Internal Combustion Engines and Carbon-Neutral Fuels: A Perspective on Emission Neutrality in the European Union

Abstract

1. Introduction

2. Electric Motor Devices: Battery Electric Vehicles and Fuel Cell Electric Vehicles

3. Internal Combustion Engines

4. State-of-the-Art of Different Neutral Fuels That Could Be Used to Feed Internal Combustion Engines in Upcoming Transition Decades

4.1. Low Carbon Emission Fuels That Could Potentially Be Used in Current Spark Ignition (SI) Engines

4.2. Low Carbon Emission Fuels That Could Potentially Be Used in Current Compression Ignition (CI) Engines as E-Kerosene or Synthetic Aviation Fuels (SAFs)

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wolf, S.; Teitge, J.; Mielke, J.; Schütze, F.; Jaeger, C. The European Green Deal—More Than Climate Neutrality. Intereconomics 2021, 56, 99–107. [Google Scholar] [CrossRef]

- Bongardt, A.; Francisco Torres, F. The European Green Deal: More than an Exit Strategy to the Pandemic Crisis, a Building Block of a Sustainable European Economic Model. J. Common. Mark. Stud. JCMS 2022, 60, 170–185. [Google Scholar] [CrossRef]

- Filipovic, S.; Lior, N.; Radovanovic, M. The green deal—Just transition and sustainable development goals Nexus. Renew. Sustain. Energy Rev. 2022, 168, 112759. [Google Scholar] [CrossRef]

- Gengnagel, V.; Zimmermann, K. The European Green Deal as a Moonshot–Caring for a Climate-Neutral Yet Prospering Continent? Hist. Soc. Res. 2022, 47, 267–302. [Google Scholar] [CrossRef]

- Sikora, A. European Green Deal—Legal and financial challenges of the climate change. ERA Forum 2021, 21, 681–697. [Google Scholar] [CrossRef]

- Luna, D.; Estevez, R. Optimization of Biodiesel and Biofuel Process. Energies 2022, 15, 5917. [Google Scholar] [CrossRef]

- Ovaere, M.; Proost, S. Cost-effective reduction of fossil energy use in the European transport sector: An assessment of the Fit for 55 Package. Energy Policy 2022, 168, 113085. [Google Scholar] [CrossRef]

- Cifuentes-Faura, J. European Union policies and their role in combating climate change over the years. Air Qual. Atmos. Health 2022, 15, 1333–1340. [Google Scholar] [CrossRef] [PubMed]

- Axsen, J.; Bhardwaj, C.; Crawford, C. Comparing policy pathways to achieve 100% zero-emissions vehicle sales by 2035. Transp. Res. Part D 2022, 112, 103488. [Google Scholar] [CrossRef]

- Zhou, W.; Hagos, D.A.; Stikbakke, S.; Huang, L.; Cheng, X.; Onstein, E. Assessment of the impacts of different policy instruments on achieving the deep decarbonization targets of island energy systems in Norway e The case of Hinnøya. Energy 2022, 246, 123249. [Google Scholar] [CrossRef]

- Schlacke, S.; Wentzien, H.; Thierjung, E.M.; Köster, M. Implementing the EU Climate Law via the ‘Fit for 55′ package. Oxf. Open Energy 2022, 1, oiab002. [Google Scholar] [CrossRef]

- Rosales-Asensio, E.; Segredo-Morales, E.; Gómez-Marín, N.; Pulido-Alonso, A.; Sierra, C. A Techno-Economic Appraisal of Green Diesel Generation through Hydrothermal Liquefaction, Leveraging Residual Resources from Seaweed and Fishing Sectors. Water 2023, 15, 3061. [Google Scholar] [CrossRef]

- Zikri, A.; Aznury, M. Green diesel production from Crude Palm Oil (CPO) using catalytic hydrogenation method. IOP Conf. Ser. Mater. Sci. Eng. 2020, 823, 012026. [Google Scholar] [CrossRef]

- Nikolopoulos, I.; Kordouli, E.; Mourgkogiannis, N.; Karapanagioti, H.K.; Lycourghiotis, A.; Kordulis, C. Valorization of Pyrolyzed Biomass Residues for the Transformation ofWaste Cooking Oil into Green Diesel. Catalysts 2023, 13, 1004. [Google Scholar] [CrossRef]

- Ameen, M.; Azizan, M.T.; Yusup, S.; Ramli, A.; Shahbaz, M.; Aqsha, A. Process optimization of green diesel selectivity and understanding of reaction intermediates. Renew. Energy 2020, 149, 1092–1106. [Google Scholar] [CrossRef]

- Tsiotsias, A.I.; Hafeez, S.; Charisiou, N.K.; Al-Salem, S.M.; Manos, G.; Constantinou, A.; AlKhoori, S.; Sebastian, V.; Hinder, S.J.; Baker, M.A.; et al. Selective catalytic deoxygenation of palm oil to produce green diesel over Ni catalysts supported on ZrO2 and CeO2–ZrO2: Experimental and process simulation modelling studies. Renew. Energy 2023, 206, 582–596. [Google Scholar] [CrossRef]

- Mayorga, M.A.; Cadavid, J.G.; López, C.A.; Suárez, O.Y.; Bonilla, J.A.; Vargas, J.C.; Narvaez, P.C.; Rodríguez, L.I. Selection of Hydrogen Donors for the Production of Renewable Diesel by In Situ Catalytic Deoxygenation of Palm Oil. Chem. Eng. Trans. 2020, 80, 61–66. [Google Scholar] [CrossRef]

