Abstract

This research looks into a systemic impact factor (SIF) as a complement to enhance the prescriptive capabilities of electric substations with the objective of improving the reliability and robustness of components. As electrical networks become increasingly complex, prescriptive analytical tools are needed to ensure sustained power delivery. The purpose is to develop a framework for evaluating failure effects, including both direct and indirect effects on substation performance. The study makes use of a multi-criteria method that incorporates safety, environment protection, reliability, and network robustness among other factors like SAIDI and SAIFI to determine the actual impact of failures to make better decisions. The methodology is illustrated using a criticality model, and a case study, focusing on operational contexts of the failure. The SIF proposal provides a better understanding of different aspects and their contribution, when a failure event occurs under a given operational context. This factor improves maintenance management by identifying critical equipment and projecting the effects of failure through a specific operation network. A case study in an electrical substation estimates the SIF for each element used in daily operations to improve support services and increase substation dependability. Therefore, SIF is an essential factor to consider in electrical substations for their maintainability and reliability evaluation.

1. Introduction

Reliability and resiliency of electrical substations are very important for the effective operation of modern power systems. When the need for electric power increases and the facilities become old, there is a higher likelihood in the chances of failures resulting in large-scale blackouts and massive economic losses. It has encouraged research into failure detection and preventative maintenance in order to anticipate any risk to the substation’s components. The goal of this research is to inform about the consequences of failures in electrical stations on the reliability and safety of the electric power system.

This study is intended to obtain a more effective analysis of potential failures in electrical substations with a higher level of detail. It will allow actions to be focused on those precise elements that generate a higher impact on the whole system. This requires an understanding on how substation components contribute to the overall systemic impact. For this reason, SIF is defined as a correlation vector, which reflects the system’s sensitivity regarding its components in multiple dimensions (vulnerability, environment, safety, production, etc.). This indicator recognizes the need to consider how such variables change depending on the station’s operational configuration. Basically, the study is intended to advance in risk assessment, improving the failure impact estimates and, consequently, the system maintenance management.

In other words, this study aims at considering SIF as a vector, which improves prescriptive capabilities, in terms of allowing a focus on those critical elements based on an assessment of failure impact on electrical substations. Therefore, by studying how certain substation components interact with their operating mode, it is intended to come up with an advanced method of risk assessment and failure prevention. The research questions to answer are as follows: What is the systemic impact factor (SIF) and how does it contribute to improving prescriptive analytics of electrical substations? How does the proposed calculation procedure help in assessing the potential influence of component failures on the overall performance of electrical substations?

The paper provides a new approach to asset criticality analysis proposing SIF, which is focused on enhancing prescriptive capabilities in electrical substations. While previous studies frequently center on individual parts or specific kinds of failures [1], this research treats the substation as an integral system in which the breakdown of one part triggers problems at a system level, impacting in a higher or lower way depending on the operational configuration of the system, which will be variable according to the energy demand of the moment. The study begins with a literature review, identifying important contributions prior to the present study and addressing gaps or discussing viewpoints in relation to the maintenance supervision of substations. After that, SIF is defined and illustrated in a practical scenario. The results provide an essential resource to establish specialized maintenance plans intended to reduce disruptions while increasing the electrical substation’s resilience and, consequently, the resilience of the power networks. Finally, essential findings are summarized outlining some possibilities for further research on this topic. The present work is designed in order to be useful for scientists and engineers dealing with the field of electrical substation maintenance, thus contributing to the wider area of energy systems operation.

2. Literature Review

Prescriptive maintenance in electrical substations is an important research field that draws much interest as it affects the reliability of the power grid and the uninterrupted power service delivery. This study has been informed by several studies, which all offer different approaches as well as conclusions. The present paper is about SIF, which is a novel factor for providing better component assessments considering the failure effect within electrical substations. This study has been established as a part of the electrical engineering discipline with emphasis mostly on the criticality analysis of the energy conversion networks. SIF assesses the impact of component failures on a system and considers the dynamics of interactions within the substation.

