Reliability Assessment of Integrated Power and Road System for Decarbonizing Heavy-Duty Vehicles

Abstract

1. Introduction

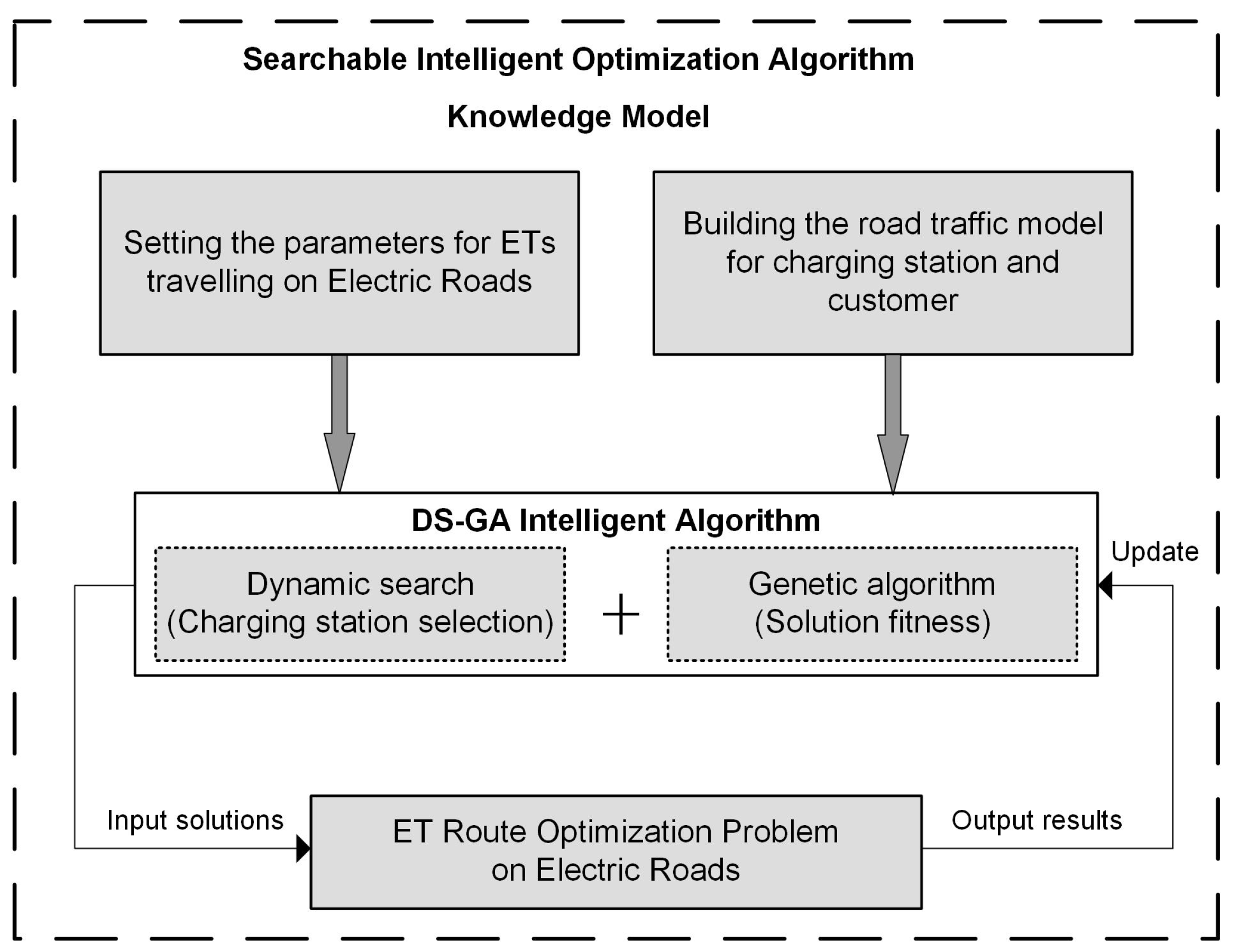

- Based on the specific charging modes of the electric road system, the ET driving and charging patterns are defined and utilized to establish the interaction model between the electric road and the power supply system;

