A Trip-Based Data-Driven Model for Predicting Battery Energy Consumption of Electric City Buses

Abstract

1. Introduction

2. Physical E-Bus Model

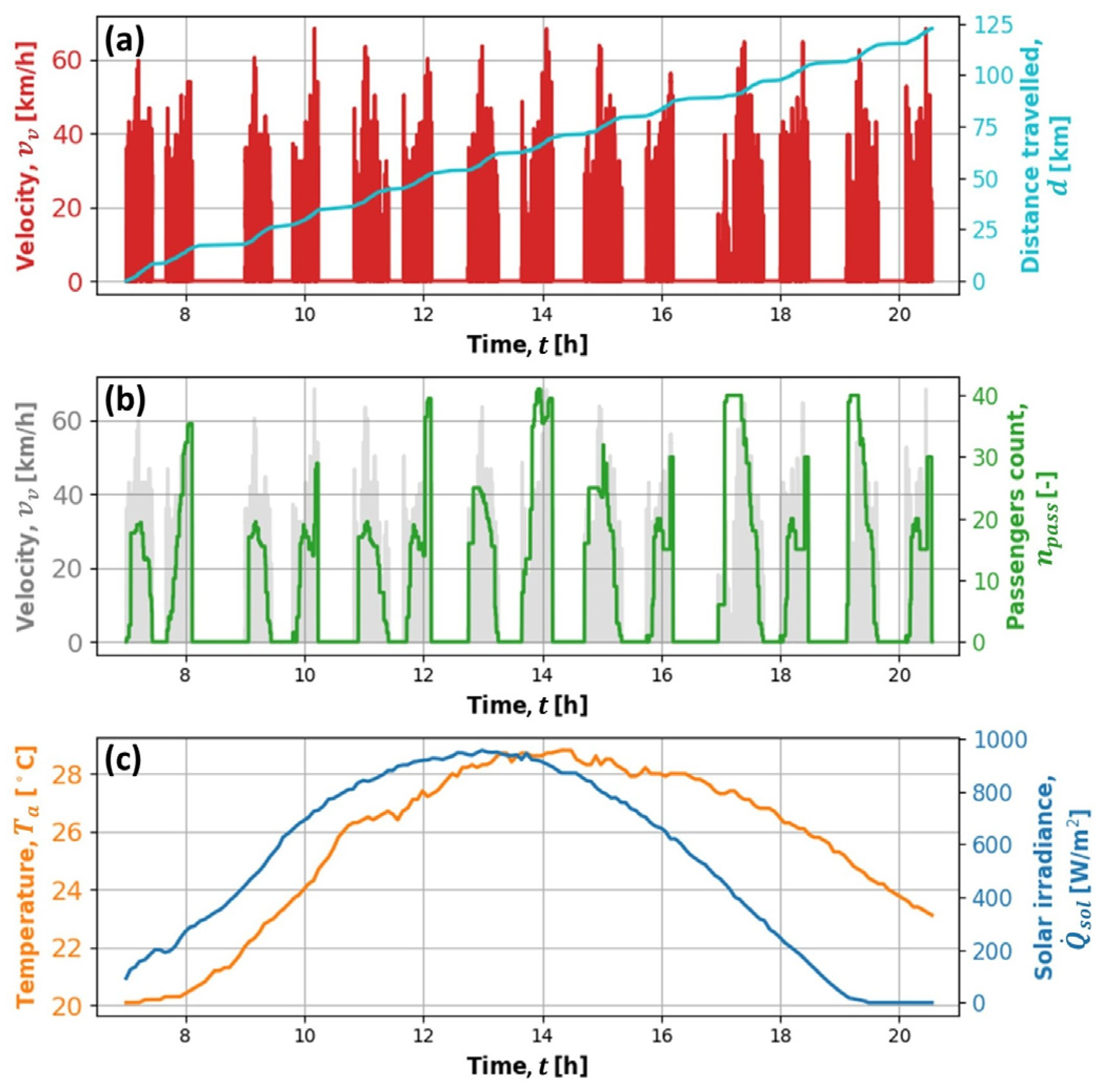

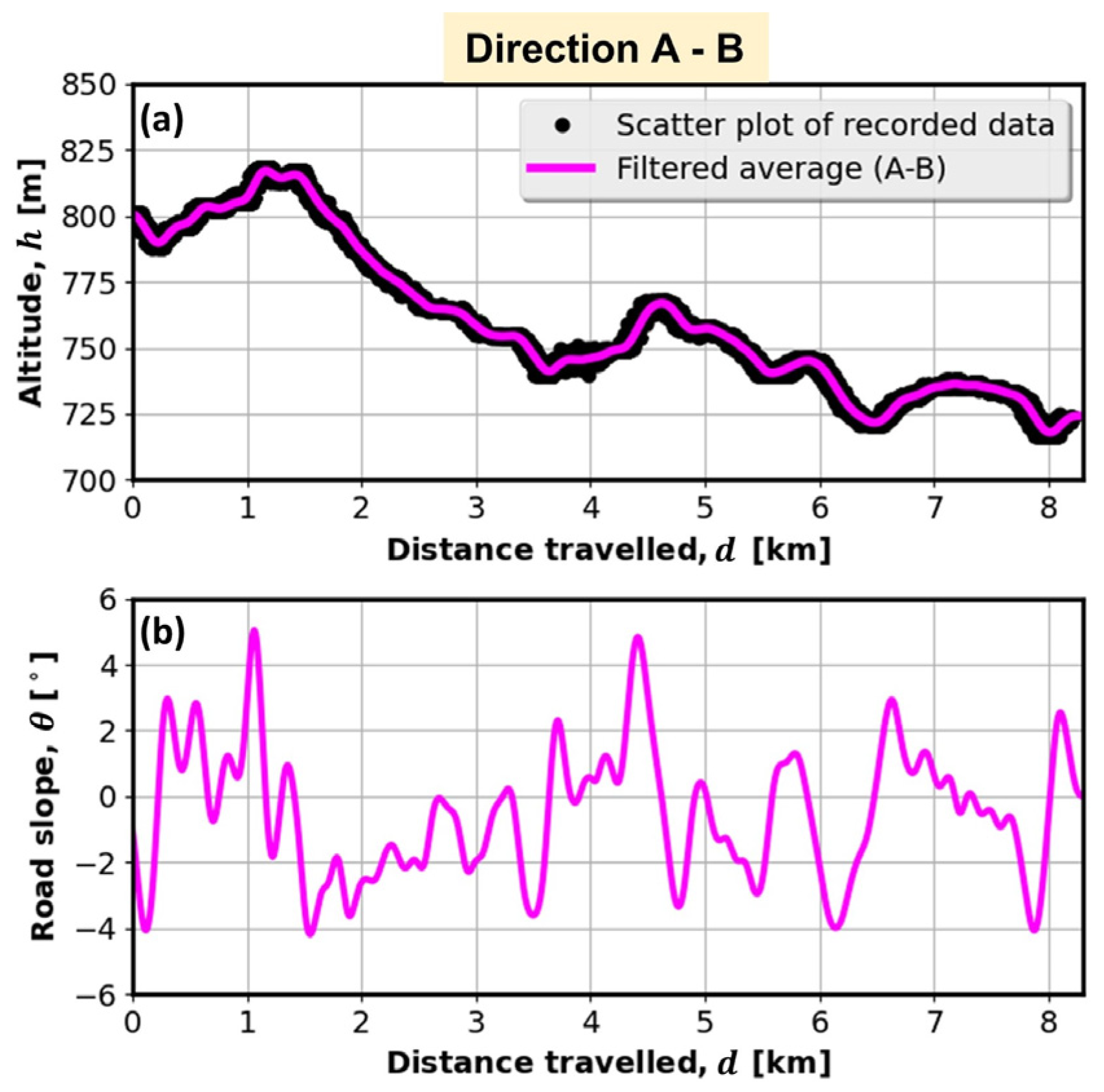

2.1. Recorded Driving Cycle and Energy Consumption Data

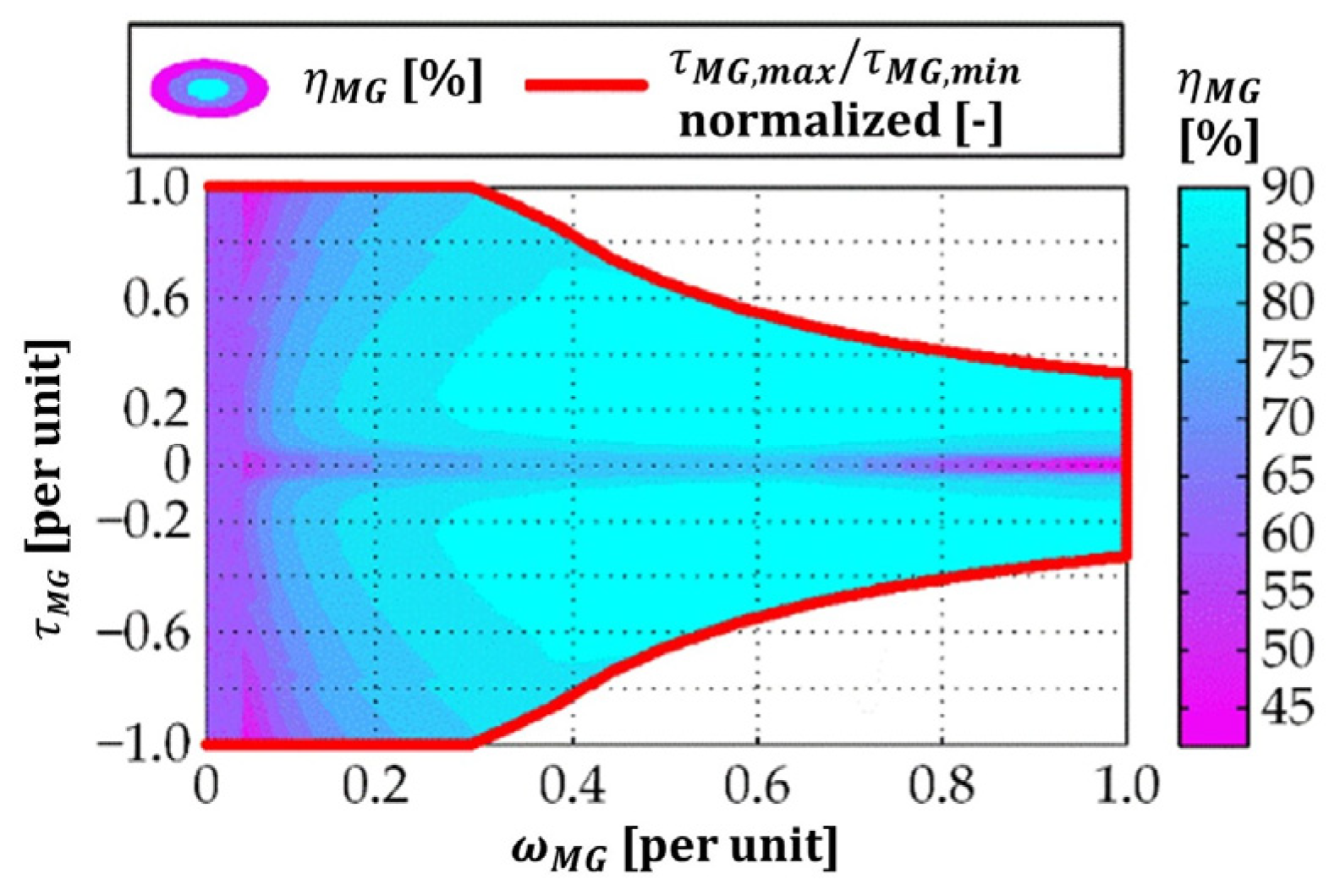

