Abstract

The efficiency, durability, and overall performance of a car engine are influenced by several critical factors. The quality and properties of engine oil play a crucial role, and oil is used in internal combustion engines for lubrication and cooling purposes. This research study aimed to compare the impact of fullerene-C60 (99.5%), Fe2O3, and TiO2 nanoparticles on the thermal properties of C.A.L.T.E.X. red engine oil with grades 10W30, 20W40, and 20W50. This study focused on the effect of a nanoparticle concentration of 0.01 wt.% in different engine oil grades at various temperature values of 30–120 °C. The nanofluids were prepared using the two-step direct mixing method, employing a magnetic stirrer and an ultrasonicator, ensuring uniform distribution of nanoparticles in the base fluids. The thermal conductivity, thermal diffusivity, and volumetric heat capacity of the base fluids and nanofluids were measured using the FLUCON LAMBDA thermal conductivity meter. Additionally, flash points were measured using the flash point tester. It was concluded that the thermal properties of TiO2 and Fe2O3 showed considerable enhancement; in contrast, fullerene only showed a 212 °C flash point.

1. Introduction

The primary role of engine oil is to lubricate the engine parts. These parts are constantly subject to friction while the engine is running, and oils wear on the engine parts. Additionally, engine oil is used in all internal combustion engines and industrial machines to prevent corrosion of the components [1]. Furthermore, engine oils serve multiple functions, such as reducing corrosion and friction, cooling and dissipating heat from the engine, as well as sealing the engine parts [2,3,4]. The overall idea of the engine oil is to improve the engine efficiency and durability while reducing fuel consumption. However, cooling and dissipation of the heat from the engine are significant roles performed by engine oils, and their thermal properties are important factors in achieving appropriate performances. Therefore, the thermal properties of engine oil play a critical role in determining its suitability for specific applications. Generally, engine oils contain a complex collection of additives to improve fluid performance. Thermal properties such as thermal conductivity, thermal diffusivity, volumetric heat capacity, and flash point play a crucial role in enhancing engine performance; for example, oils with higher thermal conductivity facilitate more efficient heat transfer. However, such thermal properties of base engine oils are insufficient to fulfill the engine performance. Therefore, numerous studies have been conducted to uplift the thermal properties of engine oil by researchers, and one well-known method involves incorporating solid materials with high thermal properties into the base fluid [5,6,7]. In heat transfer applications, solid particles show higher thermal conductivity compared with conventional fluids [1]. The nanostructure of the nanoparticle is only one parameter that affects the thermal properties of nanofluids. There are several parameters of solid materials that influence the increase of engine oil’s thermal properties, such as particle size, shape, temperature, surfactants, type and duration of ultrasonication, and accumulation of particles [8,9,10].

Recently, nanoparticles have attracted much research attention as the most promising additives, as even a low concentration of nanoparticles in engine oil is sufficient to enhance its thermal properties. There are two primary nanoparticle families have been investigated for nanofluids: metal-based nanoparticles (metals, metal oxides, e.g.,: CuO, TiO2, SiO2, ZnO, ZrO2, and Fe2O3) and carbon-based nanoparticles (nanographene, nanodiamonds, carbon nanotubes, and graphene species) [11]. However, studies have indicated that although adding nanofluids improves engine oils’ thermal properties, the degree of the enhancement depends on factors such as nanoparticle size and shape, concentration, temperature, ultrasonication time and stirring time, surfactants, and base oil [1].

To the best of our knowledge, only one previous study has been conducted to investigate the direct addition of fullerene (C60) into engine oil to prepare nanofluids and measure the thermal properties [12]; however, another study was conducted about fullerene (C60)-SiO2 hybrid nanoparticles added to engine oil to enhance its thermal properties, and it was reported that the addition of fullerene–SiO2 hybrid nanoparticle (volume fraction 1%) to 5W30 engine oil increased its thermal conductivity by 9% [13]. Titanium dioxide (TiO2) is a highly important metal oxide in experimental investigations due to its properties, such as electronic structures and wide band gap. TiO2 has three main crystal structures: anatase (tetragonal, space group I41/amd), rutile (tetragonal, space group P42/mnm), and brookite (orthorhombic, space group Pbca). Sukkar et al. investigated TiO2-added nanofluids’ thermal conductivity, and the flash point showed enhancement but not more than CuO-added nanofluids. However, with the addition of TiO2 with 0.1 wt.% nanofluid, thermal conductivity and flash point concentration were increased by 4.54% and 9.3%, respectively [14]. Furthermore, Birleanu et al. conducted a study to investigate the tribological properties such as load-carrying capacity and friction reduction of nanofluids. They found that the anti-wear abilities of the nanofluids were improved by adding surface-modified TiO2 nanoparticles at 75 °C, and the rate of improvement was increased with the volume concentration (0.01%, 0.02%, 0.05%, and 0.075%) of nanoparticles added [15]. Harandi et al. [16] reported a 30% increase in the conductivity coefficient at a temperature of 50 °C and a volumetric fraction of 2.3% of hybrid nanofluids composed of Fe2O3 nanoparticles, multi-walled carbon nanotubes, and ethylene glycol as the base fluids. Most of the research works carried out with hybrid nanoparticles, i.e., graphene/Fe2O3-added water-based nanofluids, have shown such enhancements in thermo-physical properties [17]. Furthermore, a recent experiment verified that Fe2O3/water-based nanofluids enhanced thermal conductivity by 21.35% at 0.08% volume fraction of Fe2O3 [18].

There are several mechanisms developed to explain the behavior and thermophysical properties of nanofluids. Some of them are Brownian motion, nanoparticle clustering, and thermal liquid layering.

Brownian motion is the random movement of the nanoparticles within the base fluid. Brownian motion creates collisions between the nanoparticles and the liquid molecules, which enhances the thermal conductivity of the nanofluids. Brownian motion has a major impact on thermal conductivity compared to other mechanisms. This Brownian motion also helps the thermophoresis effect: particle movement from hot to cold regions. Clustering or aggregation is also a key mechanism that explains the properties of nanofluids. However, on some occasions, there might be a positive impact from the particle aggregation that creates a thermal bridge to transfer the heat through the fluid. However, on some occasions, this might have a negative effect on the thermal properties of the nanofluid. For some nanofluids, this phenomenon makes the nanofluids unstable. The thermal-liquid layer is the thermal bridge between the nanoparticles and the liquid molecules. This layer is formed by liquid molecules around the nanoparticles. This layer helps to transfer the heat between the two phases of the nanofluid. However, further study of the mechanisms of nanofluids is required to explain their complex behavior [19,20,21].

In this study, the thermal conductivity, thermal diffusivity, volumetric heat capacity, and flash point of 10W30, 20W40, and 20W50-based nanofluids with fullerene (C60), TiO2, and Fe2O3 nanoparticles were examined, and the obtained results were compared graphically. The engine oils chosen for this study were 10W30, 20W40, and 20W50 types, which are widely used in lightweight vehicles. The intention of this work is to enhance the thermal properties of these engine oils by adding different types of nanomaterials. The temperature range and the mass concentration were 30–120 °C and 0.01 wt.%, respectively. Using a larger weight of nanoparticle will create a particle aggregation within the nanofluids, which makes the nanofluids sample more unstable, even though it increases the thermal properties of the nanofluids. Equal concentrations of the different nanoparticles were utilized, and the nanofluids were prepared using a two-step method.

2. Materials and Methods

2.1. Materials

In this study, three different engine oil grades were used as the base fluids for the nanofluids. All three grades of engine oils are multi-graded engine oils, and they are graded according to their viscosity values at hot and cold temperatures. The nanofluids were prepared using fullerene-C60 (99.5%, SIGMA-ALDRICH, St. Louis, MO, USA), TiO2 (anatase-type, Ningbo Jiweina New Material Technology Co., Ltd., Beijing, China), and Fe2O3 (SLINTEC, Homagama, Sri Lanka), with a weight percentage of 0.01 wt.%. The thermophysical properties of the fullerene-C60, TiO2, and Fe2O3 nanoparticles are given in Table 1, whereas the properties of the three selected engine oil grades are given in Table 2.

Table 1.

Thermo-physical properties of fullerene-C60, TiO2, and Fe2O3.

Table 2.

Thermo-physical properties of engine oil grades 10W30, 20W40, and 20W50.

In this study, locally available CALTEX red engine oil was chosen as the base fluid because it is a popular product in the field. The weights of the nanoparticles (0.01 wt.%) were calculated using Equation (1) while measuring the weight of fluids and nanoparticles using the BSA224S-CW (Sartorius AG, Goettingen, Germany, d = 0.1 mg) electronic balance. The weights of nanomaterials are presented in Table 3 for different grades of engine oils with a mass fraction of 0.01 wt.%. From each engine oil grade, a volume of 60 mL nanofluid was prepared for each experiment due to the 50 ± 2 mL liquid required to measure flash point using the flash point meter. The 40 ± 2 mL of liquid was used to measure other thermal properties using the thermal conductivity meter.

where and are weight of the fullerene-C60 nanoparticle and weight of the base fluid, respectively.

Table 3.

Weights of nanoparticles for different engine oil grades with 0.01 wt.%.

After the measurement of the weights of the base fluids, nanofluids, and nanoparticles, the surface temperature values were measured using a thermometer with an accuracy of ±1 °C. The measured nanoparticles were subsequently added to the measured engine oil and placed on a magnetic stirrer for 2 h at a temperature of 40 °C and 200 rpm to disperse the nanoparticles within the engine oil. After preparing the oil and nanoparticle mixture, the sample was exposed to ultrasonic waves for another 2 h at 40 °C using an ultrasonicator (Rocker, SONER 210H, AC, 220 V, 50 Hz, Rocker Scientific Co., Ltd., Kaohsiung City, Taiwan) to disperse all nanoparticles in the engine oil and eliminate their agglomerates. The photographs of the prepared nanofluid, base fluid, and nanoparticles are shown in Figure 1. This preparation method made nanofluids stable for at least two weeks without the risk of sedimentation; therefore, no surfactant was needed for stabilization.

Figure 1.

Nanoparticles ((a)—fullerene-C60, (b)—TiO2, (c)—Fe2O3), base fluid ((d)—10W30 CALTEX red engine oil), and prepared nano-fluids ((e)—fullerene-C60 0.01 wt.% added 10W30, (f)—Fe2O3 0.01 wt.% added 10W30, (g)—TiO2 0.01 wt.% added 10W30).

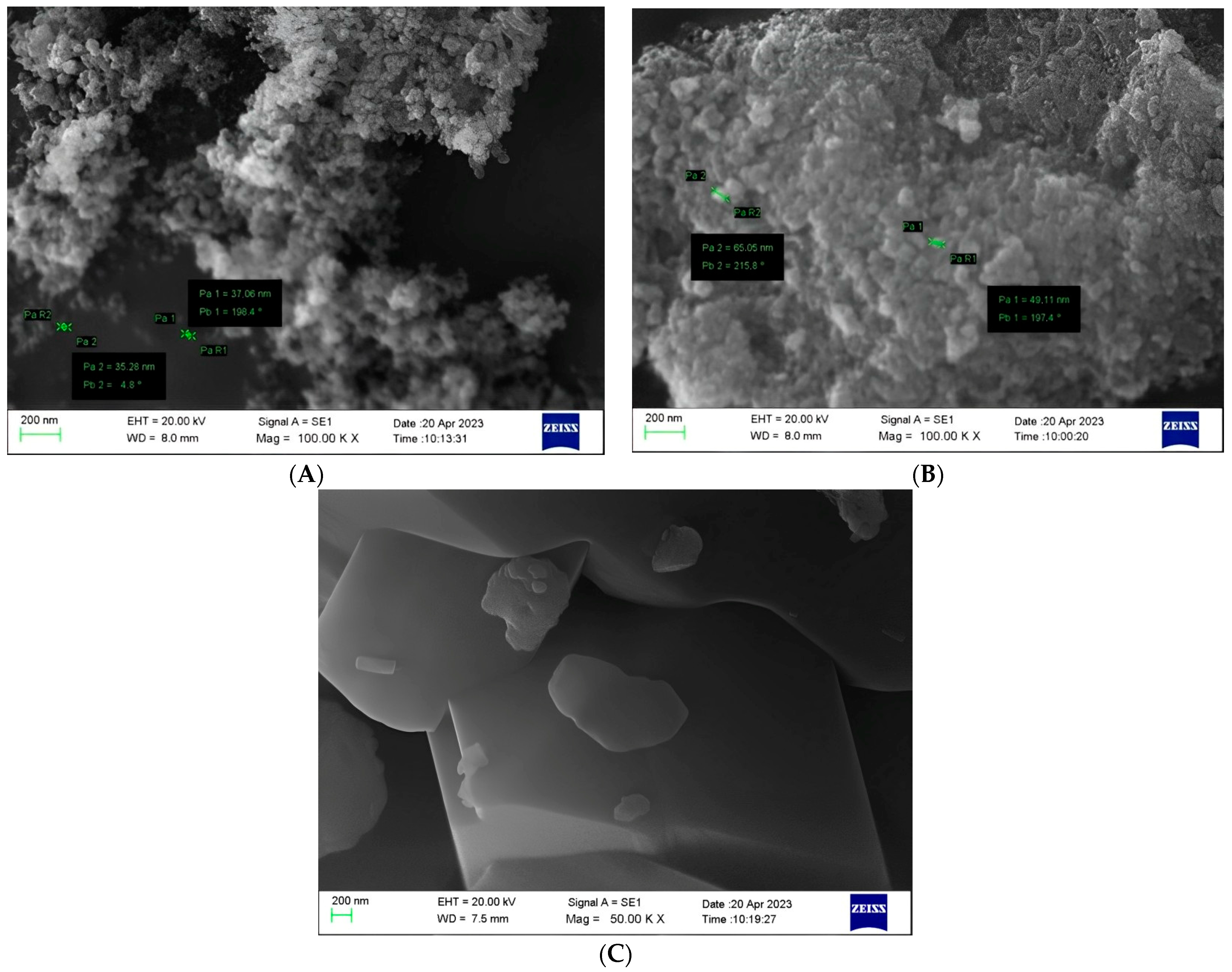

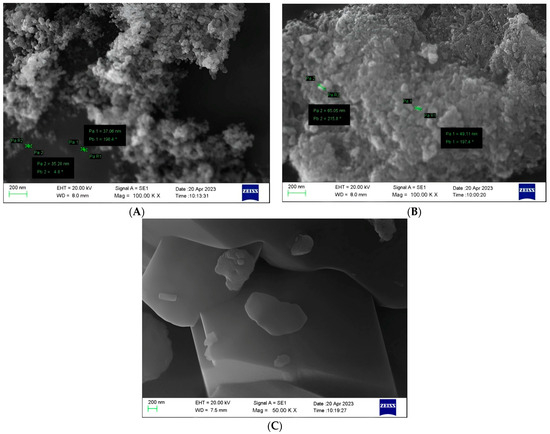

The Scanning Electron Microscope (SEM) tests were conducted to ensure the surface topography and composition of the nanoparticles. The obtained results are presented in Figure 2.

