Abstract

The current goal of the European Commission, which aims to reduce CO2 by 90% compared to values estimated in 1980, and the ever-increasing sensitivity to environmental sustainability, fully involve the construction sector, which, according to the OECD (Organization for Economic Co-Operation and Development) is responsible for over one-third of the world’s energy requirement. In this frame, numerous researchers and companies are focusing on ecologically sustainable building materials, to be used in new and existing buildings, that are able to simultaneously fulfill the constructive function and improve the energy behavior of the building envelope. The goal of the present paper is the analysis of the energy performance of some innovative locally produced natural building materials (timber, sheep wool, rammed earth, lime-based plaster, natural fibers) used in multilayer vertical closures, compared to that of more common building materials (bricks, concrete, synthetic insulation). First, the physical-mechanical characterization of the local natural materials was carried out, then the model of a building was implemented, whose energetic performance was simulated by varying the type of stratigraphy of the walls, including the use of both innovative and common materials. The building chosen for the simulation consists of one of the BESTEST ANSI/ASHRAE reported in the 140-2017 standard using the climatic data of the Mediterranean area. The results of the simulation have been presented and discussed.

1. Introduction

The concept of eco-efficiency in architecture indicates the capacity of a building or urban district to attain the achievement, production and supply objectives of goods and services using less and less resources and creating less and less waste and pollution [1,2,3,4]. For understanding the level of eco-efficiency of a particular ecosystem, it is important to consider the following three factors:

- the flow of matter, energy and information that is determined in that reality;

- the interdependence of the organisms that live in that reality;

- the effectiveness of material and intangible transfers that take place between the various levels of their organization.

According to the WBCSD (World Business Council for Sustainable Development), eco-efficiency can be pursued by providing products and services at competitive prices that meet human needs by increasing the quality of life with less consumption of natural resources and a progressively minor ecological impact. The strategies to achieve eco-efficiency are, on the one hand, to reduce the dispersion of toxic and waste materials in general and, on the other, to increase the recyclability of materials and waste, the use of renewable resources, and the duration of the components.

Some studies have highlighted how the use of sustainable materials is linked to the actual possibility of finding substitute materials to those commonly used [5]. Other studies have also highlighted that the production and use of sustainable materials is linked to cost, performance, and possible subsidies for their production or use [4].

Recent trends in eco-sustainability highlighted that in the construction sector, particularly housing, the use of building materials of natural origin, both vegetable and animal, is increasing, as these materials are seen as cost-effective, energy efficient, and healthy [6]. The use of natural building materials is often linked to the opportunity for local production, and therefore to the possibility of enhancing local production chains and the circular economy, with consequent benefits in terms of environmental, economic, and social sustainability. Natural building materials can be used directly as load-bearing structural materials, as in the case of timber buildings [7,8] and earth brick masonry [9,10], as external reinforcing elements for other load-bearing materials [11,12,13,14,15,16,17], as additives to improve the performance of other materials [18,19,20], and as insulating materials, as in the case of cork [21], sheep wool [22], wood-derived panels [23], earth-derived elements [24], etc. [17].

Despite their specific qualities, and the benefit they can bring in terms of sustainability, natural materials are not widespread in the construction sector, and conventional materials are still predominantly used. That depends on various factors, including the inadequacy of the related standards, the inefficiency of the production chains, and the non-competitive cost, due to the current low demand, the feeling that these materials, being natural, are subject to greater deterioration than conventional ones, and cannot meet the same performance requirements.

In this regard, in 2020 the European Commission launched the Renovation Wave Strategy [25], a program to improve the energy performance of buildings. This strategy assumes that minimizing the footprint of buildings requires resource efficiency and circularity combined with turning parts of the construction sector into a carbon sink, for example, through the promotion of green infrastructure and the use of organic building materials that can store carbon, such as sustainably sourced wood. The main actions of the strategy include the need to expand the market for sustainable construction products and services, also by integrating new materials and nature-based solutions and promoting their use.

This paper fits into this context, presenting the results of research aimed at evaluating the performance of some innovative natural materials of local production used in wall stratigraphy and comparing them with those of conventional materials. First, the determination, experimental or based on the literature, of the main physical-mechanical characteristics of various natural materials of potential interest for the study was carried out, then a building model was implemented, and the numerical simulation of its energy performance was carried out as the stratigraphy of the walls was varied. As part of the simulation, stratigraphies consisting entirely of natural materials, stratigraphies consisting exclusively of conventional materials, and mixed stratigraphies were considered. The building chosen for the simulation consists of one of the BESTEST ANSI/ASHRAE reported in the 140-2017 standard [26,27] using the climatic data of the Mediterranean area.

In general, the simulation highlights that the performance of walls with innovative natural materials layers and that of walls with conventional materials layers does not vary appreciably in terms of the thermal energy required for heating or cooling. This technical aspect adds to the sustainability associated with the use of locally produced natural building materials. Natural building materials use row materials already present in nature and not deriving from industrial processes often very harmful for the environment, thus they contribute to the reduction of Carbon Footprint [28,29,30]. The choice to build with natural materials falls within the interventions aimed at reducing CO2 emissions, enhancing the activities of social and environmental responsibility [31]. In fact, many synthetic materials used in buildings require significant quantities of energy and resources to be produced, which can contribute to Greenhouse Gas emissions [32,33,34]. Natural materials, on the other hand, often come from renewable resources and their production process is generally less energy demanding. During the construction phase these materials also cause less pollution from the construction site [34]. Furthermore, the use of natural materials can help reduce the amount of waste generated during the construction process since they can be recycled, reused, or disposed of more easily than synthetic alternatives [34,35]. The use of natural materials contributes to supporting biodiversity, as they come from sustainable forests and other ecologically sensitive areas, which are the subject of strict environmental compensation actions [34,36]. Obviously, since in some cases these materials may be sensitive to parasites present in nature, in this case it is necessary to apply suitable and effective production and stabilization processes.