2.2. Physical Powertrain Model

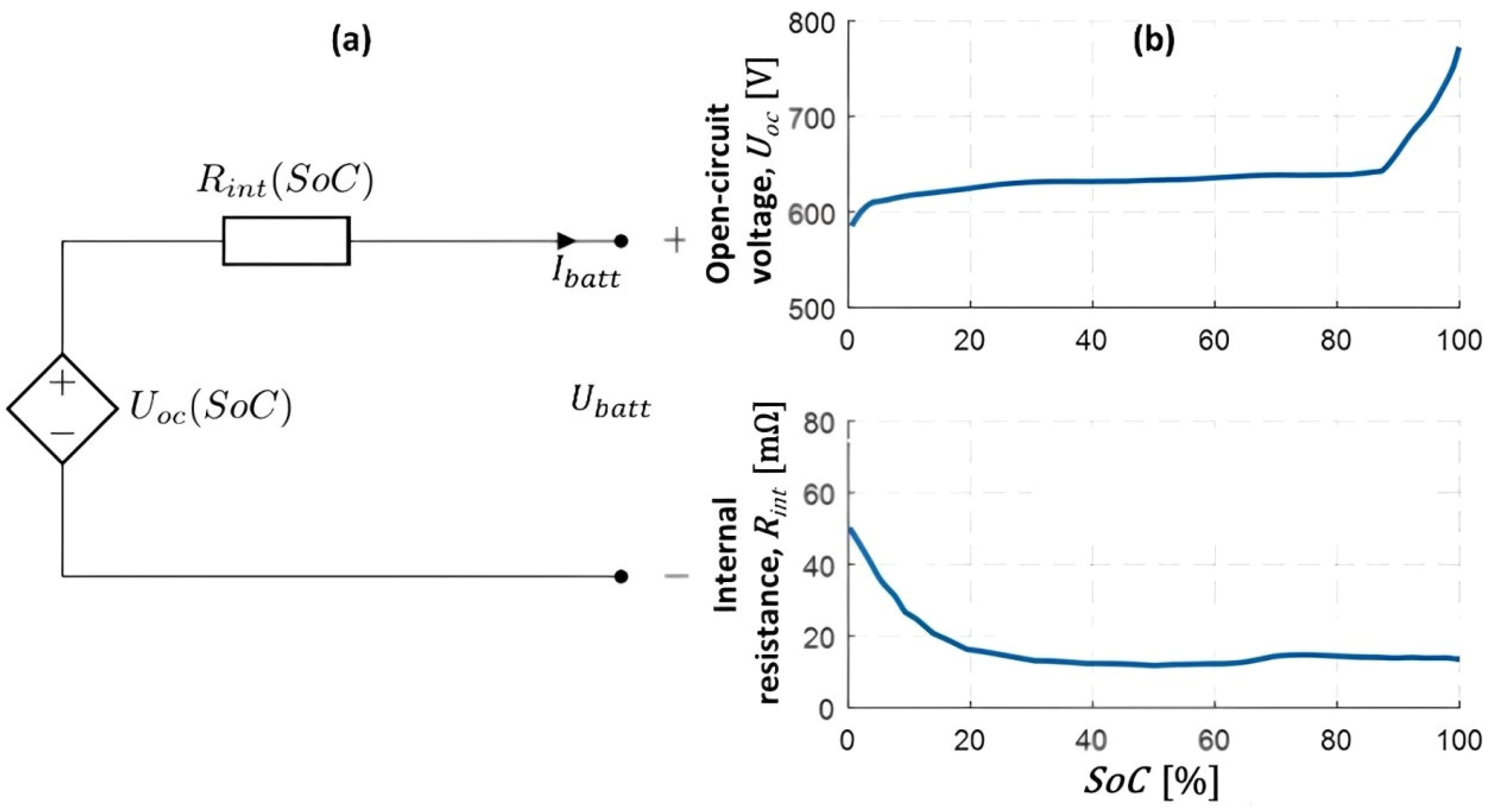

2.3. Battery Model

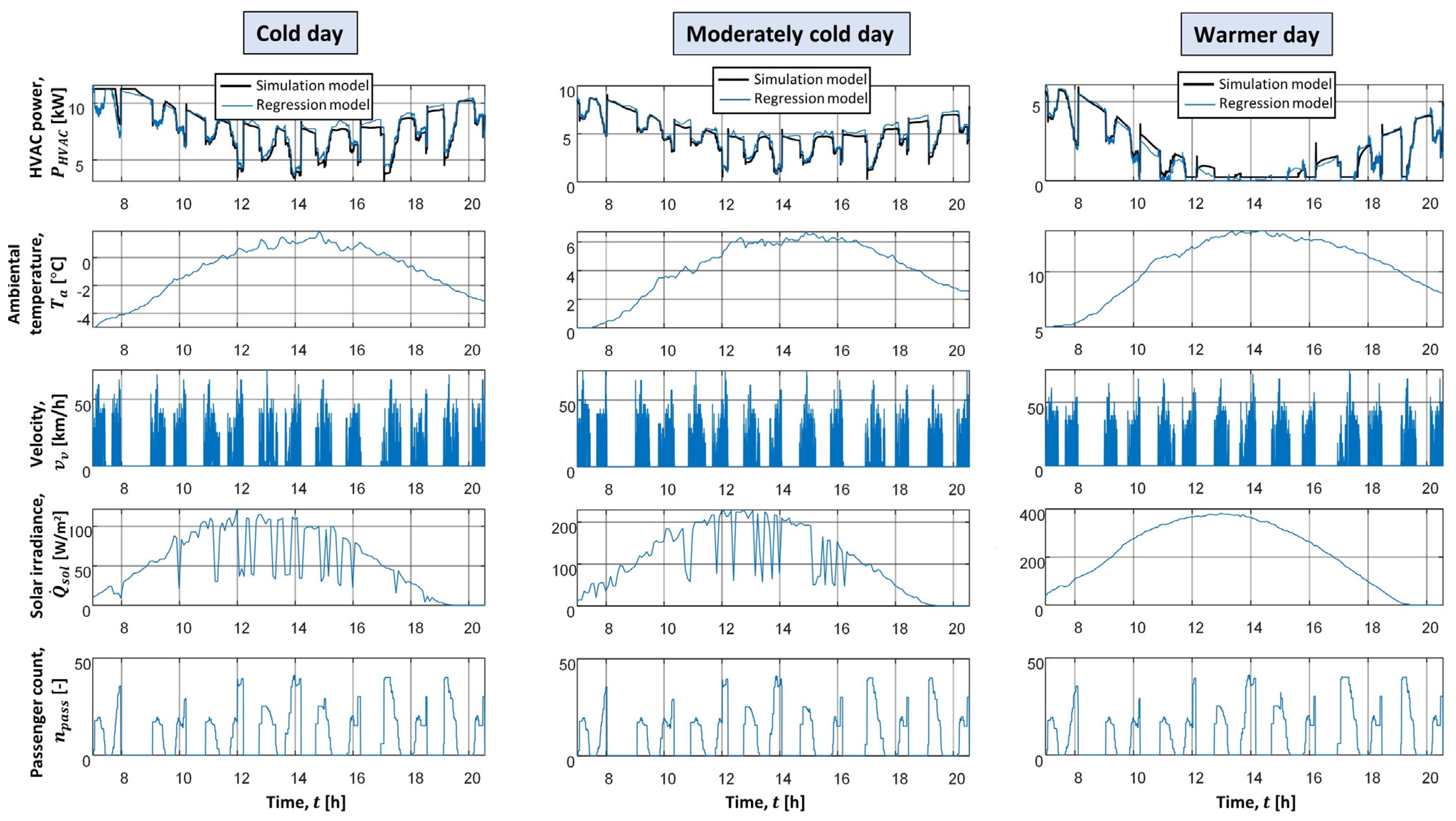

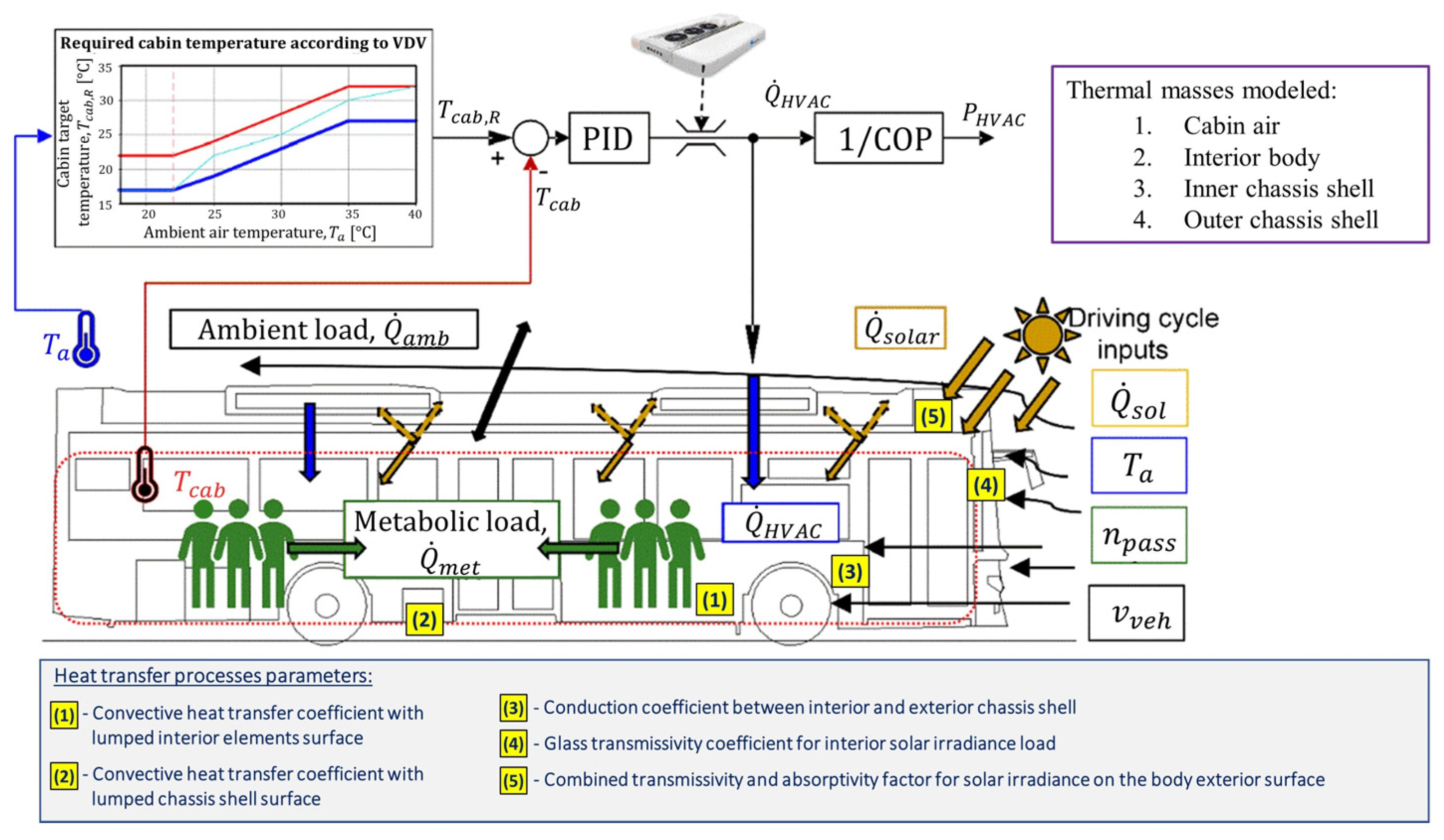

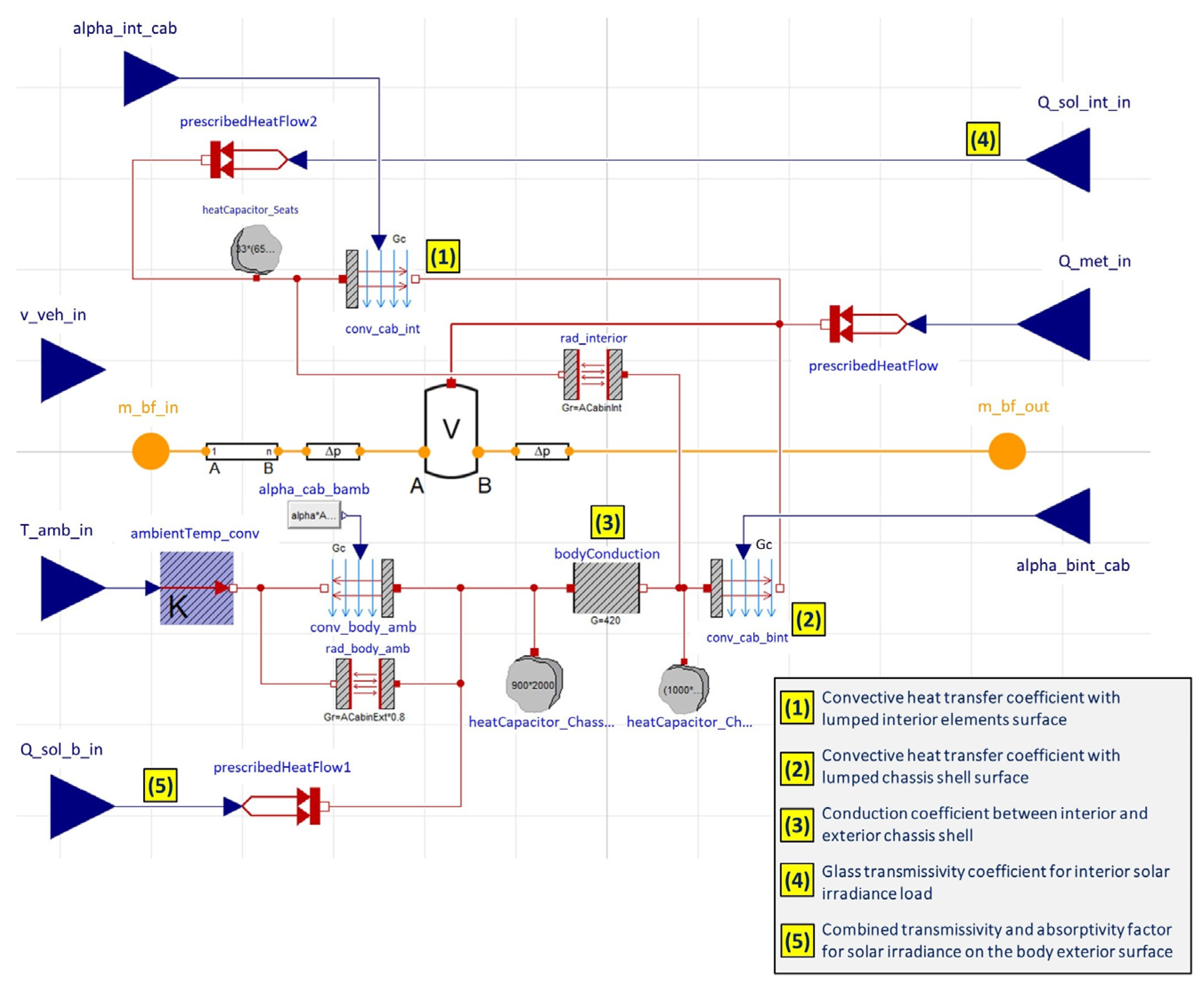

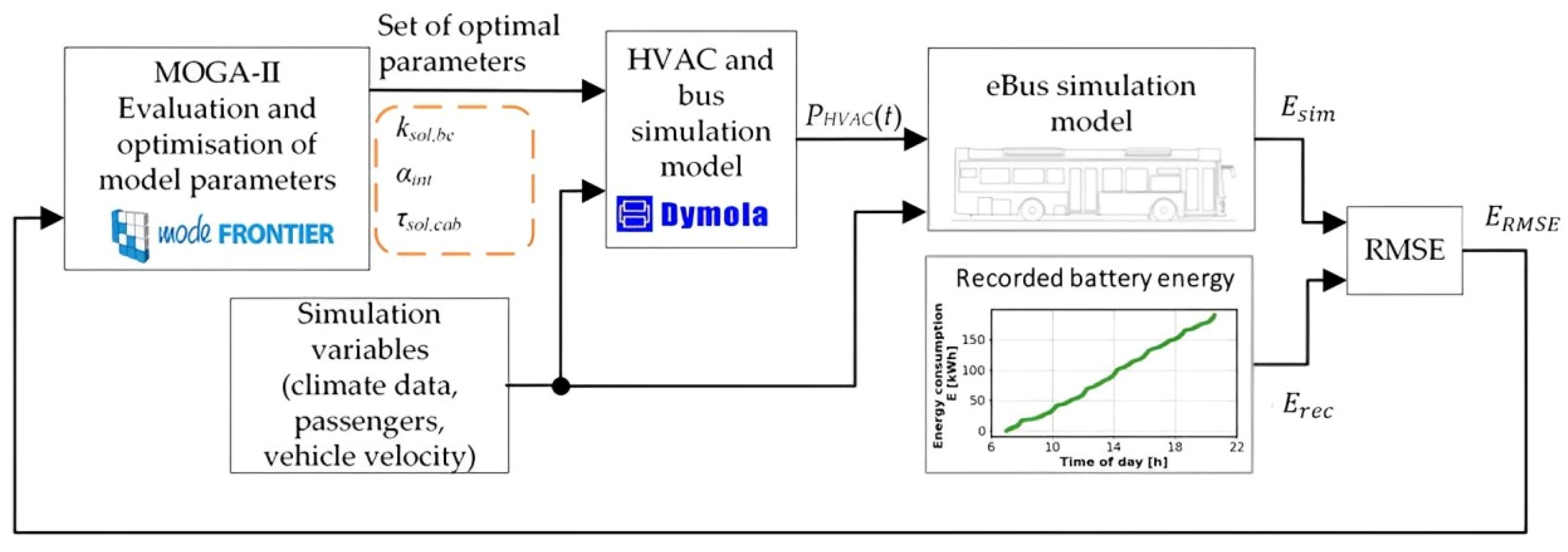

2.4. HVAC System Model

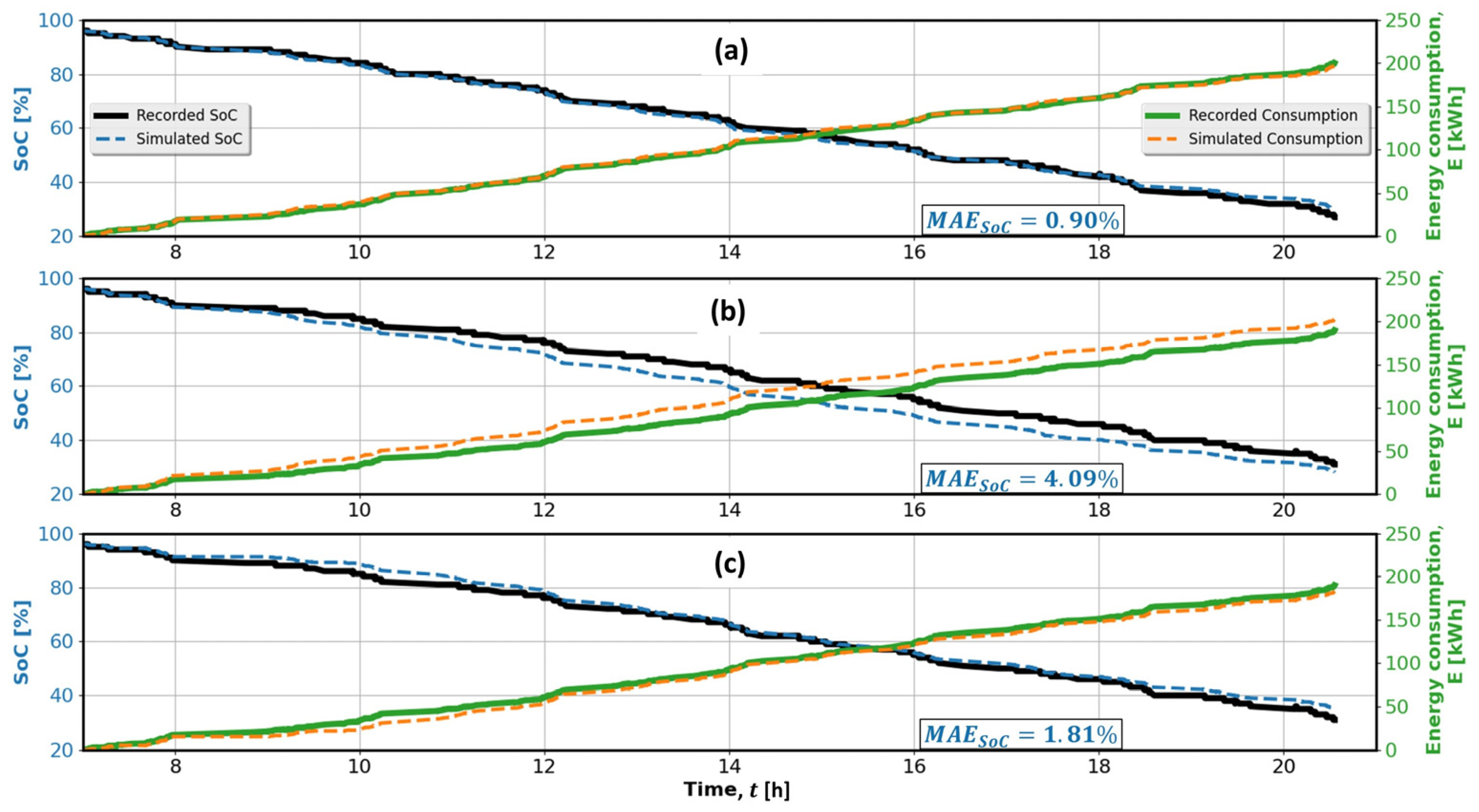

