A Survey of Photovoltaic Panel Overlay and Fault Detection Methods †

Abstract

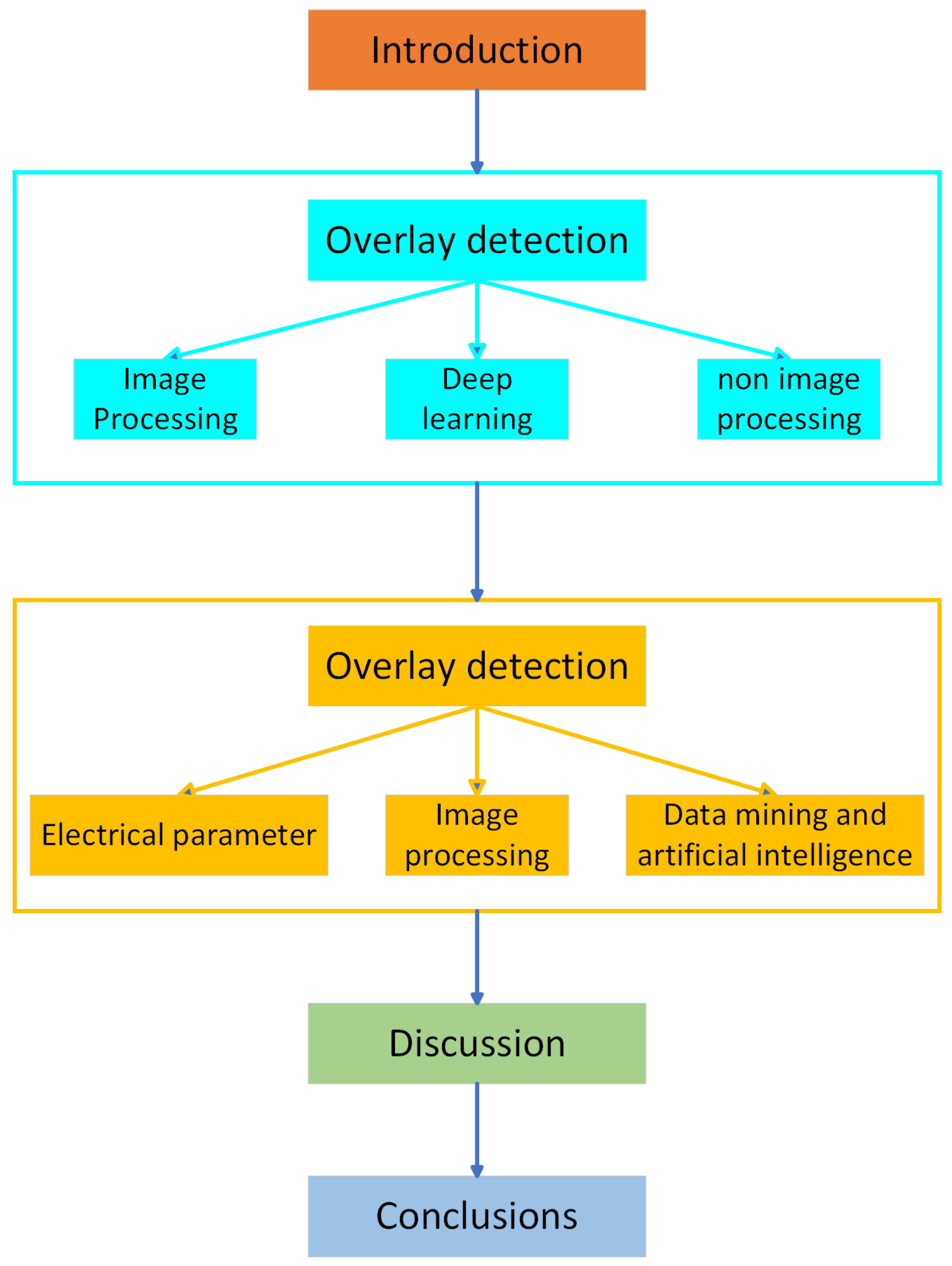

1. Introduction

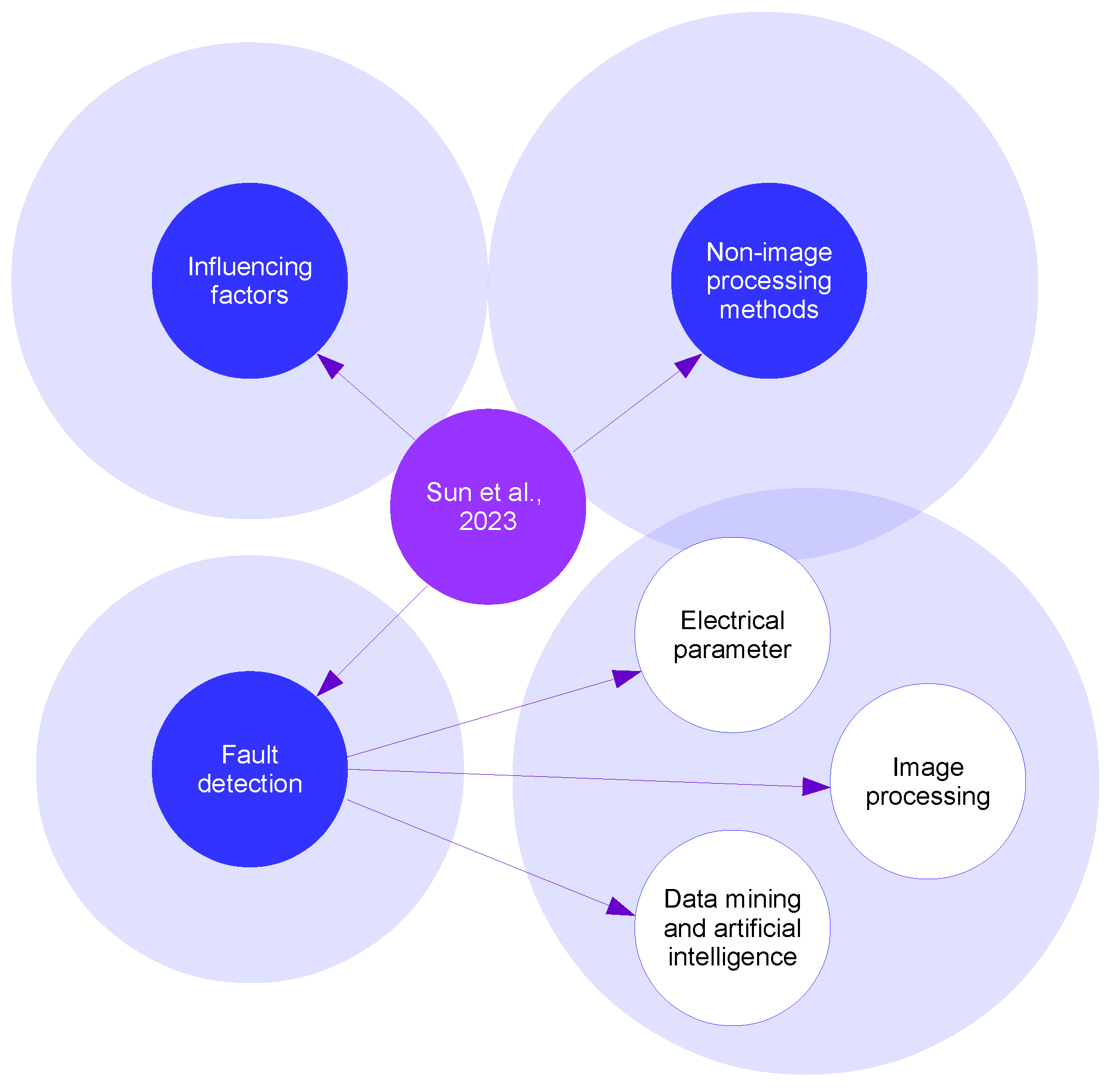

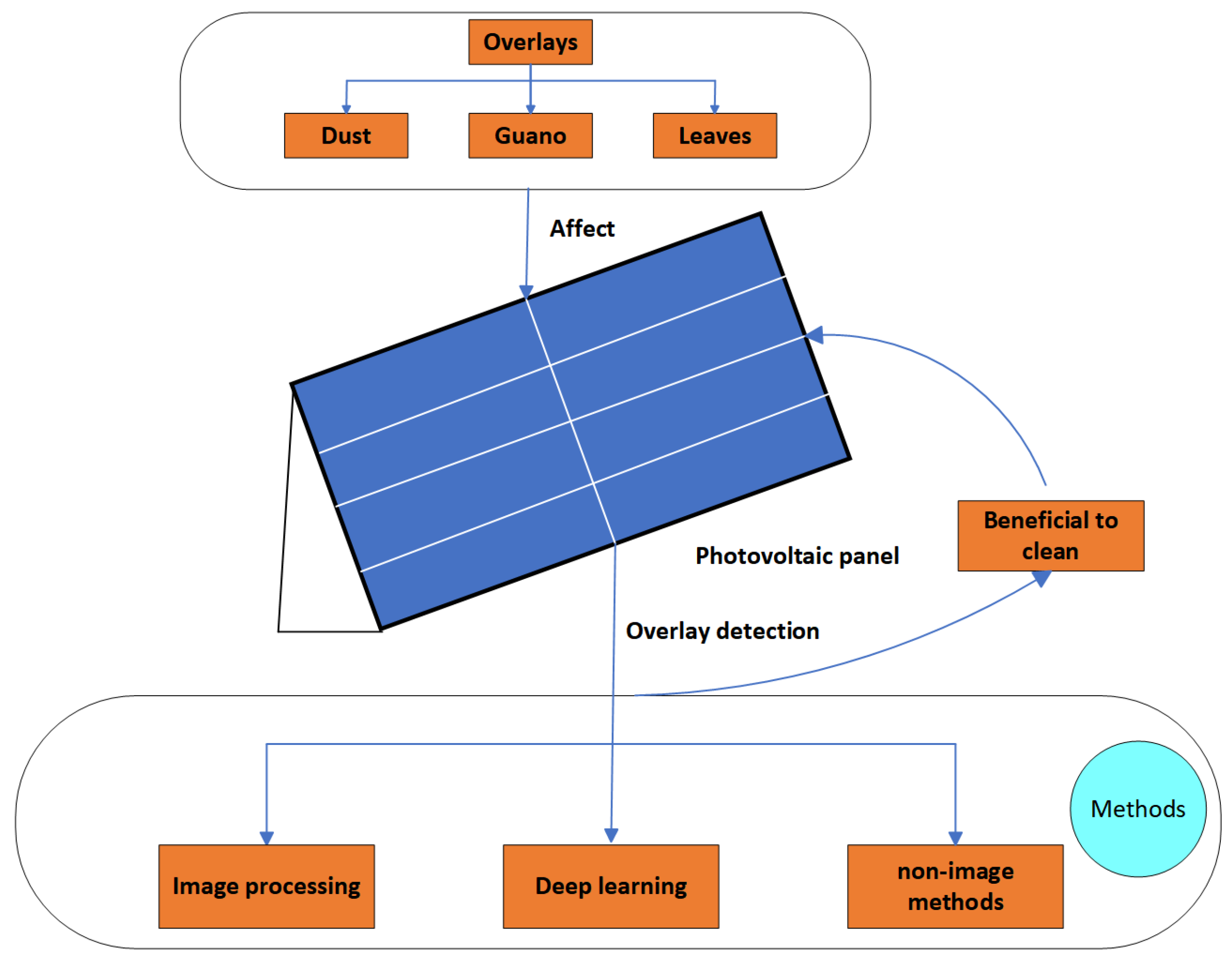

2. PV Panel Overlay Detection

- Weather conditions: Weather conditions have a significant impact on PV panel overlay detection. In clear weather, the surfaces of PV panels can be photographed and inspected relatively clearly. However, in severe weather conditions, such as cloudy, rainy or snowy days, clouds, precipitation or snow accumulation may reduce the sharpness and contrast of the image, affecting the accuracy of overlay detection [36].

- Lighting conditions: Lighting conditions can affect the reflection and scattering of the photovoltaic panel surface, thereby affecting the quality and contrast of the image. If the lighting conditions are uneven or too strong or too weak, it will lead to errors in overlay detection [37].

- Types of overlays: Different types of overlays have different effects on PV panel detection. For example, vegetation overlays such as leaves, branches, shrubs, etc., can produce complex textures and color variations in the image, which may interfere with the identification of PV panels. Other possible types of overlays include buildings, utility poles, signal lights, etc. [38].

- Geographic location: Geographic location will affect the accuracy and effectiveness of PV panel overlay detection, mainly because different geographical locations will have different climate conditions, environmental factors, and PV panel distribution. The light conditions in desert areas are better, but wind and sand pollute and wear away the surface of PV panels more, which may lead to errors in overlay detection. The light conditions in mountainous areas are poor, and the environmental factors in mountainous areas are also relatively complex, such as rain, snow, smog, leaves, etc., which may cause interference and changes on the surface of PV panels, increasing the difficulty and uncertainty of overlay detection. The lighting conditions in the city are relatively uniform, but there may be phenomena such as occlusion or reflection, which affect the clarity of and details in the image [39].

- Camera parameters: Camera parameters include resolution, focal length, viewing angle, exposure time, etc., which will affect the clarity of and details in the image. Inappropriate or unstable camera parameters may result in blurred or distorted overlay detection [40].