The study developed in this work analyzed the use of natural materials taking into account the legislative context in force in the Italian national territory. The Italian legislation, based on the receipt of the various European directives that, starting from 2002/91/EC, have followed [37,38,39], does not provide for most of the works on new or existing assessments an energy–environment balance. Most of the checks are based on the energy, balanced only by following what is reported in the ISO 13790 technical standard [40]. The calculation model created through the use of a BIM platform (Building Information Modeling) [41,42,43,44], based on national legislation, has consequently obtained results based on the energy budget only. These results do not take into account, for example, an analysis of the life cycle (Life Cycle Assessment, LCA) of the materials, an aspect developed by numerous authors for these types of materials [45,46,47], even with the use of BIM [48,49,50,51]. The choice of this evaluation is made as a consequence of the fact that on the national scene, to date, the evaluations on energy transfers do not consider energy–environment efficiency indicators that take into account the energy cost for the production of the materials used. Today in Italy, there is no national procedure that allows you to evaluate the advantages in the use of natural materials and which considers this in the energy classification provided for by national laws. Some local regulations are exceptions, such as the province of Bolzano, which applies the Clima House protocol. The LCA is a very useful tool for evaluating the environmental impact of building materials along the entire life cycle, including production, use, and disposal. The LCA should be carried out as soon as possible in the design process. This is because it allows you to carry out aware and informed assessments regarding which product is actually most suitable for a building for which sustainability is an objective. Furthermore, starting from 2030, the Directive on the Energy Performance of Buildings (EPBD) [39] of the European Union will require the quantification of total emissions (Whole-Life Carbon, WLC) for new buildings, making LCA even more relevant. It is remembered, however, as aforementioned, that the adoption of LCA in construction in Italy is still limited. To perform an analysis of the life cycle (LCA) of a building material, several pieces of data are needed. In particular, data on materials and processes are needed; these data, which can be obtained from databases such as Ecoinvent [52], are necessary to calculate the embodied carbon of materials and processes present in a project. Currently these data are not available for the materials analyzed, since they are not coded for production at an industrial level.

2. Materials and Stratigraphies

2.1. Base Materials

The study involved both innovative locally sourced natural building materials and building materials already available in the market. In detail, the natural locally sourced materials selected for the study are the following:

- Cross Laminated Timber (CLT) panels of Sardinian Maritime Pine as load-bearing material;

- Sheep wool and Rammed Earth-based panels, with added natural fibers, as insulating materials;

- Lime-based plaster, also with added natural fibers, and Sardinian Maritime Pine boards, as finishing.

These materials are sourced locally in the island of Sardinia, Italy, to guarantee an ecological and circular approach to resource management, and have been studied in the framework of a dedicated research project called PLES (Local Products for Sustainable Buildings) [6].

Table 1 shows the main characteristics of the materials involved in the study. Data concerning innovative natural locally sourced materials were obtained either from the PLES experimental activity [53] or from the literature [54,55,56], whereas data concerning materials already commercially available were inferred either from the producer or from experimental tests.

Table 1.

Physical and mechanical properties of materials.

2.2. Stratigraphies

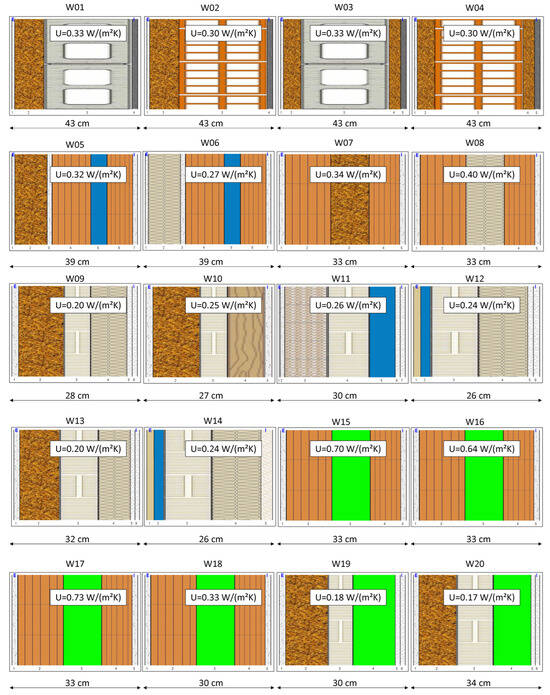

Base materials described in Table 1 have been combined to obtain 20 stratigraphies to be analyzed by numerical simulation, as shown in Figure 1. Table 2 shows the composition of the stratigraphies in terms of materials, layer disposition from outside to inside, and layer thickness.

Figure 1.

Walls stratigraphies used in the numerical simulation modeling.

Table 2.

Composition and layer thickness of the stratigraphies.

Figure 1 exhibits the twenty types of walls studied. The types from W01 to W06 represent typical walls used in Sardinia in the buildings where it is possible to intervene to improve the thermal insulation performance with an external and/or internal insulating coating, as shown in the drawings of the aforementioned examples. The types from W09 to W14 and W19 to W20 represent walls with structural wood to be used in new buildings while the types from W07 to W08 and from W15 to W18 represent new walls to be used on new constructions that put together natural materials and traditional materials.

