Tracking the Carbon Emissions Using Electricity Big Data: A Case Study of the Metal Smelting Industry

Abstract

1. Introduction

1.1. The Importance of the Metal Smelting Industry in Guangxi Province

- How can we propose a carbon emission accounting method that considers inter-regional flows and encompasses both direct and indirect carbon emissions?

- How can we establish a real-time monitoring method for enterprise carbon emissions based on electricity big data?

- What is the progress of carbon neutrality in the metal smelting industry in Guangxi, and how can precise emission reduction be achieved based on the enterprise carbon monitoring model?

1.2. Literature Review on CO2 Monitoring Methods

- This approach utilizes the carbon conductivity coefficient to replace the methods of directly monitoring carbon emissions, which can significantly reduce the measurement cost of carbon emissions. Traditional point source carbon emission monitoring methods mainly focus on chemical detection, spectral analysis, and carbon satellite monitoring, which are not only costly but also not easy to scale. This project transforms the methods by fully exploiting the existing electricity data resources of power grid companies. Based on the correlation mechanism of electricity consumption and historical carbon emission data in different industries, the carbon conduction coefficient for electricity is calculated, constructing an indirect monitoring method for enterprise carbon emissions, significantly reducing equipment and cost requirements;

- Expanding the scope of carbon emission accounting using network analysis and input-output methods, considering indirect conduction, improving the accuracy of the accounting scope. This study considers the regional heterogeneity of electricity carbon emissions and calculates the electricity emission coefficients for different regions, considering the case of purchasing electricity from outside the region. It achieves indirect carbon emission transfer accounting at the regional and industry levels, reflecting the principle of comprehensive carbon emission responsibility and providing more accurate results than traditional Scope 1 accounting, which only considers direct carbon emissions;

- Utilizing random event sequence methods to achieve real-time monitoring of carbon emissions at the enterprise level and improve time accuracy. This project utilizes the significant features of objective, precise, and real-time electricity data to establish short-term “electricity-carbon conductivity” prediction methods for different industries. Due to the high-frequency characteristics of electricity big data, this monitoring method can downscale traditional carbon emissions data from annual to hourly levels, achieving more accurate real-time monitoring of carbon emissions.

