Abstract

The Internet of Things (IoT) is introduced in systems with electrical machines, such as in electric drive systems, wind energy generating systems, and small and special machines, to remote monitor and control the operation for data acquisition and analysis. These systems can integrate with the equipment and retrofit the existing installations. At the end of the control loops there are always motors, or actuators, of big or small ratings, of rotating or linear movements, electrical or nonelectrical, which must produce the motion. This article analyses selected aspects of research and applications of IoT-based control in electric drive systems and of wind energy conversion systems with induction machines. Various applications and study cases of control systems of electrical machines with IoT technology are described. With the IoT-based control of induction machine systems operators can remotely monitor parameters and obtain accurate real-time feedback during fast changing duty cycle operation. Thus, IoT creates multipurpose instruments in the remote control of induction machines. The paper offers a comprehensive analysis of IoT-based control applications in the field of induction machines, with technical details of design, construction, experimental testing, and prototyping, that are useful to energy engineering specialists in the sector of electric drives and wind energy conversion systems.

1. Introduction

The technology of Internet of Things (IoT) connects online to the internet and integrates devices. The IoT networks different kinds of physical objects equipped with electronic modules, acquires and transmits data, allows access to devices in remote areas, and the users can monitor their operation in real time. The development of IoT technology led to the emergence of new systems which are monitoring and controlling remotely complex structures. Operators can remotely monitor multipart installations, without human presence in the space where systems are sited. The interaction between machines, actuators, systems, sensors, and displays, has developed smart manufacturing applications which generate big volumes and diversity of data. Nevertheless, at the end of the control loops there are always motors or actuators, of big or small ratings, of rotating or linear movements, electrical or nonelectrical, which must produce the motion.

Recent reports present the advancement of IoT from an interdisciplinary viewpoint, like hardware and software of computers, control systems, sensors, and networks, and for a wide range of sectors. The IoT entered in to modern life by connecting smart devices, technologies, and applications. The principles of operating IoT, and its enabling of communication technologies, internet communication protocols, cloud computing, and big data analytics are applications and research topics of interest [1].

Thus, new emerged industrial applications established the Industrial Internet of Things (IIoT) [2] that connects different components of industrial equipment using sensors, and with the use of software, transmits large amounts of data. The acquired data are processed creating smartness. Related topics of smart processing are IoT-assisted manufacturing, which uses cloud computing, big data, and ICT [3]. The introduction of IIoT in industrial sectors stimulates industry growth, involving smart machines with embedded sensors, connectivity, and managing acquired data for various applications with electrical machines. IIoT connected systems allow the operators to real-time monitor the status of electrical machines, give fast feedback and regulation, and thus, optimize production processes in factories. Already, applications of IoT found in places in many sectors of technology and life, are installed in embedded devices, in smart grids, for environmental monitoring in agriculture, in construction of buildings, in automotive industries, and in health care [4].

Applications of IoT in smart grids of energy generating systems are parts of the Internet of Energy (IoE), which has roles in monitoring, remote control and management of installations, and equipment of electric generators, such as in Wind Energy Conversion Systems (WECS) of Renewable Energy Sources (RES) generation units. Because renewables depend on climate and weather conditions, the size and quality of energy produced from renewables are variable, and moreover, have high production costs. Thus, the various RES electricity generation devices, whether connected to electricity grids or stand-alone electricity systems, must provide for the possibility of improving the quality of the power produced [5]. Other weaknesses are meeting the increasing demand of electric power by RES in a reliable and efficient way. In order to achieve consumer demand for electricity when produced by hybrid schemes with RES, fossil fuels, and backup storage, new low-cost power generation schemes need to be further explored [5,6].

Along with advances in WECS design, construction, and sizes, the wind energy industry has also progressed due to Industry 4.0, which improves performance, processes, and computing power, making it easier to acquire and process data for automation, optimization, predictive maintenance, and new applications [4Mal]. Other aspects of IoT-enabled energy systems are architectures and functionalities of smart grid systems, with focus on communication, networking, computing, sensing, and security, which make them more robust, secure, efficient, and reliable, [7].

The energy sector change from a centralized to a decentralized system, by unifying big and small energy producers and RES producers, and using ICT and IoT technology, must reach net-zero emissions sustainability goals [8]. In various enterprises, by using actuators and sensors to collect and analyze real-time data, IIoT modifies the operation of machines and devices so that they do not require human intervention. Then, based on data collected and stored in real time, IIoT supports decision making, and uses this data for periodic assessment and maintenance forecasting [9]. Thus, applications through IIoT contribute to the automation of industrial production, the management of business processes, and the transportation of goods and people. The IIoT offers the improvement of human labor conditions, or even unmanned labor, especially in conditions where people can be exposed to hazardous agents and environments, such as toxic, explosive, or radioactive environments, in mining, underwater, or at heights [9]. The United States energy management system included grid surveillance with specifics on: weather and the impact of climate changes on energy generation and demand; forecasting of peak loads; renewable energy reliability and changeability; generation increase, decision analysis, and IoE integration [10].

Operation and Maintenance (O&M) are significant parts of the lifecycle costs of manufacturing machinery and of wind plants. In offshore wind farms, the condition monitoring instrumentation is used for fault identification and improvement of performance [11]. The state-of-the-art in O&M comprises offshore wind plants, WECS condition monitoring, deterioration models, fault diagnosis, prognosis, aspects of planning O&M, using artificial intelligence, data processing, integrating technology, automation, digitalization in the offshore maintenance sector, and debating the benefits, limitations, and application of these approaches with IoT and Industry 4.0 [11].

As far as developments in building infrastructure are concerned, energy installations using IoT are notable [12,13]. Some of the elements of IoT are installed from the design phase and concern building control devices, such as sensors, hardware and software, monitoring and data collection to predict energy consumption [14], supplying appliances with electricity, optimizing energy use, and ultimately improving the quality of life of residents [12,13].

In industrial plants, induction motors (IMs) are installed as varying speed-varying torque actuators, with good performance and reliability under many operating states and duty cycles. Modelling approaches of control configurations include mathematical equations, numerical analysis, computer simulations, results for the evaluation of induction motor parameters, the behavior obtained when different control techniques are applied [15], and the basic components for online monitoring of electrical equipment with electrical machines using IoT [16].

Among the important areas of IoT use related to electrical induction machines are process control with remote operation and status monitoring, equipment fault diagnosis, and power generation control. There are other fields such as education, buildings, and medicine as well. An early detection can be based on an online automatic fault diagnostic technique for the maintenance of induction motors using the IoT [17]. The benefits of induction motor controlled systems with IoT are optimized performance, reduced costs for O&M, increased reliability, and accuracy in prediction of failures.

To enable the introduction of WECS in the IoE and the conversion of wind energy, WECS technologies and their design are transformed into decentralized structures, methods, and technologies to cover electricity generation, and depending on load requirements and weather fluctuations, to include the characteristics of cyber-physical systems: security, remote control, networking, life cycle growth, and sustainability [18]. There is a tendency to deepen knowledge of double-output induction generator DOIG control systems operating in WECS. Thus, WECS equipped with DOIG have the advantages of operating with variable rotational speed input and constant frequency output and applying the techniques of maximum power point tracker MPPT, control the generated voltage, frequency, active, and reactive power [19]. The dynamic states of power systems embedded with smart grids and instabilities due to unpredictable wind and load changes, which can cause temporary load rejection, can be addressed using artificial intelligence and forecasting to predict component failures, reduce diagnostic time, and increase accuracy and stability for DOIG [19].

The development of IoT has raised new issues for energy conversion to power IoT components and devices, such as nanogenerators, with lightweight simple construction and to make them self-driving [20]. Nanogenerators can be piezoelectric, triboelectric, or pyroelectric. Thus, the sensors connected to the IoT can be powered using nanogenerators instead of conventional power supplies.

In Table 1 are the selected generic topics regarding electrical machines, working as induction motors and as induction generators, and their IoT-based specialized control systems for industrial applications and for WECS in energy generation power plants.

Table 1.

