1. Introduction

Energy demand is increasing with population increase and urbanization in the developing world. Ethiopia, like other developing countries, shows a sheer population growth with the lowest access to electricity and clean cooking [

1]. The country’s per capita energy access and consumption is among the lowest in the world [

2]. Household energy consumption, for cooking and lighting, constitutes the largest share of the total energy utilized in the country. This demand depends on biofuel i.e., fuelwood and animal dung [

3].

Cooking is enjoyable in a friendly kitchen environment. However, many developing countries, including Ethiopia, use traditional cookstoves in unventilated kitchen setups where health, time, energy, and safety are compromised. Most Ethiopian households use biomass fuel and mud traditional stoves to prepare their food. Ethiopian food-preparation culture uses two separate stove designs for cooking stew and baking Injera. The two stoves cannot be used interchangeably.

The common traditional stew stove is a three-stone stove. In many places, this stove has been revolutionized by Indigenous knowledge. However, government institutions, improved cookstove distributors, and other stakeholders use the three-stone stove as a promotion reference in improved cookstove programs and campaigns. Yet, many improved cookstove technologies are mud-made and have stayed for decades without improvement. Because of this, some improved cook stoves tend to exhibit similar or lower performance to a custom-made traditional stew stove. Similarly, the improved Injera baking stove technologies have stayed for more than 30 years without technological improvement [

4]. Such technological gaps created end users’ dissatisfaction, low performance of clean-cooking programs, knowledge holes on stove technologies, and has led to discrepancies from SDG7 2030 targets.

The initiative for this study is the knowledge gap among the community, government, improved cookstove promotors, and manufacturers. The main objective of this paper is therefore to present scientific evidence on the performance of widely distributed improved cook stove technologies in comparison with a traditional cook stove. This result would give a baseline for different improved cookstove actors to unlock the challenges for failure of programs and low performance. In addition, it would encourage the government and scientific community to engage in advanced research for improved stove technologies.

This paper has been organized into six sections.

Section 1 gives the introductory background of the study, with a literature review in

Section 2, and research methodology in

Section 3.

Section 4 discusses the experimental and numerical results of the research. The authors give their action-oriented recommendations in

Section 5 and concluding remarks in

Section 6.

2. Literature Review

Biomass covers about 15% of global energy demands [

5] and about 2.7 billion people burn it on traditional inefficient cook stoves [

6]. This has caused millions of deaths related to indoor air pollution problems [

7]. Most people in sub-Saharan Africa and Africa in general have no access to electricity and they predominantly use biomass.

Similarly, in Ethiopia, about 85% of the population uses biomass and inefficient traditional cookstoves that cause deaths and sickness [

8,

9]. Biomass is one of the renewable energy sources; however, in countries like Ethiopia that overuse the resource in a way that limits its regeneration capacity, sustainability is a fundamental problem in addition to the health threats. Biomass emits a significant amount of greenhouse gases (GHGs) and particulate matter (PM) in everyday cooking. Indoor air pollution (IAP) from burning biomass on traditional cookstoves (TCS) causes poor respiratory health. In addition, TCSs consume intensive human labor and fuel to compensate for their inefficiency and generate products of incomplete combustion (PIC). These days, efforts to replace TCSs with improved cook stoves (ICS) have gained some results but not enough [

10].

ICSs reduce the amount of IAPs, PIC, PM, and GHG emissions. Studies show that ICSs save 40–95% of fuel consumption, and reduce associated impacts of CO, PM, and fuel consumption for cooking and heating by 50% [

11,

12,

13,

14].

Many developing countries, including Ethiopia, attempted to introduce ICSs to reduce the deforestation, GHG emission, and health impacts of TCSs and to attain their clean-cooking capabilities. However, ICS adoption showed slow tendencies despite their social, health, economic, and environmental benefits. The shift from TCSs to ICSs needs a strategy that can address local development, combat global climate changes, improve efficiency, and meet end users’ needs [

15,

16,

17].

Ethiopia is home to about 120 million people and is the third largest traditional fuel consumer in the world [

18]. Its rural areas are the source of primary energy and food [

19]. In many parts of the country, the collection of biomass fuel is the burden of women and children. They often spend much of their time and energy on this. Gebru and Bezu’s study showed that firewood fetching requires 12% of a child’s school time [

20]. In addition, it causes sexual abuse, due to disempowerment. Uncontrolled biomass utilization is also one of the main reasons for reduced forest coverage in the country. To reduce these impacts, the government and other stakeholders tried to introduce ICS technologies with limited success.

ICSs are technological devices designed to improve combustion, heat transfer, thermal performance, fuel consumption, and emissions through evolution [

21]. Technical improvement, stove cost, awareness, cooking culture, and versatility are some of the essential elements for successful ICS adoption. In addition, household economy, stove ergonomics, target group, and attraction are crucial factors that determine the acceptance of ICS [

22]. For example, a study in Addis Ababa indicated that household income is a main factor in the decision to switch from TCS to ICS [

23,

24]. Likewise, ICSs have been accepted in refugee camps, which have demands for pro-poor and robust technology [

25].

The deep-rooted dependency of Ethiopians on TCSs has rarely been researched to solve its deterrence potential to the UN 2030 universal energy plan. The hardly available research on technical improvement, ergonomics, efficiency, cost reduction, and economic and social values of stove technologies have become the main challenges for the ICS revolution in the country [

20]. The unavailability of revolutionized ICS technologies has become the main barrier to clean-cooking transformation in the country. The scientific evidence gap of available TCS and ICSs is the main research gap addressed in this study. The novelty of this study is its approach to solving the clean cooking transformation clinch through laboratory evaluation of energy saving, overall performance, and emission tendencies of ICSs compared to TCS. This result will be instrumental for the research and development of ICS, rethinking ICS program interventions and accelerating solutions to achieve the SDG7 target. It will also help the government, community, and other stockholders involved in ICS programs to understand the main reason for ICS adoption failure and give recommendation insights on where the different actors should intervene in the future.