Recent studies in the field of energy refer to prescriptive maintenance as a key tool when it comes to providing capabilities to determine failure effects in advance, with the purpose of recommending strategies and actions. Fox et al. [2] in a review of prescriptive offshore wind farm operation and maintenance propose prescriptive strategies and provide optimized maintenance actions, incorporating predictions into a wider maintenance plan to address failure modes. Additionally, they establish that, in order to achieve prescriptive maintenance, two components are required: the ability of a model to predict impending failures; and the ability to suggest outcome-focused recommendations for O&M planning, for example, an optimized O&M schedule. To achieve that, it is essential to have deep knowledge about each component independently and its impact on the whole system. The present research is focused on the determination of a factor to improve and adjust maintenance prescriptions, considering the dynamic operational conditions and the systemic impact of each component on an electrical substation. In this context, it is essential and at the same time necessary to benefit from digitization’s power for better maintenance outcomes [3]. By developing a data-informed approach, the research aims to enhance decision-making, optimize resource allocation, and ultimately heighten the reliability and safety of energy systems.

Previous studies [4] have reviewed important issues relating to the failure effect. These include, but are not limited to, criticality analysis, risk-based asset management, and advanced analytics for maintenance optimization. However, it remains difficult to accurately connect the interactions between different substation components and operation modes in order to predict the precise effects of a breakdown. This work closes this gap by a mathematical model that takes these complex interactions into account.

In line with the foregoing discussions, Martínez-Gálán et al. [5] explore failure consequences quantification in electrical network (E/N) systems establishing new concepts like loss exposure (LE) and social importance (SI). The above criteria take into account social factors like consumer satisfaction and the overall perception of the market in addition to functional loss-based cost. The network utility may be very complex and the impact of failures is also multi-dimensional, e.g., safety and network resilience (NR). These specifications, although generalized, cannot deal effectively with the interactions that occur within or between various substation components and operational mode scenarios. Gao et al. [6] note that network reliance is an adjustment factor. Such an approach acknowledges that predictive models have to take into account the flexibility of electrical networks’ topology. Nevertheless, the studies mainly deal with operational effects, including service delays rather than deeply examine the systematic ramifications that might occur due to interaction between components. Guo et al. [7] proposed a model of criticality that assesses the economic impact of failure taking into account different variables and the relative significance of diverse assets. The model is very detailed when it comes to the criticality level of assets, but it cannot entirely reflect the system-wide consequences arising from failures within the networking environment.

The present research is located in relation to those studies that revealed certain gaps and addressed them by examining the SIF as a factor that explains correlations. A unique aspect of the SIF is that it considers substation components such as breakers, power transformers, and capacitors as a single unit, which affects not only their behavior but also their topology within the system configuration. The current method is different from other studies as it considers both the systemic effect of operations modes and topological flexibility for more accurate results. In this sense, Lund et al. [8] describe the advantages and disadvantages of a prescriptive analysis versus a simulation. Considering the above, the SIF factor is proposed as a useful tool in both scenarios, rescuing the advantages of each, either allowing optimizing an objective value in the context of maintenance or simulating new scenarios for design purposes, keeping in mind that asset management deals with the entire lifecycle increasing assets dependability over the life cycle while reducing the frequency of scheduled maintenance [9].

The present research addresses the limitations of other contributions [10] that express indirect cost underestimations and the lack of consideration of topological dynamics. Incorporation of SIF increases awareness of failure impacts that assist in the development of viable maintenance practices and network reliability [4]. Bell and Gill [11] indicate that in order to address the challenges and dangers related to technical standard non-compliance in substations and distribution lines, a comprehensive and effective plan of action must be developed. But in addition to these issues, the current work provides a more sophisticated and rational solution by suggesting a functional configuration that models how electrical systems should operate effectively in the event of a failure, establishing a better preventive maintenance environment.

Apart from the above-mentioned literature, other references have been published specifically on enhancing prescriptive capabilities, incorporating a knowledge base about system aging and degradation into maintenance strategies. In 2019, Liu et al. [12]. completed a dynamic prescriptive maintenance model to adjust degradation parameters or optimize inspection time according to the condition of system health. It is therefore a significant step forward in maintenance decision-making from the linear time-based strategies that have been used previously. Bertsimas and Kallus [13] took the prospect to be even more expansive, introducing readers to transitioning from predictive analytics toward what they termed prescriptive—decision-making in an era of uncertainty. As a result, their work illustrates the possibilities for prescriptive analytics to not only foresee future outcomes but even suggest courses of action that can help improve system performance.