Generic topics regarding electrical machines with IoT-based control systems.

This paper examines the progress of electrical machines with IoT-based control from an interdisciplinary perspective, such as design and implementation, computer hardware and software, control systems, sensors and networks, and selected relevant topics from a wide range of sectors. The authors of this paper present new aspects of the technology of integration of electrical machine control systems with IoT, mainly the operation of electric machines with IoT as generators in wind energy electric power plants and as motors in controlled electric drive systems. This comprehensive study is based on our own acquired knowledge, from studies and experiments in our laboratory, and published in many technical reports. On the other hand, from a keyword-based search in databases, such as IEEE Xplore, Scopus, Scholar, and MDPI for reported discoveries, the retrieved information is selected and organized in two main topics which are: (1) the induction motors and (2) the induction generators, from the perspective of their remote control over IoT, with the specifics of structures designed for driving industrial loads and for generation of electric power from wind turbines, respectively.

This article examines the state-of-the-art developments presented in IoT from different perspectives, from a wide range of sectors, such as computer hardware and software, control systems, and sensors and networks, but always applied to the control of induction machines as a field of application. It considers both electrical machines, such as generators in renewable energy systems, and motors in electric drive systems with emphasis on new aspects of the technology of integrating electrical machine control systems with IoT.

The technical and scientific literature retrieved from the above search and based on acquired knowledge is rich in review papers related to the generics of IoT. Most papers tackle the generic topics for many branches of industry, energy, communications, society, and daily life. Moreover, our search in databases revealed that many review papers are highly downloaded and cited. In Table 1 we can see some of the representative review papers and their numbers of citations. Most of their conclusions are that the IoT technologies are attractive, suitable, and easy to be introduced in many sectors, which continue to advance, and improve productivity across various industrial sectors.

However, our search in databases reveals that there are few reviews and research papers which focus on specifics of the design and implementation of experimental tests for the construction of prototypes for particular applications with IoT. The most published articles on electrical machines with IoT do not give other researchers the necessary details to replicate such experiments, such as technical data of equipment or hardware and software, or even more, to further continuate similar experiments with new aspects. There is a gap of publications containing details of design, implementation, tests, experiments, and development of prototypes of IoT-based control of induction machines. Thus, the main novelty of our paper consists of the following:

Indeed, from a top-down assessment of the selected referred review publications in this paper, somebody could be misled to an impression of largely a review of reviews. Conversely, from a bottom-up perspective, if we begin the search and review from the basic details of design, hardware selection and creation, construction and implementation, software development, connection and communication, data collection and processing, and user interaction interfaces of IoT-based control systems of electrical machines, our novelty is established because, in most of the published papers, such specific details on “how to build it” do not exist. This gap must be filled, the publications must give full construction details, and this fact will especially positively influence the young researchers and engineers, which must develop and make the IoT-based systems work.

In the following sections of this paper are selected reports which publish the specific technical details of the IoT design, construction, and implementation. The references reviewed are selected based on terms of relevance and affinity to the subject matter. Nevertheless, this research is not exhaustive but provides an illustration of the research in the area of IoT-based control of induction machines for specific applications.

This article is structured as follows: in Section 1, the main topics of IoT-controlled industrial applications with induction motors and energy generation with induction generators are presented; in Section 2, the detailed structure of the IoT-based control system of an induction machine working as a motor in Electric Drive Systems EDS and as a generator in power plants with wind energy conversion systems WECS is presented, with description of hardware and of software; in Section 3, selected industrial manufacturing with electric drive systems applications of IoT-based control with induction motors; in Section 4 is a presentation of selected applications of IoT-based control of induction generators in WECS; in Section 5 new emerging energy conversion applications related to IoT, such as in energy harvesting, in energy education, in buildings, etc., are described; in Section 6 is the discussion, and in Section 7 are the conclusions and proposals for future research.

2. Control System of Induction Machine with IoT

The parameters of electrical equipment with electrical machines, which can be sensed and measured, are voltages, currents, energy, power factor, frequencies, vibration, and temperature. The IoT-based real-time monitoring acquires data remotely, visualizes accurately the data and parameters which are not easy to be accessed, and improves the operating process. Various aspects of electric drive control have already been investigated and experimentally tested, such as scalar control of cage rotor induction motors [21,22] and double fed induction motors [23], using Raspberry Pi microcomputers [24], Arduinos microcontrollers [24], software, and IoT connection, and their published results have been published to be used for further analysis and comparison [24].

Programmable logic controllers (PLCs) are installed in systems of electrical machines with industrial automation, to control the fast-changing duty cycles, surge voltages, and over-currents caused during the succession of stop and restart [25]. Moreover, PLCs are installed in industries to optimize automation operation, increase quality, reliability, and reduce production costs. Also, PLC-controlled protective relays manage failures such as phase losses, over-currents, power surges, uneven phase shift of supply voltages, uneven current phase shift, and uncontrolled frequent stop and restart [15].

In various applications, electric machines are installed and function in two modes using similar basic equipment, but in different settings and connections. They can operate either as electric motors for industrial loads [21,22,24] or as electric generators [26,27,28], which are preferred in RES installations [27], and mainly in WECS [28].

Power plants using renewables and IoT are considered as part of the emerging Internet of Renewable Energy Sources (IoRE), which includes networking, control, productivity, security, and sustainability [29], with lower emissions [30,31,32], optimization of economics with multiple criteria [33], depending on load demand [34], and with energy constraints [6]. However, because electricity produced from renewables is of variable quantity, power quality, and high cost, these important problems must be solved to meet electricity demand with optimized efficiency [34,35]. Despite the technological development so far, new RES schemes for continuous energy supply, of sufficient quantity, and at lower cost, are still being explored. Various energy installations connected to the IoT for renewable energy industry applications have been described in the works [36,37,38].

IoT has been installed in electric machine applications with electric drive control: the induction motor control system that communicates with the IoT, obtains feedback data from sensors, and receives commands over the internet [24,39]. The project [40] designs, implements, and tests an application for monitoring induction motors via IoT, including remote control of their operation, receiving commands, and transmitting feedback information and measurements over the internet to a database. This research was developed as part of broader experiments conducted in the authors’ Electric Driver Control Laboratory. For many years this laboratory has been engaged in the study of remote control of the performance of electric machines via the Internet [24,39,40].

The rotor cage induction motor IM is most installed in industrial processes, while the double fed induction machine (DFIM) can be installed both in EDS for slip power recovery units [23,41], and in WECS for generation of electric power from wind [28,42,43]. Operating as either a motor or a generator, the induction machine’s drive system adjusts the electromechanical energy conversion direction, switching between converting mechanical energy from electrical power or generating electrical power from mechanical input. This bidirectional energy flow necessitates the use of power converters, either rectifier-inverter or cycloconverters, to interface with the three-phase AC network.

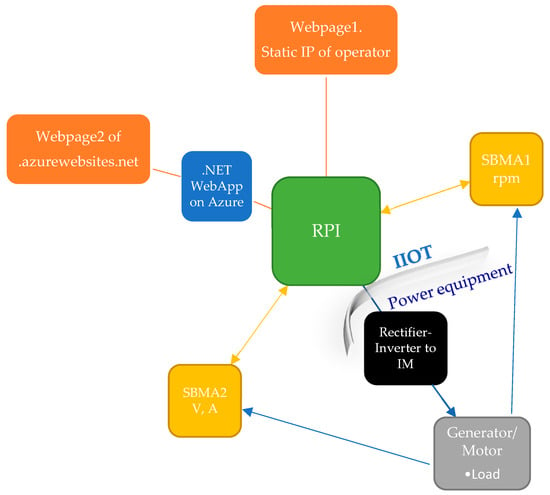

Figure 1 illustrates the architecture of an IoT-based control system for induction machines. This setup is structured and based on the single-board microcomputer Raspberry Pi (RPI) as the central electronic device. The RPI functions as a server and interfaces with a web application hosted in the Azure cloud, with a network of sensors connected to the single-board microcontrollers SBMA1 and SBMA2, and with the rectifier/inverter. Moreover, the RPI hosts a static web page directly accessible through an IP address of the operator. The RPI acts as a hub between these systems, enabling data exchange among sensors, inverter, induction motor or generator, and load.

