1. Introduction

In response to the environmental problems caused by global climate change, the Paris Agreement aims to reduce greenhouse gas emissions to near zero by the end of the century in order to keep temperature increases below 1.5 °C [

1]. According to data published by the Intergovernmental Panel on Climate Change in 2018, the transport sector accounts for 23% of total global greenhouse gas emissions [

2]. Greenhouse gas emissions of road transportation accounted for 72.06% of the greenhouse gas emissions of the entire transportation sector, and the diesel engine is still the most widely used road transportation means [

3]. In addition, fuel consumption is an important indicator of motor vehicles in terms of their economy, technical condition, and exhaust gas emissions, and it requires careful monitoring. The intensification of energy consumption and the urgent need for environmental protection have prompted the upgrading of traditional diesel engine technology to meet the requirements of efficient and clean combustion.

Extensive research has been conducted, and various innovations have been made, ranging from combustion modes to mixed combustion technologies, to further improve the ITEg of diesel engines. In terms of combustion theory, the pursuit of in-cylinder homogeneous charge combustion became a key research direction for internal combustion engines following the proposal of the homogeneous charge compression ignition combustion mode [

4]. Afterward, the premixed charge compression ignition combustion mode promoted the development of diesel engine combustion technology. However, this combustion mode still had some difficulties, such as high pressure rise rate and limited load expansion [

5]. Under heavy load conditions, heavy-duty diesel engines predominantly use diffusion combustion. The large cycle fuel injection quantity and slow combustion rate—typical of heavy load conditions—limit thermal efficiency. Enhancing the air–fuel mixing rate throughout the combustion process of a diesel engine will improve fuel economy and reduce CO

2 emissions. Researchers have made significant progress in the development of diesel engine high-mixing-rate combustion technology [

6,

7]. The most notable achievements have been the advancement of fuel injection systems, which evolved from initial mechanical systems to the currently widespread high-pressure common rail fuel injection systems, with injection pressures of up to 200 MPa. In recent years, to comply with increasingly stringent emission regulations and fuel consumption standards, diesel engine companies have opted to further increase fuel injection pressure. Mainstream fuel system suppliers, such as Bosch in Germany, Delphi in America, and Denso in Japan, have introduced ultra-high-pressure common rail fuel injection systems, with rail pressures reaching 200–300 MPa, a feat yet to be matched in China.

Scholars have conducted extensive research on combustion chamber systems and fuel injection systems. Through researching the impact of various compression ratios on engine thermal efficiency, Liu et al. [

8] discovered that there is a certain positive correlation between the compression ratio and the improvement in thermal efficiency. However, due to the increase in heat transfer losses, there is an upper limit to the improvement in thermal efficiency. Additionally, they found that, as the compression ratio increases, the optimal excess air coefficient tends to increase, reaching its peak efficiency at higher compression ratios [

9]. In addition, the combustion chamber shape affects the in-cylinder airflow motion and the air–fuel mixing development process. Lee et al. [

10] reported that when the combustion chamber adopted a structure with a curved center boss, the swirl intensity was strengthened, and the ITEg was increased. Proper combustion chamber shape optimization could improve the airflow motion conditions within a cylinder, enhance spatial usage, and accelerate the air–fuel mixing process [

11]. The fuel injection system parameters determine the initial momentum of fuel injection and the subsequent process of breakup and evaporation. The parameters of the fuel injection system determine the initial fuel injection momentum and the subsequent fragmentation and entrainment process. Jin [

12] and others studied the impact of nozzle structure on spray characteristics under ultra-high injection pressures of 100–300 MPa. They found that ultra-high-pressure injection increases the spray penetration distance and the spray area, which not only improves the fuel–air mixing process but also leads to increased flow instability at the nozzle. The increase in fuel injection pressure enhances the speed of radial air entrainment at the initial stage of fuel injection, which increases the spray development angle and significantly improves the fuel–air mixing rate [

13,

14]. The mixing energy of diesel engine combustion systems primarily comes from high-pressure fuel injection. Typically, after the end of injection, there is usually a noticeable drop in the mixing energy inside the cylinder, leading to deteriorated residual fuel mixing rates. Kamimoto et al. [

15] proposed a diesel engine combustion system with an air cell in the 1980s. This system uses the pressure difference between the air cell and the main combustion chamber to inject fresh air into the main combustion chamber during the expansion stroke, increasing the partial pressure of oxygen around the soot and promoting soot oxidation. Researchers at Toyota, including Nagano [

16], developed a spring-accumulated type air-jet generator based on this concept, which uses a spring mechanism to accumulate the kinetic energy of air movement during the compression process and release the kinetic energy as high-speed air jets during the late stage of combustion. With a limited pressure difference, the maximum jet speed can reach 300 m/s. Furthermore, experimental results indicate that this device can reduce soot emissions by 50%. Reitz and Foster [

17,

18] from the University of Wisconsin proposed an auxiliary gas injection system that uses external high-pressure nitrogen gas to generate jet disturbances. The high-pressure nitrogen gas jet affects the in-cylinder combustion process via gas cooling and enhanced mixing. This system can simultaneously reduce NOx and soot emissions. Konno et al. from Hokkaido University [

19,

20] developed the combustion chamber for a disturbance diesel combustion system, in which a small amount of fuel is injected into a separate chamber during the main combustion chamber’s burning process. The resulting strong turbulent jet flow enhances the mixing of air and fuel in the main combustion chamber during the late stage of combustion. Their experimental results show that this system significantly reduces soot emissions across all operating conditions without increasing NOx emissions.

The aforementioned research findings demonstrate that seeking additional mixing energy to intervene in the fuel–air mixing process within the main combustion chamber can effectively solve the problems of slow fuel–air mixing rates and high soot emissions in the late stage of combustion. To minimize reliance on foreign engine technology, engine manufacturing costs, and mechanical losses in engines, we explored new combustion modes based on jet disturbance technology under high load conditions and using the common rail fuel systems available in the Chinese market to enhance the fuel economy and reduced CO2 emissions from medium- and heavy-duty truck diesel engines.

2. Design and Construction of Jet Disturbance Combustion System and Research Platform

The diesel engine jet disturbance combustion system developed in this study mainly consisted of a main combustion chamber, a disturbance chamber, and jet channels. The main combustion and disturbance chambers were equipped with primary and auxiliary fuel injectors. The design objective of this separated fuel system layout was to reduce the technical demands on the fuel injection rate for high-power diesel engines, which is advantageous for improving fuel atomization and mixing quality under high fuel injection conditions. During the mid-to-late stage of combustion in the main chamber, the auxiliary injector injects a small amount of fuel into the disturbance chamber, and rapid combustion occurs inside the disturbance chamber, forming a higher pressure potential energy. Driven by the pressure difference, high-speed jets create intense axial and circumferential compound motion in the main combustion chamber, generating large-scale disturbances and several small-scale vortices; this enhances the fuel–air mixing process in the main combustion chamber and increases the fuel heat release rate and the combustion completion, all of which contribute to achieving near-homogeneous diesel combustion.

To determine the specific arrangement of the disturbance chamber system, devising the shape and volume range of the disturbance chamber is necessary. First, the volume ratio of the disturbance chamber to the main combustion chamber must be established:

where

VDisturbance is the volume of the disturbance chamber, and

VClearance is the clearance volume of the original engine. Research on various independent chamber combustion systems has shown that the independent chamber volume ratio varies widely (1–40%) [

21,

22,

23]. Herein, the design requirement for the volume of the disturbance chamber was that the diesel fuel injected into the chamber must burn quickly and completely, and the volume of the chamber must be as small as possible to ensure rapid pressure buildup inside the chamber. Taking a full load condition with a cycle fuel injection quantity of 200 mg as an example, we assessed the required volume of the disturbance chamber for rapid fuel combustion. Assuming that the fuel injection in the disturbance chamber accounts for 5% (10 mg/cyc) of the total fuel injection quantity, under 50 kg/m

3 charge density, a disturbance chamber volume of 0.003–0.0075 L can maintain a global equivalence ratio in the range of 0.4~0.5 inside disturbance chamber. This corresponds to a disturbance chamber volume ratio of 3.5–8%. Disturbance chambers are often spherical, conical, or cylindrical [

24,

25,

26]. Spherical chambers have the smallest surface area under equal volume conditions, which is conducive to reducing heat transfer loss. However, in this study, the use of a spherical disturbance chamber would increase manufacturing complexity and limit layout options. Research by Wolff et al. [

27] indicated that cylindrical disturbance chambers are more conducive to organizing uniform mixtures and have less combustion fluctuation than conical chambers. Therefore, the shape of the disturbance chamber was chosen to be cylindrical. Based on the volume and shape of the disturbance chamber, the layout of the chamber can be determined.

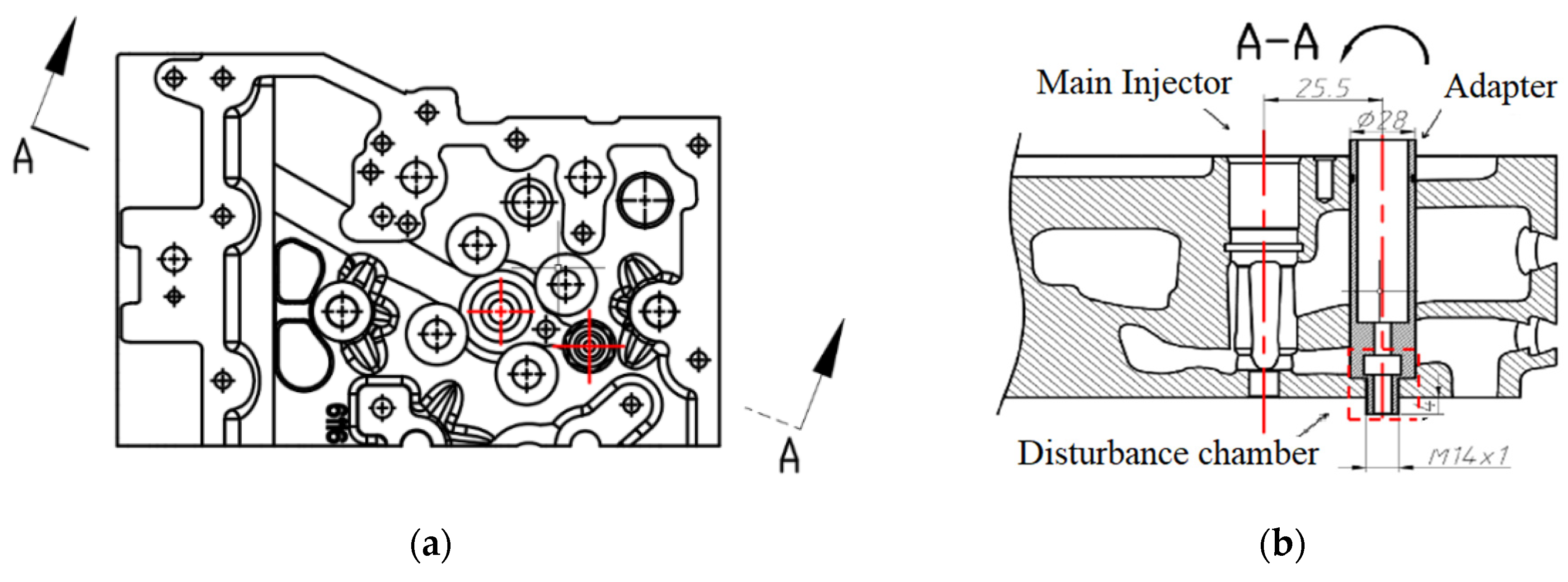

Figure 1a shows the assembly relationship between the disturbance chamber adapter and the engine cylinder head. Notably, the disturbance chamber extended downward by 4 mm, so the bottom of the chamber sunk below the bottom surface of the cylinder head into the main combustion chamber (

Figure 1b). Transitioning the jet channel outlet from the bottom to the side of the disturbance chamber kept the unconstrained jets flowing in the intended direction. The original engine piston needed to be machined such that the upward movement of the piston would not cause a collision with the disturbance chamber.

