Measurement of High-Frequency Voltage Harmonics above 2 kHz in High-Voltage Networks

Abstract

1. Introduction

1.1. Recent Trends in Electricity Supply Networks

1.2. Harmonics in Electric Power Systems

1.3. Importance of MV/HV/EHV Harmonic Measurements

1.4. Objectives of the Review and Research Gaps in the Existing Literature on MV/HV/EHV Harmonic Measurements

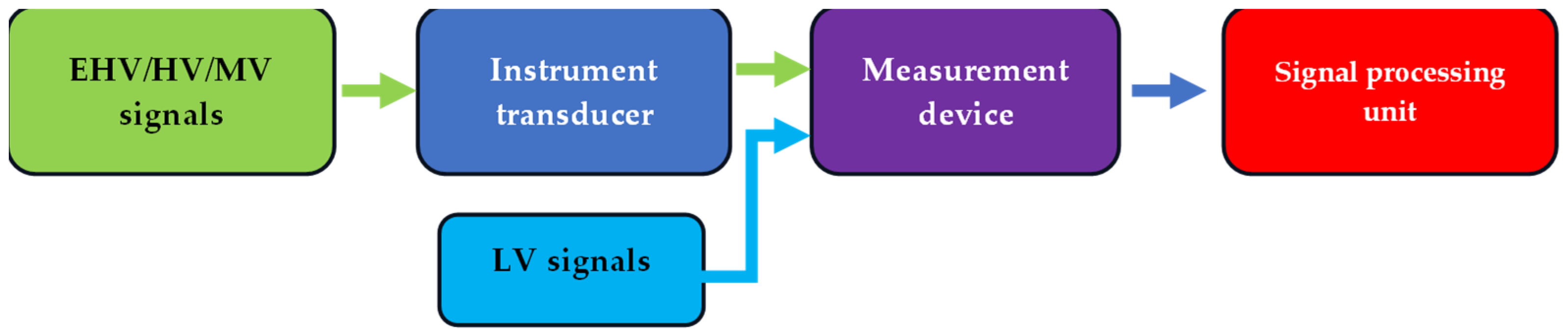

2. MV/HV/EHV Harmonic Measurement Process

2.1. Accuracy of LV Measurement Devices

- is the root-mean-square magnitude of 200 Hz band around the harmonic frequency (n).

- is the root-mean-square magnitude of spectral bin at frequency (f) calculated by the FFT algorithm.

2.2. Accuracy of Instrument Voltage Transformers

- Inductive voltage transformers (IVT);

- Capacitive voltage transformers (CVT);

- Resistive voltage dividers (RVD);

- Capacitive voltage dividers (CVD);

- Resistive–capacitive voltage dividers (RCVD);

- Optical voltage transducers (OVT);

- Non-conventional instrument transformer (NCIT).