Table 3 shows the main energetic characteristics of the building stratigraphies considered in the simulation model. The performance data of the stratigraphies have been obtained either from calculations according to standards or from the literature [53,63,64]. It is worth noting that the set of stratigraphies considered for the numerical simulation includes stratigraphies consisting of natural materials, chosen among those illustrated in Table 1, stratigraphies consisting of conventional materials, and mixed stratigraphies of natural and conventional materials.

Table 3.

Energetic and acoustic properties of building stratigraphies.

The standards to which reference has been made for the calculation of the parameters in Table 3 are the following:

- Frontal mass Ms;

- Thermal transmittance U [65];

- Periodic thermal transmittance YIE [66];

- Noise insulation index Rw [67];

- Vapor permeance Π [61];

- Internal thermal capacity for square meter k1 [66].

2.3. Numerical Simulation

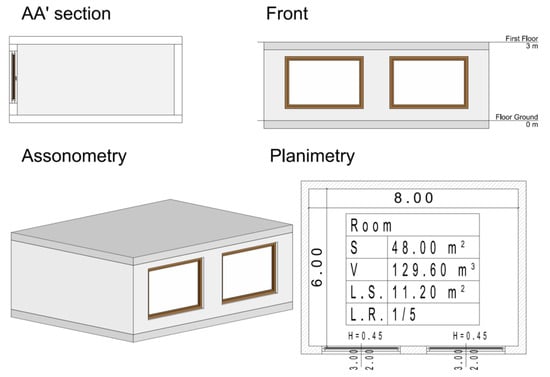

The energetic performance of the stratigraphies shown in Table 2 has been analyzed and compared with reference to the case study BEST CASE ANSI/ASHARE Standard 140-2017 140 [26], whose characteristics are shown in Figure 2. Figure 2 shows the volume, the surface of the windows, and the size of the building taken as reference for calculations. The ratio between the surface of the windows and the surface of the floor is also reported.

Figure 2.

Axonometric view and planimetric view of the BEST CASE ANSI/ASHARE Standard 140-2017 140 [26].

The simulation model used is that provided at the European level, based on the UNI EN ISO 13790 standard [40], adapted to the national climatic type of Italy and validated by the CTI (Italian thermotechnical committee).

The model evaluates the energy needs of the building for winter and summer air conditioning. The requested data are, summarily, the thermo-energy properties of the materials, the stratigraphies, the climatic data, the geometry of the building, and its orientation. For the thermo-energy data of the materials, those of the natural materials investigated experimentally in the laboratories of the University of Cagliari [53,57] and those present in the various technical standards [58,59,60] of reference in the Italian territory have been used.

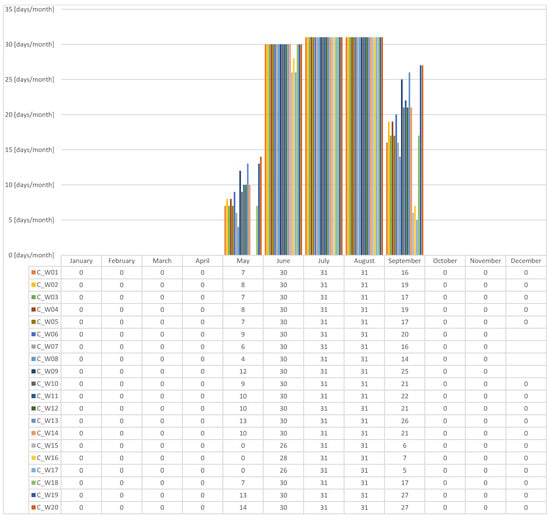

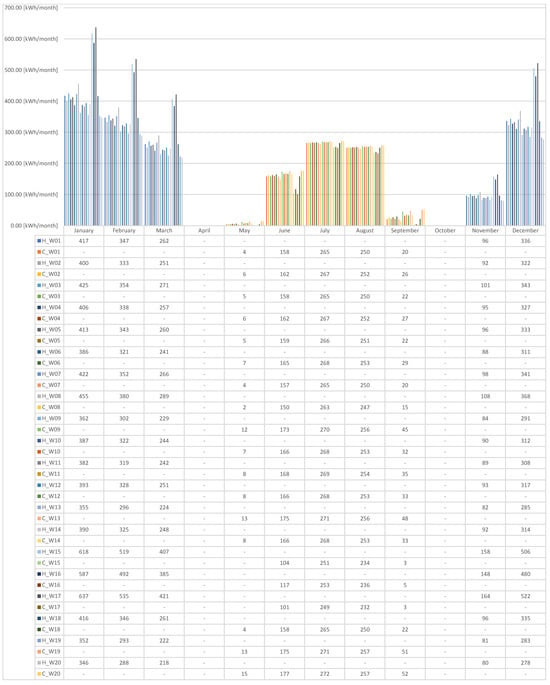

The numerical simulation consists in calculating the ideal energy needs for both heating and cooling the internal environment as a function of the various wall stratigraphies. The simulation was performed considering a set point temperature of the internal air equal to 20 °C in winter and 26 °C in summer. For the external climate, the data of the National Technical Standard of the UNI 10349 series [68,69,70] were taken as a reference considering the Mediterranean climate of the City of Cagliari in Sardinia, Italy. The simulation was carried out on each of the twenty stratigraphies described in Table 2 and Figure 1. The number of days when the intervention of the plant system is needed to maintain the set point temperature both for cooling (Figure 3) and heating (Figure 4) has been calculated. Finally, the needs of the ideal monthly energy have been calculated for both cooling and heating (Figure 5). The simulation assumes an absorption coefficient of solar thermal radiation, as defined by ISO 13786 [66], equal to 0.3 for light-colored surfaces. In this study, only the ideal energy requested by the internal environments to maintain the thermo-hygrometric conditions of the project has been evaluated, and the use of a plant system for the generation of thermal or cooling energy has not been accounted for.