The volume of the disturbance chamber, which was only 3.5–8% of the clearance volume, would inevitably lead to fuel wall impingement; therefore, optimizing the geometric structure of the disturbance chamber was necessary. Using the CONVERGE software, simulations were performed for different disturbance chamber models.

Figure 2 presents the formation process of the mixture located at the central longitudinal section of the disturbance chamber with different upper space heights. Increasing the volume of the chamber by increasing the height of the upper space slightly raised the relative position of the spray wall impingement, thereby prolonging the duration of time for which fuel flowed along the wall and making the gas flow state in the upper space more complex. Compared with the airflow movement primarily driven by spray entrainment when the upper space height was 10 mm, the airflow movement contained multiple vortices of different scales when the upper space height was 30 and 40 mm. Observing the distribution of the mixture in the disturbance chamber revealed that the distribution of residual exhaust gas post-combustion was greatly influenced by the upper space height. When the upper space height was 10 mm, the residual fuel was mainly concentrated in the dead corner area at the top of the upper space, and the unburned fuel showed no downward trend. As the height of the upper space increased, the residual mixture concentrated in the weaker flow disturbance areas, i.e., the middle of the upper space and the bottom dead corner. However, the mixture in these areas could easily enter the main combustion chamber because of the pressure difference caused by the downward movement of the piston. This is beneficial for reducing the residual mixture in the disturbance chamber in the next cycle and lowering the overall UHC and CO emissions of the engine.

Figure 3a shows the heat release conditions inside the disturbance chamber corresponding to different upper space heights. As the height of the upper space increased, combustion initiation was delayed, and the peak heat release rate increased. Considering the cumulative heat release, greater upper space heights led to a higher combustion completion inside the chamber. Statistics on carbon-containing substances entering the main combustion chamber through the spray channel reveal that the gases flowing into the main combustion chamber primarily consisted of the intermediate products CO and C

3H

7, with CO > 50%. Therefore, the combustion completion inside the disturbance chamber could be determined by the mass of CO entering the main combustion chamber (

Figure 3b). When the upper space height was 10 mm, a large amount of CO entered the main combustion chamber, indicating a low energy utilization rate inside the disturbance chamber. When the height was increased to 20 mm, the CO outflow decreased by 90%, and at a height of 30 mm, most fuel achieved complete combustion inside the chamber. Increasing the height of the upper space of the disturbance chamber extended the duration of fuel and air mixing, enhancing internal airflow movement and increasing the combustion completion. This is advantageous for increasing the overall energy of the disturbance chamber jet. However, excessively large disturbance chamber heights can compromise the overall compression ratio of the engine and affect the rapid buildup of internal pressure. Therefore, the selection of the upper space height of the disturbance chamber should balance the internal combustion quality and compression ratio of the engine.

The auxiliary injector controls the fuel flow and injection timing into the disturbance chamber, and the related parameters, along with the geometric structure of the disturbance chamber, determine the fuel developmental path and the subsequent formation and combustion of the mixture inside the chamber. To achieve a reasonable distribution of fuel in the disturbance chamber and a high-quality internal combustion process, the nozzle diameter, the number of holes, and the angle between the holes of the auxiliary injector were optimized. Because of article length constraints, details of the optimization are not included. The optimized auxiliary injector had five nozzles, each with 0.17 mm diameter and 110 deg inter-nozzle angle.

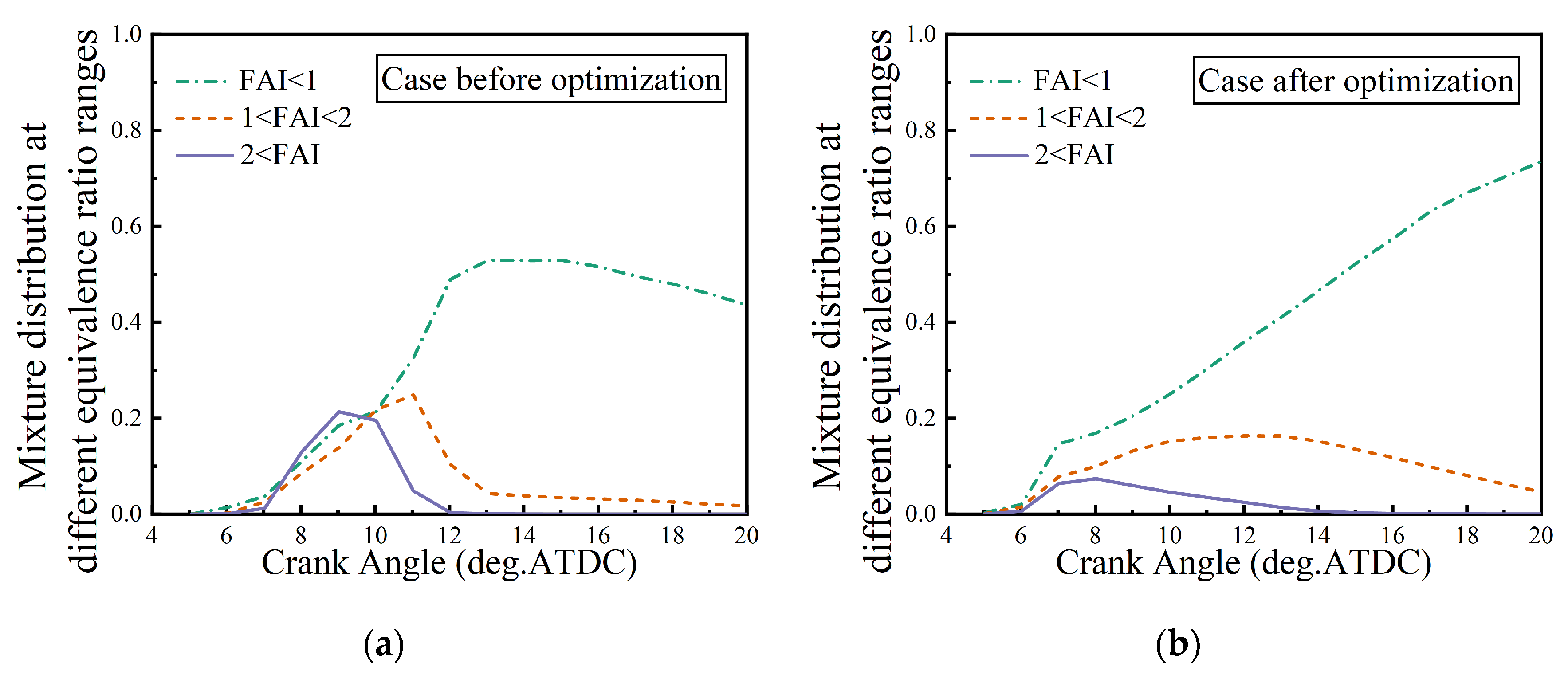

Figure 4 shows the instantaneous heat release rate and the cumulative heat release inside the disturbance chamber before and after optimization. The peak heat release rate increased from 86 J/deg to 269 J/deg, the cumulative heat release increased by 112 J, and the timing of jet occurrence advanced by 1 deg. As shown in the distribution characteristics of the mixture at different equivalence ratio ranges inside the disturbance chamber before and after optimization in

Figure 5, the mixing of fuel and air during the rapid heat release phase was significantly enhanced after optimization. The dilution rate of the rich mixture inside the disturbance chamber increased, and the peak proportions of mixtures with Φ > 2 and 1 < Φ < 2 were reduced. Furthermore, the proportion of fuel-containing gases during the late stages of combustion significantly increased, enhancing the air utilization efficiency inside the disturbance chamber. The optimized disturbance chamber system extended the retention time of the mixture inside the chamber, which increased the combustion completion inside the disturbance chamber.

Figure 6 displays the development of high-speed jets inside the main combustion chamber before and after optimization. To observe the development of high-speed jets, the simulation excluded fuel injection in the main combustion chamber. The number of jet channels of the disturbance chamber was set to two, with 30 and 16 deg inter-channel and injection angles, respectively. In

Figure 6, the three velocity isosurfaces are represented at 50 (blue), 100 (yellow), and 200 m/s (red). Before optimization, jet development only lasted until 15 deg.ATDC, after which there were no strong momentum jets present in the main combustion chamber. After optimization, the development speed of the jet inside the main combustion chamber was significantly faster. At 10 deg after the top dead center, the jet reached the piston center protrusion, and by 13 deg.ATDC, it approached the opposite wall. The jet continued to develop forward until it hit the opposite wall at 50 m/s, resulting in the jet-wall rebound phenomenon. Considering the interference effect of the main fuel spray on the development of the disturbance chamber jet, the optimized disturbance chamber system can disturb more fuel sprays in the cylinder, which speeds up the fuel–air mixing process in the main combustion chamber.