- Pelemo, J.; Inambao, F.L.; Onuh, E.I. Potential of Used Cooking Oil as Feedstock for Hydroprocessing into Hydrogenation Derived Renewable Diesel: A Review. Int. J. Eng. Res. Technol. 2020, 13, 500–519. [Google Scholar] [CrossRef]

- Asikin-Mijan, N.; Rosman, N.A.; AbdulKareem-Alsultan, G.; Mastulid, M.S.; Lee, H.V.; Nabihah-Fauzi, N.; Lokmand, I.M.; Alharthi, F.A.; Alghamdi, A.A.; Aisyahi, A.A.; et al. Production of renewable diesel from Jatropha curcas oil via pyrolytic-deoxygenation over various multi-wall carbon nanotube-based catalysts. Process Saf. Environ. Prot. 2020, 142, 336–349. [Google Scholar] [CrossRef]

- Zhang, B.; Wu, J.; Yang, C.; Qiu, Q.; Yan, Q.; Li, R.; Wang, B.; Wu, J.; Ding, Y. Recent Developments in Commercial Processes for Refining Bio-Feedstocks to Renewable Diesel. BioEnergy Res. 2018, 11, 689–702. [Google Scholar] [CrossRef]

- Norouzi, N.; Talebi, S. An overview on the green petroleum production. Chem. Rev. Lett. 2020, 3, 38–52. [Google Scholar] [CrossRef]

- Costa, A.A.F.; Pires, L.H.O.; Padron, D.R.; Balu, A.M.; Filho, G.N.R.; Luque, R.; Nascimento, L.A.S. Recent advances on catalytic deoxygenation of residues for bio-oil production: An overview. Mol. Catal. 2022, 518, 112052. [Google Scholar] [CrossRef]

- Phichitsurathaworn, N.; Simasatitkul, L.; Amornraksa, S.; Anantpinijwatna, A.; Charoensuppanimit, P.; Assabumrungrat, S. Techno-economic analysis of co-production of bio-hydrogenated diesel from palm oil and methanol. Energy Convers. Manag. 2021, 244, 114464. [Google Scholar] [CrossRef]

- Boonrod, B.; Prapainainar, P.; Varabuntoonvit, V.; Sudsakorn, K.; Prapainainar, C. Environmental impact assessment of bio-hydrogenated diesel from hydrogen and co-product of palm oil industry. Int. J. Hydrogen Energy 2021, 46, 10570–10585. [Google Scholar] [CrossRef]

- del Río, J.I.; Pérez, W.; Cardeño, F.; Marín, J.; Ríos, L.A. Pre-hydrogenation stage as a strategy to improve the continuous production of a diesel-like biofuel from palm oil. Renew. Energy 2021, 168, 505–515. [Google Scholar] [CrossRef]

- d’Ambrosio, S.; Mancarella, A.; Manelli, A. Utilization of Hydrotreated Vegetable Oil (HVO) in a Euro 6 Dual-Loop EGR Diesel Engine: Behavior as a Drop-In Fuel and Potentialities along Calibration Parameter Sweeps. Energies 2022, 15, 7202. [Google Scholar] [CrossRef]

- McCaffery, C.; Zhu, H.; Ahmed, C.M.S.; Canchola, A.; Chen, J.Y.; Li, C.; Kent, C.; Johnson, K.C.; Durbin, T.D.; Lin, Y.H.; et al. Effects of hydrogenated vegetable oil (HVO) and HVO/biodiesel blends on the physicochemical and toxicological properties of emissions from an off-road heavy-duty diesel engine. Fuel 2022, 323, 124283. [Google Scholar] [CrossRef]

- Di-Blasio, G.; Ianniello, R.; Beatrice, C. Hydrotreated vegetable oil as enabler for high-efficient and ultra-low emission vehicles in the view of 2030 targets. Fuel 2022, 310, 122206. [Google Scholar] [CrossRef]

- Parravicini, M.; Barro, C.; Boulouchos, K. Experimental characterization of GTL, HVO, and OME based alternative fuels for diesel engines. Fuel 2021, 292, 120177. [Google Scholar] [CrossRef]

- Pélerin, D.; Gaukel, K.; Härtl, M.; Jacob, E.; Wachtmeister, G. Potentials to simplify the engine system using the alternative diesel fuels oxymethylene ether OME1 and OME3−6 on a heavy-duty engine. Fuel 2020, 259, 116231. [Google Scholar] [CrossRef]

- Goeb, D.; Davidovic, M.; Cai, L.; Pancharia, P.; Bode, M.; Jacobs, S.; Beeckmann, J.; Willems, W.; Heufer, K.A.; Pitsch, H. Oxymethylene ether –n -dodecane blend spray combustion: Experimental study and large-eddy simulations. Proc. Combust. Inst. 2021, 38, 3417–3425. [Google Scholar] [CrossRef]

- Gómez, A.; García-Contreras, R.; Soriano, J.A.; Mata, C. Comparative study of the opacity tendency of alternative diesel fuels blended with gasoline. Fuel 2020, 264, 116860. [Google Scholar] [CrossRef]

- Dabi, M.; Saha, U.K. Application potential of vegetable oils as alternative to diesel fuels in compression ignition engines: A review. J. Energy Inst. 2019, 92, 1710–1726. [Google Scholar] [CrossRef]

- Oh, Y.K.; Hwang, K.R.; Kim, C.; Kima, J.R.; Lee, J.S. Recent developments and key barriers to advanced biofuels: A short review. Bioresour. Technol. 2018, 257, 320–333. [Google Scholar] [CrossRef] [PubMed]