- In order to minimize the charging cost for ETs traveling on electric roads, an optimized routing-planning algorithm is developed. It integrates ET charging cost control with the routing planning, aiming to achieve the lowest charging cost while meeting all designated delivery tasks;

- Based on the optimized energy interaction model between the electric road and power supply system, a daily GA-driven Monte Carlo simulation-based reliability assessment method for ETPSS–ER system is proposed;

- A case study is conducted to assess the reliability of an integrated power and road system with different numbers of ET charging loads. It is shown that, in the case study, introducing the load of 1000 ETs will not cause major reliability concerns on the existing system, while, as the number of ETs exceeds 3000, it is necessary to introduce additional renewable power and BESS for more reliable ETPSS–ER system operation.

2. Interaction Modeling between Electric Roads and Power Supply Systems

- Charging while traveling on ERS—ERS provides power to ET via dynamic wireless charging;

- ET is powered by the on-board battery while traveling on non-electric road;

- ET goes to a charging station to recharge the battery due to the energy shortfall before completion of the journey/task.

2.1. ET Charging Patterns

- Overnight charging (AC charging): When ETs are parked and charged overnight at depots, AC charging is the most common approach. This is usually a slow charging mode with the longest charging time and lowest cost [24];

- High-power charging at station (DC charging): Direct current charging stations are becoming more prevalent now for faster charging, which can shorten the charging time significantly. It covers various power levels from 40–350 kW with different charging tariffs [25];

- Pantograph charging (overhead line charging): Similar to DC railway or metro line traction power supply, ERS can use DC overhead lines to supply power directly to the trucks while driving. This approach sometimes is more suitable for special working conditions, like mining operations [26];

- Dynamic wireless charging (inductive rail charging): It involves embedding charging coils in the ERS and ETs are often equipped with receivers. This allows wireless charging of the ETs while they are on the move [27].

2.1.1. Static Charging Mode

2.1.2. Dynamic Charging Mode

2.2. Mathematical Model of ET Route Optimization

- Only one visit for each customer location;

- The ET journey starts from the depot with full battery capacity, and returns to the depot on completion of all tasks for overnight charging. In-between, they can charge at charging stations;

- When an ET arrives earlier at a delivery location, it will incur additional waiting time, reducing the delivery efficiency;

- If an ET arrives late at a delivery location, it may incur overtime cost;

- The battery capacity of ETs ranges between 0 and 100%.

3. Reliability Assessment Method for ETPSS–ER Systems

3.1. ET Route Simulation

- When the battery capacity of the ET is lower than what is required to reach the next delivery point, the vehicle travels to the nearest charging station/dynamic charging segment to recharge the battery;

- When the ET travels within 2 miles of a dynamic charging road section, priority is given to the on-road dynamic charging;

- The battery capacity is fully charged after each charge;

- ETs adopt fast charging mode while on duty and normal slow charging mode in depots.