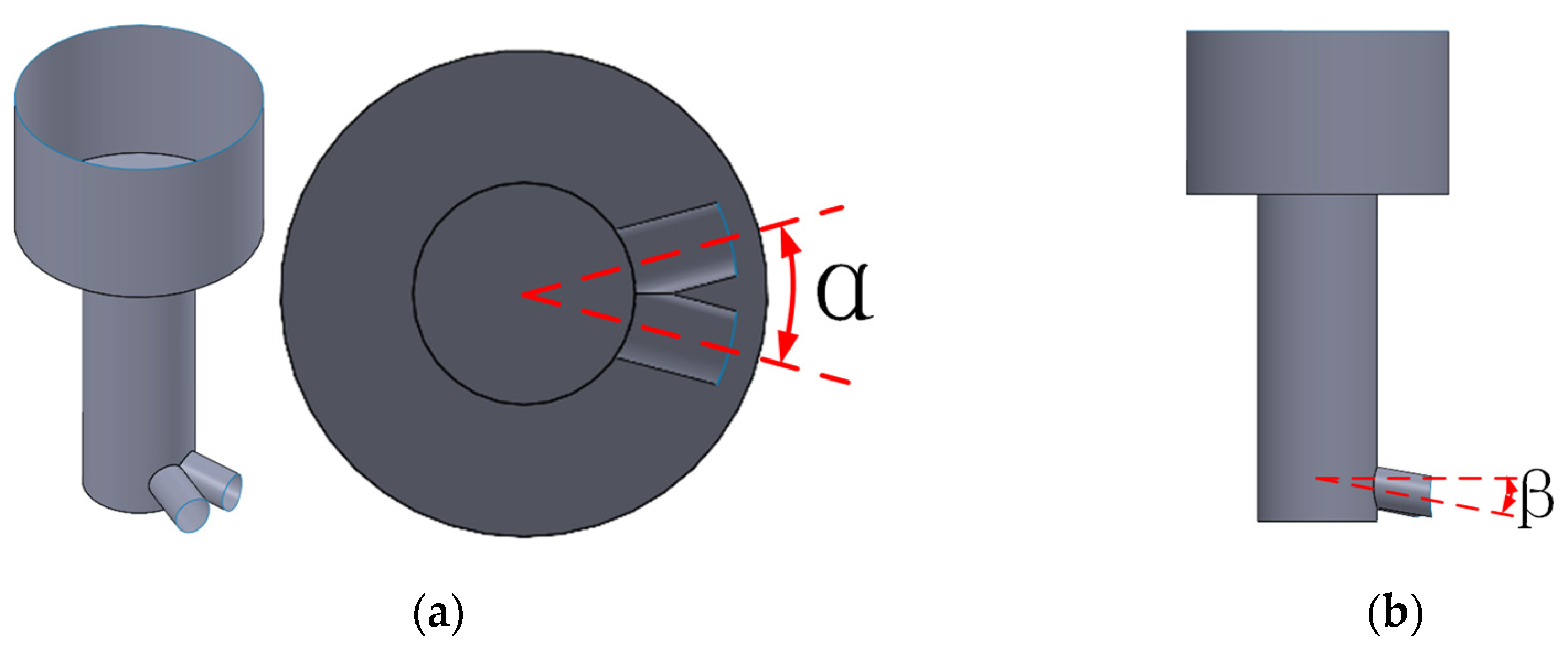

To better utilize jet energy for improving the fuel–air mixing process inside the main combustion chamber, designing and optimizing the developmental path of the disturbance chamber jet was necessary. The goal was to ensure that the jet covers as many fuel sprays as possible and accurately disturbs the target mixture, thereby enhancing the overall fuel mixing rate. Our research group previously conducted studies on a three-channel structure for the disturbance chamber. The simulation results showed that the central jet could significantly improve the mixing quality of the opposing fuel sprays. However, the disturbance range was limited to a single opposing fuel spray, and the momentum of the two lateral jets was weakened, thereby reducing the effective disturbance area of high-speed jets. Overall, the jet disturbance effect of the three-channel structure was not as good as that of a dual-channel structure. Herein, to optimize the jet channel angles based on the dual-channel structure, we divided the jet channel angles along the X and Z axes to obtain the inter-channel α angle and channel incidence

β angle, respectively (

Figure 7). The inter-channel

α angle was defined as the horizontal angle between the axes of the two channels. The channel incidence

β angle was defined as the angle between the axis of a single channel and the horizontal direction. Keeping other boundary conditions and parameters constant, we considered four inter-channel

α angles (30, 60, 90, and 110 deg) and three channel incidence

β angles (0, 10, and 20 deg), resulting in twelve simulation models. Through numerical simulation, we investigated the effects of the disturbance chamber jet channel angles on the jet developmental path and the disturbance effect on the mixture.