3. Materials and Methods

This study evaluates the performance of selected ICSs and a common TCS through intensive laboratory tests and numerical analysis. The evaluation is made based on a standard water-boiling test’s (WBT) fuel consumption, time taken, and emission level. WBT represents households’ common cooking activities, and it is instrumental to evaluate the performance of stoves based on their fuel consumption and associated impacts.

3.1. Materials

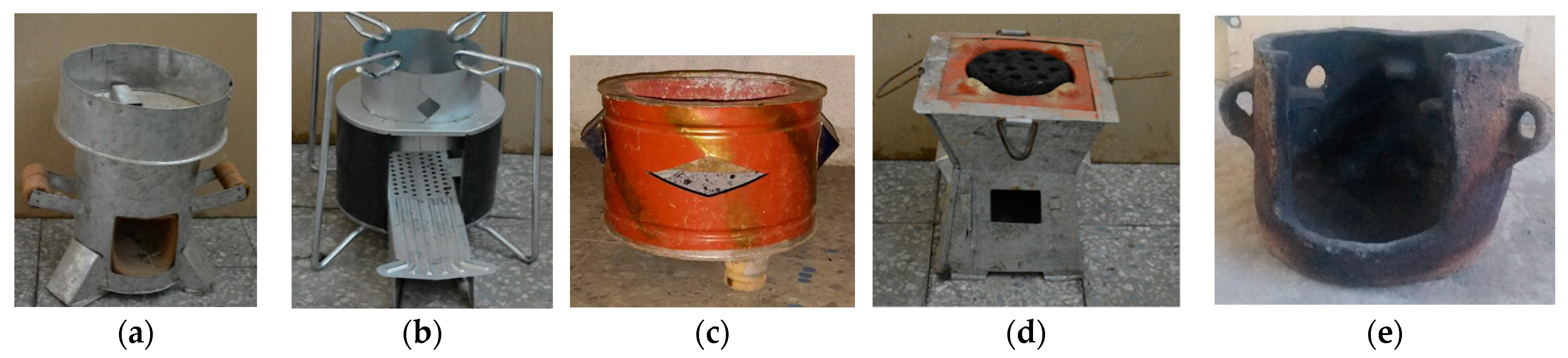

In this research, four widely distributed ICSs and one TCS shown in

Figure 1 have been chosen for evaluation purposes. K-type thermocouples, a wood-moisture tester, and a laboratory digital scale were used to record the temperature development of the boiling water, fuel moisture content, and weight, respectively. The details of the equipment and sensors used in the experiment are given in

Table 1. The mass balance and moisture tester are used to measure weight and moisture content of fuel, respectively. Thermocouple sensors are used to measure temperature. In addition, numerical analysis, site inspection, and inputs from focus-group discussions have been used to strengthen the robustness of the evaluation.

3.2. Methods

This study follows focus-group discussion, experiment, and numerical analysis as its methodologies. A detailed description of each is given in the subsequent sections.

3.2.1. Focus-Group Discussions

In Ethiopia, general access to clean cooking and adoption of ICSs in particular are slow. The major activities and plans of access to electricity and clean cooking were handled at the federal government level, and regional governments implemented cascaded plans autonomously for small-scale off-grid electrification and clean cooking. In the Tigray region, northern Ethiopia, a renewable energy steering committee was established with the objective of identifying key bottlenecks for speeding up energy transition and oversaw unlocking mechanisms to speed up the transformation in the region. The first author is a member of this committee representing academia. All members have decision-making positions (directors) and are responsible for the energy sector in their respective institutions. The committee, chaired by the energy bureau, has conducted several small and large focus-group discussions before, in parallel and after the experimental study of this research. The objective of the focus-group discussions was to gather information from different stakeholders of the energy sector that are key roadblocks of the energy transition. For the interest of this study, only inputs for ICS adoption are considered. The composition of the focus group includes experts from health, agriculture, energy, academia, microfinance, small and medium enterprises, youth associations, non-governmental organizations (NGOs), and end user representatives. Many of the wider focus-group discussions were accompanied by site visits and stories about improved energy access, clean cooking, improved hygiene, and better job-creation practices.