Figure 3.

Comparison of the number of cooling days needed to obtain the set point temperature, as a function of the stratigraphies.

Figure 4.

Comparison of the number of heating days needed to obtain the set point temperature, as a function of the stratigraphies.

Figure 5.

Comparison of monthly energy request for heating and cooling.

3. Results and Discussion

The results obtained from the numerical simulation are shown in Figure 3, Figure 4 and Figure 5 in which the days of cooling, days of heating, and monthly energy request for heating and cooling are reported.

Figure 3 clearly shows that the number of days when cooling energy is required is quite similar for the stratigraphies. The stratigraphy that requires the action of cooling systems for a higher number of days is W13, with 131 days/year, while the one that requires it for the lowest number is W08, with 110 days/year.

Figure 4 shows the number of days when it is necessary to heat the room to reach an internal temperature of 20 °C according to Italian national legislation. The W08 stratigraphy requires the action of heating systems for the highest number of days, 174 days/year, while the W13 stratigraphy requires it for the lowest number of days, 167 days/year.

Figure 5 shows the monthly request for energy. It can be noted that stratigraphy W08 needs Qc = 676 kWh/year for an ideal energy request for cooling during the summer and Qh = 1600 kWh/year for heating during the winter, while stratigraphy W13 needs Qc = 676 kWh/year for an ideal energy request for cooling during the summer and Qh = 1600 kWh/year for heating during the winter. Thus, stratigraphy W08 is better performing than W13 in the cooling period, while stratigraphy W13 is better performing than W08 during the heating period.

The results obtained from the numerical simulations clearly highlight the role played by the mass of the structures in minimizing or maximizing the energy request for heating and cooling, as shown by walls W08 and W13. Figure 3 shows that in May (cooling period) W08 requires only four days of air conditioning to reach the set point temperature, while in the same period W13 requires thirteen days of air conditioning. Figure 4 shows that in October (heating period) the situation is reversed, as W08 requires two days of heating system intervention while W13 requires zero days. This behavior is specific to considered stratigraphy according to the distribution of the mass of the insulation layer. At the same time, an important role in finding a solution that balances the envelope performance in the periods of heating and cooling is played by the position of the insulating layer, or layers, within the stratigraphy. A stratigraphy that balances the two aspects well is W04, which has insulating layers both on the external and internal side of the wall.

In summary, the use of natural building materials can bring numerous benefits for the well-being of the occupants, the environment, and the local economy. By incorporating these materials in the construction process, healthier and more sustainable buildings that offer an ideal living space for occupants, respecting the environment, can be built.

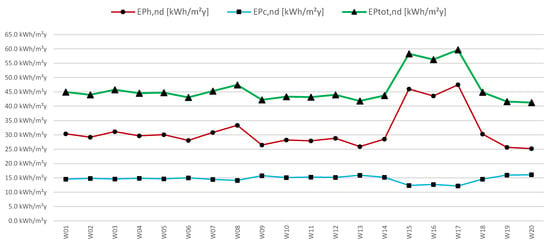

Figure 6 shows the trend in the ideal energy needs required by envelopes with different stratigraphies as studied in the cases of winter heating, summer cooling, and total needs. From the graph it is observed that the summer cooling needs are lower than that of winter heating and are less influenced by the transmittance of the walls.

Figure 6.

Comparison of primary energy need to square meters per year for heating, cooling, and total with the different walls used.

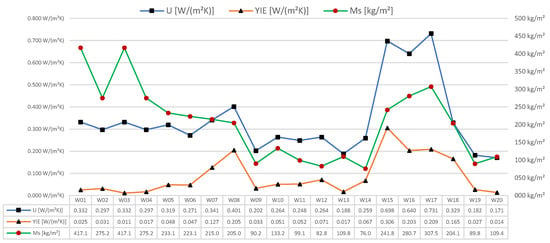

On the contrary, winter needs follow the variation in the transmittance of the different walls. This can be observed from the graphs reported, respectively, in Figure 6 and Figure 7. Figure 7 shows the variation in the performance of the different stratigraphies from the point of view of thermal transmittance, the periodic thermal transmittance, and the surface mass of the walls studied. From the trend of the three parameters, it can be seen how the variation in the surface mass of the wall affects the trend of both thermal transmittance and periodic thermal transmittance.

Figure 7.

Comparison of thermal transmittance, periodic thermal transmittance, and superficial mass of the walls.

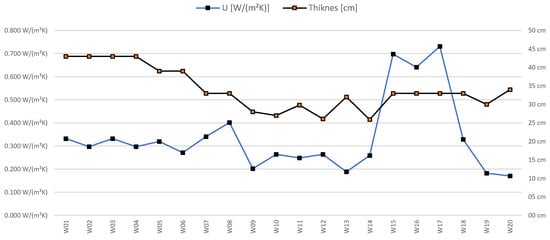

Figure 8 shows how the thermal transmittance varies according to the different thicknesses of the different types of walls used in the simulations. It can be seen that thickness and the performance in terms of isolating thermal performance do not have a direct correlation, in fact, it can be observed that the reduced thickness walls such as W09, W10, W11, and W12, have the lowest values of transmittance between the twenty types of walls examined.