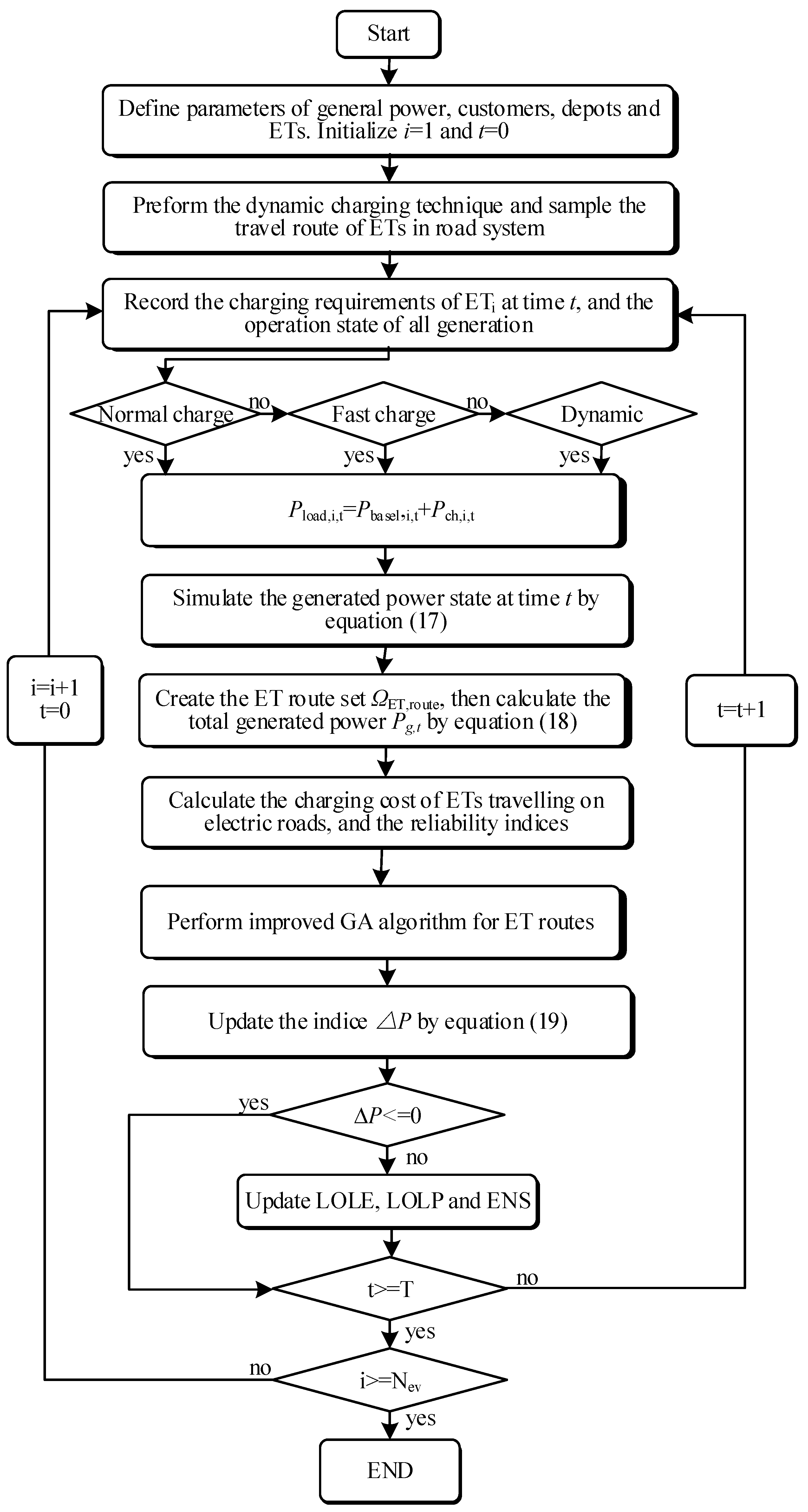

- Set the values for all the parameters of the ERS system, including the number, the location and charging power of the ETs, and the number and location of customers/depots. Further, define the GA parameters, including cross-over and mutation rates;

- Calculate the travel distance between customer locations as well as the distances from each customer point to charging stations and to the dynamic charging sections;

- Based on the randomly generated initial populations, conduct route searches and calculate the total travel distance for each route defined in the GA initial population;

- Check the feasibility of each route generated in the population. The ET needs to travel to the nearest charging station when the distance to the next customer location exceeds the maximum driving range of the existing battery capacity. And the ET needs travel to the charging road sections by checking the designed dynamic search rules while on duty. Record and insert the charging station into the planned route as an updated route;

- Calculate the charging cost for each route in the whole population, and calculate the total charging costs when all ETs are counted;

- GA conducts the cross-over and mutation operation, and elite scheme is also adopted to keep the best solutions achieved over the whole population;

- Repeat the above steps until the solutions converge. The final optimal solution gives the optimal routes for all ETs and their associated daily travel costs. This allows for determination of the daily charging requirements for all ETs.

3.2. Reliability Assessment of ETPSS–ER System

3.2.1. Cost–Benefit Indices of Road Systems

3.2.2. Reliability Indices of ETPSS–ER Systems

3.2.3. Daily GA-Driven Monte Carlo Simulation-Based Reliability Assessment Method for ETPSS–ER System

- Initialize parameters of electric road systems, including the number and charging power of trucks, the location and number of customers and depots, and the sampling time;

- Determine the required arrival time, service time, and load requirements for each customer point;

- Generate the delivery routes of ETs to calculate the corresponding charging cost. Then, obtain the optimal ET routes with minimal charging cost by the improved GA algorithm;

- Calculate the load power of ETs traveling on electric roads at time t based on the daily travel and charging routes;

- Update the EVs’ charging and annual load by the load power of trucks charging dynamically on roads;

- Count the total generated power by the annual data and sample the operation state of each generator.