3.2.2. Experimental Study

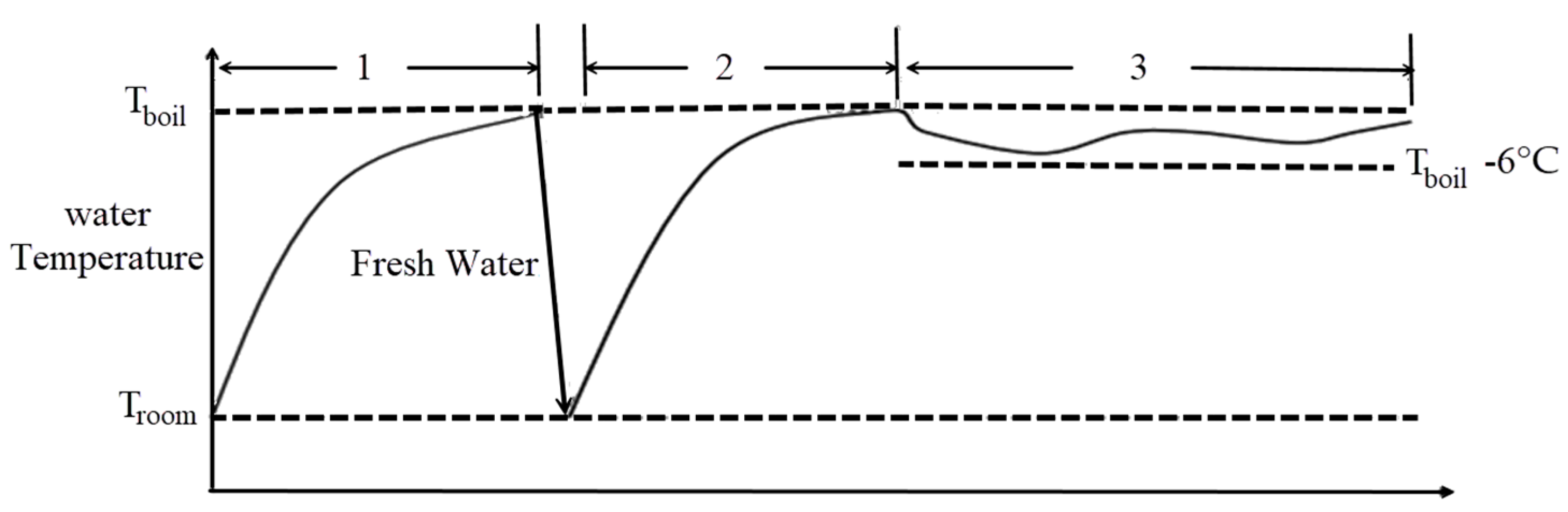

The experimental method of this study is like a controlled cooking test; however, it focuses on and follows a standard water-boiling test (WBT) procedure. The standard WBT consists of three boiling processes [

26]. The three WBT processes are cold start, hot start, and simmer.

Figure 2 gives the pictorial representation of the standard WBT process. Each of the stoves passed three qualified tests.

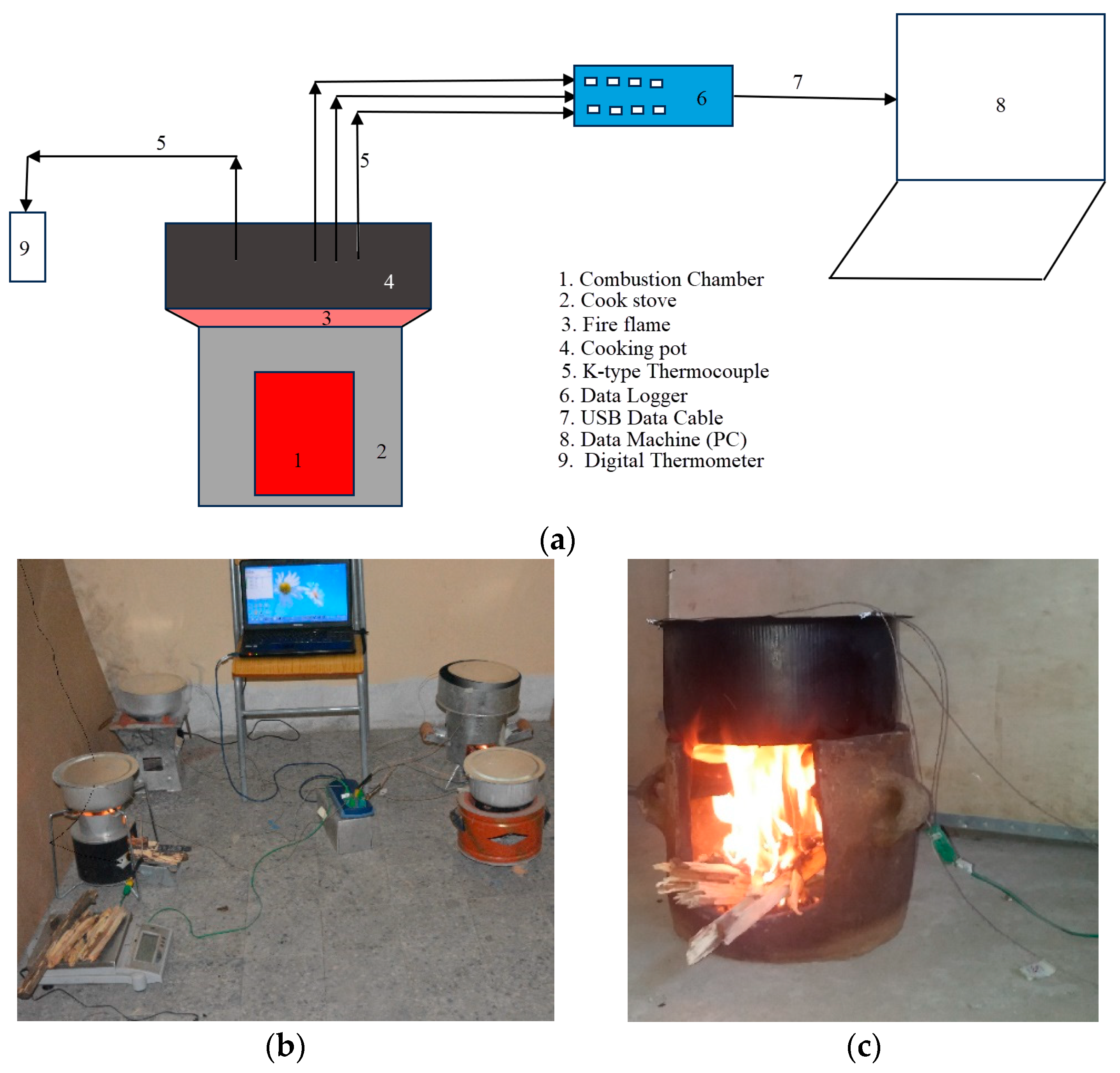

The experimental setup design schematic for this study is shown in

Figure 3a.

Figure 3b,c shows the trial test with all calibrated thermocouples and the data-acquisition system. The data-acquisition system performs data recording, has a live digital data display, and records the graphical development of temperature with time, which eased the experiment process. A digital thermocouple was used during calibration and for temperature control during the test. The boiling pot was painted black to benefit from the black-body theory of thermodynamics.

In Ethiopia, ICSs are referred to in comparison to a traditional three-stone open-fire cook stove type shown in

Figure 4. However, this stove has undergone different custom-made design developments with time. The old story of ICSs’ comparison with three-stone stoves has greatly influenced the ICS adoption programs in the country. In this study, the community made TCS shown in

Figure 3c has been used as a reference TCS for comparison purposes.