Figure 8.

Comparison of thermal transmittance and thickness of the walls.

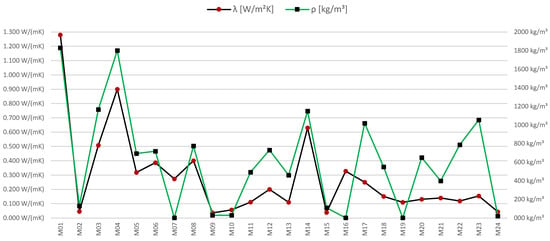

Finally, in Figure 9 the comparison between the thermal conductivity of the different materials used and their density is shown. It can be observed that some of the used materials have thermal conductivity values strongly influenced by density (for example see M01 or M02), while others such as M11, M12, M22, and M23 are influenced much less.

Figure 9.

Comparison of thermal conductivity and density of materials used in to energy simulations for the walls.

Indeed, the thermal performance of natural materials is not extremely high if compared with other non-natural materials. However, in any case, it must be considered that the values found are also good. Furthermore, if further aspects are taken into account, such as environmental goals that are not a focus in this work, there is undoubtedly an advantage in their use.

4. Conclusions

In this paper, the use of innovative locally sourced natural building materials has been evaluated from the point of view of energy performance. A numerical simulation aimed at evaluating the energy request of the case study BEST CASE ANSI/ASHARE Standard 140-2017 140 for reaching, by heating or cooling, an internal set point temperature typical of the Mediterranean climate has been implemented.

The numerical simulation has been performed for 20 different walls that include stratigraphies consisting entirely of natural materials, stratigraphies consisting exclusively of conventional materials, and mixed stratigraphies. The output of the numerical simulation is the number of days per month when the use of heating/cooling systems is necessary to reach the fixed internal set point temperature, together with the energy monthly request.

Results can be summarized as follows.

- The surface mass of the building element and the position of the insulating layers within the wall play a crucial role in the energy performance of the wall.

- For the Mediterranean climate assumed in the simulations, a building solution based on the W04 typology best balances the needs of heating and cooling energy in a building used 365 days/year; the result could change if the building is used mainly in the winter or summer.

- In general, the performance of walls with innovative natural materials layers and that of walls with conventional materials layers does not vary appreciably in terms of the thermal energy required for heating or cooling.

Only the ideal energy requested by the internal environments to maintain the chosen thermo-hygrometric conditions has been evaluated, and the use of a system for the generation of thermal or cooling energy has not been accounted for. This aspect will be addressed in future research with the aim of maximizing the self-consumption of energy produced by a RES (Renewable Energy Source) during the air conditioning of the internal environments.

In conclusion, from the point of view of the energy balance applied to the building only, natural and traditional materials did not show significative difference in terms of energy needs for heating in the winter and cooling in the summer. In fact, the need for energy, evaluated according to the legislative procedures that most of the buildings must today follow in Italy, was very similar. To appreciate the global advantages that natural materials can give, it is necessary that the verification and certification procedures turn to the environmental energy aspects by evaluating the reduced emissions for their production through the analysis of the life cycle. In our case, however, there are some situations in which it may not be convenient to perform an LCA:

Lack of data: An LCA requires a large amount of accurate data. If enough data is not avaliable, or if the available data is not reliable, the LCA may not provide precise results.

High costs: LCA can be expensive in terms of time and resources. If the benefits expected from an LCA do not justify the costs, it may not be convenient to perform it.

Complexity of the product: If the product or service is extremely complex, with many different components and complicated production processes, the LCA could become too complex and difficult to manage. The materials studied are currently in the state of prototype and have no codified production processes, consequently it has been chosen not to perform the LCA as this could lead to conflicting results. This analysis will be performed in the future when research development has clearly coded production processes and supply for raw materials, which today are not known for our materials.

Author Contributions

Conceptualization, C.C.M., G.C. and A.F.; methodology, C.C.M., G.C. and A.F.; numerical analysis, C.C.M.; investigation, C.C.M. and G.C.; data curation, C.C.M. and G.C.; writing—original draft preparation, C.C.M. and G.C.; writing—review and editing, C.C.M., G.C. and A.F.; funding acquisition, G.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by POR FESR 2014/2020—ASSE PRIORITARIO I “RICERCA SCIENTIFICA, SVILUPPO TECNOLOGICO E INNOVAZIONE”, CUP F21B17000750005”, and This study was carried out within the “e.INS—Ecosystem of Innovation for Next Generation Sardinia”, funded by the Italian Ministry of University and Research under the Next-Generation EU Programme (National Recovery and Resilience Plan—PNRR, M4C2, INVESTMENT 1.5—DD 1056 of 23 June 2022, ECS00000038), and the “NEST-Network 4 Energy Sustainable Transition”, funded by the Italian Ministry of University and Research under the Next-Generation EU Programme (National Recovery and Resilience Plan). This manuscript reflects only the authors’ views and opinions, neither the European Union nor the European Commission can be considered responsible for them.

