Experimental Investigation on Knock Characteristics from Pre-Chamber Gas Engine Fueled by Hydrogen

Abstract

1. Introduction

1.1. Knock Combustion in Conventional Internal Combustion Engines

1.2. Gasoline-Fueled Knock Combustion Tests in Pre-Chamber Systems

1.3. Characteristics of Hydrogen Combustion

- to determine the conditions of knocking combustion in the TJI system in the main chamber and the pre-chamber taking into account the variation of the excess air ratio and the center of combustion locations;

- to obtain numerical indices of knock combustion, especially in terms of IMPO index;

- to make a comparison of knock combustion indices: MAPO and IMPO in both combustion chambers.

2. Methodology of the Research Work

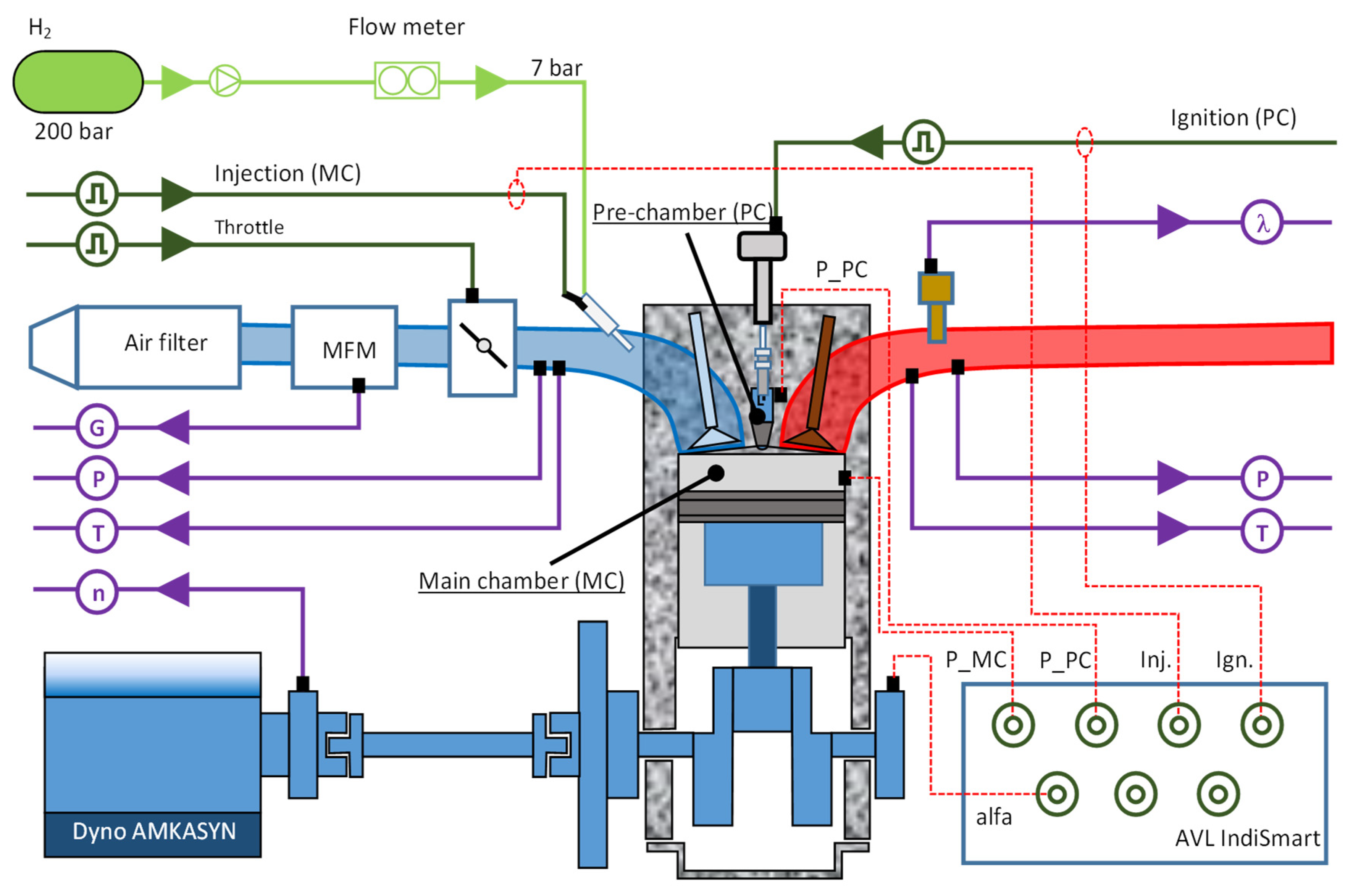

2.1. Test Stand

2.2. Measuring Equipment

3. Results of the Engine Tests

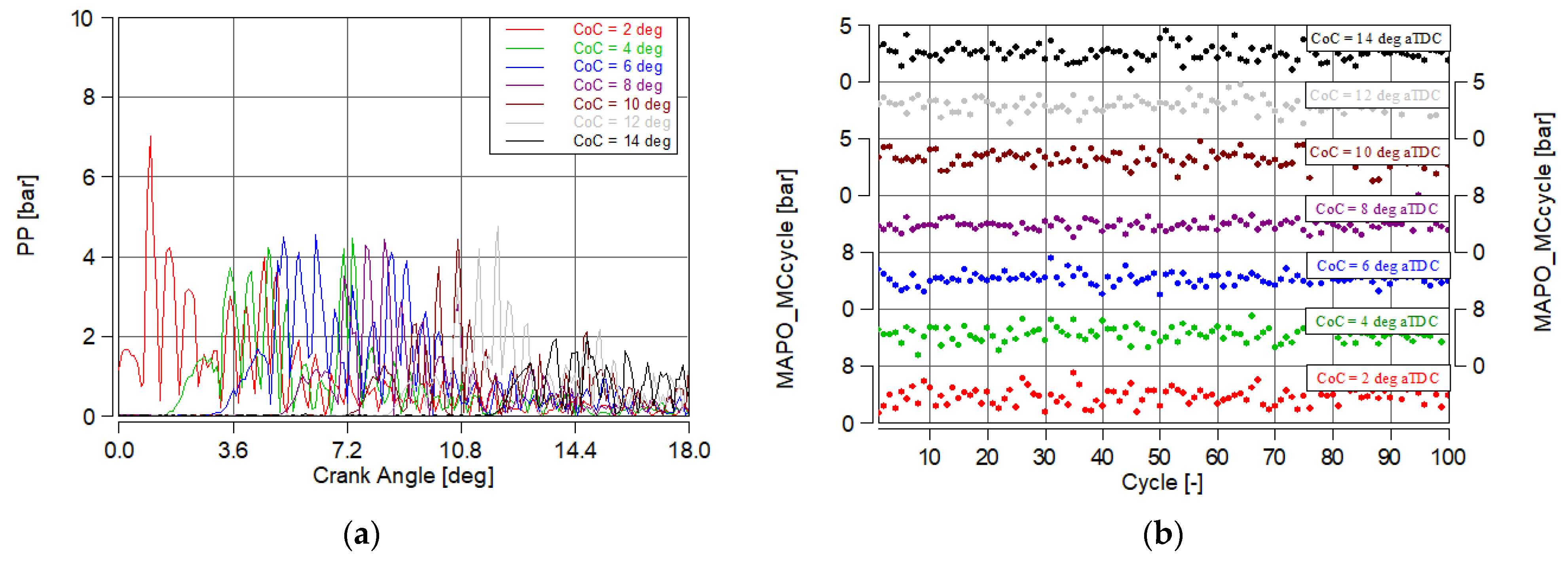