- Determine whether the power supply exceeds the power demand. If this is true, there will be no power shortage; otherwise, there will be a power shortage;

- Calculate the proposed reliability indices, such as LOLE, LOLP, and ENS;

- End the cycle if the time t reaches the total simulation time; otherwise, continue the above steps. Then, update all the reliability indices.

4. Case Study

4.1. Parameter Settings

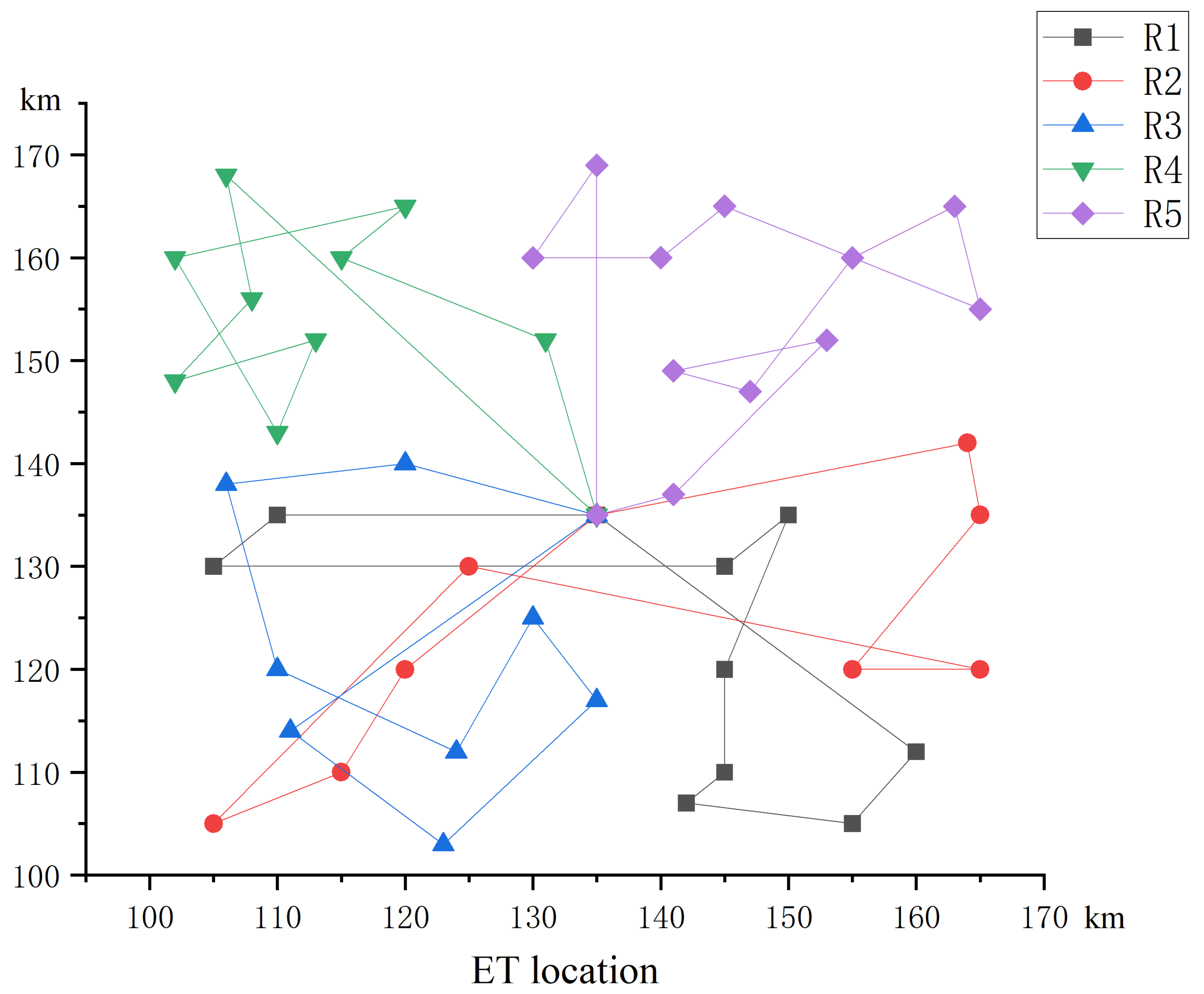

4.2. ET Routing Results

- ;

- ;

- ;

- ;

- .

