An Economic Analysis of Energy Saving and Carbon Mitigation by the Use of Phase Change Materials for Cool Energy Storage for an Air Conditioning System—A Case Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Use of Materials

2.1.1. PCMs

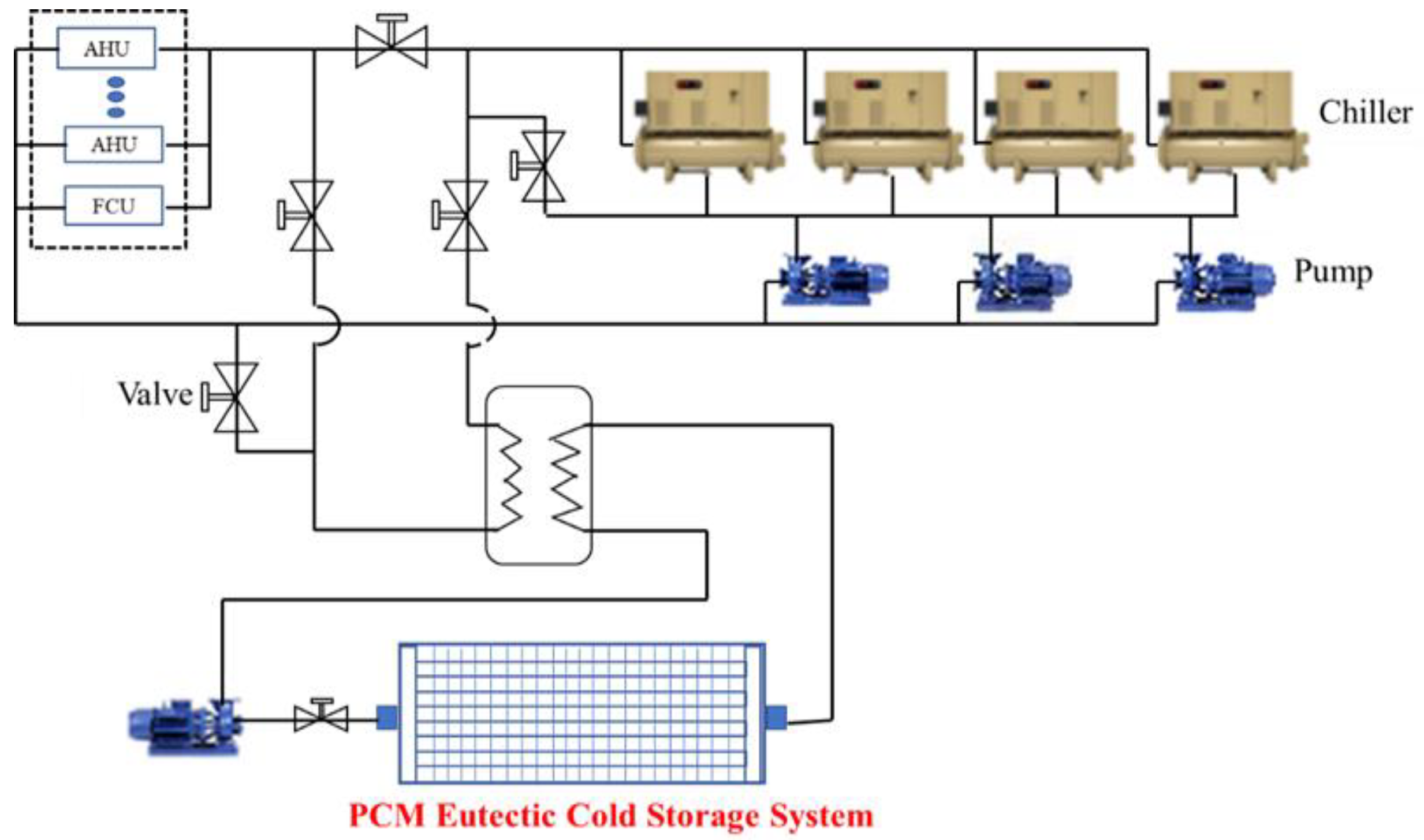

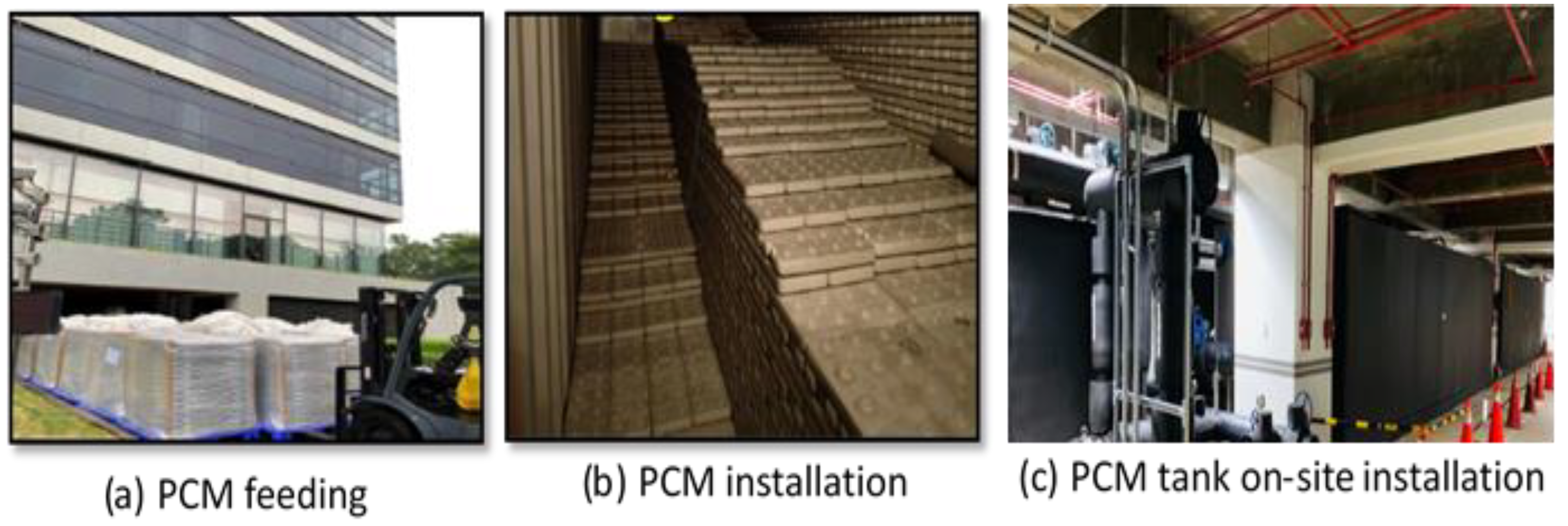

2.1.2. Installation and Setup of PCMACS

2.2. Research Method

2.2.1. Cost Analysis for PCMACS

2.2.2. Energy Consumption Analysis for a PCMACS

2.2.3. Cost-Saving and Carbon Reduction Benefits

Cost-Saving Analysis

Carbon Reduction Analysis

2.2.4. Cost and Benefit Analysis

Net Present Value (NPV)

Benefit–Cost Ratio (BCR)

Internal Rate of Return (IRR)

Payback Period (PR)