Figure 1.

General structure of IoT-based control system for Induction Machines. The arrows show the flow of data.

The following main issues need to be resolved when developing controlled IoT-based electrical machine systems:

- The connectivity of power equipment to the internet, communication with servers, software, and databases. The units directly connected are electric motors, power converters, microcontrollers, sensors, measuring instruments. Other modules are connected indirectly via a gateway, and there is two-way communication with the backend system to register devices and collect data.

- The data management: the acquisition, conversion, storage, retrieval, analysis, processing, security, visualization, and presentation of data in real time.

The diagram from Figure 1 shows an IoT-based control system for induction machines. The central electronic device is the Raspberry Pi (RPI), which communicates with:

- Azure cloud web page

- Sensors connected to single-board microcontrollers SBMA1 and SBMA2

- Rectifier/inverter which drives the induction motor

- Static control web page for direct access of operator

The RPI acts as a bridge between these elements, facilitating data exchange between the sensors, inverter, induction machine or generator, and the load. It is used in this IoT-based control system for induction machines for several reasons:

- Power efficiency: The RPI is a low-power device, which is important for embedded systems like this one. This means that it can run on a small battery or even be powered directly from the induction machine itself.

- Computational power: The RPI is a powerful device that can handle the computational tasks required for controlling the induction machine and collecting data from the sensors. This makes it a more versatile option than a simpler microcontroller.

- Ease of use: The RPI is a relatively easy-to-use device, which makes it a good choice for developers who are not familiar with embedded systems programming. There are a large number of resources available for programming the RPI, and it can be easily connected to a variety of sensors and actuators.

- Versatility: The RPI can be used for a variety of other tasks besides controlling induction machines, such as running web servers, hosting applications, and running data analysis software. This makes it a good investment for developers who need a versatile platform.

This system enables remote monitoring and control of induction machines, making it possible to optimize performance, reduce energy consumption, and improve overall efficiency. Here is a more detailed explanation of each component in the diagram:

- Raspberry Pi (RPI): A single-board microcomputer that serves as the central electronic device in the system. It is responsible for collecting data from the sensors, communicating with the cloud and web applications, and controlling the rectifier/inverter.

- Azure cloud web page: A web page hosted in the Azure cloud that provides a user interface for monitoring and controlling the induction machine. It can be used to access, visualize, and analyze data from the system.

- Sensors: Sensors that measure various parameters of the induction machine, such as speed, currents, and voltages.

- Single-board microcontrollers, SBMA1 and SBMA2: Single-board microcontrollers that interface with the sensors and send data to the RPI.

- Rectifier/inverter: A power converter that converts AC voltage to DC and DC voltage to AC. It is used to drive the speed and direction of the induction machine.

- Static web page at the operator’s IP: A web page that can be directly accessed by the operator to monitor and control the induction machine. The static web page serves two main purposes in the IoT-based control system for induction machines. (1) Real-time monitoring: The static web page provides a real-time view of the induction machine’s performance parameters. This information can be used by operators to monitor the health and condition of the machine, and to identify any potential problems. (2) Remote control: The static web page can also be used to remotely control the induction machine. Operators can use the web page to set the machine’s speed, and other parameters. This capability is particularly useful for operators who are not physically located near the machine. It offers a more straightforward and accessible interface for operators who may not require the advanced features of the cloud-based interfaces. In addition, the static web page can serve as a backup communication channel in case the internet connection is lost. This ensures that operators can still monitor and control the induction machine even if they are unable to access the cloud-based interfaces. Overall, the static web page plays a crucial role in the overall functionality of the IoT-based control system for induction machines. It provides real-time monitoring and remote-control capabilities to operators, while also complementing the dynamic functionality of the cloud-based interfaces.

Overall, the IoT-based control system for induction machines provides a comprehensive solution for remote monitoring and control of these devices. It can be used to improve performance, reduce energy consumption, and enhance overall efficiency.

2.1. Structure of Electric Drive System of Induction Motor with IoT

The induction motor IM can be controlled from the stator side, by varying the voltage and frequency [21,22]. During motor operation, three-phase IMs serve duty cycles with frequent changes in load and speed, including cut-off and reconnection. Thus, controllers must monitor the performance of IM [41]. In the case when the electrical drive system (EDS) of the induction machine with IoT performs control remotely via the internet, it uses sensors and generates data via the internet from the feedback of the control system.

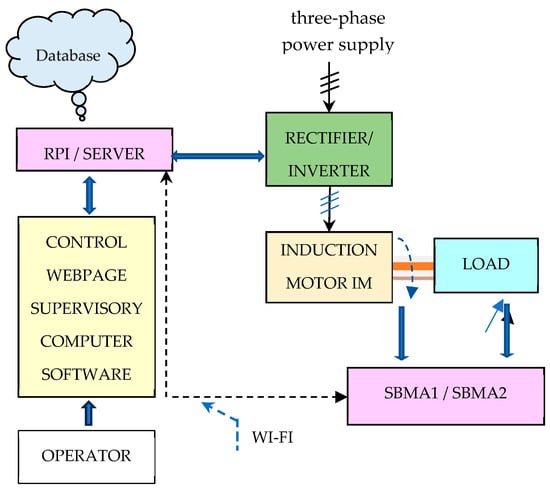

In Figure 2, the diagram of the electric drive system of the induction motor with IoT-based control is shown. This is the architecture of the control system designed in our Laboratory of Electric Drives. The design and operation were introduced and described in detail in publication [40]. This configuration (Figure 2) establishes the remote-control system of a three-phase induction motor with IoT using: one single-board microcomputer Raspberry Pi (RPI), two Single-Board Microcontrollers (SBMA1 and SBMA2), a database for the managed data with Structured Query Language (SQL) [44], and a web application in Azure cloud platform [45].

- The control system from Figure 2 consists of the following structural modules:

- The three-phase induction motor is supplied by one digitally controlled three-phase rectifier-inverter, which controls the stator frequency and produces motion of rotation, which is transmitted to mechanical load.

- The control system: one Control Webpage, one supervisory computer with access to the Control Webpage, one single-board microcomputer Raspberry Pi (RPI) linked to the rectifier-inverter which acquires the data from sensors through single-board microcontrollers SBMA1/SBMA2, and software. The RPI has the role of the local server which communicates with database by a web application in Azure cloud with an SQL database for data storage, data processing, and remote control.

- Data acquisition: The rotational speed sensor and load current sensor of the induction motor transmits data to microcontrollers SBMA1 and SBMA2, respectively.

- Networks: The IoT-based control system for induction machines has installed wired and wireless networks, including internet, local area Wi-Fi networks, and serial connections. The Internet serves to the users of the static web page hosted on the RPI. The system uses internet to connect the RPI to the Azure cloud web page. Bluetooth connectivity is established between RPI and microcontrollers. The RPI communicates with the rectifier/inverter via a serial connection; the sensors transmit data to the microcontrollers through serial connection.

Figure 2.

Electric drive system of Induction Motor with IoT-based control.

Dashed lines show connections to the internet with Wi-Fi network; block diagram arrows show the bi-directional sending/receiving of data between server-rectifier/inverter, server-supervisory computer, and one-directional sending of data between sensor single-board microcontrollers, Arduino SBMA1/SBMA2; solid lines show the three-phase power supply and the three-phase connection between rectifier/inverter and induction motor; the orange thick double line is the coupling shaft between induction motor and load.

- The remote control of the induction machine (IM) is initiated from the web interface, where the RPI receives commands and translates them into signals for the inverter using the Modbus serial communications protocol [46,47].

Remote control of the IM over the internet uses the supervisory computer and the microcomputer RPI. The RPI acts as an intermediary between the supervisory computer and the inverter, translating control commands from the former into signals that the inverter can understand. To facilitate this communication, a Modbus card is employed to establish a serial connection between the RPI and the inverter. The Modbus card is necessary because the inverter utilizes the Modbus serial communications protocol, a standardized communication protocol commonly used in industrial settings to exchange data between devices [46,47].