4.3. Reliability Indices

4.3.1. Load Cost–Benefit Model

4.3.2. Power System Reliability

- (1)

- Indexes of ET penetration in ETPSS–ER system

- (2)

- Impact of wind power for ETPSS–ER system

- (3)

- Impact of BESS for ETPSS–ER system

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Umar, M.; Ji, X.; Kirikkaleli, D.; Alola, A.A. The imperativeness of environmental quality in the United States transportation sector amidst biomass-fossil energy consumption and growth. J. Clean. Prod. 2021, 285, 124863. [Google Scholar] [CrossRef]

- Ahmadian, A.; Mohammadi-Ivatloo, B.; Elkamel, A. A review on plug-in electric vehicles: Introduction, current status, and load modeling techniques. J. Mod. Power Syst. Clean Energy 2020, 8, 412–425. [Google Scholar] [CrossRef]

- Nordin, L.; Hellman, F.; Genell, A.; Gustafsson, M. Distribution of Carbon Dioxide Emissions Produced by the Transportation Sector Worldwide in 2022, by Sub Sector; Technical Report; Statista: Hamburg, Germany, 2023. [Google Scholar]

- Barsali, S.; Ceraolo, M.; Pasini, G.; Poli, D. Managing BEV Charge to Obtain a Positive Impact on a National Power System. Energies 2024, 17, 348. [Google Scholar] [CrossRef]

- Tromans, P. Electric Car Statistics–Data and Projections; Technical Report; Statista: Hamburg, Germany, 2023. [Google Scholar]

- Jackman, J. Electric Vehicle Statistics 2023; Technical Report; Statista: Hamburg, Germany, 2023. [Google Scholar]

- Global EV Outlook 2023; Technical Report; Statista: Hamburg, Germany, 2023.

- Zacharof, N.; Bitsanis, E.; Broekaert, S.; Fontaras, G. Reducing CO2 Emissions of Hybrid Heavy-Duty Trucks and Buses: Paving the Transition to Low-Carbon Transport. Energies 2024, 17, 286. [Google Scholar] [CrossRef]

- Martinez-Boggio, S.; Monsalve-Serrano, J.; García, A.; Curto-Risso, P. High Degree of Electrification in Heavy-Duty Vehicles. Energies 2023, 16, 3565. [Google Scholar] [CrossRef]

- Prussi, M.; Laveneziana, L.; Testa, L.; Chiaramonti, D. Comparing e-Fuels and Electrification for Decarbonization of Heavy-Duty Transports. Energies 2022, 15, 8075. [Google Scholar] [CrossRef]

- Lee, K.Y.; Bühs, F.; Göhlich, D.; Park, S. Towards Reliable Design and Operation of Electric Road Systems for Heavy-Duty Vehicles Under Realistic Traffic Scenarios. IEEE Trans. Intell. Transp. Syst. 2023, 24, 10963–10976. [Google Scholar] [CrossRef]

- Bateman, D.; Leal, D.; Reeves, S.; Emre, M.; Stark, L.; Ognissanto, F.; Myers, R.; Lamb, M. Electric Road Systems: A Solution for the Future? Number 2018SP04EN; National Academies: Washington, DC, USA, 2018. [Google Scholar]

- Schulte, J.; Ny, H. Electric road systems: Strategic stepping stone on the way towards sustainable freight transport? Sustainability 2018, 10, 1148. [Google Scholar] [CrossRef]

- Wang, B.; Zhao, D.; Dehghanian, P.; Tian, Y.; Hong, T. Aggregated electric vehicle load modeling in large-scale electric power systems. IEEE Trans. Ind. Appl. 2020, 56, 5796–5810. [Google Scholar] [CrossRef]

- Almutairi, A.; Alyami, S. Load profile modeling of plug-in electric vehicles: Realistic and ready-to-use benchmark test data. IEEE Access 2021, 9, 59637–59648. [Google Scholar] [CrossRef]