Static Payback Period

Dynamic Payback Period

3. Case Study

3.1. Application of PCM in an Air Conditioning System for Cold Storage

3.2. Economic Analysis

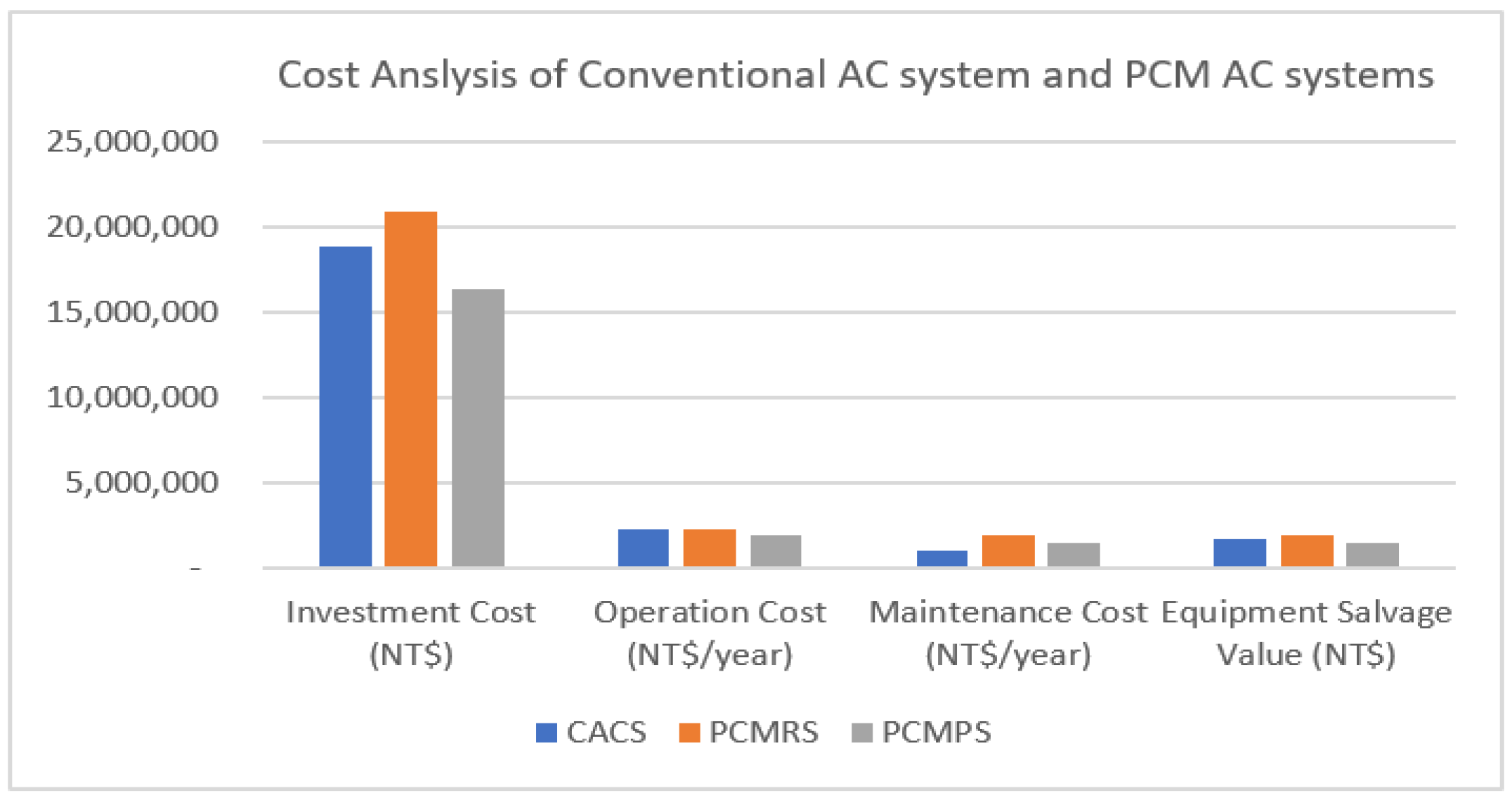

3.2.1. Investment Cost Analysis

3.2.2. Energy Consumption and Energy Saving Analysis

3.2.3. Cost Saving and Carbon Reduction Analysis

Cost Saving Analysis

Carbon Reduction Analysis

3.2.4. Total Cost and Benefit Analysis

4. Results and Discussion

4.1. Results for Investment Cost Analysis

4.2. Analysis Results for Energy Consumption and Energy Savings

4.3. Analysis Results of Cost Savings and Carbon Reduction Benefits

4.3.1. Results for Cost Savings and Benefits

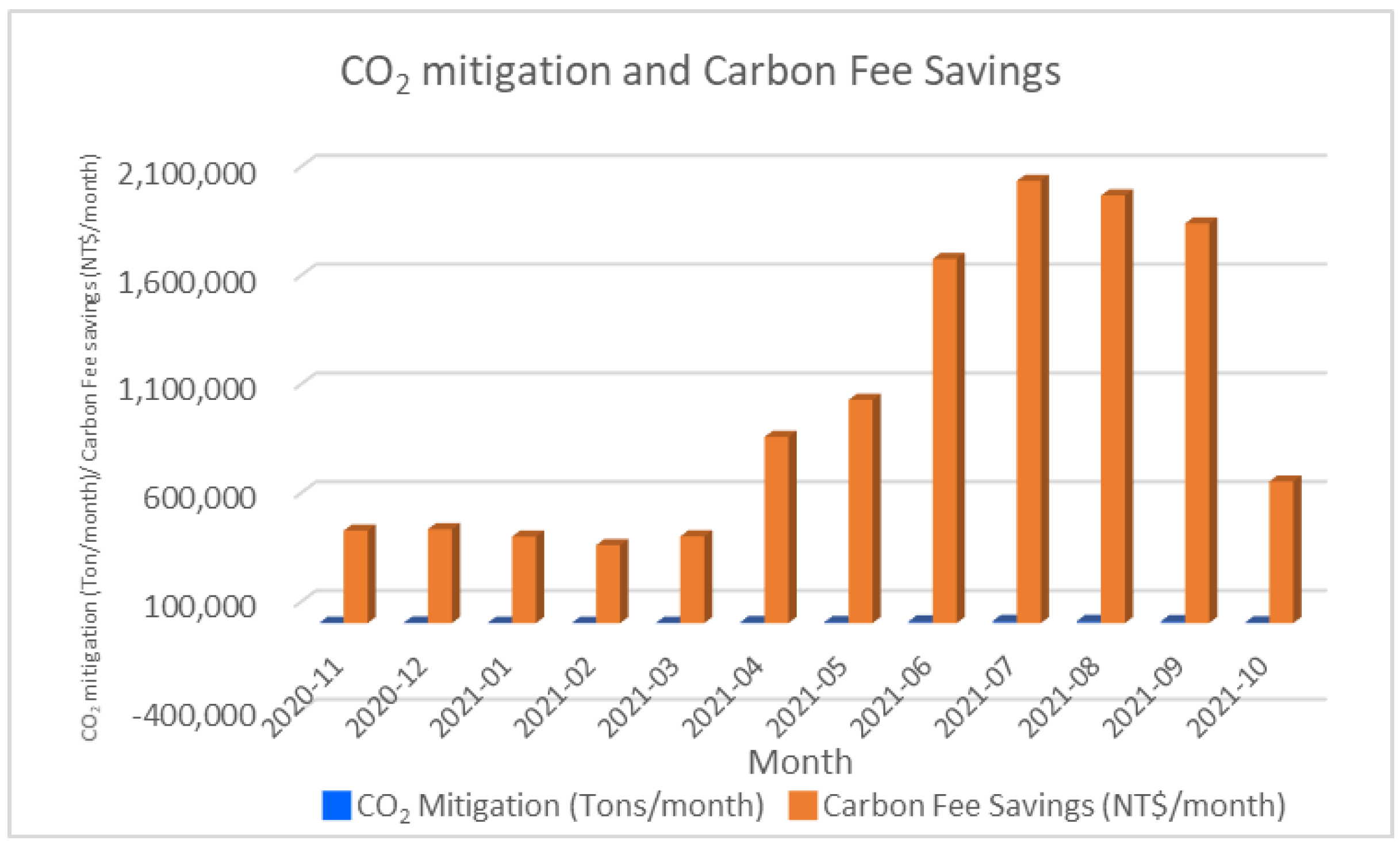

4.3.2. Results for Carbon Reduction

4.4. Results for the Cost and Benefit Analysis

- Net Present Value (NPV):

- Benefit Cost Ratio (BCR):

- Internal Rate of Return (IRR):

- Payback Period:

- Dynamic payback period:

4.5. Discussion

4.5.1. Operational Mode for a Phase Change Material Air Conditioning System

4.5.2. Future Research

5. Conclusions

- The economic analysis results show significant energy-saving and carbon reduction benefits for phase change material cold storage systems, with energy savings of 18% compared to traditional methods and an annual carbon reduction of 60,271 tons. This translates to an annual saving of NT$12,054,337 in carbon emission fees and a payback period of only 2.9 years.

- Due to temperature variations, there are differences in the frequency of air conditioning system usage with the seasons. The greater the frequency of usage, the more significant the energy savings for a PCM.

- The initial investment cost for phase change materials is 11–13% greater than that for traditional methods, so Energy Service Company (ESCO) contracts, such as leasing instead of purchasing, increase the willingness to adopt phase change material air conditioning systems and reduce costs.