Throughout the experiment process, the cold-start test started with a pre-weighed bundle of fuel and the stove started at room temperature to boil five liters of water by using the pot shown in

Figure 3c. In the process, the amount of fuel consumed, boiling temperature, and time taken to boil the water have been recorded as important parameters. Following the cold start, a hot-start test was carried out immediately while the stove was hot to boil the same quantity of water in the same pot. This test helped to compare the performance difference between cold- and hot-start stoves. This comparison is particularly important for stoves with higher thermal mass because such stoves have the potential to store heat. Finally, the simmer phase continued to simmer the boiling water below its boiling point for 45 min. This step corresponds to the cooking of legumes or pulses, which are common cooking practices. The simmer fuel consumption and boiling time vary with the water-hardness level; however, this study did not consider the impact of such variabilities. The measured experimental parameters, fuel properties, and dry-fuel characteristics for wood and charcoal have been presented in

Table 2,

Table 3 and

Table 4, respectively.

3.2.3. Numerical Analysis

Burning biomass releases emission gases such as CO2, CO, and SO2. The overall impact of these gases on the environment is eminent as biomass is a renewable resource. However, the impact of these gases on the health of households, especially when they use inefficient stoves and unventilated kitchens, is important. The concentration of these gases in the kitchen depends on fuel type, stove design, and aeration design of the kitchen. In this case, evaluating and knowing the emission level of the ICSs in the same kitchen setup is very important. This study performed ultimate analysis to estimate the emission concentrations released per kilogram of consumed fuel. To compute this analysis, a database for the fuel parameters of moisture content, dry basis, air characteristics, and combustion products of the fuel has been developed.

Equations (1)–(3) are used to calculate the mass of combustion products and oxygen requirements of the combustion product, i.e., kg of an element per kg of fuel.

- 2.

Oxygen requirement

- 3.

Associated combustion products (CO2, SO2 and H2O)

4. Results and Discussions

4.1. Focus-Group Discussion

The focus-group discussions helped to identify finance, lack of coordination and consistency in program implementation, duplication of efforts, lack of capacity building and quality control, and quality of available technologies as key challenges. Following the inputs and steering-committee discussions, the committee agreed and gave the following solutions to the overwhelming challenges. First, it made the availability of finance for ICS users and producers at a lower interest rate in the regional microfinance as a special slot for ICS, and access to off-grid electrification. Second, it created synergized and complementary efforts among the bureau of energy, and the health, agriculture, and non-governmental organizations involved in ICS activity. Third, it empowered the energy bureau to take the roles of coordination and awareness creation to avoid redundancies. Fourth, the responsibility of technological evaluation was given to the higher institutions in which this study was conducted, as part of this action, and recommendations were given for regulation improvement.

4.2. Stove Construction

The construction of the stoves in this study is presented as follows. The TCS stove is made from mud, and it was fried at an elevated temperature to absorb any thermal shocks. The EZY stove is made from metal, with primary and secondary air inlets, a grate with grooves, and air insulation surrounding the combustion chamber. The Tikikkle (single rocket) is made of mud with a metallic cover on its outside, which is assumed to protect against heat loss. End users give this name to mean the right design. The Lakech is like the Tikikkle in construction, but it uses charcoal as its fuel. The Mirchaye is also like the Tikikkle in construction, but it uses a briquette fuel-type. End users gave this name to mean favorite design.

4.3. Experimental Results

During the experiment process, the Mirchaye showed unsatisfactory results, including combustion problems, incomplete boiling, and extraordinarily long and too much human effort. The authors decided to conduct a kitchen-performance survey of this stove in different sites, including a refugee camp, to verify if the experimental results resembled the actual performance of that stove. The survey showed dissatisfaction among end users regarding the stove’s smokiness, cooking ability, and briquette quality. The briquette was produced and supplied by a group of youth associations established as a means of job creation.

The authors’ laboratory observation on the combustibility problem of the briquette was also the same as the quality issues raised in the different focus-group discussions. All end users that participated in the focus-group discussions and others interviewed on-site agreed that the briquette cooking capacity demonstrated during promotion and that available in the market are incomparable, which agrees with the limited cooking capacity observed in the experiment. In addition, briquette producers complain about the market, the government about marketing strategy, NGOs about promotion, and end users about the quality of available briquettes, which needs further study on fuel quality. The authors refrain from giving technical critiques about the performance of the Mirchaye, as briquette quality needs further investigation and is out of the scope of this study. For this reason, the stove was excluded from comparison to avoid any misleading conclusions.

The authors made further assessments of the stove manufacturing process, workmanship, and uniformity of stoves produced by different manufacturers. The government organized producers, and licensed, promoted, and incentivized all ICS programs. The assessment showed dimension discrepancies, low workmanship, and that no standard cooking test was performed before distribution, except for the EZY. This is an indicator of inadequate training, knowledge gaps, improper certification, and lack of quality control.

Biomass fuels that burn at different moisture contents have different combustion behavior and emission concentrations. In this study, eucalyptus fuel with similar moisture content has been used for all experiments. For analysis purposes, the fuels consumed during the test have been converted into dry-fuel equivalents as shown in

Table 5.

The impact of the thermal mass of stoves in fuel consumption and energy storage has been clearly shown in the Tikikkle stove. The stove’s thermal mass has used about 42% of the fuel to warm its mud mass during the cold-start process and reduce fuel consumption in hot-start process. On the other hand, the EZY stove demonstrated almost no impact on this.