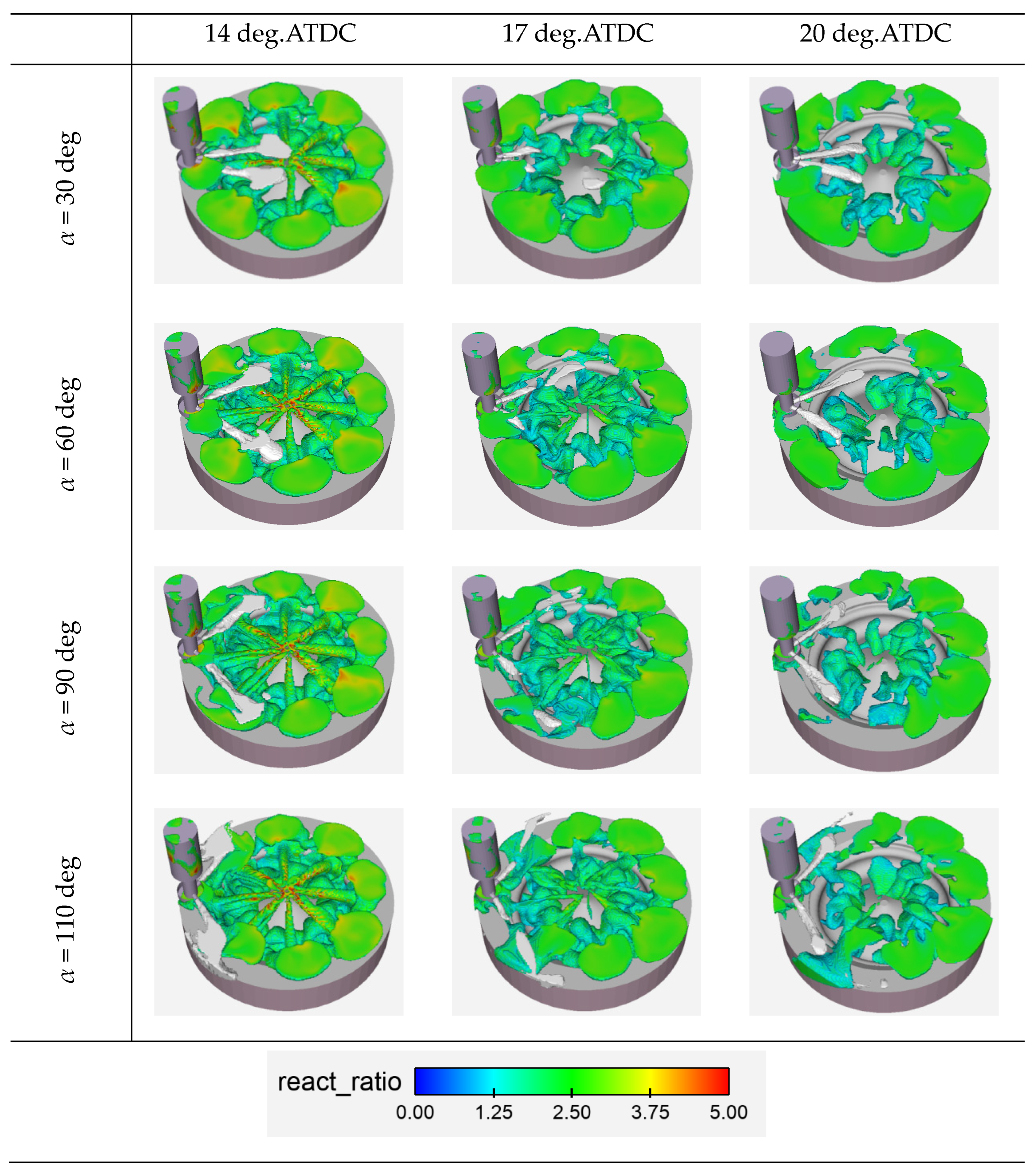

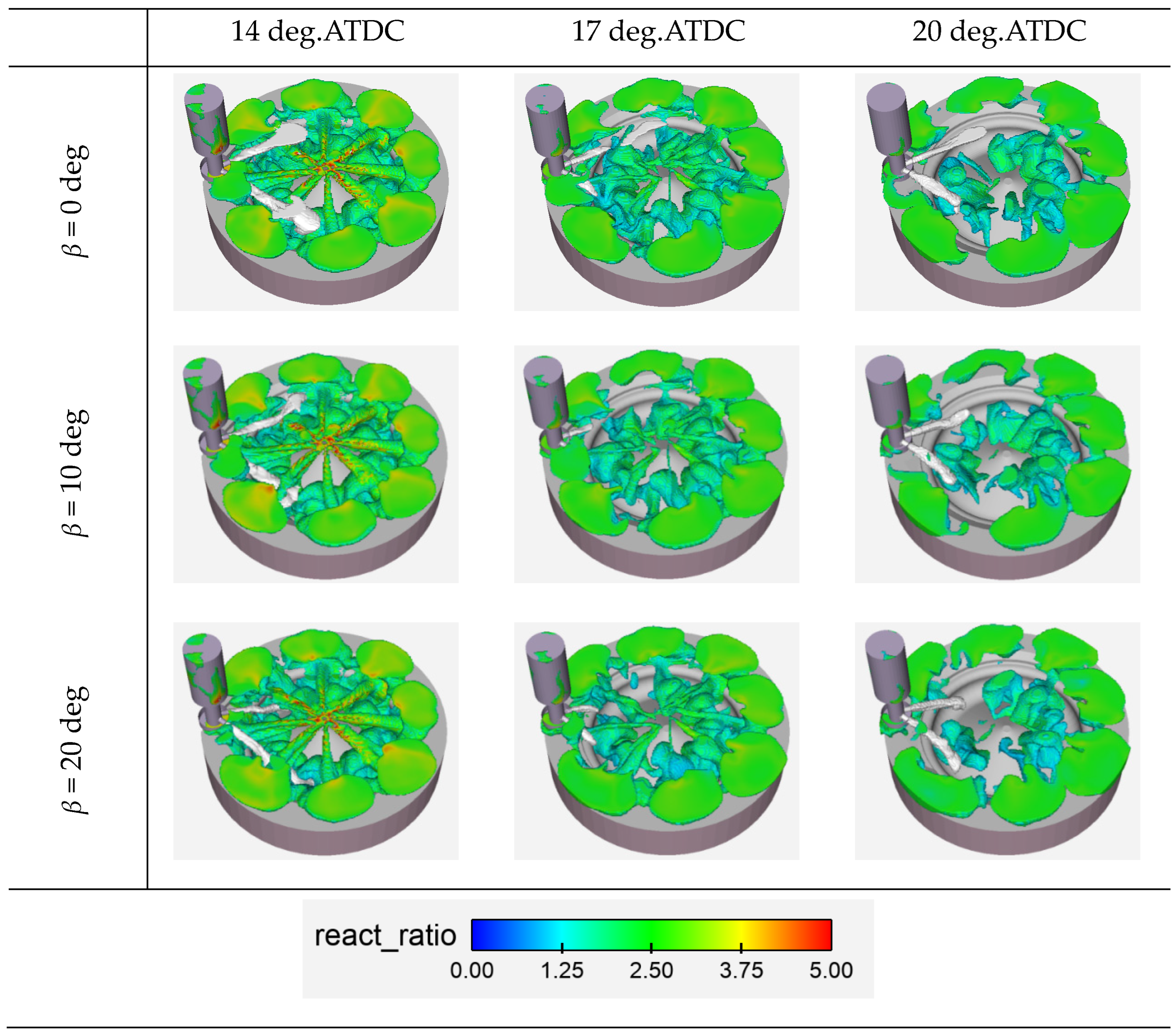

Figure 8 shows the effects of the inter-channel

α angle on the equivalence ratio distribution and jet development in the main combustion chamber, with the channel incidence

β angle fixed at 0 deg. In the figure, the white areas represent isosurfaces of velocities >80 m/s. When

α was 30 deg, the high-speed jet development area was closer to the center of the main combustion chamber. However, its impact on the fuel near the piston edges, particularly in the piston squish area, was very limited. At 20 deg.ATDC, the fuel was predominantly concentrated in the piston bowl and the top squish area, indicating that the high-speed jet had no significant disturbance effect on the freely developing spray end and the wall-wetted fuel. When

α was 110 deg, the high-speed jet effectively disturbed the residual fuel near the squish area of the entire half cylinder near the disturbance chamber, but it failed to effectively disturb the crucial fuel inside the piston bowl. Furthermore, setting

α to 110 deg restricted the overall length of high-speed jet development, significantly reducing the area of jet disturbance and leading to jet energy waste. Selecting an inter-channel angle of either 60 or 90 deg was more reasonable. Under these conditions, the high-speed jet can effectively disturbed the wall-wetted fuel in the half of the cylinder near the disturbance chamber and the residual fuel in the half of the cylinder far from the disturbance chamber. The jet could effectively disturb six or more fuel sprays. Additionally, because there was minimal interference from the piston walls on their developmental path, a high-speed jet could fully develop, allowing for the optimal utilization of jet energy; this significantly reduced the volume of residual fuel during the late stage of combustion, thus positively impacting the overall combustion heat release rate.

As evident from the aforementioned simulation results, when

β fixed at 0 deg, the development path of the high-speed jet was closer to the bottom surface of the cylinder head, which is inconsistent with the that of the main combustion chamber fuel spray; therefore, it impacted the disturbance effect on the mixture in the middle and late stages of spray-free development.

Figure 9 shows the impact of changing

β, with

α fixed at 60 deg, on the equivalence ratio distribution and jet development inside the main combustion chamber. Increasing the channel incidence angle caused the jet to develop forward while moving close to the piston bottom.

This prevented the jet from spreading along the bottom surface of the cylinder head, which reduced the momentum loss due to collisions with the cylinder walls during jet development and allowed the high-speed jet to disturb fuel sprays. These results were observed from the mixture distribution in the late stage of combustion (20 deg.ATDC) because the rich mixture in the piston bowl was noticeably reduced. Additionally, changing the channel incidence angle impacted the mixing effect on the fuel at the far end of the free development of the jet. When β was increased to 10 deg, the jet could reach the far end of the piston bowl, aiding the mixing process of the wall-wetted fuel at the far end. However, when the incidence angle was too large (β = 20 deg), the jet prematurely contacted the piston bottom, restricting its development toward the far end and adversely affecting the mixing process of the fuel there.

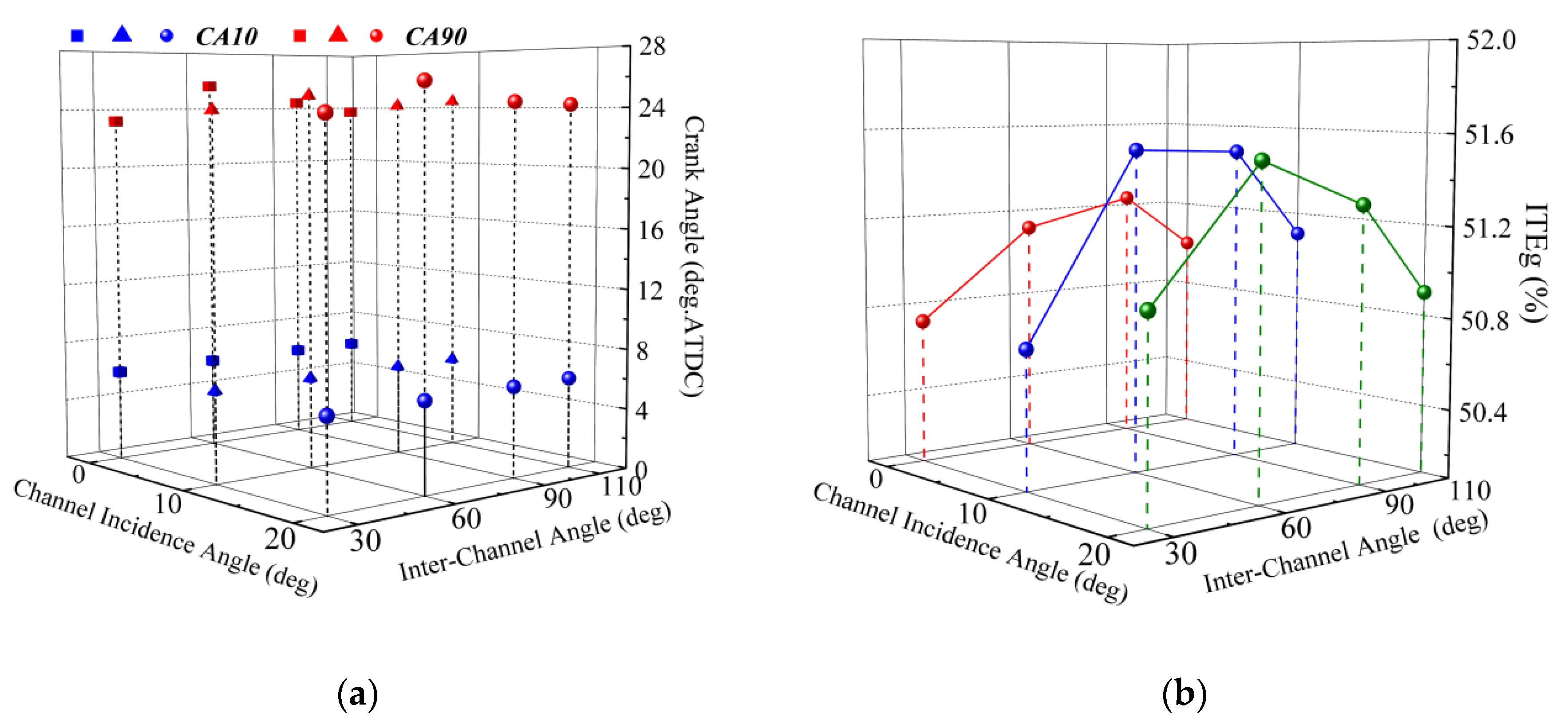

Figure 10 shows the effects of the two jet channel angles on combustion start point, combustion end point and the indicated thermal efficiency. Because the jet from the disturbance chamber occured after the beginning of combustion, the channel angle had a limited effect on CA10. By optimizing the channel angles, the duration of combustion was shortened by approximately 2 deg, with the shortest duration occurring in the simulation with

α = 60 deg and

β = 10 deg. A well-adjusted jet disturbance area enhanced the overall quality of fuel–air mixing, leading to more intense fuel heat release. The overall combustion process was concentrated around the compression top dead center, which was beneficial for improving the work capacity of the high-pressure gas inside the cylinder. The change in the indicated thermal efficiency was influenced by the work capacity of the high-pressure gas and the engine heat transfer loss. As

α increased, the developmental path of the jet moved closer to the piston edges. When

α was increased to 110 deg, the jet developed over the piston crown for a long duration, leading to significant heat losses through the bottom of the cylinder head and piston crown. This increase in heat loss was detrimental to improving the indicated thermal efficiency. Appropriately increasing

β caused the jet to develop further away from the bottom of the cylinder head, significantly reducing the heat transfer loss from the cylinder head. However, when

β was increased to 20 deg, the jet prematurely contacted the piston bottom and spread, worsening the fuel–air mixing at the far end and increasing heat transfer losses from the piston bottom, which was not conducive to the improvement in thermal efficiency. After optimizing the jet channel angles, the indicated thermal efficiency improved by 0.8%, with the highest efficiency reaching 52.23%. This demonstrates that selecting appropriate channel angles can precisely disturb the rich mixture area in the middle and late stages of combustion, increase the proportion of lean mixture within the cylinder, promote the combustion process, and enhance the indicated thermal efficiency of the engine.