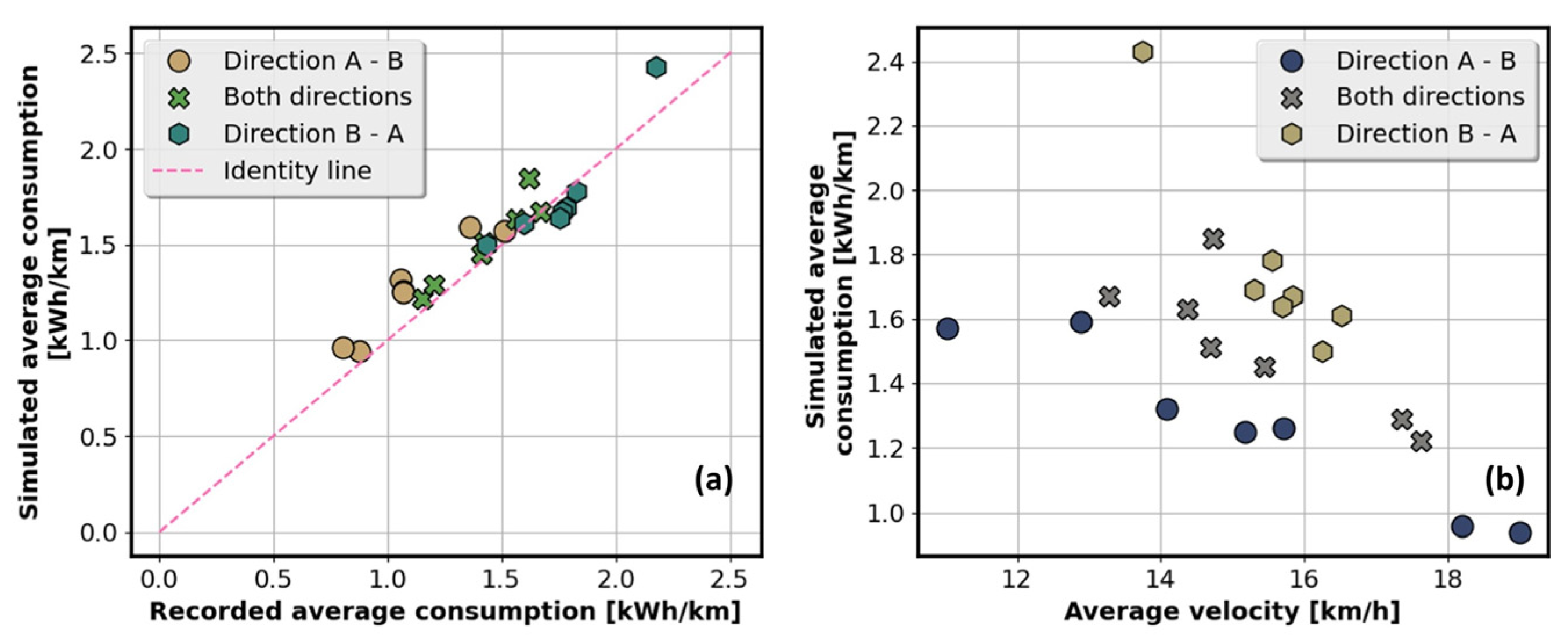

2.5. E-Bus Model Validation

3. Data Collection for Data-Driven E-Bus Modeling

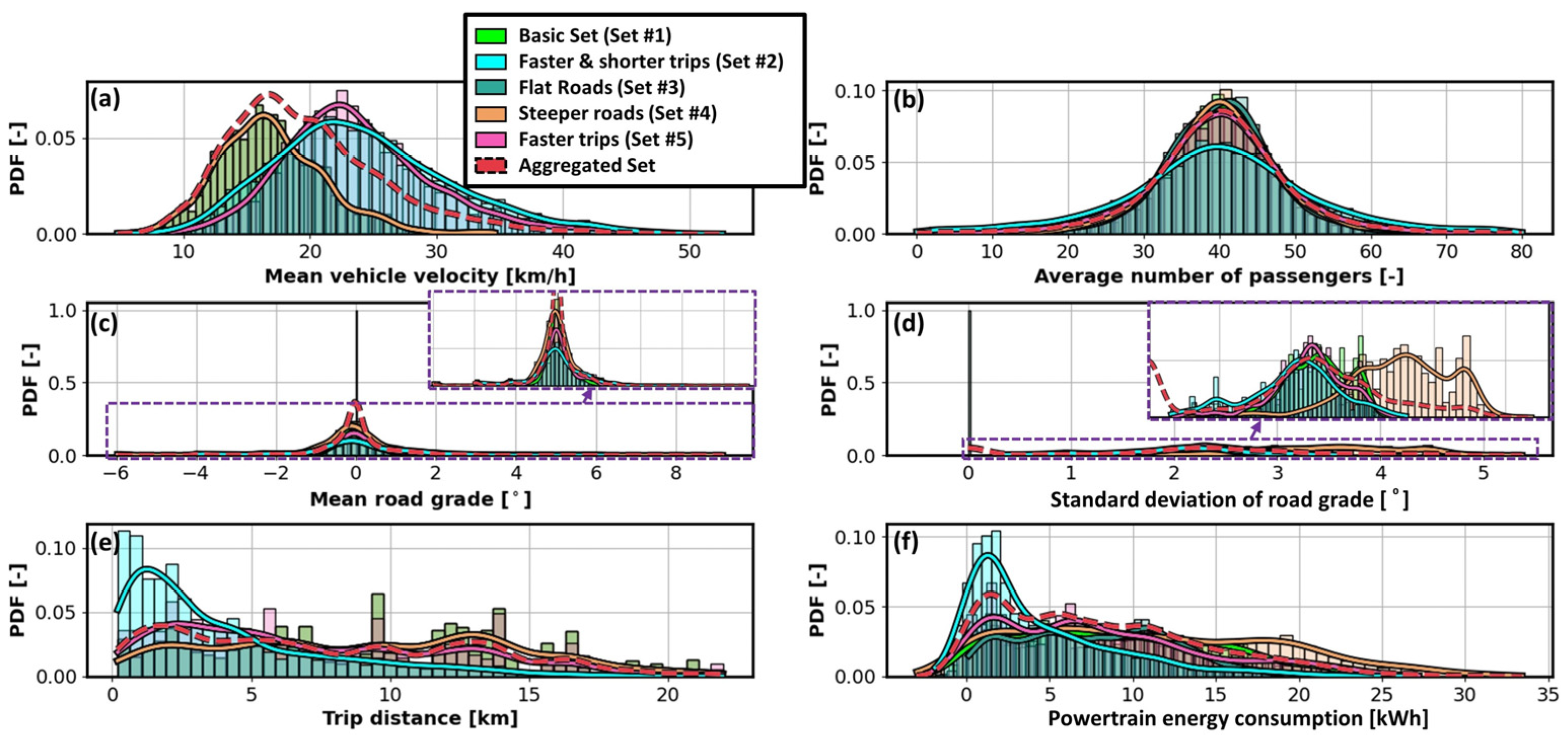

3.1. Data Collection Framework

3.2. Data Collection Framework

- Set #2: Faster and shorter trips: For each trip, the mean velocity of every bus station-to-station segment is amplified by 50% and the traveled distances are randomly reduced;

- Set #3: Flat roads: the road slope is set to zero;

- Set #4: Steeper roads scenario: the road grade profile is scaled up by 50%;

- Set #5: Faster trips: The mean velocity of each station-to-station segment is amplified by 50%.