Data Availability Statement

The data presented in this study are available on request from the corresponding authors. The data have not been included for not weighing the paper.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Cicconi, P. Eco-Design and Eco-Materials: An Interactive and Collaborative Approach. Sustain. Mater. Technol. 2020, 23, e00135. [Google Scholar] [CrossRef]

- Dahmani, N.; Benhida, K.; Belhadi, A.; Kamble, S.; Elfezazi, S.; Jauhar, S.K. Smart Circular Product Design Strategies towards Eco-Effective Production Systems: A Lean Eco-Design Industry 4.0 Framework. J. Clean. Prod. 2021, 320, 128847. [Google Scholar] [CrossRef]

- Lambrechts, W.; Gelderman, C.J.; Semeijn, J.; Verhoeven, E. The Role of Individual Sustainability Competences in Eco-Design Building Projects. J. Clean. Prod. 2019, 208, 1631–1641. [Google Scholar] [CrossRef]

- Yu, H.; Chang, X.; Liu, W. Cost-Based Subsidy and Performance-Based Subsidy in a Manufacturing-Recycling System Considering Product Eco-Design. J. Clean. Prod. 2021, 327, 129391. [Google Scholar] [CrossRef]

- Spreafico, C. Can TRIZ (Theory of Inventive Problem Solving) Strategies Improve Material Substitution in Eco-Design? Sustain. Prod. Consum. 2022, 30, 889–915. [Google Scholar] [CrossRef]

- Nowotna, A.; Pietruszka, B.; Lisowski, P. Eco-Friendly Building Materials. IOP Conf. Ser. Earth Environ. Sci. 2019, 290, 012024. [Google Scholar] [CrossRef]

- Kuzman, M.K.; Sandberg, D. A New Era for Multi-Storey Timber Buildings in Europe. In Proceedings of the 70th Forest Products Society International Convention, Portland, OR, USA, 26–29 June 2016; p. 7. [Google Scholar]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross Laminated Timber (CLT): Overview and Development. Eur. J. Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- Han, L.C.; Bin Mirasa, A.K.; Saad, I.; Bt. Bolong, N.; Bt. Asman, N.S.A.; Bte Asrah, H.; Bin Abdullah, E.S.R. Use of Compressed Earth Bricks/Blocks in Load-Bearing Masonry Structural Systems: A Review. Mater. Sci. Forum 2020, 997, 9–19. [Google Scholar] [CrossRef]

- Miccoli, L.; Müller, U.; Fontana, P. Mechanical Behaviour of Earthen Materials: A Comparison between Earth Block Masonry, Rammed Earth and Cob. Constr. Build. Mater. 2014, 61, 327–339. [Google Scholar] [CrossRef]

- Meybodian, H.; Eslami, A.; Morshed, R. Sustainable Lateral Strengthening of Traditional Adobe Walls Using Natural Reinforcements. Constr. Build. Mater. 2020, 260, 119892. [Google Scholar] [CrossRef]

- Valdes, M.; Giaccu, G.F.; Meloni, D.; Concu, G. Reinforcement of Maritime Pine Cross-Laminated Timber Panels by Means of Natural Flax Fibers. Constr. Build. Mater. 2020, 233, 117741. [Google Scholar] [CrossRef]

- Chen, C.; Yang, Y.; Zhou, Y.; Xue, C.; Chen, X.; Wu, H.; Sui, L.; Li, X. Comparative Analysis of Natural Fiber Reinforced Polymer and Carbon Fiber Reinforced Polymer in Strengthening of Reinforced Concrete Beams. J. Clean. Prod. 2020, 263, 121572. [Google Scholar] [CrossRef]

- Majumder, A.; Stochino, F.; Farina, I.; Valdes, M.; Fraternali, F.; Martinelli, E. Physical and Mechanical Characteristics of Raw Jute Fibers, Threads and Diatons. Constr. Build. Mater. 2022, 326, 126903. [Google Scholar] [CrossRef]

- Majumder, A.; Stochino, F.; Frattolillo, A.; Valdes, M.; Fraternali, F.; Martinelli, E. Sustainable Building Material: Recycled Jute Fiber Composite Mortar for Thermal and Structural Retrofitting. In Computational Science and Its Applications—ICCSA 2022 Workshops; Gervasi, O., Murgante, B., Misra, S., Rocha, A.M.A.C., Garau, C., Eds.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Switzerland, 2022; Volume 13379, pp. 657–669. ISBN 978-3-031-10544-9. [Google Scholar]

- Majumder, A.; Farina, I.; Stochino, F.; Fraternali, F.; Martinelli, E. Natural Fibers Reinforced Mortars: Composition and Mechanical Properties. Key Eng. Mater. 2022, 913, 149–153. [Google Scholar] [CrossRef]

- Majumder, A.; Stochino, F.; Frattolillo, A.; Valdes, M.; Mancusi, G.; Martinelli, E. Jute Fiber-Reinforced Mortars: Mechanical Response and Thermal Performance. J. Build. Eng. 2023, 66, 105888. [Google Scholar] [CrossRef]

- Shadheer Ahamed, M.; Ravichandran, P.; Krishnaraja, A.R. Natural Fibers in Concrete—A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1055, 012038. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Cruz, A.S.A.; Marvila, M.T.; de Oliveira, L.B.; Monteiro, S.N.; Vieira, C.M.F.; Fediuk, R.; Timokhin, R.; Vatin, N.; Daironas, M. Natural Fibers as an Alternative to Synthetic Fibers in Reinforcement of Geopolymer Matrices: A Comparative Review. Polymers 2021, 13, 2493. [Google Scholar] [CrossRef] [PubMed]

- Vatani Oskouei, A.; Afzali, M.; Madadipour, M. Experimental Investigation on Mud Bricks Reinforced with Natural Additives under Compressive and Tensile Tests. Constr. Build. Mater. 2017, 142, 137–147. [Google Scholar] [CrossRef]

- Gil, L. Cork. In Materials for Construction and Civil Engineering; Gonçalves, M.C., Margarido, F., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 585–627. ISBN 978-3-319-08235-6. [Google Scholar]

