, 426–433. [Google Scholar] [CrossRef]

- Mutegoa, E.; Malima, N.M.; Hilonga, A.; Njau, K.N. Effect of Mixing Ratios of Natural Inorlatawieganic Additives in Removing Ammonia and Sulfide in the Liquid Phase during Anaerobic Digestion of Slaughterhouse Waste. Mater. Today Chem. 2021, 20, 100415. [Google Scholar] [CrossRef]

- Pornmai, K.; Itsadanont, S.; Lertpattanapong, M.; Seneesrisakul, K.; Jiraprasertwong, A.; Leethochawalit, M.; Sekiguchi, H.; Chavadej, S. Enhancement of Methanogenic Activity by Micronutrient Control: Micronutrient Availability in Relation to Sulfur Transport. J. Environ. Sci. 2023, 127, 738–752. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Zhuang, W.; Liu, J.; Meng, X.; Zhao, X.; Zheng, Z.; Chen, S.; Ying, H.; Cai, Y. Trace Elements’ Deficiency in Energy Production through Methanogenesis Process: Focus on the Characteristics of Organic Solid Wastes. Sci. Total Environ. 2023, 878, 163116. [Google Scholar] [CrossRef] [PubMed]

- DIN 38414-8; Deutsche Einheitsverfahren zur Wasser-, Abwasser- und Schlammuntersuchung; Schlamm und Sedimente (Gruppe S); Bestimmung des Faulverhaltens (S 8) [German Standard Methods for the Examination of Water, Waste Water and Sludge; Sludge And Sediments (Group S); Determination of the Amenability to Anaerobic Digestion (S 8)]. Beuth Verlag: Berlin, Germany, 1985.

- ISO 1443:1973; Meat and Meat Products—Determination of Total Fat Content. International Organization for Standardization: Geneva, Switzerland, 1973.

- PN-ISO 6060:2006; Water Quality—Determination of the Chemical Oxygen Demand. Polish Committee for Standardization: Warsaw, Poland, 2006.

- Guo, Z.; Jalalah, M.; Alsareii, S.A.; Harraz, F.A.; Thakur, N.; Salama, E.-S. Biochar Addition Augmented the Microbial Community and Aided the Digestion of High-Loading Slaughterhouse Waste: Active Enzymes of Bacteria and Archaea. Chemosphere 2022, 309, 136535. [Google Scholar] [CrossRef] [PubMed]

- Ware, A.; Power, N. Biogas from Cattle Slaughterhouse Waste: Energy Recovery towards an Energy Self-Sufficient Industry in Ireland. Renew. Energy 2016, 97, 541–549. [Google Scholar] [CrossRef]

- Almomani, F.; Shawaqfah, M.; Bhosale, R.R.; Kumar, A.; Khraisheh, M.A.M. Intermediate Ozonation to Enhance Biogas Production in Batch and Continuous Systems Using Animal Dung and Agricultural Waste. Int. Biodeterior. Biodegrad. 2017, 119, 176–187. [Google Scholar] [CrossRef]

- Li, H.; Chang, L.; Li, H.; Li, Q.; Wang, Y. Whole-Component Anaerobic Methanogenesis of Pre-Acidized Sludge: Optimal Process and Promotion Mechanisms. Chem. Eng. Sci. 2024, 289, 119871. [Google Scholar] [CrossRef]

- Fava, F.E.; Romanelli, T.L. Biogas and Biomethane Production Routes in the Sugar-Energy Sector: Economic Efficiency and Carbon Footprint. Bioresour. Technol. Rep. 2023, 22, 101388. [Google Scholar] [CrossRef]

- Galván, M.J.; Degano, S.; Cagnolo, M.; Becker, A.; Hilbert, J.; Fuentes, M.; Acevedo, D. Batch Optimization of Biogas Yield from Pasteurized Slaughterhouse By-Products Incorporating Residues from Corn Sieving. Biomass Bioenergy 2021, 151, 106136. [Google Scholar] [CrossRef]

- Zieliński, M.; Dębowski, M.; Krzemieniewski, M. Effect of Method of Post-Slaughter Waste Conditioning on Amount and Composition of Biogas Produced in Thermophilic Fermentation. Annu. Set Environ. Prot. 2011, 12, 895–907. [Google Scholar]

- Sari, Ö.; Özdemir, S.; Celebi, A. Utilization and Management of Poultry Slaughterhouse Wastes with New Methods. In Proceedings of the EurAsia Waste Management Symposium, İstanbul, Turkey, 2–4 May2016; pp. 1–6. [Google Scholar]

- Kazemi-Bonchenari, M.; Alizadeh, A.; Javadi, L.; Zohrevand, M.; Odongo, N.E.; Salem, A.Z.M. Use of Poultry Pre-Cooked Slaughterhouse Waste as Ruminant Feed to Prevent Environmental Pollution. J. Clean. Prod. 2017, 145, 151–156. [Google Scholar] [CrossRef]

- Otero, A.; Mendoza, M.; Carreras, R.; Fernández, B. Biogas Production from Slaughterhouse Waste: Effect of Blood Content and Fat Saponification. Waste Manag. 2021, 133, 119–126. [Google Scholar] [CrossRef]