4. Feature Selection

4.1. Data Collection Framework

4.2. Quadratic Regression Model

4.3. Feature Selection Techniques

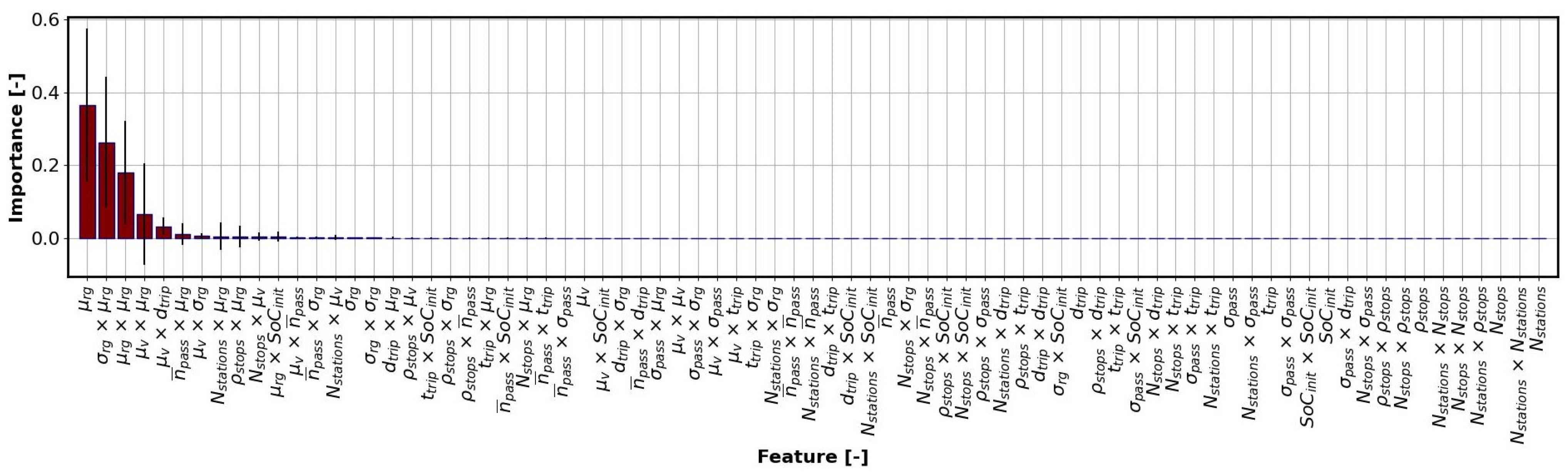

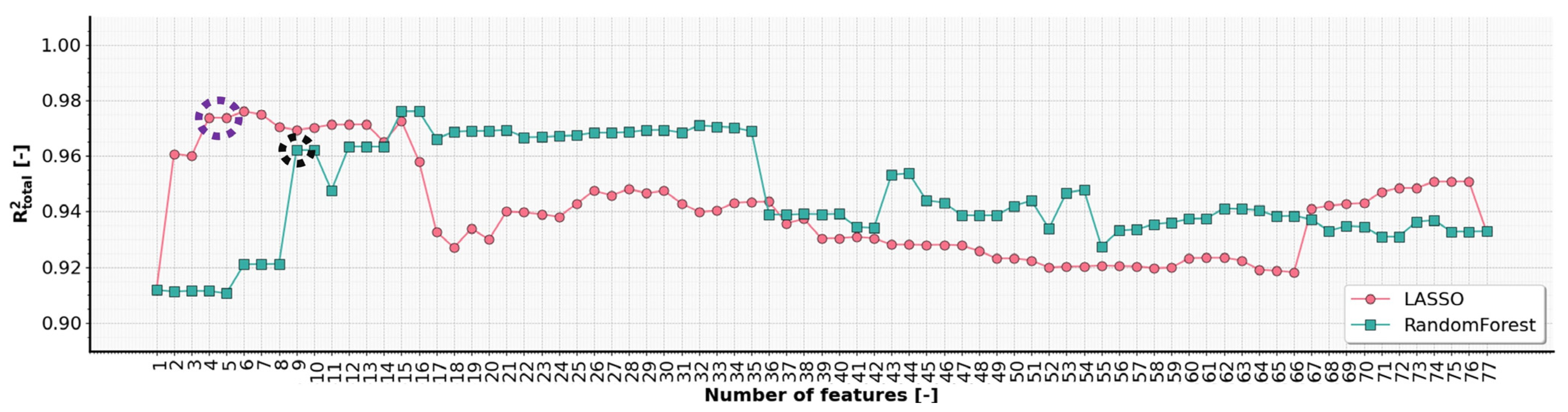

4.3.1. LASSO and RANDOM Forest Importance Methods

4.3.2. Wrapper Methods

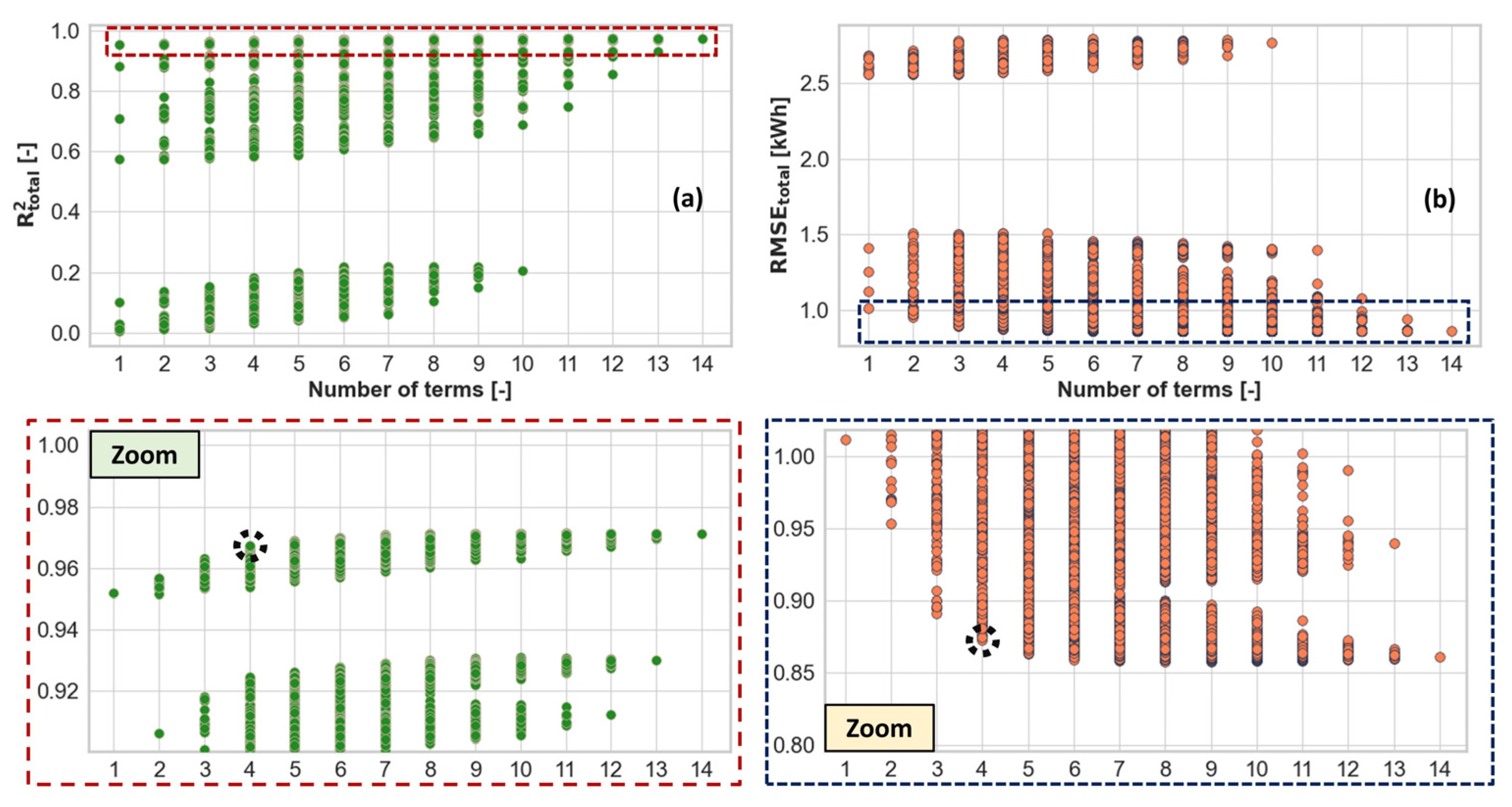

4.3.3. Best Subset Method

4.4. Comparative Analysis of Model Gained by Various Feature Selection Methods

5. Final Model and Its Performance Assessment

5.1. Powertrain Trip-Based Model

5.1.1. Assessment of Alternative Machine Learning Algorithms

- LASSO Regression: The parameter λ is set in the range from 0.0001 to 0 with increments of 0.00001;

- Ridge Regression: The parameter λ is varied in the same range as for LASSO Regression;

- Decision Trees: The maximum depth parameter ranges from 10 to 100, with increments of 1;

- Random Forest: The number of estimators is in the range from 4 to 200, with increments of 1;

- Gradient Boosting: The number of estimators is set in the same way as with the Random forest method;

- K-nearest Neighbors: The algorithm is set with neighbors ranging from 1 to 200;

- Support Vector Regression: various kernels, including Radial Basis Function, and first-, second-, and third-order polynomials are examined;

- Multilayer Perceptron (MLP) Neural Networks: The number of layers and nodes varies from 1 to 4 and from 16 to 512, respectively;

- 1D Convolution Neural Networks: the same architecture parameters are considered as with MLP neural network, all with the stride of 1.