- Zach, J.; Korjenic, A.; Petránek, V.; Hroudová, J.; Bednar, T. Performance Evaluation and Research of Alternative Thermal Insulations Based on Sheep Wool. Energy Build. 2012, 49, 246–253. [Google Scholar] [CrossRef]

- Czajkowski, Ł.; Olek, W.; Weres, J.; Guzenda, R. Thermal Properties of Wood-Based Panels: Specific Heat Determination. Wood Sci. Technol. 2016, 50, 537–545. [Google Scholar] [CrossRef]

- Cagnon, H.; Aubert, J.E.; Coutand, M.; Magniont, C. Hygrothermal Properties of Earth Bricks. Energy Build. 2014, 80, 208–217. [Google Scholar] [CrossRef]

- Renovation Wave: Doubling the Renovation Rate to Cut Emissions, Boost Recovery and Reduce Energy Poverty. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_20_1835 (accessed on 31 January 2024).

- ANSI/ASHRAE Standard 140-2017 (Supersedes ANSI/ASHRAE Standard 140-2014) Includes ANSI/ASHRAE Addendum listed in Annex C; Standard Method of Test for the Evaluation of Building Energy Analysis Computer Programs. American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2017.

- ANSI/ASHRAE Addendum a to ANSI/ASHRAE Standard 140-2017; Standard Method of Test for the Evaluation of Building Energy Analysis Computer Programs. American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2020.

- ISO 14064-1; Greenhouse Gases—Part 1: Specification with Guidance at the Organization Level for Quantification and Reporting of Greenhouse Gas Emissions and Removals. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 14064-2; Greenhouse Gases—Part 2: Specification with Guidance at the Project Level for Quantification, Monitoring and Reporting of Greenhouse Gas Emission Reductions or Removal Enhancements. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 14064-3; Greenhouse Gases—Part 3: Specification with Guidance for the Verification and Validation of Greenhouse Gas Statements. International Organization for Standardization: Geneva, Switzerland, 2019.

- EEA European Environment Agency. Available online: https://www.eea.europa.eu/en (accessed on 27 January 2024).

- Hasan, S.; Khan, S.; Akhtar, I.; Kirmani, S. Study of Natural Insulation Materials and Compared It with No Insulation Building. Mater. Today Proc. 2021, 46, 10692–10697. [Google Scholar] [CrossRef]

- Basu, P.; Kumar, R.; Das, M. Natural and Manmade Fibers as Sustainable Building Materials. Mater. Today Proc. 2023, S2214785323040919. [Google Scholar] [CrossRef]

- Zhao, J.R.; Zheng, R.; Tang, J.; Sun, H.J.; Wang, J. A Mini-Review on Building Insulation Materials from Perspective of Plastic Pollution: Current Issues and Natural Fibres as a Possible Solution. J. Hazard. Mater. 2022, 438, 129449. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Trabelsi, A.; El Mankibi, M. Hygrothermal Properties of Insulation Materials from Rice Straw and Natural Binders for Buildings. Constr. Build. Mater. 2023, 372, 130770. [Google Scholar] [CrossRef]

- Sabbarese, C.; Ambrosino, F.; D’Onofrio, A.; Roca, V. Radiological Characterization of Natural Building Materials from the Campania Region (Southern Italy). Constr. Build. Mater. 2021, 268, 121087. [Google Scholar] [CrossRef]

- Directive 2002/91/EC of the European Parliament and of the Council 2002. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2003:001:0065:0071:en:PDF (accessed on 27 January 2024).

- Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings. 23. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2010:153:0013:0035:EN:PDF (accessed on 27 January 2024).

- Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency. 17. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv%3AOJ.L_.2018.156.01.0075.01.ENG (accessed on 27 January 2024).

- ISO 13790; Energy Performance of Buildings-Calculation of Energy Use for Space Heating and Cooling. International Organization for Standardization: Geneva, Switzerland, 2008.

- IFC BIM-Based Methodology for Semi-Automated Building Energy Performance Simulation; CIB W78 International Conference on Information Technology; Leonardo, R., Ed.; Universidad de Talca, Departamento de Ingeniería y Gestión de la Construcción: Santiago, Chile, 2008. [Google Scholar]

- Gerrish, T.; Ruikar, K.; Cook, M.; Johnson, M.; Phillip, M.; Lowry, C. BIM Application to Building Energy Performance Visualisation and Management: Challenges and Potential. Energy Build. 2017, 144, 218–228. [Google Scholar] [CrossRef]

- Ivanova, I.; Kiesel, K.; Mahdavi, A. BIM-Generated Data Models for EnergyPlus: A Comparison of gbXML and IFC Formats; Free University of Bozen-Bolzano: Bozen-Bolzano, Italy, 4 February 2015; pp. 407–414. [Google Scholar]

- Pan, X.; Mateen Khan, A.; Eldin, S.M.; Aslam, F.; Kashif Ur Rehman, S.; Jameel, M. BIM Adoption in Sustainability, Energy Modelling and Implementing Using ISO 19650: A Review. Ain Shams Eng. J. 2023, 15, 102252. [Google Scholar] [CrossRef]

- Bruhn, S.; Sacchi, R.; Cimpan, C.; Birkved, M. Ten Questions Concerning Prospective LCA for Decision Support for the Built Environment. Build. Environ. 2023, 242, 110535. [Google Scholar] [CrossRef]

- Scherz, M.; Kreiner, H.; Passer, A. Sustainable Procurement for Carbon Neutrality of Buildings: A Life Cycle Assessment (LCA)-Based Bonus/Malus System to Consider External Cost in the Bid Price. Dev. Built Environ. 2023, 14, 100161. [Google Scholar] [CrossRef]