2. Methods for Enterprise CO2 Emissions Monitoring Using Electricity Big Data

2.1. Calculation Methods for Direct Carbon Emissions

2.2. Calculation Methods for Indirect Carbon Emissions

2.3. Construction of Industry Carbon-Conductivity Coefficient

3. Results and Discussion

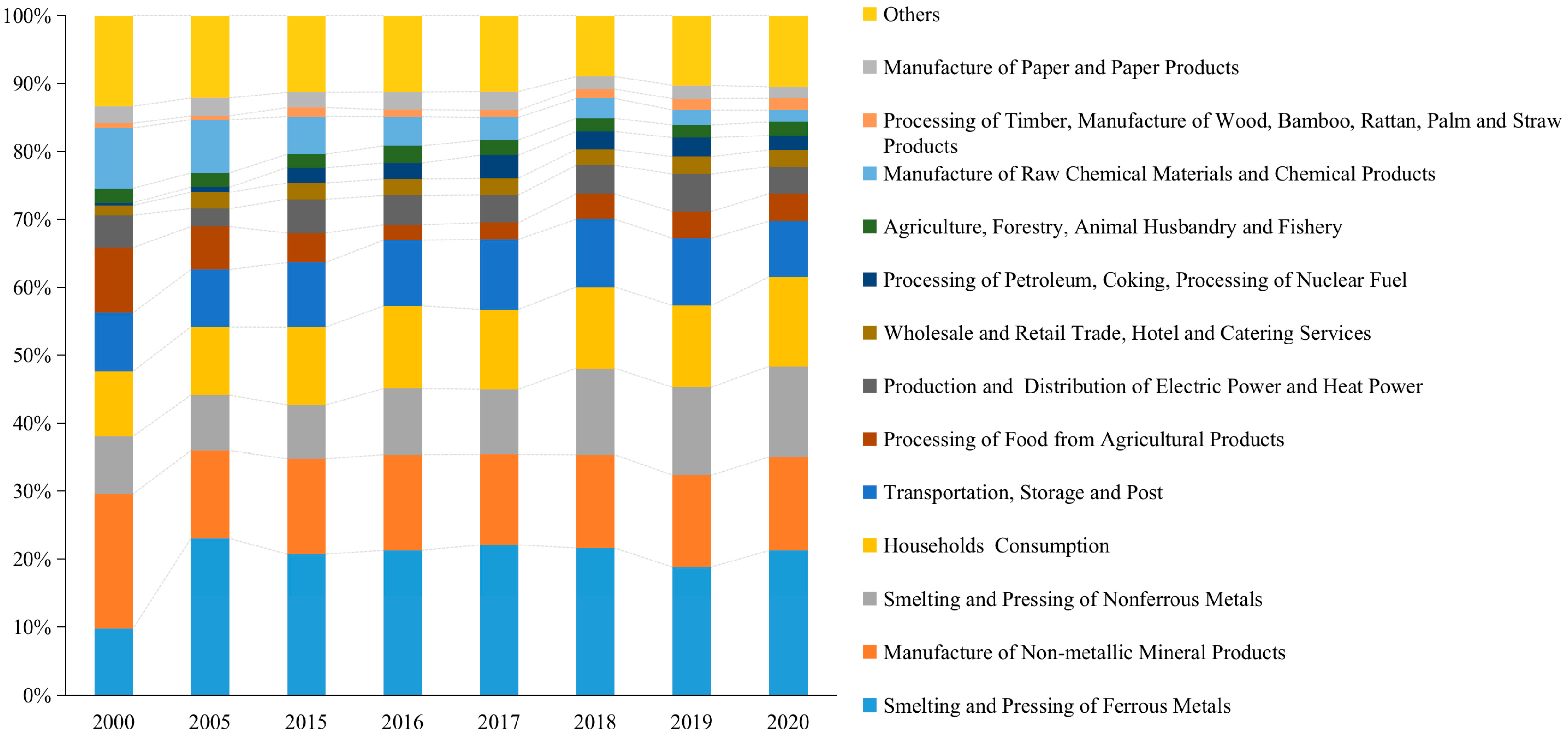

3.1. Results of Total Carbon Emissions in Guangxi Metal Smelting Industry