- Detection algorithm: A detection algorithm refers to a computational method for identifying and segmenting PV panel overlays, usually based on techniques such as image processing or deep learning. The performance and complexity of the detection algorithm will affect the accuracy and speed of overlay detection. If the detection algorithm is not robust or efficient, it may lead to errors or delays in overlay detection [41].

- Shooting point: The selection and angle of the shooting point will also affect the outcome of overlay detection. Different shooting points may result in different lighting conditions, viewing angles, and image distortions, which may complicate the detection of overlays. Moreover, the distance and height between the shooting point and the PV panel will also affect overlay detection within the image [42]. If the distance between the shooting point and the PV panel is too far or the height angle is too low, it may cause an insufficient image resolution, making it impossible to accurately identify the overlays [43].

2.1. Overlay Detection Technology Based on Image Processing

2.2. Overlay Detection Technology Based on Deep Learning

2.3. Overlay Detection Technology Based Non-Image Methods

2.3.1. Gray Box Model Method

2.3.2. Data-Driven Method

2.3.3. Dust Concentration and Photoelectric Conversion Efficiency (DC-PCE) Model

2.3.4. Condition Monitoring System

2.3.5. Arduino-Based Dust Removal System

3. PV Panel Fault Detection

3.1. Intelligent Method

3.2. Analytical Method

- I-V curve method: This method analyzes the output power, conversion efficiency, series resistance, parallel resistance, and other parameters of the photovoltaic panel by measuring the current–voltage (I-V) curve of the photovoltaic panel, thereby determining whether the photovoltaic panel has hot spots, short circuits, Open circuit, aging, and other faults.

- P-V curve method: This method analyzes the maximum power point, maximum power tracking (MPPT) effect, array mismatch, and other parameters of the photovoltaic panel by measuring the power–voltage (P-V) curve of the photovoltaic panel to determine whether the photovoltaic panel exists. Shadows, contamination, hidden cracks, and other faults.

- Temperature method: This method analyzes the thermal characteristics, heat loss, thermal stress, and other parameters of the photovoltaic panel by measuring the surface temperature of the photovoltaic panel to determine whether the photovoltaic panel has hot spots, damage, aging, and other faults.