Koops et al. [14] proposed prescriptive analytics to support maintenance–dedication decisions, which incorporates probabilistic cost–benefit analysis. This is especially appropriate for the management of the uncertainty and inevitable difficulties in maintenance work, offering a systematic approach to comparing the relative advantages or disadvantages of various specialists’ maintenance. In addition to this, Karim et al. [15] argue that data-driven maintenance is a new area of knowledge for maintenance, which they call “maintenance analytics”—a term similar to business analytics. They indicate that through the use of analytics, one can learn more about maintenance requirements and become faster at handling them. Finally, Matyas et al. [16] have put forward a procedural approach to the implementation of prescriptive maintenance planning in manufacturing enterprises. Nevertheless, their focus is on prescriptive maintenance or implementation of a manual that can take industries through the whole process of moving toward data-driven maintenance.

In any case, there are still areas where publications fall short; consider for example the subject of electrical substations. Most of the current research looks at isolated segments or single maintenance activities, while ignoring how failures in one area of a substation network may affect others. The present research aims to fill this gap by taking systems into account at the substations and addressing issues of component failure. The study has also been able to expand the scope of failure impact analysis by incorporating an SIF approach. This is further evidence that it might be possible in the future to develop more precise prescriptive maintenance methods for electrical substations as well. The reviewed papers have indeed their strong points in terms of methodology, such as new ways to perform maintenance modeling and decision-making. On the other hand, their drawbacks are that they do not address systemic effects and those of electrical substations.

Basically, although there is a vast amount of literature on the impacts of failures in electrical substations, this research is intended to fill some gaps by taking into consideration the systems’ perspective based on components and operational modes of substations. This work addresses the weaknesses of previous studies on substation dependability and takes a holistic approach that incorporates risk assessment, criticality analysis, and advanced analytical methodologies. More precise failure impact estimation can result in targeted maintenance strategies focused on enhancing the stability and effectiveness of the electrical grid.

3. Calculation Procedure

A logical functional model of an electrical system in a substation is proposed to be used as a model that illustrates a systemic model considering possible cases of failure. Once the most likely component failure event(s) are formulated based on demand scenarios and operating modes; the effect of each scenario on the asset criticality index is determined for various operational modes, and an SIF vector is derived by scaling and normalizing the former values. Some terminological explanations are given to aid in understanding the following:

- -

- SIF: A numerical vector that indicates the potential influence that a component’s failure may have on the system’s overall performance and its consequences.

- -

- Logical Functional Model: A diagram showing the system’s components that interact and explain system behavior under different conditions. It allows the weighted impact of each component on the system to be calculated.

- -

- Digital Model Diagrams: Digital representation of a system that presents connections and dependencies among components and that allows the construction of the functional logical model.

- -

- Operational Modes: Active and standby components of different configurations or states, in which a substation may operate depending on the demand for energy.

The approach includes system evaluation of the electrical system of the substation, with emphasis on data collection about peak demand, failure scenarios, and asset ranking. Digital diagrams are used to develop a logical functional model, which contributes in a key way to the calculation of the SIF. The use of statistical and computational methods is applied in the analysis of the data to develop the SIF.

For the calculation of the SIF vector, it is considered that:

where VF, SASA, SSA, OMF, and TFO are explained in Section 3.2, Section 3.3, Section 3.4, Section 3.5 and Section 3.6. Next, Section 3.1 will briefly describe a study scenario. Section 3.2, Section 3.3, Section 3.4, Section 3.5 and Section 3.6 describe theoretically each parameter and integrate examples applied to the mentioned scenario.

3.1. Study Scenario

The SIF approach is explained and calculated based on a practical example, which refers to an electrical substation (ES). The ES under consideration is an important nodal point between transmission and a distribution network, supplying more than 94,000 customers, with an installed capacity of 75 MVA. The ES has 80 assets that need to be evaluated and operates regularly, within 3 power transformers with different capacities. This modern substation has different ways to operate that can be reduced to 21 different operating modes, which facilitates its adaption according to varying demand scenarios and maintenance events.