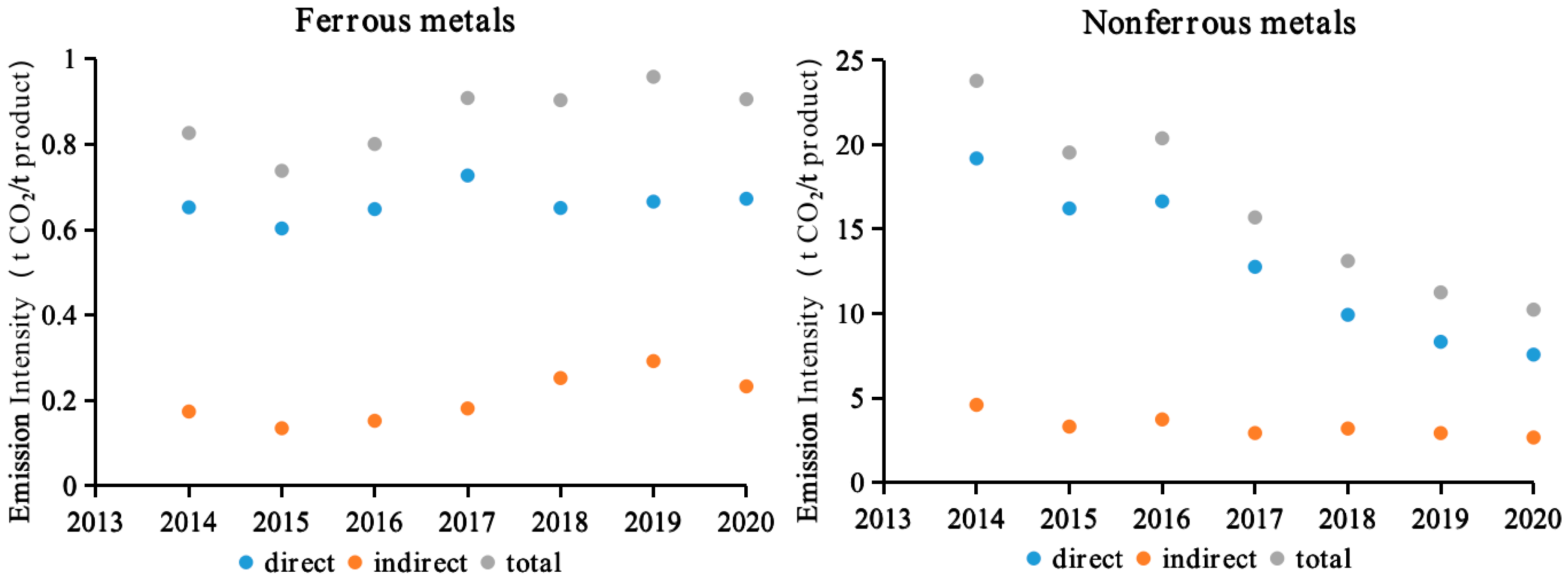

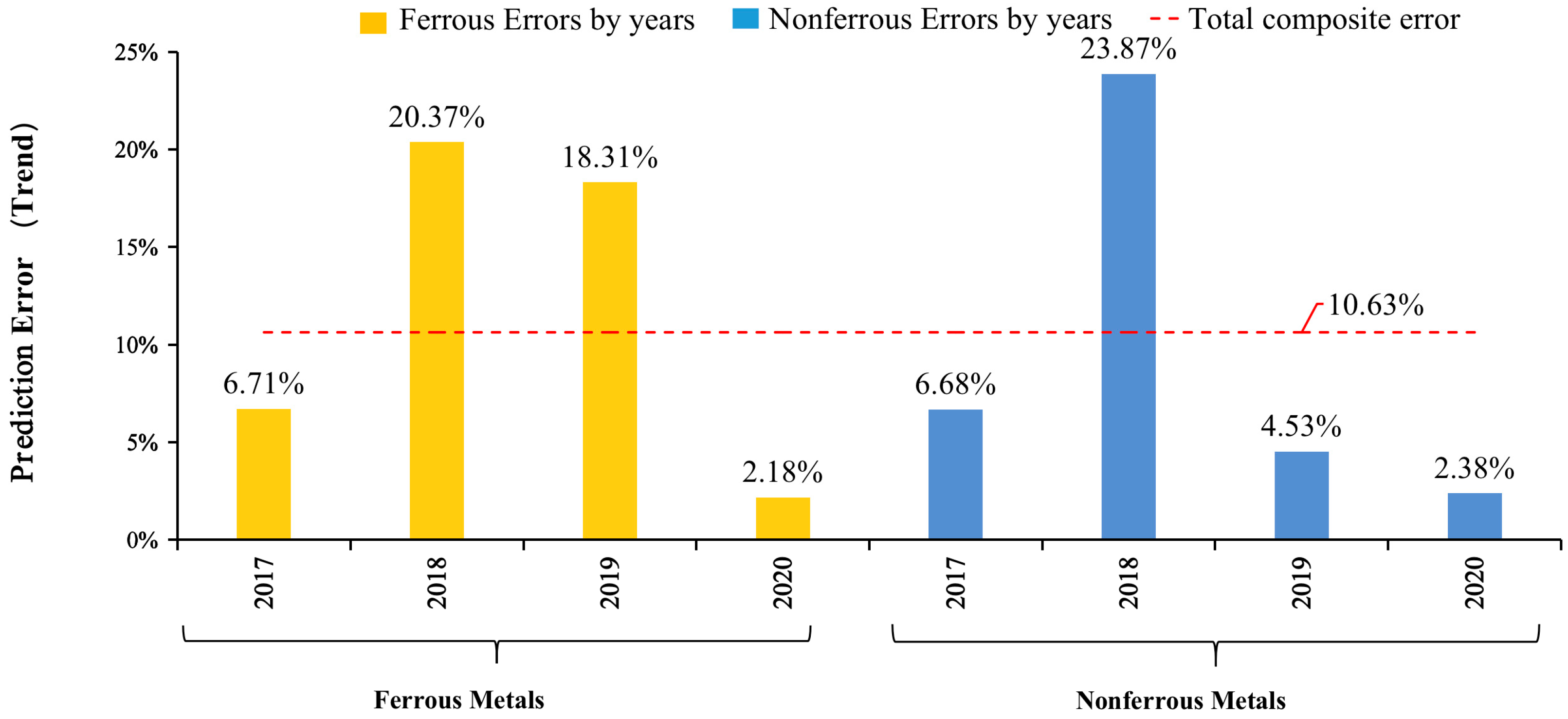

3.2. Electric-Carbon Coefficient of Guangxi Metal Smelting Industry

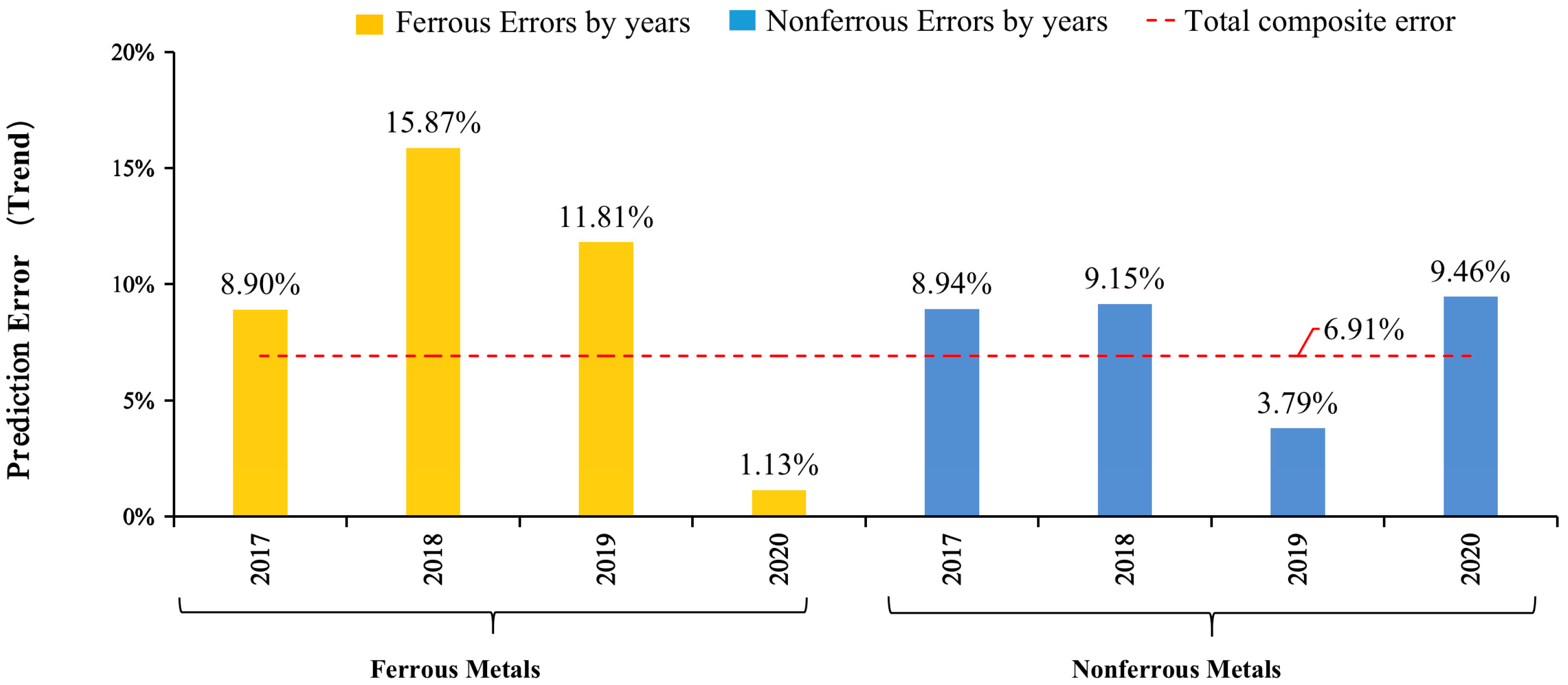

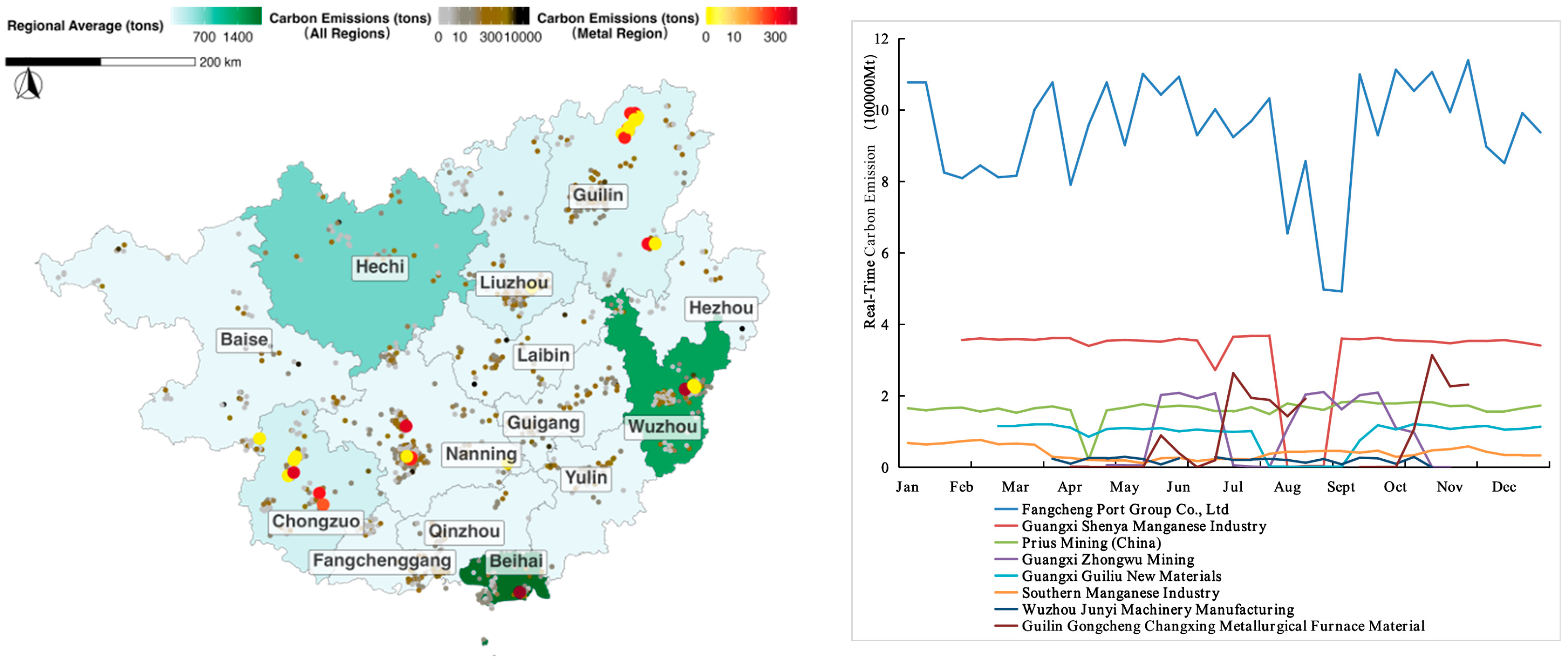

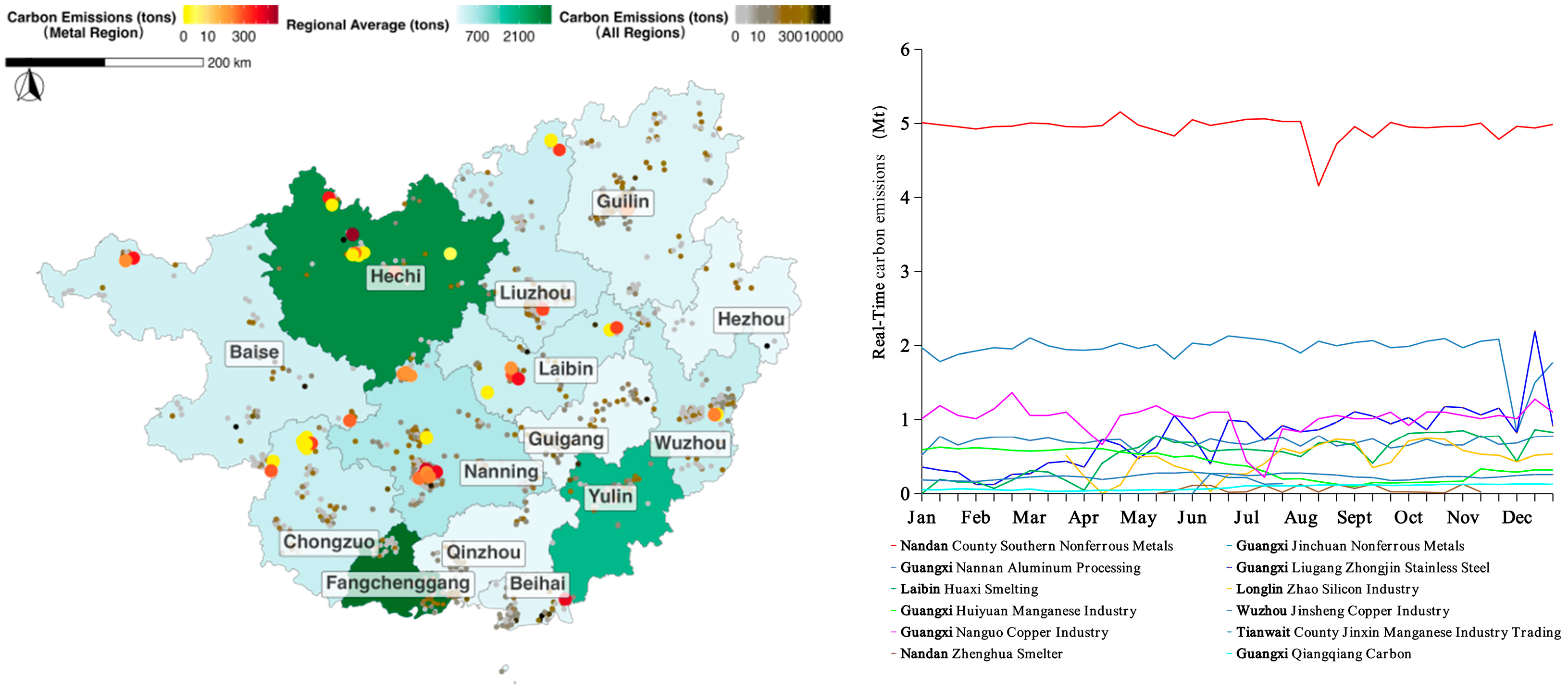

3.3. Carbon Emission Monitoring of Enterprises Based on Big Data of Electricity

4. Conclusions and Implications