- SolarEdge’s P-Series optimizers can achieve maximum power point tracking (MPPT) at the component level, and transmit the performance data of each component to the monitoring platform through wireless communication for fault diagnosis and maintenance [124].

- Tigo Energy’s TS4-A-O optimizer can be connected to a cloud server through a wireless bridge to realize component-level intelligent monitoring and fast shutdown functions to improve power generation efficiency and safety.

- SolarPoint’s SP-1 photovoltaic power optimizer can realize MPPT optimization, intelligent monitoring, and fast shutdown functions, and upload the power generation data (such as power, voltage, current, temperature) from each component to the server through the wireless sensor network, so that it can perform data analysis and exception handling.

3.3. Hybrid Method

- Method based on image processing and neural networks: This method collects visible light and infrared images of photovoltaic panels by using equipment such as drones and cameras, and then uses image processing technologies such as filtering, segmentation, feature extraction, etc., to pre-process the images, thereby, removing noise and background and highlighting the features of the photovoltaic panels. Then they use neural network technology, such as convolutional neural network, recurrent neural network, deep neural network, etc., to classify and identify the image to determine whether there is a fault in the photovoltaic panel, as well as the type and location of the fault.

- Method based on parameter measurement and fuzzy logic: This method determines whether there is a fault in the photovoltaic panel by measuring and analyzing the voltage, current, temperature, and other parameters of the photovoltaic panel, as well as the type and location of the fault. Then fuzzy logic techniques, such as fuzzy sets, fuzzy relationships, fuzzy reasoning, etc., are used to fuzzify and comprehensively evaluate the parameters to determine the status and extent of the fault in the photovoltaic panel.

- Image- and parameter-based fusion method: This method improves the efficiency and accuracy of photovoltaic panel fault detection by combining image processing and neural network methods, as well as parameter measurement and fuzzy logic methods. This method can utilize the complementarity of images and parameters, as well as the synergy of artificial intelligence technology and mathematical models, to achieve optimization and improvement of photovoltaic panel fault detection.

3.4. Metaheuristic Method

- Genetic algorithm: This method optimizes photovoltaic panel fault detection by simulating the process of biological evolution, such as selection, crossover, mutation, etc. Genetic algorithms can use diverse populations to avoid falling into local optimality and can handle multi-objective problems.

- Particle swarm algorithm: This method optimizes photovoltaic panel fault detection by simulating the behavior of a flock of birds or a school of fish, such as following, chasing, exploring, etc. The particle swarm algorithm can use individual and group information to balance global search and local search, and can handle nonlinear problems.

- Ant colony algorithm: This method optimizes photovoltaic panel fault detection by simulating the behavior of ants, such as information exchange, path selection, information update, etc. The ant colony algorithm can use the positive feedback mechanism to enhance the probability of excellent solutions and can handle discrete problems.

4. Discussion

4.1. Opportunities and Challenges of Overlay Detection

4.2. Opportunities and Challenges of Fault Detection

4.3. Connection between PV Panel Coverlay Detection Fault Detection

4.3.1. Commonly Used in Solar Power Generation System

4.3.2. Based on Image Processing and Machine Learning Technology

4.3.3. Data Acquisition and Monitoring System

4.3.4. Part of Maintenance and Administration

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PV | Photovoltaic |

| UAVs | unmanned aerial vehicles |

| SVM | support vector machine |

| KNN | K-Nearest Neighbor |

| SSD | Solid State Drive |

| CNN | convolutional neural networks |

| LSTM | long short-term memory |

| GLCM | gray level co-occurrence matrix |

| GEE | Google Earth Engine |

| NDSI | normalized difference sand index |

| RNDSI | ratio normalized difference soil index |

| DBSI | Dry Bare Soil Index |

| LST | land surface temperature |

| GAN | generative adversarial network |

| SGD | stochastic gradient descent |

| SOAT | state-of-the-art |

| R-CNN | region-convolutional neural networks |

| DRNN | deep residual neural network |

| EL | electroluminescence |

| RMVDM | real-time multivariate deep learning model |

| RHA | region-based histogram approximation |

| GSQA | gray scale quantization algorithm |

| DCS | deficiency class support |

| DBN | deep belief networks |

| SCADA | supervisory control and data acquisition |

| DC-PCE | dust concentration and photoelectric conversion efficiency |

| I-V | current-voltage |

| MPPT | maximum power point tracking |

| PSC | partial shading conditions |

| P-V | power-voltage |

| ODS | observed degradation system |

| RCNN | region-based convolutional neural network |

| DNN | deep neural network |

| PVMs | photovoltaic modules |

| DWT | discrete wavelet transform |

| FFT | fast Fourier transform |

| GLDM | gray level difference method |

| CBAM | Convolutional Block Attention Module |

| AUC | area under the curve |

| MRFF | multi-scale receptive field fusion |

References

- Yadav, A.; Pillai, S.R.; Singh, N.; Philip, S.A.; Mohanan, V. Preliminary investigation of dust deposition on solar cells. Mater. Today: Proc. 2021, 46, 6812–6815. [Google Scholar] [CrossRef]

- Zhao, J.; Dong, K.; Dong, X.; Shahbaz, M. How renewable energy alleviate energy poverty? A global analysis. Renew. Energy 2022, 186, 299–311. [Google Scholar] [CrossRef]

- Gielen, D.; Gorini, R.; Leme, R.; Prakash, G.; Wagner, N.; Janeiro, L.; Collins, S.; Kadir, M.; Asmelash, E.; Ferroukhi, R.; et al. World Energy Transitions Outlook: 1.5° C Pathway; International Renewable Energy Agency (IRENA): Masdar City, United Arab Emirates, 2021. [Google Scholar]

- Chiteka, K.; Arora, R.; Sridhara, S.; Enweremadu, C. Influence of irradiance incidence angle and installation configuration on the deposition of dust and dust-shading of a photovoltaic array. Energy 2021, 216, 119289. [Google Scholar] [CrossRef]

- Yoro, K.O.; Daramola, M.O. CO2 emission sources, greenhouse gases, and the GW effect. In ACC; Elsevier: Amsterdam, The Netherlands, 2020; pp. 3–28. [Google Scholar]

- Ostergaard, P.A.; Duic, N.; Noorollahi, Y.; Mikulcic, H.; Kalogirou, S. Sustainable development using renewable energy technology. Renew. Energy 2020, 146, 2430–2437. [Google Scholar] [CrossRef]

- Aldalbahi, A.; El-Naggar, M.E.; El-Newehy, M.H.; Rahaman, M.; Hatshan, M.R.; Khattab, T.A. Effects of technical textiles and synthetic nanofibers on environmental pollution. Polymers 2021, 13, 155. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, H.A.; Baha’a, A.; Al-Mejibli, I.S. Smart system for dust detecting and removing from solar cells. J. Physics: Conf. Ser. 2018, 1032, 012055. [Google Scholar] [CrossRef]

- Raina, G.; Sinha, S. Outlook on the Indian scenario of solar energy strategies: Policies and challenges. Energy Strategy Rev. 2019, 24, 331–341. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, Z.; Zhu, C.; Yang, R.; Yan, B.; Jiang, G. Green or not? Environmental challenges from photovoltaic technology. Environ. Pollut. 2023, 320, 121066. [Google Scholar] [CrossRef] [PubMed]

- Priyadharsini, K.; JR, D.K.; Srikanth, A.; Sounddar, V.; Senthamilselvan, M. Elegant method to improve the efficiency of remotely located solar panels using IoT. Mater. Today: Proc. 2021, 45, 8094–8104. [Google Scholar]

- Derakhshandeh, J.F.; AlLuqman, R.; Mohammad, S.; AlHussain, H.; AlHendi, G.; AlEid, D.; Ahmad, Z. A comprehensive review of automatic cleaning systems of solar panels. Sustain. Energy Technol. Assessments 2021, 47, 101518. [Google Scholar] [CrossRef]