Hardware units are external: a speed encoder for speed feedback and a current sensor for load current feedback [40]. The software runs on the supervisory computer through the control website, which is accessible at the IP address reserved for laboratory experiments. The programmed functions in the software code are commands of the operator, selected from the website such as:

- the frequency command for forward rotation

- the reverse direction command to rotate backwards

- the command to start the rotation

- the end of rotation command

The software monitors the speed during load changes, while the inverter, controlled by the software, executes the frequency commands [40]. Analogue speed and current signals are converted into digital signals by two microcontrollers, Arduino SBMA1 and SBMA2, and transmitted to the microcomputer RPI. The SBMA1 receives the speed signal from the speed encoder and sends it to the RPI, using the Wi-Fi connection and software. The RPI reads the required frequency from the operator’s website and the actual rotation frequency of the IM, calculates the difference between the two frequencies and generates the error signal, which is usually non-zero, as a result of which the RPI reads the error signal, changes the frequency that the converter has, and, accordingly, corrects speed. Thus, the error signal is converted into a control signal sent by the RPI to the digital input of the inverter and corrects the frequency. The required frequency and also, the actual frequency calculated from the feedback signal, are displayed on the operators’ website. Digitized signals from measurements are stored in the Azure cloud in the SQL database.

2.2. Structure of Double Output Induction Generator with IoT-Based Control System for WECS

The cage rotor construction of induction machines is not suitable for generator operation, because it needs self-excitation which must be produced by an additional bank of capacitors [43]. On the other hand, the wound rotor induction machine can be supplied from the stator and from the rotor windings, and thus, received the name of doubly fed induction machine (DFIM). A thorough investigation has been carried out for the DFIM: using the feature of doubly controlled machine, the DFIM has increased consideration in wind generating power plants in WECS. Many times, the DFIM is named double output induction generator (DOIG), or double fed induction generator (DFIG) [27,28].

The DOIG is frequently installed in wind power plants, where it controls the generated voltage and frequency and the active and reactive power.

The components of WECS are the turbine, the induction generator, the mechanical coupling, and the controllers. The wind turbine converts the wind energy to kinetic and the DOIG converts the kinetic energy to electrical energy. Wind turbines can generate electrical energy during strong winds, but it is fluctuating [27].

Some wind turbines cannot follow the wind speed and rotate only at a single speed. There are two ways of operating at a fixed speed: to use a synchronous generator or an induction generator. Fixed speed turbines have the disadvantage of a lagging power factor of the grid-connected induction generator and demand large capacitor banks to compensate for it [43]. The energy from the wind is a function of wind speed, and the energy captured by the turbine propeller is a function of rotor speed and wind speed, thus fixed speed wind turbines fail to capture the maximum power. In contrast, variable speed DOIG can recover the maximum energy of the wind.

In the cage induction generator configuration, the power is generated when the shaft is rotating above the synchronous speed only. In the configuration with DOIG, electric power is generated at all speeds: higher than synchronous speed and lower than synchronous speed, too. Thus, the WECS with DOIG functioning at variable speed have some advantages [28]:

- The rotor excitation voltage and frequency permit a bi-directional flow of electric power in the rotor, and a slip power recovery, instead of being lost by heating the windings. This increases generated energy, and efficiency too, are a consequence of an increased quantity of converted wind power.

- At variable wind speed, the rotor excitation voltage controls the DOIG and generates constant frequency at the demanded value of the grid. Also, the active power is generated from the wind power at any time instant, under or above synchronous speed. The DOIG provides control of reactive power, close to unitary power factor, and eliminates the need for capacitor banks. Power quality improves because DOIG connects and disconnects from the grid, without high transient currents during cut-in or cut-out. The instabilities of wind generate higher order harmonics [48,49], which impacts the generated power quality, especially in fast transient states of the wind, and also, in weak or isolated autonomous grids [35,48]. With the DOIG, the higher order harmonics are reduced due to the high switching frequency of the power converter in the rotor, and the levels of the 5th and 7th harmonics are lower [50,51]. Causes of generated distortion and noise at different operating points can be the negative or close to zero power values when wind speed is above cut-in speed or with scattered data [48,51].

- The power converter in the rotor has lower ratings because the rotor draws up to 35% of the rated power of DOIG.

- Mechanical loading reduces because the operation at variable speeds produces lower stress transferred through the coupling components than in the case of fixed speed generators.

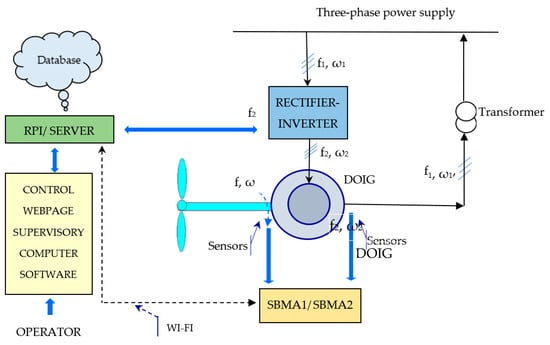

A variable speed WECS is shown in Figure 3, in an experimental configuration [27,28,39], with the induction generator in DOIG connection. The wind turbine which drives the rotor shaft of DOIG is emulated in laboratory by a variable speed dc motor. The wind turbine rotates the DOIG in the same direction as the air gap synchronous magnetic field. The rotor windings of DOIG receive excitation voltage fed by a digital rectifier-inverter from the three-phase power supply. The inverter controls the excitation voltage and frequency in the rotor. The stator windings are connected to the three-phase power supply and send the generated electric power to the grid. The control of rotor voltage and frequency during fluctuating speeds of the wind turbine is required in order to generate constant volts and hertz in the stator windings.

Figure 3.

Wind Energy Conversion System with Double Output Induction Generator and with IoT-based control.

At speeds ω lower than synchronous ω1, ω < ω1, the slip power is supplied to the rotor and the generated power is sent to the grid. At speeds higher than synchronous speed, ω > ω1, the slip power is recovered from the rotor, is sent back to the excitation source and the generated power is sent from stator to grid [28]. Controlling the rotor voltage and frequency for rotor excitation results in the control of voltage and frequency generated at the stator side. The generated active power at the stator has a linear variation with the excitation frequency of the rotor [28]. At speeds higher than the synchronous speed, ω < ω1, the efficiency increases when there are increases in the wind speed.

Thus, in wind power plants, the preferred electrical machine is the DOIG, because of its capability to regulate the unexpected wind speed fluctuations using the slip excitation frequency control technique [27,28].

Figure 3 is the block diagram of the DOIG driven by a wind turbine and with the controlled system over the internet. The stator windings of the DOIG are connected to the three-phase power supply via a voltage three-phase transformer, while the rotor windings are connected to an ac/dc/ac rectifier/inverter [39].

The slip frequency control consists of injecting at the rotor windings of DOIG a three-phase voltage at slip frequency f2, as in Equation (1)

where:

f2 = f1 − f

ω2 = ω1 − ω

- f1 is the power network frequency and produces the synchronous speed of air-gap magnetic field ω1

- f is the angular rotational frequency of the shaft, which is imposed by the driving force of the wind, and is computed from the mechanical rotational speed of rotor ω,

- f2 is the slip frequency of the voltage injected in the rotor windings and produces the rotational speed ω2 of the magnetic field of the rotor

Therefore,

where s is the slip of the DOIG. A three-phase transformer adjusts the voltage magnitude of the grid at 380 V [27,42].

f2 = s ∙ f1

The DOIG has a bidirectional flow of power in the rotor: at super-synchronous speeds ω > ω1 the rotor sends power to the grid; at sub-synchronous speeds ω < ω1 the rotor absorbs power from grid. Thus, the DOIG works well at both sub-synchronous and super-synchronous speeds, within a speed range of ±35%·ω1. The power converter in the rotor regulates the voltage amplitude, frequency, and phase angle [27], and the generated frequency at the stator side is constant, even if the turbine turns at a variable speed ω [28]. The ratings of the power converter are up to 35% of the rated power of the DOIG, the losses are lower, the efficiency is higher, and the investment of initial capital for installed equipment is reduced. By using the DOIG technology, the ratings of wind park installations reduce, the efficiency improves, and it reduces the duration of the return of invested capitals [28]. Because the various magnitudes in WECS are difficult to access and measure, they can be estimated using the state space model of the DOIG wind turbine and using a nonlinear observer, a linearization near the operating point [27], or using Lyapunov stability theory [52].