Figure 2.

SEM images of the nanoparticles used in this research work. (A): TiO2. (B): Fe2O3. (C): fullerene-C60.

2.2. Thermal Conductivity, Thermal Diffusivity, and Volumetric Heat Capacity Measurements

The thermal properties of liquids can be measured using various methods such as the steady state method, temperature oscillation method, transient hot wire method, etc. [1]. In this research work, the transient hot-wire method was used to measure thermal properties using the instrument TECNE UCAL 400+ dry block calibrator and FLUCON Lambda thermal conductivity meter, which can be employed to obtain thermal conductivity and thermal diffusivity of both the base fluids and nanofluids, which were measured within a temperature range of 30 to 120 °C.

The LAMBDA Thermal Conductivity Meter uses the hot wire transient method for thermal conductivity, thermal diffusivity, and volumetric heat capacity according to ASTM D7896-19 standardization [22]. the LAMBDA Thermal Conductivity Meter has a platinum wire to transfer the heat to liquid.

According to the theory of the hot-wire transient method, it produces a constant heat stream. This heat stream is time dependent. Equation (2) can be developed to calculate the thermal conductivity of the liquid.

where λ is thermal conductivity (Wm−1 K−1), q is a constant heat stream (Wm−1), and ϑ is the temperature at time t.

The accuracy of the instrument at a temperature below 200 °C is ±0.03 °C. The volumetric heat capacity of the fluids in each temperature value was calculated using Equation (3).

where —volumetric heat capacity, —thermal conductivity, —thermal diffusivity.

2.3. Flash Point Measurement

The flash point of the base fluids and nanofluids was measured using the open-cup flash point tester (Anton Paar PMA500, Ostfildern, Germany). The flash point is the lowest temperature at which a liquid forms a gas above its surface in sufficient concentration to ignite. The sample was placed in the test cup and slowly heated up automatically to reach the flash point, and the measuring standard was ASTM D93 [23]. The samples were discarded after measuring the flash point due to the samples’ temperature exceeding 200 °C degrees.

2.4. Measurements of Base Fluids

The base fluids’ thermal properties were measured using the same instruments at the same temperature range to evaluate the performances of the nano lubricants. The measured thermal conductivity and flash point values of engine oil grades 10W30, 20W40, and 20W50 were compared with their nanofluids.

3. Results and Discussion

Table 4 represents several research works carried out by previous researchers and in this study, and it includes the thermal conductivity and flash point percentages of different nanoparticles added to different base fluids with temperature ranges and weight or volume fractions. By looking at Table 4, it can be seen that the engine oil-based nanofluids’ thermal conductivity percentage shows considerable enhancement, while the Mg/MWCNT nanoparticle-added nanofluid took the highest percentage (65%) with weight fractions 0.25–2 wt.% at a temperature range of 25–50 °C. The engine oil-based nanofluids flash point percentage shows significant enhancement, while the graphene nanoparticle-added-to-engine-oil-based nanofluids demonstrate the highest percentage (25.4%), with low weight fractions. In this study, thermal property percentages did not reach notable enhancement due to the experienced weight fraction being very low, at 0.01 wt.%. However, it can be concluded that nanomaterials can make a considerable impact on the thermal properties of different fluids, even at lower concentrations.

Table 4.

Summary of the thermal conductivity and flash point of nanofluids examined by previous researchers and in this study.

The morphology of the TiO2 and Fe2O3 nanoparticles were spherical to some extent, which provided a good rolling mediator inside the engine oil. The SEM images prove that the average particle sizes of TiO2, Fe2O3, and fullerene-C60 are about 30–60 nm, 40–70 nm, and 100–200 nm, respectively.

3.1. Effect of Temperature Values and Nanomaterials on Thermal Properties

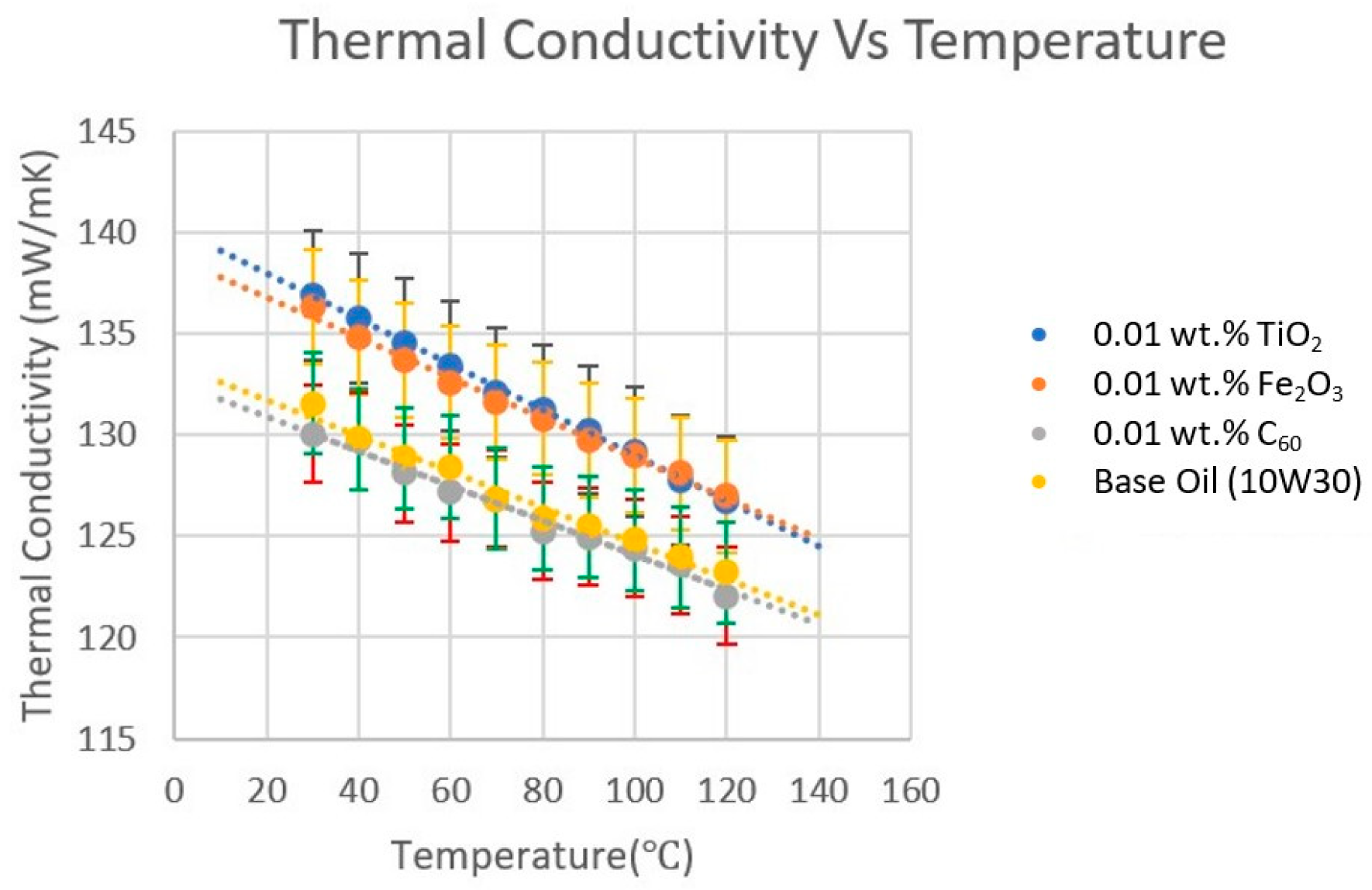

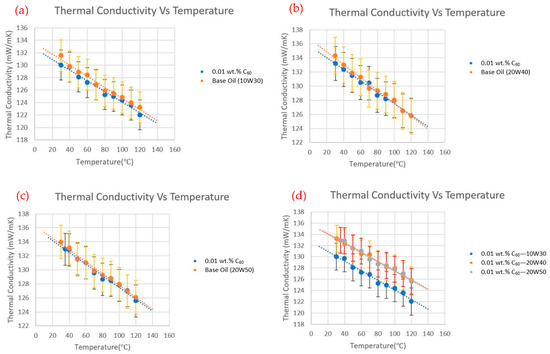

3.1.1. Thermal Conductivity

Thermal conductivity can be explained as the ability of a material to conduct heat. A large value of thermal conductivity of liquid is considered good as a cooling agent for motor engines. A fluid with high thermal conductivity absorbs more heat in the engine, reduces heat loss, and enhances the performance of the engine. Generally, the thermal conductivity of engine oil is inversely proportional to the temperature due to molecules of the liquid moving apart when a liquid is heated. Hence, their mean free path increases. This leads to a reduced probability of collision of molecules, and therefore, there is a reduction in thermal conductivity with an increase in temperature for liquids. However, in nanofluids, the nanoparticles will be placed through liquid molecules, reducing the distance between the two molecules. Therefore, this enhances the interaction, resulting in an increment of the heat exchange within nanofluids. Furthermore, the dispersed nanoparticles in these nanofluid samples can be explained by the Brownian motion and the particle–particle interaction. The Brownian motion is the random movement of nanoparticles within the nanofluid sample. Theis random movement helps to transfer energy from the heated areas to cold areas. Also, these particles collide with the liquid molecules, which enhances the heat-transferring process by passing the kinematic energy.