- Thomas, S.K.; Joseph, S.; Sarrop, T.; Haris, S.B.; Roopak, R. Solar Panel Automated Cleaning (SPAC) System. In Proceedings of the 2018 International Conference on Emerging Trends and Innovations in Engineering and Technological Research (ICETIETR), Arakunnam, India, 11–13 July 2018; pp. 1–3. [Google Scholar]

- Zainuddin, N.F.; Mohammed, M.; Al-Zubaidi, S.; Khogali, S.I. Design and development of smart self-cleaning solar panel system. In Proceedings of the 2019 IEEE International Conference on Automatic Control and Intelligent Systems (I2CACIS), Shah Alam, Malaysia, 29 June 2019; pp. 40–43. [Google Scholar]

- Rahman, A.; Farrok, O.; Haque, M.M. Environmental impact of renewable energy source based electrical power plants: Solar, wind, hydroelectric, biomass, geothermal, tidal, ocean, and osmotic. Renew. Sustain. Energy Rev. 2022, 161, 112279. [Google Scholar] [CrossRef]

- Chanchangi, Y.N.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Dust and PV Performance in Nigeria: A review. Renew. Sustain. Energy Rev. 2020, 121, 109704. [Google Scholar] [CrossRef]

- Salamah, T.; Ramahi, A.; Alamara, K.; Juaidi, A.; Abdallah, R.; Abdelkareem, M.A.; Amer, E.C.; Olabi, A.G. Effect of dust and methods of cleaning on the performance of solar PV module for different climate regions: Comprehensive review. Sci. Total. Environ. 2022, 827, 154050. [Google Scholar] [CrossRef] [PubMed]

- Dantas, G.M.; Mendes, O.L.C.; Maia, S.M.; de Alexandria, A.R. Dust detection in solar panel using image processing techniques: A review. Res. Soc. Dev. 2020, 9, e321985107. [Google Scholar] [CrossRef]

- Akram, M.W.; Li, G.; Jin, Y.; Chen, X. Failures of Photovoltaic modules and their Detection: A Review. Appl. Energy 2022, 313, 118822. [Google Scholar] [CrossRef]

- Hasan, D.S.; Farhan, M.S.; ALRikabi, H.T. Impact of temperature and dust deposition on PV panel performance. In Proceedings of the AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2022; Volume 2394. [Google Scholar]

- Al Dahoud, A.; Fezari, M.; Al Dahoud, A. Automatic solar panel cleaning system Design. In Proceedings of the 2021 29th Telecommunications Forum (TELFOR), Belgrade, Serbia, 23–24 November 2021; pp. 1–4. [Google Scholar]

- Shairi, N.A.S.; Ghoni, R.; Ali, K. Solar panel dust monitoring system. Eng. Herit. J. 2020, 4, 44–45. [Google Scholar] [CrossRef]

- Kumar, S.S.; Murthy, K. Solar Powered PV Panel Cleaning Robot. In Proceedings of the 2020 International Conference on Recent Trends on Electronics, Information, Communication & Technology (RTEICT), Bangalore, India, 12–13 November 2020; pp. 169–172. [Google Scholar]

- Dhaouadi, R.; Al-Othman, A.; Aidan, A.A.; Tawalbeh, M.; Zannerni, R. A characterization study for the properties of dust particles collected on photovoltaic (PV) panels in Sharjah, United Arab Emirates. Renew. Energy 2021, 171, 133–140. [Google Scholar] [CrossRef]

- Brownlee, J. Deep Learning for Computer Vision: Image Classification, Object Detection, and Face Recognition in Python; Machine Learning Mastery: Vermont, Australia, 2019. [Google Scholar]

- Bhuyan, M.K. Computer Vision and Image Processing: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Nixon, M.; Aguado, A. Feature Extraction and Image Processing for Computer Vision; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Hassaballah, M.; Awad, A.I. Deep Learning in Computer Vision: PRINCIPLES and Applications; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Dong, S.; Wang, P.; Abbas, K. A survey on deep learning and its applications. Comput. Sci. Rev. 2021, 40, 100379. [Google Scholar] [CrossRef]

- Janiesch, C.; Zschech, P.; Heinrich, K. Machine learning and deep learning. Electron. Mark. 2021, 31, 685–695. [Google Scholar] [CrossRef]

- Paul, M.M.R.; Kannan, R.; Moses, M.L.; Bhuvanesh, A. Fault identification in a grid connected solar PV system using Back propagation Neural Network. Proc. Iop Conf. Ser. Mater. Sci. Eng. 2021, 1084, 012109. [Google Scholar] [CrossRef]

- Dhanraj, J.A.; Mostafaeipour, A.; Velmurugan, K.; Techato, K.; Chaurasiya, P.K.; Solomon, J.M.; Gopalan, A.; Phoungthong, K. An effective evaluation on fault detection in solar panels. Energies 2021, 14, 7770. [Google Scholar] [CrossRef]

- Belik, M. Detection and prediction of photovoltaic panels malfunctions. Renew. Energy Power Qual. J. 2018, 16, 544–548. [Google Scholar] [CrossRef]

- Kellil, N.; Aissat, A.; Mellit, A. Fault diagnosis of photovoltaic modules using deep neural networks and infrared images under Algerian climatic conditions. Energy 2023, 263, 125902. [Google Scholar] [CrossRef]

- Sun, F.; Yang, C.; Cui, H.; Lv, Z.; Shao, J.; Zhao, B.; He, K. Dust Detection Techniques for Photovoltaic Panels from a Machine Vision Perspective: A Review. In Proceedings of the 2023 8th Asia Conference on Power and Electrical Engineering (ACPEE), Tianjin, China, 14–16 April 2023; pp. 1413–1418. [Google Scholar] [CrossRef]

- Hachicha, A.A.; Al-Sawafta, I.; Said, Z. Impact of dust on the performance of solar photovoltaic (PV) systems under United Arab Emirates weather conditions. Renew. Energy 2019, 141, 287–297. [Google Scholar] [CrossRef]

- Sun, C.; Zou, Y.; Qin, C.; Zhang, B.; Wu, X. Temperature effect of photovoltaic cells: A review. Adv. Compos. Hybrid Mater. 2022, 5, 2675–2699. [Google Scholar] [CrossRef]

- Darwish, Z.A.; Sopian, K.; Fudholi, A. Reduced output of photovoltaic modules due to different types of dust particles. J. Clean. Prod. 2021, 280, 124317. [Google Scholar] [CrossRef]

- Tanesab, J.; Parlevliet, D.; Whale, J.; Urmee, T. The effect of dust with different morphologies on the performance degradation of photovoltaic modules. Sustain. Energy Technol. Assessments 2019, 31, 347–354. [Google Scholar] [CrossRef]

- Ren, J.; Guan, F.; Wang, T.; Qian, B.; Luo, C.; Cai, G.; Kan, C.; Li, X. High precision calibration algorithm for binocular stereo vision camera using deep reinforcement learning. Comput. Intell. Neurosci. 2022, 2022. [Google Scholar] [CrossRef]

- Villegas-Mier, C.G.; Rodriguez-Resendiz, J.; Álvarez-Alvarado, J.M.; Rodriguez-Resendiz, H.; Herrera-Navarro, A.M.; Rodríguez-Abreo, O. Artificial neural networks in MPPT algorithms for optimization of photovoltaic power systems: A review. Micromachines 2021, 12, 1260. [Google Scholar] [CrossRef]

- Vergura, S. Criticalities of the Outdoor Infrared Inspection of Photovoltaic Modules by Means of Drones. Energies 2022, 15, 5086. [Google Scholar] [CrossRef]