- Shao, S.; Guan, W.; Bi, J. Electric vehicle-routing problem with charging demands and energy consumption. IET Intell. Transp. Syst. 2018, 12, 202–212. [Google Scholar] [CrossRef]

- Miao, H.; Chen, G.; Li, C.; Dong, Z.Y.; Wong, K.P. Operating expense optimization for EVs in multiple depots and charge stations environment using evolutionary heuristic method. IEEE Trans. Smart Grid 2017, 9, 6599–6611. [Google Scholar] [CrossRef]

- Lin, J.; Zhou, W.; Wolfson, O. Electric vehicle routing problem. Transp. Res. Procedia 2016, 12, 508–521. [Google Scholar] [CrossRef]

- Lu, H.; Shao, C.; Hu, B.; Xie, K.; Li, C.; Sun, Y. En-Route Electric Vehicles Charging Navigation Considering the Traffic-Flow-Dependent Energy Consumption. IEEE Trans. Ind. Inform. 2021, 18, 8160–8171. [Google Scholar] [CrossRef]

- Morlock, F.; Rolle, B.; Bauer, M.; Sawodny, O. Time optimal routing of electric vehicles under consideration of available charging infrastructure and a detailed consumption model. IEEE Trans. Intell. Transp. Syst. 2019, 21, 5123–5135. [Google Scholar] [CrossRef]

- Shen, H.; Zhou, X.; Ahn, H.; Lamantia, M.; Chen, P.; Wang, J. Personalized Velocity and Energy Prediction for Electric Vehicles with Road Features in Consideration. IEEE Trans. Transp. Electrif. 2023, 9, 3958–3969. [Google Scholar] [CrossRef]

- Jia, Y.H.; Mei, Y.; Zhang, M. A bilevel ant colony optimization algorithm for capacitated electric vehicle routing problem. IEEE Trans. Cybern. 2021, 52, 10855–10868. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zhu, Y.; Lee, K.Y. Route Optimization of Electric Vehicles Based on Re-insertion Genetic Algorithm. IEEE Trans. Transp. Electrif. 2023, 9, 3753–3768. [Google Scholar] [CrossRef]

- Engel, H.; Hensley, R.; Knupfer, S.; Sahdev, S. Charging ahead: Electric-vehicle infrastructure demand. McKinsey Cent. Future Mobil. 2018, 8. [Google Scholar]

- Danese, A.; Torsæter, B.N.; Sumper, A.; Garau, M. Planning of high-power charging stations for electric vehicles: A review. Appl. Sci. 2022, 12, 3214. [Google Scholar] [CrossRef]

- Al-Saadi, M.; Bhattacharyya, S.; Tichelen, P.V.; Mathes, M.; Käsgen, J.; Van Mierlo, J.; Berecibar, M. Impact on the Power Grid Caused via Ultra-Fast Charging Technologies of the Electric Buses Fleet. Energies 2022, 15, 1424. [Google Scholar] [CrossRef]

- Shanmugam, Y.; Narayanamoorthi, R.; Vishnuram, P.; Bajaj, M.; Aboras, K.M.; Thakur, P. A systematic review of dynamic wireless charging system for electric transportation. IEEE Access 2022, 10, 133617–133642. [Google Scholar] [CrossRef]

- Liu, P.; Wang, C.; Hu, J.; Fu, T.; Cheng, N.; Zhang, N.; Shen, X. Joint route selection and charging discharging scheduling of EVs in V2G energy network. IEEE Trans. Veh. Technol. 2020, 69, 10630–10641. [Google Scholar] [CrossRef]

- The Global Electric Vehicle Market Overview In 2023: Statistics & Forecasts; Technical Report; Statista: Hamburg, Germany, 2023.