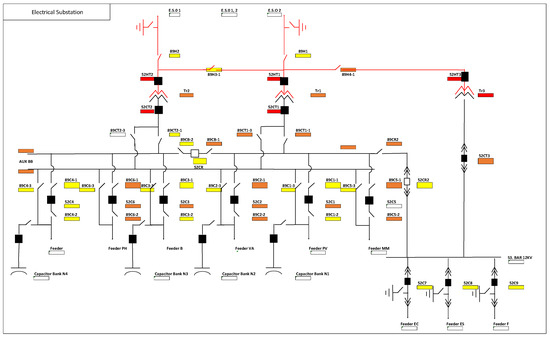

The possible impact of component failures in this substation has been evaluated using SIF, taking into account the interdependence of its components and its specific operating regime. In the example shown in Figure 1, an overview of substation electrical equipment can be observed. After applying SIF, results are represented with a color scale referring to the criticality from the highest (in red) to the lowest (in yellow or white). This real application was obtained considering 20 operational modes, and the integration of all results provides a heat map on the systemic impact of each component with respect to the total equipment in the substation.

Figure 1.

Example of substation electrical equipment SIF application.

3.2. Vulnerability Factor (VF)

Let us consider all the equipments of the electrical substation independently, where each equipment is recognized as (i), and each of the dimensions that determine its level of vulnerability is identified as , where is the weighting of each of the dimensions. In this case, vulnerability refers to the susceptibility or weakness of a system, entity, or individual to potential threats, risks, or attacks. The value of the vulnerability factor for each element (i) will be determined by:

Each dimension will acquire a value from 1 to 5 according to the table for each condition, as shown in Table 1.

Table 1.

Example of “n” dimensions to determine the value of vulnerability.

Previously to the assessment, technical experts formulate the conditions to be evaluated and their respective scales to consider in the model, according to their own operational reality. In the example, scales 1–5 are considered, but the possibility is left open for each case to include its own operational context. In some cases, there may exist standardized tables of vulnerability at the corporate level.

VF Application Example

For the VF application, various industry-specific criteria are used in conjunction with the substation senior personnel’s judgment. The development process, in this example, takes into account six dimensions: failure frequency, results of the last inspection, asset age, exposure to external factors, proximity to segregated or marginal populations, and access to the substation electrical equipment (maintenance). The evaluation employs a standardized scale with assigned values to determine a rating between 1 and 5, where 1 indicates lower vulnerability and 5 indicates higher vulnerability.

The outcome of this assessment allows for a qualitative evaluation of each asset individually, as shown in Table 2.

Table 2.

Example of vulnerability calculated for one specific equipment “a”.

Then, .

3.3. SAIDI and SAIFI Factors (SASA)

An important element in the industry is the cost associated with penalties due to service interruption. Where PSAIDI and PSAIDI are the penalties received as a result of the loss of service caused by element (i).

where represents a value between 0 and 1 to give a prorated specific value for each factor.

SASA Application Example

The SAIDI and SAIFI indicators are also standardized, allowing them to be worked on a common scale ranging from 1 to 5. In any case, penalties will depend specifically on the region and country where it is applied. In order to simplify its understanding, it is proposed that the normalization of these indicators could be based directly on penalties (see Table 3) or as follows:

Table 3.

Example of normalized penalties for SAIDI and SAIFI for one specific equipment “a”.

- The number of affected customers, with a defined scale between 0 and 100 customers, 100 and 1000, 1001 and 10,000, 10,001 and 25,000, and more than 25,000. These values are specific to the analyzed case, and the normalization of these factors should be adjusted to the capacity and potential customers.

- Downtime is normalized considering intervals of 2 h. This includes less than 2 h, between 2 and 4 h, between 4 and 8 h, then between 8 and 12 h, and finally, more than 12 h.

Then, 2.8.

3.4. Environment and Safety Factor (SSA)

The SSA factor is calculated according to the individual impact of the failure in each of these dimensions; it will be weighted for each piece of equipment according to the value of each dimension and its weighting.

where is the impact value associated with the environment, is the impact value associated with safety, and represents a value between 0 and 1 to give a prorated specific value for each factor.

SSA Application Example

The environmental factor, being a relevant element based on new regulations that are increasingly stringent, is considered on a scale from 1 to 5 (See example in Table 4). This scale describes various types of environmental damage that may result from improper operation or failure of the substation’s electrical equipment. The scale ranges from receiving a warning from the local government to the closure of the electrical substation due to irreparable damage.

Table 4.

Example of SSA calculated for one specific equipment “a”.

Then, .