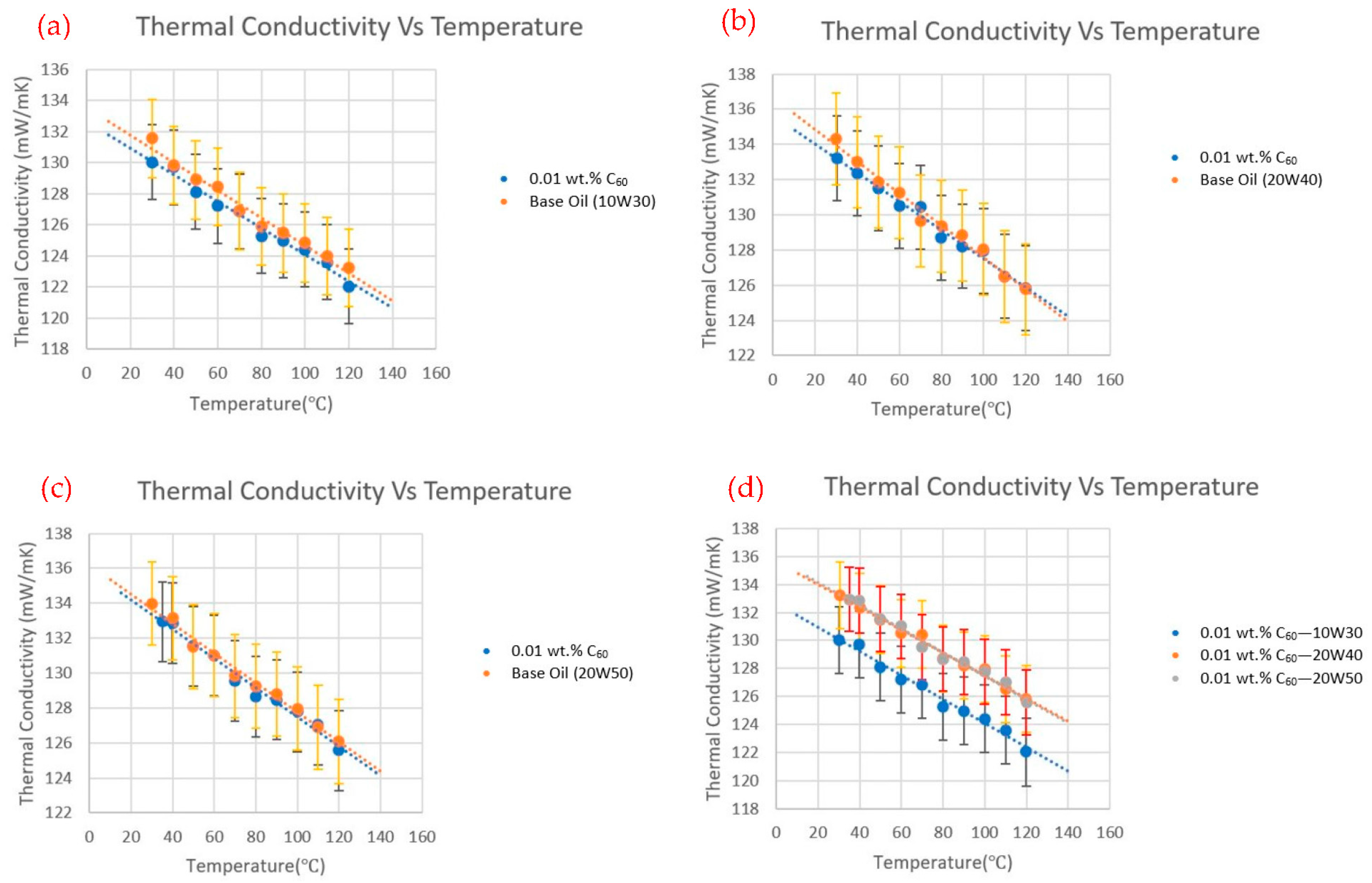

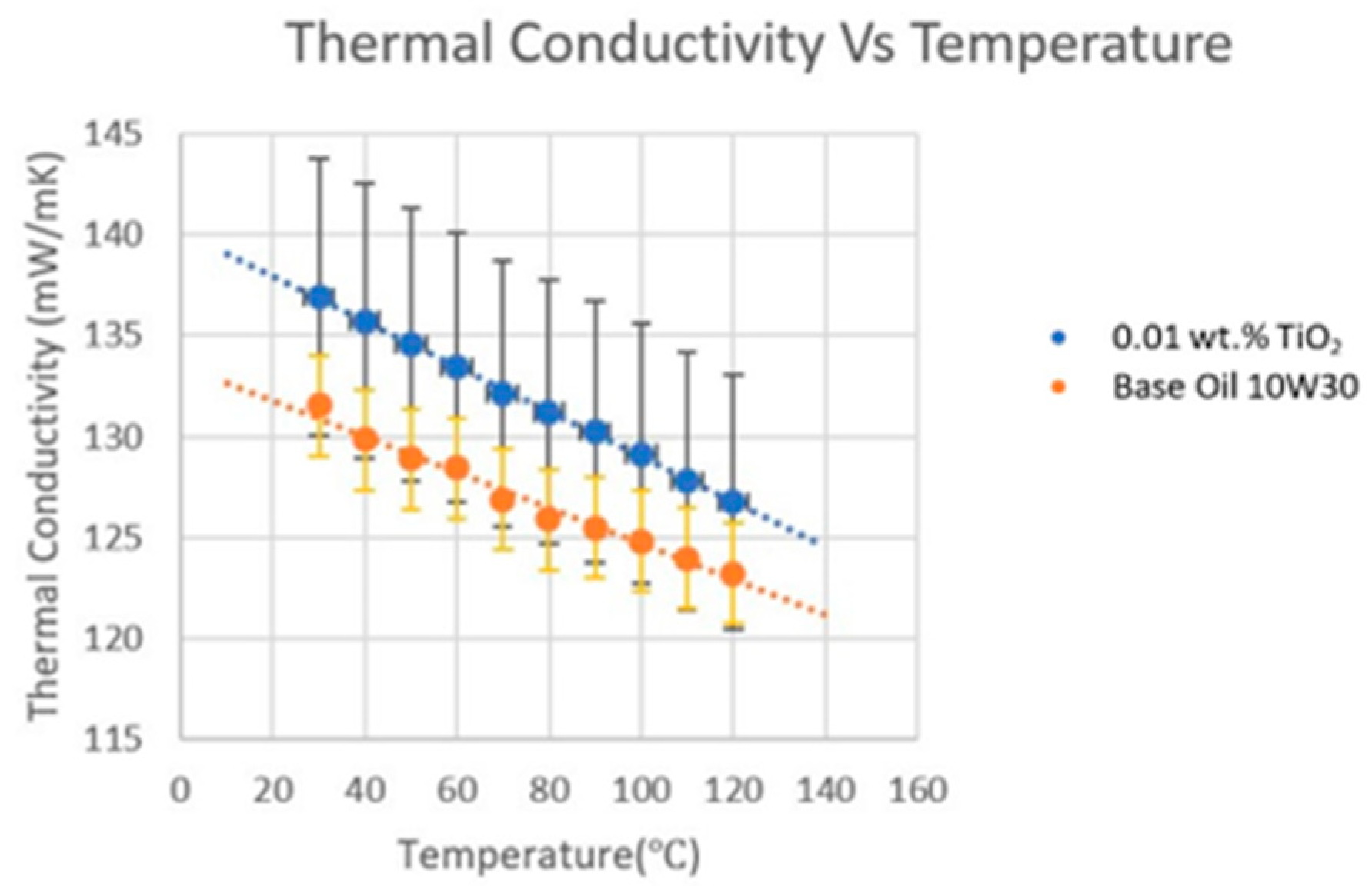

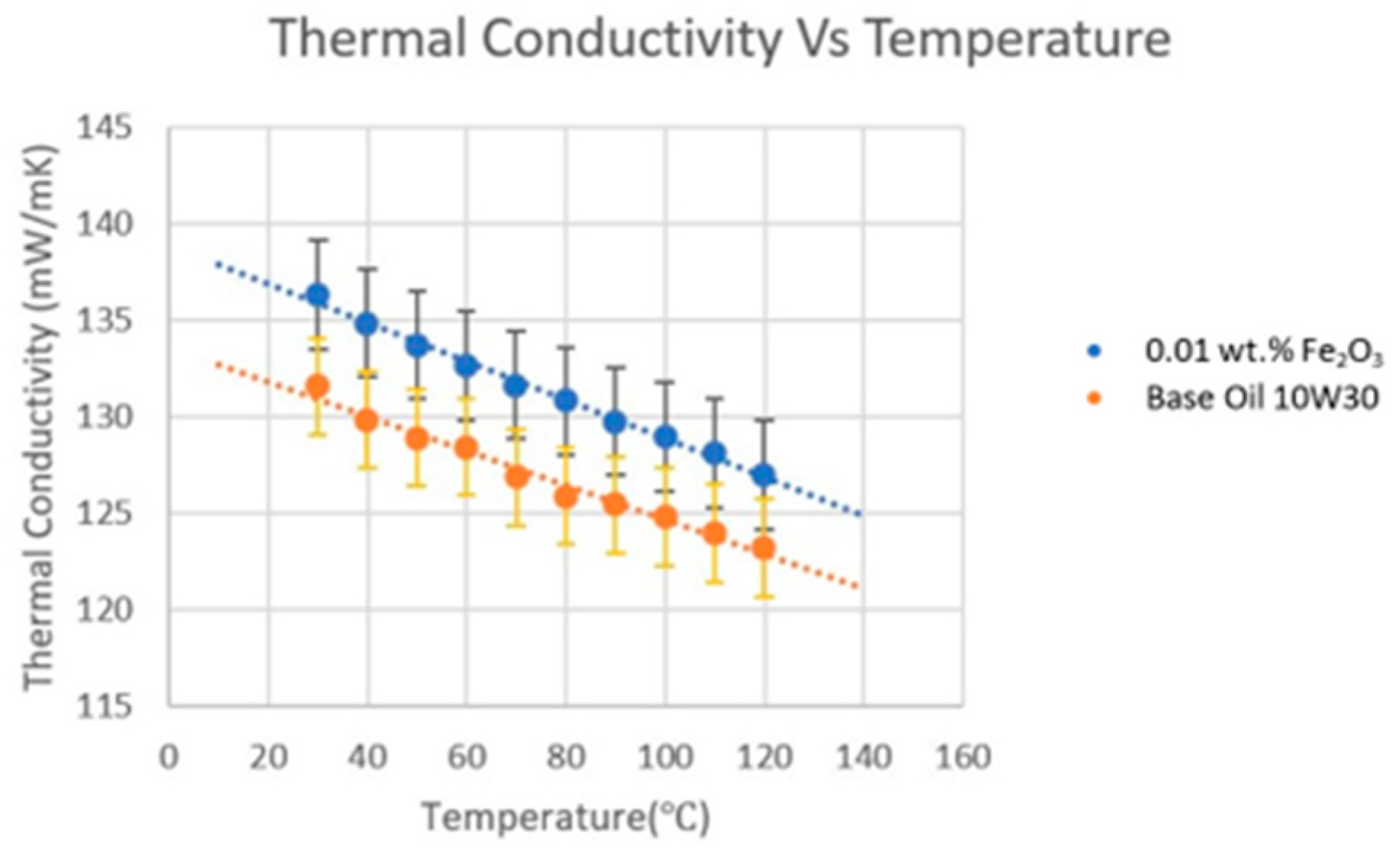

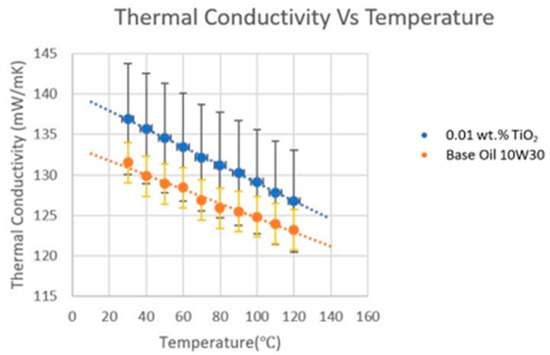

Figure 3 compares the thermal conductivity results of 10W30, 20W40, and 20W50 engine oils with fullerene (C60) 0.01 wt.%-added nanofluids within the 30–120 °C temperature range. Nevertheless, the result of the enhancement of the nanofluid’s thermal conductivity does not agree with some other experimental results, because these experimental results incorporated large amount of nanoparticles (0.25–4 wt.%) [1]. When increasing the nanoparticle amount in the nanofluid, it shows the properties of the nanoparticles rather than base fluid. Furthermore, most of the studies carried out by researchers who worked with small amounts of nanoparticles to prepare nanofluids agree with the results which are obtained in this work. However, both base fluid and nanofluid display a decrement in thermal conductivity when the temperature is increased while keeping the graphs’ slopes approximately equal. Figure 4 and Figure 5 show the thermal conductivity results of TiO2 and Fe2O3 0.01 wt.%-added nanofluids with the base fluid (10W30) results in the temperature range 30–120 °C. Both figures display a substantial improvement in the thermal conductivity values of nanofluids compared to their respective base fluids, i.e., 4.5% and 3.9%, for TiO2- and Fe2O3-added nanofluids, respectively.

Figure 3.

Effect of temperature on thermal conductivity of fullerene-C60 0.01 wt.% added nano-fluids with base fluids ((a)—10W30, (b)—20W40, (c)—20W50, (d)—comparison of thermal conductivity of three nanofluids).

Figure 4.

Effect of thermal conductivity on 10W30/TiO2 0.01 wt.% added nano-fluid.

Figure 5.

Effect of thermal conductivity on 10W30/Fe2O3 0.01 wt.% added nano-fluid.

It can be concluded that the results obtained from this study are consistent with most previous studies’ results.