3.1. Overall Test Results

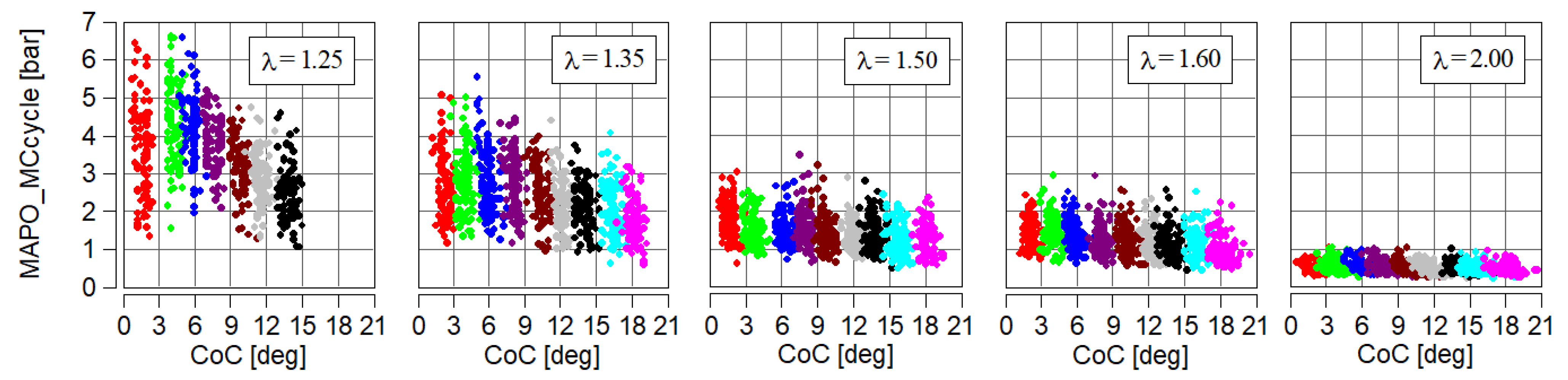

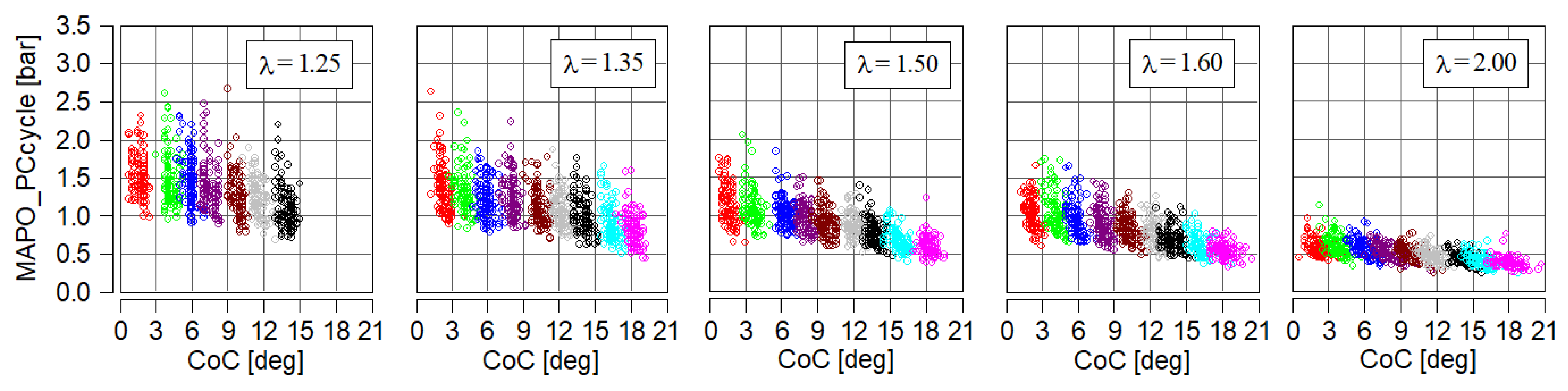

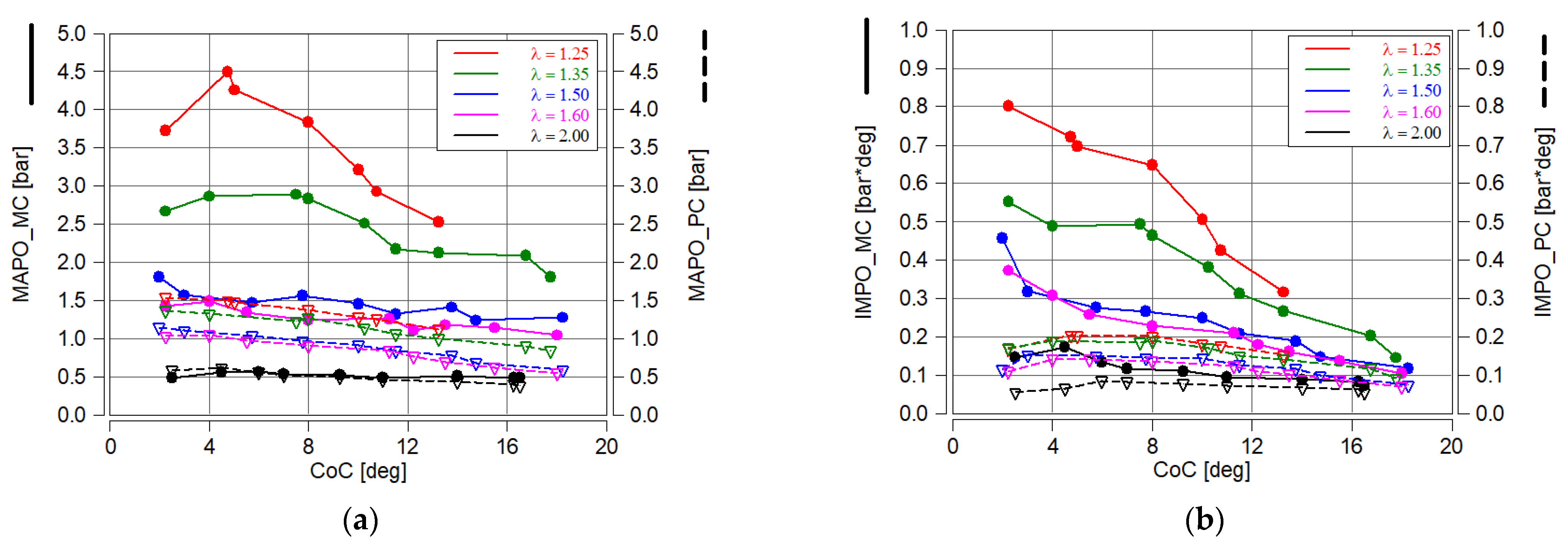

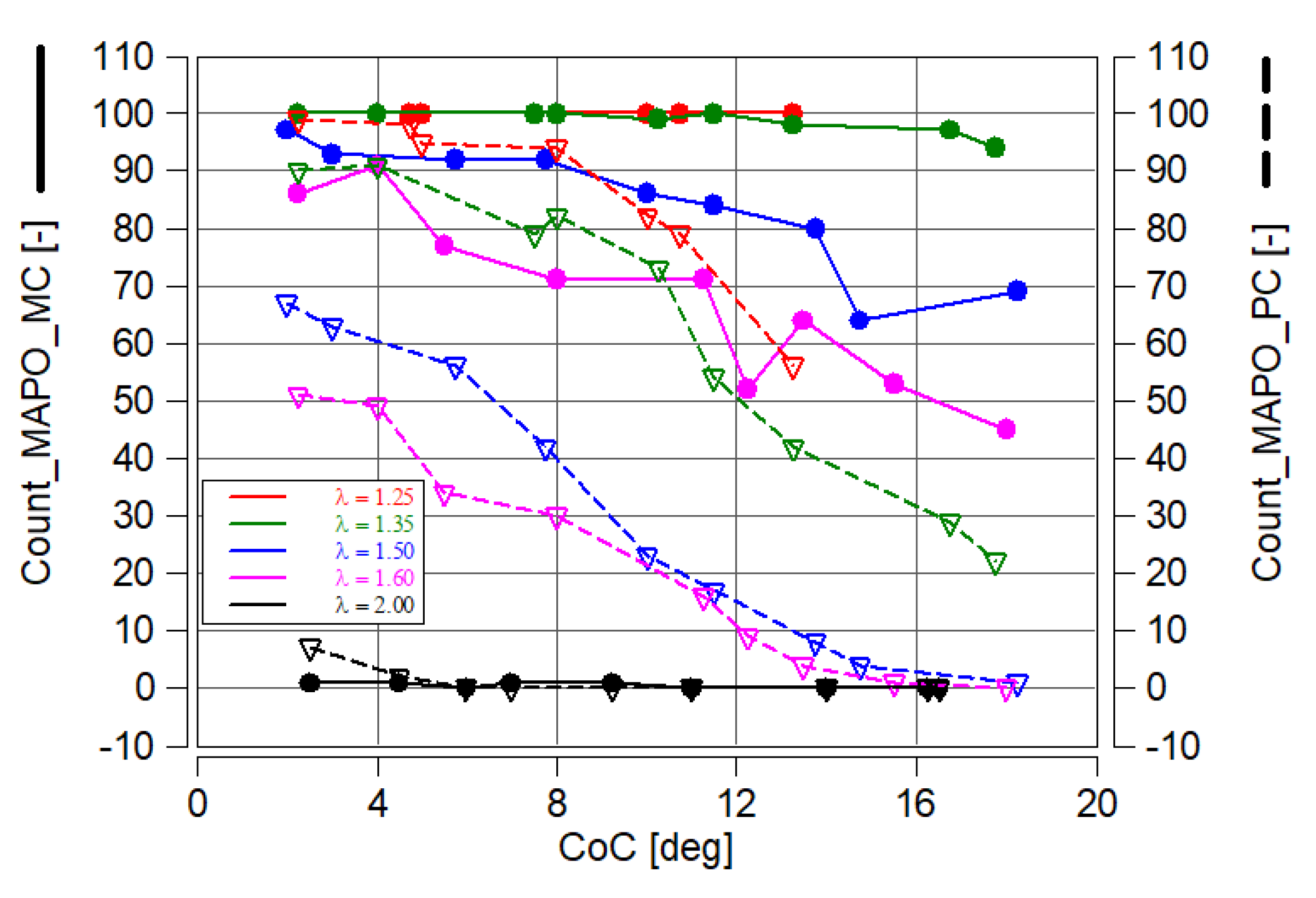

3.2. MAPO Analysis

3.3. IMPO Analysis

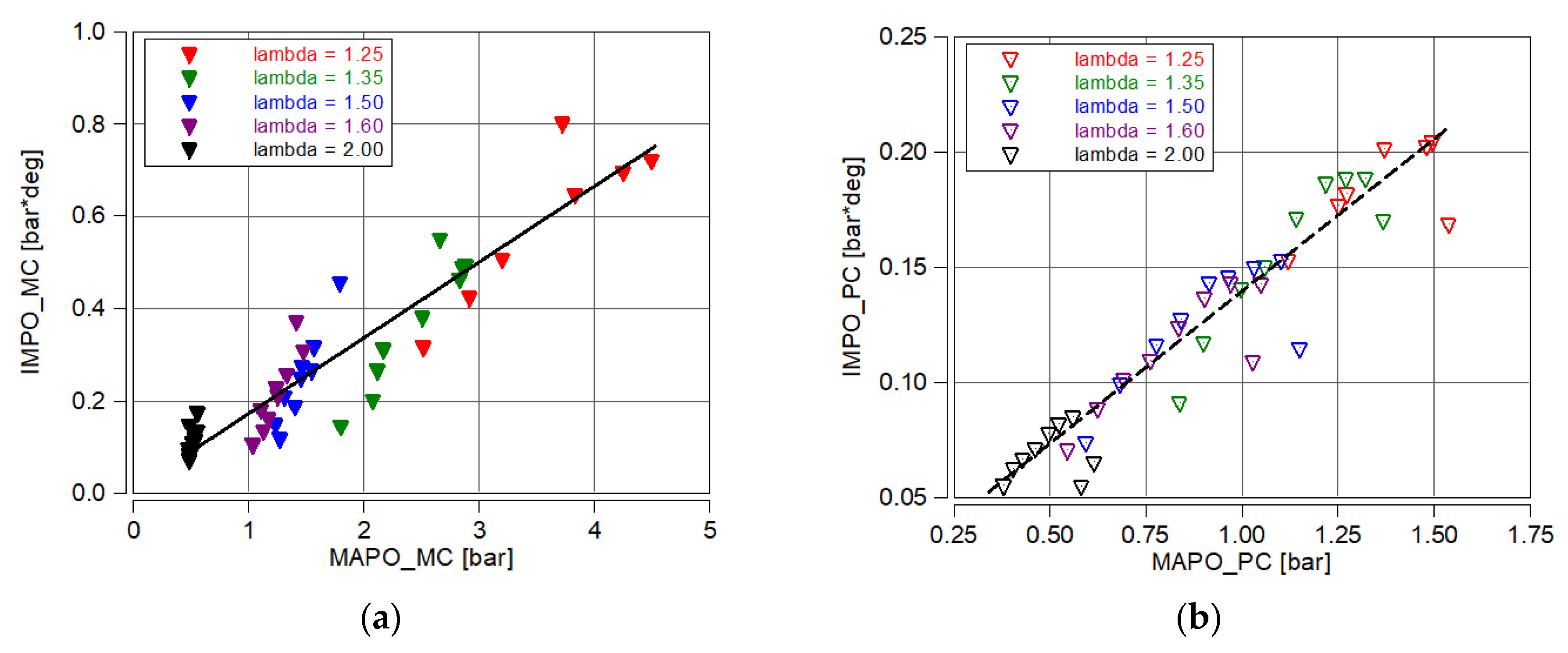

3.4. Comparison of MAPO and IMPO Indicators

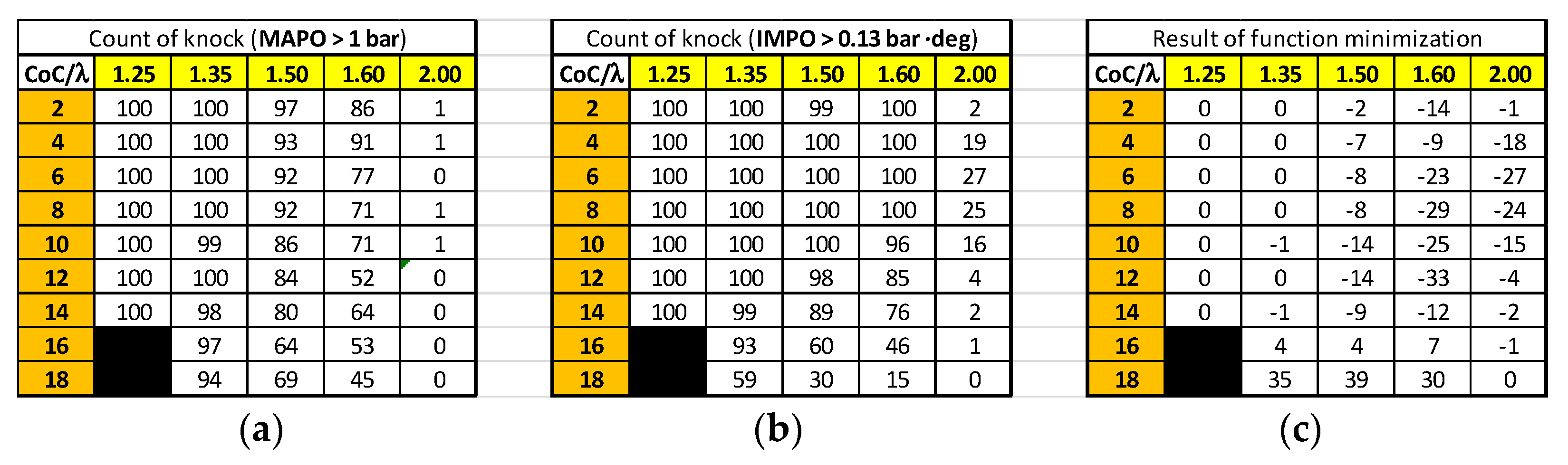

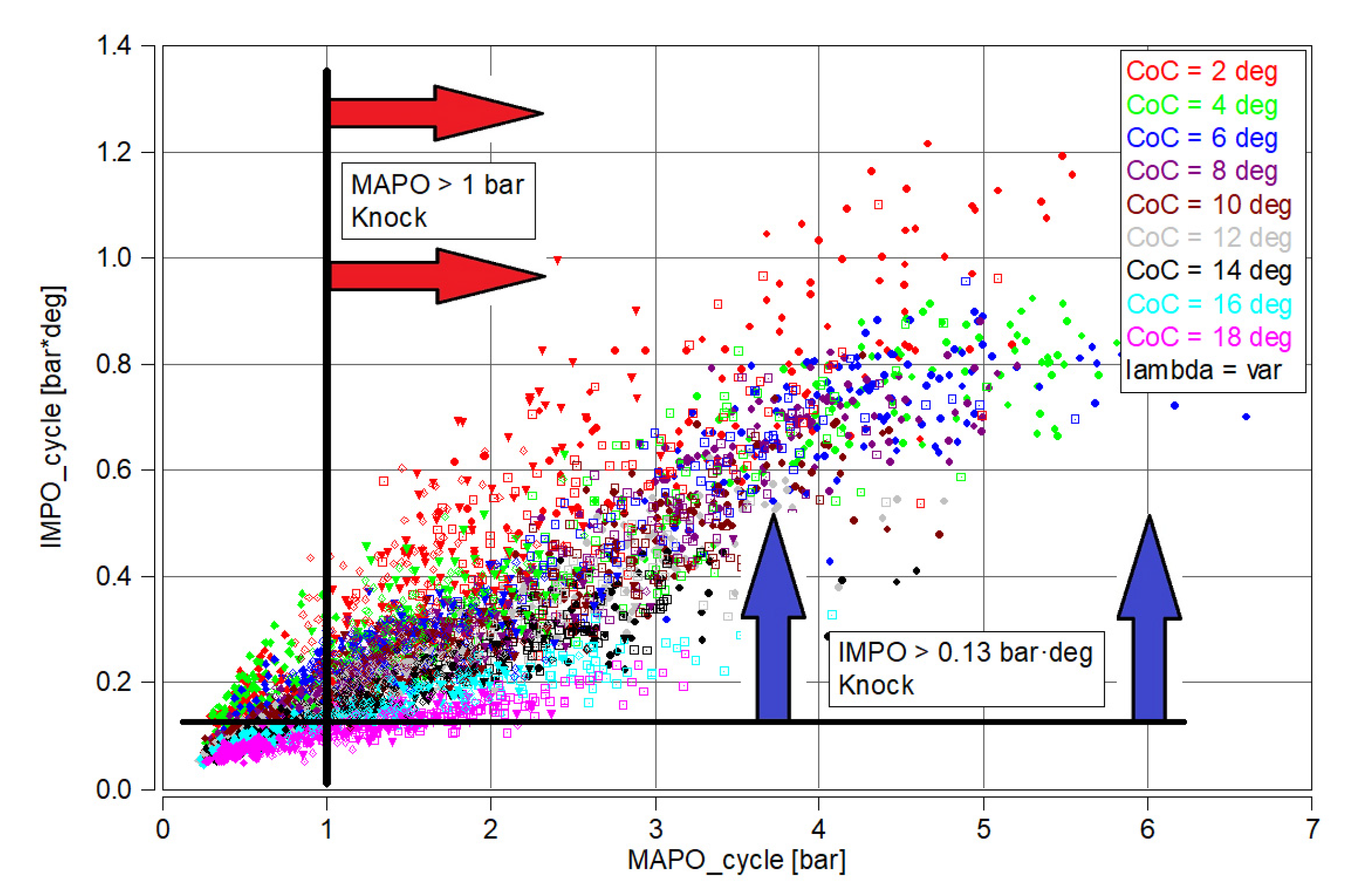

3.5. Determination of IMPO Limits

- MAPO_cycle > 1 and IMPO_cycle > 0.13 → 65.72% of research points

- MAPO_cycle > 1 and IMPO_cycle ≤ 0.13 → 3.09% of research points

- MAPO_cycle < 1 and IMPO_cycle > 0.13 → 7.33% of research points

- MAPO_cycle < 1 and IMPO_cycle ≤ 0.13 → 23.86% of research points

- knock combustion analysis conducted only with MAPO > 1 bar indicates an overestimation of the number of knock combustion cycles by more than 3% (takes into account point 2 of the above breakdown);