3.5. Operational Mode Factor (OMF)

Considering that the electrical substation will be able to operate in N different modes according to the energy demand of the system and reliability level, the operational mode factor determines the actual impact on the total capacity of the electrical substation.

where,

N = the totality of the operations modes ();

= circulating energy in the equipment in the ;

= total energy of .

OMF Application Example

For the assessment of the operational mode factor, the various configurations of the substation electrical equipment are considered. This involves taking into account the different capabilities that each specific configuration can provide and the demand that is affected. To achieve this factor, it is necessary to identify each case and inquire about what would happen if an asset is not present and how the electrical substation is reorganized. In the analyzed case, 21 modes of operation are identified, and for each, the degree of asset participation is established.

The result of this analysis is typically obtained as a percentage. The outcome for each asset must be weighted by the frequency of utilization of the operational mode to consider the aspects of the potential use of each one (See example in Table 5).

Table 5.

Example OMF calculated for 3 specific equipments “a,b,c” (MW).

3.6. Topological Factor (TFO)

According to the incidence (I) provided by each piece of equipment i depending on a given operational mode (j), the topological factor is defined as follows:

where,

I = percentage impact on the system that generates each failure, determined by its logical configuration with respect to it, for example;

N = the totality of the operations modes ().

Then, if under that operational mode, there is only one transformer working, the impact of a failure on it and its components will be 100% on the energy demand; however, if the electrical substation is operating with three transformers at full load and one of them fails, the impact on the system alone will be 33% of the operational mode demanded.

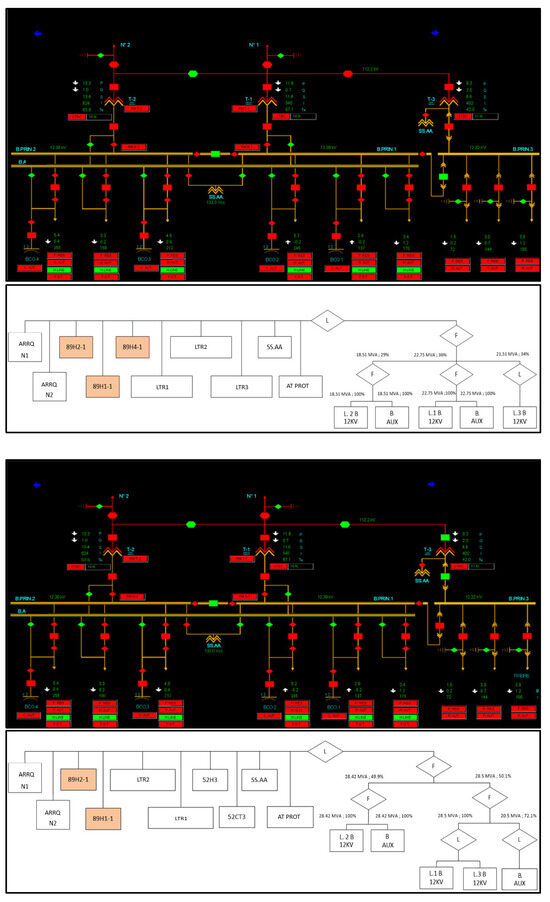

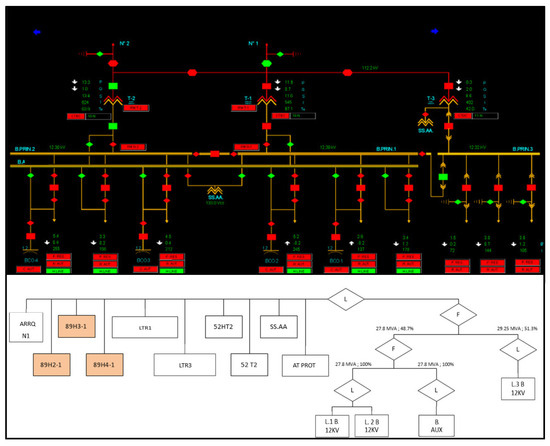

TFO Application Example

To evaluate the topological factor of the analyzed substation electrical equipment, it is necessary to assess the dependence among the various equipment and how susceptible the operation mode is to failure. This factor measures the resilience to failure of each section in the way the electrical substation is operated. This entails digitally modeling the process by depicting the logical dependency among various assets. To achieve this, the authors use a functional logical modeling technique with logical gates that facilitate the transition between different operational modes. In Figure 2, see three different operational modes and their respective logical functional configuration, which allow an estimate of the real impact of each equipment in each operational mode (See example in Table 6).