- Trends in Electric Heavy-Duty Vehicles; Technical Report; Statista: Hamburg, Germany, 2023.

| Notation | Definition |

|---|---|

| Set of ETs | |

| Set of customers | |

| Set of fixed charging stations | |

| Set of dynamic charging points | |

| Set of depots | |

| Set of total static charging stations | |

| Set of routes |

| Parameters | Definition |

|---|---|

| Charging cost factor of charging station, GBP/minute | |

| Charging cost factor of electric road, GBP/minute | |

| Fixed costs of EVs, GBP | |

| Optimized route k | |

| Advanced time to customer point i on route k | |

| Delay time to customer point i on route k | |

| Penalty factor for advanced arrival | |

| Penalty factor for delayed arrival |

| Parameter | Value |

|---|---|

| Electric trucks number | 5 |

| EV charging point ratio (dynamic/static charging point) | |

| EV full-charge driving distance (km) | 150 |

| EV full-load capacity (kg) | 200 |

| EV static/dynamic charging power in mid-time (kW) | 40 |

| EV slow charging power in depot station (kW) | 6 |

| Route | Charging Moment (Time t) | ||

|---|---|---|---|

| Static Charging Midtime | Dynamic Charging Midtime | Static Charging Depot | |

| 1 | - | 14:44 | 15:23 |

| 2 | 13:37 | - | 15:34 |

| 3 | 14:13 | - | 15:01 |

| 4 | 13:41 | - | 15:39 |

| 5 | 13:55 | - | 15:55 |

| Indexes | COC (GBP) | MCOC (GBP) | FOC (Times/per ET) | RDC |

|---|---|---|---|---|

| Value | 517.1918 | 103.4384 | 2 | 10% |

| Indexes | LOLE (h) | LOLP | ENS (MWh) |

|---|---|---|---|

| Basic ETPSS–ER | 35.0000 | 0.0040 | 147.6334 |

| ETPSS–ER with wind power | 6.0000 | 6.8681 × | 21.5492 |

| Truck Number | LOLE (h) | LOLP | ENS (MWh) |

|---|---|---|---|

| 100 | 35.0000 | 0.0040 | 148.2694 |

| 300 | 35.0000 | 0.0040 | 149.5412 |

| 500 | 36.0000 | 0.0041 | 150.8484 |

| 1000 | 36.3833 | 0.0042 | 156.1793 |

| 3000 | 55.9500 | 0.0064 | 297.3056 |

| 4000 | 202.7000 | 0.0232 | 2647.4440 |

| 5000 | 356.4500 | 0.0408 | 10,523.0063 |

| Truck Number | LOLE (h) | LOLP () | ENS (MWh) |

|---|---|---|---|

| 100 | 6.0000 | 6.8681 | 21.5492 |

| 300 | 6.0000 | 6.8681 | 21.5492 |

| 500 | 6.0000 | 6.8681 | 21.5492 |

| 1000 | 6.2333 | 7.1352 | 21.5692 |

| 3000 | 13.5333 | 15.4914 | 60.7609 |

| 4000 | 110.1667 | 126.1065 | 1420.1682 |

| 5000 | 285.4167 | 326.7133 | 7895.4413 |

| Truck Number | LOLE (h) | LOLP | ENS (MWh) |

|---|---|---|---|

| 3000 | 13.5333 | 0.0015 | 60.7609 |

| 4000 | 109.4000 | 0.0125 | 1418.8391 |

| 5000 | 281.2000 | 0.0322 | 7863.9448 |

| 6000 | 381.7167 | 0.0437 | 17,543.9211 |

| 7000 | 429.1333 | 0.0491 | 29,216.4485 |

| 8000 | 454.5500 | 0.0520 | 41,285.3816 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuo, W.; Li, K. Reliability Assessment of Integrated Power and Road System for Decarbonizing Heavy-Duty Vehicles. Energies 2024, 17, 934. https://doi.org/10.3390/en17040934

Zuo W, Li K. Reliability Assessment of Integrated Power and Road System for Decarbonizing Heavy-Duty Vehicles. Energies. 2024; 17(4):934. https://doi.org/10.3390/en17040934

Chicago/Turabian StyleZuo, Wei, and Kang Li. 2024. "Reliability Assessment of Integrated Power and Road System for Decarbonizing Heavy-Duty Vehicles" Energies 17, no. 4: 934. https://doi.org/10.3390/en17040934

APA StyleZuo, W., & Li, K. (2024). Reliability Assessment of Integrated Power and Road System for Decarbonizing Heavy-Duty Vehicles. Energies, 17(4), 934. https://doi.org/10.3390/en17040934