- Khalid, H.M.; Rafique, Z.; Muyeen, S.; Raqeeb, A.; Said, Z.; Saidur, R.; Sopian, K. Dust accumulation and aggregation on PV panels: An integrated survey on impacts, mathematical models, cleaning mechanisms, and possible sustainable solution. Sol. Energy 2023, 251, 261–285. [Google Scholar] [CrossRef]

- Sriram, A.; Sudhakar, T. Photovoltaic Cell Panels Soiling Inspection Using Principal Component Thermal Image Processing. Comput. Syst. Sci. Eng. 2023, 45, 2761–2772. [Google Scholar] [CrossRef]

- Yahya, Z.; Imane, S.; Hicham, H.; Ghassane, A.; Safia, E.B.I. Applied imagery pattern recognition for photovoltaic modules’ inspection: A review on methods, challenges and future development. Sustain. Energy Technol. Assessments 2022, 52, 102071. [Google Scholar] [CrossRef]

- de Oliveira, A.K.V.; Aghaei, M.; Rüther, R. Automatic inspection of photovoltaic power plants using aerial infrared thermography: A review. Energies 2022, 15, 2055. [Google Scholar] [CrossRef]

- Høiaas, I.; Grujic, K.; Imenes, A.G.; Burud, I.; Olsen, E.; Belbachir, N. Inspection and condition monitoring of large-scale photovoltaic power plants: A review of imaging technologies. Renew. Sustain. Energy Rev. 2022, 161, 112353. [Google Scholar] [CrossRef]

- Zhao, R. Photovoltaic (PV) Solar Panel Identification and Fault Detection Using Unmanned Aerial Vehicles (UAVs): A Case Study of a 0.5 MW PV System. Ph.D. Thesis, Department of Earth and Planetary Sciences, Yale University, New Haven, CT, USA, 2022. [Google Scholar]

- Monicka, S.G.; Manimegalai, D.; Karthikeyan, M.; Gunasekari, R. Image Processing Based Hot-Spot Detection on Photovoltaic Panels. Int. J. Intell. Syst. Appl. Eng. 2023, 11, 510–518. [Google Scholar]

- Arnaudo, E.; Blanco, G.; Monti, A.; Bianco, G.; Monaco, C.; Pasquali, P.; Dominici, F. A Comparative Evaluation of Deep Learning Techniques for Photovoltaic Panel Detection from Aerial Images. IEEE Access 2023, 11, 47579–47594. [Google Scholar] [CrossRef]

- Pathak, S.P.; Patil, S.A. Analysis and Evaluation of Pre-processing Techniques for Fault Detection in Thermal Images of Solar Panels. In Emerging Research in Computing, Information, Communication and Applications: Proceedings of ERCICA 2022; Springer: Berlin, Germany, 2022; pp. 673–690. [Google Scholar]

- Maithreyan, G.; Gumaste, V.V. Comparison of Various Machine Learning and Deep Learning Classifiers for the Classification of Defective Photovoltaic Cells. In Proceedings of the Intelligent Control, Robotics, and Industrial Automation: Proceedings of International Conference, Dongguan, China, 16–18 December 2022; Association for Computing Machinery: New York, NY, USA, 2023; Volume 1066, p. 471. [Google Scholar]

- Zhao, X.; Song, C.; Zhang, H.; Sun, X.; Zhao, J. HRNet-based automatic identification of photovoltaic module defects using electroluminescence images. Energy 2023, 267, 126605. [Google Scholar] [CrossRef]

- Wang, S.; Han, K.; Jin, J. Review of image low-level feature extraction methods for content-based image retrieval. Sens. Rev. 2019, 39, 783–809. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, X.; Ding, L.; Tang, X.; Zhang, H. A robust visual tracking method via local feature extraction and saliency detection. Vis. Comput. 2020, 36, 683–700. [Google Scholar] [CrossRef]

- Herraiz, Á.H.; Marugán, A.P.; Márquez, F.P.G. Photovoltaic plant condition monitoring using thermal images analysis by convolutional neural network-based structure. Renew. Energy 2020, 153, 334–348. [Google Scholar] [CrossRef]

- Prabhakaran, S.; Uthra, R.A.; Preetharoselyn, J. Feature Extraction and Classification of Photovoltaic Panels Based on Convolutional Neural Network. Comput. Mater. Contin. 2023, 74, 1437–1455. [Google Scholar] [CrossRef]

- Humeau-Heurtier, A. Texture feature extraction methods: A survey. IEEE Access 2019, 7, 8975–9000. [Google Scholar] [CrossRef]

- Kuo, C.F.J.; Chen, S.H.; Huang, C.Y. Automatic detection, classification and localization of defects in large photovoltaic plants using unmanned aerial vehicles (UAV) based infrared (IR) and RGB imaging. Energy Convers. Manag. 2023, 276, 116495. [Google Scholar]

- Tang, Y.; Chen, M.; Wang, C.; Luo, L.; Li, J.; Lian, G.; Zou, X. Recognition and localization methods for vision-based fruit picking robots: A review. Front. Plant Sci. 2020, 11, 510. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Ji, N. A bright spot detection and analysis method for infrared photovoltaic panels based on image processing. Front. Energy Res. 2023, 10, 978247. [Google Scholar] [CrossRef]

- Junchao, W.; Chang, Z. Defect detection on solar cells using mathematical morphology and fuzzy logic techniques. J. Opt. 2023, 1–11. [Google Scholar] [CrossRef]

- Ayyagari, K.S.; Munian, Y.; Inupakutika, D.; Reddy, B.K.; Gonzalez, R.; Alamaniotis, M. Simultaneous Detection and Classification of Dust and Soil on Solar PhotoVoltaic Arrays Connected to A Large-Scale Industry: A Case Study. In Proceedings of the 2022 18th International Conference on the European Energy Market (EEM), Ljubljana, Slovenia, 13–15 September 2022; pp. 1–6. [Google Scholar]

- Abuqaaud, K.A.; Ferrah, A. A novel technique for detecting and monitoring dust and soil on solar photovoltaic panel. In Proceedings of the 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 4 February–9 April 2020; pp. 1–6. [Google Scholar]

- Czarnecki, T.; Bloch, K. The use of drone photo material to classify the purity of photovoltaic panels based on statistical classifiers. Sensors 2022, 22, 483. [Google Scholar] [CrossRef]

- Supe, H.; Avtar, R.; Singh, D.; Gupta, A.; Yunus, A.P.; Dou, J.; A. Ravankar, A.; Mohan, G.; Chapagain, S.K.; Sharma, V.; et al. Google earth engine for the detection of soiling on photovoltaic solar panels in arid environments. Remote Sens. 2020, 12, 1466. [Google Scholar] [CrossRef]

- Fan, S.; Wang, X.; Wang, Z.; Sun, B.; Zhang, Z.; Cao, S.; Zhao, B.; Wang, Y. A novel image enhancement algorithm to determine the dust level on photovoltaic (PV) panels. Renew. Energy 2022, 201, 172–180. [Google Scholar] [CrossRef]

- Zhou, Y.J.; Sun, H.R. Water photovoltaic plant contaminant identification using visible light images. Sustain. Energy Technol. Assessments 2022, 53, 102476. [Google Scholar] [CrossRef]

- Di Tommaso, A.; Betti, A.; Fontanelli, G.; Michelozzi, B. A Multi-Stage model based on YOLOv3 for defect detection in PV panels based on IR and Visible Imaging by Unmanned Aerial Vehicle. Renew. Energy 2022, 193, 941–962. [Google Scholar] [CrossRef]

- Saquib, D.; Nasser, M.N.; Ramaswamy, S. Image Processing Based Dust Detection and prediction of Power using ANN in PV systems. In Proceedings of the 2020 Third International Conference on Smart Systems and Inventive Technology (ICSSIT), Tirunelveli, India, 20–22 August 2020; pp. 1286–1292. [Google Scholar]