Figure 2.

Example of 3 operational modes (SCADA) and logical functional diagram.

Table 6.

Example of OMF calculated for 3 specific equipments “a,b,c” (%) considering only 3 OM. Then, with the value of incidence (I) calculated for each equipment, it is normalized.

4. SIF Application as a Prescriptive Factor

Fox et al. [2] describe prescriptive maintenance as a technique that involves not only the ability to anticipate future failures but also the capacity to offer outcome-focused recommendations for operations and maintenance (O&M) planning, as discussed in the literature review (Section 2). As a result, a prescriptive factor will be an aspect that helps formulate suggestions or particular tasks within a maintenance approach. Due to the granularity that allows SIF, it refines the criticality assessment by taking into account several criteria under different operational configurations; thus, the recommendations can be better focused. In other words, the effect of each component on the whole system can be assessed by the inclusion of more details. Although TFO and OFM are illustrated in Section 3.5 and Section 3.6 in a simplified way, further studies will be able to analyze them using more sophisticated computational techniques.

The SIF method considers an assessment for each individual element, given the substation’s topology and its operational mode (according to demand fluctuations). This method allows estimating failure consequences (impact) in advance, as it allows each piece of equipment to be characterized according to multiple attributes capable of estimating a loss value according to the operational mode to which it is subjected. As commented before, SIF is a vector that provides the basis for an integral method of addressing substations ‘component interactions and operational status. It is important to note that it requires up-to-date data and, if it is integrated with the computerized maintenance management system, its efficiency may improve, enabling, for instance, actions automatically and based on a permanent evaluation. In this way, the maintenance framework can be tailored to aim for higher system availability and lower failure rates while also controlling preventative maintenance costs.

Traditional criticality assessment is usually represented by a matrix with two dimensions: failure frequency and consequence, where the consequence is obtained from several factors (e.g., operational impact, maintenance impact, environmental impact, availability, and cost). Following this same philosophy, but with a higher level of depth and granularity, the purpose behind SIF is the assessment considering multiple dynamic and systemic variables represented in a n-dimension vector. From this vector, a single figure is also possible to obtain in order to rank the different components. The risk value of each element (i) is determined by a systemic risk number (SRN), which is defined as the product between SIF and W, where W represents the vector of weights assigned to each SIF dimension. The expression for each component (i) is as follows:

Table 7.

Example of SRN calculated for 3 specific equipment “a, b, c”.

In summary, the improvement in prescription capabilities is reflected in an increase in the precision in identifying those critical elements, which really impact the whole system. On the other hand, given the level of detail with which each piece of equipment is characterized, for example, in its vulnerability factor, it is possible to adjust the model to estimate more accurately which equipment will fail. Subsequent studies may incorporate machine learning tools, capable of recognizing multiple operational scenarios and their variations, where the SIF vector will be able to provide better results by managing numerous attributes capable of refining the level of correlation.

5. Analysis and Results

A correlation vector SIF has been used for a better prescription of failure effects in an electric substation. To make an analysis of the problem, a root cause analysis or bottom-up approach was used. The approach provided a complete analysis of the substation’s weaknesses and the possible impact of different types of failures.

This is demonstrated by the way it incorporates a number of factors, such as the resilience and loss exposure criterion, into a more comprehensive assessment of systemic impact. The approach is multi-dimensional and differs from conventional methods that could focus on singular factors such as failure frequency or degree and consequences, without taking into consideration the interactions among elements in a substation.

The SIF provides an improved perspective than other approaches when looking at substations as a whole. The SIF considers a variety of elements, including economic loss, network robustness, and reliability measurements, in contrast to other systems that focus more on a single or small set of reliability indicators. When maintenance managers adopt a holistic viewpoint, they may make informed decisions about the best maintenance practices by using continuous data and successfully intervening.

The SIF was implemented in the use case as expected, producing a list of components that were prioritized and potentially have an impact on the substation’s performance. It is clear from the study’s results that the high SRN value components, in fact, directly affected the substation’s dependability and service quality. These results provide confidence to the notion that when determining how to best distribute resources and make maintenance decisions, it is essential to take into account projected failure repercussions from a systemic perspective.