- If the construction of phase change material air conditioning systems involves modifying existing systems, the construction cost is prohibitively high. However, if the planning and configuration of a traditional air conditioning system includes provisions for phase change materials from the beginning, some construction costs can be saved. Both approaches are feasible from an energy-saving and carbon reduction perspective.

- Future research will determine the effect of different phase change materials, different phase change temperatures, or different storage tank methods to improve energy-saving performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- EIA. International Energy Outlook; EIA: Washington, DC, USA, 2019. [Google Scholar]

- Kebede, A.A.; Kalogiannis, T.; Van Mierlo, J.; Berecibar, M. A comprehensive review of stationary energy storage devices for large scale renewable energy sources grid integration. Renew. Sustain. Energy Rev. 2022, 159, 112213. [Google Scholar] [CrossRef]

- Lee, S.-K.; Chen, W.-L. An energy consumption and management mode study in a high-tech factory. J. Sci. Eng. Technol. 2009, 5, 57–68. [Google Scholar]

- Hu, S.C.; Chuah, Y.K. Power consumption of semiconductor fabs in Taiwan. Energy 2003, 28, 895–907. [Google Scholar] [CrossRef]

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Famileh, I.Z.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A review on phase change material (PCM) for sustainable passive cooling in building envelopes. Renew. Sustain. Energy Rev. 2016, 60, 1470–1497. [Google Scholar] [CrossRef]

- Ni, J.; Bai, X. A review of air conditioning energy performance in data centers. Renew. Sustain. Energy Rev. 2017, 67, 625–640. [Google Scholar] [CrossRef]

- Residovic, C. The new NABERS Indoor environment tool—The next Frontier for Australian buildings. Procedia Eng. 2017, 180, 303–310. [Google Scholar] [CrossRef]