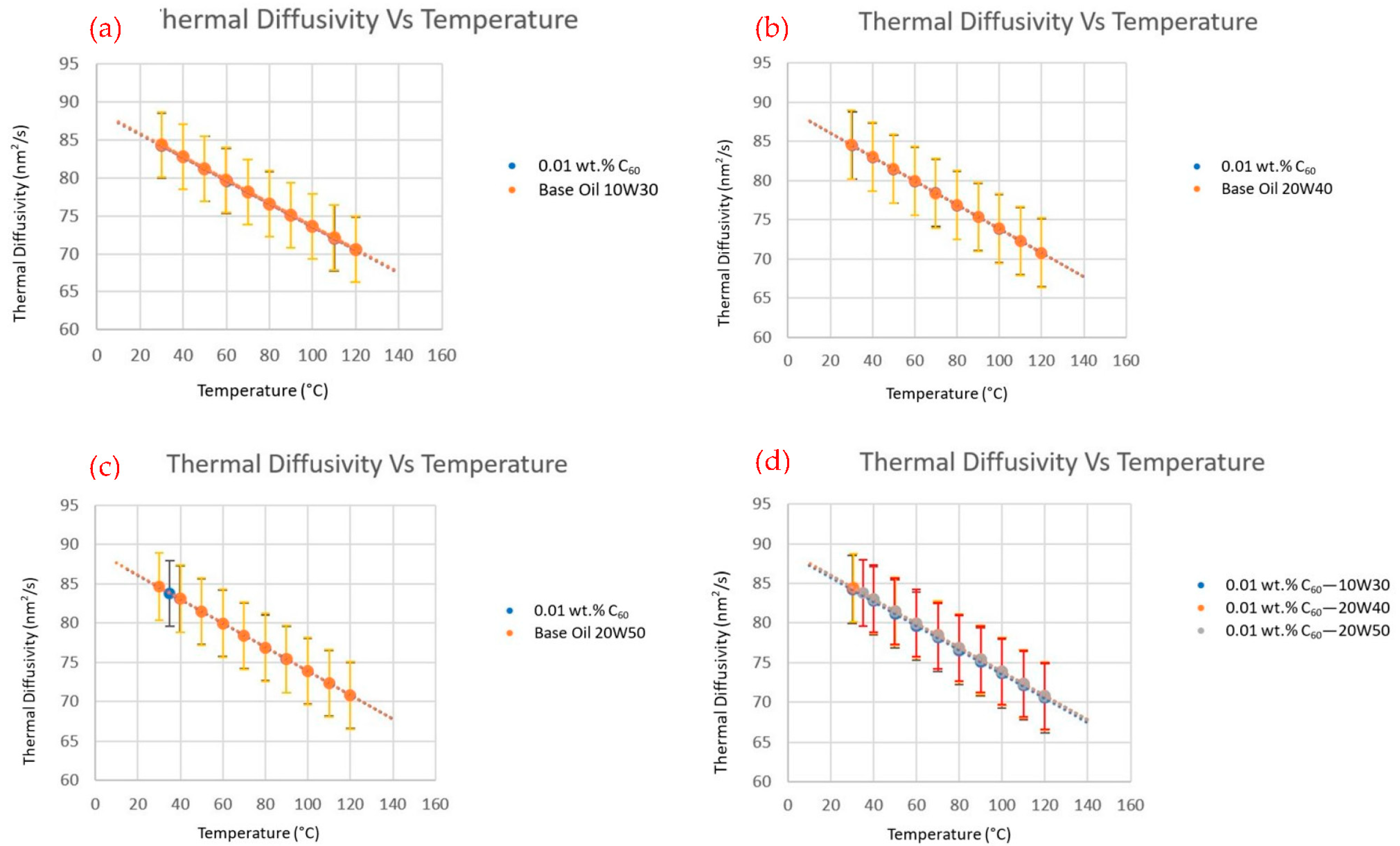

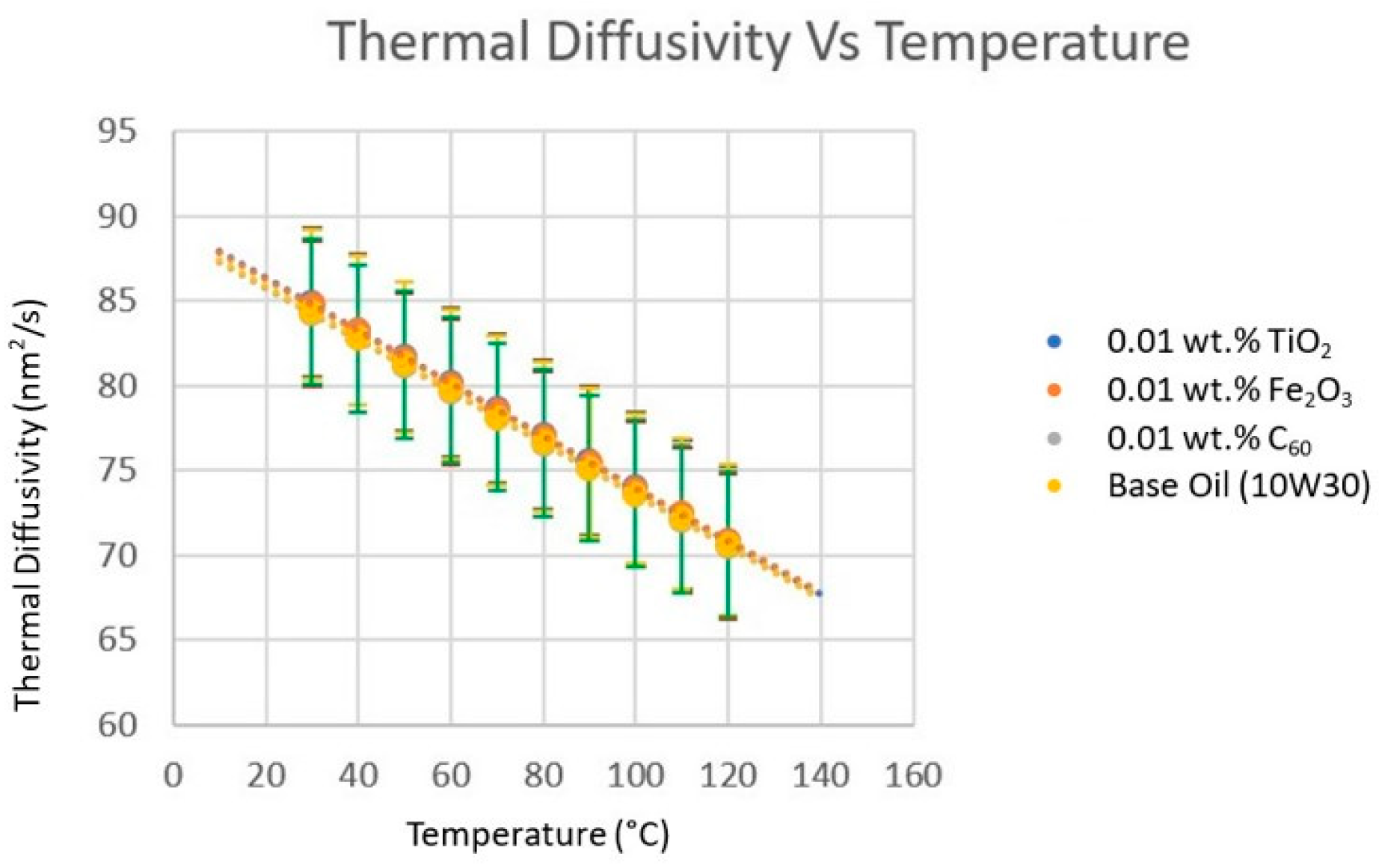

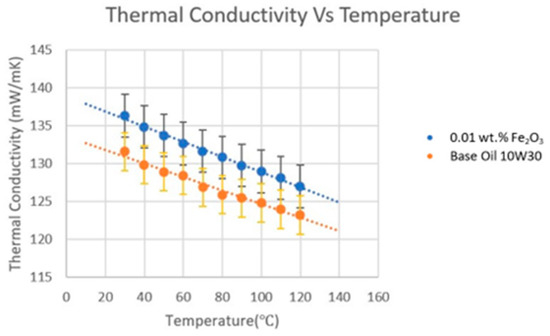

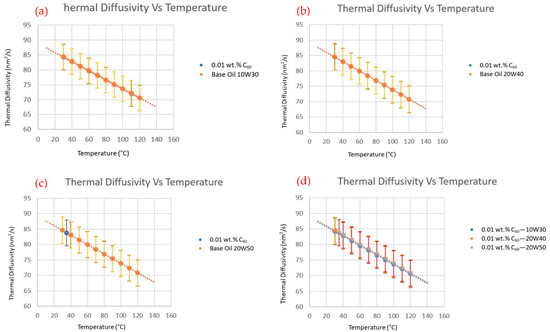

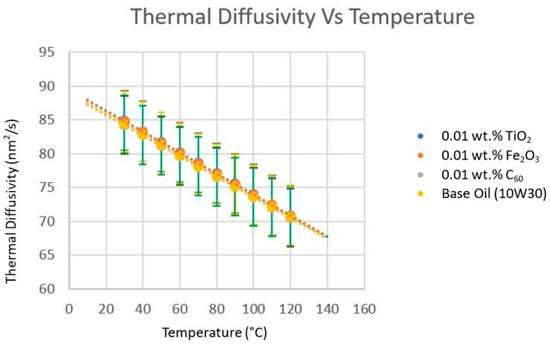

3.1.2. Thermal Diffusivity

The rate of heat transfer through a medium is called thermal diffusivity. Figure 6 shows the results of thermal diffusivity values of base fluids 10W30, 20W40, and 20W50 and fullerene (C60)-added nanofluids with mass fraction 0.01 wt.% in the temperature range of 30–120 °C. As is clearly observed in the figure, there was no significant improvement in the thermal diffusivity of C60-added nanofluids with the increment of the temperature of the samples compared to their respective base fluids.

Figure 6.

Effect of temperature on thermal diffusivity of fullerene-C60 0.01 wt.% added nano-fluids with base fluids ((a)—10W30, (b)—20W40, (c)—20W50, (d)—comparison of thermal diffusivity of three nanofluids).

The gradients of the graphs for both the base fluid and its nanofluid were nearly equal while decreasing the thermal diffusivity values when increasing the temperature from 30–120 °C. These findings align with theoretical expectations and are consistent with previous studies [43,44].