- knock combustion analysis conducted only with consideration of IMPO > 0.13 bar-deg indicates an overestimation of the number of knock combustion cycles by more than 7% (takes into account point 3 of the above breakdown);

- consideration of simultaneous MAPO and IMPO indicates the possibility of effectively reducing cycles involving knock combustion underestimated by MAPO or IMPO separately.

4. Conclusions

- At small values of the excess air ratio λ, significant ignition delay (associated with significant CoC delay) does not lead to the disappearance of knock. This means that the elimination of knock combustion under certain conditions must be associated additionally with an increase in the excess air ratio.

- When burning hydrogen lean mixtures during knock, it may be advisable to temporarily increase charge depletion than to delay ignition (or CoC). Analyses show (Figure 4) a much higher efficiency of knock reduction by reducing the excess air ratio than by delaying ignition (or CoC).

- Analysis of IMPO indicates that its highest values (IMPO = 0.8 bar·deg) in the main chamber were obtained at λ = 1.25 and at CoC = 4 deg aTDC. The maximum values of MAPO are more than five times higher than IMPO. The trend of changes in both indices makes IMPO more dependent on CoC than MAPO (which at high values λ does not depend on CoC).

- The indication of the absolute values of MAPO and IMPO indicators makes it possible to fully analyze knock combustion and at the same time reduce the number of this combustion.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BDC | bottom dead center |

| CoC | center of combustion |

| EGR | exhaust gas recirculation |

| EM | electromagnetic |

| f | frequency |

| IMPO | integral modulus of pressure oscillation |