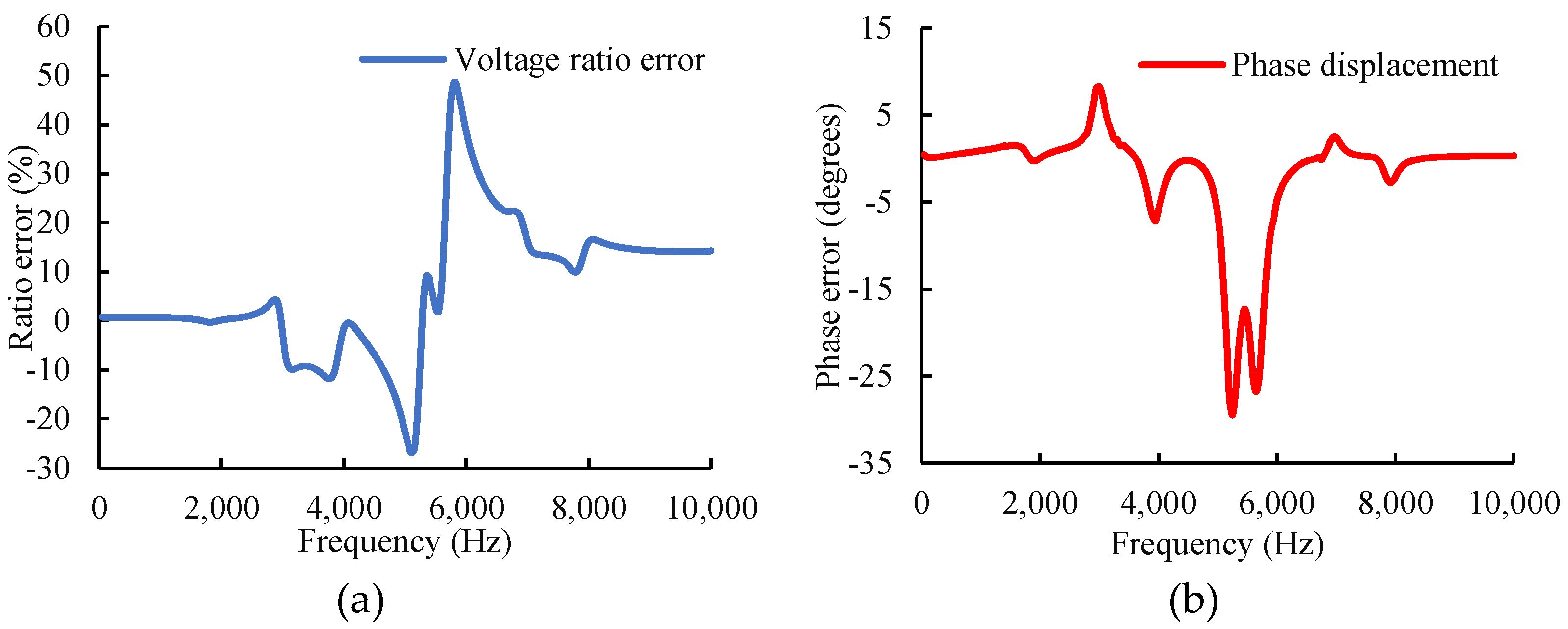

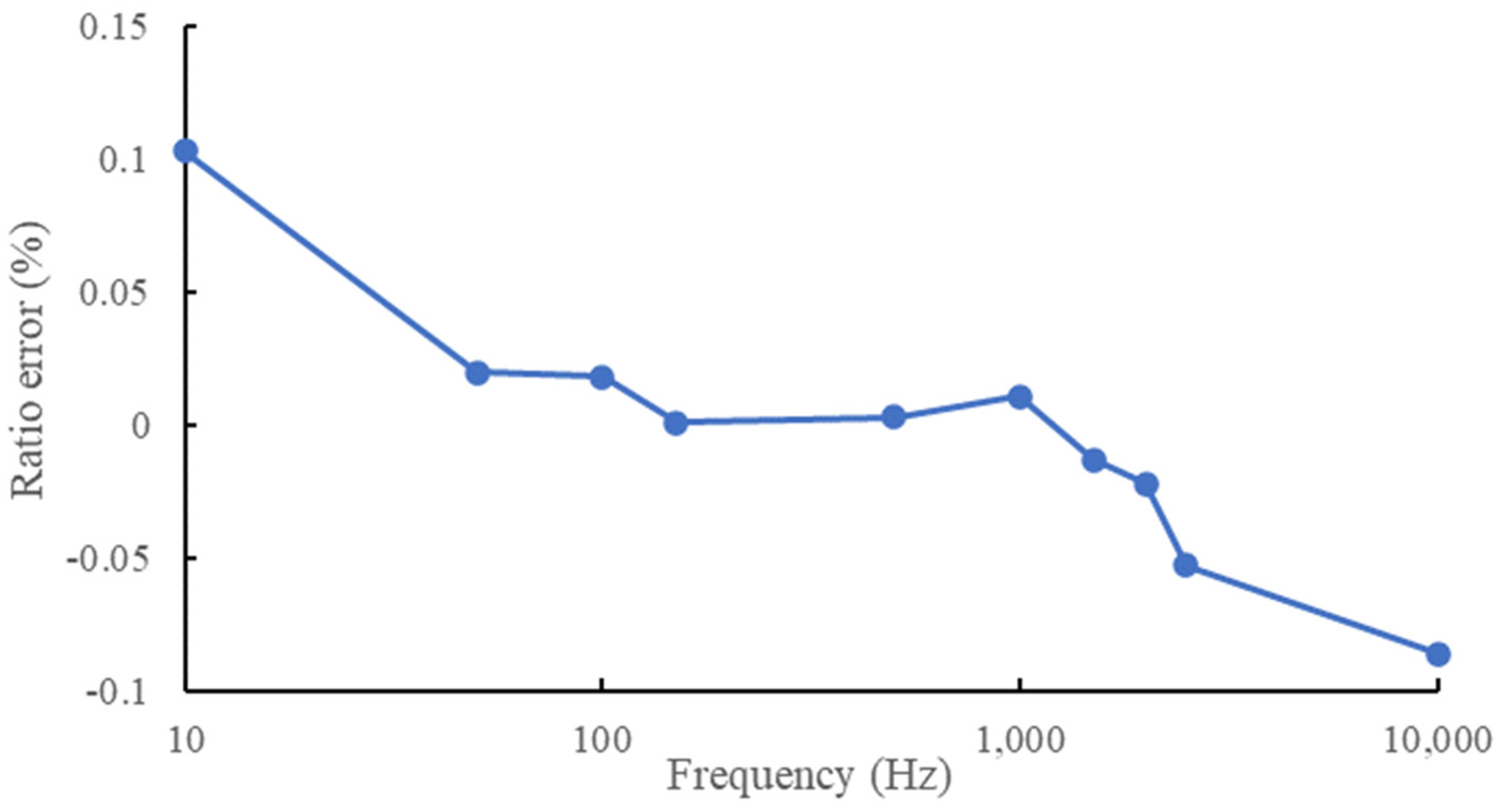

2.2.1. Inductive Voltage Transformers

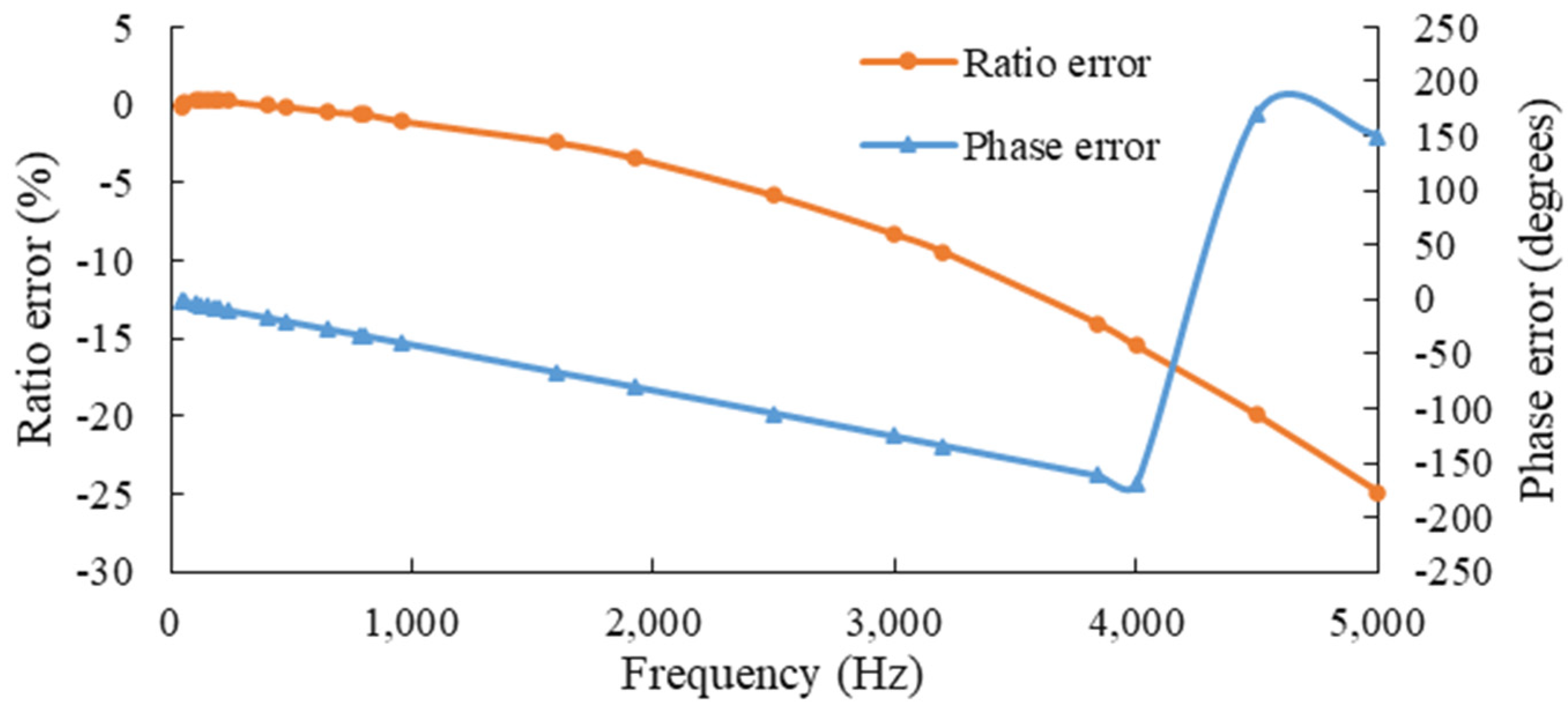

2.2.2. Capacitive Voltage Transformers

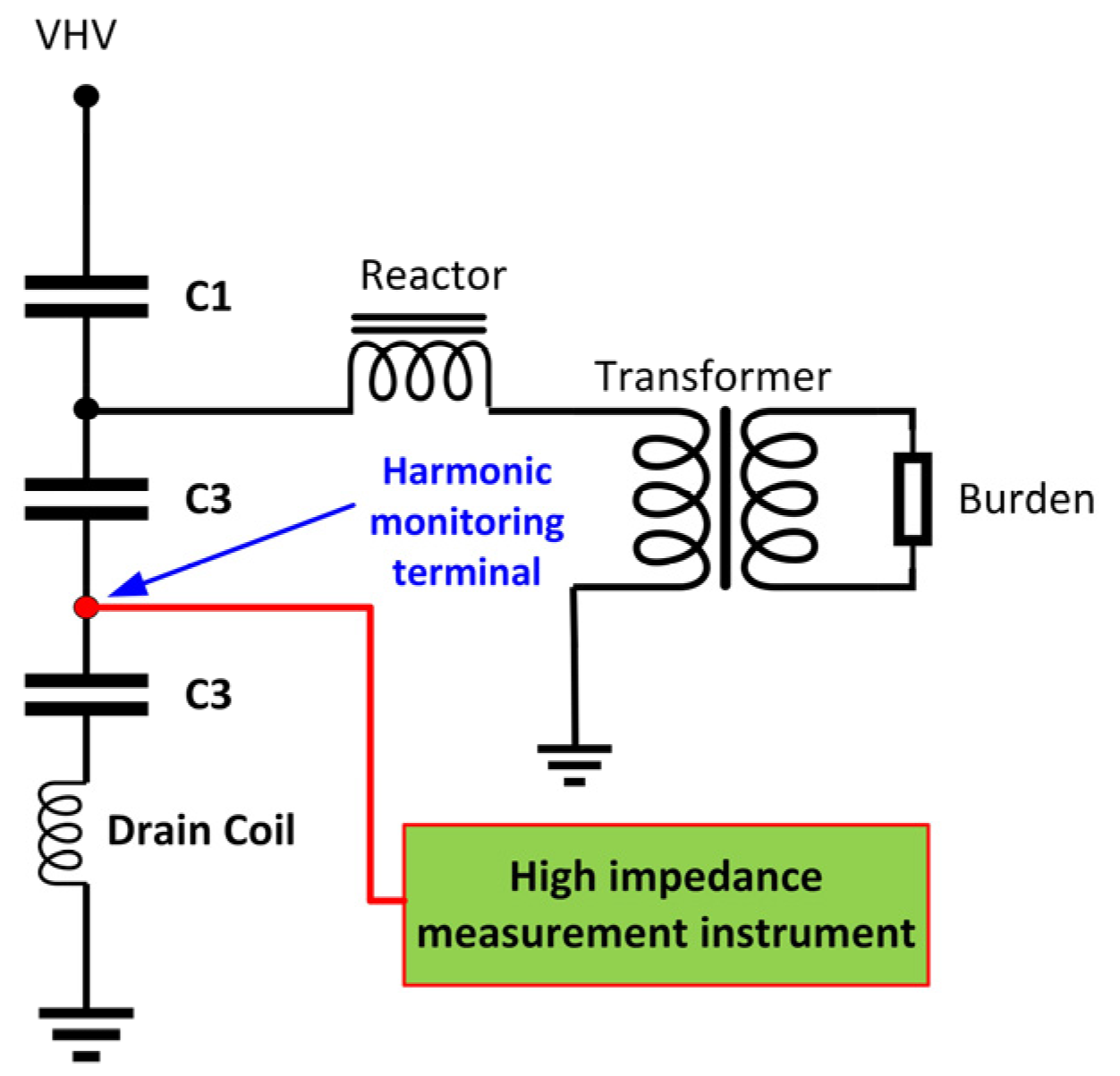

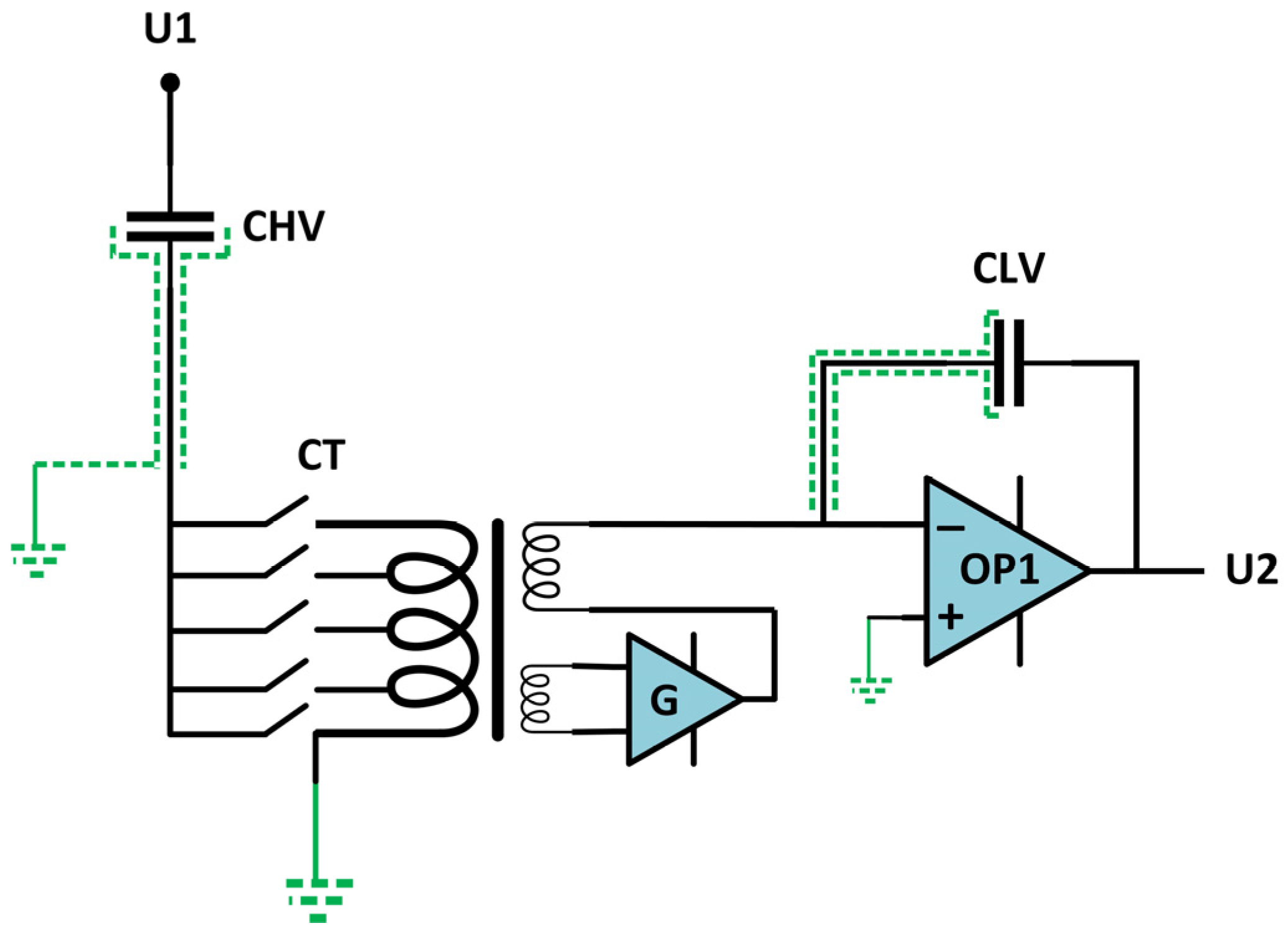

- CVT with dedicated harmonic monitoring terminals

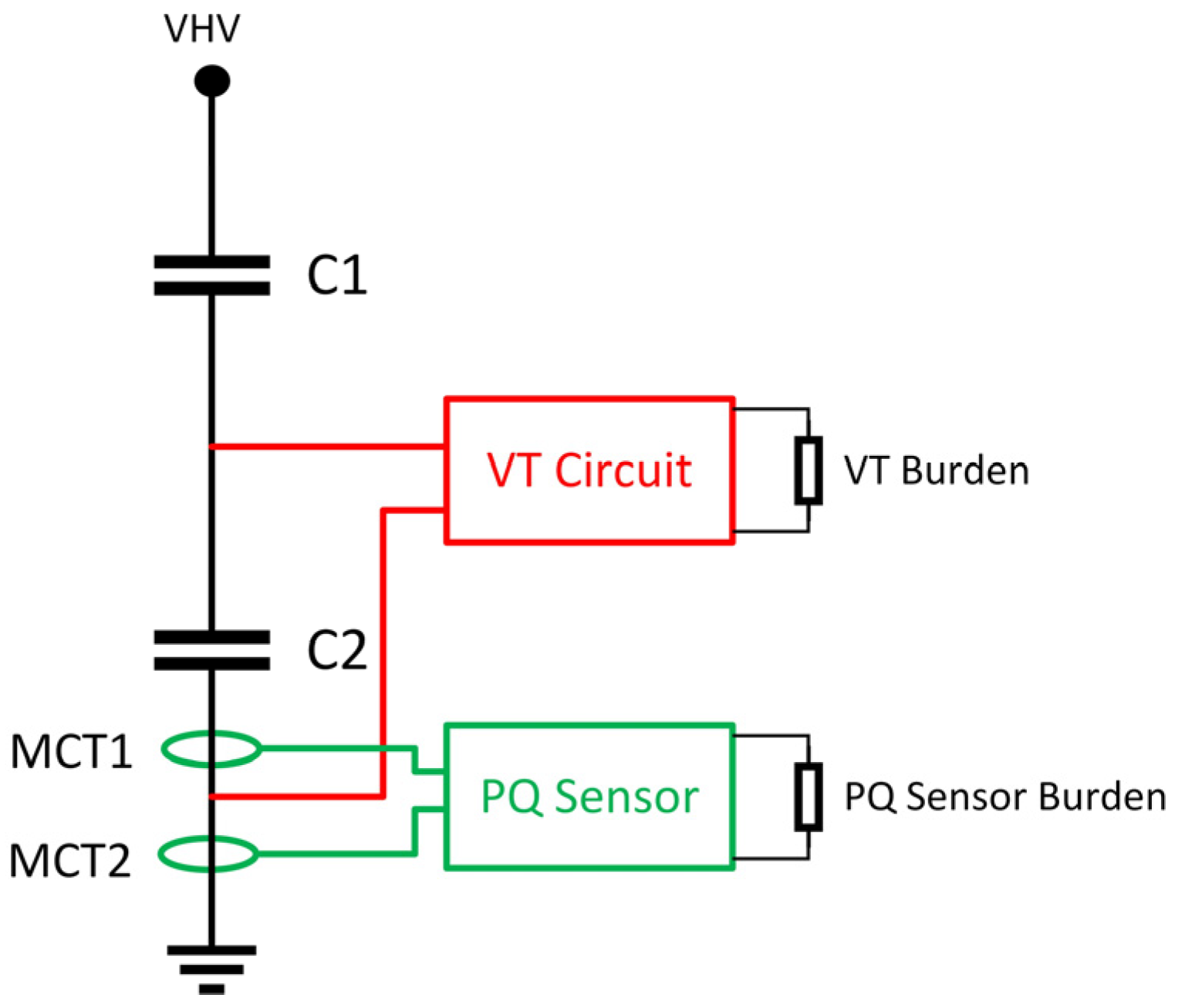

- PQ SensorTM (Manufactured by BVM systems, Gilford, United Kingdom) for capacitive voltage transformers

- s = jω

- IC1(s) and IC2(s) are the currents flowing through the HV capacitor (C1) and LV capacitor (C2), respectively.

- IC1 and IC2 can be calculated from current measurements IMCT1 and IMCT2 that are taken from MCT1 and MCT2, respectively, according to the following Equation (4):