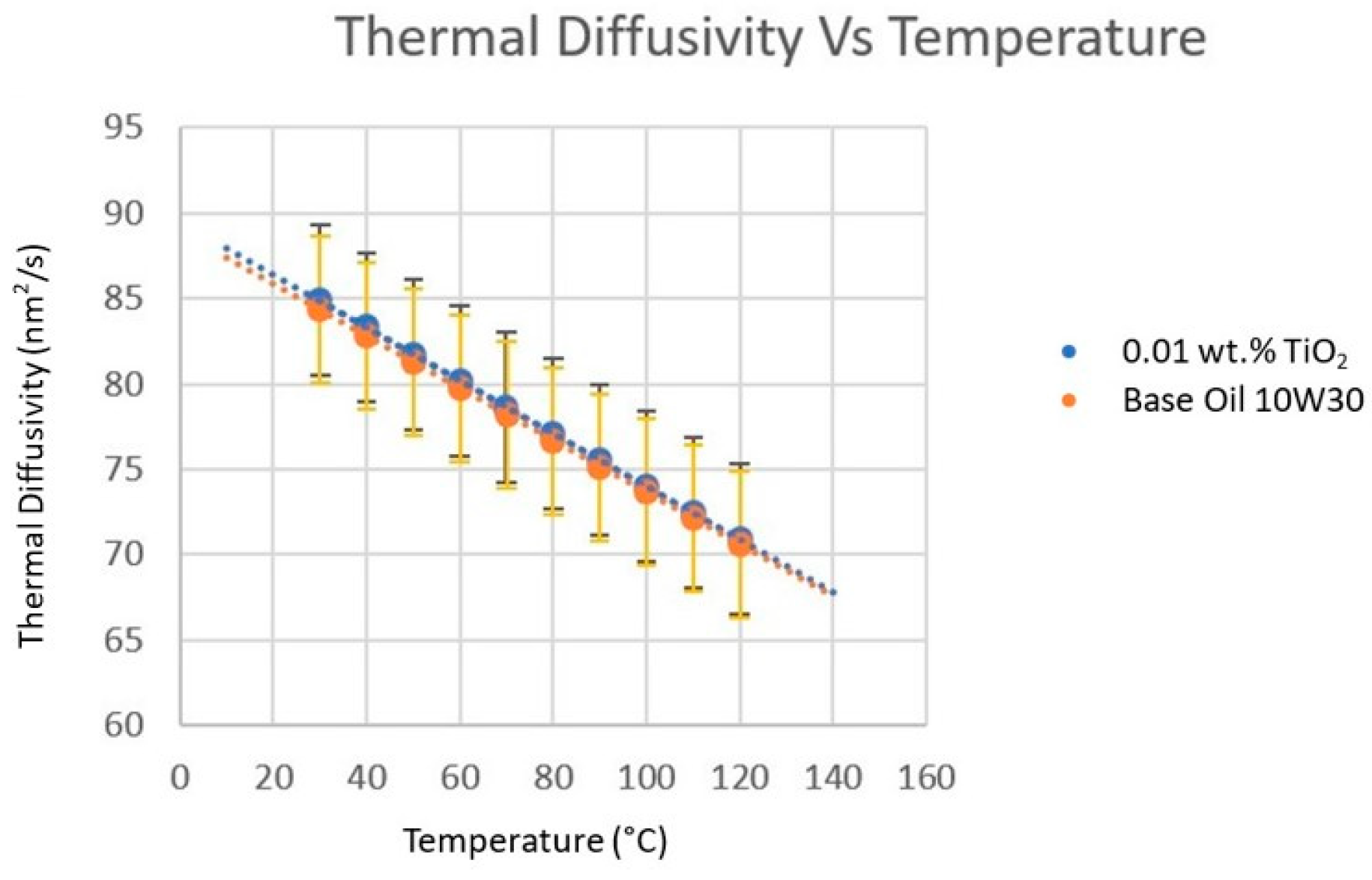

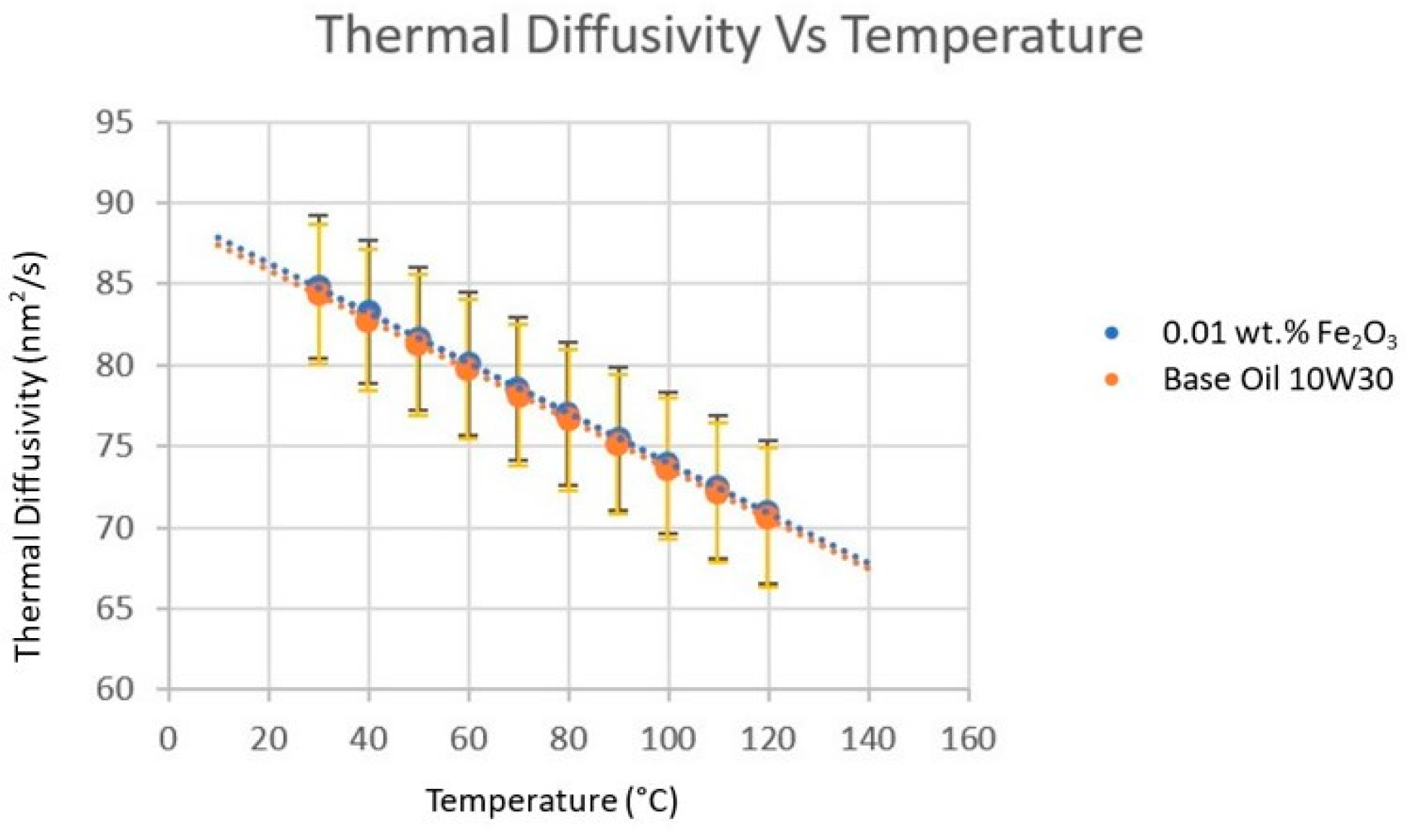

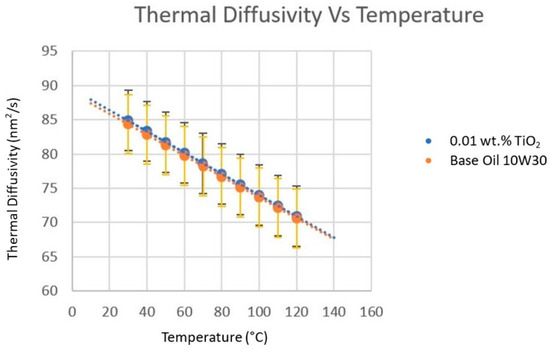

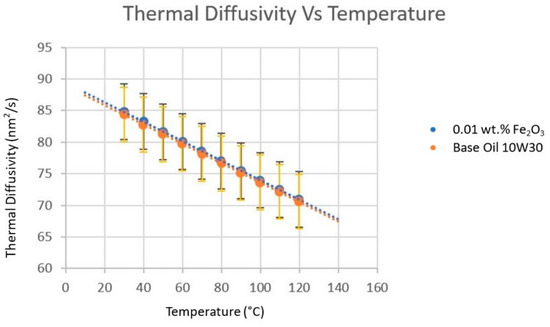

The thermal diffusivity values of TiO2 and Fe2O3 added nanofluids with 0.01 wt.% and base fluid (10W30) values comparison are represented in Figure 7 and Figure 8, respectively. Both graphs exhibit a linear shape and do not show significant enhancements of the thermal diffusivity within the temperature range of 30–120 °C.

Figure 7.

Effect of thermal diffusivity on 10W30/TiO2 0.01 wt.% added nano-fluid.

Figure 8.

Effect of thermal diffusivity on 10W30/Fe2O3 0.01 wt.% added nano-fluid.