| MAPO | maximum amplitude pressure oscillation |

| MC | main chamber |

| MPRR | maximum pressure rise rate |

| n | engine speed |

| P | pressure |

| PC | pre-chamber |

| PFI | port fuel injection |

| PJI | pre-chamber jet ignition |

| PP | peak pressure |

| ST | spark timing |

| t | time |

| TDC | top dead center |

| TJI | turbulent jet ignition |

| λ | air excess ratio |

References

- Gracz, W.; Marcinkowski, D.; Golimowski, W.; Szwajca, F.; Strzelczyk, M.; Wasilewski, J.; Krzaczek, P. Multifaceted comparison efficiency and emission characteristics of multi-fuel power generator fueled by different fuels and biofuels. Energies 2021, 14, 3388. [Google Scholar] [CrossRef]

- Stępień, Z.; Żak, G.; Markowski, J.; Wojtasik, M. Investigation into the impact of the composition of ethanol fuel deposit control additives on their effectiveness. Energies 2021, 14, 604. [Google Scholar] [CrossRef]

- Zadrąg, R.; Kniaziewicz, T. Evaluation of the engine technical condition based on criterial analysis of exhaust emission indicators. Transp. Res. Proc. 2019, 40, 940–948. [Google Scholar] [CrossRef]

- Kalghatgi, G.; Algunaibet, I.; Morganti, K. On knock intensity and superknock in SI engines. SAE Int. J. Engines 2017, 10, 1051–1063. [Google Scholar] [CrossRef]

- Venkatraman, G.; Giribabu, N.; Mohan, P.S.; Muttiah, B.; Govindarajan, V.K.; Alagiri, M.; Rahman, P.S.A.; Karsani, S.A. Environmental impact and human health effects of polycyclic aromatic hydrocarbons and remedial strategies: A detailed review. Chemosphere 2024, 351, 141227. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhen, X.; Wang, Y.; Liu, D.; Tian, Z. The knock study of high compression ratio SI engine fueled with methanol in combination with different EGR rates. Fuel 2019, 257, 116098. [Google Scholar] [CrossRef]