Dashed lines show connection to the internet with a Wi-Fi network; block diagram arrows show the bi-directional sending and receiving of data between server and rectifier/inverter and server and supervisory computer; other block diagram arrows show the one-directional sending data between sensors and single board microcontrollers Arduino, SBMA1/SBMA2; solid lines show the three-phase power supply and the three-phase connections between rectifier/inverter and DOIG; the thick double line is the coupling shaft of the wind turbine and DOIG.

As mentioned above, some modules are present in both configurations of the electric drive system with induction motor (Figure 2) and of the power generation system with DOIG (Figure 3): the rectifier/inverter, the induction machine, the supervisory computer, the operator website, the microcomputer RPI, the two microcontrollers Arduino SBMA1 and SBMA2, the speed sensors, the current sensors, and the Wi-Fi Internet connection.

3. Applications of IoT-Based Control for Electric Drive Systems

When the integration of IoT technologies is in industry, some features refer to real-time processes, such as: data acquisition, process observability, auto-ID, decision making, and intelligent production systems [38,53,54]. For the web-based remote monitoring and automation of manufacturing processes, Programmable Logic Controller PLC modular units are installed in open architectures and connected to the web using Ethernet and Internet [15,25].

In Table 2 are selected cases of industrial applications of IoT-based control of electric drive systems with induction motors with specifications of technical aspects.

Table 2.

Technical aspects of applications of IoT-based control of Electric Drive Systems.

The implementation of induction motors control uses commands sent and received over IoT and are accompanied by details of design, with experimental tests and results, [24,40]. The architecture of the experimental systems with internet-based access to laboratory equipment, for the testing of induction motors via an application programming interface API and with Message Queuing Telemetry Transport (MQTT) communication protocol, can be presented to learners as a workshop [55].

IoT-based control systems can address vibration and temperature interference to improve the efficiency of electric motors and generators [56]. Further involvement of IoT in monitoring and control installations with induction motors, with remote drive inverters and with software for handling the acquired data, creates smart electrical drives and increases the efficiency and reliability of electrical machines [56]. Using a mobile app via Wi-Fi and IoT, an operator can control a three-phase induction motor by applying the direct torque control method, with space vector and pulse width modulation (PWM) for the inverter [57]. The obtained results show low harmonic distortion of the output voltage from the inverter [57]. A three-phase inverter with space vectors and field-oriented control, which improves the quality of voltage by eliminating harmonics, is installed for obtaining the IoT operation [58]. The output signal is sampled and quantified in real time, is communicated to other industrial systems within a real-time remote monitoring configuration, is made available for operation, and also, is provided to the user interface [58]. Due to additional features of smartness and self-learning, this kind of inverter can analyze voltages and frequencies, and predict and inform the operator, thus helping in critical and safe operation of the system over the IoT [58]. If a warning, or malfunction occurs, the inverter can control and eliminate dangerous situations [58].

The software that implements the control for the induction motor for the requested operation, the fine-tuning of the parameters and the interface to the IoT, can be built by using personal computers [59]. In the case of controlling a single-phase induction motor, the IoT monitors parameters such as speed and temperature, and the data received from the sensors is stored in the cloud [60]. The speed control system including the inverter, is simulated in the PSIM power electronics software [60].

Another application refers to a monitoring system for compaction operation, which is equipped with an intelligent IoT-based vibratory roller, with the designed hardware for the real-time monitoring, including the sensors and the signal conditioning modules [61]. The evaluation and analysis of the compaction real-time data were integrated into a prototype system with IoT for further development [61].

To monitor and determine the condition of an induction machine, the process consists of detecting currents, voltages, temperatures, and vibrations, then the data is processed for fault prediction and maintenance decisions [62]. More specifically, data received from sensors is transmitted wirelessly to the cloud, processed, downloaded from the cloud, and analyzed [62]. Other aspects include IoT-based energy management at the production level and a framework is needed to integrate energy data [63]. With IoT capabilities, an integration framework where real-time information is recorded, creates a real-time information integration service, providing new IoT models [64].

Real-time decisions for fault diagnosis can be executed using online monitoring for prevention and recovery of failures, thus obtaining accurate information and improved performance. In Table 3 are selected cases of industrial applications of IoT-based diagnosis of induction motors with specifications of technical aspects.

Table 3.

Technical Aspects of industrial applications of IoT-based diagnosis and maintenance of induction motors.

The technology of monitoring systems received influence from the IoT, mainly due to networking of equipment [65]. Thus, predictive maintenance can be done noninvasively, using temperature and current sensors and computer simulation for digital twins of thermomagnetic behavior [65]. Because induction motors are important parts of equipment in many industries, for their monitoring, an industrial wireless ammeter based on Zigbee technology is proposed as a tool for maintenance, and to identify when the IMs work unusually and to prevent failures [66]. This technology allows a wireless sensor network with remote measurements of currents to monitor the power supply. By means of wireless ammeters, and with open-source software, users can decide about machinery maintenance. In many industrial applications with IoT, the predictive maintenance of equipment by continuous monitoring and estimation of real risk situations involves sensors, connected to the internet, sending data to the cloud, from where data can be retrieved and visualized for real-time remote maintenance [67].

An IIoT solution, the NGS-PlantOne system [68], is designed for universal monitoring of electrical machines through IoT sensing devices, thus allowing predictive maintenance, for real electrical power plants. The installed system, with many IoT sensing devices, performs monitoring of temperature and vibration, and has been operated and offered solutions for predictive maintenance and monitoring operation of IM [68].

A microcomputer RPI, current, voltage, and temperature sensors are used to detect faults and simultaneously monitor the rotational speed of an IM [69]. Data is sent to the RPI, processed, and stored in a database, then commands are generated to control the system [69]. IoT in applications with electric machines offers web-based monitoring and fault diagnosis for induction motor operation, optimized performance, improved fault prediction, increased reliability, and reduced costs for O&M [70].

A smart control panel, using vibration and temperature sensors for resistive, inductive, capacitive, and IM devices, provides operation with intelligent motor protection, fault analysis, and protection techniques, combining local and IoT control, in both manual and automatic modes [71]. To acquire information that predict a motor’s failure, the temperature and vibrations of induction motors are analyzed in real time using IoT [72]. By analyzing the vibration signals it is possible to detect the differences between the operation of a healthy and damaged motor [72].

Diagnosis algorithms for condition monitoring and solving voltage imbalance using an IoT gateway and wireless sensors have been developed in [73]. Other applications of IoT in electrical machine diagnostics include fault detection with current signature analysis and the propagation of fault signals from motors to IoT [74]. Error signals that have a very low amplitude and are close to the fundamental frequency are transmitted from one machine to another and are interfered with by environmental noise [74]. The distributed observations are analyzed to improve the reliability and quality of diagnosis [74].

Monitoring must be continuous for preventive maintenance of industrial IMs in order to detect performance deviations and the prospect of hardware failure. An intelligent shutdown and recovery tool with backup system, which can automatically cut off the engine before it exceeds threshold values, and thus, avoid damages, can then initialize a backup system, and thus, reduces downtime, and increases efficiency and reliability [75].