The use case’s obtained experimental outcomes highlight SIF’s effectiveness in improving failure impact prescription. It can consider the operational mode of the substation that it was initially designed for. Also, it can consider the relevance of the substation operation. For example, it accounts for the degree to which customers may be dissatisfied with their services being interrupted.

All things considered, the SIF is a useful method for determining the impact of a component failure from the perspective of the entire electrical substation. Since it may consider several aspects and make adjustments based on current information, this technique appears to be preferable to alternative options. The result is effective maintenance strategies with improved operational resilience.

6. Discussion

The application of this approach to electrical substations is even more significant if it utilizes advances in model analysis techniques. Further development may consider a correlation vector that takes into account aspects, such as loss exposure, network strength, and social importance. By considering such an approach, the SIF methodology can perform multi-criteria and customized analysis of possible effects from component failures. It gives a complete picture of performance, and stations that are weak or defective can be responded to or attended to immediately. In this sense, it should be noted that SIF complements the current methodologies of criticality analysis, not replaces them, since these have proven to be very effective in obtaining a first strategic approximation. Without prejudice to this, SIF provides a perspective that aims to become the next step, supported by digitalization and the ability to obtain data on demand; the high degree of parameterization provides an almost instantaneous ability to assess risk, much more dynamically and accurately than traditional approaches.

Taking into account the two factors mentioned by Fox et al. [2], until now, the frequency can be predicted by traditional statistical methods, which in future research may be replaced by machine learning algorithms that learn the patterns of behavior. On the other hand, the targeting of recommendations will no longer be at the level of the substation but can be focused directly on the components with high criticality. Moreover, given the complexity of some of the factors that depend on highly variable conditions, the attributes of the SIF vector themselves can also be used to improve the estimation of the impact on the system, leading to an improvement in prescriptive capacities.

The current study also made clear that, in order to better support SIF, future research should attempt to develop even more comprehensive data collection and analysis strategies. Further research could focus on how to combine SIF with predictive maintenance systems in order to develop a comprehensive solution for managing substations. This work also serves as an indication of future trends.

Compared with past research, this study confirms that a rational approach to the reduction in risk can help in making decisions regarding both resource allocation and safety. The study’s outcome is that SIF not only can be extended to other kinds of networks but also to critical infrastructures that are connected. In the end, SIF is contributing greatly to electric substation maintenance and reliability analysis. It could also serve as a model of how engineering policy drives technological advancement in developing resilient, sustainable energy systems.

7. Conclusions

The research into the SIF as a support tool for evaluating the grid impact of component failure has provided solid groundwork in terms of understanding the significance of components within systems. The motivation has been to enhance the reliability and safety of electric power systems through a comprehensive knowledge of substation dynamics and the development of customized maintenance plans. For that reason, the purpose of the study is to raise the level of stability and reliability in our electrical network by improving current maintenance and risk management. The study uses a multi-criteria framework that considers various types of impacts of failure, mainly loss exposure level, safety factor, network resilience, and social significance, defining the vector SIF. This methodology has been applied to a real case study, considering the interdependencies of operational systems at substations and revealing strengths in critical assets that can be prioritized.

This research has real-world applications for the energy industry (especially for asset management and maintenance efficiency). SIF methodology enables utility firms to better anticipate failure effects, decide on repair priorities, and make more effective use of personnel and materials. This means that failure recovery is more effective, resulting in increased customer satisfaction and low downtimes, as well as high service reliability. As part of the larger field of analysis related to criticality in network utilities, this research offers a model that attempts to reflect the dynamic nature at work among components within a given system.

The study advances electrical engineering and energy conversion system diagnosis. In addition to promoting engineering policy through experimentation and theoretical validity, this proposal provides a step forward for technological innovation in the development of robust and sustainable energy systems. Further research directions include making the SIF approach even more fluid by improving data acquisition procedures. Moreover, the SIF can be combined with analytic algorithms to continue raising maintenance management standards.

Author Contributions

Conceptualization, M.R. and V.G.-P.; methodology, M.R..; software, M.R.; validation, A.C.; formal analysis, M.R.; investigation, V.G.-P.; resources, M.R.; data curation, M.R.; writing—original draft preparation, V.G.-P.; writing—review and editing, M.R., V.G.-P. and A.C.; visualization, M.R.; supervision, A.C.; project administration, M.R. All authors have read and agreed to the published version of the manuscript.

