Multi-Criteria Study on Ground Source Heat Pump with Different Types of Heat Exchangers

Abstract

1. Introduction

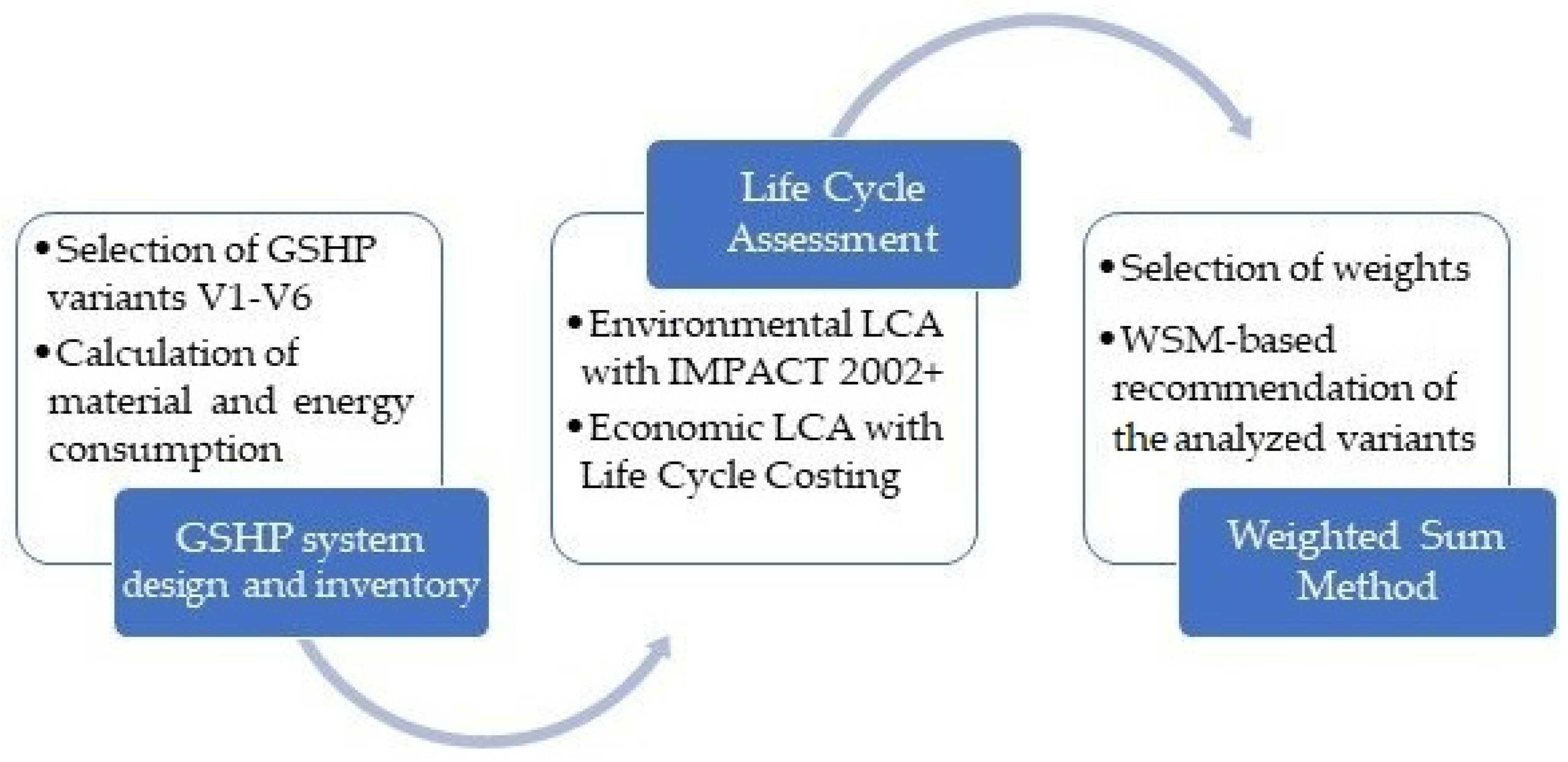

2. Materials and Methods

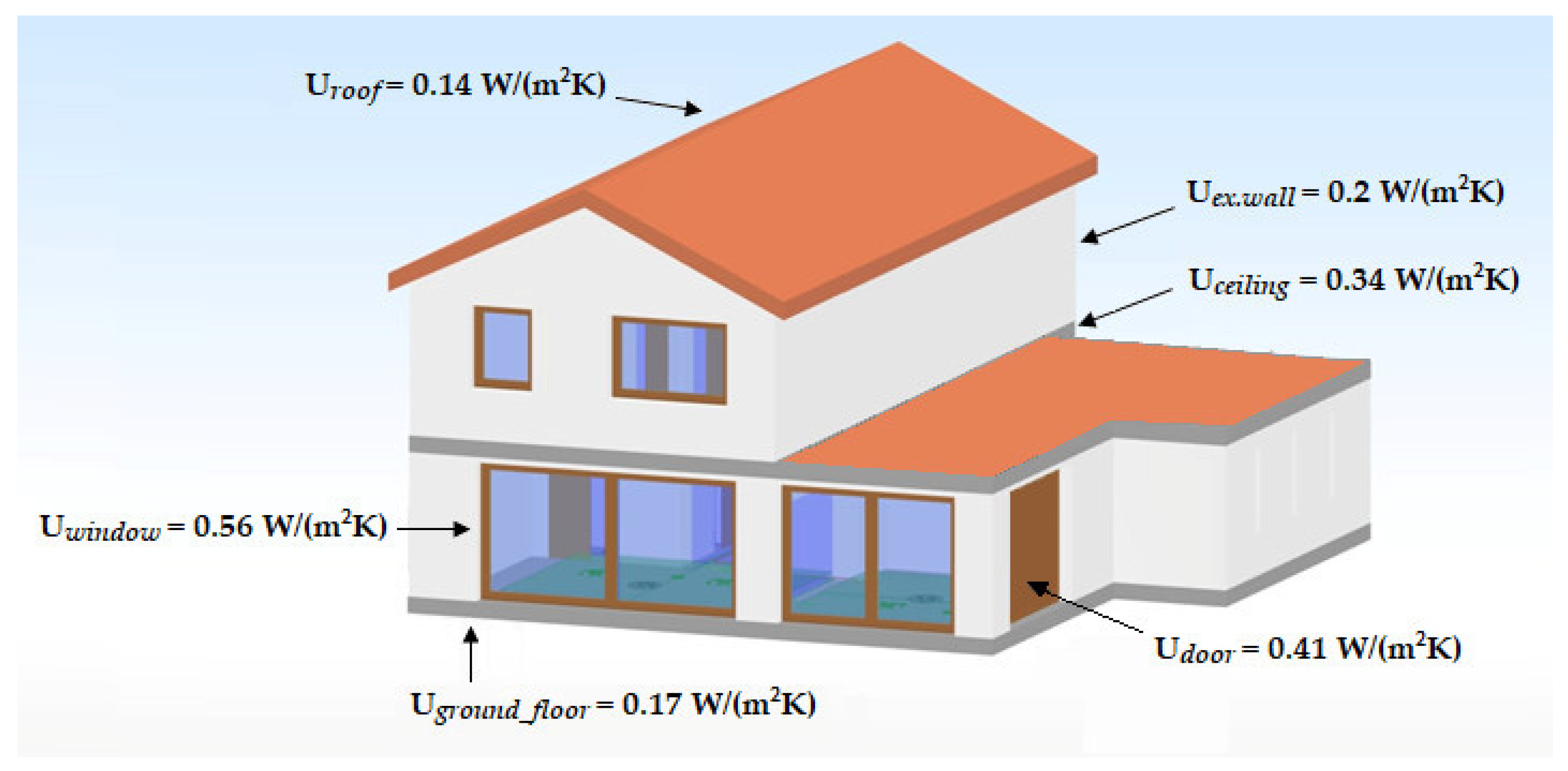