4. Applications of IoT-Based Control in Energy Generation from WECS

IoT technology in control systems for RES generation remote monitors optimizes production and saves energy. The price of generated electric energy depends on fuel costs, electric load demand, and on installation limitations. The smart grids can optimize the energy costs and decrease the peak load demands [6,34]. In RES generating units, the IoT supports real-time decisions regarding the monitoring, performance, efficiency, prevention, and recovery of failures. Operators can access real-time performance data, change settings, run diagnostics remotely, and perform maintenance. WECS embedded with sensors acquire and send real-time data of wind speed, turbine speed, temperature, vibration, and energy generated to the IoT, to the administrator, and make data available to other wind power plants and other smart grids. The data are processed for economic dispatch optimization, for performing predictive maintenance, for early detection, and for deciding failure recoveries in an efficient way, as well as warnings for the system. The optimization of wind turbine performance is based on data acquired from sensors and maximizes the energy generation depending on wind situations. Data are analyzed to forecast and manage energy generation, to integrate wind energy into the grid, and to optimize wind energy penetration. IoT sensors can monitor environmental conditions, detect extreme weather situations, avoid safety risks, and can keep operations safe.

Hybrid power plants interconnected to Internet of Renewable Energy (IoRE) can lower downtime and O&M costs by early scheduling repairs. The emerging Internet of Energy (IoE) is presented in terms of architecture, energy routers, benefits, and challenges of its operation in large-scale distributed architecture with the inclusion of RES [76].

In Table 4 are selected cases of IoT-based control of energy generation from WECS with technical aspects.

Table 4.

Technical aspects of IoT-based control for energy generation from WECS.

The performance of interconnected wind farms using communication networks and with different scenarios can be simulated in MATLAB [77]. The structure of an experimental IoT-based control system for WECS is in [39]. Centralized control in microgrids involves voltage control, power quality, surveillance, and active power and reactive power sharing [78]. Smart sensors are developed for remote condition monitoring and are integrated within distributed control of microgrid systems with IoT [78]. In addition, in a microgrid, automation includes data acquisition, access to a user-friendly man–machine interface, supervisory control, and physical and cybersecurity with authentication and access control [78].

The integration in one hybrid system of the large-scale energy producers with many small energy producers, such as rooftop photovoltaic panels, wind farms, or solar plants, become a feasible structure by using the IoT and IoE, as well as ICT and digitalization [79]. For data acquisition and remote monitoring, various information and communication technologies are introduced for hybrid wind and photovoltaic systems, such as SCADA [80]. A multi-microgrid system connected to an IoT platform can improve imbalance and compensate for the neutral current by using voltage source inverters [81]. The microgrid has two layers of communication to connect to the cloud server: it uses modbus transmission control protocol/internet protocol (TCP/IP) for local communication and uses the Message Queuing Telemetry Transport Protocol (MQTT) for global communication [81].

Usually, the wind power plants are situated in remote areas or offshore, thus, WECS condition monitoring must be resolved using IoT [82]. An industrial IoT algorithm with associated hardware prototype monitors the condition of WECS in the real-time environment [82]. The algorithm includes a proportional-integral (PI) vector control with pulse width modulation PWM to minimize ripples of output voltages, solve voltage asymmetry, increase power quality, avoid errors in the dc-link capacitor of the PWM converter, and monitor WECS [82].

Detection of short circuits in windings of WECS using vibration data to avoid wind turbine failure [83], is made by using Lapisco Image Interface for Application Development (LINDA) web application: it contains one system in Java which runs the web service and achieves the sending and processing of images between devices and workstations of the platform in a computational cloud; a second system is a database in PostgreSQL for storing the algorithms (extractors and classifiers) [83]. LINDA is a generic tool, which can solve many problems, not only of wind turbines. A cloud-based IoT solution for recognition, identification, and localization of faults in power distributed systems, can sense multiple simultaneous faults using multiple current sensor devices [84].

5. Other Energy Applications of IoT Control

5.1. Energy Harvesting from Other Sources

In Table 5, selected emerging technologies for energy conversion related to IoT control are shown.

Table 5.

Emerging technologies for energy conversion control and IoT.

Biodegradable, harmless to the ecosystem, fiber-based materials, like paper, become paper-based triboelectric nanogenerators and show outcomes for different energy collecting applications, such as high-productivity energy collecting sensors for the IoT [85]. Such materials are present in the so called “green” IoT devices [85].

Energy harvesters and power conditioning units are required for remote sensors and actuators in IoT applications. A linear induction machine (LIM) operating as a generator harvests electric energy from kinetic energy of a moving conductive body [86]. Since LIMs are moving bodies, a layer of a conductive coating such as copper increases the efficiency of the harvester [86]. A wind energy harvesting device for low power requests, based on piezoelectric effect, converts the kinetic into electric energy [87]. The wind generator’s shaft is connected to a converter of rotary-to-linear motion, which produces mechanical vibrations, and the piezoelectric stack generates electric voltage. The power generated from the wind energy harvester, for different thickness of piezoelectric material and wind speeds, is analogous to the third power of wind speed and can be used for IoT connected devices. Wind energy harvesting is employed to collect energy and supply low power electronic systems connected to IoT systems, such as sensors, surveillance devices, health monitoring instrumentation, and manufacturing processes [87]. A prototype for a mini three-phase wind energy harvester is accompanied by the analysis of operation, the deduction of the characteristic parameters using an equivalent electromechanical model, and the verification of accuracy of the prototype [88].

Other applications of energy harvesting for very low ambient energy include the results from measurements inside cargo containers, which allow the joint piezoelectric and thermoelectric generation to extend the lifetime of batteries of the IoT end nodes [89].

A wind-driven energy harvesting system, designed with a rotor with pairs of magnetic poles and with an iron shield to increase magnetic flux density, was designed for an IoT-based monitoring system of humidity and temperature [90]. The obtained energy is in the range of mW and can be valorized in autonomous IoT monitoring systems for smart agriculture applications [90].

The harvested kinetic energy, ambient energy, piezoelectric energy, and triboelectric energy are converted to electrical energy by small generators, which are used as power suppliers to small devices, sensors, or for recharging batteries for IoT components. Triboelectric nanogenerators, which have simple manufacturing and are lightweight, are new energy topics which emerged with the development of IoT [20]. Further developments involve a triboelectric nanogenerator for self-powered IoT devices [91], and a smart energy harvester system for IoT networks [92].

There are solar array trackers in solar installations connected to IoT [93] and also, for the monitoring of photovoltaic generation in decentralized power plants using the IoT [94]. An IoT system of low-cost for photovoltaics, that monitors voltage, current, power, and measures weather conditions, connects to the internet, uses open software, creates a measurement dataset, stores it locally and in the cloud database, and uses the network time protocol to synchronize device clocks [95]. Thus, experiments with this system showed reliability for the production of smart photovoltaic systems [95]. Photovoltaic panels controlled by IoT can function as a power supply for induction motors, with high power generation and low cost [96].

5.2. IoT in Energy Education and Other Sectors

IoT was introduced into the educational sciences as a continuation and evolution to existing and recognized teaching and learning techniques, which are distance learning, the use of e-learning platforms, modernization of education technologies, and project-based learning with simulated experiments [97,98].

To meet the expectations and demands of IoT-based technologies, these must be included in academic laboratory experiments [99], so that learners gain knowledge about their technical scientific basis, how they are applied in practice, and how they can extend them to industry [100,101]. A good curriculum must cover aspects of teaching techniques close to actual professional activities, must concentrate on theoretical and simulated strategies, and should meet high standards and expectations of all stakeholders including learners, graduates, and lecturers [102]. Also, knowledge of IoT technologies will prepare internships where students can use IoT [103] or offer access to education and work to underrepresented groups of people and to teachers’ training [104].

In Table 6 selected aspects of energy education which apply knowledge about IoT-based control of electrical machines are shown.

Table 6.

Energy education in IoT control of electrical machines.

To reduce the impact of the COVID pandemic on students’ education, a remote laboratory system was developed, which was able to safely and effectively support practical lessons and applied experiments. Such initiatives are important because they offer hands-on experience so as to prepare the student’s learning experience for post-campus jobs [55].

Another experimental IoT-based control system which monitors a microgrid simulated in a laboratory test bench consists of diverse RES, loads, and wireless sensors [105]. The internet allows monitoring and controlling devices by using a mobile application, which includes a security software for system protection against cyber-attacks at several levels, encryption and decryption of data, authentication of users, firewall and detection and prevention of network intrusion [105].