- Hassan, F.; Jamil, F.; Hussain, A.; Ali, H.M.; Janjua, M.M.; Khushnood, S.; Farhan, M.; Altaf, K.; Said, Z.; Li, C. Recent advancements in latent heat phase change materials and their applications for thermal energy storage and buildings: A state of the art review. Sustain. Energy Technol. Assess. 2022, 49, 101646. [Google Scholar] [CrossRef]

- Mondal, S. Phase change materials for smart textiles–An overview. Appl. Therm. Eng. 2008, 28, 1536–1550. [Google Scholar] [CrossRef]

- Luo, J.; Zou, D.; Wang, Y.; Wang, S.; Huang, L. Battery thermal management systems (BTMs) based on phase change material (PCM): A comprehensive review. Chem. Eng. J. 2022, 430, 132741. [Google Scholar] [CrossRef]

- Huang, Y.-H.; Cheng, W.-L.; Zhao, R. Thermal management of Li-ion battery pack with the application of flexible form-stable composite phase change materials. Energy Convers. Manag. 2019, 182, 9–20. [Google Scholar] [CrossRef]

- Mohammed, A.G.; Wang, Q.; Elfeky, K.E. Rapid cooling effectiveness of Li-ion battery module with multiple phase change materials for plug-in hybrid electric vehicle. Int. J. Therm. Sci. 2023, 185, 108040. [Google Scholar] [CrossRef]

- Rostamian, F.; Etesami, N.; Haghgoo, M. Management of electronic board temperature using heat sink containing pure and microencapsulated phase change materials. Int. Commun. Heat Mass Transf. 2021, 126, 105407. [Google Scholar] [CrossRef]

- Calati, M.; Hooman, K.; Mancin, S. Thermal storage based on phase change materials (PCMs) for refrigerated transport and distribution applications along the cold chain: A review. Int. J. Thermofluids 2022, 16, 100224. [Google Scholar] [CrossRef]

- Anupam, B.R.; Sahoo, U.C.; Rath, P. Phase change materials for pavement applications: A review. Constr. Build. Mater. 2020, 247, 118553. [Google Scholar] [CrossRef]

- Madad, A.; Mouhib, T.; Mouhsen, A. Phase change materials for building applications: A thorough review and new perspectives. Buildings 2018, 8, 63. [Google Scholar] [CrossRef]

- Berardi, U.; Gallardo, A.A. Properties of concretes enhanced with phase change materials for building applications. Energy Build. 2019, 199, 402–414. [Google Scholar] [CrossRef]

- Li, C.Z.; Zhang, L.; Liang, X.; Xiao, B.; Tam, V.W.Y.; Lai, X.; Chen, Z. Advances in the research of building energy saving. Energy Build. 2022, 254, 111556. [Google Scholar] [CrossRef]

- Iqbal, K.; Khan, A.; Sun, D.; Ashraf, M.; Rehman, A.; Safdar, F.; Basit, A.; Maqsood, H.S. Phase change materials, their synthesis and application in textiles—A review. J. Text. Inst. 2019, 110, 625–638. [Google Scholar] [CrossRef]

- Prajapati, D.G.; Kandasubramanian, B. A review on polymeric-based phase change material for thermo-regulating fabric application. Polym. Rev. 2019, 60, 389–419. [Google Scholar] [CrossRef]

- Leong, K.Y.; Rahman, M.R.A.; Gurunathan, B.A. Nano-enhanced phase change materials: A review of thermo-physical properties, applications and challenges. J. Energy Storage 2019, 21, 18–31. [Google Scholar] [CrossRef]

- Alehosseini, E.; Jafari, S.M. Nanoencapsulation of phase change materials (PCMs) and their applications in various fields for energy storage and management. Adv. Colloid Interface Sci. 2020, 283, 102226. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Kong, X.; Ren, J.; Fan, M.; Li, H. Novel hybrid composite phase change materials with high thermal performance based on aluminium nitride and nanocapsules. Energy 2022, 238, 121775. [Google Scholar] [CrossRef]

- Li, Z.; Ma, T.; Zhao, J.; Song, A.; Cheng, Y. Experimental study and performance analysis on solar photovoltaic panel integrated with phase change material. Energy 2019, 178, 471–486. [Google Scholar] [CrossRef]

- Saxena, R.; Rakshit, D.; Kaushik, S. Phase change material (PCM) incorporated bricks for energy conservation in composite climate: A sustainable building solution. Solar Energy 2019, 183, 276–284. [Google Scholar] [CrossRef]

- Thambidurai, M.; Panchabikesan, K.; Ramalingam, V. Review on phase change material based free cooling of buildings—The way toward sustainability. J. Energy Storage 2015, 4, 74–88. [Google Scholar] [CrossRef]