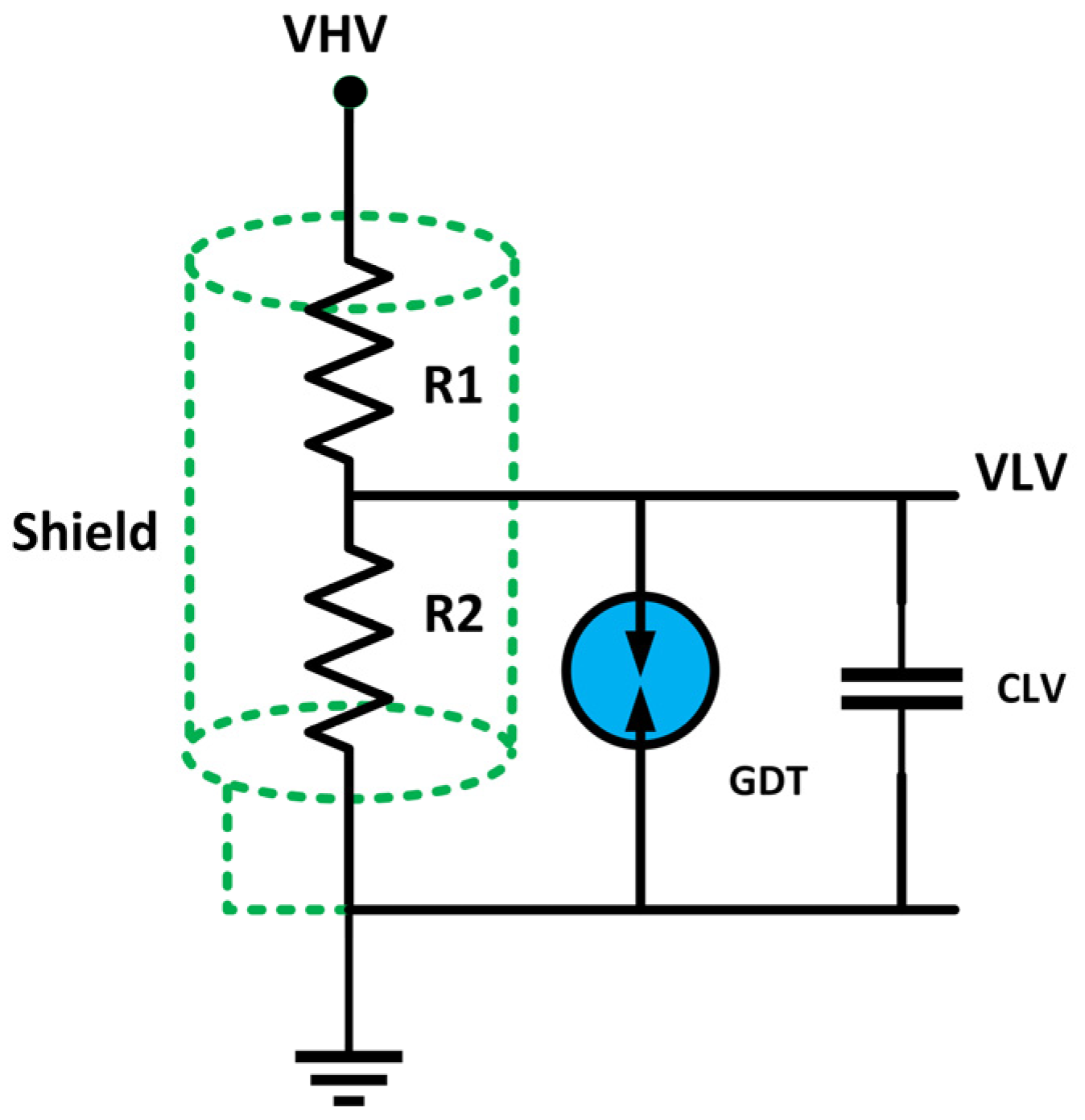

2.2.3. Resistive Voltage Dividers

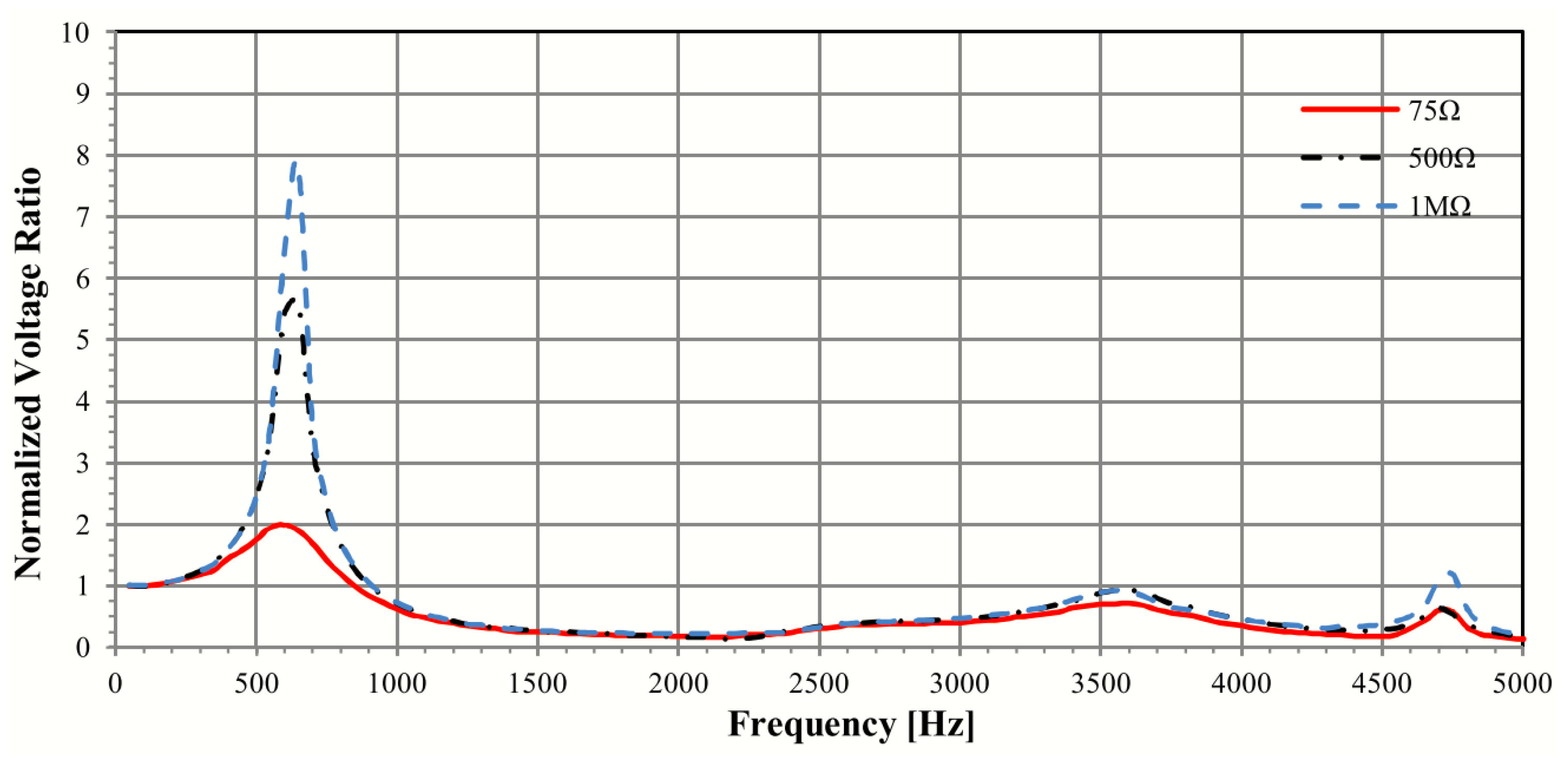

2.2.4. Capacitive Voltage Dividers

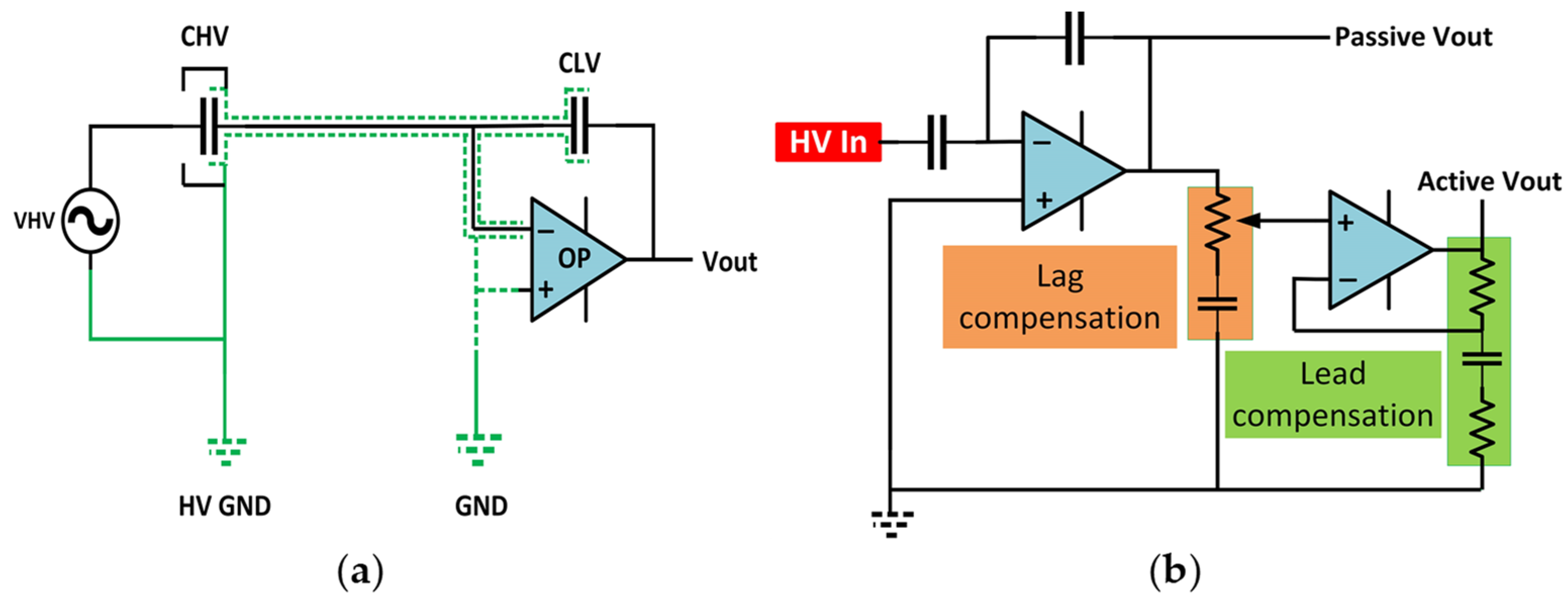

- CVDs with active low-voltage arms

- s = jω;

- is the parallel equivalent capacitance of the low-voltage arm consisting of a low-voltage capacitor (), cable capacitance (), and the measurement instrument capacitance (). The cable impedance mainly consists of its capacitance to the ground and the instrument impedance consists of input resistance in parallel with the input capacitance.

- DC voltage feedback for the operational amplifier (op-amp) should be provided to avoid saturation of its output.

- The operational amplifier finite open loop gain can cause distortion of the divider output waveform, especially at higher frequencies. Sufficient loop gain is required to make the operation of a practical op-amp as close to its ideal behavior as possible. Otherwise, the transfer function of the amplifier depends on amplifier internal components rather than on the external passive components.