- Arvizu-Piña, V.A.; Armendáriz López, J.F.; García González, A.A.; Barrera Alarcón, I.G. An Open Access Online Tool for LCA in Building’s Early Design Stage in the Latin American Context. A Screening LCA Case Study for a Bioclimatic Building. Energy Build. 2023, 295, 113269. [Google Scholar] [CrossRef]

- Forth, K.; Hollberg, A.; Borrmann, A. BIM4EarlyLCA: An Interactive Visualization Approach for Early Design Support Based on Uncertain LCA Results Using Open BIM. Dev. Built Environ. 2023, 16, 100263. [Google Scholar] [CrossRef]

- Guignone, G.; Calmon, J.L.; Vieira, D.; Bravo, A. BIM and LCA Integration Methodologies: A Critical Analysis and Proposed Guidelines. J. Build. Eng. 2023, 73, 106780. [Google Scholar] [CrossRef]

- Tam, V.W.; Zhou, Y.; Shen, L.; Le, K.N. Optimal BIM and LCA Integration Approach for Embodied Environmental Impact Assessment. J. Clean. Prod. 2023, 385, 135605. [Google Scholar] [CrossRef]

- Boriskina, Y. BIM Technologies’ Effect on Transformation of a Property Life Cycle. E3S Web Conf. 2019, 91, 08030. [Google Scholar] [CrossRef]

- Ecoinvent-Not-for-Profit Association. 2024. Available online: https://Ecoinvent.Org/ (accessed on 27 January 2024).

- Concu, G.; Achenza, M.M.; Baccoli, R.; Frattolillo, A.; Innamorati, R.; Mastino, C.C.; Riu, R.; Valdes, M. Local Supply Chains and Circular Economy for Building Materials. The PLES Project in Sardinia. In Computational Science and Its Applications–ICCSA 2021; Gervasi, O., Murgante, B., Misra, S., Garau, C., Blečić, I., Taniar, D., Apduhan, B.O., Rocha, A.M.A.C., Tarantino, E., Torre, C.M., Eds.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Switzerland, 2021; Volume 12958, pp. 44–58. ISBN 978-3-030-87015-7. [Google Scholar]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Majumder, A.; Canale, L.; Mastino, C.C.; Pacitto, A.; Frattolillo, A.; Dell’Isola, M. Thermal Characterization of Recycled Materials for Building Insulation. Energies 2021, 14, 3564. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation Materials for the Building Sector: A Review and Comparative Analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Majumder, A.; Achenza, M.; Mastino, C.C.; Baccoli, R.; Frattolillo, A. Thermo-Acoustic Building Insulation Materials Fabricated with Recycled Fibers—Jute, Wool and Loofah. Energy Build. 2023, 293, 113211. [Google Scholar] [CrossRef]

- UNI 10351:2021; Materiali e Prodotti per Edilizia-Proprietàtermoigrometriche-Procedura per la Scelta dei Valori di Progetto. UNI: Rome, Italy, 2021.

- UNI 10355:1994; Murature e Solai. Valori della Resistenza Termica e Metodo di Calcolo. UNI: Rome, Italy, 1994.

- EN 1745; Masonry and Masonry Products-Methods for Determining Thermal Properties. UNI: Rome, Italy, 2020.

- ISO 13788; Hygrothermal Performance of Building Components and Building Elements—Internal Surface Temperature to Avoid Critical Surface Humidity and Interstitial Condensation—Calculation Methods. International Organization for Standardization: Geneva, Switzerland, 2018.

- CEN/TC 124 EN 14081-1:2016+A1:2019; Timber Structures-Strength Graded Structural Timber with Rectangular Cross Section—Part 1: General Requirements. CEN: Brussels, Belgium, 2019.

- Karamanos, A.; Hadiarakou, S.; Papadopoulos, A.M. The Impact of Temperature and Moisture on the Thermal Performance of Stone Wool. Energy Build. 2008, 40, 1402–1411. [Google Scholar] [CrossRef]

- Bakhshoodeh, R.; Ocampo, C.; Oldham, C. Thermal Performance of Green Façades: Review and Analysis of Published Data. Renew. Sustain. Energy Rev. 2022, 155, 111744. [Google Scholar] [CrossRef]

- ISO 6946; Building Components and Building Elements—Thermal Resistance and Thermal Transmittance–Calculation Methods. International Organization for Standardization: Geneva, Switzerland, 2007.

- ISO 13786; Thermal Performance of Building Components—Dynamic Thermal Characteristics—Calculation Methods. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 12354-1:2017; Building Acoustics—Estimation of Acoustic Performance of Buildings from the Performance of Elements—Part 1: Airborne Sound Insulation between Rooms. International Organization for Standardization: Geneva, Switzerland, 2017.

- UNI 10349-1:2016; Climatic Data—Part 1: Monthly Average for the Evaluation of the Thermo-Energy Performance of the Building and Methods to Start Solar Irradiance in the Direct and Widespread Fraction and to Calculate Solar Irradiance on an Inclined Surface. UNI: Rome, Italy, 2016.

- UNI/TR 10349-2:2016; Heating and Cooling of Buildings-Climate Data—Part 2: Project Data. UNI: Rome, Italy, 2016.

- UNI 10349-3:2016; Heating and Cooling of Buildings-Climate Data—Part 3: Differences in Cumulated Temperature (Day Degrees) and Other Synthetic Indices. UNI: Rome, Italy, 2016.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).