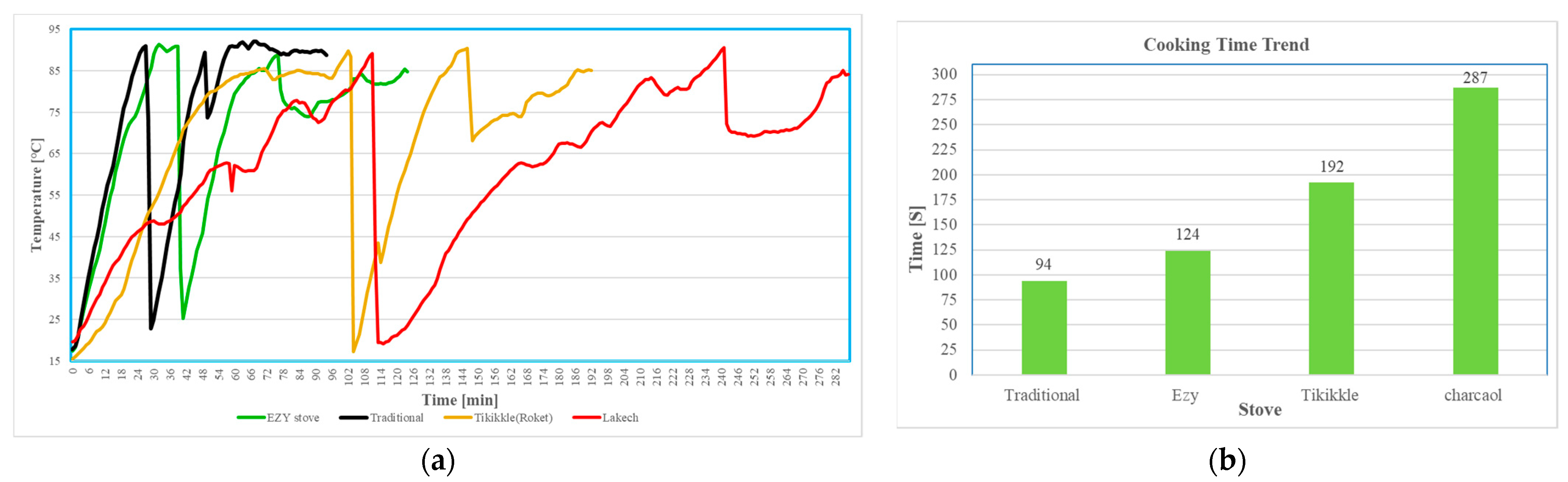

Figure 5a gives the average results of three qualified standard WBT experiments of the stoves under study. The stoves took 1:30, 2:00, 3:00, and 5:00 h to perform the standard WBT as shown in

Figure 5b.

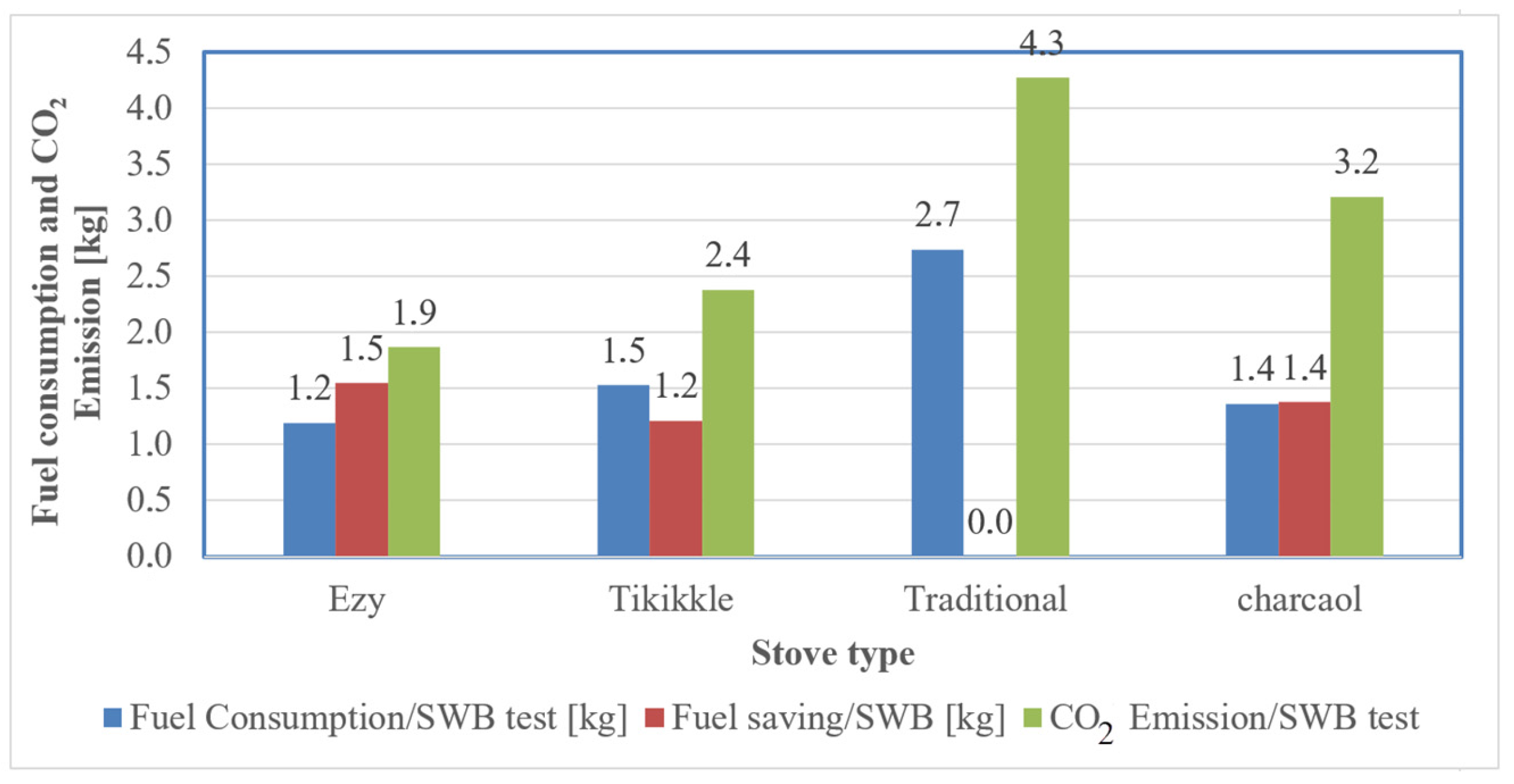

The order of the stoves in terms of higher fuel consumption tendency is traditional, Lakech, Tikikkle, and EZY, respectively. A similar ranking order was also obtained for their CO

2 emission contribution as presented in

Figure 6.