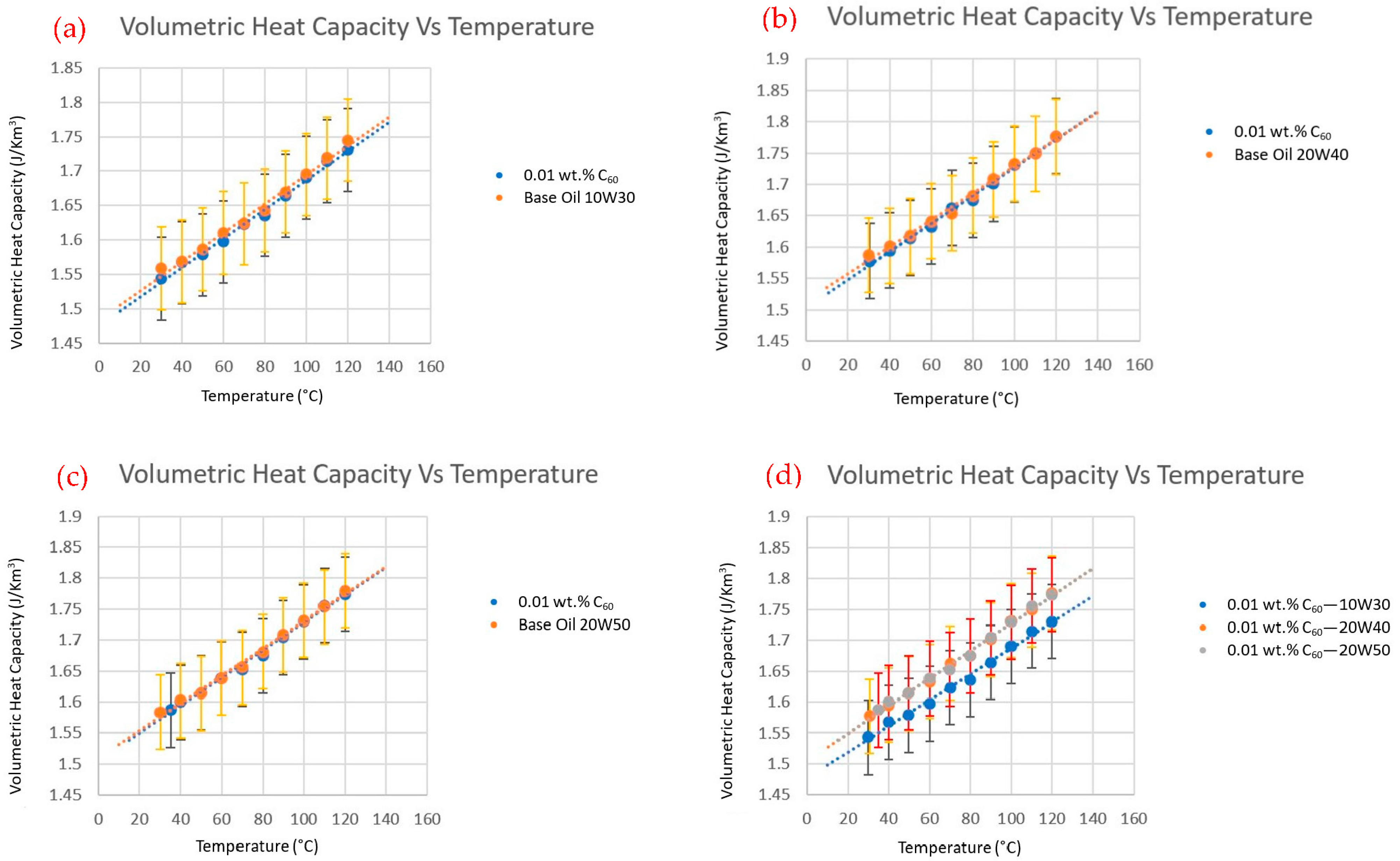

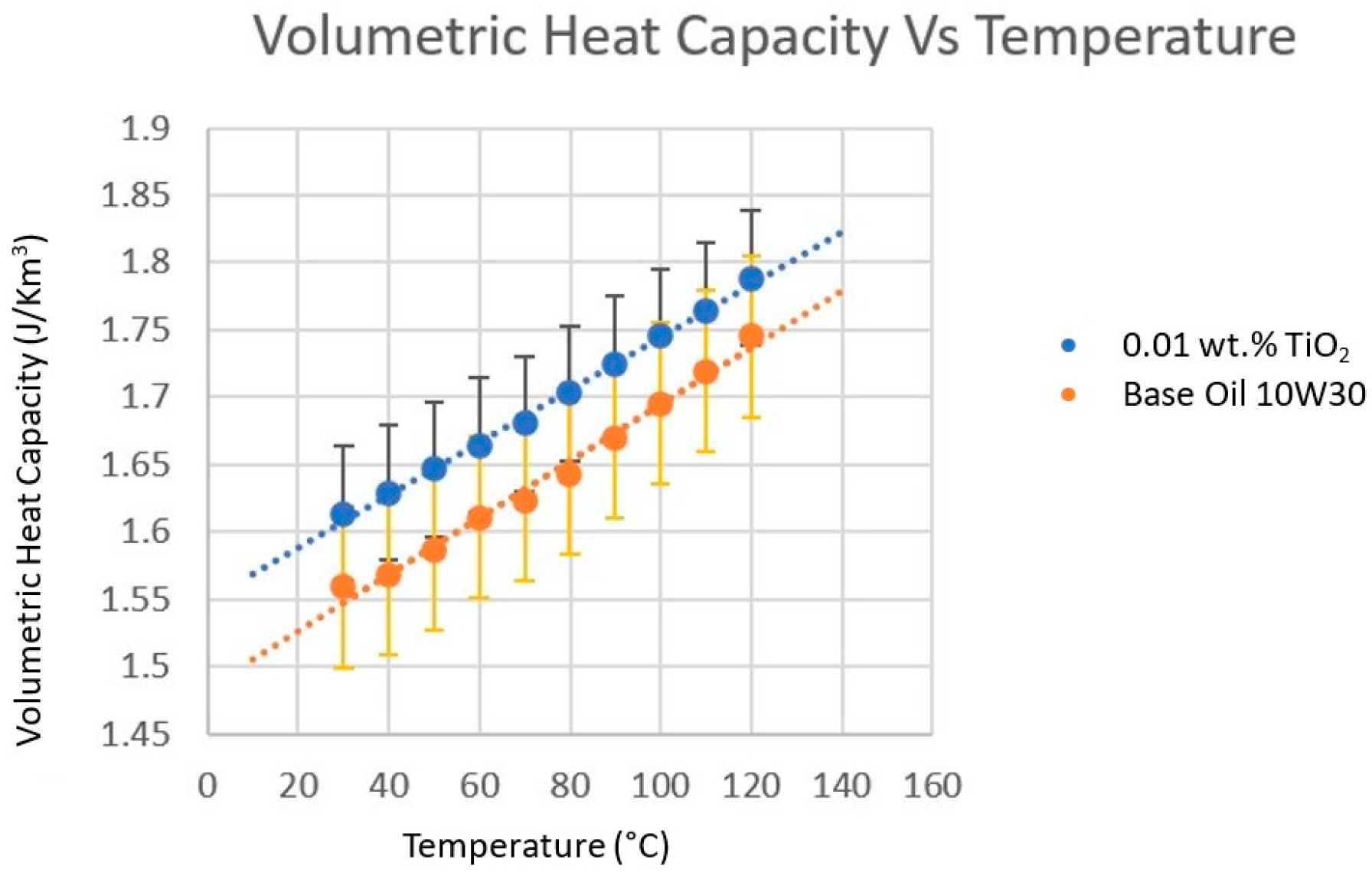

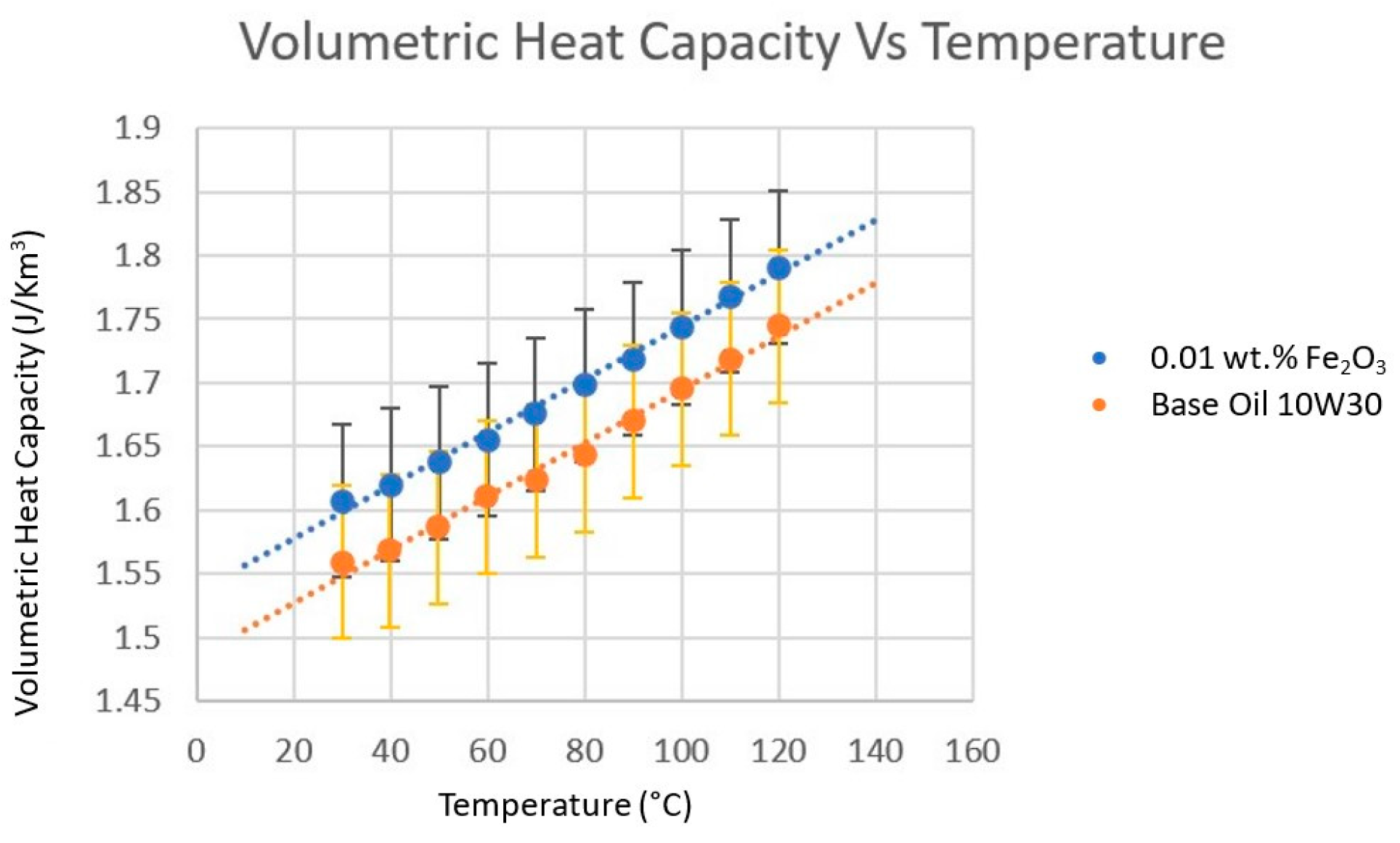

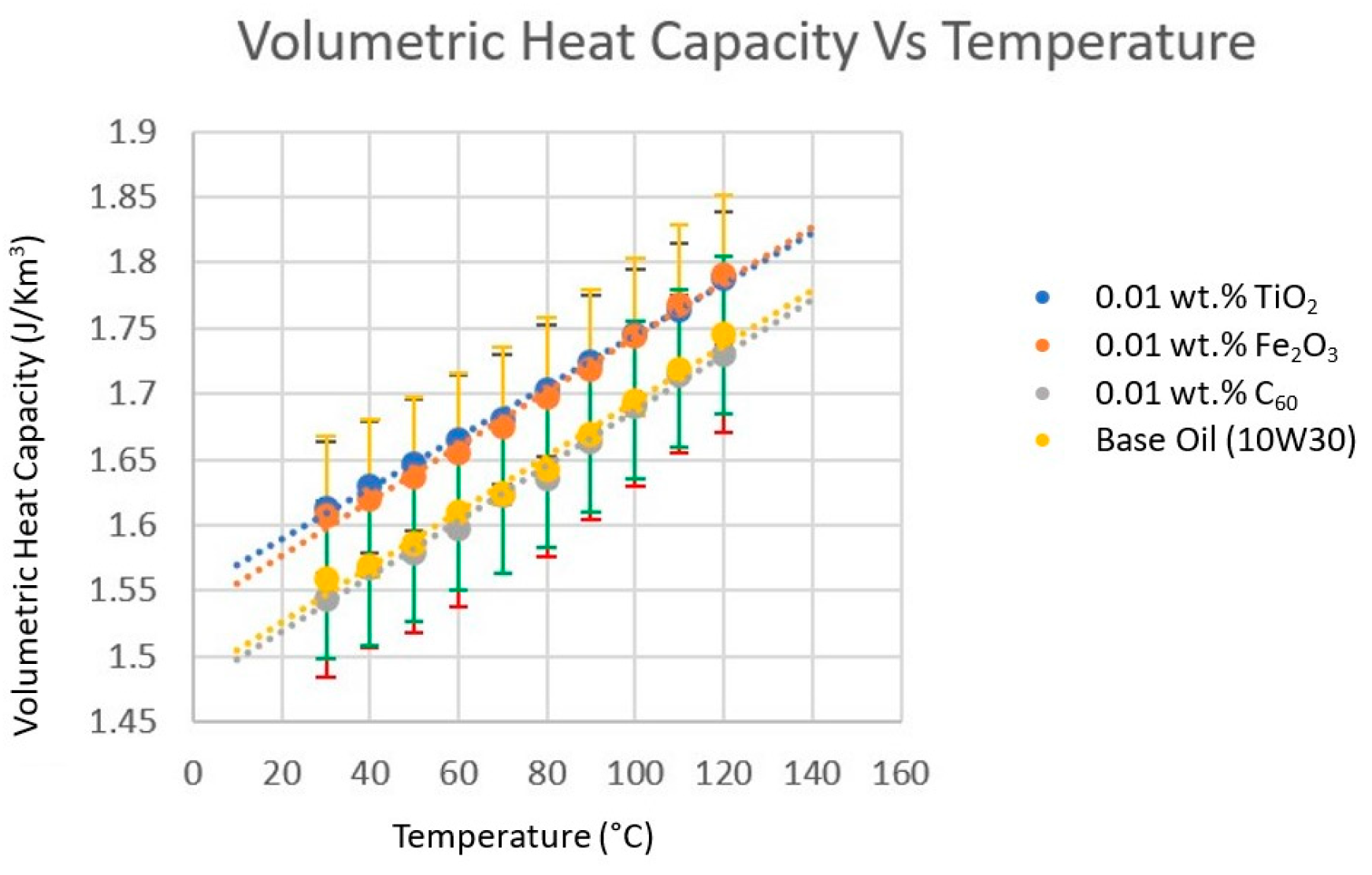

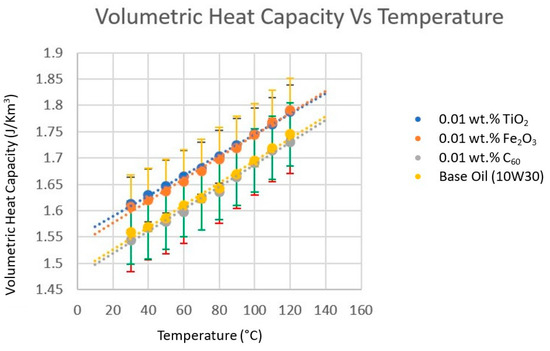

3.1.3. Volumetric Heat Capacity

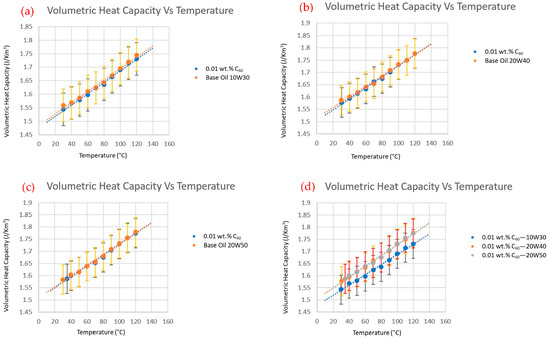

The ratio of thermal conductivity to thermal diffusivity is called volumetric heat capacity. Figure 9 compares the volumetric heat capacity values of base fluids (10W30, 20W40, and 20W50) and Fullerene (C60)-based nanofluids with 0.01 wt.% in the temperature range of 30–120 °C. The graph shows an increase in the volumetric heat capacity values of the nanofluids as the temperature of the sample increases. This increase has a positive gradient on the graph, but the enhancement of the values compared to the base fluid is not substantial.

Figure 9.

Effect of temperature on volumetric heat capacity of fullerene-C60 0.01 wt.% added nano-fluids with base fluids ((a)—10W30, (b)—20W40, (c)—20W50, (d)—comparison of volumetric heat capacity of three nanofluids).

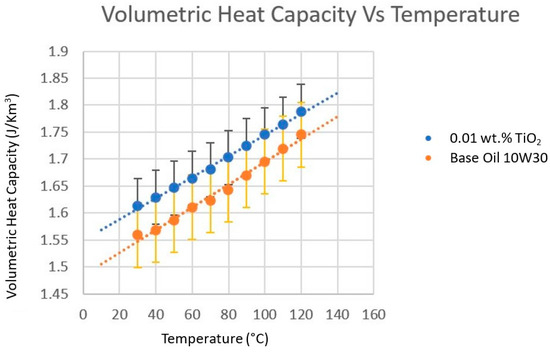

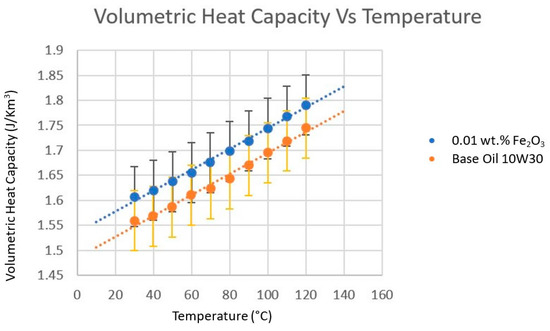

These results should be expected because the slope of thermal diffusivity graphs is greater than the respective thermal conductivity graph slope. The volumetric heat capacity values of TiO2-and Fe2O3-added nanofluids with 0.01 wt.% and base fluid (10W30) values comparison are represented in Figure 10 and Figure 11, respectively.

Figure 10.

Effect of volumetric heat capacity on 10W30/TiO2 0.01 wt.% added nano-fluid.

Figure 11.

Effect of volumetric heat capacity on 10W30/Fe2O3 0.01 wt.% added nano-fluid.

All graphs were linear, while volumetric heat capacity vs. temperature graphs kept a positive gradient.