- Palage, K.; Lundmark, R.; Söderholm, P. The impact of pilot and demonstration plants on innovation: The case of advanced biofuel patenting in the European Union. Int. J. Prod. Econ. 2019, 210, 42–55. [Google Scholar] [CrossRef]

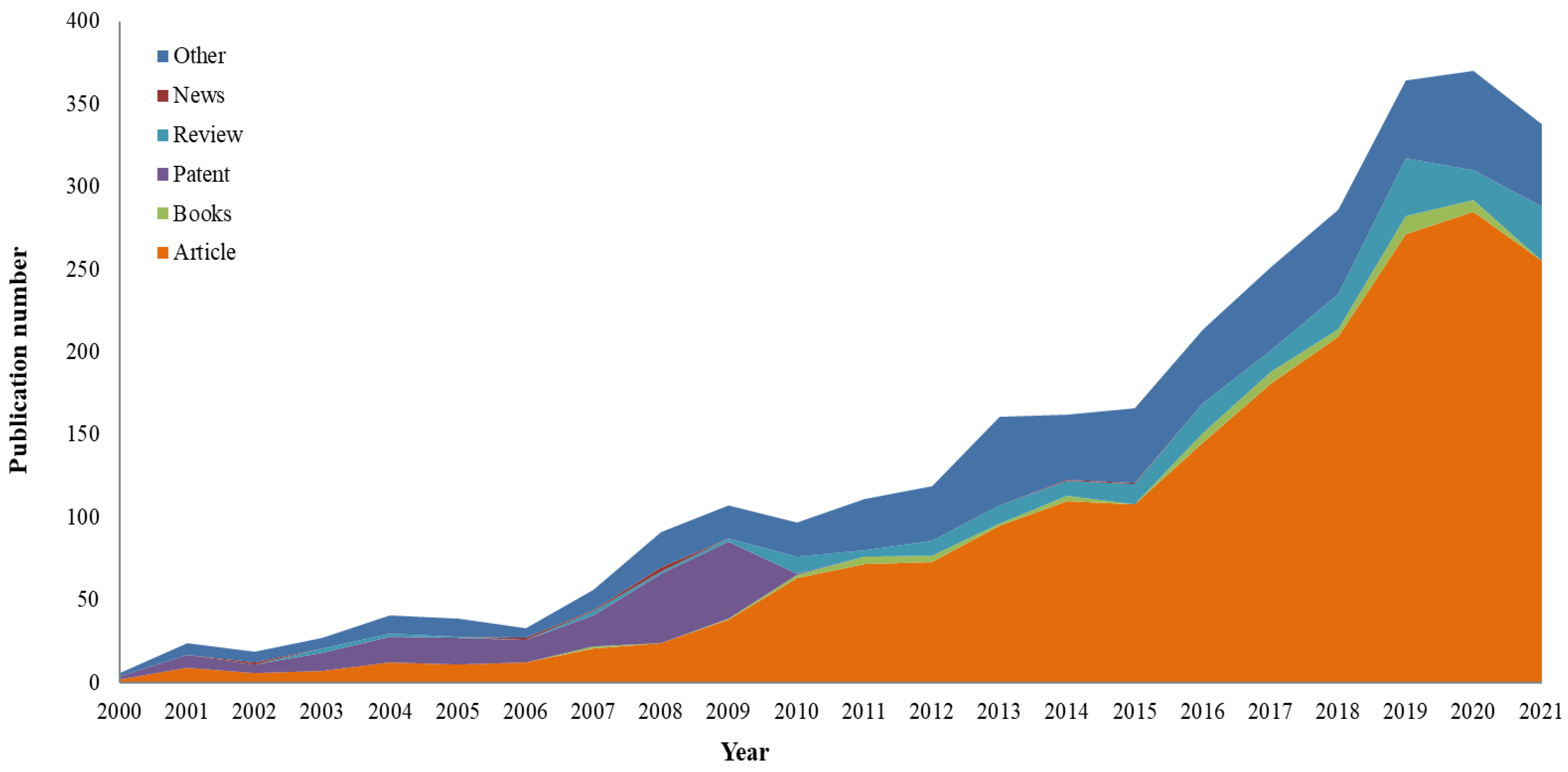

- Estevez, R.; Aguado-Deblas, L.; López-Tenllado, F.J.; Luna, C.; Calero, J.; Romero, A.A.; Bautista, F.M.; Luna, D. Biodiesel is dead: Long life to advanced biofuels. A 2 comprehensive critical review. Energies 2022, 15, 3173. [Google Scholar] [CrossRef]

- Hájek, M.; Vávra, A.; de Paz Carmona, H.; Kocík, J. The Catalysed Transformation of Vegetable Oils or Animal Fats to Biofuels and Bio-Lubricants: A Review. Catalysts 2021, 11, 1118. [Google Scholar] [CrossRef]