4.4. Numerical Results

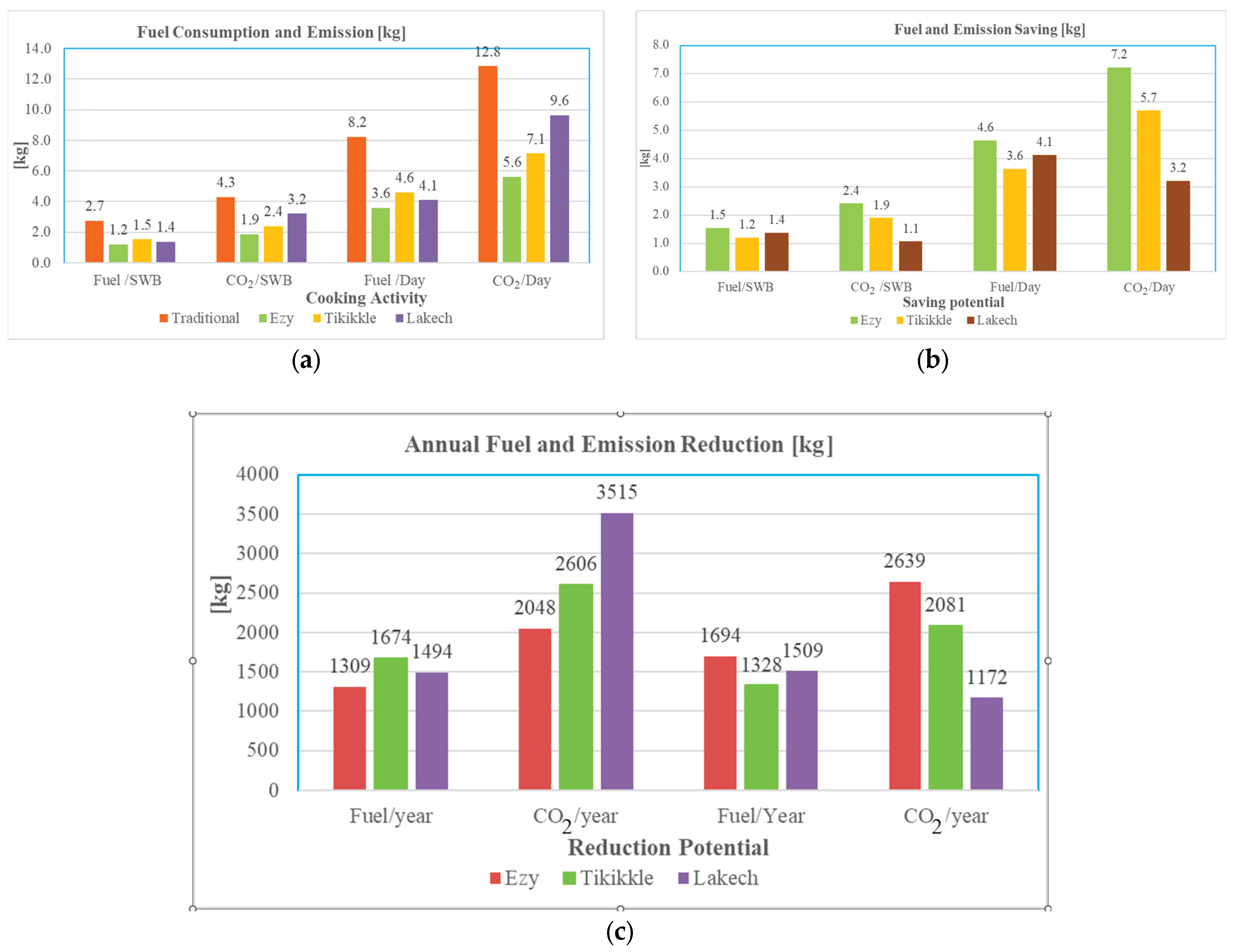

The estimation for daily and annual fuel consumption of conventional cooking has been performed by considering three cooking activities per day, i.e., equivalent to three standard WBTs. Accordingly, the fuel consumption, saving, reduction potential, and associated CO

2 emission of the stoves have been shown in

Figure 7a–c.

In the numerical analysis, the ultimate analyses for wood fuel and charcoal have been treated separately. The analysis result showed a significant rise of CO

2 concentration compared to the other emission elements. As a result, only CO

2 was considered as an important compassion parameter in the study. The tabulated data produced from analysis results of this research have been shown in

Table 6,

Table 7,

Table 8,

Table 9,

Table 10 and

Table 11.

The Lakech stove took a longer cooking time compared to the others, as shown in

Figure 5a, for common cooking activities such as legumes. This indicates the limited capacity of the stove for different heavy-duty cooking techniques. Usually, users took hot char or dried char left from other cooking periods, for example from injera baking or cooking from TCS, to operate their Lakech stove. This stove is good for coffee making, water warming, and light and slow cooking such as cooking Shiro stew. Similar tendencies have been observed for the Tikikkle stove too. Users assumed these stoves were not the right technologies to replace their TCSs, regardless of their energy and emission-saving advantages. In addition, the ICS implementation amendments made by the steering committee do not bring change amid the bigger resistance of end users to these technologies.