- Mathew, A.; Amudha, P.; Sivakumari, S. Deep learning techniques: An overview. Advanced Machine Learning Technologies and Applications: Proceedings of AMLTA 2020; Springer: Berlin, Germany, 2021; pp. 599–608. [Google Scholar]

- Bengio, Y.; Lecun, Y.; Hinton, G. Deep learning for AI. Commun. ACM 2021, 64, 58–65. [Google Scholar] [CrossRef]

- Muteri, V.; Cellura, M.; Curto, D.; Franzitta, V.; Longo, S.; Mistretta, M.; Parisi, M.L. Review on life cycle assessment of solar photovoltaic panels. Energies 2020, 13, 252. [Google Scholar] [CrossRef]

- Su, D.; Batzelis, E.; Pal, B. Machine learning algorithms in forecasting of photovoltaic power generation. In Proceedings of the 2019 International Conference on Smart Energy Systems and Technologies (SEST), Porto, Portugal, 9–11 September 2019; pp. 1–6. [Google Scholar]

- Bischl, B.; Binder, M.; Lang, M.; Pielok, T.; Richter, J.; Coors, S.; Thomas, J.; Ullmann, T.; Becker, M.; Boulesteix, A.L.; et al. Hyperparameter optimization: Foundations, algorithms, best practices, and open challenges. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2023, 13, e1484. [Google Scholar] [CrossRef]

- Ganaie, M.A.; Hu, M.; Malik, A.; Tanveer, M.; Suganthan, P. Ensemble deep learning: A review. Eng. Appl. Artif. Intell. 2022, 115, 105151. [Google Scholar] [CrossRef]

- Agrawal, T. Hyperparameter Optimization in Machine Learning: Make Your Machine Learning and Deep Learning Models More Efficient; Springer: Berlin, Germany, 2021. [Google Scholar]

- Shihavuddin, A.; Rashid, M.R.A.; Maruf, M.H.; Hasan, M.A.; ul Haq, M.A.; Ashique, R.H.; Al Mansur, A. Image based surface damage detection of renewable energy installations using a unified deep learning approach. Energy Rep. 2021, 7, 4566–4576. [Google Scholar] [CrossRef]

- Onim, M.S.H.; Sakif, Z.M.M.; Ahnaf, A.; Kabir, A.; Azad, A.K.; Oo, A.M.T.; Afreen, R.; Hridy, S.T.; Hossain, M.; Jabid, T.; et al. SolNet: A Convolutional Neural Network for Detecting Dust on Solar Panels. Energies 2022, 16, 155. [Google Scholar] [CrossRef]

- Pathak, S.P.; Patil, S.; Patel, S. Solar panel hotspot localization and fault classification using deep learning approach. Procedia Comput. Sci. 2022, 204, 698–705. [Google Scholar] [CrossRef]

- Li, Q.; Yu, K.; Chen, D. SolarDiagnostics: Automatic damage detection on rooftop solar photovoltaic arrays. Sustain. Comput. Inform. Syst. 2021, 32, 100595. [Google Scholar] [CrossRef]

- El Ydrissi, M.; Ghennioui, H.; Alae, A.; Abraim, M.; Taabane, I.; Farid, A. Dust InSMS: Intelligent soiling measurement system for dust detection on solar mirrors using computer vision methods. Expert Syst. Appl. 2023, 211, 118646. [Google Scholar] [CrossRef]

- Fan, S.; Wang, Y.; Cao, S.; Zhao, B.; Sun, T.; Liu, P. A deep residual neural network identification method for uneven dust accumulation on photovoltaic (PV) panels. Energy 2022, 239, 122302. [Google Scholar] [CrossRef]

- Tella, H.; Mohandes, M.; Liu, B.; Rehman, S.; Al-Shaikhi, A. Deep Learning System for Defect Classification of Solar Panel Cells. In Proceedings of the 2022 14th International Conference on Computational Intelligence and Communication Networks (CICN), Al-Khobar, Saudi Arabia, 4–6 December 2022; pp. 448–453. [Google Scholar]

- Khilar, R.; Suba, G.M.; Kumar, T.S.; Samson Isaac, J.; Shinde, S.K.; Ramya, S.; Prabhu, V.; Erko, K.G. Improving the efficiency of photovoltaic panels using machine learning approach. Int. J. Photoenergy 2022, 2022. [Google Scholar] [CrossRef]

- Prabhakaran, S.; Uthra, R.A.; Preetharoselyn, J. Deep Learning-Based Model for Defect Detection and Localization on Photovoltaic Panels. Comput. Syst. Sci. Eng. 2023, 44. [Google Scholar] [CrossRef]

- Hanafy, W.A.; Pina, A.; Salem, S.A. Machine learning approach for photovoltaic panels cleanliness detection. In Proceedings of the 2019 15th International Computer Engineering Conference (ICENCO), Giza, Egypt, 29–30 December 2019; pp. 72–77. [Google Scholar]

- Rodil, M.C.; Montenegro, J.P.; Kampouropoulos, K.; Andrade, F.; Romeral, L. A novel methodology for determination of soiling on PV panels by means of grey box modelling. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; Volume 1, pp. 2271–2276. [Google Scholar]

- Shaaban, M.F.; Alarif, A.; Mokhtar, M.; Tariq, U.; Osman, A.H.; Al-Ali, A. A New Data-Based Dust Estimation Unit for PV Panels. Energies 2020, 13, 3601. [Google Scholar] [CrossRef]

- Fan, S.; Wang, Y.; Cao, S.; Sun, T.; Liu, P. A novel method for analyzing the effect of dust accumulation on energy efficiency loss in photovoltaic (PV) system. Energy 2021, 234, 121112. [Google Scholar] [CrossRef]

- Márquez, F.P.G.; Ramírez, I.S. Condition monitoring system for solar power plants with radiometric and thermographic sensors embedded in unmanned aerial vehicles. Measurement 2019, 139, 152–162. [Google Scholar] [CrossRef]

- Malik, H.; Alsabban, M.; Qaisar, S.M. Arduino Based Automatic Solar Panel Dust Disposition Estimation and Cloud Based Reporting. Procedia Comput. Sci. 2021, 194, 102–113. [Google Scholar] [CrossRef]

- Bodnár, I.; Matusz-Kalász, D.; Boros, R.R. Exploration of Solar Panel Damage and Service Life Reduction Using Condition Assessment, Dust Accumulation, and Material Testing. Sustainability 2023, 15, 9615. [Google Scholar] [CrossRef]

- He, B.; Lu, H.; Zheng, C.; Wang, Y. Characteristics and cleaning methods of dust deposition on solar photovoltaic modules—A review. Energy 2023, 263, 126083. [Google Scholar] [CrossRef]

- Li, X.; Mauzerall, D.L.; Bergin, M.H. Global reduction of solar power generation efficiency due to aerosols and panel soiling. Nat. Sustain. 2020, 3, 720–727. [Google Scholar] [CrossRef]

- Li, X.; Wagner, F.; Peng, W.; Yang, J.; Mauzerall, D.L. Reduction of solar photovoltaic resources due to air pollution in China. Proc. Natl. Acad. Sci. USA 2017, 114, 11867–11872. [Google Scholar] [CrossRef] [PubMed]

- El-Banby, G.M.; Moawad, N.M.; Abouzalm, B.A.; Abouzaid, W.F.; Ramadan, E. Photovoltaic system fault detection techniques: A review. Neural Comput. Appl. 2023, 35, 1–14. [Google Scholar] [CrossRef]

- Chaichan, M.T.; Kazem, H.A.; Ibrahim, S.I.; Radhi, A.A.; Mahmoud, B.K.; Ali, A.J. Photovoltaic panel type influence on the performance degradation due dust accumulation. Proc. Iop Conf. Ser. Mater. Sci. Eng. 2020, 928, 022092. [Google Scholar] [CrossRef]