5.1.2. Assessment of Station-to-Station Segment-Based Modeling Approach

5.1.3. Incorporation of Additional Features

5.2. HVAC Trip-Based System Model

5.3. Overall E-Bus Model

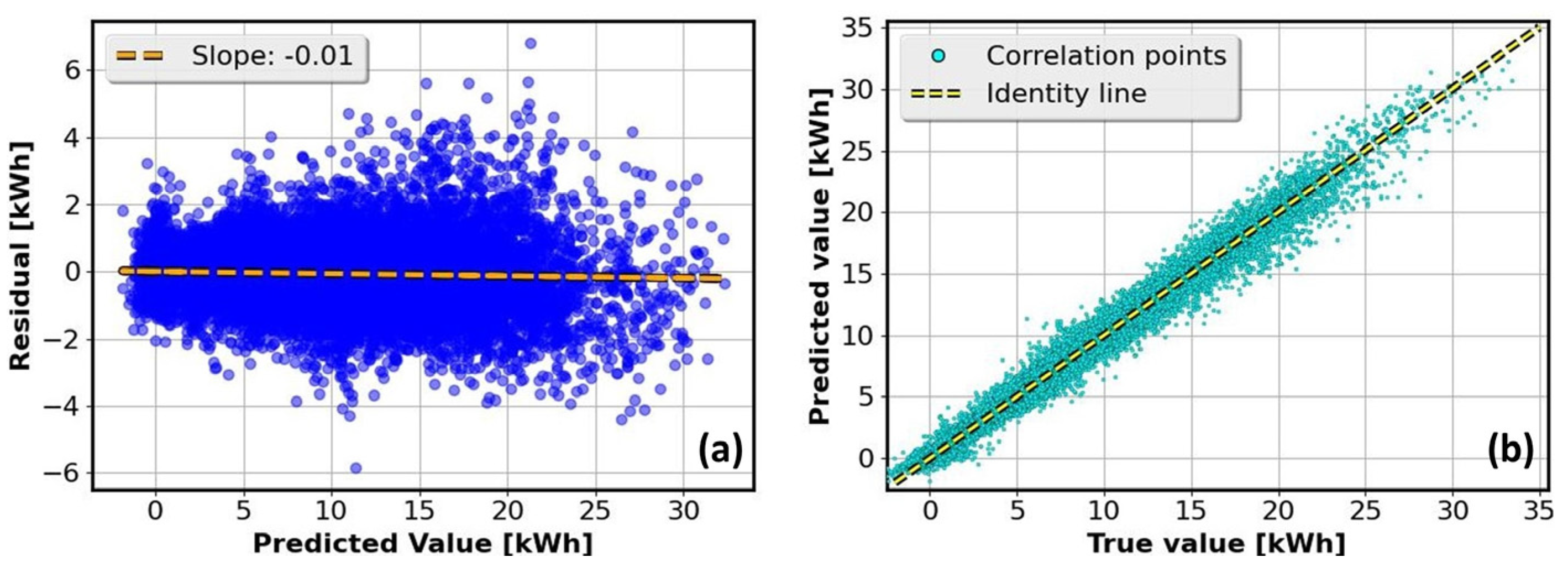

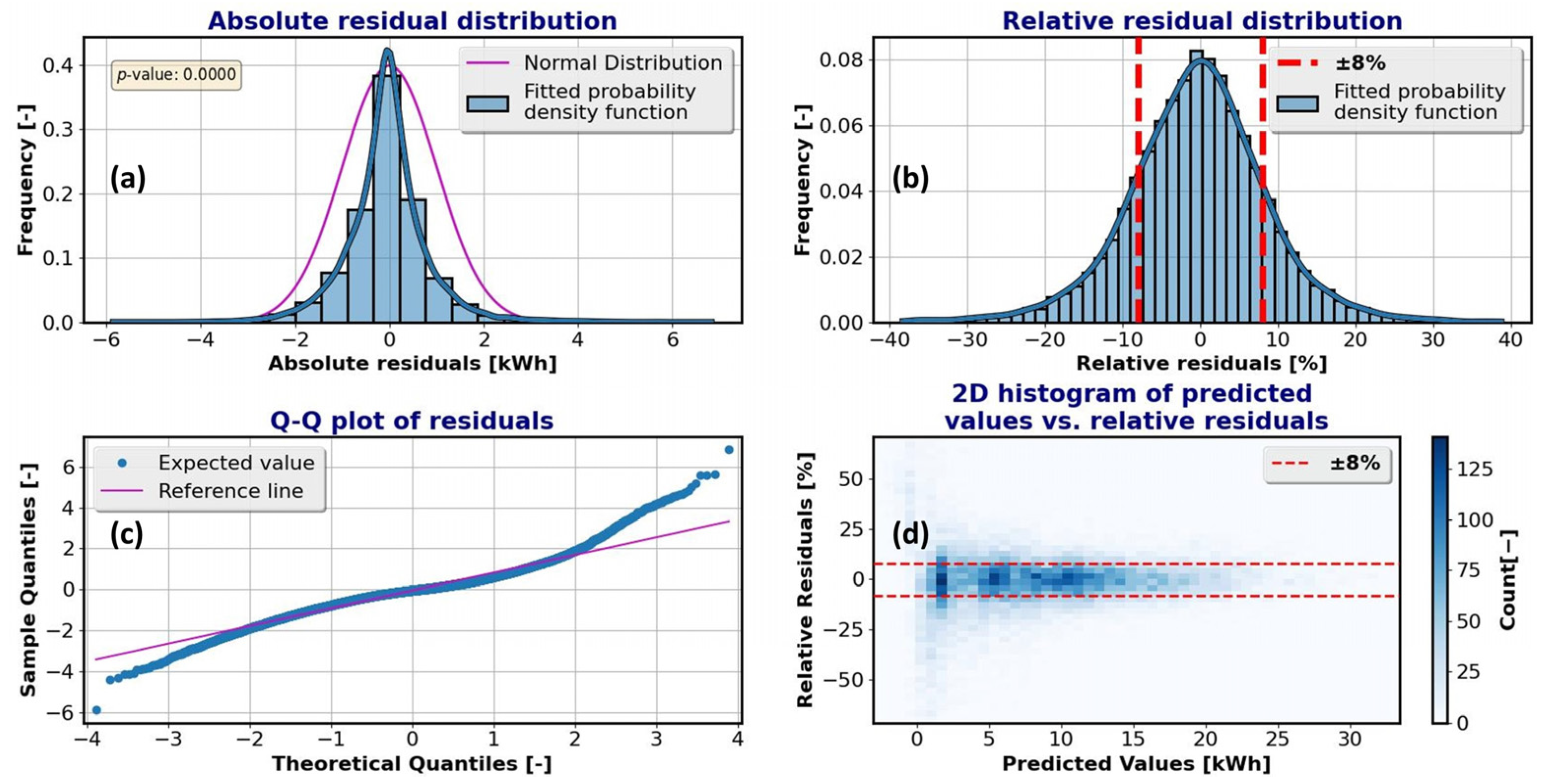

6. Analysis of Model Residuals

6.1. Powertrain Model

6.2. HVAC Model

6.3. Overall Model

7. Conclusions

- A backward-looking physical model of a 12 m electric city bus was developed, with an emphasis on the heating, ventilation, and air conditioning (HVAC) system submodel. For the sake of e-bus model implementation simplicity and numerical efficiency, a quadratic regression HVAC model was set up and its parameters were optimized based on the responses of a physical HVAC model developed in Dymola 2018 FD01. The developed e-bus model was successfully validated with respect to several recorded datasets not used in the stage of model parameterization;

- The emphasis was then placed on the data-driven model, derived from simulations of the physical model under a wide set of traffic, road, and ambient conditions. The model relies on typically available trip-related data, as opposed to the physical model, which requires high-sampling-rate driving cycle data. It consists of independent powertrain and HVAC submodels to resemble the structure of the physical model. For the powertrain, a feature selection method was used to find an optimal quadratic regression model for the specific energy consumption (in kWh/km), where the selected features include the mean road grade and its square, the road grade standard deviation square, and the product of mean velocity and ridership. The model performance (characterized by the validation R2 value of 0.975) is comparable to more complex methods such as neural networks and gradient boosting but with the added advantage of greater simplicity and generalization (i.e., robustness);

- An exploration into a better quantized, station-to-station segment modeling approach did not enhance the modeling accuracy when compared to the trip-based approach. On the other hand, the modeling accuracy was found to notably grow when extending the feature set with vehicle acceleration and deceleration features, thus underscoring the significance of including a broader set of relevant features as opposed to making the quantization of the basic feature set denser. However, the vehicle acceleration features are usually unavailable in real city bus transport systems. Thus, the basic, narrow feature set-based quadratic regression model is generally recommended for applications due to low data demands, simplicity, and favorable accuracy;

- The original HVAC system model with four inputs (ambient temperature, solar irradiance, vehicle velocity, and ridership) was reformulated to have (i) a mean value form to be applicable to trip-based inputs of the data-driven model and (ii) a linear structure to suppress the influence of velocity and ridership variation on mean value modeling accuracy;

- When validating the overall model on an aggregated dataset, it registered a notable R2 score of 0.981. It executes approximately 1,900,000 times faster than the physical model, thereby offering both accurate energy consumption predictions and computational efficiency for large-scale simulation and optimization studies of city bus fleet electrification planning;