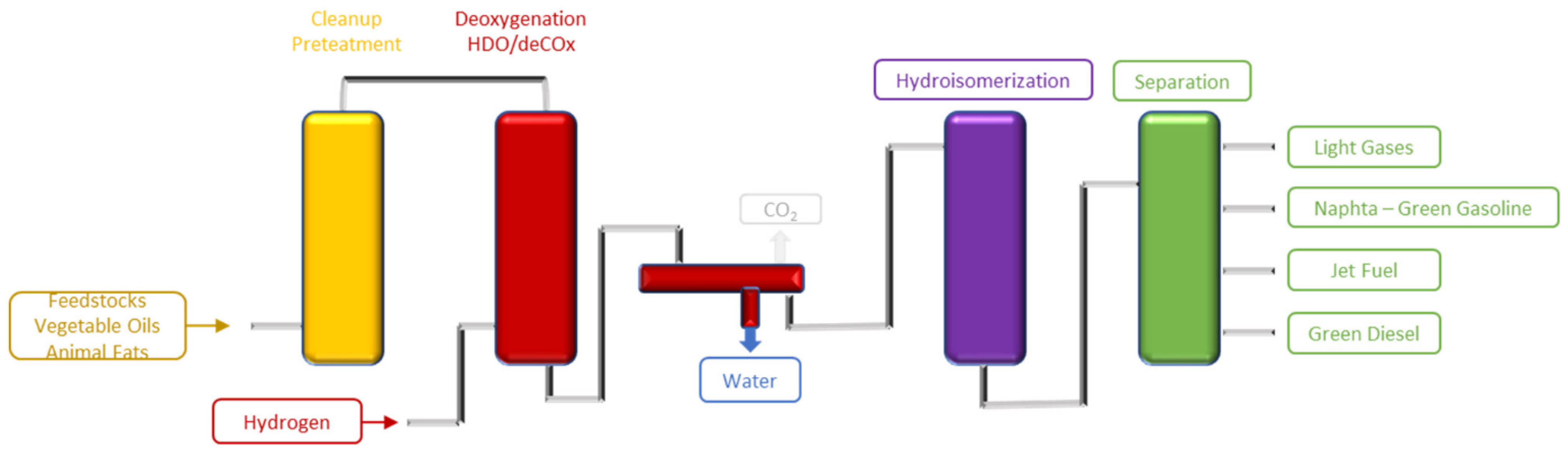

- Douvartzides, S.L.; Charisiou, N.D.; Papageridis, K.N.; Goula, M.A. Green diesel: Biomass feedstocks, production technologies, catalytic research, fuel properties and performance in compression ignition internal combustion engines. Energies 2019, 12, 809. [Google Scholar] [CrossRef]

- de Paz Carmona, H.; Svobodová, E.k.; Tišler, Z.k.; Akhmetzyanova, U.; Strejcová, K.i. Hydrotreating of Atmospheric Gas Oil and Co-Processing with Rapeseed Oil Using Sulfur-Free PMoCx/Al2O3 Catalysts. ACS Omega 2021, 6, 7680–7692. [Google Scholar] [CrossRef]

- Teske, S.; Bratzel, S.; Tellermann, R.; Stephan, B.; Vargas, M. Net Zero: The Remaining Global Market Volume for Internal Combustion Engines in Light-Duty Vehicles under a 1.5 °C Carbon Budget Trajectory. Energies 2022, 15, 8037. [Google Scholar] [CrossRef]

- Reitz, R.D.; Ogawa, H.; Payri, R.; Fansler, T.; Kokjohn, S.; Moriyoshi, Y.; Agarwal, A.K.; Arcoumanis, D.; Assanis, D.; Bae, C.; et al. IJER editorial: The future of the internal combustion engine. Int. J. Engine Res. 2020, 21, 3–10. [Google Scholar] [CrossRef]

- Zhao, F.; Chen, K.; Hao, H.; Liu, Z. Challenges, Potential and Opportunities for Internal Combustion Engines in China. Sustainability 2020, 12, 4955. [Google Scholar] [CrossRef]

- Kalghatgi, G. Is it really the end of internal combustion engines and petroleum in transport? Appl. Energy 2018, 225, 965–974. [Google Scholar] [CrossRef]

- Aklilu, A.Z. Gasoline and diesel demand in the EU: Implications for the 2030 emission goal. Renew. Sustain. Energy Rev. 2020, 118, 109530. [Google Scholar] [CrossRef]

- O’Driscoll, R.; Stettler, M.E.J.; Molden, N.; Oxley, T.; ApSimon, H.M. Real world CO2 and NOx emissions from 149 Euro 5 and 6 diesel, gasoline and hybrid passenger cars. Sci. Total Environ. 2018, 621, 282–290. [Google Scholar] [CrossRef]

- Morgan, C.; Goodwin, J. Impact of the Proposed Euro 7 Regulations on Exhaust Aftertreatment System Design New Euro standards of global importance to the automotive industry. Johns. Matthey Technol. Rev. 2023, 67, 239–245. [Google Scholar] [CrossRef]

- Mulholland, E.; Miller, J.; Bernard, Y.; Lee, K.; Rodríguez, F. The role of NOx emission reductions in Euro 7/VII vehicle emission standards to reduce adverse health impacts in the EU27 through 2050. Transp. Eng. 2022, 9, 100133. [Google Scholar] [CrossRef]

- Rajon-Bernard, M.; Hall, D.; Lutsey, N. Update on Electric Vehicle Uptake in European Cities; ICCT Working Paper; 2021 International Council on Clean Transportation: Budapest, Hungary, 2021. [Google Scholar]

- Aguilar, P.; Groß, B. Battery electric vehicles and fuel cell electric vehicles, an analysis of alternative powertrains as a mean to decarbonize the transport sector. Sustain. Energy Technol. Assess. 2022, 53, 102624. [Google Scholar] [CrossRef]

- Cunanan, C.; Tran, M.K.; Lee, Y.; Kwok, S.; Leung, V.; Fowler, M. A Review of Heavy-Duty Vehicle Powertrain Technologies: Diesel Engine Vehicles, Battery Electric Vehicles, and Hydrogen Fuel Cell Electric Vehicles. Clean. Technol. 2021, 3, 474–489. [Google Scholar] [CrossRef]