On the other hand, users described the EZY stove as a viable candidate technology, except for its compact size. This stove is very compact and versatile for any cooking type. However, there are safety issues associated with its bearing stability during heavy cooking in the presence of children. Children burning and the cooking pot falling over with its contents after a slight contact were common incidents. This technical issue is because of the small stove-pot size aspect ratio.

5. Recommendations

The authors recommend the following actionable thoughts to improve the current low performance of ICS programs and aspire to meet the United Nations 2030 sustainability goal of clean cooking in the remaining time frame.

The mud-made ICS technologies stayed in promotion programs for an exceptionally long time. The pace of scientific advancement on these stoves is slow compared to the custom-made traditional stove revolution. In this case, the community’s attitude to accept these stoves as improved solutions is incredibly low. For this reason, the government needs to focus on developing highly improved stove technologies and stop pumping resources into the promotion of these stoves.

Generally, the ICS technologies are in the order of Tier 0 to 2 [

27]. The government should shift its resources to research and development, new technology development, institutional reorganization, better program planning, and an implementation roadmap instead of continuing its present track record.

The technological order of today’s traditional and mud-made improved cookstoves is in the same range. This technology order has higher influence on economic, societal, and environmental impacts. The government is advised to give the highest priority to high-performance stove technology (≥40%), and development of its clean-cooking programs to bring a significant comeback to its 2025 and 2030 SDG target.

The EZY stove included scientific concepts that result in overall performance improvements. However, continuous technical improvement is required to shift its technological order into higher tiers and the developers are advised to go for that. The developers are highly advised to solve the stability issue of the stove immediately. The authors are willing to give a straightforward engineering solution to this problem if needed.

For a successful shift from TCS to ICS or clean cooking, the country is advised to intervene in the next ICS generation by incorporating end users’ demand, proper training, licensing, certification, quality control, advanced research and development, and continued awareness programs.

6. Conclusions

The dependency of people on biomass energy in Ethiopia will continue into the future unless universal access to clean electricity is achieved. Replacing all TCSs with higher performance ICSs is the way forward for the near future of the country. In this research, the stoves demonstrated an average fuel and emission saving performance of 56% for the EZY and 44% for the Tikikkle, and 50% fuel savings and 25% emission savings for the Lakech. Similarly, thermal efficiencies of 25, 17, and 19% for the EZY, Tikikkle, and Lakech were demonstrated, respectively. Based on these results, promoting the EZY stove with a small stability improvement would have overall economic, social, and environmental gains. In addition, the end users’ good appetite to own the EZY stove regardless of its inflated cost is a good indication for welcoming improved technologies. The EZY stove incorporates insulation, combustion, and versatility concepts that improve fuel consumption and emission contribution, and address end users’ demands. On the other hand, the three- and five-hours’ cooking time for the Tikikkle and Lakech, respectively, with limited versatility for large/heavy cooking are discouraging. Moreover, the shorter cooking time of the TCS attracted end users to stick to it regardless of its higher fuel consumption, emission contribution, and associated health impacts. The thermal efficiency of these ICSs is in the order of lower technologies like the traditional stoves. This similarity has highly influenced the adoption rate. Unless the technological order of these ICS technologies is improved to higher thermal efficiencies, 40 to 50%, achieving clean cooking as part of SDG 7, SDG 13, and the country’s climate-resilient green-economy strategy will be highly compromised.

Author Contributions

A.T.: conceptualization, experimentation, analysis, investigation, manuscript writing, manuscript revision, supervision. M.B.K.: conceptualization, manuscript revision. A.B.G.: experimentation, analysis. All authors have read and agreed to the published version of the manuscript.

Funding

This research has not been funded by any registered project and there will not be any partial or full claim of the results.

Data Availability Statement

Data are contained within the article, however, if further data are required it will be available on request.

Acknowledgments

The authors want to acknowledge Mekelle University for providing lab facilities to conduct the experiments, Tigray Energy Bureau for giving the improved stove prototypes, and Paradigm East Africa Manufacturing PLC (Ezylife) for their interest in evaluating their EZY stove performance by a third party that initiated the authors’ interest to evaluate the performance of the other ICSs and compare their performance with the TCS, as the cookstove energy efficiency issue is a visible gap with little attention from the government. Lat but not least, the authors want to acknowledge Abebe Embaye for his technical support in the lab.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| GHG | Greenhouse gases |

| IAP | Indoor air pollution |

| ICS | Improved cookstove |

| Mc | Mass of compound |

| Me | Mass of element |

| Mf | Mass of fuel |

| MO2 | Mass of oxygen |

| NGO | Non-governmental organization |

| PIC | Products of incomplete combustion |

| PM | Particulate matter |

| SDG | Sustainable development goal |

| SO2 | Sulfur dioxide |

| SWB | Standard water boiling |

| TCS | Traditional cookstove |

| WBT | Water-boiling test |

References

- Bellur, S.; Mathew, P.; Besnard, J. Access to Clean Cooking and Electricity-Righting the Policy; Live wire, 2022/121; World Bank: Washington, DC, USA, 2022. [Google Scholar]

- Yalew, A.W. The Ethiopian energy sector and its implications for the SDGs and modeling. Renew. Sustain. Energy Transit. 2022, 2, 100018. [Google Scholar] [CrossRef]

- Degefa, M.W. Energy analysis in rural Ethiopia Eastern Amhara households. MRS Energy Sustain. 2020, 7, E40. [Google Scholar] [CrossRef]

- Tesfay, A.H.; Tsegay, K.; Kahsay, M.B.; Hailu, M.H.; Adaramola, M.S. Performance comparison of three prototype biomass stoves with traditional and Mirt stoves for baking Injera. Energy Sustain. Soc. 2024, 14, 11. [Google Scholar] [CrossRef]