- Jamuna, V.; Muniraj, C.; Periasamy, P. Fault detection for photovoltaic panels in solar power plants by using linear iterative fault diagnosis (LIFD) technique based on thermal imaging system. J. Electr. Eng. Technol. 2023, 18, 1–13. [Google Scholar] [CrossRef]

- Li, L.; Wang, Z.; Zhang, T. Gbh-yolov5: Ghost convolution with bottleneckcsp and tiny target prediction head incorporating yolov5 for pv panel defect detection. Electronics 2023, 12, 561. [Google Scholar] [CrossRef]

- Kayci, B.; Demír, B.E.; Demír, F. Deep learning based fault detection and diagnosis in photovoltaic system using thermal images acquired by UAV. Politeknik Dergisi 2023, 1. [Google Scholar] [CrossRef]

- Liu, J.; Jiao, Z.; Chen, C.; Duan, C.; Pang, C. Advanced data-driven methods and applications for smart power and energy systems. Front. Energy Res. 2023, 10, 1064305. [Google Scholar] [CrossRef]

- Wang, J.; Gao, D.; Zhu, S.; Wang, S.; Liu, H. Fault diagnosis method of photovoltaic array based on support vector machine. Energy Sources, Part A Recover. Util. Environ. Eff. 2023, 45, 5380–5395. [Google Scholar] [CrossRef]

- Et-taleby, A.; Chaibi, Y.; Allouhi, A.; Boussetta, M.; Benslimane, M. A combined convolutional neural network model and support vector machine technique for fault detection and classification based on electroluminescence images of photovoltaic modules. Sustain. Energy Grids Netw. 2022, 32, 100946. [Google Scholar] [CrossRef]

- Balasubramani, G.; Thangavelu, V. Thermal Image Analysis of Photovoltaic Panel for Condition Monitoring Using Hybrid Thermal Pixel Counting Algorithm and XGBoost Classifier. Electr. Power Components Syst. 2023, 1–14. [Google Scholar] [CrossRef]

- Espinosa, A.R.; Bressan, M.; Giraldo, L.F. Failure signature classification in solar photovoltaic plants using RGB images and convolutional neural networks. Renew. Energy 2020, 162, 249–256. [Google Scholar] [CrossRef]

- Cavieres, R.; Barraza, R.; Estay, D.; Bilbao, J.; Valdivia-Lefort, P. Automatic soiling and partial shading assessment on PV modules through RGB images analysis. Appl. Energy 2022, 306, 117964. [Google Scholar] [CrossRef]

- Venkatesh, S.N.; Jeyavadhanam, B.R.; Sizkouhi, A.M.; Esmailifar, S.M.; Aghaei, M.; Sugumaran, V. Automatic detection of visual faults on photovoltaic modules using deep ensemble learning network. Energy Rep. 2022, 8, 14382–14395. [Google Scholar] [CrossRef]

- Sharifani, K.; Amini, M. Machine Learning and Deep Learning: A Review of Methods and Applications. World Inf. Technol. Eng. J. 2023, 10, 3897–3904. [Google Scholar]

- Bhatti, U.A.; Tang, H.; Wu, G.; Marjan, S.; Hussain, A. Deep learning with graph convolutional networks: An overview and latest applications in computational intelligence. Int. J. Intell. Syst. 2023, 2023, 1–28. [Google Scholar] [CrossRef]

- Prabhakaran, S.; Uthra, R.A.; Roselyn, J.P. Defect analysis of faulty regions in photovoltaic panels using deep learning method. In Security, Privacy and Data Analytics: Select Proceedings of ISPDA 2021; Springer: Berlin, Germany, 2022; pp. 63–78. [Google Scholar]

- Alves, R.H.F.; de Deus Junior, G.A.; Marra, E.G.; Lemos, R.P. Automatic fault classification in photovoltaic modules using Convolutional Neural Networks. Renew. Energy 2021, 179, 502–516. [Google Scholar] [CrossRef]

- Korkmaz, D.; Acikgoz, H. An efficient fault classification method in solar photovoltaic modules using transfer learning and multi-scale convolutional neural network. Eng. Appl. Artif. Intell. 2022, 113, 104959. [Google Scholar] [CrossRef]

- Lu, F.; Niu, R.; Zhang, Z.; Guo, L.; Chen, J. A generative adversarial network-based fault detection approach for photovoltaic panel. Appl. Sci. 2022, 12, 1789. [Google Scholar] [CrossRef]

- Seghiour, A.; Abbas, H.A.; Chouder, A.; Rabhi, A. Deep learning method based on autoencoder neural network applied to faults detection and diagnosis of photovoltaic system. Simul. Model. Pract. Theory 2023, 123, 102704. [Google Scholar] [CrossRef]

- Et-taleby, A.; Chaibi, Y.; Benslimane, M.; Boussetta, M. Applications of Machine Learning Algorithms for Photovoltaic Fault Detection: A Review. Stat. Optim. Inf. Comput. 2023, 11, 168–177. [Google Scholar] [CrossRef]

- Abubakar, A.; Jibril, M.M.; Almeida, C.F.; Gemignani, M.; Yahya, M.N.; Abba, S.I. A Novel Hybrid Optimization Approach for Fault Detection in Photovoltaic Arrays and Inverters Using AI and Statistical Learning Techniques: A Focus on Sustainable Environment. Processes 2023, 11, 2549. [Google Scholar] [CrossRef]

- Wang, X.; Yang, W.; Qin, B.; Wei, K.; Ma, Y.; Zhang, D. Intelligent monitoring of photovoltaic panels based on infrared detection. Energy Rep. 2022, 8, 5005–5015. [Google Scholar] [CrossRef]

- Yao, S.; Kang, Q.; Zhou, M.; Abusorrah, A.; Al-Turki, Y. Intelligent and data-driven fault detection of photovoltaic plants. Processes 2021, 9, 1711. [Google Scholar] [CrossRef]

- Lin, P.; Qian, Z.; Lu, X.; Lin, Y.; Lai, Y.; Cheng, S.; Chen, Z.; Wu, L. Compound fault diagnosis model for Photovoltaic array using multi-scale SE-ResNet. Sustain. Energy Technol. Assessments 2022, 50, 101785. [Google Scholar] [CrossRef]

- Chen, X.; Gao, W.; Hong, C.; Tu, Y. A novel series arc fault detection method for photovoltaic system based on multi-input neural network. Int. J. Electr. Power Energy Syst. 2022, 140, 108018. [Google Scholar] [CrossRef]

- Sarikh, S.; Raoufi, M.; Bennouna, A.; Benlarabi, A.; Ikken, B. Fault diagnosis in a photovoltaic system through IV characteristics analysis. In Proceedings of the 2018 9th International Renewable Energy Congress (IREC), Hammamet, Tunisia, 20–22 March 2018; pp. 1–6. [Google Scholar]

- Abid, A.J.; Obed, A.; Al-Naima, F.M. Detection and control of power loss due to soiling and faults in photovoltaic solar farms via wireless sensor network. Int. J. Eng. Technol. 2018, 7, 718–724. [Google Scholar] [CrossRef]

- Schmid, F.; Behrendt, F. Genetic sizing optimization of residential multi-carrier energy systems: The aim of energy autarky and its cost. Energy 2023, 262, 125421. [Google Scholar] [CrossRef]

- Khodapanah, M.; Ghanbari, T.; Moshksar, E.; Hosseini, Z. Partial shading detection and hotspot prediction in photovoltaic systems based on numerical differentiation and integration of the P- V curves. IET Renew. Power Gener. 2023, 17, 279–295. [Google Scholar] [CrossRef]

- Hocine, L.; Samira, K.M.; Tarek, M.; Salah, N.; Samia, K. Automatic detection of faults in a photovoltaic power plant based on the observation of degradation indicators. Renew. Energy 2021, 164, 603–617. [Google Scholar] [CrossRef]