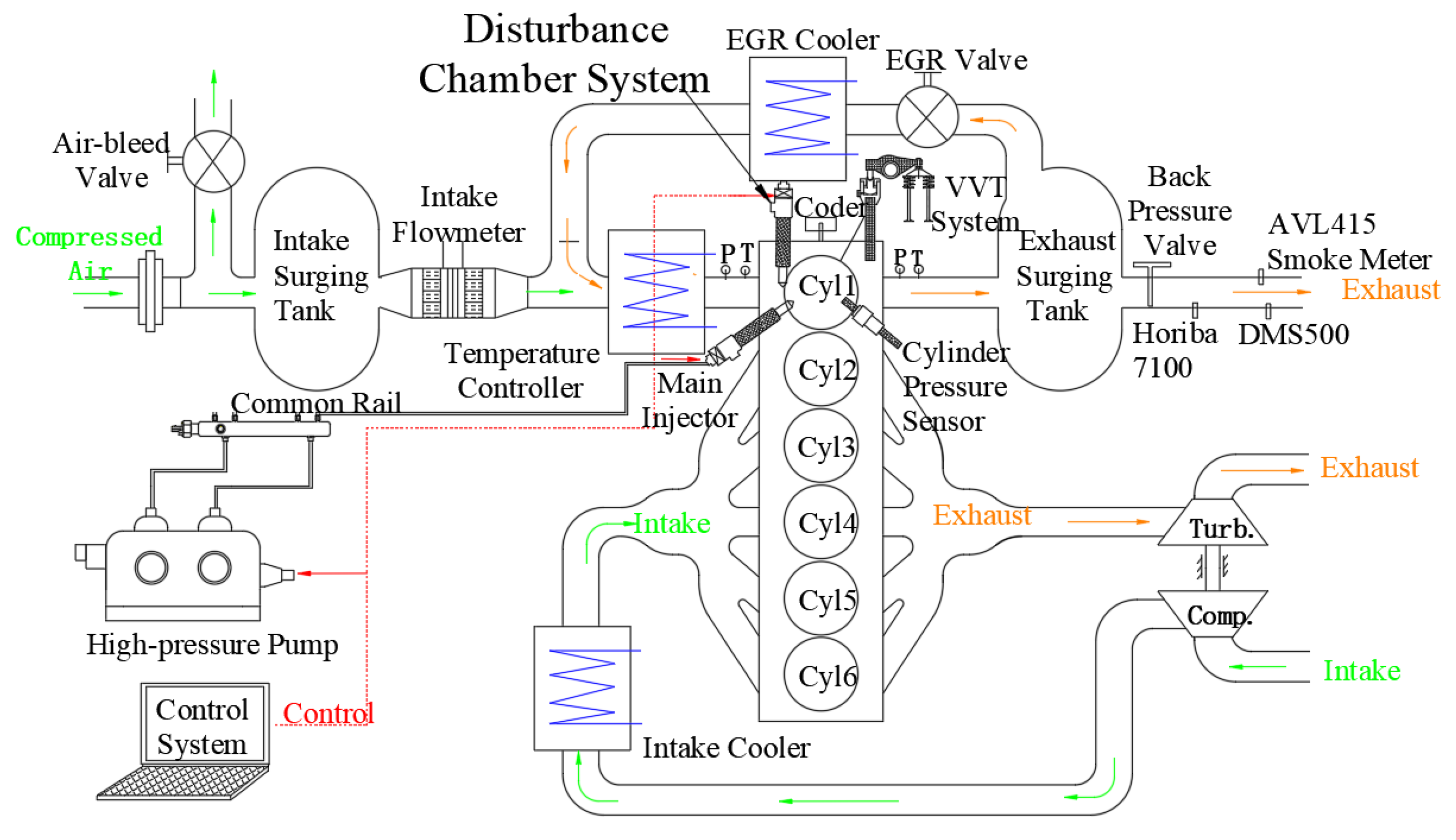

The optimized disturbance chamber was installed on a single-cylinder test engine modified from a six-cylinder diesel engine. The original engine is a six-cylinder heavy-duty diesel engine, which is mainly used in tractors, heavy-duty trucks, loaders, and cranes. The parameters of the test engine are provided in

Table 1, and the test platform for the jet disturbance combustion system is shown in

Figure 11. During the testing process, the first cylinder of the original engine was used as the test cylinder. The intake system of the test cylinder employed external simulated supercharging combined with intake air heating and an independent exhaust gas recirculation system to allow for the flexible control of intake air pressure, temperature, and EGR rate. The auxiliary injector in the disturbance chamber shared a common rail injection system with the main injector of the test cylinder and was controlled by a self-developed ECU, enabling the flexible adjustment of fuel injection quantity and timing for both injectors. Cylinder pressure signals were collected using a 6125C cylinder pressure sensor and 5165A charge amplifier by the Kistler company. Single-cylinder exhaust components were detected using a Horiba 7100 exhaust gas analyzer, and soot emissions were measured with an AVL 415 smoke meter. The relationship between the fuel quantity injected by the electronic control injector and the injection signal pulse width was calibrated on an EFS fuel pump test bench. The specific information on the measuring instruments and their error rates are shown in

Table 2.

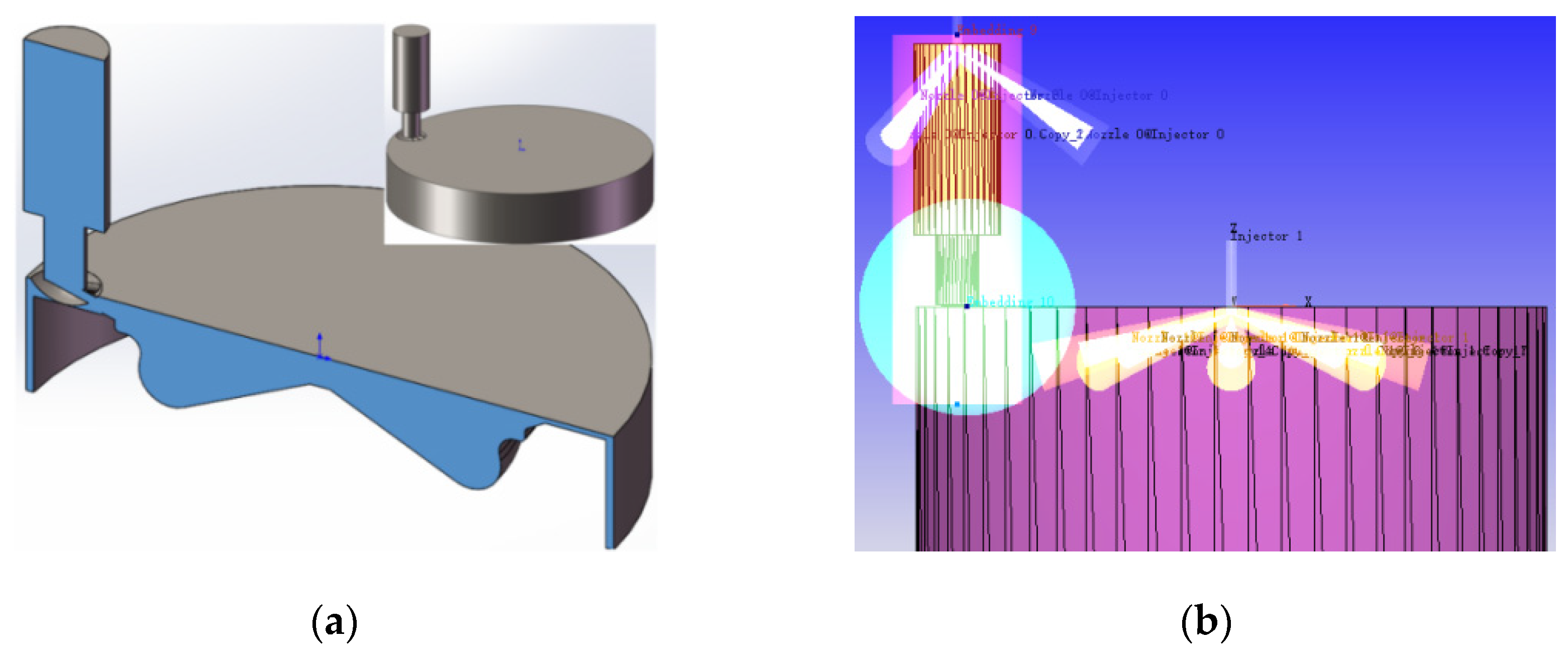

Numerical simulation methods were utilized to evaluate the mechanism of the disturbance chamber jet disturbance combustion system. Based on the geometric parameters of the disturbance chamber and its relative position with the main combustion chamber, the entire combustion chamber was modeled using SolidWorks. Additionally, the simulation model was established using the computational fluid dynamics simulation software CONVERGE. The base grid size was 4.0 mm. The final three-dimensional model and simulation model are presented in

Figure 12. The important mathematical models used in the simulation calculations are listed in

Table 3.

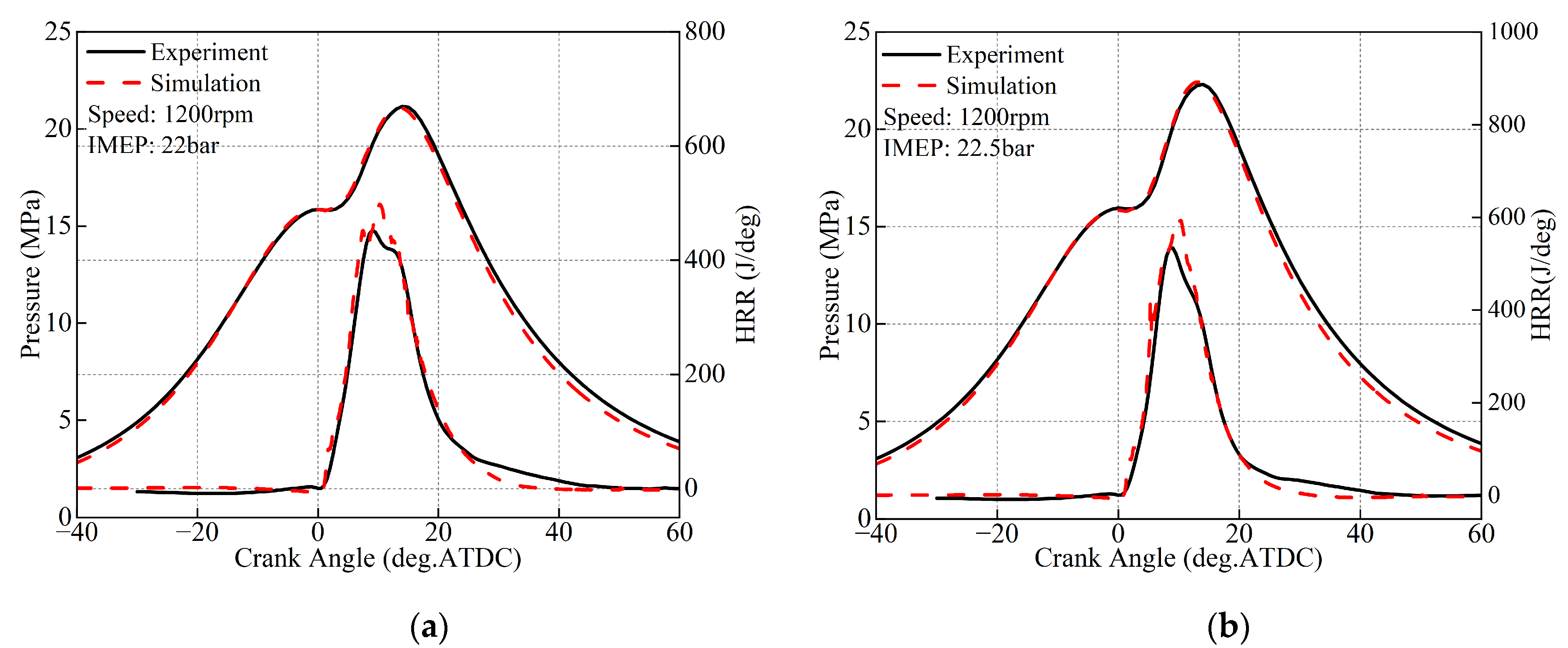

The simulation model was calibrated and validated based on the experimental data. The total cycle fuel injection quantity was 180 mg, and the injection timing of the main injector was −2 deg.ATDC. The simulation results without and with intervention by the disturbance chamber jet (auxiliary injection timing and quantity at 4 deg.ATDC and 4 mg, respectively) were compared with the experimental results (

Figure 13). The simulation results for both sets of conditions, when compared with the experimental results, showed that the peak cylinder pressure error was <1%, the error in the crankshaft angle corresponding to the peak cylinder pressure was <0.5 deg, and the peak heat release rate error was <2%. These results suggested that the simulation and experimental data were fundamentally consistent, indicating that the established simulation model accurately described the combustion process of the jet disturbance combustion system.