- Wei, H.; Feng, D.; Pan, J.; Shao, A.; Pan, M. Knock characteristics of SI engine fueled with n-butanol in combination with different EGR rate. Energy 2017, 118, 190–196. [Google Scholar] [CrossRef]

- Liu, F.; Zhou, L.; Hua, J.; Liu, C.; Wei, H. Effects of pre-chamber jet ignition on knock and combustion characteristics in a spark ignition engine fueled with kerosene. Fuel 2021, 293, 120278. [Google Scholar] [CrossRef]

- Toulson, E.; Schock, H.; Attard, W. A review of pre-chamber initiated jet ignition combustion systems. In SAE Technical; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Palakunnummal, M.; Sahu, P.; Ellis, M.; Nazha, M. A cylinder pressure-based knock detection method for pre-chamber ignition gasoline engine. SAE Int. J. Engines 2021, 14, 405–417. [Google Scholar] [CrossRef]

- Corrigan, D.J.; Di Blasio, G.; Ianniello, R.; Silvestri, N.; Breda, S.; Fontanesi, S.; Beatrice, C. Engine knock detection methods for spark ignition and prechamber combustion systems in a high-performance gasoline direct injection engine. SAE Int. J. Engines 2022, 15, 883–897. [Google Scholar] [CrossRef]

- Lee, D.; Yu, X.; Baur, A.; Qiao, L. Visualization and statistical analysis of passive pre-chamber knock in a constant-volume optical engine. SAE Int. J. Engines 2024, 17, 1–18. [Google Scholar] [CrossRef]

- Horner, T. Knock detection using spectral analysis techniques on a Texas Instruments TMS320 DSP. In SAE Technical; SAE International: Warrendale, PA, USA, 1996. [Google Scholar] [CrossRef]

- Cavina, N.; Corti, E.; Minelli, G.; Moro, D.; Solieri, L. Knock indexes normalization methodologies. In SAE Technical; SAE International: Warrendale, PA, USA, 2006. [Google Scholar] [CrossRef]

- Ponte, S.; Andrade, J.M.; Vazquez, C.; Ferreiro, B.; Cobas, C.; Perez, A.; Rey, M.; Vales, C.; Pellitero, J.; Santacruz, B.; et al. Modeling the natural gas knocking behaviour using gas-phase infrared spectra and multivariate calibration. J. Nat. Gas Sci. Eng. 2021, 90, 103944. [Google Scholar] [CrossRef]

- Brecq, G.; Bellettre, J.; Tazerout, M. A new indicator for knock detection in gas SI engines. Int. J. Therm. Sci. 2003, 42, 523–532. [Google Scholar] [CrossRef]

- Hudson, C.; Gao, X.; Stone, R. Knock measurement for fuel evaluation in spark ignition engines. Fuel 2001, 80, 395–407. [Google Scholar] [CrossRef]

- Xiaofeng, G.; Stone, R.; Hudson, C.; Bradbury, I. The detection and quantification of knock in spark ignition engines. In SAE Technical; SAE International: Warrendale, PA, USA, 1993. [Google Scholar] [CrossRef]

- Chun, K.M.; Heywood, J.B. Characterization of knock in a spark-ignition engine. In SAE Technical; SAE International: Warrendale, PA, USA, 1989. [Google Scholar] [CrossRef]

- Benson, G.; Fletcher, E.A.; Murphy, T.E.; Scherrer, H.C. Knock (detonation) control by engine combustion chamber shape. In SAE Technical; SAE International: Warrendale, PA, USA, 1983. [Google Scholar] [CrossRef]

- Leppard, W.R. Individual-cylinder knock occurrence and intensity in multicylinder engines. In SAE Technical; SAE International: Warrendale, PA, USA, 1982. [Google Scholar] [CrossRef]

- Pan, M.; Wei, H.; Feng, D. Effects of exhaust gas recirculation on knock intensity of a downsized gasoline spark ignition engine. J. Energy Res Technol. 2019, 141, 011101. [Google Scholar] [CrossRef]

- Zhou, L.; Kang, R.; Wie, H.; Feng, D.; Hua, J.; Pan, J.; Chen, R. Experimental analysis of superknock occurrence based on a spark ignition engine with high compression ratio. Energy 2018, 165, 68–75. [Google Scholar] [CrossRef]

- Thomas, J.R.; Clarke, D.P.; Collins, J.M.; Sakonji, T.; Ikeda, K.; Shoji, F.; Furushima, K. A test to evaluate the influences of natural gas composition and knock intensity. Trans. ASME J. ICE 1994, 22. [Google Scholar]

- Szwaja, S.; Naber, J.D. Dual nature of hydrogen combustion knock. Int. J. Hydrogen Energy 2013, 38, 12489–12496. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, Z.; Sun, B.; Zhang, S.; Lai, F.; Ma, N.; Ju, X.; Luo, Q.; Bao, L.-Z. Experimental investigation of the working boundary limited by abnormal combustion and the combustion characteristics of a turbocharged direct injection hydrogen engine. Energy Convers. Manag. 2024, 299, 117861. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, X.; Tang, Q.; Wang, Y.; Li, Y. Knock recognition of knock sensor signal based on wavelet transform and variational mode decomposition algorithm. Energy Convers. Manag. 2023, 287, 117062. [Google Scholar] [CrossRef]