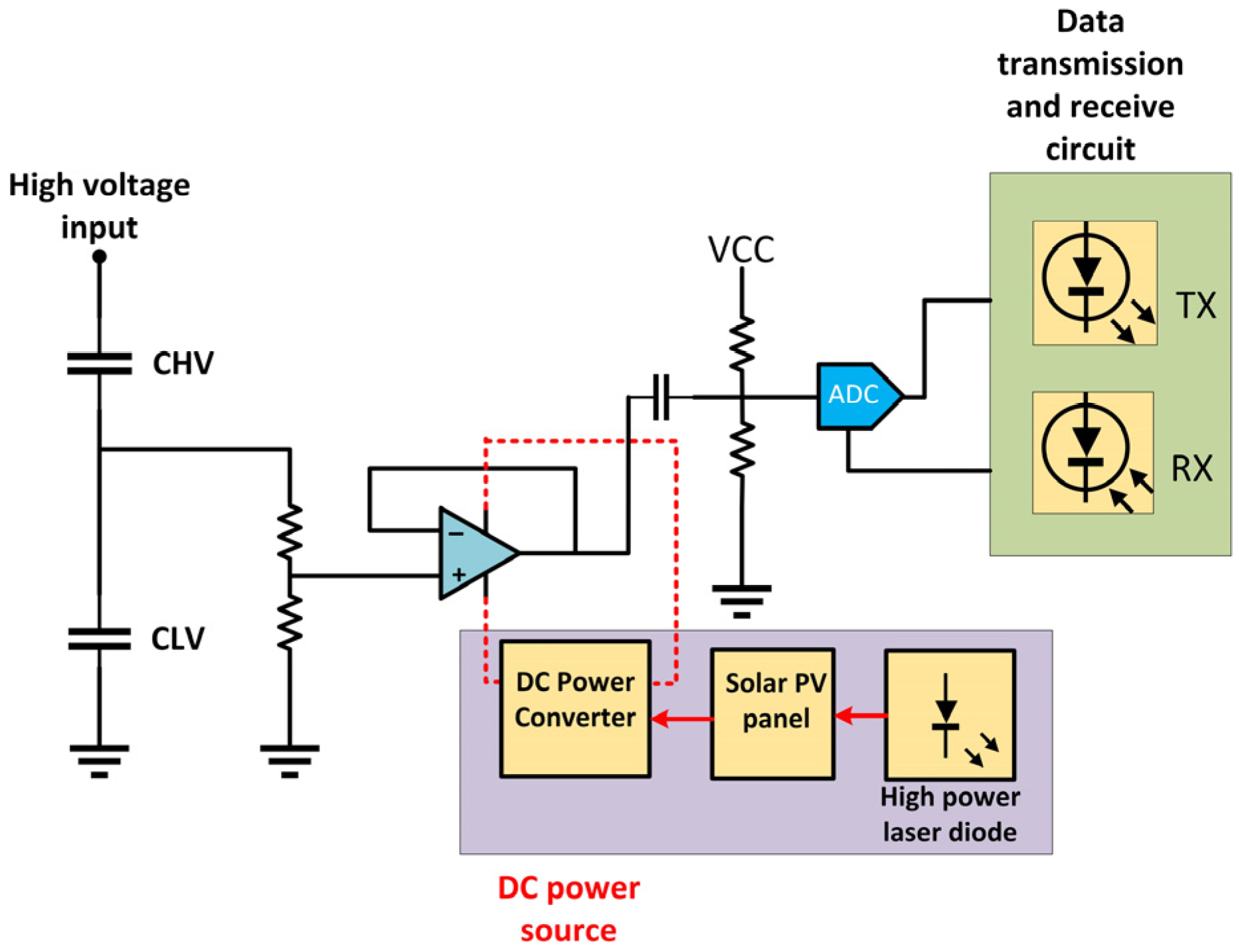

- Active capacitive voltage divider with integrated optical power supplies

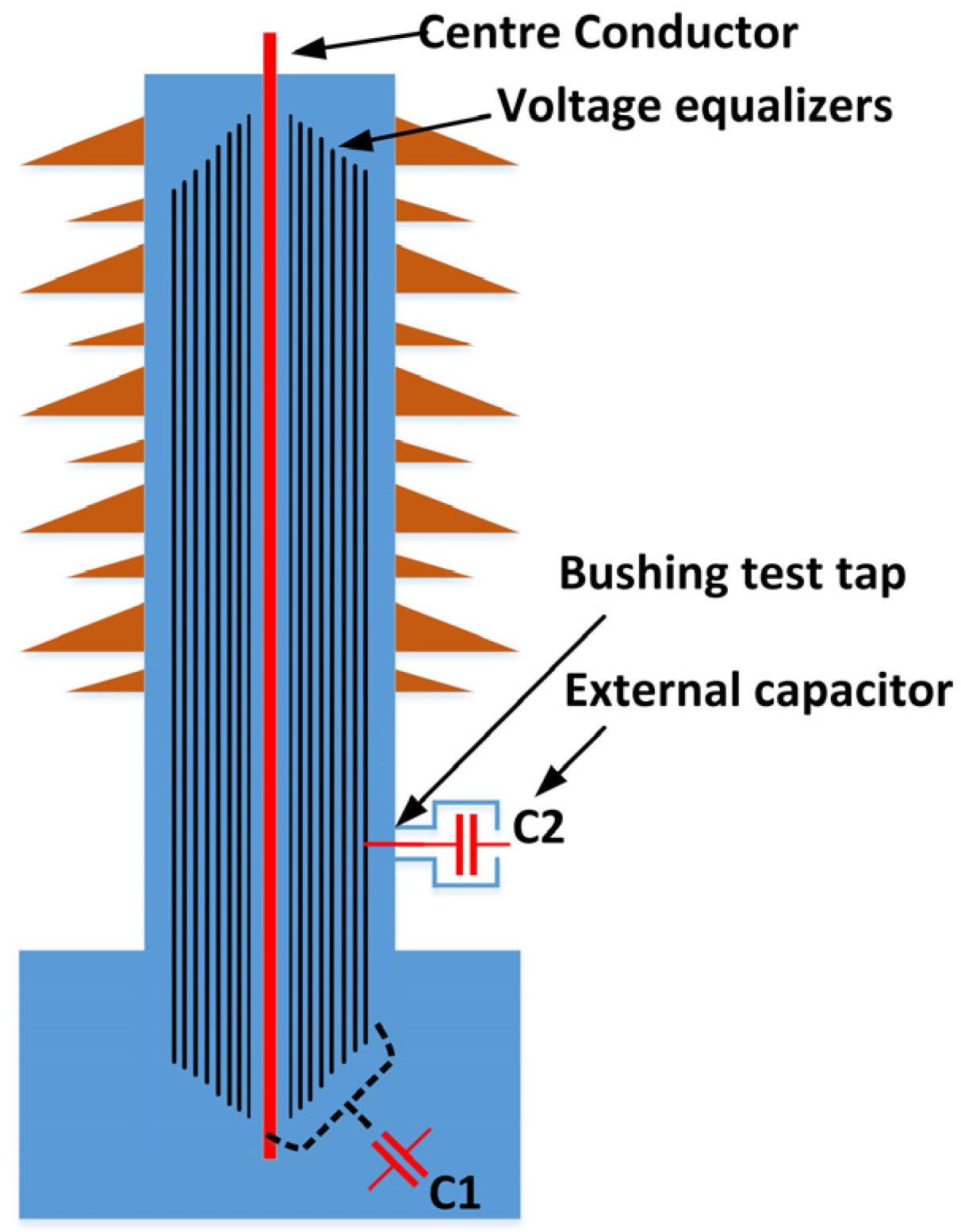

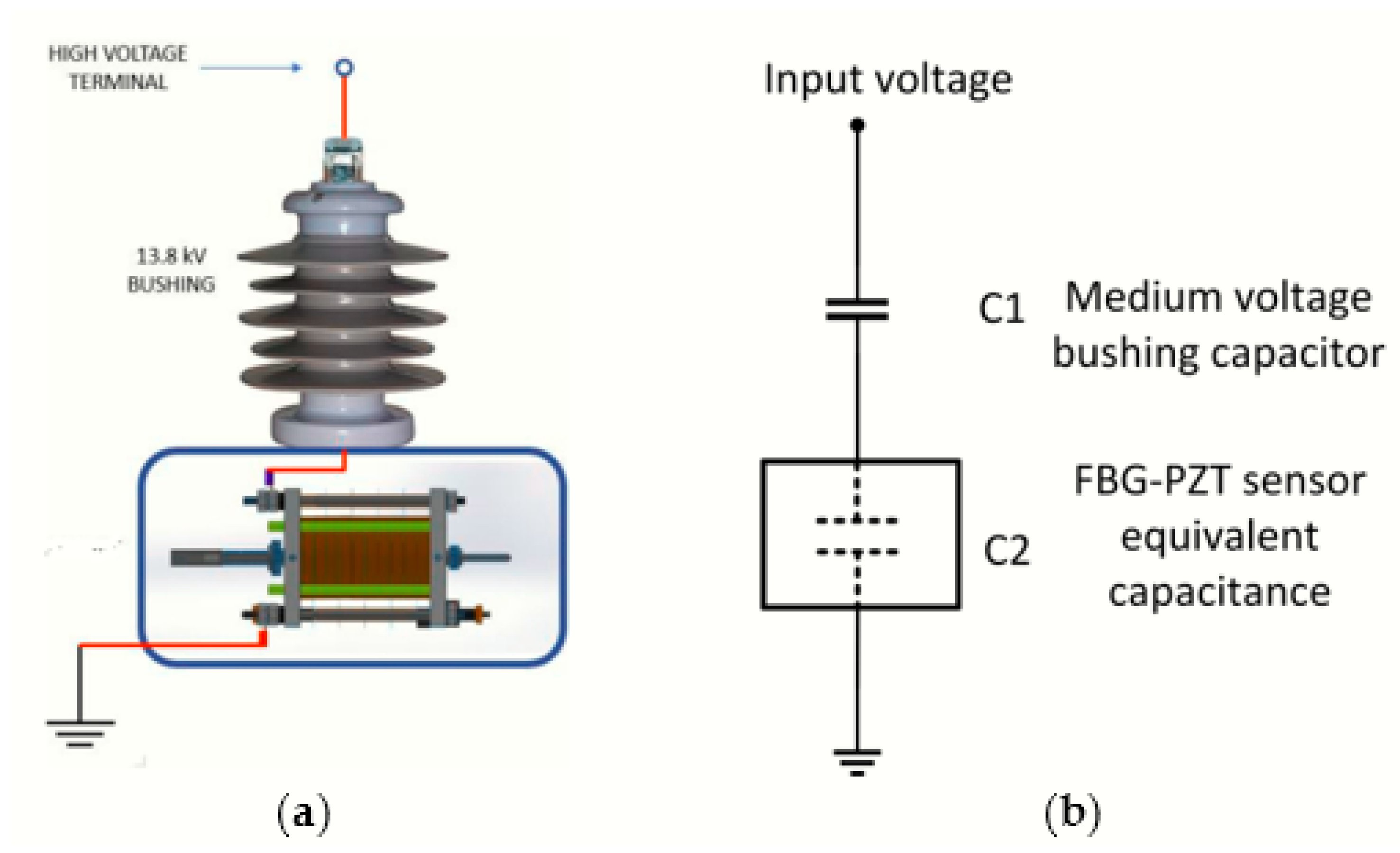

- High-voltage bushing-based capacitive divider

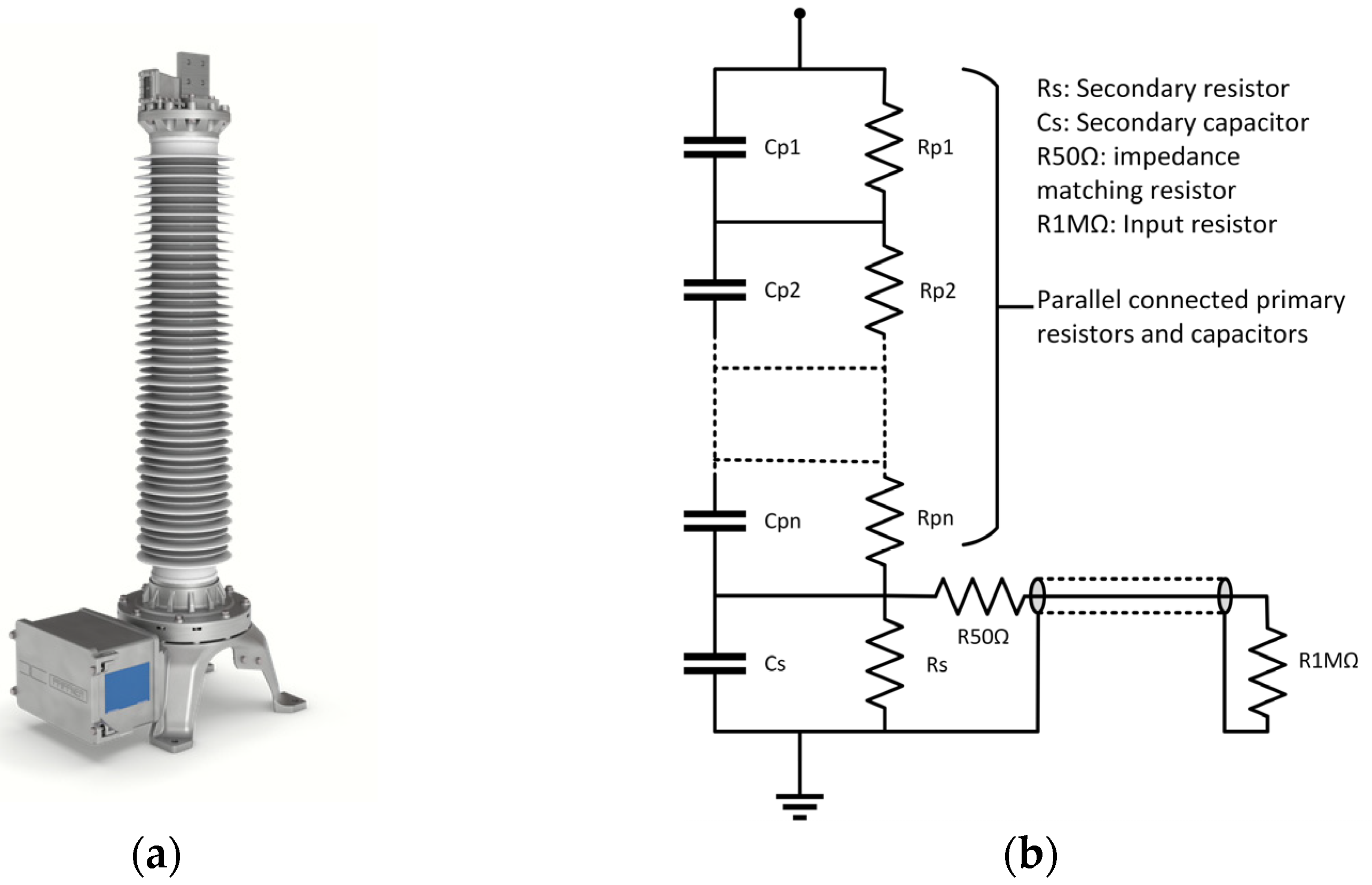

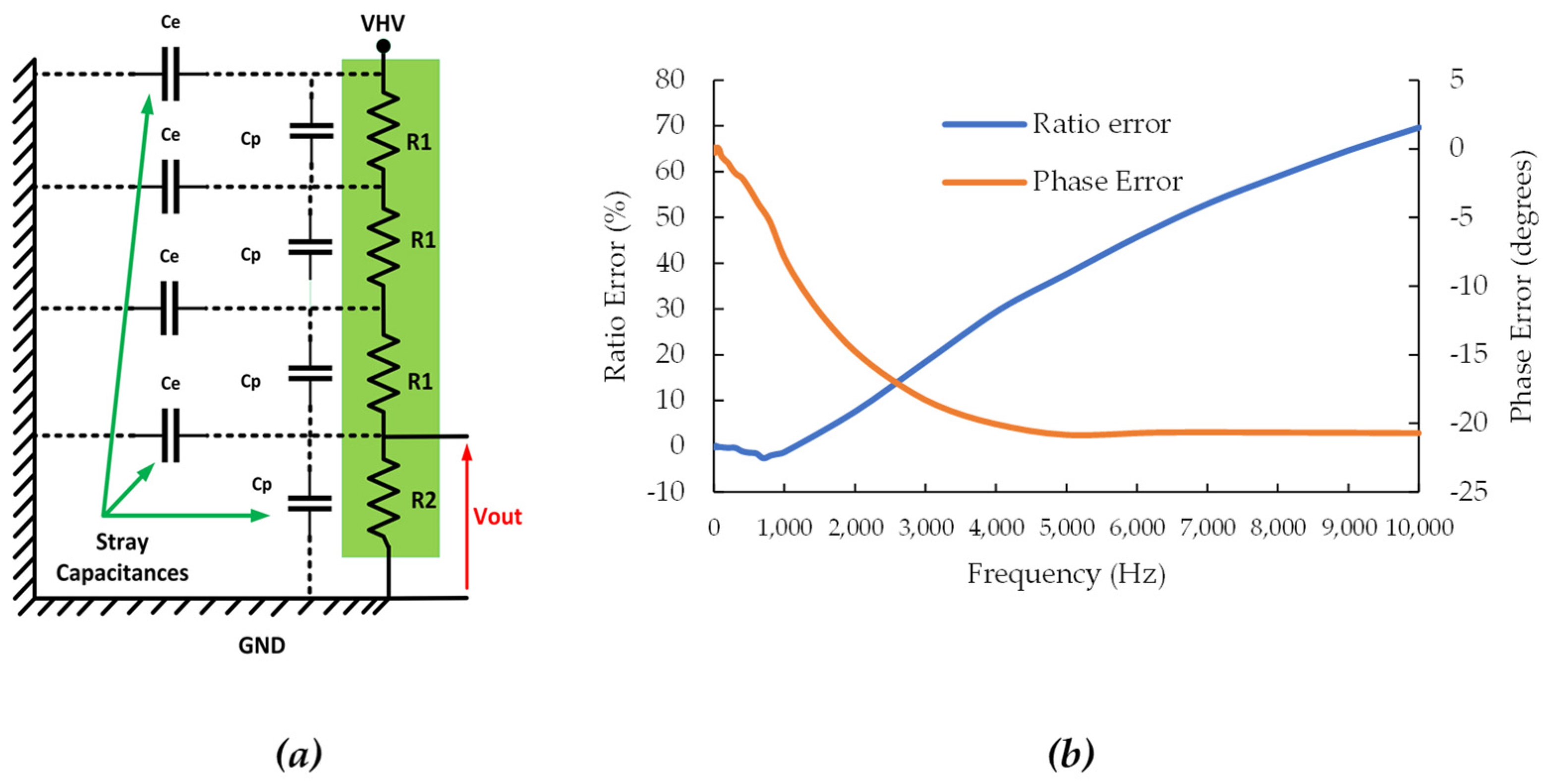

2.2.5. Resistive–Capacitive Voltage Dividers

- Vout is the secondary voltage;

- Vin is the measured high voltage;

- ω is the angular frequency of the voltage.

2.2.6. Optical Voltage Transducers

- External electro-optic modulation-based OVTs, where the measured external voltage modulates the light wave carrier of the OVT sensor.

- Internal electro-optic modulation-based OVTs, where the measured voltage directly modulates the electroluminescent material of the sensor.

- Optical voltage transducers based on the Pockels effect

- Optical voltage transducers based on the electro-gyration effect

2.2.7. Non-Conventional Instrument Transformers

- Optical voltage transformers based on fiber Bragg grating (FBG) and piezoelectric ceramic (PZT) materials

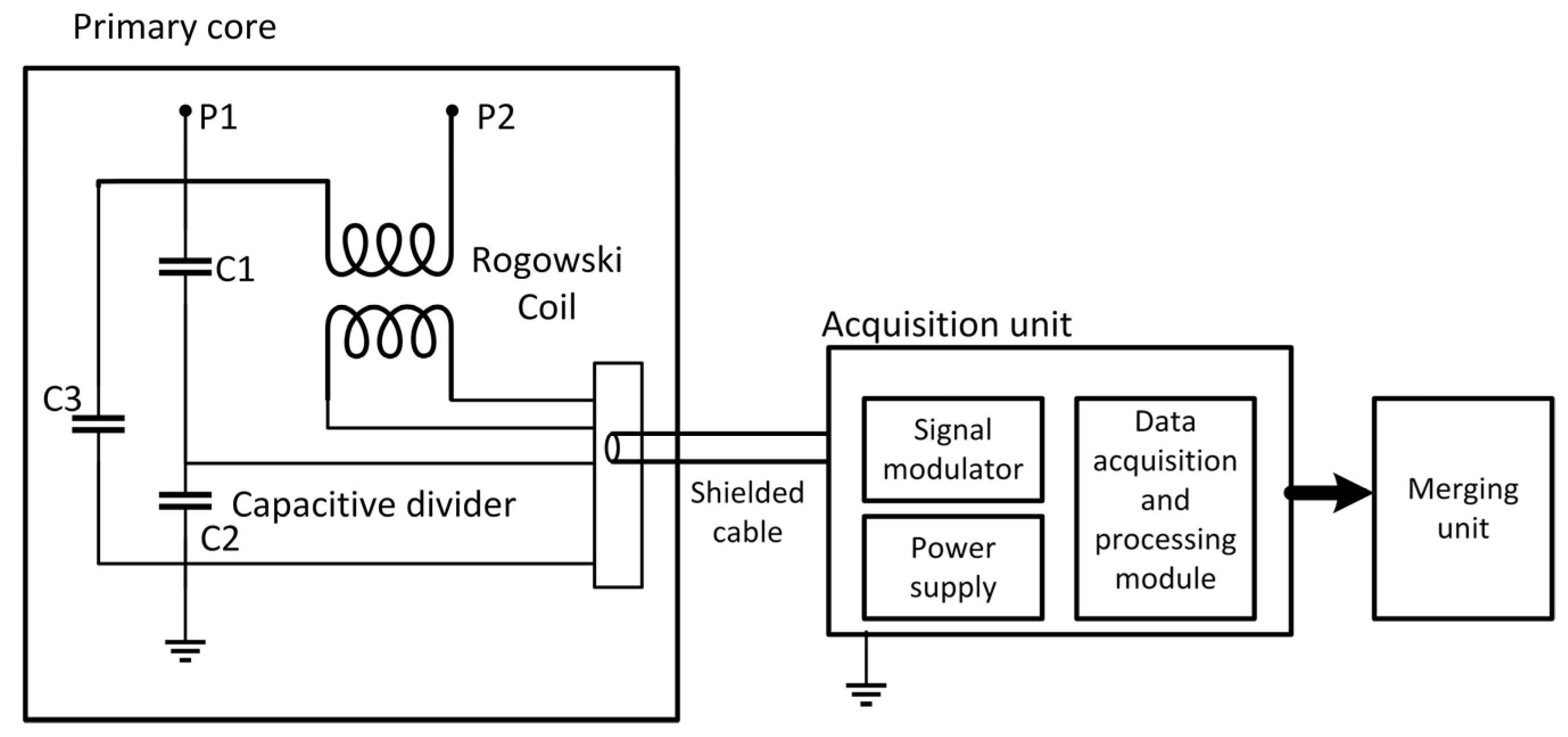

- Dry type insulation combined electronic voltage and current transformer

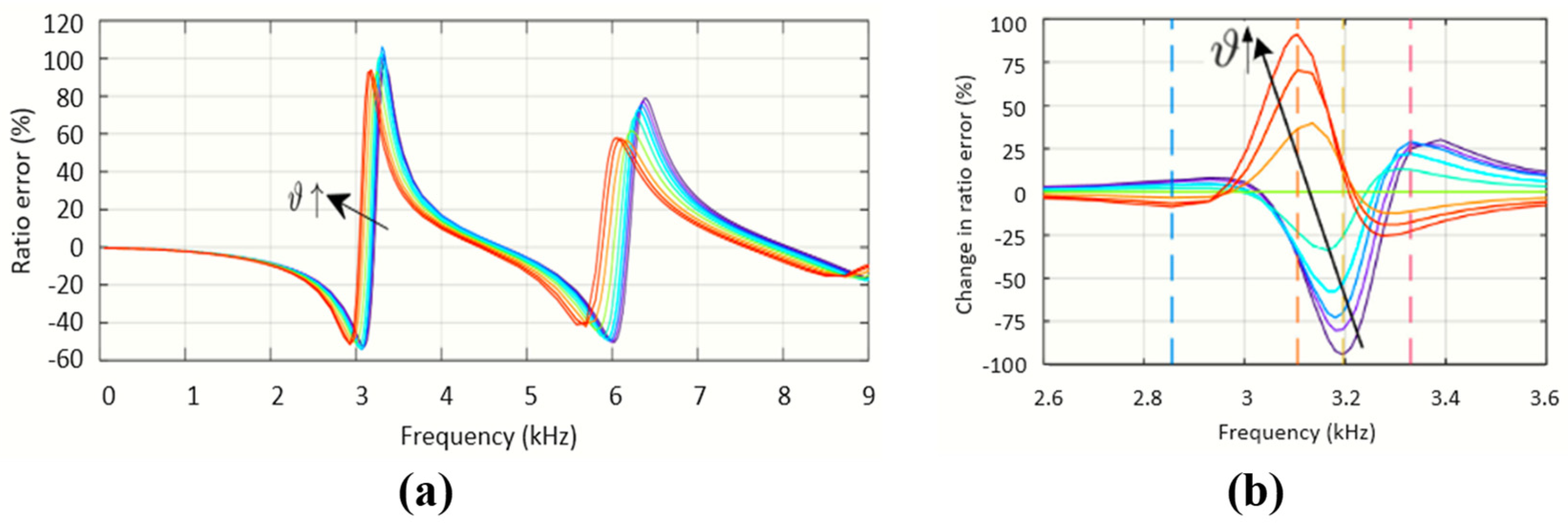

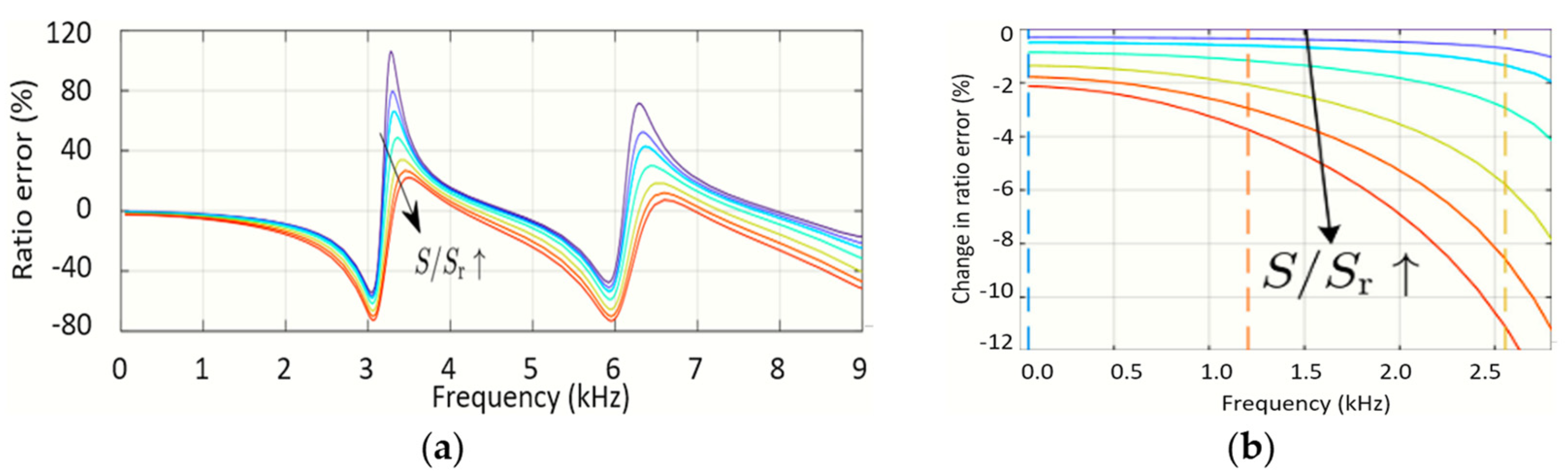

2.3. Impact of External Factors on Instrument Transformer Frequency Response

- (a)