3. The Influence Mechanism of Jet Disturbance Combustion System on Fuel-Air Mixing Process and Combustion Process

The mechanism analysis of the jet disturbance combustion system was conducted through numerical simulation. As previously mentioned, the intervention of high-speed jets causes large-scale disturbances to the mixture in the jet developmental path and generates several small-scale turbulences within the cylinder. Therefore, analyzing the impact of high-speed jets on the gas flow state inside the cylinder is necessary. Moreover, vorticity—as a derived quantity of the flow field representing the rotation rate of the velocity field at a point—can more intuitively reflect the ability of vortices to entrain fresh air [

28,

29]. Vorticity could be used to describe the evolution of vortices within the cylinder, demonstrating the complexity of air movement in the disturbance chamber combustion system. It is defined as follows:

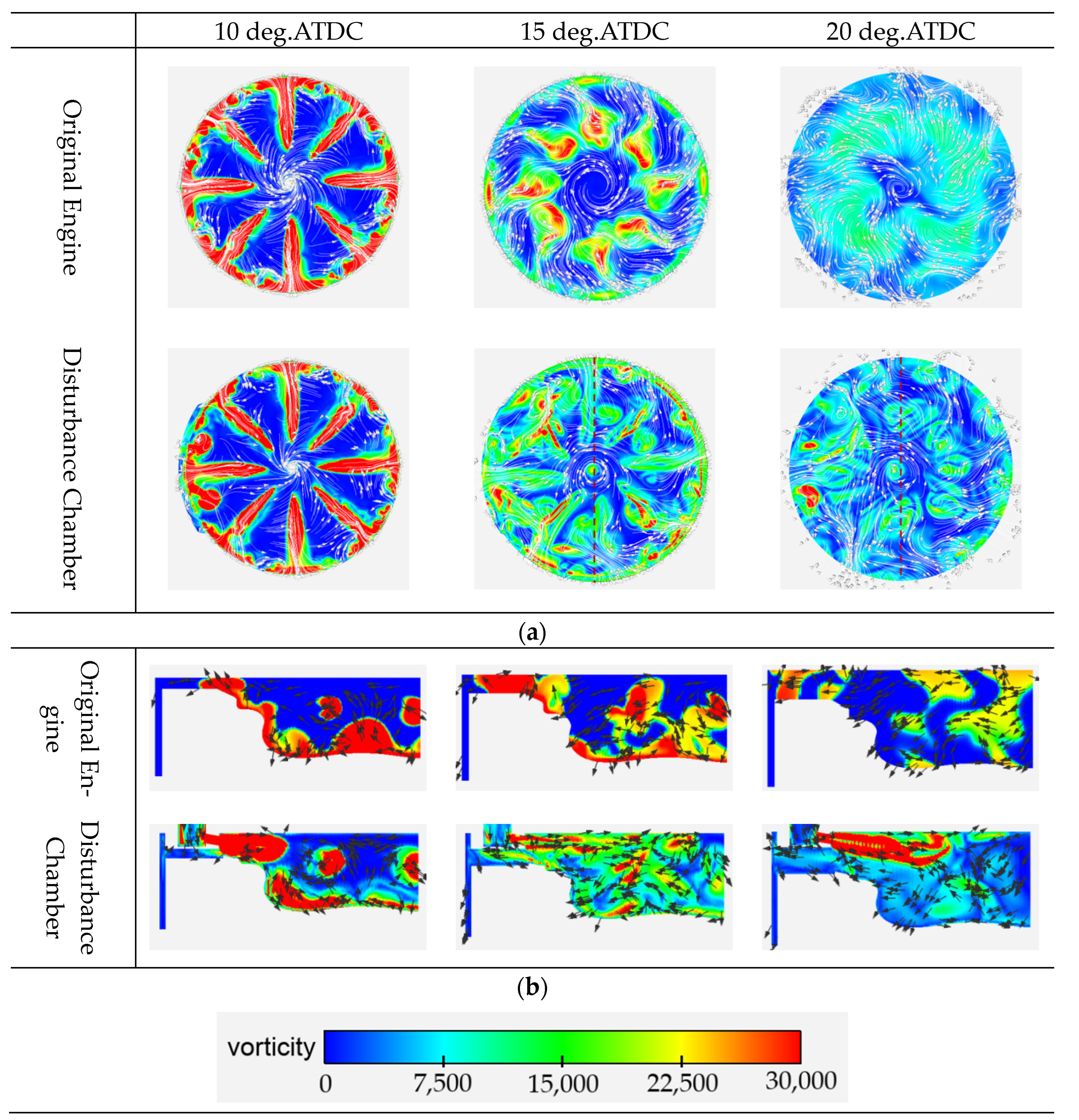

Figure 14 shows the gas flow state and vorticity distribution in the original engine and the engine with the disturbance chamber combustion system. Slice 1 is a horizontal section 5 mm below the bottom of the cylinder head, and Slice 2 is a plumb section along the left jet channel axis of the disturbance chamber. At 10 deg.ATDC, the intervention of the high-speed jet into the main combustion chamber changed the existing counterclockwise vortex motion within the combustion chamber. Simultaneously, large-scale vortices were divided into smaller-scale vortices of various sizes, and the vorticity in the jet developmental path area was significantly increased. Moreover, the high-speed jet directly impacted the fuel sprays adjacent to the disturbance chamber, resulting in a complex distribution of vortices around these fuel sprays. In the subsequent 5 deg of time, the strong vorticity areas, initially only around the fuel sprays, expanded to cover the entire half of the cylinder near the disturbance chamber. Furthermore, multiple fuel sprays directly impacted by the jet were surrounded by numerous small-scale vortices. The velocity differences at the vortex interfaces caused intense velocity fluctuations, enhancing the fuel–air mixing process within the cylinder [

27]. In the late combustion stage, in contrast to the concentrated strong vorticity areas of the original engine, the engine with the disturbance chamber combustion system exhibited multiple regions with small-scale strong vorticity. This complex gas flow state is beneficial for mixing residual fuel inside the cylinder.

Figure 15 shows the distribution of the equivalence ratio of the mixture in specific areas within the cylinder for the original engine and the engine with the disturbance chamber combustion system, with slices defined as in

Figure 14. From the equivalence ratio distribution in Slice 1, the high-speed jet from the disturbance chamber first disturbed the fuel sprays adjacent to it. At 15 deg.ATDC, the adjacent fuel sprays directly impacted by the jet exhibited a significantly increased rate of air entrainment in the middle and late stages of their free development compared with the original engine. The rich mixture with >1 equivalence ratio near the spray head was rapidly diluted. As the combustion progressed, the effect of the high-speed jet in accelerating fuel dilution became increasingly apparent, especially in half of the cylinder near the disturbance chamber. By 25 deg.ATDC, the half near the disturbance chamber was almost devoid of rich mixture regions, with only sporadic rich mixture areas along the fuel developmental path on the half far from the disturbance chamber. Overall, the fuel–air mixing and heat release rates were significantly enhanced compared with the original engine conditions. In the region directly affected by the high-speed jet, namely the jet developmental path (Slice 2), the change in the equivalence ratio was more pronounced than in other regions. Due to the direct injection of additional energy, the fuel–air mixing rate in this area significantly increased, and the distribution area of the rich mixture notably decreased. Moreover, the jet caused the formation of small-scale turbulent regions around the fuel sprays. This complex airflow movement altered the developmental path of the rich mixture gas, which originally adhered closely to the piston walls. The mixture near the wall detached and moved toward the piston center, increasing the contact area between the fuel and fresh air. This effectively promoted the combustion process of the low-momentum density wall-wetted fuel at the piston bottom and in the squish area.