The starting of new IoT-based experiments in academic laboratories for the education of students aims for the enrichment of studies in energy engineering and better prepared engineers for the job market [24]. From an educational viewpoint, selected topics of research and development of IoT can be considered in smart control systems with electrical machines for energy generation from wind and for electric motion drives [39].

By online monitoring, deduction of real-time decisions for fault diagnosis, prevention and recovery of failures, and power restauration can be obtained [106]. Experiments for recovery from power shutdown are introduced for the training of the operators in control centers of power generating units [106].

Other aspects show the IoT-based control introduced for the demand-side management system of an educational institution to minimize the electricity consumption. For the monitoring of energy demand, IoT-based smart demand management system hardware was developed in an academic RES laboratory. By prioritizing the photovoltaics generated from solar energy during peak hours and using the shifting and rescheduling of the electric loads, a significantly lower electricity cost and lower peak demand was obtained, with educational benefits for the students and for the institute [107]. By using IoT a more effective energy management in smart buildings can be obtained [12,14].

A system composed of a microcomputer Raspberry Pi RPI, with sensors and multispectral cameras, was set to acquire crop image data, at specific timing intervals during the spring, and evaluate crop growth [108]. The system was connected to IoT-based sensors for real-time crop monitoring. Many acquired images were processed to extract plant characteristics and markers, representing crop growth, health, and interaction with the weather [108].

Integrating IoT into energy education of students enhances technical skills, fosters critical thinking, and problem solving. It introduces students to careers in the emerging fields of energy conversion and management, where IoT technologies are gaining an increasingly important role.

6. Discussion

A comparison between the different topics that are published can be made from more points of view and criteria. One criterion is the interest of researchers and readers in the topics and disciplines so far. For this criterion we used the citation numbers as they have been included in the respective “Citations” columns of Table 1, Table 2, Table 3, Table 4, Table 5 and Table 6. The second criterion of interest is the technology used to implement the control systems of electrical machines with IoT. For this criterion we searched in the selected publications for technical data related to hardware, sensors, data collection, conversion of analogue signals to digital, data transmission networks, storage, processing, data search, and software. In Table 2, Table 3 and Table 4 we have compiled and classified the technical details describing these elements.

The citation numbers of retrieved and selected publications, which are shown in Table 1, Table 2, Table 3, Table 4, Table 5 and Table 6, confirm the awareness and interest of readers, scientists, and researchers, to become informed and contribute to the issues of IoT-based control of electrical machines. Based on the number of referrals, we find that, so far, the following issues have taken the lead.

Among the most studied topics of induction motors is the design of IoT-based performance control systems and maintenance monitoring for early fault detection with web-based automatic diagnostic techniques, and includes component technical specifications in Table 1 [16,17], and in Table 2 [24,40]. The monitoring and analysis of the condition of induction machines is achieved by detecting and measuring currents, voltages, temperatures, and vibrations, collecting data, and transmitting them to the cloud, and processing and evaluating them for fault prediction and maintenance decisions [62,72].

- With the development of wireless sensor networks and specialized software, research prioritized sending data to the cloud, storing and retrieving it, and processing and visualizing data results for real-time control and decision making in Table 3 [67,68,73].

- Of the most studied topics of induction generators are the technologies that allow WECS to connect to IoE, such as the requirements for networking and remote control, and avoiding or solving load rejection from instabilities due to the wind and load demands Table 1 [18,19].

- Also, the integration and monitoring of the hybrid wind-photovoltaics with IoT and ICT technologies, gained interest in the field of power supply restoration with early diagnosis and fault recovery in Table 4 [80].

- Supervisory control, and fault detection and location using IoT, both in microgrids and power distribution systems, with applications for smart sensor networks for data acquisition, communication, and connection to the cloud, finding other useful data from the cloud, and data security, improves neutral current compensation, elimination of higher harmonics and, ultimately, power quality in Table 4 [78,81,84].

Regarding the implementation of the control systems, we found a diversity of components and devices, which are detailed in Table 2, Table 3 and Table 4, and the main modules and units are summarized below:

- In all layouts described in Table 2, Table 3 and Table 4, a computer, or microcomputer, is installed which can be:

- (1)

- one microcomputer Raspberry Pi, in [24,39,40,60,62,66,69,81,82]

- (2)

- one PC or a Single Board Computer, in [58]

- (3)

- a laptop, in [61]

- (4)

- a server, in [56,57,65,67,72,83,84]

- (5)

- one IoT gateway, in [60,68,73,75,78]

- (6)

- an IoT platform, in [70,71].

- Many layouts have Arduino microcontrollers, of different models and versions, in [24,39,40,56,57,60,62,66,69,73,75,82].

- Communication protocols are needed in all cases, such as:

- (1)

- the serial communications protocol Modbus, in [24,39,40,77,78,81,84], or,

- (2)

- the Message Queuing Telemetry Transport MQTT protocol, in [55,70,81].

From a manufacturing point of view, it is practically difficult to compare different layouts and devices due to the variety of designs and components used. From an operational point of view, all the aforementioned devices and systems have been tested and found to function satisfactorily, which is why their results have been published. From the perspective of technological progress, it is not yet possible to compare dissimilar layouts, precisely because electronics and telecommunications technology are constantly evolving.

In conclusion, we find that there is no standardization of these systems, everything is in a phase of evolution and constant change, depending on needs, ratings, technology, available budget, and managerial decisions.

IoT is being introduced in academic laboratories for experiments with electric motion controllers and for research on induction generators with WECS [24,39,55]. It is also installed in electrical energy control centers for operator training, and in hybrid microgrid management centers, for conducting studies to control and monitor the security of data transmission via IoT in interconnected RES networks, in Table 6 [105,106].

Small machines and actuators for converting other forms of energy into electricity, or for mechanical motion, such as triboelectric nanogenerators and piezoelectric wind energy harvesters which are used for sensors in the IoT, in self-powered devices and in power supplies for components of green IoT devices, are under study and development, in Table 5 [20,85,87,89,91].

7. Conclusions

This article presented new aspects of integrating the control systems of electric machines with the IoT. Various aspects of the operation of electric machines were analyzed, either as generators in wind power stations, or as motors in controlled electric drive systems, or in other devices for converting energy into electricity.

The IoT-based control system of the performance of induction motor systems shows high accuracy during rapidly changing duty cycles. The system proves controlled speed at load variations, full torque at a large speed range, reliable cut-off and reconnection of the mains, and increased efficiency.

In IoT-controlled induction generators in WECS, the voltage and frequency output and the quality of the electricity generated are monitored over wind speed fluctuations. The online and IoT-based preventive maintenance of electrical machines, whether industrial equipment or electric power plants, avoids failures, and increases the reliability and lifetime of machines.

While basically, the control of electrical machines applies verified and recognized methods such as scalar and vector control of systems, with criteria to maximize efficiency and improve the quality of the electricity produced, the development of IoT, with networking and communications, opens up new research topics. Thus, IoT proved to be a new developed control environment for many industrial applications. The diversity of research topics depends on the variety of applications, on the one hand for industrial loads and, on the other, in electricity generation with an emphasis on renewable sources.

The described schemes demonstrate that IoT can be adopted and integrated into controlled systems of electrical machines, for operation monitoring, energy management, and preventive maintenance. In most cases, the main issues addressed concern:

- the connectivity of electrical power equipment to the IoT and ICT,

- the variety of sensors, to convert physical quantities into digital signals, quickly, accurately, reliably, and compatible with the IoT and ICT,

- the acquisition, storage, transmission, processing, protection, access, and security of data,

- nanogenerators and other energy harvesters for small power supplies of remote IoT components.

Also, similar experiments to those described in this work can be developed and applied in academic laboratories, for graduates and researchers interested in IoT projects. Controlled electrical machine systems can experiment with different duty cycles, using layouts and electronic devices that are interconnected with the IoT, and experimental remote systems connected to platforms and the internet. This aspect of applied electrical engineering education is still lagging behind and should be strengthened.