- Ghorbani, B.; Mehrpooya, M.; Ardehali, A. Energy and exergy analysis of wind farm integrated with compressed air energy storage using multi-stage phase change material. J. Clean. Prod. 2020, 259, 120906. [Google Scholar] [CrossRef]

- Said, M.A.; Hassan, H. Parametric study on the effect of using cold thermal storage energy of phase change material on the performance of air-conditioning unit. Appl. Energy 2018, 230, 1380–1402. [Google Scholar] [CrossRef]

- Ismail, M.; Zahra, W.K.; Ookawara, S.; Hassan, H. Boosting the air conditioning unit performance using phase change material: Impact of system configuration. J. Energy Storage 2022, 56, 105864. [Google Scholar] [CrossRef]

- Alam, M.; Jamil, H.; Sanjayan, J.; Wilson, J. Energy saving potential of phase change materials in major Australian cities. Energy Build. 2014, 78, 192–201. [Google Scholar] [CrossRef]

- Hunger, M.; Entrop, A.; Mandilaras, I.; Brouwers, H.; Founti, M. The behavior of self-compacting concrete containing micro-encapsulated phase change materials. Cem. Concr. Compos. 2009, 31, 731–743. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M.; Sarcinella, A. Phase change materials for energy efficiency in buildings and their use in mortars. Materials 2019, 12, 1260. [Google Scholar] [CrossRef]

- Iten, M.; Liu, S. A work procedure of utilising PCMs as thermal storage systems based on air-TES systems. Energy Convers. Manag. 2014, 77, 608–627. [Google Scholar] [CrossRef]

- Oro, E.; de Gracia, A.; Castell, A.; Farid, M.M.; Cabeza, L.F. Review on phase change materials (PCMs) for cold thermal energy storage applications. Appl. Energy 2012, 99, 513–533. [Google Scholar] [CrossRef]

- Socaciu, L.; Giurgiu, O.; Banyai, D.; Simion, M. PCM selection using AHP method to maintain thermal comfort of the vehicle occupants. Energy Procedia 2016, 85, 489–497. [Google Scholar] [CrossRef]

- Nicolalde, J.F.; Cabrera, M.; Martínez-Gómez, J.; Salazar, R.B.; Reyes, E. Selection of a PCM for a vehicle’s rooftop by multicriteria decision methods and simulation. Appl. Sci. 2021, 11, 6359. [Google Scholar] [CrossRef]

- Zhai, X.Q.; Wang, X.L.; Wang, T.; Wang, R.Z. A review on phase change cold storage in air-conditioning system: Materials and applications. Renew. Sustain. Energy Rev. 2013, 22, 108–120. [Google Scholar] [CrossRef]

- Li, S.F.; Liu, Z.H.; Wang, X.J. A comprehensive review on positive cold energy storage technologies and applications in air conditioning with phase change materials. Appl. Energy 2019, 255, 113667. [Google Scholar] [CrossRef]

- Kneifel, J.; Webb, D. Life Cycle Costing Manual for the Federal Energy Management Program; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2022. [Google Scholar]

- Barnard, S.S.S.; Smit, A.M.; Middelberg, S.L.; Botha, M.J. A cost-benefit analysis of implementing a 54 MW solar PV plant in a South African platinum mining company: A case study. J. Energy S. Afr. 2021, 32, 76–88. [Google Scholar] [CrossRef]

- Mathioulakis, E.; Panaras, G.; Belessiotis, V. Cost-Benefit Analysis of Renewable Energy Systems Under Uncertainties. In Proceedings of the 16th International Congress of Metrology, Paris, France, 7–10 October 2013. [Google Scholar]

- Rodrigues, N.; Pintassilgo, P.; Calhau, F.; González-Gorbeña, E.; Pacheco, A. Cost-benefit analysis of tidal energy production in a coastal lagoon: The case of Ria Formosa–Portugal. Energy 2021, 229, 120812. [Google Scholar] [CrossRef]

- Logar, I.; Brouwer, R.; Paillex, A. Do the societal benefits of river restoration outweigh their costs? A cost-benefit analysis. J. Environ. Manag. 2019, 232, 1075–1085. [Google Scholar]

- Arena, C.; Genco, M.; Mazzola, M.R. Environmental benefits and economical sustainability of urban wastewater reuse for irrigation—A cost-benefit analysis of an existing reuse project in Puglia, Italy. Water 2020, 12, 2926. [Google Scholar] [CrossRef]

- Lo, S.-L. Environmental Economic Analysis, 1st ed.; Xiaoyuan: Taipei, Taiwan, 2007. [Google Scholar]