- Li, J.; Liang, M.; Cheng, W.; Wang, S. Life cycle cost of conventional, battery electric, and fuel cell electric vehicles considering traffic and environmental policies in China. Int. J. Hydrogen Energy 2021, 46, 9553–9566. [Google Scholar] [CrossRef]

- Verma, S.; Dwivedi, G.; Verma, P. Life cycle assessment of electric vehicles in comparison to combustion engine vehicles: A review. Mater. Today Proc. 2022, 49, 217–222. [Google Scholar] [CrossRef]

- Sinha, P.; Brophy, B. Life cycle assessment of renewable hydrogen for fuel cell passenger vehicles in California. Sustain. Energy Technol. Assess. 2021, 45, 101188. [Google Scholar] [CrossRef]

- Breuer, J.L.; Samsun, R.C.; Stolten, D.; Peters, R. How to reduce the greenhouse gas emissions and air pollution caused by light and heavy-duty vehicles with battery electric, fuel cell-electric and catenary trucks. Environ. Int. 2021, 152, 106474. [Google Scholar] [CrossRef] [PubMed]

- Kosai, S.; Hanqing, L.; Zhang, Z.; Matsubae, K.; Yamasue, E. Multi-regional land disturbances induced by mineral use in a product-based approach: A case study of gasoline, hybrid, battery electric and fuel cell vehicle production in Japan. Resour. Conserv. Recycl. 2022, 178, 106093. [Google Scholar] [CrossRef]

- Tanç, B.; Arat, H.T.; Conker, Ç.; Baltacioglu, E.; Aydin, K. Energy distribution analyses of an additional traction battery on hydrogen fuel cell hybrid electric vehicle. Int. J. Hydrogen Energy 2020, 45, 26344–26356. [Google Scholar] [CrossRef]

- Samsun, R.C.; Antoni, L.; Rex, M.; Stolten, D. Deployment Status of Fuel Cells in Road Transport: 2021 Update; Energie & Umwelt/Energy & Environment: Copenhagen, Denmark, 2021; Volume 542, ISBN 978-3-95806-556-7. Available online: https://juser.fz-juelich.de/record/894093?ln=en (accessed on 29 February 2024).

- van Oorschot, J.; Sprecher, B.; Roelofs, B.; van der Horst, J.; van der Voet, E. Towards a low-carbon and circular economy: Scenarios for metal stocks and flows in the Dutch electricity system. Resour. Conserv. Recycl. 2022, 178, 106105. [Google Scholar] [CrossRef]

- Guo, Y.; Kelly, J.A.; Clinch, J.P. Road transport electrification—Is timing everything? Implications of emissions analysis’ outcomes for climate and air policy. Transp. Res. Interdiscip. Perspect. 2021, 12, 100478. [Google Scholar] [CrossRef]

- Rabiega, W.; Gorzałczyski, A.; Jeszke, R.; Mzyk, P.; Szczepanski, K. How Long Will Combustion Vehicles Be Used? Polish Transport Sector on the Pathway to Climate Neutrality. Energies 2021, 14, 7871. [Google Scholar] [CrossRef]

- Gis, M.; Gis, W. The current state and prospects for hydrogenisation of motor transport in Northwestern Europe and Poland. Combust. Engines 2022, 190, 61–71. [Google Scholar] [CrossRef]

- Schmidt, M.; Zmuda-Trzebiatowski, P.; Kicinski, M.; Sawicki, P.; Lasak, K. Multiple-Criteria-Based Electric Vehicle Charging Infrastructure Design Problem. Energies 2021, 14, 3214. [Google Scholar] [CrossRef]

- Samet, M.J.; Liimatainen, H.; van Vliet, O.P.R.; Pöllänen, M. Road Freight Transport Electrification Potential by Using Battery Electric Trucks in Finland and Switzerland. Energies 2021, 14, 823. [Google Scholar] [CrossRef]

- Afshar, S.; Macedo, P.; Mohamed, F.; Disfani, V. Mobile charging stations for electric vehicles—A review. Renew. Sustain. Energy Rev. 2021, 152, 111654. [Google Scholar] [CrossRef]

- Rose, P.K.; Neumann, F. Hydrogen refueling station networks for heavy-duty vehicles in future power systems. Transp. Res. Part. D Transp. Environ. 2020, 83, 102358. [Google Scholar] [CrossRef]

- Lin, R.H.; Ye, Z.Z.; Wu, B.D. A review of hydrogen station location models. Int. J. Hydrogen Energy 2020, 45, 20176–20183. [Google Scholar] [CrossRef]

- Genovese, M.; Blekhman, D.; Dray, M.; Fragiacomo, P. Hydrogen station in situ back-to-back fueling data for design and modeling. J. Clean. Prod. 2021, 329, 129737. [Google Scholar] [CrossRef]

- Needell, Z.; Wei, W.; Trancik, J.E. Strategies for beneficial electric vehicle charging to reduce peak electricity demand and store solar energy. Cell Rep. Phys. Sci. 2023, 4, 101287. [Google Scholar] [CrossRef]

- Stöck, F.; Schill, W.P.; Zerrahn, A. Optimal supply chains and power sector benefits of green hydrogen. Sci. Rep. 2021, 11, 14191. [Google Scholar] [CrossRef]

- García, A.; Monsalve-Serrano, J.; Villalta, D.; Guzmán-Mendoza, M. Optimization of low carbon fuels operation on a CI engine under a simplified driving cycle for transportation de-fossilization. Fuel 2022, 310, 122338. [Google Scholar] [CrossRef]