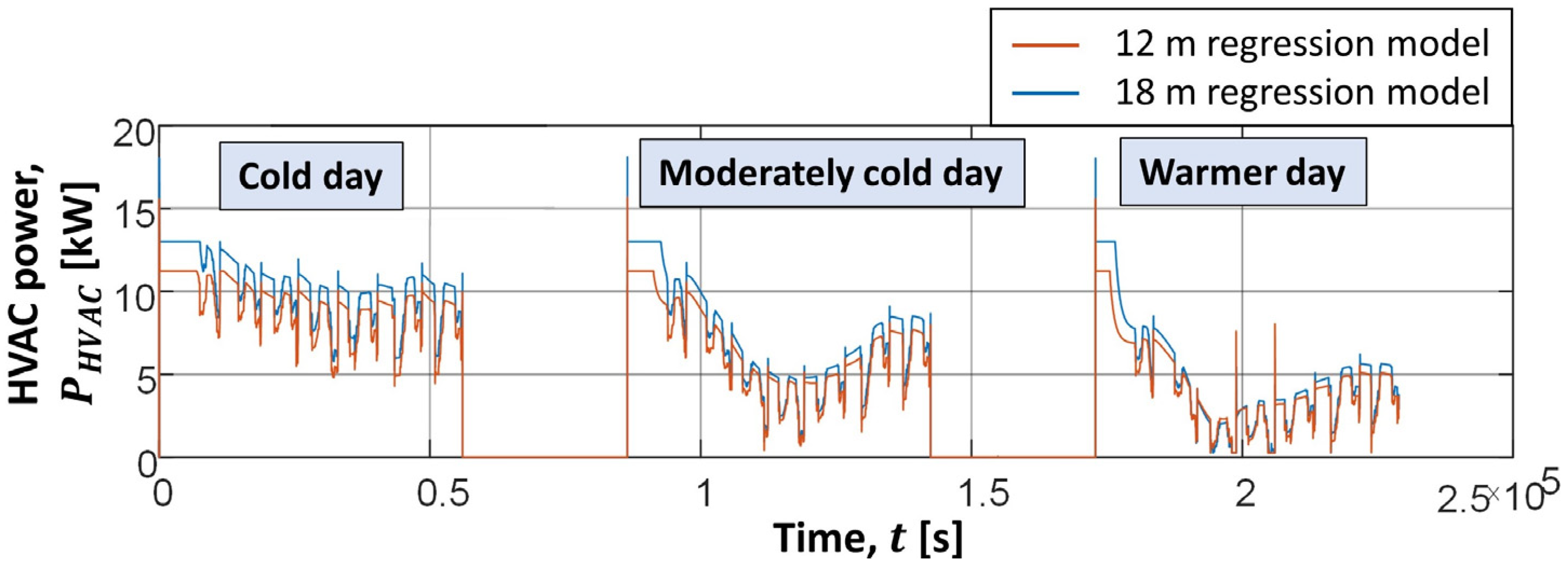

- Although the proposed modeling approach was demonstrated on a 12 m fully electric city bus and A/C operating mode, it can be readily applied to other sizes (e.g., 18 m) and types of city buses (e.g., HEV, PHEV, and H2 buses), as well as for other operating conditions (e.g., heat pump mode).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Modification of HVAC Model for Heat Pump Mode and 18 m E-Bus

References

- Miles, J.M.; Potter, S. Developing a Viable Electric Bus Service: The Milton Keynes Demonstration Project. Res. Transp. Econ. 2014, 48, 357–363. [Google Scholar] [CrossRef]

- Li, J. Battery-Electric Transit Bus Developments and Operations: A Review. Int. J. Sustain. Transp. 2014, 10, 157–169. [Google Scholar] [CrossRef]

- Kang, J.; Huang, X.; Maharjan, S.; Zhang, Y.; Hossain, E. Enabling Localized Peer-to-Peer Electricity Trading Among Plug-in Hybrid Electric Vehicles Using Consortium Blockchains. IEEE Trans. Ind. Inform. 2017, 13, 3154–3164. [Google Scholar] [CrossRef]

- Deur, J.; Cvok, I.; Ratković, I.; Topić, J.; Soldo, J.; Maletić, F. Backward-looking Modelling of a Fully Electric City Bus with Emphasis on Cabin Heating and Cooling Subsystem. In Proceedings of the 18th Conference on Sustainable Development of Energy, Water and Environment Systems (SDEWES), Dubrovnik, Croatia, 24–29 September 2023. [Google Scholar]

- Tim, J.; Hunter, C.D.; Macht, G.A. Quantifying the Impact of Traffic on Electric Vehicle Efficiency. World Electr. Veh. J. 2022, 13, 15. [Google Scholar] [CrossRef]

- Perumal, S.S.G.; Lusby, R.M.; Larsen, J. Electric Bus Planning & Scheduling: A Review of Related Problems and Methodologies. 2022. Available online: https://ideas.repec.org/a/eee/ejores/v301y2022i2p395-413.html (accessed on 9 December 2023).

- Teng, J.; Chen, T.; Fan, W. Integrated Approach to Vehicle Scheduling and Bus Timetabling for an Electric Bus Line. J. Transp. Eng. Part A Syst. 2019, 146, 04019073. [Google Scholar] [CrossRef]

- Matković, D.; Topić, J.; Škugor, B.; Deur, J. Search Space Reduction-Supported Multi-objective Optimization of Charging System Configuration for Electrified City Bus Transport System. In Proceedings of the 17th Conference on Sustainable Development of Energy, Water and Environment Systems (SDEWES), Paphos, Cyprus, 6–10 November 2022. [Google Scholar]

- An, K. Battery Electric Bus Infrastructure Planning under Demand Uncertainty. Transp. Res. Part C Emerg. Technol. 2020, 111, 572–587. [Google Scholar] [CrossRef]

- Zhao, L.; Alipour-Fanid, A.; Slawski, M.; Zeng, K. Prediction-Time Efficient Classification Using Feature Computational Dependencies. In Proceedings of the 24th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining, London, UK, 19–23 August 2018. [Google Scholar] [CrossRef]

- Jahic, A.; Eskander, M.; Avdevicius, E.; Schulz, D. Energy Consumption of Battery- Electric Buses: Review of Influential Parameters and Modelling Approaches. B&H Electr. Eng. 2023, 17, 7–17. [Google Scholar] [CrossRef]

- Perugu, H.; Collier, S.; Tan, Y.; Yoon, S.; Herner, J. Characterization of Battery Electric Transit Bus Energy Consumption by Temporal and Speed Variation. Energy 2023, 263, 125914. [Google Scholar] [CrossRef]

- Dabčević, Z.; Škugor, B.; Topić, J.; Deur, J. Synthesis of Driving Cycles Based on Low-Sampling-Rate Vehicle-Tracking Data and Markov Chain Methodology. Energies 2022, 15, 4108. [Google Scholar] [CrossRef]

- Al-Ogaili, A.S.; Ramasamy, A.K.; Tengku Hashim, T.J.; Al-Masri, A.N.; Hoon, Y.; Jebur, M.N.; Verayiah, R.; Marsadek, M. Estimation of the Energy Consumption of Battery Driven Electric Buses by Integrating Digital Elevation and Longitudinal Dynamic Models: Malaysia as a Case Study. Appl. Energy 2020, 280, 115873. [Google Scholar] [CrossRef]

- Lin, K.-C.; Lin, C.-H.; Ying, J.J.-C. Construction of Analytical Models for Driving Energy Consumption of Electric Buses through Machine Learning. Appl. Sci. 2020, 10, 6088. [Google Scholar] [CrossRef]

- Ji, J.; Bie, Y.; Zeng, Z.; Wang, L. Trip Energy Consumption Estimation for Electric Buses. Commun. Transp. Res. 2022, 2, 100069. [Google Scholar] [CrossRef]

- Pamuła, T.; Pamuła, W. Estimation of the Energy Consumption of Battery Electric Buses for Public Transport Networks Using Real-World Data and Deep Learning. Energies 2020, 13, 2340. [Google Scholar] [CrossRef]

- Abdelaty, H.; Mohamed, M. A Prediction Model for Battery Electric Bus Energy Consumption in Transit. Energies 2021, 14, 2824. [Google Scholar] [CrossRef]

- Pamuła, T.; Pamuła, D. Prediction of Electric Buses Energy Consumption from Trip Parameters Using Deep Learning. Energies 2022, 15, 1747. [Google Scholar] [CrossRef]

- Qin, W.; Wang, L.; Liu, Y.; Xu, C. Energy Consumption Estimation of the Electric Bus Based on Grey Wolf Optimization Algorithm and Support Vector Machine Regression. Sustainability 2021, 13, 4689. [Google Scholar] [CrossRef]

- Vehviläinen, M.; Lavikka, R.; Rantala, S.; Paakkinen, M.; Laurila, J.; Vainio, T. Setting Up and Operating Electric City Buses in Harsh Winter Conditions. Appl. Sci. 2022, 12, 2762. [Google Scholar] [CrossRef]

- Vepsäläinen, J.; Ritari, A.; Lajunen, A.; Kivekäs, K.; Tammi, K. Energy Uncertainty Analysis of Electric Buses. Energies 2018, 11, 3267. [Google Scholar] [CrossRef]

- Xing, Y.; Li, Y.; Liu, W.; Li, W.; Meng, L.-X. Operation Energy Consumption Estimation Method of Electric Bus Based on CNN Time Series Prediction. Math. Probl. Eng. 2022, 2022, 6904387. [Google Scholar] [CrossRef]

- Guzzella, L.; Sciarretta, A. Vehicle Propulsion Systems; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- André, D.; Meiler, M.; Steiner, K.; Walz, H.; Soczka-Guth, T.; Sauer, D.U. Characterization of High-Power Lithium-Ion Batteries by Electrochemical Impedance Spectroscopy. II: Modelling. J. Power Sources 2011, 196, 5349–5356. [Google Scholar] [CrossRef]

- Göhlich, D.; Fay, T.-A.; Jefferies, D.; Lauth, E.; Kunith, A.; Zhang, X. Design of urban electric bus systems. Des. Sci. 2018, 4, e15. [Google Scholar] [CrossRef]

- Zhang, T.; Gao, C.; Gao, Q.; Wang, G.; Liu, M.; Guo, Y.; Xiao, C.; Yan, Y.Y. Status and development of electric vehicle integrated thermal management from BTM to HVAC. Appl. Therm. Eng. 2015, 88, 398–409. [Google Scholar] [CrossRef]

- Freedman, D.; Pisani, R.; Purves, R. Statistics, 3rd ed.; W.W. Norton: New York, NY, USA, 1998. [Google Scholar]

- Seber, G.A.F.; Lee, A.J. Linear Regression Analysis, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Stańczyk, U.; Jain, L. Feature Selection for Data and Pattern Recognition; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Bie, Y.; Jinhua, J.; Wang, X.; Qu, X. Optimization of electric bus scheduling considering stochastic volatilities in trip travel time and energy consumption. Comput. Aided Civ. Infrastruct. Eng. 2021, 36, 1530–1548. [Google Scholar] [CrossRef]