2.1. Object Description

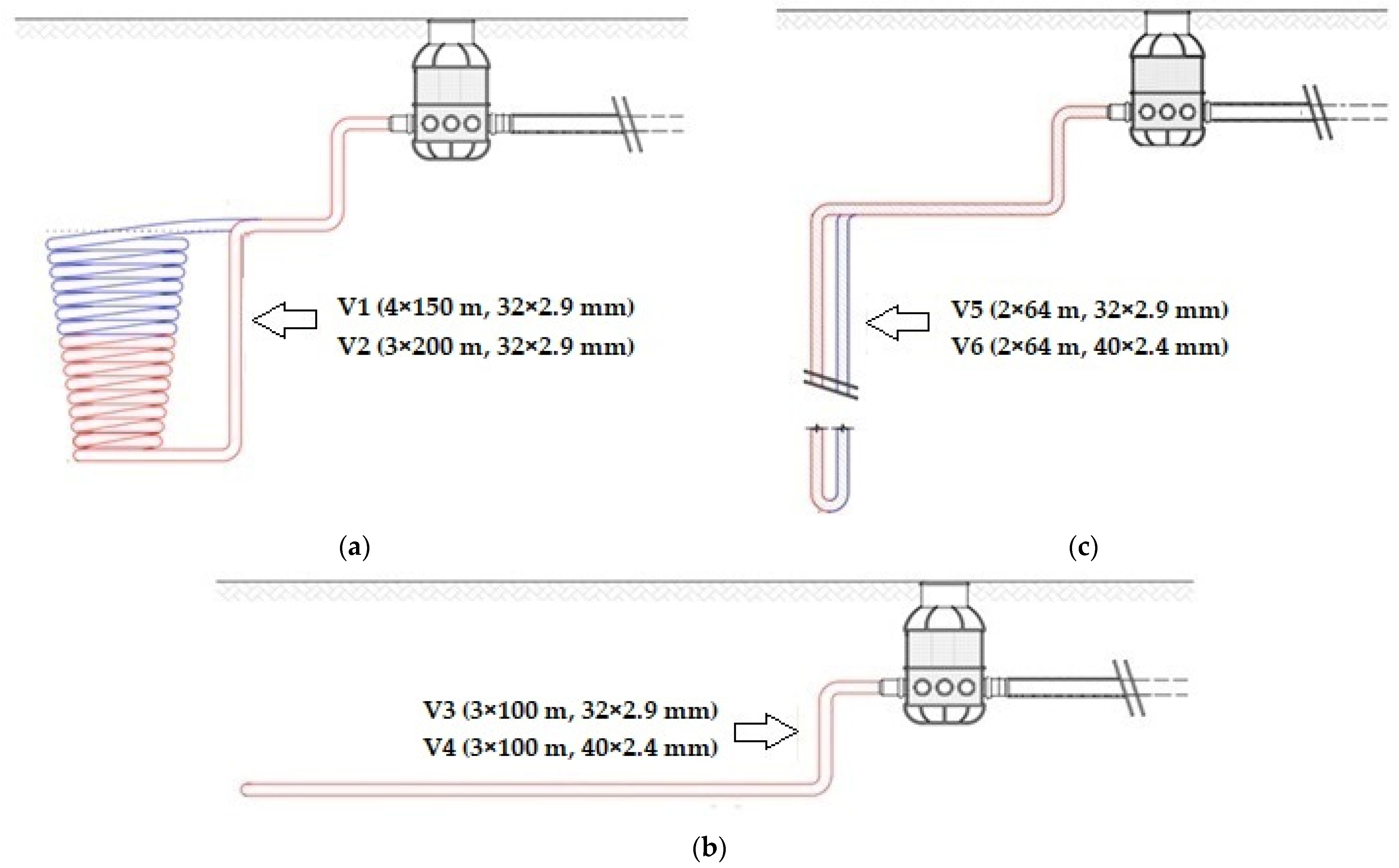

2.2. System Description