- Jeuland, M.A.; Bhojvaid, V.; Kar, A.; Lewis, J.J.; Patange, O.; Pattanayak, S.K.; Ramanathan, N.; Rehman, I.H.; Tan Soo, J.S.; Ramanathan, V. Preferences for improved cook stoves: Evidence from rural villages in north India. Energy Econ. 2015, 52, 287–298. [Google Scholar] [CrossRef]

- Lombardi, F.; Riva, F.; Bonamini, G.; Barbieri, J.; Colombo, E. Laboratory protocols for testing of Improved Cooking Stoves (ICSs): A review of state-of-the-art and further developments. Biomass Bioenergy 2017, 98, 321–335. [Google Scholar] [CrossRef]

- Tucho, G.T.; Weesie, P.D.M.; Nonhebel, S. Assessment of renewable energy resources potential for large scale and standalone applications in Ethiopia. Renew. Sustain. Energy Rev. 2014, 40, 422–431. [Google Scholar] [CrossRef]

- Pennise, D.; Brant, S.; Agbeve, S.M.; Quaye, W.; Mengesha, F.; Tadele, W.; Wofchuck, T. Indoor air quality impacts of an improved wood stove in Ghana and an ethanol stove in Ethiopia. Energy Sustain. Dev. 2009, 13, 71–76. [Google Scholar] [CrossRef]

- Sanbata, H.; Asfaw, A.; Kumie, A. Indoor air pollution in slum neighborhoods of Addis Ababa, Ethiopia. Atmos. Environ. 2014, 89, 230–234. [Google Scholar] [CrossRef]

- Lindgren, S.A. Clean cooking for all? A critical review of behavior, stakeholder engagement, and adoption for the global diffusion of improved cookstoves. In Energy Research and Social Science; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; Volume 68. [Google Scholar] [CrossRef]

- Chowdhury, Z.; Campanella, L.; Gray, C.; Al Masud, A.; Marter-Kenyon, J.; Pennise, D.; Charron, D.; Zuzhang, X. Measurement and modeling of indoor air pollution in rural households with multiple stove interventions in Yunnan, China. Atmos. Environ. 2013, 67, 161–169. [Google Scholar] [CrossRef]

- Harijan, K.; Uqaili, M.A. Potential of Biomass Conservation Through Dissemination of Efficient Cook Stoves in Pakistan. APCBEE Procedia 2013, 5, 358–362. [Google Scholar] [CrossRef]

- MacCarty, N.; Ogle, D.; Still, D.; Bond, T.; Roden, C. A laboratory comparison of the global warming impact of five major types of biomass cooking stoves. Energy Sustain. Dev. 2008, 12, 56–65. [Google Scholar] [CrossRef]

- Singh, A.; Tuladhar, B.; Bajracharya, K.; Pillarisetti, A. Assessment of effectiveness of improved cook stoves in reducing indoor air pollution and improving health in Nepal. Energy Sustain. Dev. 2012, 16, 406–414. [Google Scholar] [CrossRef]

- Gill, J. Improved stoves in developing countries: A critique. Energy Policy 1987, 15, 135–144. [Google Scholar] [CrossRef]

- IEA; IRENA; UNSD; World Bank; WHO. Tracking SDG7 A Joint Report of the Custodian Agencies. 2022. Available online: www.worldbank.org (accessed on 4 February 2024).

- Simon, G.L.; Bumpus, A.G.; Mann, P. Win-win scenarios at the climate–development interface: Challenges and opportunities for stove replacement programs through carbon finance. Glob. Environ. Change 2012, 22, 275–287. [Google Scholar] [CrossRef]

- Bizzarri, M. Safe Access to Firewood and Alternative Energy in Ethiopia: An Appraisal Report; World Food Program: Rome, Italy, 2010. [Google Scholar]

- Rawles, S. Oxfam, Annual Report, 2012–2013; Oxfam: Hong Kong, China, 2012. [Google Scholar]

- Gebru, B.; Bezu, S. Environmental Resource Collection versus Children’s Schooling: Evidence from Tigray, Northern Ethiopia. Addis Ababa, Ethiopia: EDRI 2011. Available online: http://www.edri.org.et/ (accessed on 4 February 2024).

- Mekonnen, A.; Beyene, A.; Bluffstone, R.; Gebreegziabher, Z.; Martinsson, P.; Toman, M.; Vieider, F. Do improved biomass cookstoves reduce fuelwood consumption and carbon emissions? Evidence from a field experiment in rural Ethiopia. Ecol. Econ. 2022, 198, 107467. [Google Scholar] [CrossRef]

- Rogers, C.; Sovacool, B.K.; Clarke, S. Sweet nectar of the Gaia: Lessons from Ethiopia’s “Project Gaia”. Energy Sustain. Dev. 2013, 17, 245–251. [Google Scholar] [CrossRef]

- Beyene, A.D.; Koch, S.F. Clean fuel-saving technology adoption in urban Ethiopia. Energy Econ. 2013, 36, 605–613. [Google Scholar] [CrossRef]

- Takama, T.; Tsephel, S.; Johnson, F.X. Evaluating the relative strength of product-specific factors in fuel switching and stove choice decisions in Ethiopia. A discrete choice model of household preferences for clean cooking alternatives. Energy Econ. 2012, 34, 1763–1773. [Google Scholar] [CrossRef]

- Kebede, B.; Bekele, A.; Kedir, E. Can the urban poor afford modern energy? The case of Ethiopia. Energy Policy 2002, 30, 1029–1045. [Google Scholar] [CrossRef]

- US Environmental Protection Agency. The Water Boiling Test Environmental Protection Agency, Partnership for Clean Indoor Air (PCIA), with Updates Coordinated by PCIA and the Global Alliance for Clean Cookstoves (Alliance); US Environmental Protection Agency: Washington, DC, USA, 2014.

- Sutar, K.B. Energy Efficiency, Emissions and Adoption of Biomass Cookstoves. 2022. Available online: www.intechopen.com (accessed on 4 February 2024).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).