- Doppalapudi, A.T.; Azad, A.K.; Khan, M.M.K. Combustion chamber modifications to improve diesel engine performance and reduce emissions: A review. Renew. Sustain. Energy Rev. 2021, 152, 111683. [Google Scholar] [CrossRef]

- Shi, L.; Shu, G.; Tian, H.; Deng, S. A review of modified Organic Rankine cycles (ORCs) for internal combustion engine waste heat recovery (ICE-WHR). Renew. Sustain. Energy Rev. 2018, 92, 95–110. [Google Scholar] [CrossRef]

- Albatayneh, A.; Assaf, M.N.; Alterman, D.; Jaradat, M. Comparison of the Overall Energy Efficiency for Internal Combustion Engine Vehicles and Electric Vehicles. Environ. Clim. Technol. 2020, 24, 669–680. [Google Scholar] [CrossRef]

- Senecal, P.K.; Leach, F. Diversity in transportation: Why a mix of propulsion technologies is the way forward for the future fleet. Results Eng. 2019, 4, 100060. [Google Scholar] [CrossRef]

- Leach, F.; Kalghatgi, G.; Stone, R.; Miles, P. The scope for improving the efficiency and environmental impact of internal combustion engines. Transp. Eng. 2020, 1, 100005. [Google Scholar] [CrossRef]

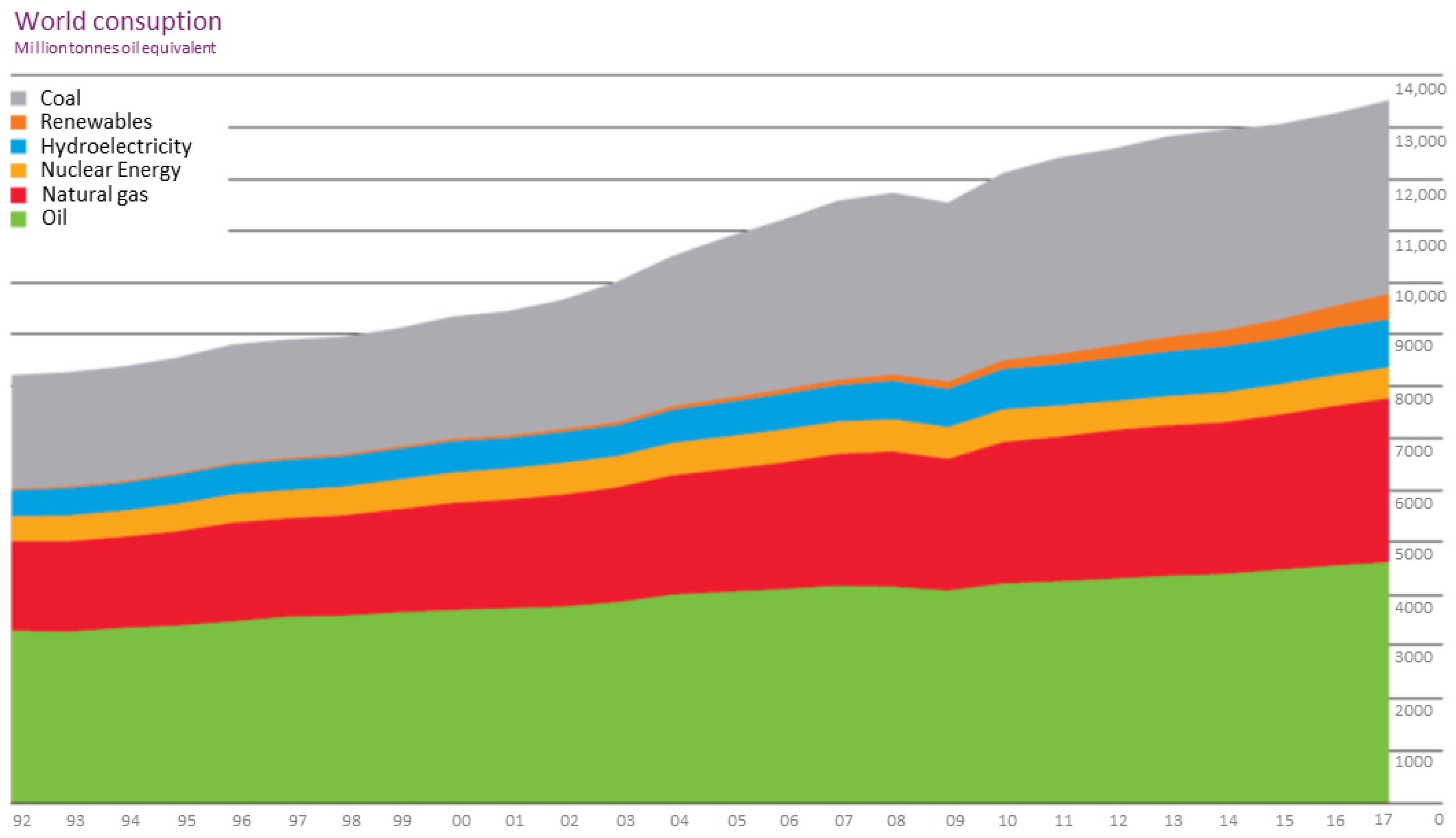

- Tian, J.; Yu, L.; Xue, R.; Zhuang, S.; Shan, Y. Global low-carbon energy transition in the post-COVID-19 era. Appl. Energy 2022, 307, 118205. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Pamminger, M.; Wallner, T. Impact of fuel and engine operating conditions on efficiency of a heavy duty truck engine running compression ignition mode using energy and exergy analysis. Appl. Energy 2019, 254, 113645. [Google Scholar] [CrossRef]