- Chiou, C.-R.; Want, S.-L.; Yao, S.-L.; Lee, D.-R.; Lin, Y.-J. Case study on economic evaluation of gasification investment using bamboo processing residue in Zhushan area, Taiwan. Taiwan J. For. Sci. 2020, 35, 13–35. [Google Scholar]

| Property | Value |

|---|---|

| Phase change temperature | 8 °C |

| Density | 1503 kg/m3 |

| Latent heat of fusion | 182 kJ/kg |

| Cooling capacity | 12.5 RT/m2 |

| Specific heat capacity | 1.8 kJ/kg-K |

| Thermal conductivity | 0.8 W/m-K |

| Weight | 5.81 kg/plate |

| Size | 500 × 250 × 325 mm |

| Year | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|---|---|

| Carbon Emission Factor | 0.525 | 0.530 | 0.554 | 0.533 | 0.509 | 0.502 | 0.509 |

| AC Systems | Cost of Piping (Including Valves, Pipes, Pumps, Floats, Meters, Heat Exchangers, Insulation Materials, Construction Costs) | Cost of Chiller | Cost of Instrument and Electrical Engineering (Including Power Distribution, PLC, Temperature Sensor, Flow Meter) | Cost of Ice Plate | Other Costs (Moving, Cleaning, Insurance, Public Security) |

|---|---|---|---|---|---|

| CACS | 5,053,732 | 6,100,000 | 5,500,000 | 0 | 2,150,000 |

| PCMRS | 6,891,733 | 1,612,000 | 7,744,765 | 936,000 | 3,758,252 |

| PCMPS | 3,840,000 | 1,612,000 | 6,744,765 | 936,000 | 3,237,000 |

| Month | Peak Hour Electricity Rate (NT$) | Off-Peak Hour Electricity Rate (NT$) | Difference in Electricity Prices (NT$) | Operation Days | CACS Monthly Electricity Consumption (kWh/month) | PCMACS Monthly Electricity Consumption (kWh/month) | Electricity Savings by PCMACS (kWh/month) |

|---|---|---|---|---|---|---|---|

| November 2020 | 3.33 | 1.39 | 1.94 | 24 | 23,207 | 19,030 | 4177 |

| December 2020 | 3.33 | 1.39 | 1.94 | 24 | 23,562 | 19,321 | 4241 |

| January 2021 | 3.33 | 1.39 | 1.94 | 22 | 21,700 | 17,794 | 3906 |

| February 2021 | 3.33 | 1.39 | 1.94 | 20 | 19,545 | 16,027 | 3518 |

| March 2021 | 3.33 | 1.39 | 1.94 | 22 | 21,767 | 17,849 | 3918 |

| April 2021 | 3.33 | 1.39 | 1.94 | 22 | 46,694 | 38,289 | 8405 |

| May 2021 | 3.33 | 1.39 | 1.94 | 22 | 55,985 | 45,908 | 10,077 |

| Jun 2021 | 3.42 | 1.46 | 1.96 | 23 | 91,373 | 74,925 | 16,447 |

| July 2021 | 3.42 | 1.46 | 1.96 | 23 | 110,939 | 90,970 | 19,969 |

| August 2021 | 3.42 | 1.46 | 1.96 | 22 | 107,282 | 87,971 | 19,311 |

| September 2021 | 3.42 | 1.46 | 1.96 | 22 | 100,265 | 82,218 | 18,048 |

| October 2021 | 3.33 | 1.39 | 1.94 | 22 | 35,525 | 29,131 | 6395 |

| Total (kWh/Year) | 268 | 657,844 | 539,432 | 118,412 |

| Month | Electricity Savings (kWh/month) | Carbon Emission Factor (Kg CO2/kWh) | CO2 Mitigation (Kg CO2/month) | Carbon Fee Savings (NT$/month) |

|---|---|---|---|---|

| November 2020 | 4177 | 0.509 | 2126 | 425,249 |

| December 2020 | 4241 | 0.509 | 2159 | 431,746 |

| January 2021 | 3906 | 0.509 | 1988 | 397,632 |

| February 2021 | 3518 | 0.509 | 1791 | 358,138 |

| March 2021 | 3918 | 0.509 | 1994 | 398,867 |

| April 2021 | 8405 | 0.509 | 4278 | 855,624 |

| May 2021 | 10,077 | 0.509 | 5129 | 1,025,870 |

| Jun 2021 | 16,447 | 0.509 | 8372 | 1,674,310 |

| July 2021 | 19,969 | 0.509 | 10,164 | 2,032,840 |

| August 2021 | 19,311 | 0.509 | 9829 | 1,965,838 |

| September 2021 | 18,048 | 0.509 | 9186 | 1,837,262 |

| October 2021 | 6395 | 0.509 | 3255 | 650,961 |

| Total | 118,412 | 60,272 | 12,054,338 |

| AC Systems | Parameters | Description | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | Present Value (NT$) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CACS | K | Investment Cost | 18,803,732 | 18,803,732 | ||||||||||