In this work we have selected representative reports that provide technical details and guidelines for future constructions and experiments with such systems. However, as a general conclusion, mention should be made of the low number of publications in the technical literature that provide complete details on the design, implementation, experimental testing, and construction of prototype control systems of electrical machines based on IoT. Most of the retrieved and analyzed documents offer rich generic information, but without giving specific instructions on the full design line of an IoT-based system, or exact details of hardware, software, sensors, data acquisition, and communications.

The diversity of existent installed IoT controlled systems attracts the interest and efforts of researchers in many academic laboratories, to continue with the design, development, and prototyping of new layouts, with combinations of existing components and testing new discovered devices and new ideas.

Author Contributions

Conceptualization, S.A.P. and M.G.I.; methodology, A.P.S., S.A.P. and M.G.I.; investigation, E.E.S. and M.E.S.; resources, A.P.S., S.A.P. and M.G.I.; writing—original draft preparation, S.A.P. and M.G.I.; writing—review and editing, A.P.S., S.A.P. and M.G.I.; supervision M.G.I.; project administration, M.G.I.; funding acquisition, M.G.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Al-Fuqaha, A.; Guizani, M.; Mohammadi, M.; Aledhari, M.; Ayyash, A. Internet of Things: A Survey on Enabling Technologies, Protocols and Applications. IEEE Commun. Surv. Tutor. 2015, 17, 2347–2376. [Google Scholar] [CrossRef]

- Milić, S.D.; Babić, B.M. Toward the Future—Upgrading Existing Remote Monitoring Concepts to IIoT Concepts. IEEE Internet Things 2020, 7, 11693–11700. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Malik, P.K.; Sharma, R.; Singh, R.; Gehlot, A.; Satapathy, S.C.; Alnumay, W.S.; Pelusi, D.; Ghosh, U.; Nayak, J. Industrial Internet of Things and its Applications in Industry 4.0: State of The Art. Comput. Commun. 2021, 166, 125–139. [Google Scholar] [CrossRef]

- Pali, B.S.; Vadhera, S. Renewable energy systems for generating electric power: A review. In Proceedings of the 2016 IEEE 1st International Conference on Power Electronics, Intelligent Control and Energy Systems (ICPEICES), Delhi, India, 4–6 July 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Papazis, S.A. Integrated Economic Optimization of Hybrid Thermosolar Concentrating System Based on Exact Mathematical Method. Energies 2022, 15, 7019. [Google Scholar] [CrossRef]

- Abir, S.M.A.A.; Anwar, A.; Choi, J.; Kayes, A.S.M. IoT-enabled smart energy grid: Applications and challenges. IEEE Access 2021, 9, 50961–50981. [Google Scholar] [CrossRef]

- Biegańska, M. IoT-Based Decentralized Energy Systems. Energies 2022, 15, 7830. [Google Scholar] [CrossRef]

- Wójcicki, K.; Bieganska, M.; Paliwoda, B.; Górna, J. Internet of Things in Industry: Research Profiling, Application, Challenges and Opportunities—A Review. Energies 2022, 15, 1806. [Google Scholar] [CrossRef]

- Sakib, N.; Hossain, E.; Ahamed, S.I. A Qualitative Study on the United States Internet of Energy: A Step towards Computational Sustainability. IEEE Access 2020, 8, 69003–69037. [Google Scholar] [CrossRef]

- Rinaldi, G.; Thies, P.R.; Johanning, L. Current Status and Future Trends in the Operation and Maintenance of Offshore Wind Turbines: A Review. Energies 2021, 14, 2484. [Google Scholar] [CrossRef]

- Elsisi, M.; Tran, M.-Q.; Mahmoud, K.; Lehtonen, M.; Darwish, M.M.F. Deep Learning-Based Industry 4.0 and Internet of Things towards Effective Energy Management for Smart Buildings. Sensors 2021, 21, 1038. [Google Scholar] [CrossRef]

- Yaïci, W.; Krishnamurthy, K.; Entchev, E.; Longo, M. Recent Advances in Internet of Things (IoT) Infrastructures for Building Energy Systems: A Review. Sensors 2021, 21, 2152. [Google Scholar] [CrossRef]

- de Oliveira Cavalcanti, G.; Pimenta, H.C.D. Electric Energy Management in Buildings Based on the Internet of Things: A Systematic Review. Energies 2023, 16, 5753. [Google Scholar] [CrossRef]

- Sengamalai, U.; Anbazhagan, G.; Thamizh Thentral, T.M.; Vishnuram, P.; Khurshaid, T.; Kamel, S. Three Phase Induction Motor Drive: A Systematic Review on Dynamic Modeling, Parameter Estimation, and Control Schemes. Energies 2022, 15, 8260. [Google Scholar] [CrossRef]

- Kulkarni, P.P.; Patil, M.; Shibi, S.; Patle, M.; Kale, R. Review on Online Monitoring of Electrical Machine using IoT. In Proceedings of the 2019 International Conference on Nascent Technologies in Engineering (ICNTE), Navi Mumbai, India, 4–5 January 2019; pp. 1–4. [Google Scholar] [CrossRef]

- De Jesús Rangel-Magdaleno, J. Induction Machines Fault Detection: An Overview. IEEE Instrum. Meas. Mag. 2021, 24, 63–71. [Google Scholar] [CrossRef]

- Moness, M.; Moustafa, A.M. A Survey of Cyber-Physical Advances and Challenges of Wind Energy Conversion Systems: Prospects for Internet of Energy. IEEE Internet Things J. 2016, 3, 134–145. [Google Scholar] [CrossRef]

- Behara, R.K.; Saha, A.K. Artificial Intelligence Control System Applied in Smart Grid Integrated Doubly Fed Induction Generator-Based Wind Turbine: A Review. Energies 2022, 15, 6488. [Google Scholar] [CrossRef]

- Vinoth Kumar, K.; Omer, M.; Singh, S.S.; Nayrah, M.A. A Review on Triboelectric Nanogenerators (TENGs) using Internet of Things. In Proceedings of the 2021 International Conference on Forensics, Analytics, Big Data, Security (FABS), Bengaluru, India, 21–22 December 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Ioannides, M.G.; Papazis, S.A.; Ioannidou, F.G. Implementation of scalar control scheme for variable frequency induction motor actuator system. Sens. Actuators A Phys. 2003, 106, 306–309. [Google Scholar] [CrossRef]

- Lysenko, O.A. Sensorless Scalar Asynchronous Electric Drive for Pressure Stabilization of the Pumping Unit. In Proceedings of the 2021 Dynamics of Systems, Mechanisms and Machines (Dynamics), Omsk, Russia, 9–11 November 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Ioannides, M.G.; Tegopoulos, J.A. Generalized optimization slip power recovery drives. IEEE Trans. Energy Convers. 1990, 5, 91–97. [Google Scholar] [CrossRef]

- Stamelos, A.P.; Papoutsidakis, A.; Vikentios, V.; Papazis, S.A.; Ioannides, M.G. Experimental Educational System of AC Electric Drives with Internet of Things. In Proceedings of the XXIII International Conference on Electrical Machines ICEM 2018, Alexandroupoli, Greece, 3–6 September 2018; pp. 1497–1502. [Google Scholar] [CrossRef]

- Kowsalya, M.; Pradeep, R.; Elakya, A.; Gunapriya, D. PLC Based Critical Composition Control for Industries. In Proceedings of the 2022 8th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, India, 25–26 March 2022; pp. 1636–1639. [Google Scholar] [CrossRef]

- Ansari, A.A.; Dyanamina, G. Fault Ride-Through Operation Analysis of Doubly Fed Induction Generator-Based Wind Energy Conversion Systems: A Comparative Review. Energies 2022, 15, 8026. [Google Scholar] [CrossRef]

- Ioannides, M.G. State space formulation and transient stability of the double output asynchronous generator. IEEE Trans. Energy Convers. 1993, 8, 732–738. [Google Scholar] [CrossRef]