- Ravi, S.S.; Brace, C.; Larkin, C.; Aziz, M.; Leach, F.; Turner, J.W.G. On the pursuit of emissions-free clean mobility—Electric vehicles versus e-fuels. Sci. Total Environ. 2023, 875, 162688. [Google Scholar] [CrossRef] [PubMed]

- Andersson, J.; Grönkvist, S. Large-scale storage of hydrogen. Int. J. Hydrogen Energy 2019, 44, 11901–11919. [Google Scholar] [CrossRef]

- Simon Araya, S.; Liso, V.; Cui, X.; Li, N.; Zhu, J.; Sahlin, S.L.; Jensen, S.H.; Nielsen, M.P.; Kær, S.K. A review of the methanol economy: The fuel cell route. Energies 2020, 13, 596. [Google Scholar] [CrossRef]

- Ren, M.; Zhang, Y.; Wang, X.; Qiu, H. Catalytic Hydrogenation of CO2 to Methanol: A Review. Catalysts 2022, 12, 403. [Google Scholar] [CrossRef]

- Eckert, C.T.; Frigo, E.P.; Albrecht, L.P.; Albrecht, A.J.P.; Christ, D.; Santos, W.G.; Berkembrock, E.; Egewarth, V.A. Maize ethanol production in Brazil: Characteristics and perspectives. Renew. Sustain. Energy Rev. 2018, 82, 3907–3912. [Google Scholar] [CrossRef]

- Wojcieszyk, M.; Knuutila, L.; Kroyan, Y.; Balsemão, M.P.; Tripathi, R.; Keskivali, J.; Karvo, A.; Santasalo-Aarnio, A.; Blomstedt, O.; Larmi, M. Performance of Anisole and Isobutanol as Gasoline Bio-Blendstocks for Spark Ignition Engines. Sustainability 2021, 13, 8729. [Google Scholar] [CrossRef]

- De Luna, P.; Hahn, C.; Higgins, D.; Jaffer, S.A.; Jaramillo, T.F.; Sargent, E.H. What would it take for renewably powered electrosynthesis to displace petrochemical processes? Science 2019, 364, 6438. [Google Scholar] [CrossRef] [PubMed]

- Pleyer, O.; Vrtiška, D.; Straka, P.; Vráblík, A.; Jencík, J.; Šimácek, P. Hydrocracking of a Heavy Vacuum Gas Oil with Fischer–Tropsch Wax. Energies 2020, 13, 5497. [Google Scholar] [CrossRef]

- Swiderski, E.; Stengel, B.; Pinkert, F.; Buchholz, B. Influence of E-fuels on Flame Structures and Combustion Processes of Large Diesel Engines. MTZ Worldw. 2022, 83, 54–61. [Google Scholar] [CrossRef]

- Hunicz, J.; Mikulski, M.; Shukla, P.C.; Geca, M.S. Partially premixed combustion of hydrotreated vegetable oil in a diesel engine: Sensitivity to boost and exhaust gas recirculation. Fuel 2022, 307, 121910. [Google Scholar] [CrossRef]

- Cabrera, E.; Melo de Sousa, J.M. Use of Sustainable Fuels in Aviation—A Review. Energies 2022, 15, 2440. [Google Scholar] [CrossRef]

- Atsonios, K.; Li, J.; Inglezakis, V.J. Process analysis and comparative assessment of advanced thermochemical pathways for e-kerosene production. Energy 2023, 278, 127868. [Google Scholar] [CrossRef]