- Operating temperature;

- (b)

- Variation in instrument transformer burden;

- (c)

- Effect of vibration;

- (d)

- Proximity effects due to metallic objects;

- (e)

- Electric and magnetic fields created by nearby energized conductors;

- (f)

- Magnitude of the fundamental voltage component.

2.3.1. Operating Temperature

2.3.2. Impact of Burden

2.3.3. Impact of Proximity, Field Effects, and Vibration

2.3.4. Impact of External Influencing Factors on Low-Power Instrument Transformers (LPITs)

2.4. Overall Comparison between the Accuracy of Instrument Transducers in the Frequency Range from 2 kHz to 9 kHz

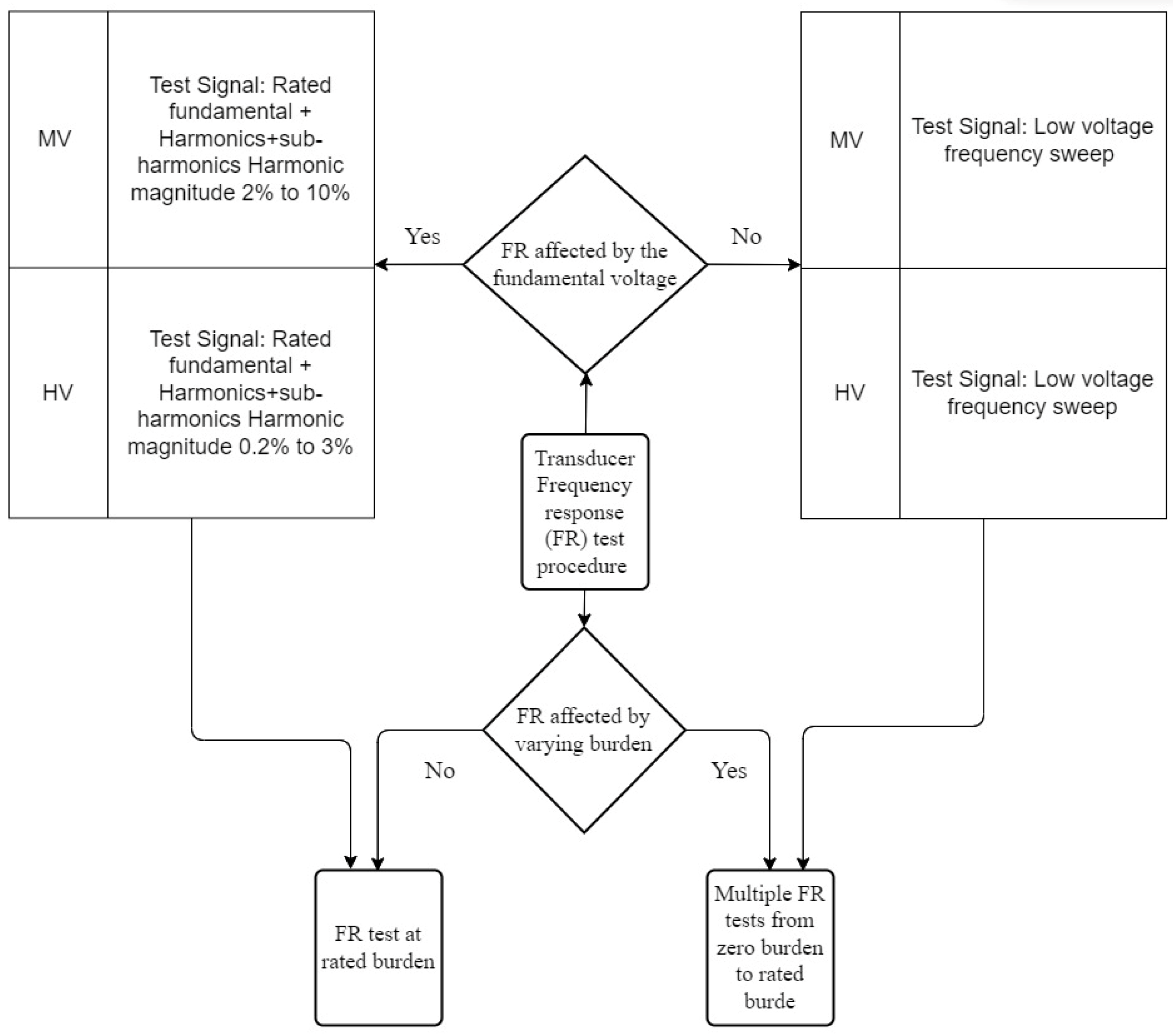

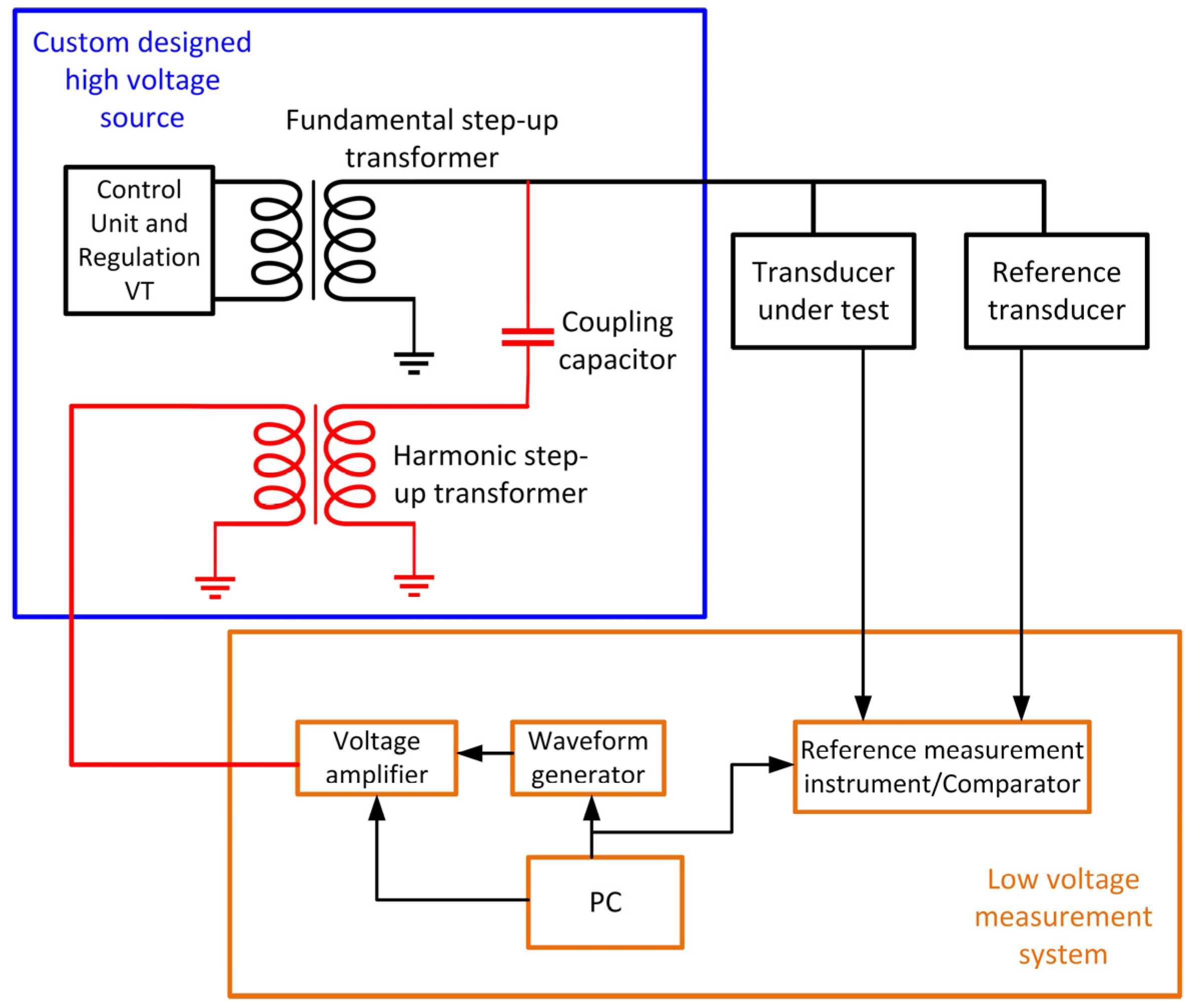

3. High-Voltage Calibration Systems to Evaluate Instrument Transformer Frequency Response

3.1. Instrument Voltage Transformer Calibration Process

- The high-voltage composite signal calibration setup;

- Low-voltage frequency sweep calibration setup.

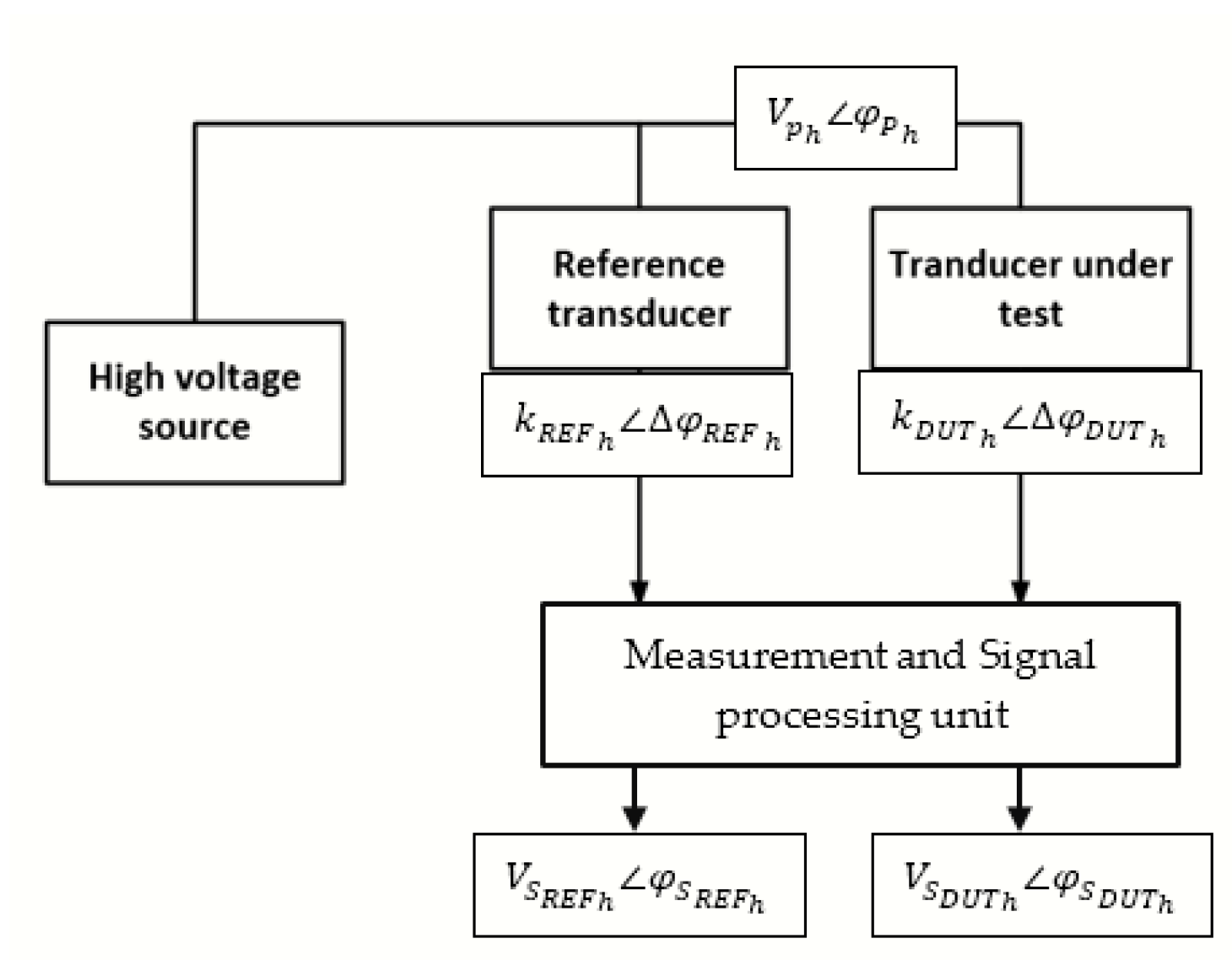

3.1.1. High-Voltage Calibration by Comparison against Reference Standard Transducer

- is the magnitude of the DUT secondary voltage signal at harmonic order (h);

- is the magnitude of the primary high-voltage signal at harmonic order (h);

- is the phase angle of the DUT secondary voltage signal at harmonic order (h);

- is the phase angle of the primary voltage signal at harmonic order (h).

- is the reference transducer output signal magnitude at harmonic order (h);

- is the voltage ratio of the reference transducer at harmonic order (h);

- is the phase error of the reference transducer at harmonic order (h);

- is the phase angle of the reference transducer output voltage signal at harmonic order (h).

- is the secondary output voltage signal of the IVT at harmonic order (h);

- is the primary input voltage signal applied to the IVT at harmonic order (h).

3.1.2. Low-Voltage Frequency Sweep Response Calibration Method

3.2. Application of Composite MV/HV/EHV Signals for Instrument Transformer Calibration

3.3. Standards Governing MV/HV Instrument Transformer Accuracy Requirements

- Accuracy limits for low-frequency harmonics (shown in Table 11);

- 2.

- Accuracy limits for low bandwidth measurements (shown in Table 12)

- 3.