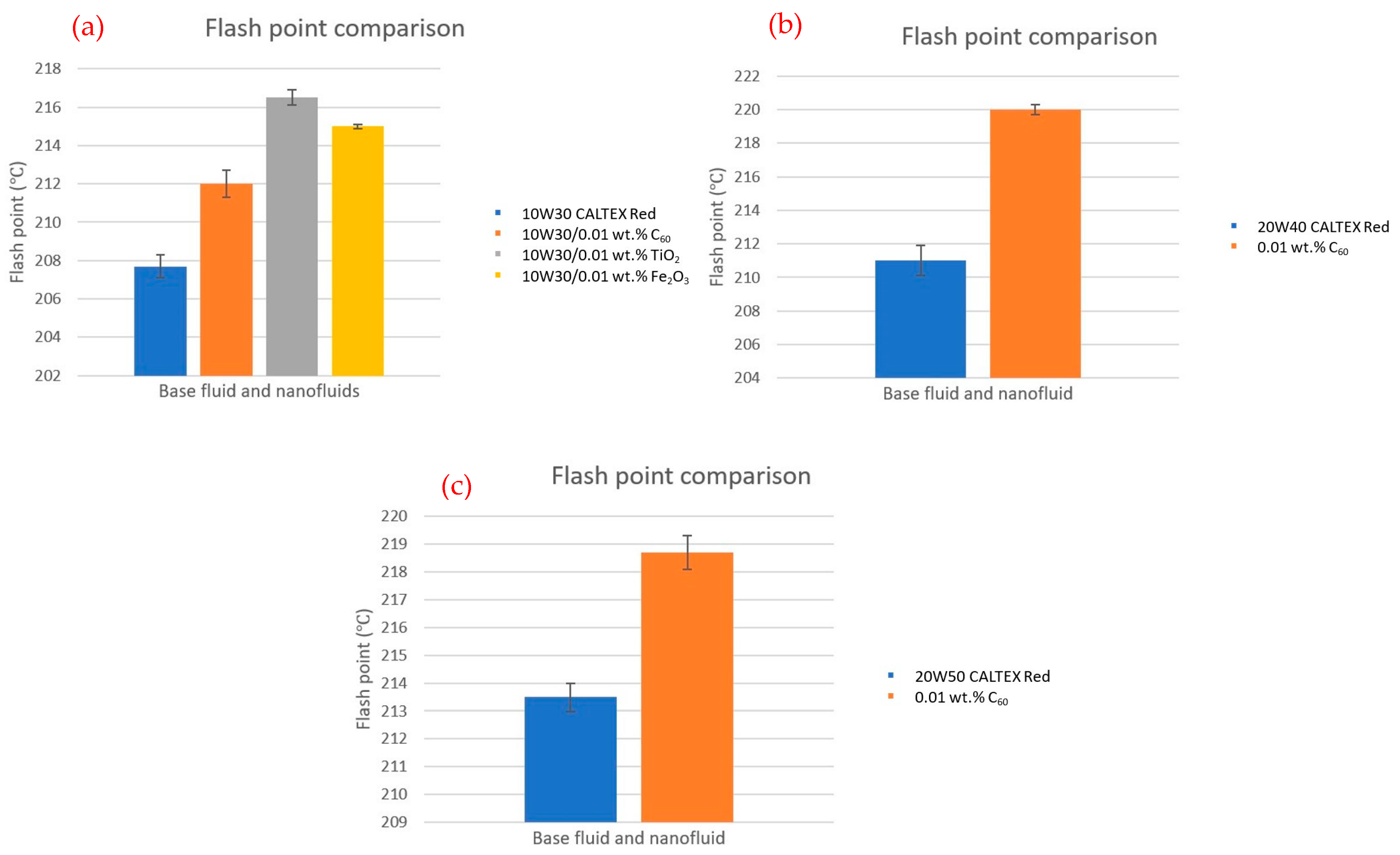

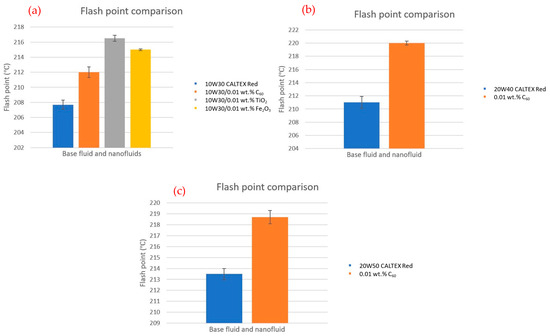

3.1.4. Flash Point

Table 5 and Figure 12 present a comparison of the flash point values of three different graded engine oils with their relevant fullerene-C60-, TiO2-, and Fe2O3-added nanofluids. The results proved a considerable impact on the flash point of engine oil with 0.01 wt.% of fullerene-C60, TiO2, and Fe2O3 nanomaterials. The effect on the flash point regarding three engine oil grades was approximately equal. However, when comparing the effect on the flash points from nanomaterials, a decrement was observed with TiO2, Fe2O3, and fullerene-C60, respectively.

Table 5.

Maximum thermal property ratios of 10W30/nanofluids fullerene-C60, TiO2, and Fe2O3 at 0.01 wt.%.

Figure 12.

The comparison of flash point values of three different engine oils with their nano-fluids ((a)—10W30 and C60, TiO2, Fe2O3 0.01 wt.% added nanofluids, (b)—20W40 and C60 0.01 wt.% added nanofluid, (c)—20W50 and C60 0.01 wt.% added nanofluid).

3.2. Thermal Property Ratios

This section presents the ratio of thermal conductivity, thermal diffusivity, volumetric heat capacity, and flash point of nanofluid to the base fluid.

3.2.1. Thermal Conductivity, Thermal Diffusivity, and Volumetric Heat Capacity Ratios

The ratios of thermal conductivity, thermal diffusivity, and volumetric heat capacity can be calculated using Equation (4), Equation (5), and Equation (6), respectively.

3.2.2. Flash Point Ratio

The flashpoint ratio can be calculated by referring to Equation (7) and the nanofluid based on TiO2 with 0.01 wt.% exhibits the highest flash point ratio.

Table 5 represents the maximum enhancements in the thermal properties of the nanofluids.

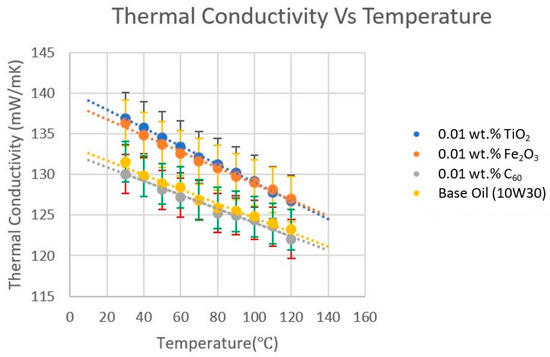

3.3. Correlations of Thermal Properties

According to the literature, the thermal and physical properties of nanofluids depend on different factors such as characteristics of the nanoparticles (size, shape, material), nanoparticle concentration, temperature, surfactant, base fluid, nanofluid preparation method, and ultrasonication and stirring duration [45,46,47,48,49,50,51,52,53,54,55,56,57,58,59]. Figure 13, Figure 14 and Figure 15 compare the thermal properties of 10W30-based nanofluids. These charts represent the thermal properties of the nano lubricant using different nanomaterials at a temperature range of 30–120 °C.

Figure 13.

Effect of thermal conductivity on 10W30/nanoparticles with mass fraction 0.01 wt.%.

Figure 14.

Effect of thermal diffusivity on 10W30/nanoparticles with mass fraction 0.01 wt.%.

Figure 15.

Effect of volumetric heat capacity on 10W30/nanoparticles with mass fraction 0.01 wt.%.

4. Conclusions

The numerous applications, as well as potential for economic and energy efficiency, make it important to improve the thermal properties of engine oil through the addition of nanoparticles. This study discusses the preparation procedure of several nanofluids, namely fullerene-C60/10W30, fullerene-C60/20W40, fullerene-C60/20W50, TiO2/10W30, and Fe2O3/10W30, as well as their thermal properties, including thermal conductivity, thermal diffusivity, volumetric heat capacity, and flash point. These properties were investigated in each nanofluid sample as a function of temperature range of 30–120 °C and mass fraction of 0.01 wt.%.

Since a low mass fraction was used in this study, the stability of the nanofluids was acceptable, and surfactants were not required. The two-step preparation method with magnetic stirring, ultrasonic waves, and heating process helped to prevent sedimentation and agglomeration.

The following observations were obtained through the experimental results.

- The thermal properties of engine oil-based nanofluids of metal oxide nanoparticles (TiO2 and Fe2O3) displayed significant increments compared to their respective base fluids.

- The TiO2/10W30 nanofluid showed the highest percentage increment of thermal properties in this experiment, with a 4.5% thermal conductivity ratio at a temperature of 40 °C, a 0.6% thermal diffusivity ratio at a temperature of 50 °C, a 3.7% volumetric heat capacity ratio at a temperature of 50 °C, and a 4.2% of flash point ratio.

- The Fe2O3/10W30 nanofluid was proved to have a 3.9% thermal conductivity ratio at a temperature of 80 °C, a 0.5% thermal diffusivity ratio at a temperature range of 30–80 °C, a 3.4% volumetric heat capacity ratio at a temperature of 80 °C, and a 3.5% flash point ratio, where it was observed that the Fe2O3/10W30 nanofluid has better thermal properties in higher temperatures compared to the TiO2/10W30 nanofluid.

- The fullerene-C60-based nanofluids exhibited a notable increase of 2.1% in flash points while not showing significant enhancements in the other thermal properties.

It can be concluded that the thermal properties of engine oils can be enhanced using both metal oxide nanoparticles (TiO2 and Fe2O3) and fullerene-C60 nanoparticles. The obtained results show that the thermal property enhancement ability of metal oxide nanoparticles is comparatively higher than fullerene-C60 nanoparticles in nanofluids.

Author Contributions

Conceptualization, C.G., A.I., V.V., P.M. and K.R.K.; methodology, C.G., A.I., V.V., P.M. and K.R.K.; validation., A.I. and V.V.; formal analysis, V.V., P.M. and K.R.K.; investigation, C.G.; resources, K.R.K.; data curation, C.G., A.I. and V.V.; writing—original draft preparation, C.G., A.I. and V.V.; writing—review and editing, C.G., A.I., V.V., P.M. and K.R.K.; visualization, C.G. and A.I.; supervision, P.M. and K.R.K.; project administration, K.R.K.; funding acquisition, K.R.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Science and Technology Human Resource Development Project, Ministry of Education, Sri Lanka, funded by the Asian Development Bank (Grant No CRG-R2-SB-1).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tahmasebi Sulgani, M.; Karimipour, A. Improve the thermal conductivity of 10w40-engine oil at various temperature by addition of Al2O3/Fe2O3 nanoparticles. J. Mol. Liq. 2019, 283, 660–666. [Google Scholar] [CrossRef]

- Nojoomizadeh, M.; Karimipour, A. The effects of porosity and permeability on fluid flow and heat transfer of multi walled carbon nano-tubes suspended in oil (MWCNT/Oil nano-fluid) in a microchannel filled with a porous medium. Phys. E Low-Dimens. Syst. Nanostruct. 2016, 84, 423–433. [Google Scholar] [CrossRef]

- (PDF) 123137893-Lubricant-Additives-Chemistry-and-Applications|Abdou Benkirane—Academia.edu. Available online: https://www.academia.edu/3892345/123137893_lubricant_additives_chemistry_and_applications (accessed on 11 October 2023).

- Asadi, A.; Asadi, M.; Rezaniakolaei, A.; Rosendahl, L.A.; Wongwises, S. An experimental and theoretical investigation on heat transfer capability of Mg (OH)2/MWCNT-engine oil hybrid nano-lubricant adopted as a coolant and lubricant fluid. Appl. Therm. Eng. 2018, 129, 577–586. [Google Scholar] [CrossRef]

- Ranjbarzadeh, R.; Karimipour, A.; Afrand, M.; Isfahani, A.H.M.; Shirneshan, A. Empirical analysis of heat transfer and friction factor of water/graphene oxide nanofluid flow in turbulent regime through an isothermal pipe. Appl. Therm. Eng. 2017, 126, 538–547. [Google Scholar] [CrossRef]

- Das, S.K.; Choi, S.U.S.; Patel, H.E. Heat Transfer in Nanofluids—A Review. Heat Transf. Eng. 2006, 27, 3–19. [Google Scholar] [CrossRef]

- Ghasemi, S.; Karimipour, A. Experimental investigation of the effects of temperature and mass fraction on the dynamic viscosity of CuO-paraffin nanofluid. Appl. Therm. Eng. 2018, 128, 189–197. [Google Scholar] [CrossRef]

- Koca, H.D.; Doganay, S.; Turgut, A.; Tavman, I.H.; Saidur, R.; Mahbubul, I.M. Effect of particle size on the viscosity of nanofluids: A review. Renew. Sustain. Energy Rev. 2018, 82, 1664–1674. [Google Scholar] [CrossRef]

- Hamzah, M.H.; Sidik, N.A.C.; Ken, T.L.; Mamat, R.; Najafi, G. Factors affecting the performance of hybrid nanofluids: A comprehensive review. Int. J. Heat Mass Transf. 2017, 115, 630–646. [Google Scholar] [CrossRef]

- Ranjbarzadeh, R.; Meghdadi Isfahani, A.H.; Afrand, M.; Karimipour, A.; Hojaji, M. An experimental study on heat transfer and pressure drop of water/graphene oxide nanofluid in a copper tube under air cross-flow: Applicable as a heat exchanger. Appl. Therm. Eng. 2017, 125, 69–79. [Google Scholar] [CrossRef]

- Pavía, M.; Alajami, K.; Estellé, P.; Desforges, A.; Vigolo, B. A critical review on thermal conductivity enhancement of graphene-based nanofluids. Adv. Colloid Interface Sci. 2021, 294, 102452. [Google Scholar] [CrossRef]

- Ettefaghi, E.; Rashidi, A.; Ahmadi, H.; Mohtasebi, S.S.; Pourkhalil, M. Thermal and rheological properties of oil-based nanofluids from different carbon nanostructures. Int. Commun. Heat Mass Transf. 2013, 48, 178–182. [Google Scholar] [CrossRef]

- Rostamian, S.H.; Saedodin, S.; Asgari, S.A.; Salarian, A.H. Effect of C60-SiO2 hybrid nanoparticles on thermophysical and tribological properties of a multigrade engine oil: An experimental study. J. Therm. Anal. Calorim. 2022, 147, 155–167. [Google Scholar] [CrossRef]

- Sukkar, K.A.; Karamalluh, A.A.; Jaber, T.N. Rheological and Thermal Properties of Lubricating Oil Enhanced by the Effect of CuO and TiO2 Nano-Additives. Al-Khwarizmi Eng. J. 2019, 15, 24–33. [Google Scholar] [CrossRef]

- Birleanu, C.; Pustan, M.; Cioaza, M.; Molea, A.; Popa, F.; Contiu, G. Effect of TiO2 nanoparticles on the tribological properties of lubricating oil: An experimental investigation. Sci. Rep. 2022, 12, 5201. [Google Scholar] [CrossRef]

- Sarbolookzadeh Harandi, S.; Karimipour, A.; Afrand, M.; Akbari, M.; D’Orazio, A. An experimental study on thermal conductivity of F-MWCNTs–Fe3O4/EG hybrid nanofluid: Effects of temperature and concentration. Int. Commun. Heat Mass Transf. 2016, 76, 171–177. [Google Scholar] [CrossRef]

- Borode, A.; Tshephe, T.; Olubambi, P.; Sharifpur, M.; Meyer, J. Stability and Thermophysical Properties of GNP-Fe2O3 Hybrid Nanofluid: Effect of Volume Fraction and Temperature. Nanomaterials 2023, 13, 1238. [Google Scholar] [CrossRef]

- Faisal, K.M.; Abdullah Mohammed, B. Design of Nanofluid-Based Spring Water/Tap Water and Nanoparticles of Fe2O3/ZnO as a Coolant for the Engines. Diyala J. Eng. Sci. 2023, 147–163. [Google Scholar] [CrossRef]

- Eneren, P.; Aksoy, Y.T.; Vetrano, M.R. Experiments on Single-Phase Nanofluid Heat Transfer Mechanisms in Microchannel Heat Sinks: A Review. Energies 2022, 15, 2525. [Google Scholar] [CrossRef]

- Ali, A.R.I.; Salam, B. A review on nanofluid: Preparation, stability, thermophysical properties, heat transfer characteristics and application. SN Appl. Sci. 2020, 2, 1636. [Google Scholar] [CrossRef]

- Kong, L.; Sun, J.; Bao, Y. Preparation, characterization and tribological mechanism of nanofluids. RSC Adv. 2017, 7, 12599–12609. [Google Scholar] [CrossRef]

- ASTM D7896-19; Standard Test Method for Thermal Conductivity, Thermal Diffusivity and Volumetric Heat Capacity of Engine Coolants and Related Fluids by Transient Hot Wire Liquid Thermal Conductivity Method. ASTM International: Conshohocken, PA, USA, 2019.