4.1. Conclusions

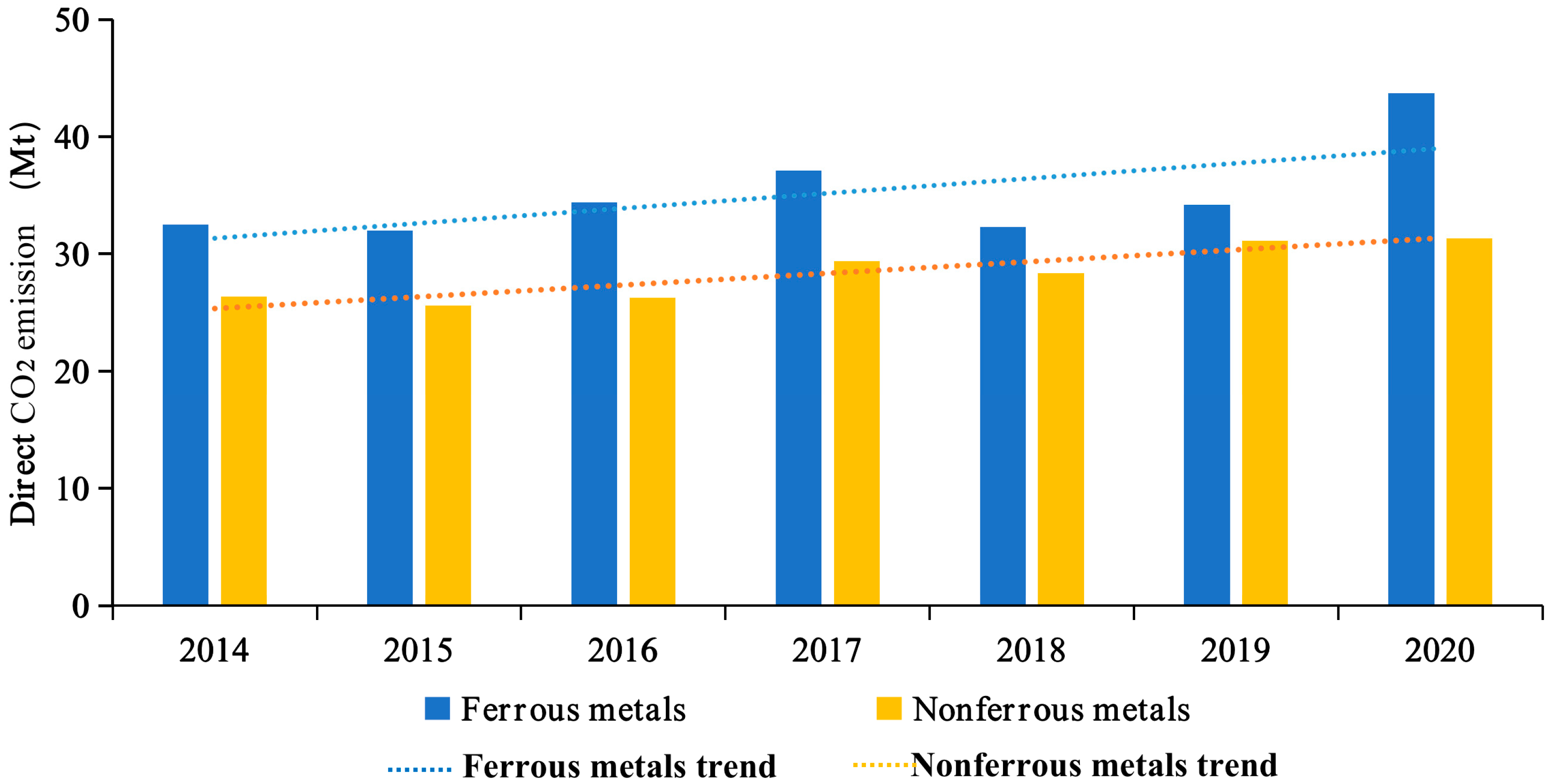

- Currently, the carbon emissions of the metal smelting industry in Guangxi Province are still in the upward phase of the carbon peak path, with both direct carbon emissions and actual carbon emission coefficients showing an upward trend. In 2020, the comprehensive carbon emissions of the ferrous metal smelting industry reached 58.84 Mt, an increase of 42.78% compared to 2014. In 2020, the comprehensive carbon emissions of the nonferrous metal smelting industry were 42.35 Mt, showing an increase of 29.50% compared to 2014. The industry has not achieved significant carbon emissions reductions in the past five years, indicating a great need for future development and the potential for emission reductions;