Funding

This work has been developed as part of the AMADIT Project (PID2022-137748OB-C32), funded by MCIN/AEI/10.13039/501100011033/FEDER, EU.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Nepal, B.; Yadav, O.; Monplaisir, L.; Murat, A. A framework for capturing and analyzing the failures due to system/component interactions. Qual. Reliab. Eng. Int. 2008, 24, 265–289. [Google Scholar] [CrossRef]

- Fox, H.; Pillai, A.C.; Friedrich, D.; Collu, M.; Dawood, T.; Johanning, L. A Review of Predictive and Prescriptive Offshore Wind Farm Operation and Maintenance. Energies 2022, 15, 504. [Google Scholar] [CrossRef]

- Crespo Márquez, A. Driving the Introduction of Digital Technologies to Enhance the Maintenance Management Process and Framework BT—Digital Maintenance Management: Guiding Digital Transformation in Maintenance; Crespo Márquez, A., Ed.; Springer International Publishing: Cham, Switzerland, 2022; pp. 25–30. [Google Scholar] [CrossRef]

- Chemweno, P.; Pintelon, L.; Meyer, A.; Muchiri, P.; Horenbeek, A.; Wakiru, J. A Dynamic Risk Assessment Methodology for Maintenance Decision Support. Qual. Reliab. Eng. Int. 2017, 33, 551–564. [Google Scholar] [CrossRef]

- Martínez-Galán, P.; Gómez, J.F.; Crespo, A.; Guillén, A.; de la Fuente, A.; Candón, E. Criticality analysis for network utilities asset management. IFAC-PapersOnLine 2019, 52, 2074–2079. [Google Scholar] [CrossRef]

- Gao, J.; Liu, X.; Li, D.; Havlin, S. Recent Progress on the Resilience of Complex Networks. Energies 2015, 8, 12187–12210. [Google Scholar] [CrossRef]

- Guo, L.; Gao, J.; Yang, J.; Kang, J. Criticality evaluation of petrochemical equipment based on fuzzy comprehensive evaluation and a BP neural network. J. Loss Prev. Process Ind. 2009, 22, 469–476. [Google Scholar] [CrossRef]

- Lund, H.; Arler, F.; Østergaard, P.A.; Hvelplund, F.; Connolly, D.; Mathiesen, B.V.; Karnøe, P. Simulation versus optimisation: Theoretical positions in energy system modelling. Energies 2017, 10, 840. [Google Scholar] [CrossRef]

- Crespo Márquez, A. Benefits of Digital Transformation for Maintenance Management Systems. Market Trends. In Springer Series in Reliability Engineering; Springer Science and Business Media Deutschland GmbH: Berlin, Germany, 2022; pp. 3–11. [Google Scholar] [CrossRef]

- Palmintier, B.; Webster, M. Impact of Operational Flexibility on Electricity Generation Planning With Renewable and Carbon Targets. IEEE Trans. Sustain. Energy 2016, 7, 672–684. [Google Scholar] [CrossRef]

- Bell, K.; Gill, S. Delivering a highly distributed electricity system: Technical, regulatory and policy challenges. Energy Policy 2018, 113, 765–777. [Google Scholar] [CrossRef]

- Liu, B.; Lin, J.; Zhang, L.; Kumar, U. A dynamic prescriptive maintenance model considering system aging and degradation. IEEE Access 2019, 7, 94931–94943. [Google Scholar] [CrossRef]

- Bertsimas, D.; Kallus, N. From predictive to prescriptive analytics. Manag. Sci. 2020, 66, 1025–1044. [Google Scholar] [CrossRef]

- Koops, L.G. Optimized maintenance decision-making—A simulation-supported prescriptive analytics approach based on probabilistic cost-benefit analysis. PHM Soc. Eur. Conf. 2020, 5, 14. [Google Scholar]

- Karim, R.; Westerberg, J.; Galar, D.; Kumar, U. Maintenance analytics–the new know in maintenance. IFAC-PapersOnLine 2016, 49, 214–219. [Google Scholar] [CrossRef]

- Matyas, K.; Nemeth, T.; Kovacs, K.; Glawar, R. A procedural approach for realizing prescriptive maintenance planning in manufacturing industries. CIRP Ann. 2017, 66, 461–464. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).