- Accuracy limits for high bandwidth measurements (shown in Table 13)

4. Discussion

- MV/HV/EHV IVTs, known for their cost-effectiveness, exhibit significant voltage ratio errors in the 2 kHz to 9 kHz frequency range due to internal resonances. However, proper calibration can correct these errors, enabling IVTs to be used for both harmonic amplitude and phase angle measurements.

- Generally, CVTs cannot be utilized for harmonic measurements unless special adaptation techniques, such as harmonic monitoring terminals and PQ sensorsTM (Manufactured by BVM systems, Gilford, UK), are employed. These techniques offer cost-effective solutions for employing conventional CVTs for harmonic measurement in the 2 kHz to 9 kHz frequency range.

- RVDs without internal shielding may be severely affected by stray capacitances and should not be used for harmonic measurements. However, shielded RVDs can be employed in the considered frequency range. The accuracy of RVD harmonic measurement may decrease significantly with increasing frequency and voltage rating. Hence, the voltage ratio error and phase error of the RVD should be characterized within its entire operating range.

- CVDs are suitable for harmonic amplitude measurements in the 2 kHz to 9 kHz frequency range in MV/HV/EHV networks. However, phase angle measurements of CVDs are affected by loading effects from measuring cables and instruments. These limitations are mitigated by novel techniques, such as the use of active low-voltage arms. The cost of implementation may vary depending on the specific characteristics of CVD construction.

- RCVDs are considered to be the most accurate type of instrument transformer for both harmonic amplitude and phase angle measurements in the 2 kHz to 9 kHz frequency range. However, the significant cost of implementation limits the widespread application of these devices.

- OVTs are considered as a novel instrument transducer type which provides accurate harmonic amplitude measurements in the frequency range from 2 kHz to 9 kHz, However, the working voltage of such OVTs is limited to a range of several kilovolts. This requires the use of additional voltage dividers to be combined with OVTs in order to adapt these transducers for the measurement of harmonics in MV/HV/EHV electricity networks. In such cases, it is essential to characterize these transducer frequency responses using an accurate calibration system. Similar to the RCVDs, the cost of OVT implementation is considerably higher than the conventional IVTs and CVTs, which limits their widespread application for harmonic voltage measurements.

- The accuracy characteristics of NCITs could vary significantly due to the differences in their construction principles. Therefore, it is difficult to provide generalized conclusions regarding their accuracy of harmonic measurements in the frequency range from 2 kHz to 9 kHz. Hence, it is advisable to calibrate each NCIT for their frequency response using accurate calibration systems.

- A suitable standard test procedure should be developed to evaluate the high-voltage instrument transformer harmonic measurement accuracy. Manufacturers use different types of instrument transformer frequency response characterization procedures. The establishment of a standard test procedure would facilitate comparability among different manufacturers.

- There is a wide variety of test waveforms used for instrument transformer calibration. A proper specification regarding the waveform characteristics should be defined by standardization authorities similar to the test signal requirements specified at the rated fundamental frequency.

- There is a lack of suitable high-voltage sources that can generate the required composite test waveforms for the calibration of instrument transformers under realistic conditions. Further research should focus on developing new high-voltage sources that would provide wideband high-voltage waveforms.

- Investigation of external influencing factors on instrument transformer frequency response has not been consolidated properly. The investigation of these parameters should be combined into a standard test procedure which should be defined in agreement with the equipment manufacturers, national metrological laboratories, and standardization authorities.

- National metrological laboratories should focus on the development of suitable reference transducers that could provide traceable calibrations for high-voltage harmonic measurements under realistic distorted test waveforms.

- The international standards covering the harmonic measurements in the frequency range from 2 kHz to 150 kHz are not properly consolidated. Most of the requirements are provided on an informative basis. However, with the increasing use of power electronic converters which contribute to high-frequency harmonic emissions, proper definitions of measurement techniques will be required for inclusion as essential requirements.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CISPR | International Special Committee on Radio Interference |

| CVD | Capacitive voltage divider |

| CVT | Capacitive voltage transformer |

| DUT | Device under test |

| EHV | Extra high voltage |

| EV | Electric vehicle |

| FACTS | Flexible alternating current transmission system |

| FBG | Fiber Bragg grating |

| FFT | Fast Fourier transform |

| FR | Frequency response |

| HV | High voltage |

| HVDC | High-voltage direct current |

| IEC | International electrotechnical commission |

| IEEE | Institute of electrical and electronics engineers |

| IVT | Inductive voltage transformer |

| LCR | Inductance-capacitance-resistance |

| LPIT | Low-power instrument transformers |

| LV | Low voltage |

| MCT | Measurement current transformer |

| MV | Medium voltage |

| NCIT | Non-conventional instrument transformers |

| OVT | Optical voltage transducer |

| PbWO4 | Lead tungstate |

| PLC | Programmable logic controllers |

| PQ | Power quality |

| PV | Photovoltaic |

| PWM | Pulse width modulation |

| PZT | Piezoelectric ceramic materials |

| RCF | Ratio correction factor |

| RCVD | Resistive–capacitive voltage divider |

| RVD | Resistive voltage divider |

| SMPS | Switch-mode power supplies |

| VA | Volt–ampere |

| VNA | Vector network analyzer |

| Sulphur hexa-fluoride |

References

- IRENA. Renewable Energy Statistics 2023; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2023. [Google Scholar]

- Rönnberg, S.; Bollen, M. Power quality issues in the electric power system of the future. Electr. J. 2016, 29, 49–61. [Google Scholar] [CrossRef]

- Mariscotti, A. Harmonic and Supraharmonic Emissions of Plug-In Electric Vehicle Chargers. Smart Cities 2022, 5, 496–521. [Google Scholar] [CrossRef]

- Alibegovic, L.; Paulsson, E.F. Harmonic Emissions in Microgrids A Case Study of Simris. Master’s Thesis, Lund University, Lund, Sweden, 2021. [Google Scholar]

- Adineh, B.; Keypour, R.; Davari, P.; Blaabjerg, F. Harmonic Mitigation Methods in Microgrids. In Deregulated Electricity Structures and Smart Grids; CRC Press: Boca Raton, FL, USA, 2022; pp. 25–46. [Google Scholar]

- Romero-L, M.; Quintero-Molina, V.; Garzón, C.; Pavas, A.; Blanco, A.M.; Kannan, S.; Meyer, J. Analysis of supraharmonic emission in a microgrid in islanded and interconnected operation. In Proceedings of the 2022 20th International Conference on Harmonics & Quality of Power (ICHQP), Naples, Italy, 29 May–1 June 2022; pp. 1–6. [Google Scholar]

- Sulistyowati, R.; Widiatmoko, D.; Sujono, H.A. Harmonics Analysis of Inverter Circuits on Smart Grid System. J. Phys. Conf. Ser. 2021, 2117, 012009. [Google Scholar] [CrossRef]

- Vijayalakshmi, S.; Shenbagalakshmi, R.; Kamalini, C.P.; Marimuthu, M.; Venugopal, R. Power Quality Issues in Smart Grid/Microgrid. In Planning of Hybrid Renewable Energy Systems, Electric Vehicles and Microgrid: Modeling, Control and Optimization; Bohre, A.K., Chaturvedi, P., Kolhe, M.L., Singh, S.N., Eds.; Springer Nature Singapore: Singapore, 2022; pp. 403–442. [Google Scholar]

- Sosnina, E.; Bedretdinov, R.; Ivanov, A. Assessment of FACTS Devices Nonsinusoidality in Smart Grid. In Proceedings of the 2022 20th International Conference on Harmonics & Quality of Power (ICHQP), Naples, Italy, 29 May–1 June 2022; pp. 1–5. [Google Scholar]

- Zheng, Y.; Li, X.; Huang, H. Harmonic characteristics of HVDC transmission system and its suppression method system. J. Phys. Conf. Ser. 2022, 2401, 012045. [Google Scholar] [CrossRef]

- IEC 61000-3-6; Electromagnetic Compatibility (EMC)—Part 3–6: Limits—Assessment of Emission Limits for the Connection of Distorting Installations to MV, HV and EHV Power Systems. IEC: Geneva, Switzerland, 2008.

- Yaghoobi, J.; Alduraibi, A.; Martin, D.; Zare, F.; Eghbal, D.; Memisevic, R. Impact of high-frequency harmonics (0–9 kHz) generated by grid-connected inverters on distribution transformers. Int. J. Electr. Power Energy Syst. 2020, 122, 106177. [Google Scholar] [CrossRef]

- Kulkarni, S.V.; Khaparde, S.A. Transformer Engineering, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Ahmed, I.; Shames, M.Z.; Alam, M. An Overview of Harmonic Sources in Power System. IOSR J. Electr. Electron. Eng. 2013, 7, 1–3. [Google Scholar] [CrossRef]

- Awais, Q.; Jamil, M.; Hashmi, G.M.; Syed, Z.A. Harmonics in Adjustable Speed Drives: Causes, Effects, and Solutions. In Proceedings of the International Conference on Information and Emerging Technologies, Karachi, Pakistan, 6–7 July 2007. [Google Scholar]

- Srivastava, A.; Singh, A. Harmonics generated by Electric Arc Furnace in Electric Power System—A Review. SAMRIDDHI J. Phys. Sci. Eng. Technol. 2019, 57–62. [Google Scholar] [CrossRef][Green Version]

- Gandhare, W.Z.; Lulekar, D. Analyzing electric power quality in arc furnaces. Renew. Energy Power Qual. J. 2007, 1, 286–290. [Google Scholar] [CrossRef]

- De La Rosa, F. Harmonics and Power Systems; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Das, J.C. Power System Harmonics. In Power System Harmonics and Passive Filter Designs; Wiley: Hoboken, NJ, USA, 2015; pp. 1–29. [Google Scholar]

- Arrilaga, J. Harmonic Analysis. In Power System Harmonics; Wiley: Hoboken, NJ, USA, 2003; pp. 17–59. [Google Scholar]

- Alkahtani, A.A.; Alfalahi, S.T.Y.; Athamneh, A.A.; Al-Shetwi, A.Q.; Mansor, M.B.; Hannan, M.A.; Agelidis, V.G. Power Quality in Microgrids Including Supraharmonics: Issues, Standards, and Mitigations. IEEE Access 2020, 8, 127104–127122. [Google Scholar] [CrossRef]

- Ackermann, F.; Moghadam, H.; Meyer, J.; Müller, S.; Domagk, M.; Santjer, F.; Athamna, I.; Klosse, R. Characterization of Harmonic Emission of Individual Wind Turbines and PV inverters based on measurements—Part I—Photovoltaic Inverters. In Proceedings of the 6th Solar Integration Workshop, Vienna, Austria, 14–15 November 2016. [Google Scholar]

- Hong, S.; Zuercher, M. Harmonics and Noise in Photovoltaic (PV) Inverter and Mitigation Strategies; Solectria Renewables: Lawrence, MA, USA, 2015. [Google Scholar]

- Jape, V.S.; Bankar, D.S.; Kulkarni, H.H.; Borkar, R.V. Effects of harmonics on major equipment in power distribution network. Int. J. Sci. Technol. Res. 2019, 8, 827–830. [Google Scholar]

- IEC-TR-61869-103; Instrument Transformers—The Use of Instrument Transformers for Power Quality Measurement. IEC: Geneva, Switzerland, 2012; p. 84.

- Al-Sharif, Y.M.; Sowilam, G.M.; Kawady, T.A. Harmonic Analysis of Large Grid-Connected PV Systems in Distribution Networks: A Saudi Case Study. Int. J. Photoenergy 2022, 2022, 8821192. [Google Scholar] [CrossRef]

- Al-Shetwi, A.; Sujod, M. Harmonic Distortion and Voltage Imbalance Study of Photovoltaic Power Plant Connected to the Malaysian Grid. J. Telecommun. Electron. Comput. Eng. 2018, 10, 1–6. [Google Scholar]

- Domagk, M.; Meyer, J.; Mühlberg, M.; Ackermann, F.; Reichert, S.; Meyer, M.; Kaatz, G.; Fricke, B.; Safargholi, F.; Vennegeerts, H.; et al. Impact of Renewable Generation on the Harmonic Distortion in Distribution Networks: Key Findings of the Research Project Netzharmonie. In Proceedings of the 25th International Conference on Electricity Distribution (CIRED), Madrid, Spain, 3–6 June 2019. [Google Scholar]

- Domagk, M.; Stiegler, R.; Meyer, J. Measurement Based Identification of Equivalent Circuit Models for Aggregated Harmonic Impedances of Public Low Voltage Grids. In Proceedings of the IEEE Milan PowerTech, Milan, Italy, 23–27 June 2019; pp. 1–6. [Google Scholar]

- Kumar, A.; Das, B.; Sharma, J. Determination of location of multiple harmonic sources in a power system. Int. J. Electr. Power Energy Syst. 2004, 26, 73–78. [Google Scholar] [CrossRef]

- Klatt, M.; Meyer, J.; Elst, M.; Schegner, P. Frequency Responses of MV voltage transformers in the range of 50 Hz to 10 kHz. In Proceedings of the 14th International Conference on Harmonics and Quality of Power, Bergamo, Italy, 26–29 September 2010. [Google Scholar]

- Blanco, A.M.; Stiegler, R.; Meyer, J.; Schwenke, M. Implementation of harmonic phase angle measurement for power quality instruments. In Proceedings of the 2016 IEEE International Workshop on Applied Measurements for Power Systems (AMPS), Aachen, Germany, 28–30 September 2016; pp. 1–6. [Google Scholar]

- Robinson, D.A.; Gosbell, V.J.; Perera, S. Harmonic Allocation Constant for Implementation of AS/NZS 61000.3.6. In Proceedings of the Australasian Universities Power Engineering Conference (AUPEC), Perth, Australia; 2001; pp. 142–147. [Google Scholar]

- Ackermann, F.; Moghadam, H.; Rogalla, S.; Santjer, F.; Athamna, I.; Klosse, R.; Malekian, K.; Adloff, S.; Meyer, M.F.; Kaatz, G.; et al. Large Scale Investigation of Harmonic Summation in Wind- and PV-Power Plants. In Proceedings of the 16th Wind Integration Workshop, Berlin, Germany, 25–27 October 2017. [Google Scholar]

- Peiris, K.; Elphick, S.; David, J.; Robinson, D. Impact of multiple grid connected solar PV inverters on harmonics in high frequency range. In Proceedings of the Australasian Universities Power Engineering Conference, Ballarat, Australia, 25–27 September 2023. [Google Scholar]

- Yang, K.; Bollen, M.H.J.; Larsson, E.O.A.; Wahlberg, M. Measurements of harmonic emission versus active power from wind turbines. Electr. Power Syst. Res. 2014, 108, 304–314. [Google Scholar] [CrossRef]

- Ronnberg, S.; Bollen, M. Measurements of primary and secondary emission in the supraharmonic frequency range, 2–150 kHz. In Proceedings of the International Conference and Exhibition on Electricity Distribution, Lyon, France, 15–18 June 2015. [Google Scholar]

- IEC_61000-4-30/A1-2021; Testing and Measurement Techniques—Power Quality Measurement Methods. IEC: Geneva, Switzerland, 2015; p. 292.

- IEEE-519; IEEE Recommended Practice and Requirements for Harmonic Control in Electric Power Systems. IEEE: New York, NY, USA, 2014.

- IEC-61000-4-7, IEC 61000-4-7:2002/A1; 2008 Electromagnetic Compatibility (EMC)—Part 4–7: Testing and Measurement Techniques—General Guide on Harmonics and Interharmonics Measurements and Instrumentation, for Power Supply Systems and Equipment Connected Thereto. IEC: Geneva, Switzerland, 2009.

- Wikipedia Fast Fourier Transform—Wikipedia. Available online: https://en.wikipedia.org/wiki/Fast_Fourier_transform (accessed on 2 September 2023).