- There are significant differences in emission coefficients among regions, with notable variations in the values and trends of direct and comprehensive carbon emissions, therefore comprehensive accounting of carbon emissions is of great significance for accurately formulating efficient carbon reduction policies. The emission coefficients of each province range from 14 g CO2/KWh to 940 g CO2/KWh, with an average of 524 g CO2/KWh; the numbers range significantly, with coefficients in northern provinces, such as Hebei and Inner Mongolia, generally higher than those of southern provinces like Xizang. From 2014 to 2020, the direct carbon emissions of the ferrous metal smelting industry increased from 32.52 Mt to 43.69 Mt, showing an increase of 34.33%. The direct carbon emissions of the nonferrous metal smelting industry increased from 26.39 Mt to 31.33 Mt, with an increase of 18.75%. Compared to ferrous metals, the direct carbon emissions of the nonferrous metal industry are relatively low in value and increase amplitude. For the comprehensive carbon emission coefficient, the nonferrous metal industry has always been higher than that of the ferrous metal industry, and the upward trend is not significant;

- The technologies used in ferrous metal smelting and nonferrous metal smelting are significantly different, leading to heterogeneous emission properties. For example, nonferrous metals can be decomposed using electrolysis, resulting in high electricity consumption. Therefore, targeted policy regulatory schemes should be adopted. In 2020, the indirect carbon emissions of the nonferrous metal smelting industry were 4.86 Mt, an increase of 74.41% compared to 2014. From 2014 to 2020, the average level of indirect carbon emissions from the nonferrous industry, considering electricity distribution, accounted for 24% of comprehensive carbon emissions, significantly higher than that of the ferrous metal smelting industry. Among the increases in carbon emissions, only 36.65% of the ferrous metal smelting industry was contributed by the increase in indirect carbon emissions, with the rest being contributed by the increase in direct carbon emissions; however, 49% of emissions from the nonferrous metal smelting industry were contributed by the increase in indirect carbon emissions.

4.2. Policy Implications

- Accurately calculating and regulating the actual carbon emissions of major industries such as metal smelting is of great significance for effectively reducing carbon emissions. On the one hand, the metal smelting industry, as one of the industries with the highest carbon emissions, accounts for a large proportion of carbon emissions and has significant regulatory achievements and emissions reduction potential. On the other hand, if the actual carbon emissions are not accurately identified, it will cause significant errors in the judgment of the carbon emission structure and the identification of emission sources, leading to biases in regulatory focus and policy formulation. Meanwhile, the metal smelting industry has not yet achieved significant carbon reductions in the past five years; therefore, in the future, it is still necessary to focus on researching its technological transformation and regulatory incentive plans;

- Using real-time carbon emission monitoring at the enterprise level can promote the optimization of carbon emission policies, independent emission reduction innovation, and carbon market construction. On the one hand, real-time carbon emission monitoring provides governments with real-time and accurate emission data, enabling policymakers to adjust and improve carbon emission policies more flexibly, helping to ensure the effectiveness of policies and better respond to the challenges of climate change. On the other hand, enterprise-level carbon emission monitoring encourages enterprises to actively seek emission reduction opportunities. Through real-time monitoring, enterprises can better understand their emission status, identify potential emission reduction measures, and strengthen independent emission reduction innovation, which helps them to improve production efficiency, reduce costs, and gain a competitive advantage in a low-carbon economy. Meanwhile, real-time emissions data are the foundation of carbon market operations, and can be used to track the emissions of enterprises and serve as a basis for carbon trading. Real-time monitoring at the enterprise level provides transparency for the carbon market, helps to build trust, and promotes market development and maturity;

- Although a monitoring method for corporate carbon emissions has been established in this study and achieved good results, there are still several areas that can be addressed in future research. First, it is meaningful to compare current emissions levels with the level required to achieve carbon neutrality goals, identify the target gap, and accurately develop emissions reduction strategies. Secondly, more big data can be combined to mutually verify and supplement each other, such as the manufacturing production index, financial transaction index, etc. Finally, actual emissions can be compared with predicted emissions to verify monitoring accuracy and analyze the reasons for errors. These improvements will better utilize big data to promote the smooth achievement of carbon neutrality goals.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- IEA. An Energy Sector Road Map to Carbon Neutrality in China. 2021. Available online: https://www.iea.org/reports/an-energy-sector-roadmap-to-carbon-neutrality-in-china (accessed on 10 April 2023).