- Aramburu, A.; Guido, C.; Bares, P.; Pla, B.; Napolitano, P.; Beatrice, C. Knock detection in spark ignited heavy duty engines: An application of machine learning techniques with various knock sensor locations. Measurement 2024, 224, 113860. [Google Scholar] [CrossRef]

- Pla, B.; Bares, P.; Jimenez, I.; Guardiola, C. Increasing knock detection sensitivity by combining knock sensor signal with a control oriented combustion model. Mech. Syst. Signal Process. 2022, 168, 108665. [Google Scholar] [CrossRef]

- Güdden, A.; Pischinger, S.; Geiger, J.; Heuser, B.; Müther, M. An experimental study on methanol as a fuel in large bore high speed engine applications—Port fuel injected spark ignited combustion. Fuel 2021, 303, 121292. [Google Scholar] [CrossRef]

- Puzinauskas, P.V. Examination of methods used to characterize engine knock. In SAE Technical; SAE International: Warrendale, PA, USA, 1992. [Google Scholar] [CrossRef]

- Shi, H.; Tang, Q.; Uddeen, K.; Magnotti, G.; Turner, J. Optical diagnostics and multi-point pressure sensing on the knocking combustion with multiple spark ignition. Combust. Flame 2022, 236, 111802. [Google Scholar] [CrossRef]

- Nazir, H.; Muthuswamy, N.; Louis, C.; Jose, S.; Prakash, J.; Buan, M.E.M.; Flox, C.; Chavan, S.; Shi, X.; Kauranen, P.; et al. Is the H2 economy realizable in the foreseeable future? Part III: H2 usage technologies, applications, and challenges and opportunities. Int. J. Hydrogen Energy 2020, 45, 28217–28239. [Google Scholar] [CrossRef]

- Gurz, M.; Baltacioglu, E.; Hames, Y.; Kaya, K. The meeting of hydrogen and automotive: A review. Int. J. Hydrogen Energy 2017, 42, 23334–23346. [Google Scholar] [CrossRef]

- Yip, H.L.; Srna, A.; Yuen, A.C.Y.; Kook, S.; Taylor, R.A.; Yeoh, G.H.; Medwell, P.R.; Chan, Q.N. A review of hydrogen direct injection for internal combustion engines: Towards carbon-free combustion. Appl. Sci. 2019, 9, 4842. [Google Scholar] [CrossRef]

- Bao, L.; Sun, B.; Luo, Q. Experimental investigation of the achieving methods and the working characteristics of a near-zero NOx emission turbocharged direct-injection hydrogen engine. Fuel 2022, 319, 123746. [Google Scholar] [CrossRef]

- Barış, O.; Güler, İ.; Yaşgül, A. The effect of different charging concepts on hydrogen fuelled internal combustion engines. Fuel 2023, 343, 127983. [Google Scholar] [CrossRef]

- Molina, S.; Novella, R.; Gomez-Soriano, J.; Olcina-Girona, M. Impact of medium-pressure direct injection in a spark-ignition engine fueled by hydrogen. Fuel 2024, 360, 30618. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Engine | – | 1-cyl., 4-valve, SI, TJI |

| Fuel type | – | hydrogen |

| Fuel pressure | bar | 7 bar |

| Displacement | dm3 | 0.5107 |

| Bore × stroke | mm | 85 × 90 |

| Compression ratio | – | 15.5 |

| Fueling | – | PFI (EM injectors); passive pre-chamber |

| Air system | – | naturally-aspirated |

| Dyno | – | AMKASYN AVL AMK DW13-170 |

| Parameter | Name | Value |

|---|---|---|

| Indicating system | AVL IndiSmart | 8-canal, 0.5 deg CA; crank angle AVL 365C |

| Pressure sensor (MC) | AVL GH14D | 0–25 MPa |

| Pressure sensor (PC) | Kistler M3.5 6081 AQ22 | 0–25 MPa |

| Air flow meter | ABB SensyFlow | 0–720 kg/h; error < ±0.8% |

| Injection control | Mechatronika | 0–20 ms; ±0.1 ms |

| Methane, hydrogen flowmeter | Micro Motion ELITE CMFS010M Coriolis Meter | 0.1–2 kg/h; accuracy ±0.25% |

| Lambda probe | Bosch LSU 4.9 | 0.7 to 12.5 |

| Throttle | Bosch ETB 32 mm | ±1 deg |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pielecha, I.; Szwajca, F.; Skobiej, K. Experimental Investigation on Knock Characteristics from Pre-Chamber Gas Engine Fueled by Hydrogen. Energies 2024, 17, 937. https://doi.org/10.3390/en17040937

Pielecha I, Szwajca F, Skobiej K. Experimental Investigation on Knock Characteristics from Pre-Chamber Gas Engine Fueled by Hydrogen. Energies. 2024; 17(4):937. https://doi.org/10.3390/en17040937

Chicago/Turabian StylePielecha, Ireneusz, Filip Szwajca, and Kinga Skobiej. 2024. "Experimental Investigation on Knock Characteristics from Pre-Chamber Gas Engine Fueled by Hydrogen" Energies 17, no. 4: 937. https://doi.org/10.3390/en17040937

APA StylePielecha, I., Szwajca, F., & Skobiej, K. (2024). Experimental Investigation on Knock Characteristics from Pre-Chamber Gas Engine Fueled by Hydrogen. Energies, 17(4), 937. https://doi.org/10.3390/en17040937