- ASTM D93; Standard Test Methods for Flash Point by Pensky-Martens Closed Cup Tester. ASTM International: Conshohocken, PA, USA, 2013. Available online: https://www.astm.org/d0093-20.html (accessed on 11 October 2023).

- Wei, B.; Zou, C.; Li, X. Experimental investigation on stability and thermal conductivity of diathermic oil based TiO2 nanofluids. Int. J. Heat Mass Transf. 2017, 104, 537–543. [Google Scholar] [CrossRef]

- Abid, M.A.; Khan, I.; Ullah, Z.; Ullah, K.; Haider, A.; Ali, S.M. Dielectric and Thermal Performance Up-Gradation of Transformer Oil Using Valuable Nano-Particles. IEEE Access 2019, 7, 153509–153518. [Google Scholar] [CrossRef]

- Aberoumand, S.; Jafarimoghaddam, A. Experimental study on synthesis, stability, thermal conductivity and viscosity of Cu–engine oil nanofluid. J. Taiwan Inst. Chem. Eng. 2017, 71, 315–322. [Google Scholar] [CrossRef]

- Asadi, M.; Asadi, A.; Aberoumand, S. An experimental and theoretical investigation on the effects of adding hybrid nanoparticles on heat transfer efficiency and pumping power of an oil-based nanofluid as a coolant fluid. Int. J. Refrig. 2018, 89, 83–92. [Google Scholar] [CrossRef]

- Aberoumand, S.; Jafarimoghaddam, A. Tungsten (III) oxide (WO3)—Silver/transformer oil hybrid nanofluid: Preparation, stability, thermal conductivity and dielectric strength. Alex. Eng. J. 2018, 57, 169–174. [Google Scholar] [CrossRef]

- Ettefaghi, E.; Ahmadi, H.; Rashidi, A.; Nouralishahi, A.; Mohtasebi, S.S. Preparation and thermal properties of oil-based nanofluid from multi-walled carbon nanotubes and engine oil as nano-lubricant. Int. Commun. Heat Mass Transf. 2013, 46, 142–147. [Google Scholar] [CrossRef]

- Sathishkumar, S.D.; Rajmohan, T. Preparation and Analysis of the Thermal properties of Engine oil Reinforced with Multi-walled Carbon Nanotubes. IOP Conf. Ser. Mater. Sci. Eng. 2018, 390, 012068. [Google Scholar] [CrossRef]

- Aberoumand, S.; Jafarimoghaddam, A.; Moravej, M.; Aberoumand, H.; Javaherdeh, K. Experimental study on the rheological behavior of silver-heat transfer oil nanofluid and suggesting two empirical based correlations for thermal conductivity and viscosity of oil based nanofluids. Appl. Therm. Eng. 2016, 101, 362–372. [Google Scholar] [CrossRef]

- Farbod, M.; Kouhpeymani Asl, R.; Noghreh Abadi, A.R. Morphology dependence of thermal and rheological properties of oil-based nanofluids of CuO nanostructures. Colloids Surf. Physicochem. Eng. Asp. 2015, 474, 71–75. [Google Scholar] [CrossRef]

- Ettefaghi, E.; Ahmadi, H.; Rashidi, A.; Mohtasebi, S.S.; Alaei, M. Experimental evaluation of engine oil properties containing copper oxide nanoparticles as a nanoadditive. Int. J. Ind. Chem. 2013, 4, 28. [Google Scholar] [CrossRef]

- Chua Abdullah, M.I.H.; Abdollah, M.F.; Amiruddin, H.; Tamaldin, N.; Mat Nuri, N.R. Effect of hBN/Al2O3 Nanoparticle Additives on the Tribological Performance of Engine Oil. J. Teknol. 2014, 66. [Google Scholar] [CrossRef]

- Yu, W.; Xie, H.; Wang, X.; Wang, X. Significant thermal conductivity enhancement for nanofluids containing graphene nanosheets. Phys. Lett. A 2011, 375, 1323–1328. [Google Scholar] [CrossRef]

- Ranjbarzadeh, R.; Chaabane, R. Experimental Study of Thermal Properties and Dynamic Viscosity of Graphene Oxide/Oil Nano-Lubricant. Energies 2021, 14, 2886. [Google Scholar] [CrossRef]

- Agarwal, D.K.; Vaidyanathan, A.; Sunil Kumar, S. Experimental investigation on thermal performance of kerosene–graphene nanofluid. Exp. Therm. Fluid Sci. 2016, 71, 126–137. [Google Scholar] [CrossRef]

- Alqahtani, B.; Hoziefa, W.; Abdel Moneam, H.M.; Hamoud, M.; Salunkhe, S.; Elshalakany, A.B.; Abdel-Mottaleb, M.; Davim, J.P. Tribological Performance and Rheological Properties of Engine Oil with Graphene Nano-Additives. Lubricants 2022, 10, 137. [Google Scholar] [CrossRef]

- Li, Z.; Asadi, S.; Karimipour, A.; Abdollahi, A.; Tlili, I. Experimental study of temperature and mass fraction effects on thermal conductivity and dynamic viscosity of SiO2-oleic acid/liquid paraffin nanofluid. Int. Commun. Heat Mass Transf. 2020, 110, 104436. [Google Scholar] [CrossRef]

- Desai, N.; Nagaraj, A.M.; Sabnis, N. Analysis of thermo-physical properties of SAE20W40 engine oil by the addition of SiO2 nanoparticles. Mater. Today Proc. 2021, 47, 5646–5651. [Google Scholar] [CrossRef]

- Khalil, W.; Mohamed, A.; Bayoumi, M.; Osman, T.A. Thermal and Rheological Properties of Industrial Mineral Gear Oil and Paraffinic Oil/CNTs Nanolubricants. Iran. J. Sci. Technol. Trans. Mech. Eng. 2018, 42, 355–361. [Google Scholar] [CrossRef]

- Yang, L.; Mao, M.; Huang, J.; Ji, W. Enhancing the thermal conductivity of SAE 50 engine oil by adding zinc oxide nano-powder: An experimental study. Powder Technol. 2019, 356, 335–341. [Google Scholar] [CrossRef]

- Murshed, S.M.S. Simultaneous Measurement of Thermal Conductivity, Thermal Diffusivity, and Specific Heat of Nanofluids. Heat Transf. Eng. 2012, 33, 722–731. [Google Scholar] [CrossRef]

- Wong, K.V.; De Leon, O. Applications of Nanofluids: Current and Future. Adv. Mech. Eng. 2010, 2, 519659. [Google Scholar] [CrossRef]

- Yu, W.; Xie, H.; Bao, D. Enhanced thermal conductivities of nanofluids containing graphene oxide nanosheets. Nanotechnology 2010, 21, 055705. [Google Scholar] [CrossRef]

- Simpson, S.; Schelfhout, A.; Golden, C.; Vafaei, S. Nanofluid Thermal Conductivity and Effective Parameters. Appl. Sci. 2018, 9, 87. [Google Scholar] [CrossRef]

- Jia, L.; Chen, Y.; Lei, S.; Mo, S.; Luo, X.; Shao, X. External electromagnetic field-aided freezing of CMC-modified graphene/water nanofluid. Appl. Energy 2016, 162, 1670–1677. [Google Scholar] [CrossRef]

- Taherialekouhi, R.; Rasouli, S.; Khosravi, A. An experimental study on stability and thermal conductivity of water-graphene oxide/aluminum oxide nanoparticles as a cooling hybrid nanofluid. Int. J. Heat Mass Transf. 2019, 145, 118751. [Google Scholar] [CrossRef]

- Karimipour, A.; Taghipour, A.; Malvandi, A. Developing the laminar MHD forced convection flow of water/FMWNT carbon nanotubes in a microchannel imposed the uniform heat flux. J. Magn. Magn. Mater. 2016, 419, 420–428. [Google Scholar] [CrossRef]

- Goodarzi, M.; Safaei, M.R.; Oztop, H.F.; Karimipour, A.; Sadeghinezhad, E.; Dahari, M.; Kazi, S.N.; Jomhari, N. Numerical Study of Entropy Generation due to Coupled Laminar and Turbulent Mixed Convection and Thermal Radiation in an Enclosure Filled with a Semitransparent Medium. Sci. World J. 2014, 2014, e761745. [Google Scholar] [CrossRef]

- Hemmat Esfe, M.; Abbasian Arani, A.A.; Niroumand, A.H.; Yan, W.-M.; Karimipour, A. Mixed convection heat transfer from surface-mounted block heat sources in a horizontal channel with nanofluids. Int. J. Heat Mass Transf. 2015, 89, 783–791. [Google Scholar] [CrossRef]

- Akbari, M.; Afrand, M.; Arshi, A.; Karimipour, A. An experimental study on rheological behavior of ethylene glycol based nanofluid: Proposing a new correlation as a function of silica concentration and temperature. J. Mol. Liq. 2017, 233, 352–357. [Google Scholar] [CrossRef]

- Khodadadi, H.; Toghraie, D.; Karimipour, A. Effects of nanoparticles to present a statistical model for the viscosity of MgO-Water nanofluid. Powder Technol. 2019, 342, 166–180. [Google Scholar] [CrossRef]

- Shahsavar, A.; Khanmohammadi, S.; Karimipour, A.; Goodarzi, M. A novel comprehensive experimental study concerned synthesizes and prepare liquid paraffin-Fe3O4 mixture to develop models for both thermal conductivity & viscosity: A new approach of GMDH type of neural network. Int. J. Heat Mass Transf. 2019, 131, 432–441. [Google Scholar] [CrossRef]

- Karimipour, A.; Hemmat Esfe, M.; Safaei, M.R.; Toghraie Semiromi, D.; Jafari, S.; Kazi, S.N. Mixed con vection of copper–water nanofluid in a shallow inclined lid driven cavity using the lattice Boltzmann method. Phys. Stat. Mech. Its Appl. 2014, 402, 150–168. [Google Scholar] [CrossRef]

- Karimipour, A.; Hossein Nezhad, A.; D’Orazio, A.; Hemmat Esfe, M.; Safaei, M.R.; Shirani, E. Simulation of copper–water nanofluid in a microchannel in slip flow regime using the lattice Boltzmann method. Eur. J. Mech.-B/Fluids 2015, 49, 89–99. [Google Scholar] [CrossRef]

- Nafchi, P.M.; Karimipour, A.; Afrand, M. The evaluation on a new non-Newtonian hybrid mixture composed of TiO2 /ZnO/EG to present a statistical approach of power law for its rheological and thermal properties. Phys. Stat. Mech. Its Appl. 2019, 516, 1–18. [Google Scholar] [CrossRef]

- Alrashed, A.A.A.A.; Karimipour, A.; Bagherzadeh, S.A.; Safaei, M.R.; Afrand, M. Electro- and thermophysical properties of water-based nanofluids containing copper ferrite nanoparticles coated with silica: Experimental data, modeling through enhanced ANN and curve fitting. Int. J. Heat Mass Transf. 2018, 127, 925–935. [Google Scholar] [CrossRef]

- Karimipour, A.; Bagherzadeh, S.A.; Goodarzi, M.; Alnaqi, A.A.; Bahiraei, M.; Safaei, M.R.; Shadloo, M.S. Synthesized CuFe2O4/SiO2 nanocomposites added to water/EG: Evaluation of the thermophysical properties beside sensitivity analysis & EANN. Int. J. Heat Mass Transf. 2018, 127, 1169–1179. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).