- Zhang, S. Reflection on Optimizing and Adjusting the Carbon Emission Factors of the Power Grid under the Background of “Dual Carbon”. China Electr. Power Enterp. Manag. 2022, 22, 62–65. [Google Scholar]

- Zhao, S.; Fu, H.; Liu, J. Promoting high-quality development of Sinopec in all aspects. Sinopec 2021, 1, 6–8. [Google Scholar]

- Shan, Y.; Huang, Q.; Guan, D.; Hubacek, K. China CO2 emission accounts 2016–2017. Sci. Data 2020, 7, 54. [Google Scholar] [CrossRef] [PubMed]

- Guan, Y.; Shan, Y.; Huang, Q.; Chen, H.; Wang, D.; Hubacek, K. Assessment to China’s recent emission pattern shifts. Earth’s Future 2021, 9, e2021EF002241. [Google Scholar] [CrossRef]

- Chen, X.; Li, H.; Mu, Y. Difficulties and Suggestions for Carbon Peaking and Carbon Neutrality in Guangxi. Volkswagen Technol. 2022, 7, 155–158. [Google Scholar]

- Bing, L.; Akintoye, A.; Edwards, P.; Hardcastle, C. The allocation of risk in PPP/PFI construction projects in the UK. Int. J. Proj. Manag. 2005, 23, 25–35. [Google Scholar] [CrossRef]

- Wu, J.; Liao, J. Guangxi Statistical Yearbook. 2021. Available online: http://tjj.gxzf.gov.cn/tjsj/tjnj/ (accessed on 20 April 2023).

- Wei, Y.; Liu, L.; Fan, Y.; Wu, G. China Energy Report 2008: Carbon Emissions Study; Science Press: Beijing, China, 2008. [Google Scholar]

- Zhang, Q.; Zhang, D.; Zhang, X. Application of Online Monitoring to China’s Carbon Emission Trading System: Key Issues and Policy Recommendations. J. Environ. Econ. 2021, 6, 136–146. [Google Scholar]

- Pan, J. Construction, challenges and market expansion of emissions trading system. China Popul. Resour. Environ. 2016, 26, 1–5. [Google Scholar]

- Liu, Z.; Guan, D.; Wei, W. Carbon emission accounting in China. Sci. China Earth Sci. 2018, 48, 878–887. (In Chinese) [Google Scholar]

- Qian, H.; Xu, S.; Cao, J.; Ren, F.; Wu, L. Air pollution reduction and climate co-benefits in China’s industries. Nat. Sustain. 2021, 4, 417–425. [Google Scholar] [CrossRef]

- Caldeira, K.; Davis, S.J. Accounting for carbon dioxide emissions: A matter of time. Proc. Natl. Acad. Sci. USA 2011, 108, 8533–8534. [Google Scholar] [CrossRef]

- Yu, S.; Zheng, S.; Li, X.; Li, L. China can peak its energy-related carbon emissions before 2025: Evidence from industry restructuring. Energy Econ. 2018, 73, 91–107. [Google Scholar] [CrossRef]

- Zhou, Y.; Shan, Y.; Liu, G.; Guan, D. Emissions and low-carbon development in Guangdong-Hong Kong-Macao Greater Bay Area cities and their surroundings. Appl. Energy 2018, 228, 1683–1692. [Google Scholar] [CrossRef]

- Chen, G.; Shan, Y.; Hu, Y.; Tong, K.; Wiedmann, T.; Ramaswami, A.; Guan, D.; Shi, L.; Wang, Y. Review on City-Level Carbon Accounting. Environ. Sci. Technol. 2019, 53, 5545–5558. [Google Scholar] [CrossRef] [PubMed]

- Hao, H.; Geng, Y.; Li, W.; Guo, B. Energy consumption and GHG emissions from China’s freight transport sector: Scenarios through 2050. Energy Policy 2015, 85, 94–101. [Google Scholar] [CrossRef]

- Yang, L.; Lin, B. Carbon dioxide-emission in China׳ s power industry: Evidence and policy implications. Renew. Sustain. Energy Rev. 2016, 60, 258–267. [Google Scholar] [CrossRef]

- Gabrielli, P.; Gazzani, M.; Mazzotti, M. The role of carbon capture and utilization, carbon capture and storage, and biomass to enable a net-zero-CO2 emissions chemical industry. Ind. Eng. Chem. Res. 2020, 59, 7033–7045. [Google Scholar] [CrossRef]

- Lippiatt, N.; Ling, T.C.; Pan, S.Y. Towards carbon-neutral construction materials: Carbonation of cement-based materials and the future perspective. J. Build. Eng. 2020, 28, 101062. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, H.; Long, Y. A factor-based bottom-up approach for the long-term electricity consumption estimation in the Japanese residential sector. J. Environ. Manag. 2020, 270, 110750. [Google Scholar] [CrossRef] [PubMed]

- Brohé, A. The Handbook of Carbon Accounting; Routledge: Oxfordshire, UK, 2017. [Google Scholar]

- Eggleston, H.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. 2006 IPCC Guidelines for National Greenhouse Gas Inventories. 2006. Available online: https://www.osti.gov/etdeweb/biblio/20880391 (accessed on 20 April 2023).