- Fluke 1773/1775/1777 3 Phase Power Quality Analyzer Product Specifications. Available online: https://www.fluke.com/en-au/product/electrical-testing/power-quality/1773-1775-1777# (accessed on 19 December 2023).

- Elspec Elspec G4500 3-Phase Power Quality Analyzer. Available online: https://www.elspec-ltd.com/metering-protection/power-quality-analyzers/g4500-power-qaulity-analyzer-portable/ (accessed on 10 October 2023).

- Hioki Hioki Power Quality Analyzer PQ3198. Available online: https://www.hioki.com/sg-en/products/pqa/power-quality/id_6735?gclid=EAIaIQobChMIz_OM6cnrgQMVwiNgCh2wrwe1EAAYASAAEgJtAfD_BwE (accessed on 10 October 2023).

- Lei, T.; Cristaldi, L.; Faifer, M.; Ottoboni, R.; Toscani, S.; Cherbaucich, C.; Mazza, P. Behavior of voltage transformers under distorted conditions. In Proceedings of the 2016 IEEE International Instrumentation and Measurement Technology Conference Proceedings, Taipei, Taiwan, 23–26 May 2016; pp. 1–6. [Google Scholar]

- Crotti, G.; Gallo, D.; Giordano, D.; Landi, C.; Luiso, M.; Modarres, M. Frequency Response of MV Voltage Transformer Under Actual Waveforms. IEEE Trans. Instrum. Meas. 2017, 66, 1146–1154. [Google Scholar] [CrossRef]

- IEC. CISPR 16-1-2:2014+AMD1:2017. Specification for Radio Disturbance and Immunity Measuring Apparatus and Methods—Part 1–2; Internation Electrotechnical Commission: Geneva, Switzerland, 2017; p. 391. [Google Scholar]

- Meyer, J.; Stiegler, R.; Elst, M.; Sperling, E.; Klatt, M. Accuracy of harmonic voltage measurements in the frequency range up to 5 kHz using conventional instrument transformers. In Proceedings of the 21st International Conference on Electricity Distribution, Frankfurt, Germany, 6–9 June 2011. [Google Scholar]

- Douglass, D.A. Potential Transformer Accuracy at 60HZ Voltages Above and Below Rating and at Frequencies Above 60 HZ. IEEE Trans. Power Appar. Syst. 1981, PAS-100, 1370–1375. [Google Scholar] [CrossRef]

- Faifer, M.; Laurano, C.; Ottoboni, R.; Toscani, S.; Zanoni, M. Harmonic Distortion Compensation in Voltage Transformers for Improved Power Quality Measurements. IEEE Trans. Instrum. Meas. 2019, 68, 3823–3830. [Google Scholar] [CrossRef]

- RITZ. GSES24D with Optional Extended Frequency Range; RITZ: Hamburg, Germany, 2016. [Google Scholar]

- Seyedi, H.; Daryani, N. Evidence Theory-Based Identification of Aging for Capacitive Voltage Transformers. IET Gener. Transm. Distrib. 2016, 10, 3646–3653. [Google Scholar]

- Lin, D.; Bin, C.; Weigen, C. Research on the measurement error of capacitor voltage transformer under various insulation characteristics. In Proceedings of the 2016 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016; pp. 1–4. [Google Scholar]

- Jamatlou, M. Accuracy and Behaviour of Capacitive Voltage Transformers. Master’s Dissertation, University of Bologna, Bologna, Italy, 2020. [Google Scholar]

- Le, J.; Zhang, H.; Gao, C.; Zhou, Q. Harmonic voltage measurement error of the capacitor voltage transformer. PLoS ONE 2018, 13, e0205231. [Google Scholar] [CrossRef]

- Zhao, S.P. Design and Implementation of a Frequency Response Test System for Instrument Voltage Transformer Performance Studies. Ph.D. Thesis, University of Manchester, Manchester, UK, 2013. [Google Scholar]

- Seljeseth, H.; Saethre, E.A.; Ohnstad, T.; Lien, I. Voltage transformer frequency response. Measuring harmonics in Norwegian 300 kV and 132 kV power systems. In Proceedings of the 8th International Conference on Harmonics and Quality of Power. Proceedings (Cat. No.98EX227), Athens, Greece, 14–16 October 1998; Volume 2, pp. 820–824. [Google Scholar]

- Vermeulen, H.J.; Strauss, J.M. In Estimation of Capacitive Voltage Transformer Parameters from Secondary Terminal Measurements. In Proceedings of the 21st International Symposium on High Voltage Engineering, Budapest, Hungary, 26–30 August 2020; Németh, B., Ed.; Springer International Publishing: Cham, Switzerland, 2020; pp. 916–928. [Google Scholar]

- Vermeulen, H.J.; Dann, L.R.; Rooijen, J.V. Equivalent circuit modelling of a capacitive voltage transformer for power system harmonic frequencies. IEEE Trans. Power Deliv. 1995, 10, 1743–1749. [Google Scholar] [CrossRef]

- Kojovic, L.; Kezunovic, M.; Fromen, C.W. A new method for the CCVT performance analysis using field measurements, signal processing and EMTP modeling. IEEE Trans. Power Deliv. 1994, 9, 1907–1915. [Google Scholar] [CrossRef]

- Trench. CVT Harmonic Monitoring; Trench Limited: Scarborough, ON, Canada, 2012. [Google Scholar]

- Tanaskovic, M.; Nabi, A.; Misur, S.; Diamanti, P.; McTaggart, R. Coupling Capacitor Voltage Transformers as Harmonics Distortion Monitoring Devices in Transmission Systems. In Proceedings of the International Conference on Power Systems Transients, Montreal, QC, Canada, 19–23 June 2005. [Google Scholar]

- Li, G.; Chen, L.; Zhang, J.; Wang, D. Research on Harmonic Transfer Characteristics of Capacitive Voltage Transformer and Design of Testing Device. J. Phys. Conf. Ser. 2023, 2465, 012009. [Google Scholar] [CrossRef]

- Zhao, S.; Li, H.Y.; Ghassemi, F.; Crossley, P. Impact of Power Quality Sensor technique on power system protection voltage transient measurements. In Proceedings of the 10th IET International Conference on Developments in Power System Protection (DPSP 2010), Managing the Change, Manchester, UK, 29 March–1 April 2010; pp. 1–4. [Google Scholar]

- BVM Limited. PQSensor™ Broadband Voltage Transducer; BVM: Gilford, UK, 2010. [Google Scholar]

- BVM Limited. PQSensor™ MkVIa Installation & Commissioning Manual; BVM Systems: Gilford, UK, 2014; p. 14. [Google Scholar]

- Shen, X.; Shu, H.-C.; Cao, M. Research on Capacitance Voltage Transformer Harmonic Measurement. Sens. Mater. 2019, 31, 14. [Google Scholar] [CrossRef]

- Schon, K. High Voltage Measurement Techniques: Fundamentals, Measuring Instruments, and Measuring Methods; Springer International Publishing: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Naiqiu, S. Application of Capacitive Voltage Divider in Measuring Harmonics of High Voltage System. Water Resour. Power 2012, 4, 164–167. [Google Scholar]

- Tenbohlen, S.; Kattmann, C.; Brügger, T.; Siegel, M.; Konermann, M.; Junge, E.; Christian, J. Power Quality Monitoring in Power Grids focusing on Accuracy of High Frequency Harmonics; CIGRE: Paris, France, 2018. [Google Scholar]

- Blajszczak, G. Resistive voltage divider for higher harmonics measurement in 400 kV network. In Proceedings of the 11th International Conference on Electrical Power Quality and Utilisation, Lisbon, Portugal, 17–19 October 2011; pp. 1–4. [Google Scholar]

- Pawelek, R.; Wasiak, I. Comparative measurements of voltage harmonics in transmission grid of 400 kV. In Proceedings of the 2014 16th International Conference on Harmonics and Quality of Power (ICHQP), Bucharest, Romania, 25–28 May 2014; pp. 606–610. [Google Scholar]

- RITZ. Sensors: Current & Voltage Measurement for the Grid of the Future; RITZ: Hamburg, Germany, 2021. [Google Scholar]

- 61869-6:2016; Instrument Transformers—Part 6: Additional General Requirements for Low-Power Instrument Transformers. IEC: Geneva, Switzerland, 2016.

- Campos, A.C.S.P.; Cardoso, K.R.; Cruz, V.P.; Fortes, M.Z. Frequency Response of Capacitive Voltage Dividers for Evaluation of Harmonic Components. In Proceedings of the 2019 IEEE PES Innovative Smart Grid Technologies Conference—Latin America (ISGT Latin America), Gramado, Brazil, 15–18 September 2019; pp. 1–6. [Google Scholar]

- Hillhouse, D.L.; Peterson, A.E. A 300-kV Compressed Gas Standard Capacitor with Negligible Voltage Dependence. IEEE Trans. Instrum. Meas. 1973, 22, 408–416. [Google Scholar] [CrossRef]

- Shuai, G.; Shuo, Z.; Zhanhe, X.; Lin, Z.; Xiaokun, Y. The Development of active capacitive voltage divider based on current transformer with compensation circuit. J. Phys. Conf. Ser. 2021, 1750, 012060. [Google Scholar] [CrossRef]

- Li, Y.; Pokorny, P.; Lohrasby, A.; Ediriweera, M. Frequency response characterisation of a high-voltage capacitive voltage divider used at mains frequency. In Proceedings of the Metrology Society of Australia Conference, Geelong, Australia, 19–21 October 2011. [Google Scholar]

- Yu, B.-X.; Li, R.; Su, J.-C.; Zhao, L.; Zhang, Y.; Zheng, L.; Zeng, B.; Cheng, J.; Gao, P.-C.; Qiu, X.; et al. Analysis on match problem of capacitive voltage divider with long measurement cable. Meas. Sci. Technol. 2017, 28, 095009. [Google Scholar] [CrossRef]

- Zamora, J.A.; Aguilera, E.; Soto, E. Characterization of a capacitive voltage divider. Electr. Power Syst. Res. 2023, 223, 109635. [Google Scholar] [CrossRef]

- Mohns, E.; Chunyang, J.; Badura, H.; Raether, P. An Active Low-Voltage Capacitor for Capacitive HV Dividers. In Proceedings of the Conference on Precision Electromagnetic Measurements, Paris, France, 8–13 July 2018. [Google Scholar]

- Hällström, J.; Havunen, J.; Lehtonen, T.; Suomalainen, E.-P. Active Voltage Divider with Small Phase Error; VTT Technical Research Centre of Finland Ltd.: Espoo, Finland, 2021. [Google Scholar]

- Mohns, E.; Roeissle, G.; Fricke, S.; Pauling, F. A Sampling-Based Ratio Bridge for Calibrating Voltage Transformers. In Proceedings of the 2018 Conference on Precision Electromagnetic Measurements (CPEM 2018), Paris, France, 8–13 July 2018; pp. 1–2. [Google Scholar]

- Jiang, C.; Zhou, F.; Yang, S.; Yuan, J. Development of Broadband Capacitive Voltage Divider. High Volt. Appar. 2017, 53, 151–156. [Google Scholar]

- Jiang, C.; Liu, H.; Zhou, F.; Yin, X.; Yuan, J.; Li, M. The development of an active capacitive voltage divider. Electr. Meas. Instrum. 2019, 56, 148–152. [Google Scholar]

- Hrbac, R.; Kolar, V.; Bartłomiejczyk, M.; Mlcak, T.; Orsag, P.; Vanc, J. A Development of a Capacitive Voltage Divider for High Voltage Measurement as Part of a Combined Current and Voltage Sensor. Elektron. Elektrotech. 2020, 26, 25–31. [Google Scholar] [CrossRef]

- Svelto, C.; Ottoboni, M.; Ferrero, A.M. Optically-supplied voltage transducer for distorted signals in high-voltage systems. IEEE Trans. Instrum. Meas. 2000, 49, 550–554. [Google Scholar] [CrossRef]

- Sperling, E.; Schegner, P. A possibility to measure power quality with RC-divider. In Proceedings of the 22nd International Conference and Exhibition on Electricity Distribution (CIRED 2013), Stockholm, Sweden, 10–13 June 2013; pp. 1–4. [Google Scholar]

- Zong, W.; Li, Y.; Cheng, Y.; Zhang, C.; Xue, Y.; Li, G. The design of a wide-band high-voltage divider. In Proceedings of the 2010 International Conference on Power System Technology, Hangzhou, China, 24–28 October 2010; pp. 1–5. [Google Scholar]

- Pfiffner_Group Resistive Capacitive Voltage Divider ROF. Available online: https://www.pfiffner-group.com/products-solutions/details/resistive-capacitive-voltage-divider-rof (accessed on 2 September 2023).

- Trench. Compensated Voltage Divider for HVDC Transmission Systems; Trench Group: Saint-Louis, France, 2012. [Google Scholar]

- Türkmen, C.A. Calibration of Conventional Measurement Transformers against Harmonic Components by Using Field Measurements of Optical Transducers and Resistive-Capacitive Voltage Transformers. Master’s Thesis, Middle East Technical University, Ankara, Turkey, 2010. [Google Scholar]

- Bi, L.; Li, H. An Overview of Optical Voltage Sensor. In Proceedings of the 2012 International Conference on Computer Science and Electronics Engineering, Hangzhou, China, 23–25 March 2012; pp. 197–201. [Google Scholar]

- Brändle, K.B.P.G.H. Fiber-Optic Current and Voltage Sensors for High-Voltage Substations. In Proceedings of the 16th International Conference on Optical Fiber Sensors, Nara, Japan, 14–17 October 2003. [Google Scholar]

- Li, C. Optical Voltage Sensors: Principle, Problem and Research Proposal; SPIE: Bellingham, WA, USA, 2016; Volume 10158. [Google Scholar]

- Long, F.; Zhang, J.; Xie, C.; Yuan, Z. Application of the Pockels Effect to High Voltage Measurement. In Proceedings of the 2007 8th International Conference on Electronic Measurement and Instruments, Xi’an, China, 16–18 August 2007; pp. 495–499. [Google Scholar]

- Wikipedia Birefringence—Wikipedia. Available online: https://en.wikipedia.org/wiki/Birefringence (accessed on 5 November 2023).

- Rahmatian, F.; Chavez, P.P.; Jaeger, N.A.F. 138 kV and 345 kV wide-band SF6-free optical voltage transducers. In Proceedings of the Power Engineering Society Winter Meeting, New York, NY, USA, 27–31 January 2002; Volume 2, pp. 1472–1477. [Google Scholar]

- Rahmatian, F.; Romalo, D.; Lee, S.; Fekete, A.; Liu, S.; Jaeger, N.; Chavez, P. Optical Voltage Transducers for High-Voltage Applications. In Proceedings of the 2nd EPRI Optical Sensor Systems Workshop, Atlanta, GA, USA, 26–28 January 2000. [Google Scholar]

- Chavez, P.; Jaeger, N.; Rahmatian, F.; Yakymyshyn, C. Integrated-Optic Voltage Transducer for High-Voltage Applications; SPIE: Bellingham, WA, USA, 2000; Volume 4087. [Google Scholar]

- IEC-60044-2; Instrument Transformers—Part 2: Inductive Voltage Transformers. IEC: Geneva, Switzerland, 2003.