| C1 | Operation Costs | 2,227,507 | 2,227,507 | 2,227,507 | 2,227,507 | 2,227,507 | 2,227,507 | 2,227,507 | 2,227,507 | 2,227,507 | 2,227,507 | 13,687,067 | ||

| C2 | Maintenance Costs | 940,187 | 940,187 | 940,187 | 940,187 | 940,187 | 940,187 | 940,187 | 940,187 | 940,187 | 940,187 | 5,777,040 | ||

| B1 | Electricity Bill Savings | - | ||||||||||||

| B2 | Carbon Fee Savings | - | ||||||||||||

| D | Salvage Value | 1,692,337 | 652,469 | |||||||||||

| PCMRS | K | Investment Cost | 20,942,750 | 20,942,750 | ||||||||||

| C1 | Operation Costs | 2,237,710 | 2,237,710 | 2,237,710 | 2,237,710 | 2,237,710 | 2,237,710 | 2,237,710 | 2,237,710 | 2,237,710 | 2,237,710 | 13,749,759 | ||

| C2 | Maintenance Costs | 1,884,848 | 1,884,848 | 1,884,848 | 1,884,848 | 1,884,848 | 1,884,848 | 1,884,848 | 1,884,848 | 1,884,848 | 1,884,848 | 11,581,572 | ||

| B1 | Electricity Bill Savings | 709,797 | 709,797 | 709,797 | 709,797 | 709,797 | 709,797 | 709,797 | 709,797 | 709,797 | 709,797 | 4,361,397 | ||

| B2 | Carbon Fee Savings | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 74,068,688 | ||

| D | Salvage Value | 1,884,849 | 726,691 | |||||||||||

| PCMPS | K | Investment Cost | 16,369,765 | 16,369,765 | ||||||||||

| C1 | Operation Costs | 1,937,710 | 1,937,710 | 1,937,710 | 1,937,710 | 1,937,710 | 1,937,710 | 1,937,710 | 1,937,710 | 1,937,710 | 1,937,710 | 11,906,389 | ||

| C2 | Maintenance costs | 1,473,279 | 1,473,279 | 1,473,279 | 1,473,279 | 1,473,279 | 1,473,279 | 1,473,279 | 1,473,279 | 1,473,279 | 1,473,279 | 9,052,661 | ||

| B1 | Electricity Bill Savings | 709,797 | 709,797 | 709,797 | 709,797 | 709,797 | 709,797 | 709,797 | 709,797 | 709,797 | 709,797 | 4,361,397 | ||

| B2 | Carbon Fee Savings | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 12,054,338 | 74,068,688 | ||

| D | Salvage Value | 1,473,280 | 568,013 |

| Item | CACS | PCMRS | PCMPS |

|---|---|---|---|

| Net Present Value (NT$) | −37,615,370 | 32,882,693 | 41,669,282 |

| Benefit–cost ratio | −0.17 | 0.41 | 0.57 |

| Internal rate of return (%) | - | 39.8% | 56.5% |

| Payback period (year) | −5.9 | 2.4 | 1.8 |

| Dynamic payback period (year) | −4.9 | 2.9 | 2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, S.-H.; Lo, S.-L. An Economic Analysis of Energy Saving and Carbon Mitigation by the Use of Phase Change Materials for Cool Energy Storage for an Air Conditioning System—A Case Study. Energies 2024, 17, 912. https://doi.org/10.3390/en17040912

Peng S-H, Lo S-L. An Economic Analysis of Energy Saving and Carbon Mitigation by the Use of Phase Change Materials for Cool Energy Storage for an Air Conditioning System—A Case Study. Energies. 2024; 17(4):912. https://doi.org/10.3390/en17040912

Chicago/Turabian StylePeng, Shun-Hsiung, and Shang-Lien Lo. 2024. "An Economic Analysis of Energy Saving and Carbon Mitigation by the Use of Phase Change Materials for Cool Energy Storage for an Air Conditioning System—A Case Study" Energies 17, no. 4: 912. https://doi.org/10.3390/en17040912

APA StylePeng, S.-H., & Lo, S.-L. (2024). An Economic Analysis of Energy Saving and Carbon Mitigation by the Use of Phase Change Materials for Cool Energy Storage for an Air Conditioning System—A Case Study. Energies, 17(4), 912. https://doi.org/10.3390/en17040912