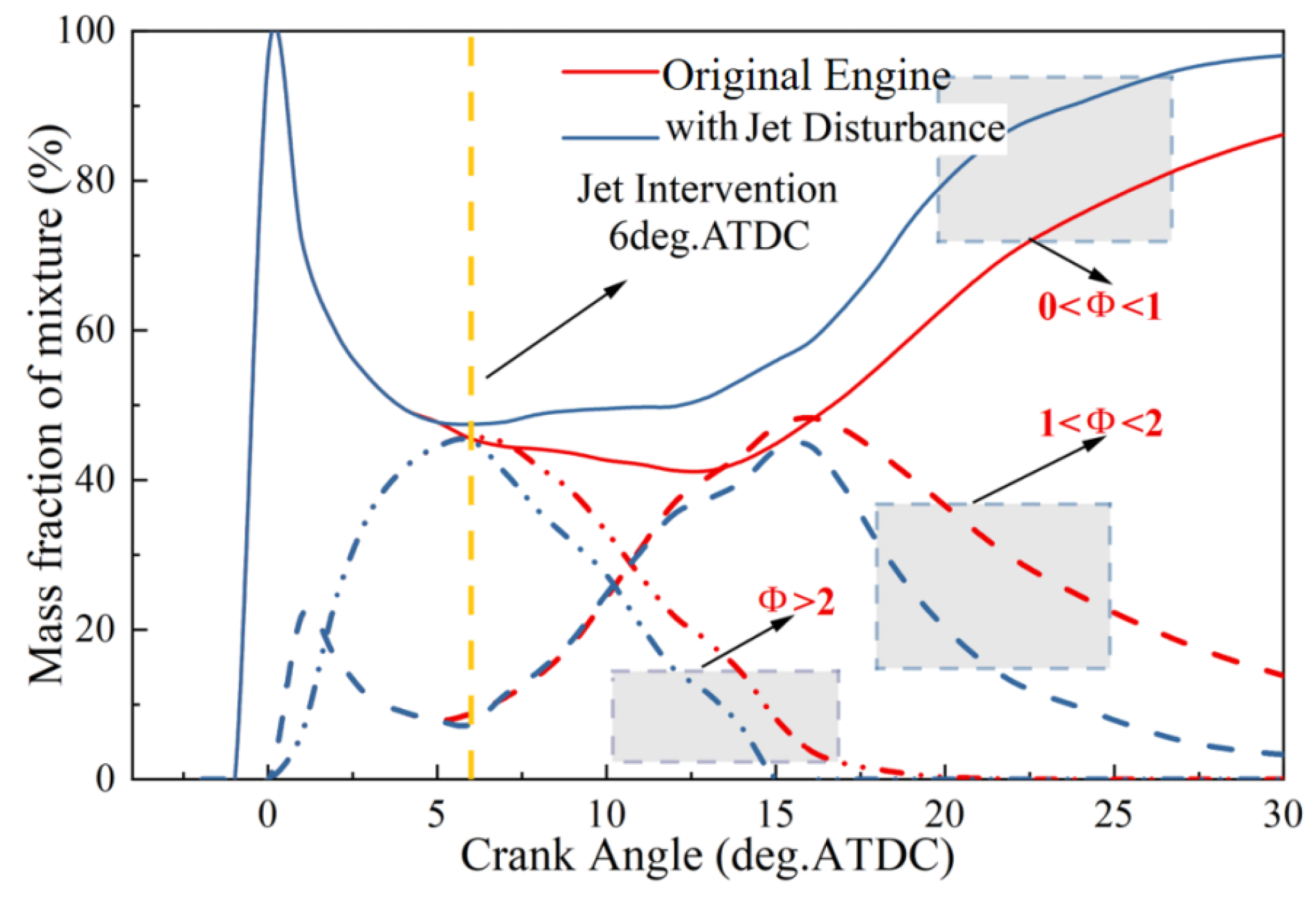

To quantify the impact of the disturbance chamber combustion system on the equivalence ratio distribution of the cylinder, the mass fractions of the mixture at different equivalence ratio ranges within the cylinder were calculated for the original engine and the engine with the disturbance chamber combustion system (

Figure 16). The proportion of the lean mixture (0 < Φ < 1)—a crucial characteristic—affected the overall diesel combustion process. Increasing the proportion of the lean mixture inside the spray increased the heat release during the premixed combustion stage. Moreover, it significantly reduced the dependence on the mixing rate during the diffusion combustion stage, making the overall heat release process more concentrated. Before the intervention of the jet in the original engine condition and the disturbance chamber combustion system, the distribution of the mixture was essentially the same. However, once the high-speed jet started entering the main combustion chamber (6 deg.ATDC), the free development spray was disrupted by the jet impact, which increased the dilution rate of the over-rich mixture (Φ > 2) predominantly found in the spray core area, resulting in a significantly higher mass fraction of lean mixture compared with the original engine. Upon the completion of injection in the main combustion chamber (16 deg.ATDC), the original engine condition experienced a sharp decrease in mixing energy, leading to poor mixing rates of the residual fuel. At 25 deg.ATDC, overly 20% of the rich mixture was present in the cylinder, causing a noticeable “trailing” phenomenon during the overall combustion. In contrast, the disturbance chamber combustion system—benefiting from the disturbance effect of the high-speed jet and the complex airflow movement it induced—maintained a higher mixing rate for the residual mixture in the cylinder. The complete dilution of the over-rich mixture occurred 5 deg earlier compared with the original engine, and the rate of diluting the rich mixture was 70% higher than that in the original engine, with a mass fraction of lean mixture far exceeding that of the original combustion system.

To validate the effectiveness of the diesel engine jet disturbance combustion system in enhancing fuel–air mixing in the main combustion chamber and improving engine thermal efficiency, related experimental research was conducted based on the jet disturbance combustion system test platform.

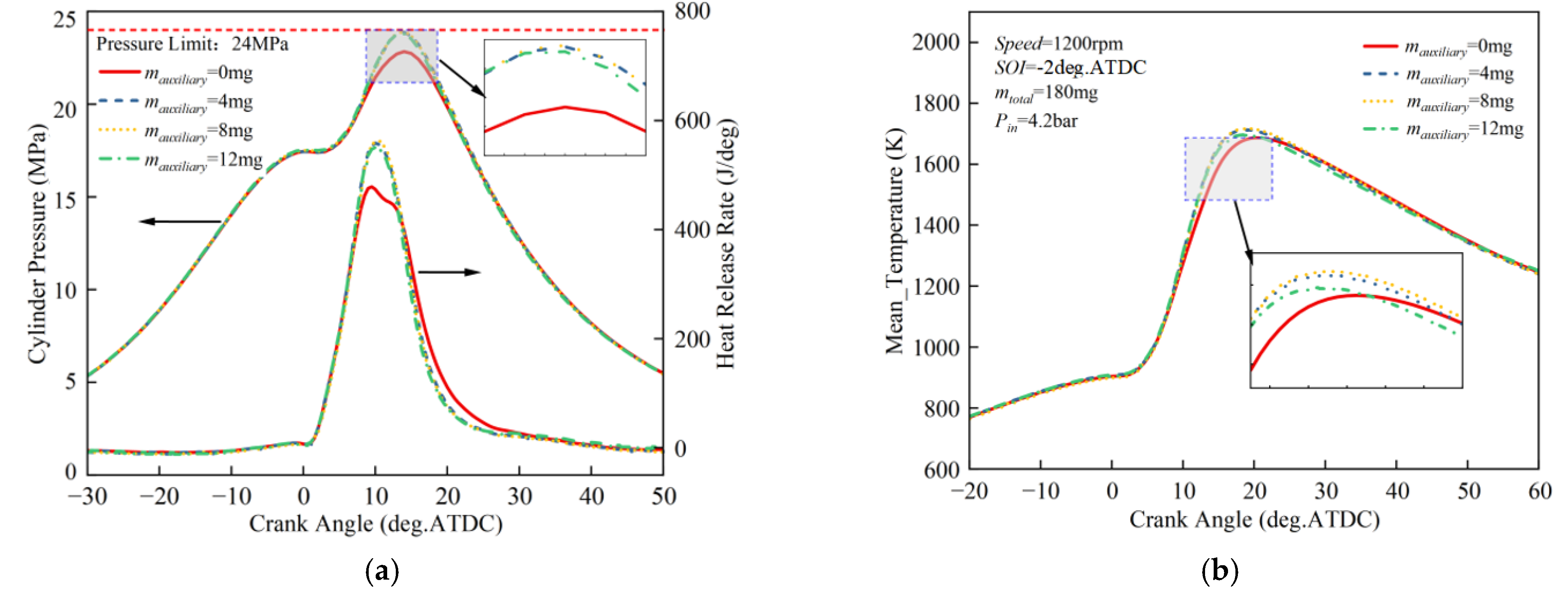

Figure 17 presents the cylinder pressure, heat release rate, and average temperature corresponding to different auxiliary injection quantities in the disturbance chamber. Compared with the condition without the disturbance chamber jet, the jet disturbance system significantly promoted the combustion heat release process within the main combustion chamber. The peak values of cylinder pressure, the instantaneous heat release rate, and the average temperature during combustion rose, making the overall combustion process intense and concentrated. Under nearly equal fuel supply rates, the combustion heat release rate was significantly increased, proving that the jet disturbance generated by the disturbance chamber notably enhanced the fuel–air mixing process in the main combustion chamber. Furthermore, when the auxiliary injection quantity was 8 mg, the intensification of combustion in the main combustion chamber was most pronounced, with an increase of 17.5% in the peak heat release rate. The absolute mass of oxygen is fixed in the limited space inside the disturbance chamber. Excess fuel entering the disturbance chamber cannot achieve complete combustion within a brief residence time. Subsequently, excess fuel or intermediate products enter the main combustion chamber. This weakens the energy of the disturbance chamber jet and increases the concentration of rich mixture areas in the main combustion chamber.