- Wang, S.; Jena, U.; Das, K.C. Long Term Performance of Pilot Methanogenic Digester Filled with Seashell Wastes Treating Slaughterhouse Wastes: Biogas Production and Environmental Impact. Biochem. Eng. J. 2022, 187, 108651. [Google Scholar] [CrossRef]

- Wang, S.; Hawkins, G.L.; Kiepper, B.H.; Das, K.C. Treatment of Slaughterhouse Blood Waste Using Pilot Scale Two-Stage Anaerobic Digesters for Biogas Production. Renew. Energy 2018, 126, 552–562. [Google Scholar] [CrossRef]

- Li, B.; Ruan, P.; Xu, X.; He, Z.; Zhu, X.; Pan, L.; Peng, Z.; Liu, Y.; Zhou, B.; Lu, B.; et al. Covalent Organic Framework with 3D Ordered Channel and Multi-Functional Groups Endows Zn Anode with Superior Stability. Nano-Micro Lett. 2024, 16, 76. [Google Scholar] [CrossRef] [PubMed]

- Chaikitkaew, S.; Wongfaed, N.; Mamimin, C.; O-Thong, S.; Reungsang, A. Conversion of Carbon Dioxide in Biogas into Acetic Acid by Clostridium thailandense Immobilized on Porous Support Materials. Heliyon 2024, 10, e26378. [Google Scholar] [CrossRef] [PubMed]

- Eftaxias, A.; Diamantis, V.; Aivasidis, A. Anaerobic Digestion of Thermal Pre-Treated Emulsified Slaughterhouse Wastes (TESW): Effect of Trace Element Limitation on Process Efficiency and Sludge Metabolic Properties. Waste Manag. 2018, 76, 357–363. [Google Scholar] [CrossRef]

| Fermentor | Slaughterhouse Waste | Emulsifier 1 | Emulsifier 2 | Biochar |

|---|---|---|---|---|

| Control | + | |||

| EM1 | + | + | ||

| EM2 | + | + | ||

| EM1BC | + | + | + | |

| EM2BC | + | + | + |

| Ca | Cu | Fe | K | Li | Mg | Mn | Mo | P | S | Se |

|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 0.50 | 13.0 | 100 | 0.10 | 120 | 1.00 | 0.07 | 50.0 | 22.0 | 0.01 |

| Parameter | Unit | Batch I | Batch II | Batch III | Mean | RSD % |

|---|---|---|---|---|---|---|

| Dry matter | % DM | 39.31 | 34.19 | 29.53 | 34.34 | 14 |

| Ash | 10.35 | 12.06 | 13.39 | 11.94 | 13 | |

| C | 57.00 | 58.04 | 58.68 | 57.91 | 1 | |

| N | 4.304 | 4.924 | 5.854 | 5.027 | 16 | |

| Fat | 52.32 | 48.55 | 42.91 | 47.93 | 10 | |

| Protein | 24.09 | 30.27 | 34.40 | 29.59 | 18 | |

| Carbohydrates | 14.26 | 15.33 | 15.32 | 17.99 | 6 | |

| Organic matter | 89.65 | 87.94 | 86.61 | 88.06 | 2 | |

| C:N | - | 13.24 | 11.79 | 10.02 | 11.69 | 3 |

| CODgeneral | g O2/kg DM | 1590 | 1527 | 1514 | 1544 | 3 |

| CODD | 132.3 | 141.6 | 317.9 | 197.3 | 53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuboń, M.; Komorowska, M.; Niemiec, M.; Sikora, J.; Szeląg-Sikora, A.; Olech, E.; Molik, E.; Gajda, J. The Impact of Biochar Additives and Fat-Emulsifying Substances on the Efficiency of the Slaughterhouse Waste Biogasing Process. Energies 2024, 17, 3065. https://doi.org/10.3390/en17133065

Kuboń M, Komorowska M, Niemiec M, Sikora J, Szeląg-Sikora A, Olech E, Molik E, Gajda J. The Impact of Biochar Additives and Fat-Emulsifying Substances on the Efficiency of the Slaughterhouse Waste Biogasing Process. Energies. 2024; 17(13):3065. https://doi.org/10.3390/en17133065

Chicago/Turabian StyleKuboń, Maciej, Monika Komorowska, Marcin Niemiec, Jakub Sikora, Anna Szeląg-Sikora, Elżbieta Olech, Edyta Molik, and Jakub Gajda. 2024. "The Impact of Biochar Additives and Fat-Emulsifying Substances on the Efficiency of the Slaughterhouse Waste Biogasing Process" Energies 17, no. 13: 3065. https://doi.org/10.3390/en17133065

APA StyleKuboń, M., Komorowska, M., Niemiec, M., Sikora, J., Szeląg-Sikora, A., Olech, E., Molik, E., & Gajda, J. (2024). The Impact of Biochar Additives and Fat-Emulsifying Substances on the Efficiency of the Slaughterhouse Waste Biogasing Process. Energies, 17(13), 3065. https://doi.org/10.3390/en17133065