- Dodge, Y. Analysis of Residuals, 1st ed.; Springer: New York, NY, USA, 2008. [Google Scholar]

| Auxiliary Device | [W] | [-] | [s] |

|---|---|---|---|

| Servo steering | 2500 | 0.09 | 400 |

| Air compressor | 2000 | 0.15 | 100 |

| DC/DC converter with low voltage devices | 184 | 1 | N/A |

| Number of Features | Selected Features | |||||||

|---|---|---|---|---|---|---|---|---|

| LASSO | ||||||||

| 4 | , , , | 0.9777 0.8873 | 0.9776 0.8862 | 0.9650 0.8720 | 0.9829 0.5911 | 0.9575 1.5901 | 0.9592 1.2487 | 0.9738 1.0126 |

| 5 | , , , , | 0.9776 0.8883 | 0.9776 0.8881 | 0.9656 0.8649 | 0.9816 0.6124 | 0.9568 1.6032 | 0.9601 1.2350 | 0.9737 1.0153 |

| Random forest importance | ||||||||

| 9 | , , , , , , , , | 0.9752 0.9346 | 0.9750 0.9381 | 0.9645 0.8783 | 0.9312 1.185 | 0.9374 1.9290 | 0.9576 1.2731 | 0.9621 1.1896 |

| Forward selection | ||||||||

| 8 | , , , , , , , | 0.9787 0.8673 | 0.9785 0.8682 | 0.9636 0.8895 | 0.8790 1.5719 | 0.9625 1.4927 | 0.9556 1.3017 | 0.9638 1.1652 |

| Backward elimination | ||||||||

| 10 | , , , ,,, , , , | 0.9781 0.8787 | 0.9780 0.8788 | 0.9656 0.8640 | 0.9464 1.0462 | 0.9617 1.5088 | 0.9571 1.2799 | 0.9710 1.0761 |

| Stepwise regression | ||||||||

| 6 | , , , , , | 0.9783 0.8755 | 0.9782 0.8752 | 0.9647 0.8757 | 0.9840 0.5719 | 0.9660 1.4222 | 0.9569 1.2825 | 0.9760 0.9839 |

| Best subset | ||||||||

| 3 | , , | 0.9778 0.8860 | 0.9777 0.8849 | 0.9662 0.8567 | 0.9828 0.5923 | 0.9574 1.5919 | 0.9591 1.2504 | 0.9739 1.0104 |

| 4 | , , , | 0.9784 0.8727 | 0.9784 0.8721 | 0.9639 0.8855 | 0.9825 0.5978 | 0.9666 1.4091 | 0.9546 1.3161 | 0.9755 0.9922 |

| 5 | , , , , | 0.9786 0.8694 | 0.9785 0.8690 | 0.9642 0.8817 | 0.9821 0.6047 | 0.9681 1.3774 | 0.9547 1.3153 | 0.9759 0.9862 |

| 6 | , , , , , | 0.9781 0.8782 | 0.9781 0.8782 | 0.9666 0.8521 | 0.9823 0.6010 | 0.9662 1.4178 | 0.9582 1.2630 | 0.9763 0.9817 |

| Number of Features | Features/Predictor Variables | |||||||

|---|---|---|---|---|---|---|---|---|

| Quadratic Regression | ||||||||

| 4 | , , , | 0.9756 0.9922 | 0.9756 0.9922 | 0.9639 0.8855 | 0.9825 0.5978 | 0.9666 1.4091 | 0.9546 1.3161 | 0.9669 1.0521 |

| LASSO Regression | ||||||||

| 4 | , , , | 0.9756 0.9922 | 0.9756 0.9922 | 0.9639 0.8855 | 0.9825 0.5978 | 0.9666 1.4091 | 0.9546 1.3161 | 0.9669 1.0521 |

| RIDGE Regression | ||||||||

| 4 | , , , | 0.9756 0.9922 | 0.9756 0.9922 | 0.9639 0.8855 | 0.9825 0.5978 | 0.9666 1.4091 | 0.9546 1.3161 | 0.9669 1.0521 |

| Decision Trees | ||||||||

| 4 | 1.0000 0.0079 | 0.9558 1.3208 | 0.9253 1.2769 | 0.9488 1.0245 | 0.8676 2.8035 | 0.9124 1.8356 | 0.9135 1.7351 | |

| Random Forest | ||||||||

| 4 | 0.9969 0.3518 | 0.9771 0.9500 | 0.9569 0.9700 | 0.9815 0.6165 | 0.9076 2.3422 | 0.9520 1.3593 | 0.9495 1.3220 | |

| Gradient Boosting | ||||||||

| 4 | 0.9789 0.9124 | 0.9776 0.9399 | 0.9546 0.9936 | 0.5272 3.1140 | 0.8388 3.0933 | 0.9462 1.4393 | 0.8167 2.1600 | |

| K-nearest Neighbors | ||||||||

| 4 | 0.9801 0.8868 | 0.9760 0.9848 | 0.9174 1.3427 | −1.3900 7.0018 | 0.5985 4.8820 | 0.9009 1.9527 | 0.2567 3.7948 | |

| Support Vector Regression | ||||||||

| 4 | 0.9774 0.9448 | 0.9772 0.9477 | 0.9437 1.1089 | 0.7150 2.4177 | 0.5231 5.3207 | 0.9405 1.5121 | 0.7806 2.5898 | |

| MLP Neural Networks | ||||||||

| 4 | 0.9774 0.9450 | 0.9772 0.9473 | 0.9648 0.8760 | 0.8337 1.8465 | 0.9505 1.7138 | 0.9564 1.2945 | 0.9263 1.4327 | |

| 1D Convolution Neural Networks | ||||||||

| 4 | 0.9767 0.9581 | 0.9767 0.9582 | 0.9643 0.8823 | 0.3889 3.5405 | 0.9672 1.3961 | 0.9557 1.3053 | 0.8190 1.7810 | |

| Number of Features | Approach | Features/Predictor Variables | [kWh] | [kWh] | ||

|---|---|---|---|---|---|---|

| 3 | Trip-based | , , | 1.0026 | 1.0026 | 0.9743 | 0.9743 |

| 3 | S2S based | , , | 1.0045 | 1.0046 | 0.9670 | 0.9669 |

| 4 | Trip-based | , , , | 0.9922 | 0.9922 | 0.9756 | 0.9756 |

| 4 | S2S based | , , , | 1.0270 | 1.0275 | 0.9734 | 0.9733 |

| 5 | Trip-based | , , , , | 0.9862 | 0.9862 | 0. 9760 | 0.9760 |

| 5 | S2S based | , , , , | 0.9935 | 0.9941 | 0.9755 | 0.9754 |

| Number of Features | Features/Predictor Variables | [kWh] | [kWh] | ||

|---|---|---|---|---|---|

| Quadratic Regression | |||||

| 4 | , , , | 0.9922 | 0.9922 | 0.9756 | 0.9756 |

| MLP Neural Networks | |||||

| 4 | 0.9450 | 0.9473 | 0.9774 | 0.9772 | |

| 9 | 0.6994 | 0.6996 | 0.9892 | 0.9890 | |

| Number of Features | Features/Predictor Variables | [kWh] | [kWh] | ||

|---|---|---|---|---|---|

| Quadratic Regression | |||||

| 4 | , , , | 0.9922 | 0.9922 | 0.9756 | 0.9756 |

| 5 | , , ,, | 0.9846 | 0.9846 | 0.9761 | 0.9761 |

| Regression Model | |

|---|---|

| This study | |

| Abdelaty et al. [18] | |

| Vepsäläinen et al. [22] | |

| Pamula et al. [17] | |

| Pamula et al. [19] | |

| Vehviläinen et al. [21] | |

| Bie et al. [31] | |

| Xing et al. [23] |

| Mean | Std. | 1% | 5% | 10% | 15% | 25% | 50% | 75% | 85% | 90% | 95% | 99% | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Abs. [kWh] | −0.06 | 0.85 | −2.31 | −1.43 | −1.02 | −0.78 | −0.47 | −0.06 | 0.31 | 0.62 | 0.87 | 1.35 | 2.56 |

| Rel. [%] | −0.50 | 6.93 | −18.70 | −11.51 | −8.52 | −6.75 | −4.43 | −0.45 | 3.46 | 5.87 | 7.65 | 10.72 | 17.83 |

| Mean | Std. | 1% | 5% | 10% | 15% | 25% | 50% | 75% | 85% | 90% | 95% | 99% | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Abs. [kWh] | 0.02 | 0.11 | −0.25 | −0.16 | −0.09 | −0.05 | −0.02 | 0.01 | 0.06 | 0.11 | 0.16 | 0.25 | 0.37 |

| Rel. [%] | 0.85 | 2.05 | −2.86 | −2.05 | −1.64 | −1.29 | −0.51 | 0.52 | 2.09 | 3.19 | 3.74 | 4.48 | 6.28 |

| Type of Model | * | Average Execution Time per Trip |

|---|---|---|

| Physical model | 2920 s | 0.14 s |

| Regression model | 1.5 ms | 74 ns |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dabčević, Z.; Škugor, B.; Cvok, I.; Deur, J. A Trip-Based Data-Driven Model for Predicting Battery Energy Consumption of Electric City Buses. Energies 2024, 17, 911. https://doi.org/10.3390/en17040911

Dabčević Z, Škugor B, Cvok I, Deur J. A Trip-Based Data-Driven Model for Predicting Battery Energy Consumption of Electric City Buses. Energies. 2024; 17(4):911. https://doi.org/10.3390/en17040911

Chicago/Turabian StyleDabčević, Zvonimir, Branimir Škugor, Ivan Cvok, and Joško Deur. 2024. "A Trip-Based Data-Driven Model for Predicting Battery Energy Consumption of Electric City Buses" Energies 17, no. 4: 911. https://doi.org/10.3390/en17040911

APA StyleDabčević, Z., Škugor, B., Cvok, I., & Deur, J. (2024). A Trip-Based Data-Driven Model for Predicting Battery Energy Consumption of Electric City Buses. Energies, 17(4), 911. https://doi.org/10.3390/en17040911