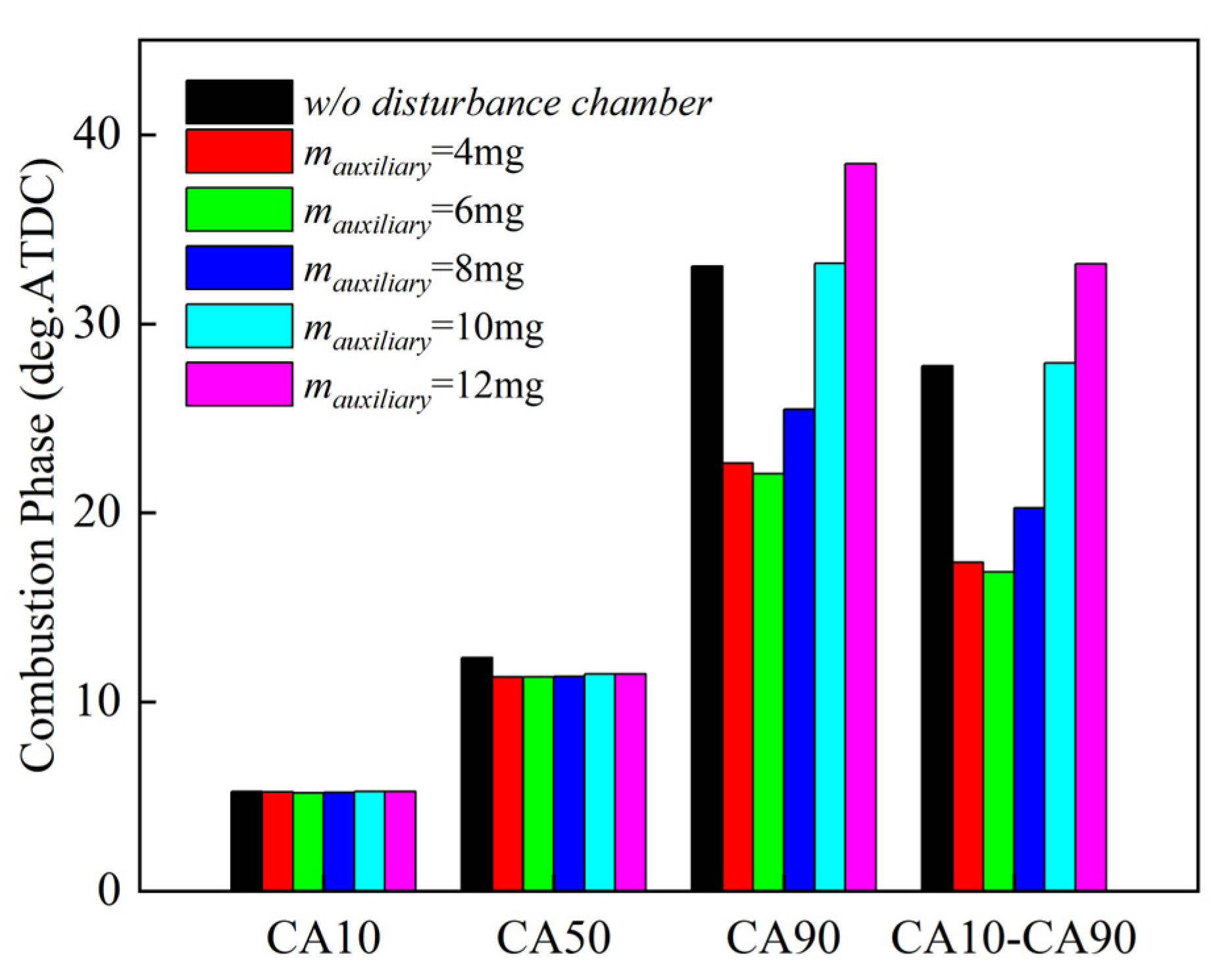

Figure 18 shows the combustion phases corresponding to different auxiliary injection quantities. The intervention of the disturbance chamber jet significantly affected CA90. When the auxiliary injection quantity was 6 mg, CA90 was closest to the top dead center, with a 21.98 deg combustion duration. This was a reduction of 14.7% compared with 25.77 deg in the case without the disturbance chamber jet. As the auxiliary injection quantity continued to increase, the effect of jet disturbance on combustion duration gradually weakened. This is consistent with the conclusions drawn from

Figure 17.

Figure 19 presents the indicated thermal efficiency corresponding to different auxiliary injection quantities. Owing to the reduction in the experimental cylinder geometric compression ratio from 18.5 to 17.86, the indicated thermal efficiency for the case without the disturbance chamber jet decreased from 51.5% to 51.34% for the original engine. The intervention of high-speed jets can significantly improve the indicated thermal efficiency of the diesel engine combustion process. At 6 mg auxiliary injection quantity, the highest indicated thermal efficiency reached 52.12%, an increase of 0.62% compared with the optimum efficiency point of the original engine system.

Figure 20 summarizes the optimization path of engine thermal efficiency in the jet disturbance combustion system study. The optimization process included numerical simulation and single-cylinder engine experiments. Although the geometric compression ratio of the piston was slightly reduced after the modification of the experimental engine, and the indicated thermal efficiency was lower than the optimum point of the original engine condition, the disturbance chamber combustion system effectively compensated for the thermal efficiency loss caused by the reduced compression ratio. Numerical simulations revealed that the highest thermal efficiency reached 52.23% by optimizing the parameters of the disturbance chamber and the jet developmental path. This was validated by the single-cylinder engine test bench with an indicated thermal efficiency of 52.12%—an improvement of 0.62% compared to the optimum efficiency point of the original engine condition. These results validate the effectiveness of the jet disturbance combustion system in promoting fuel–air mixing and combustion processes and enhancing engine thermal efficiency. Additionally, they support the use of this technology as an additive approach in the development of ultra-high thermal efficiency diesel engines.

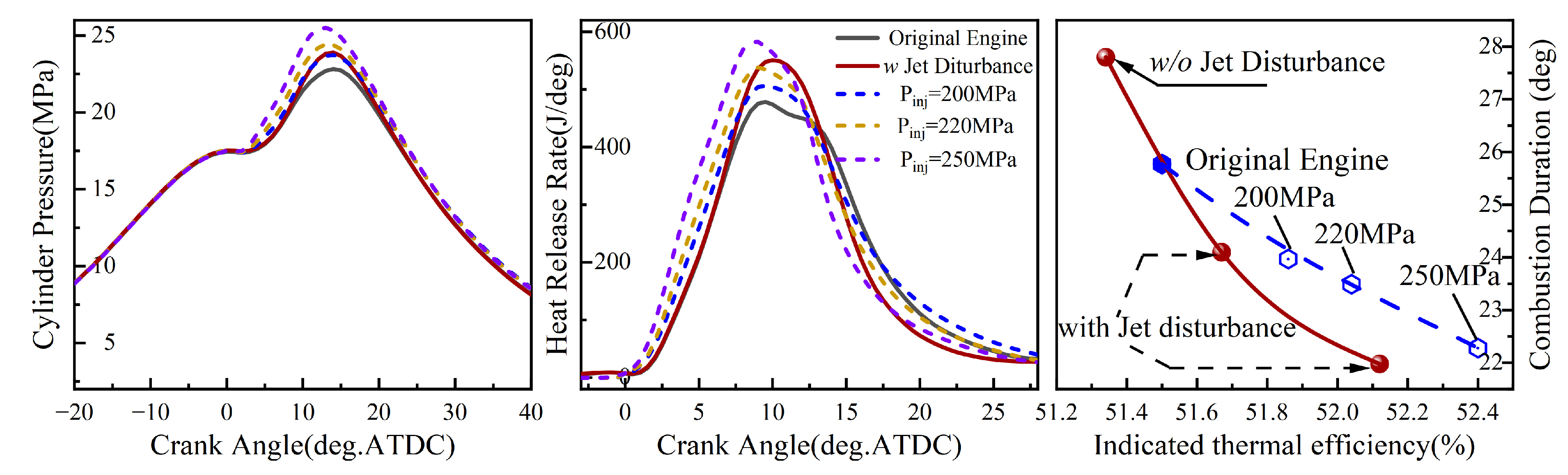

As previously mentioned, outside China, diesel engine technology often involves the use of ultra-high-pressure common rail injection systems. Therefore, numerical simulation was used to compare these two technologies (

Figure 21). Increasing the common rail pressure can significantly enhance the fuel injection rate and promote the in-cylinder combustion heat release process; however, it cannot resolve the problem of the rapid decrease in mixing energy after fuel injection. The use of jet disturbance technology allows for the flexible adjustment of jet intervention timing. It enhances the mixing rate throughout the combustion cycle and alleviates the problem of an excessively concentrated heat release, which causes an excessively high peak cylinder pressure. The effect of the jet disturbance combustion system in promoting combustion lies between the conditions of 220 MPa and 250 MPa rail pressure. However, its peak cylinder pressure was the lowest among the aforementioned three cases and required the least engine body strength. Concerning the indicated thermal efficiency, increasing the common rail pressure led to an increase in the indicated thermal efficiency. Simulation results showed that the 250 MPa rail pressure led to an indicated thermal efficiency of 52.4%. However, considering the whole engine, further increasing the common rail pressure will inevitably bring high mechanical losses, resulting in less improvement to effective thermal efficiency than expected. The jet disturbance combustion system, while offering comparable benefits, significantly reduces the demand for ultra-high-pressure common rail technology and high-strength materials. In addition, it offers broad application scenarios and reduces product costs.

4. Conclusions

A jet disturbance combustion system for heavy-duty diesel engines was proposed, the key components of the jet disturbance combustion system were designed, and a research platform was constructed for system evaluation. Mechanism studies on enhancing fuel–air mixing rate and strengthening the main combustion chamber process in the jet disturbance combustion system were conducted based on single-cylinder engine tests and numerical simulation platforms. The following conclusions were drawn:

The quality of internal combustion within the disturbance chamber largely determined the effectiveness of high-speed jet disturbance. Organizing the high-quality combustion within the disturbance chamber can enhance the overall combustion process. Increasing the volume of the disturbance chamber enhanced the complexity of gas movement, extending the dwell time of the fuel in the chamber, thereby improving the combustion completion. However, excessively increasing the volume of the disturbance chamber reduced the combustion benefits while sacrificing the overall compression ratio. Considering the quality of internal combustion and changes in the compression ratio of the engine, a disturbance chamber height of 30 mm was selected.

Through the comprehensive optimization of the spatial parameters of the disturbance chamber and the auxiliary injection system parameters, a reasonable fuel developmental path inside the disturbance chamber was achieved, improving air utilization efficiency and promoting the dilution process of rich mixtures inside the disturbance chamber. The proportion of rich mixtures inside the chamber significantly decreased, the peak heat release rate in the chamber increased from 86 J/deg to 269 J/deg, the cumulative heat release increased by 112 J, and the timing of jet occurrence advanced by 1 deg.

Considering the combustion quality and the heat transfer losses from the piston, the injection angle of the jet channel in the disturbance chamber was set at 10 deg, with a 60 deg inter-channel angle. Optimizing the angle of the jet channels allowed the jet to precisely disturb the accumulation area of rich mixtures in the middle and late stages of combustion; this significantly improved the mixing quality of fuel far from the disturbance chamber. The mass fraction of lean mixtures in the middle and late stages of combustion was approximately 4% higher than before optimization, with the indicated thermal efficiency reaching 52.23%, which is an improvement of 0.8% compared with before optimization.

Numerical simulation results showed that high-speed jets entering the main combustion chamber impacted multiple fuel sprays, disrupting their free development configuration. The mass fraction of the overly rich mixtures, predominantly in the core area of the spray, rapidly decreased. The large-scale counterclockwise vortices originally present in the combustion chamber were divided into groups of smaller-scale vortices of different sizes. The vorticity in the jet developmental path area was significantly enhanced. The residual fuel in the cylinder maintained a high mixing rate after the completion of the fuel injection process despite its low momentum density. The dilution rate of rich mixtures was 70% higher than that in the original engine, and the mass fraction of lean mixtures was higher than that in the original combustion system. Single-cylinder engine test results showed that a diesel engine with the jet disturbance system and a 180 MPa common rail pressure fuel system achieved 52.12% thermal efficiency.

The future research direction is the optimization of engine control strategy under all operating conditions based on jet disturbance combustion system. Based on different boundary conditions such as intake pressure, intake temperature, injection pressure, and engine speed, the control strategy will be optimized to broaden the application range of this combustion system.