- Oda, T.; Maksyutov, S.; Andres, R.J. The Open-source Data Inventory for Anthropogenic CO2, version 2016 (ODIAC2016): A global monthly fossil fuel CO2 gridded emissions data product for tracer transport simulations and surface flux inversions. Earth Syst. Sci. Data 2018, 10, 87–107. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Sun, L.; Geng, Y.; Dong, H.; Ren, J.; Liu, Z.; Tian, X.; Yabar, H.; Higano, Y. Examining industrial structure changes and corresponding carbon emission reduction effect by combining input-output analysis and social network analysis: A comparison study of China and Japan. J. Clean. Prod. 2017, 162, 61–70. [Google Scholar] [CrossRef]

- Sun, L.; Qin, L.; Taghizadeh-Hesary, F.; Zhang, J.; Mohsin, M.; Chaudhry, I.S. Analyzing carbon emission transfer network structure among provinces in China: New evidence from social network analysis. Environ. Sci. Pollut. Res. 2020, 27, 23281–23300. [Google Scholar] [CrossRef]

- Chen, H.; Wang, R.; Liu, X.; Du, Y.; Yang, Y. Monitoring the enterprise carbon emissions using electricity big data: A case study of Beijing. J. Clean. Prod. 2023, 396, 136427. [Google Scholar] [CrossRef]

- Abdi, R.; Taki, M.; Akbarpour, M. An Analysis of Energy input-output and Emissions of Greenhouse Gases from Agricultural Productions. Int. J. Nat. Eng. Sci. 2012, 6, 73–79. [Google Scholar]

- Qu, S.; Liang, S.; Xu, M. CO2 emissions embodied in interprovincial electricity transmissions in China. Environ. Sci. Technol. 2017, 51, 10893–10902. [Google Scholar] [CrossRef]

- Poblete-Cazenave, M.; Pachauri, S. A model of energy poverty and access: Estimating household electricity demand and appliance ownership. Energy Econ. 2021, 98, 105266. [Google Scholar] [CrossRef]

- Singh, P.; Kansal, A.; Carliell-Marquet, C. Energy and carbon footprints of sewage treatment methods. J. Environ. Manag. 2016, 165, 22–30. [Google Scholar] [CrossRef]

- Hamamoto, M. Energy-saving behavior and marginal abatement cost for household CO2 emissions. Energy Policy 2013, 63, 809–813. [Google Scholar] [CrossRef]

- Chancel, L. Are younger generations higher carbon emitters than their elders?: Inequalities, generations and CO2 emissions in France and in the USA. Ecol. Econ. 2014, 100, 195–207. [Google Scholar] [CrossRef]

- Liu, Z.; Guan, D.; Wei, W.; Davis, S.J.; Ciais, P.; Bai, J.; Peng, S.; Zhang, Q.; Hubacek, K.; Marland, G. Reduced carbon emission estimates from fossil fuel combustion and cement production in China. Nature 2015, 524, 335–338. [Google Scholar] [CrossRef] [PubMed]

- China Carbon Emissions Database. Available online: https://www.ceads.net/ (accessed on 20 April 2023).

- 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Available online: https://www.ipcc-nggip.iges.or.jp/public/2019rf/ (accessed on 10 April 2023).

- Wei, W.; Zhang, P.; Li, J. The framework of regional electricity-related carbon emissions accounting and its application. China Popul. Resour. Environ. 2020, 30, 9. [Google Scholar]

- Li, W.; Liang, C.; Dong, X.; Li, Y.; Li, S. Analysis of the Impact of Green Electricity and Green Certificate Trading on Carbon Emission Factors in Electricity. Value Eng. 2023, 42, 13–15. [Google Scholar]

- Vidovic, D.; Marmier, A.; Zore, L.; Moya, J. Greenhouse Gas Emission Intensities of the Steel, Fertilisers, Aluminium and Cement Industries in the EU and Its Main Trading Partners; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar]

- Available online: https://baijiahao.baidu.com/s?id=1701507758246891378&wfr=spider&for=pc (accessed on 3 January 2024).

- Available online: https://www.huaon.com/channel/distdata/875847.html (accessed on 3 January 2024).

- Available online: https://www.toutiao.com/article/7215637230218527291/?wid=1705464821861 (accessed on 3 January 2024).

- Available online: https://baijiahao.baidu.com/s?id=1785269024649166773&wfr=spider&for=pc (accessed on 3 January 2024).

- Wang, W.; Wu, J.; Ge, Y.; Li, Q. Carbon emission accounting method and strategy analysis under the dual carbon background–Taking the copper and aluminum industry as an example. Nonferrous Met. (Smelt. Part) 2022, 4, 1–11. [Google Scholar]

- Available online: https://wenku.baidu.com/view/fa80aec20329bd64783e0912a216147917117ee2.html (accessed on 3 January 2024).

- Zhou, C.; Lin, X.; Wang, R.; Song, B. Real-time carbon emissions monitoring of high-energy-consumption enterprises in Guangxi based on electricity big data. Energies 2023, 16, 5124. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, C.; Tang, Y.; Zhu, D.; Cui, Z. Tracking the Carbon Emissions Using Electricity Big Data: A Case Study of the Metal Smelting Industry. Energies 2024, 17, 652. https://doi.org/10.3390/en17030652

Zhou C, Tang Y, Zhu D, Cui Z. Tracking the Carbon Emissions Using Electricity Big Data: A Case Study of the Metal Smelting Industry. Energies. 2024; 17(3):652. https://doi.org/10.3390/en17030652

Chicago/Turabian StyleZhou, Chunli, Yuze Tang, Deyan Zhu, and Zhiwei Cui. 2024. "Tracking the Carbon Emissions Using Electricity Big Data: A Case Study of the Metal Smelting Industry" Energies 17, no. 3: 652. https://doi.org/10.3390/en17030652

APA StyleZhou, C., Tang, Y., Zhu, D., & Cui, Z. (2024). Tracking the Carbon Emissions Using Electricity Big Data: A Case Study of the Metal Smelting Industry. Energies, 17(3), 652. https://doi.org/10.3390/en17030652