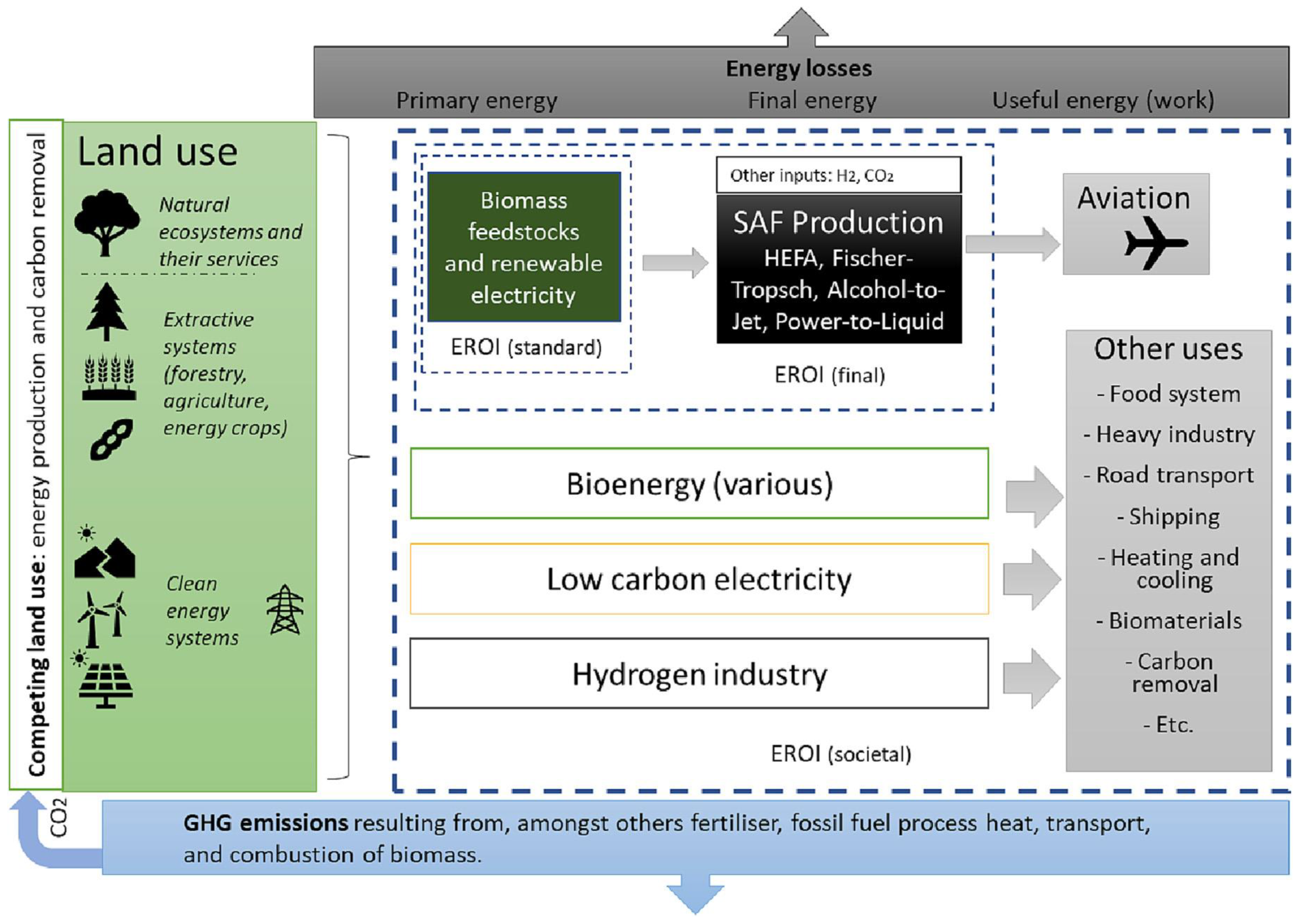

- Becken, S.; Mackey, B.; Lee, D.S. Implications of preferential access to land and clean energy for Sustainable Aviation Fuels. Sci. Total Environ. 2023, 886, 163883. [Google Scholar] [CrossRef]

- Muller-Casseres, E.; Szklo, A.; Fonte, C.; Carvalho, F.; Portugal-Pereira, J.; Baptista, L.B.; Maia, P.; Rochedo, P.R.R.; Draeger, R.; Schaeffer, R. Are there synergies in the decarbonization of aviation and shipping? An integrated perspective for the case of Brazil. iScience 2022, 25, 105248. [Google Scholar] [CrossRef]

- Mukherjee, A.; Bruijnincx, P.; Junginger, M. Techno-economic competitiveness of renewable fuel alternatives in the marine sector. Renew. Sustain. Energy Rev. 2023, 174, 113127. [Google Scholar] [CrossRef]

- Al-Enazi, A.; Okonkwo, E.C.; Bicer, Y.; Al-Ansari, T. A review of cleaner alternative fuels for maritime transportation. Energy Rep. 2021, 7, 1962–1985. [Google Scholar] [CrossRef]

- Teoh, Y.H.; How, H.G.; Le, T.D.; Nguyen, H.T.; Loo, D.L.; Rashid, T.; Sher, F. A review on production and implementation of hydrogen as a green fuel in internal combustion engines. Fuel 2023, 333, 126525. [Google Scholar] [CrossRef]

- Tan, D.; Wu, Y.; Lv, J.; Li, J.; Ou, X.; Meng, Y.; Lan, G.; Chen, Y.; Zhang, Z. Performance optimization of a diesel engine fueled with hydrogen/biodiesel with water addition based on the response surface methodology. Energy 2023, 263, 125869. [Google Scholar] [CrossRef]

- Kurien, C.; Mittal, M. Review on the production and utilization of green ammonia as an alternate fuel in dual-fuel compression ignition engines. Energy Convers. Manag. 2022, 251, 114990. [Google Scholar] [CrossRef]

- Aguado-Deblas, L.; López-Tenllado, F.J.; Luna, D.; Bautista, F.M.; Romero, A.A.; Estevez, R. Advanced Biofuels from ABE (Acetone/Butanol/Ethanol) and Vegetable Oils (Castor or Sunflower Oil) for Using in Triple Blends with Diesel: Evaluation on a Diesel Engine. Materials 2022, 15, 6493. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Estevez, R.; Aguado-Deblas, L.; López-Tenllado, F.J.; Bautista, F.M.; Romero, A.A.; Luna, D. Internal Combustion Engines and Carbon-Neutral Fuels: A Perspective on Emission Neutrality in the European Union. Energies 2024, 17, 1172. https://doi.org/10.3390/en17051172

Estevez R, Aguado-Deblas L, López-Tenllado FJ, Bautista FM, Romero AA, Luna D. Internal Combustion Engines and Carbon-Neutral Fuels: A Perspective on Emission Neutrality in the European Union. Energies. 2024; 17(5):1172. https://doi.org/10.3390/en17051172

Chicago/Turabian StyleEstevez, Rafael, Laura Aguado-Deblas, Francisco J. López-Tenllado, Felipa M. Bautista, Antonio A. Romero, and Diego Luna. 2024. "Internal Combustion Engines and Carbon-Neutral Fuels: A Perspective on Emission Neutrality in the European Union" Energies 17, no. 5: 1172. https://doi.org/10.3390/en17051172

APA StyleEstevez, R., Aguado-Deblas, L., López-Tenllado, F. J., Bautista, F. M., Romero, A. A., & Luna, D. (2024). Internal Combustion Engines and Carbon-Neutral Fuels: A Perspective on Emission Neutrality in the European Union. Energies, 17(5), 1172. https://doi.org/10.3390/en17051172