- Zhang, Q.; Plum, E.; Ou, J.-Y.; Pi, H.; Li, J.; MacDonald, K.F.; Zheludev, N.I. Electrogyration in Metamaterials: Chirality and Polarization Rotatory Power that Depend on Applied Electric Field. Adv. Opt. Mater. 2021, 9, 2001826. [Google Scholar] [CrossRef]

- Vlokh, O.G.; Vlokh, R.O. The Electrogyration Effect. Opt. Photonics News 2009, 20, 34–39. [Google Scholar] [CrossRef]

- Novikov, M.A.; Stepanov, A.A.; Khyshov, A.A. An electric sensor based on the electrogyration effect in a lead tungstate crystal. Tech. Phys. Lett. 2017, 43, 372–375. [Google Scholar] [CrossRef]

- MarsEnergo. Optical Voltage and Current Current Instrument Transducers for Digital Substation Digital Substation Applications; MarsEnergo: St. Petersburg, Russia, 2023. [Google Scholar]

- Gonçalves, M.N.; Werneck, M.M. Optical Voltage Transformer Based on FBG-PZT for Power Quality Measurement. Sensors 2021, 21, 2699. [Google Scholar] [CrossRef]

- Fusiek, G.; Niewczas, P. Construction and Evaluation of an Optical Medium Voltage Transducer Module Aimed at a 132 kV Optical Voltage Sensor for WAMPAC Systems. Sensors 2022, 22, 5307. [Google Scholar] [CrossRef]

- Middleton, E.E.R. New Dry Type Insulated Non-Conventional Instrument Transformers for Your IEC 61850 Digital Substation. In Proceedings of the 2023 CIGRE Canada Conference, Vancouver, BC, Canada, 25–28 September 2023; CIGRE: Vancouver, BC, Canada, 2023. [Google Scholar]

- Rangelov, Y.; Nikolaev, N.; Ivanova, M. The IEC 61850 standard—Communication networks and automation systems from an electrical engineering point of view. In Proceedings of the 2016 19th International Symposium on Electrical Apparatus and Technologies (SIELA), Bourgas, Bulgaria, 29 May–1 June 2016; pp. 1–4. [Google Scholar]

- RITZ. KGBEA36/KGBEI36 as Wideband Transformers; RITZ: Hamburg, Germany, 2017. [Google Scholar]

- Stiegler, R.; Meyer, J. Impact of external influences on the frequency dependent transfer ratio of resin cast MV voltage instrument transformers. In Proceedings of the 2022 20th International Conference on Harmonics & Quality of Power (ICHQP), Naples, Italy, 29 May–1 June 2022; pp. 1–6. [Google Scholar]

- Letizia, P.S.; Crotti, G.; Mingotti, A.; Tinarelli, R.; Chen, Y.; Mohns, E.; Agazar, M.; Istrate, D.; Ayhan, B.; Çayci, H.; et al. Characterization of Instrument Transformers under Realistic Conditions: Impact of Single and Combined Influence Quantities on Their Wideband Behavior. Sensors 2023, 23, 7833. [Google Scholar] [CrossRef]

- Agazar, M.; Istrate, D.; Pradayrol, P. Evaluation of the Accuracy and Frequency Response of Medium-Voltage Instrument Transformers under the Combined Influence Factors of Temperature and Vibration. Energies 2023, 16, 5012. [Google Scholar] [CrossRef]

- IEC-61869-3:2011; Instrument Transformers—Part 3: Additional Requirements for Inductive Voltage Transformers. IEC: Geneva, Switzerland, 2011.

- Cataliotti, A.; Cosentino, V.; Crotti, G.; Giordano, D.; Modarres, M.; Cara, D.D.; Tinè, G.; Gallo, D.; Landi, C.; Luiso, M. Metrological performances of voltage and current instrument transformers in harmonics measurements. In Proceedings of the 2018 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Houston, TX, USA, 14–17 May 2018; pp. 1–6. [Google Scholar]

- Cataliotti, A.; Cosentino, V.; Crotti, G.; Femine, A.D.; Cara, D.D.; Gallo, D.; Giordano, D.; Landi, C.; Luiso, M.; Modarres, M.; et al. Compensation of Nonlinearity of Voltage and Current Instrument Transformers. IEEE Trans. Instrum. Meas. 2019, 68, 1322–1332. [Google Scholar] [CrossRef]

- Imanka, J.; Wei, Y.; Frederick, E.; Yi, L.; Dimitrios, G.; Ilya, B.; Duane, R. Calibration System for High Voltage Transformers with Multi-tone Signals at Frequencies up to 10 kHz. In Proceedings of the Conference on Precision Electromagnetic Measurements. Conference Digest, CPEM 2022, Wellington, New Zealand, 12–16 December 2022. [Google Scholar]

- Kaczmarek, M.; Stano, E. Measuring system for testing the transformation accuracy of harmonics of distorted voltage by medium voltage instrument transformers. Measurement 2021, 181, 109628. [Google Scholar] [CrossRef]

- Faifer, M.; Laurano, C.; Ottoboni, R.; Toscani, S.; Zanoni, M.; Crotti, G.; Giordano, D.; Barbieri, L.; Gondola, M.; Mazza, P. Overcoming Frequency Response Measurements of Voltage Transformers: An Approach Based on Quasi-Sinusoidal Volterra Models. IEEE Trans. Instrum. Meas. 2019, 68, 2800–2807. [Google Scholar] [CrossRef]

- Toscani, S.; Faifer, M.; Ferrero, A.; Laurano, C.; Ottoboni, R.; Zanoni, M. Compensating Nonlinearities in Voltage Transformers for Enhanced Harmonic Measurements: The Simplified Volterra Approach. IEEE Trans. Power Deliv. 2021, 36, 362–370. [Google Scholar] [CrossRef]

- Zhao, S.; Li, H.; Crossley, P.; Ghassemi, F. Test and analysis of harmonic responses of high voltage instrument voltage transformers. In Proceedings of the 12th IET International Conference on Developments in Power System Protection, Copenhagen, Denmark, 31 March–3 April 2014; pp. 1–6. [Google Scholar]

- MarsEnergo. MarsTest-VT-PQ Frequency Response Measurement System; MarsEnergo: St. Petersburg, Russia, 2023. [Google Scholar]

- IEC. Instrument Transformers—Part 1: General Requirements; IEC: Geneva, Switzerland, 2007; Volume 61869-1, p. 130. [Google Scholar]

- IEC. Instrument Transformers—Part 1: General Requirements; IEC: Geneva, Switzerland, 2023; Volume 61869-1. [Google Scholar]

- IEC. Instrument Transformers—Part 5: Additional Requirements for Capacitor Voltage Transformers; IEC: Geneva, Switzerland, 2011; Volume 61869-5, p. 106. [Google Scholar]

- IEC. Instrument Transformers—Part 11: Additional Requirements for Low Power Passive Voltage Transformers; IEC: Geneva, Switzerland, 2017; Volume 61869-11, p. 67. [Google Scholar]

| Voltage Level | Voltage Range |

|---|---|

| Low voltage (LV) | Un ≤ 1000 V |

| Medium voltage (MV) | 1000 V < Un ≤ 35 kV |

| High voltage (HV) | 35 kV < Un ≤ 230 kV |

| Extra high voltage (EHV) | 230 kV < Un |

| Harmonic Emission Type | Frequency Range |

|---|---|

| Low frequency | 100 Hz ≤ f ≤ 2 kHz |

| High frequency | 2 kHz < f ≤ 9 kHz |

| Low-frequency conducted | 9 kHz < f ≤ 150 kHz |

| High-frequency conducted | 150 kHz < f ≤ 30 MHz |

| Radiated | 30 MHz < f |

| Equipment | Harmonic Emission Range |

|---|---|

| Industrial scale converters | 9 kHz to 150 kHz |

| Streetlamps | up to 20 kHz |

| Electric vehicle (EV) chargers | 15 kHz to 100 kHz |

| Photovoltaic (PV) inverters | 4 kHz to 20 kHz |

| Household electronics | 2 kHz to 150 kHz |

| Programmable logic controllers (PLC) in meter reading | 9 kHz to 95 kHz |

| Instrument | Maximum Input Voltage | Harmonic Measurement Bandwidth |

|---|---|---|

| Fluke 1770 3-phase power quality analyzer (Manufactured by Fluke, Everett, WA, USA) | 1 kV | 30 kHz |

| Elspec G4500 3-phase power quality analyzer (Manufactured by Elspec, Caesarea, Israel) | 1 kV | 25.55 kHz |

| Hioki PQ3198 3-phase power quality analyzer (Manufactured by Hioki, Nagano, Japan) | 600 V | 80 kHz |

| Instrument Accuracy Class | Measurement Voltage Range | Maximum Error * |

|---|---|---|

| Class I | Um ≥ 1% Unom | ±5% Um |

| Um < 1% Unom | ±0.05% Unom | |

| Class II | Um ≥ 3% Unom | ±5% Um |

| Um < 3% Unom | ±0.15% Unom |

| Frequency (Hz) | Ratio Error at 0 VA (%) | Ratio Error at 200 VA (%) |

|---|---|---|

| 180 | −0.2 | 2.9 |

| 300 | 3.1 | 2.8 |

| 420 | −1.5 | 3.7 |

| 560 | −3.4 | 3.5 |

| 660 | −2.9 | 4.8 |

| 780 | 7.5 | 4.6 |

| 900 | −0.2 | 6.3 |

| 1020 | −0.7 | 3.0 |

| 1140 | 13.2 | 7.2 |

| 1260 | −3.1 | 4.9 |

| 1500 | 4.6 | 5.2 |

| 1620 | 1.2 | 8.9 |

| 1740 | −3.9 | 9.0 |

| 2000 | 3.2 | 9.0 |

| 3000 | 1.5 | 7.8 |

| Transducer Type | E-Field and M-Field Effects | Proximity Effects | Combined Impact of Proximity and Field Effects |

|---|---|---|---|

| RVD | Medium impact | Medium impact | High impact |

| CVD | Low impact | No impact | No impact due to proximity |

| RVCD | Medium impact | High impact | High impact |

| Transducer Type | Accuracy of Amplitude Measurement | Accuracy of Phase Angle Measurement | Ability to Measure 2 kHz–9 kHz Harmonics | Cost of Implementation | Impact of External Factors | Type of Calibration Required for Error Correction |

|---|---|---|---|---|---|---|

| IVT | Low (possibility of correction by calibration) | Low (possibility of correction by calibration) | Acceptable after calibration | Low | Low impact with possibility of correction by calibration | HV multi-tone signal calibration preferred (LV sinusoidal calibration acceptable with increased error) |

| CVT | Very low | Very low | Unacceptable | Low | Severe impact | Not applicable |

| CVT with harmonic terminals | Acceptable | Acceptable | Acceptable with increased margin of error | Low | Unknown | LV sinusoidal acceptable |

| CVT with PQ sensor | Good | Good | Acceptable | Medium | No significant impact | LV sinusoidal acceptable |

| RVD | Depends on provision of shielding | Depends on shielding | Depends on provision of shielding | Low to medium | Medium impact (avoidable by shielding) | LV sinusoidal acceptable for shielded RVDs |

| CVD | Good | Poor | Acceptable | Medium to high | No significant impact | LV sinusoidal acceptable |

| CVD with active LV arm | Better | Good | Acceptable | Medium to high | No significant impact | LV sinusoidal acceptable |

| RCVD | Excellent | Excellent | Acceptable | High | No impact | LV sinusoidal acceptable |

| OVT | Good | Depends on the type | Acceptable | High | No impact | LV sinusoidal acceptable |

| NCIT | To be decided after calibration | To be decided after calibration | To be decided after calibration | Depends on the type | To be decided after calibration | To be decided after calibration |

| Reference | Test Signal Type | Reference Transducer (If Any) | Tested Harmonic Bandwidth (Max 50 Hz/Max Harmonic Amplitude) |

|---|---|---|---|

| [112,113,115,116] | Composite signal (50 Hz + single harmonic) | RCVD | 30 kV at 50 Hz/2% at 9 kHz |

| [117] | Composite signal (50 Hz + multiple harmonics) | CVD | 92.5 kV at 50 Hz/10% at 10 kHz |

| [118] | Composite signal (50 Hz + single harmonic) | RCVD | 20/ kV at 50 Hz/10% at 5 kHz |

| [119,120] | Composite signal (50 Hz + multiple harmonics) | RCVD | 20/ kV at 50 Hz/3% at 1.25 kHz |

| [56,121] | Composite signal (50 Hz + single harmonic) | RCVD | 230 kV at 50 Hz/1% at 1 kHz or 0.2% at 5 kHz |

| Instrument Transformer Class | Ratio Error Harmonic Frequencies | Phase Error at Harmonic Frequencies | ||

|---|---|---|---|---|

| 100 Hz ≤ f ≤ 2.5 kHz | 2.5 kHz < f < 250 kHz | 100 Hz ≤ f ≤ 2.5 kHz | 2.5 kHz < f < 250 kHz | |

| PQ1 | ±5% | ±10% | N/D | |

| PQ2 | ±10% | ±20% | N/D | |

| PQ3 | N/D | N/D | N/D | N/D |

| PQ4 | N/D | N/D | N/D | N/D |

| Accuracy Class at Rated Frequency | Ratio Error (%) Harmonic Orders | Phase Error (°) Harmonic Orders | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 2–4 | 5–6 | 7–9 | 10–13 | 13 < h | 2–4 | 5–6 | 7–9 | 10–13 | |

| 0.1 | ±1% | ±2% | ±4% | ±8% | +8% > > −100% | ||||

| 0.2 | ±2% | ±4% | ±8% | ±16% | +16% > > −100% | ||||

| 0.5 | ±5% | ±10% | ±20% | ±20% | +20% > > −100% | ||||

| 1.0 | ±10% | ±20% | ±20% | ±20% | +20% > > −100% | ||||

| Accuracy Class at Rated Frequency | Ratio Error (%) Harmonic Frequency Range | Phase Error (°) | ||||

|---|---|---|---|---|---|---|

| (0.1 ≤ f < 1) kHz | (1 ≤ f < 1.5) kHz | (1.5 ≤ f < 3) kHz | (0.1 ≤ f < 1) kHz | (1 ≤ f < 1.5) kHz | (1.5 ≤ f < 3) kHz | |

| 0.1 | ±1% | ±2% | ±5% | |||

| 0.2 | ±2% | ±4% | ±5% | |||

| 0.5 | ±5% | ±10% | ±10% | |||

| 1.0 | ±10% | ±20% | ±20% | |||

| Accuracy Class at Rated Frequency | Ratio Error (%) Harmonic Frequency Range | Phase Error (°) | ||||

|---|---|---|---|---|---|---|

| (0.1 ≤ f < 5) kHz | (5 ≤ f < 10) kHz | (10 ≤ f < 20) kHz | (0.1 ≤ f < 5) kHz | (5 ≤ f < 10) kHz | (10 ≤ f < 20) kHz | |

| 0.1 | ±1% | ±2% | ±5% | |||

| 0.2 | ±2% | ±4% | ±5% | |||

| 0.5 | ±5% | ±10% | ±10% | |||

| 1.0 | ±10% | ±20% | ±20% | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dewayalage, I.; Robinson, D.A.; Elphick, S.; Perera, S. Measurement of High-Frequency Voltage Harmonics above 2 kHz in High-Voltage Networks. Energies 2024, 17, 892. https://doi.org/10.3390/en17040892

Dewayalage I, Robinson DA, Elphick S, Perera S. Measurement of High-Frequency Voltage Harmonics above 2 kHz in High-Voltage Networks. Energies. 2024; 17(4):892. https://doi.org/10.3390/en17040892

Chicago/Turabian StyleDewayalage, Imanka, Duane A. Robinson, Sean Elphick, and Sarath Perera. 2024. "Measurement of High-Frequency Voltage Harmonics above 2 kHz in High-Voltage Networks" Energies 17, no. 4: 892. https://doi.org/10.3390/en17040892

APA StyleDewayalage, I., Robinson, D. A., Elphick, S., & Perera, S. (2024). Measurement of High-Frequency Voltage Harmonics above 2 kHz in High-Voltage Networks. Energies, 17(4), 892. https://doi.org/10.3390/en17040892