- Sarikh, S.; Raoufi, M.; Bennouna, A.; Ikken, B. Characteristic curve diagnosis based on fuzzy classification for a reliable photovoltaic fault monitoring. Sustain. Energy Technol. Assessments 2021, 43, 100958. [Google Scholar] [CrossRef]

- Sebbane, S.; Akchioui, N.E. Artificial neural network optimized by whale optimization algorithm for partial shading fault detection. AIP Conference Proceedings 2023, 2814, 040013. [Google Scholar]

- El-kenawy, E.M.; Albalawi, F.; Ward, S.A.; Ghoneim, S.S.M.; Eid, M.M.; Abdelhamid, A.A.; Bailek, N.; Ibrahim, A. Feature selection and classification of transformer faults based on novel meta-heuristic algorithm. Mathematics 2022, 10, 3144. [Google Scholar] [CrossRef]

- Meribout, M.; Tiwari, V.K.; Herrera, J.P.P.; Baobaid, A.N.M.A. Solar panel inspection techniques and prospects. Measurement 2023, 209, 112466. [Google Scholar] [CrossRef]

- Artaş, S.B.; Kocaman, E.; Bilgiç, H.H.; Tutumlu, H.; Yağlı, H.; Yumrutaş, R. Why PV panels must be recycled at the end of their economic life span? A case study on recycling together with the global situation. Process. Saf. Environ. Prot. 2023, 174, 63–78. [Google Scholar] [CrossRef]

- Abuzaid, H.; Awad, M.; Shamayleh, A. Impact of dust accumulation on photovoltaic panels: A review paper. Int. J. Sustain. Eng. 2022, 15, 264–285. [Google Scholar] [CrossRef]

- Jathar, L.D.; Ganesan, S.; Awasarmol, U.; Nikam, K.; Shahapurkar, K.; Soudagar, M.E.M.; Fayaz, H.; El-Shafay, A.; Kalam, M.; Boudila, S.; et al. Comprehensive review of environmental factors influencing the performance of photovoltaic panels: Concern over emissions at various phases throughout the lifecycle. Environ. Pollut. 2023, 326, 121474. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, M.; Mu, J.; Yi, J. Alternative cleaning and dust detection method for PV modules and its application. J. Renew. Sustain. Energy 2020, 12, 053503. [Google Scholar] [CrossRef]

- Kavya, V.; Keshav, R.M. Solar dust detection system. In Proceedings of the 2018 International Conference on Power Energy, Environment and Intelligent Control (PEEIC), Greater Noida, India, 13–14 April 2018; pp. 138–140. [Google Scholar]

- Lazzaretti, A.E.; Costa, C.H.d.; Rodrigues, M.P.; Yamada, G.D.; Lexinoski, G.; Moritz, G.L.; Oroski, E.; Goes, R.E.d.; Linhares, R.R.; Stadzisz, P.C.; et al. A monitoring system for online fault detection and classification in photovoltaic plants. Sensors 2020, 20, 4688. [Google Scholar] [CrossRef]

- Hong, Y.Y.; Pula, R.A. Methods of photovoltaic fault detection and classification: A review. Energy Rep. 2022, 8, 5898–5929. [Google Scholar] [CrossRef]

| References | Year | Advantages | Disadvantages |

|---|---|---|---|

| [63] | 2022 | Determine the optimal cleaning solution based on image classification, and adjust the cleaning frequency according to the dust | Unable to generate electricity on rainy days; takes up a lot of space |

| [64] | 2020 | Does not require any sensors | Can only detect overlays such as dust or soil |

| [65] | 2022 | Use drones to capture images from different angles and heights | Images captured by drones require preprocessing |

| [66] | 2020 | GEE provides free satellite data and semi-automated processing | GEE does not currently support the processing of high-resolution imagery (such as drone imagery) |

| [67] | 2022 | The distribution and concentration of dust on photovoltaic panels can be obtained in real time without dismantling or moving the panels | It is necessary to consider the influence of light, angle, color and other factors on image quality |

| [68] | 2022 | Extracting complete edge information of PV Panels by dynamic thresholding segmentation and shape features | This method does not consider the influence of lighting conditions, shooting angles, image quality, and other factors on image segmentation and classification. |

| [69] | 2022 | Simultaneous acquisition of infrared and visible light images | The influence of environmental factors needs to be considered to reduce errors and noise |

| [70] | 2020 | Cleaning signals can be triggered based on predicted results | Requires significant computing resources and time to process images |

| References | Year | Advantages | Disadvantages |

|---|---|---|---|

| [79] | 2022 | Uses electrostatic repulsion to dislodge dust particles without the need for water or brushes | Requires an additional power supply and controller to generate and regulate the electrostatic field |

| [80] | 2022 | Efficient image segmentation and classification tasks using different deep learning models | Deep learning models can be affected by noise, bias, outliers, etc. |

| [81] | 2021 | An unsupervised segmentation algorithm is used to avoid interference from other factors (such as shadows, dust, snow, etc.) | Requires a lot of computing resources and time to train and test the model |

| [82] | 2023 | Able to adapt to different lighting conditions and sky changes | Large-scale field testing and validation has not yet been carried out |

| [83] | 2022 | DRNN can solve deep neural network training difficulties and degradation problems | Experimental conditions need to be strictly controlled to increase the diversity of image types |

| [84] | 2022 | Solve the problem of data imbalance through data enhancement and other methods | Appropriate network structure and hyperparameter selection are required |

| [85] | 2022 | Deep belief networks (DBN) can effectively use hidden layers to improve performance | The training process of DBN is more complicated |

| [86] | 2023 | The area histogram approximation algorithm and the gray quantization algorithm are used to preprocess and feature extract the photovoltaic image | Need to test and verify in more PV panel types and scenarios |

| [87] | 2019 | Apply automatic background removal and extraction of complex features | No consideration is given to images of other types or conditions |

| References | Year | Advantages | Disadvantages |

|---|---|---|---|

| [88] | 2019 | Does not require any additional equipment or human intervention | Need to adapt theoretical models of photovoltaic panels to different types and sizes of panels |

| [89] | 2020 | Does not rely on theoretical models or assumptions, more realistic and reliable | Model training and testing requires a lot of data |

| [90] | 2021 | Considering the nonlinear power generation characteristics of photovoltaic modules under low irradiance, and introducing the concept of saturated irradiance point | Need to use the weight difference of the glass pieces to calculate the dust concentration, which requires additional equipment and operation |

| [91] | 2019 | Verifying the reliability of radiometer data with thermal imaging sensors | Consider drone flight safety, stability, and regulations |

| [92] | 2021 | Improve the power generation efficiency and service life of solar panels | System requires additional hardware and software costs |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Sun, F.; Zou, Y.; Lv, Z.; Xue, L.; Jiang, C.; Liu, S.; Zhao, B.; Cui, H. A Survey of Photovoltaic Panel Overlay and Fault Detection Methods. Energies 2024, 17, 837. https://doi.org/10.3390/en17040837

Yang C, Sun F, Zou Y, Lv Z, Xue L, Jiang C, Liu S, Zhao B, Cui H. A Survey of Photovoltaic Panel Overlay and Fault Detection Methods. Energies. 2024; 17(4):837. https://doi.org/10.3390/en17040837

Chicago/Turabian StyleYang, Cheng, Fuhao Sun, Yujie Zou, Zhipeng Lv, Liang Xue, Chao Jiang, Shuangyu Liu, Bochao Zhao, and Haoyang Cui. 2024. "A Survey of Photovoltaic Panel Overlay and Fault Detection Methods" Energies 17, no. 4: 837. https://doi.org/10.3390/en17040837

APA StyleYang, C., Sun, F., Zou, Y., Lv, Z., Xue, L., Jiang, C., Liu, S., Zhao, B., & Cui, H. (2024). A Survey of Photovoltaic Panel Overlay and Fault Detection Methods. Energies, 17(4), 837. https://doi.org/10.3390/en17040837