2.3. Multi-Criteria Analysis

2.3.1. Environmental Criteria

2.3.2. Economic Criterion

2.3.3. Weighted Sum Method

3. Results and Discussion

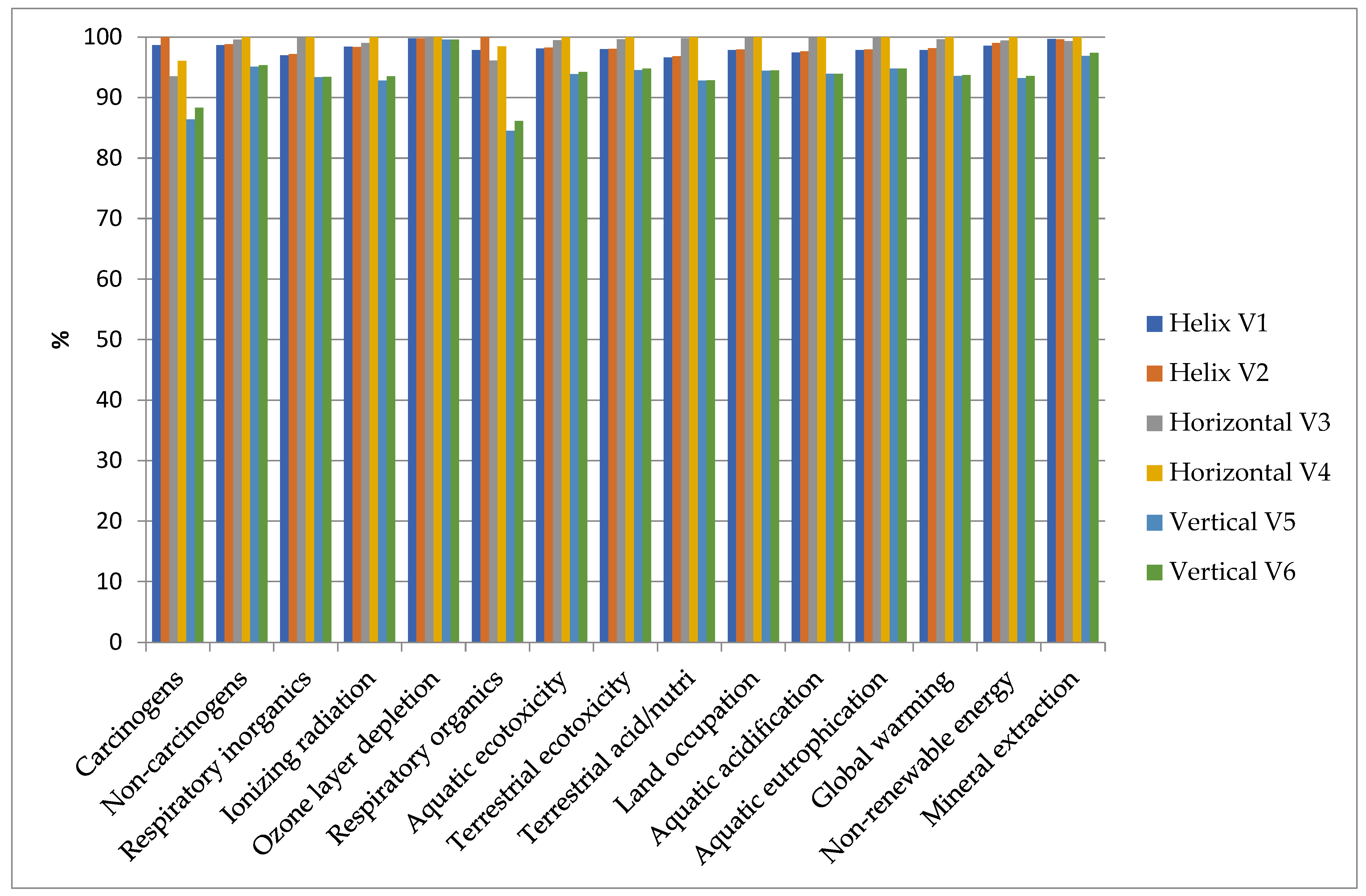

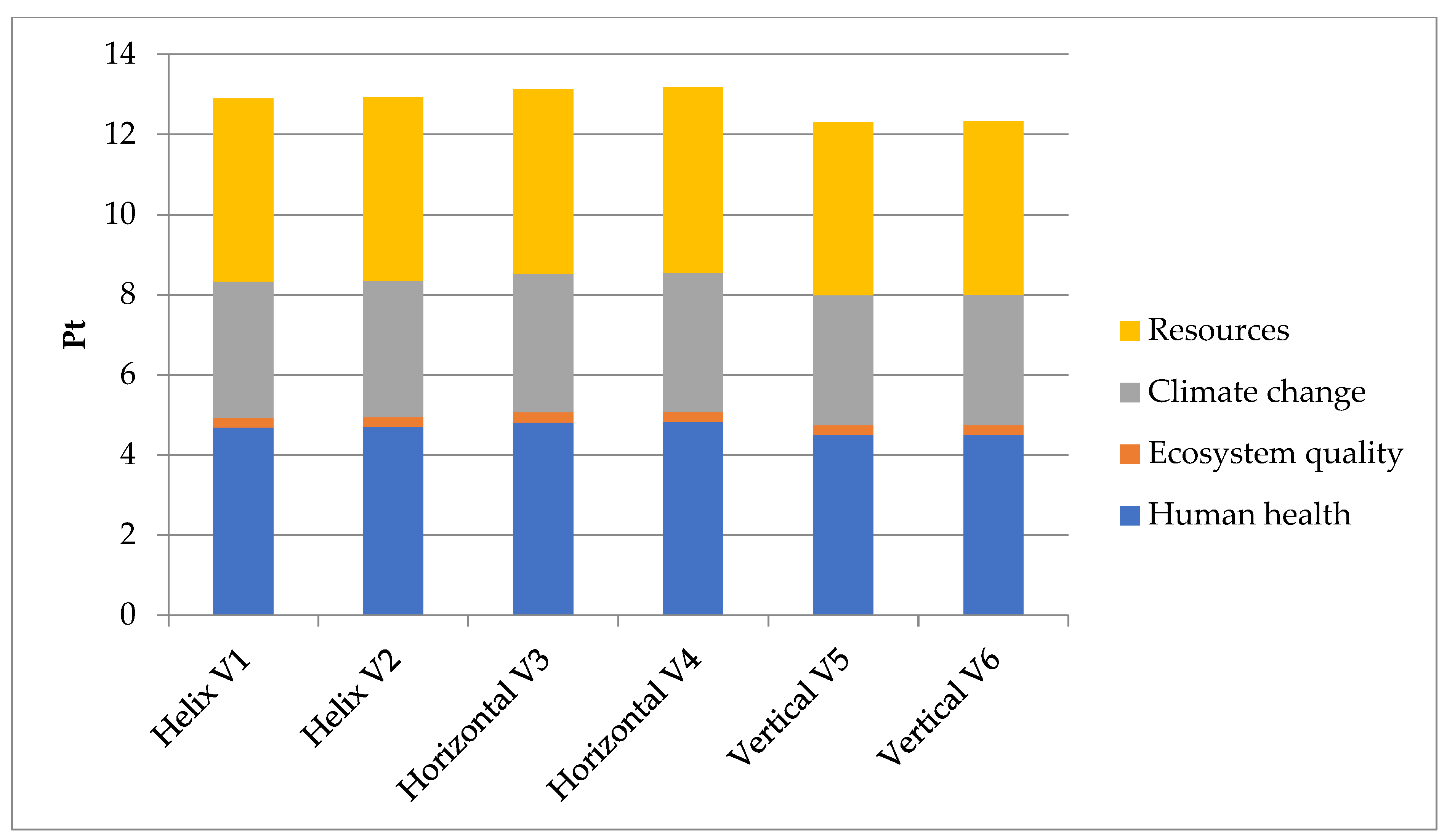

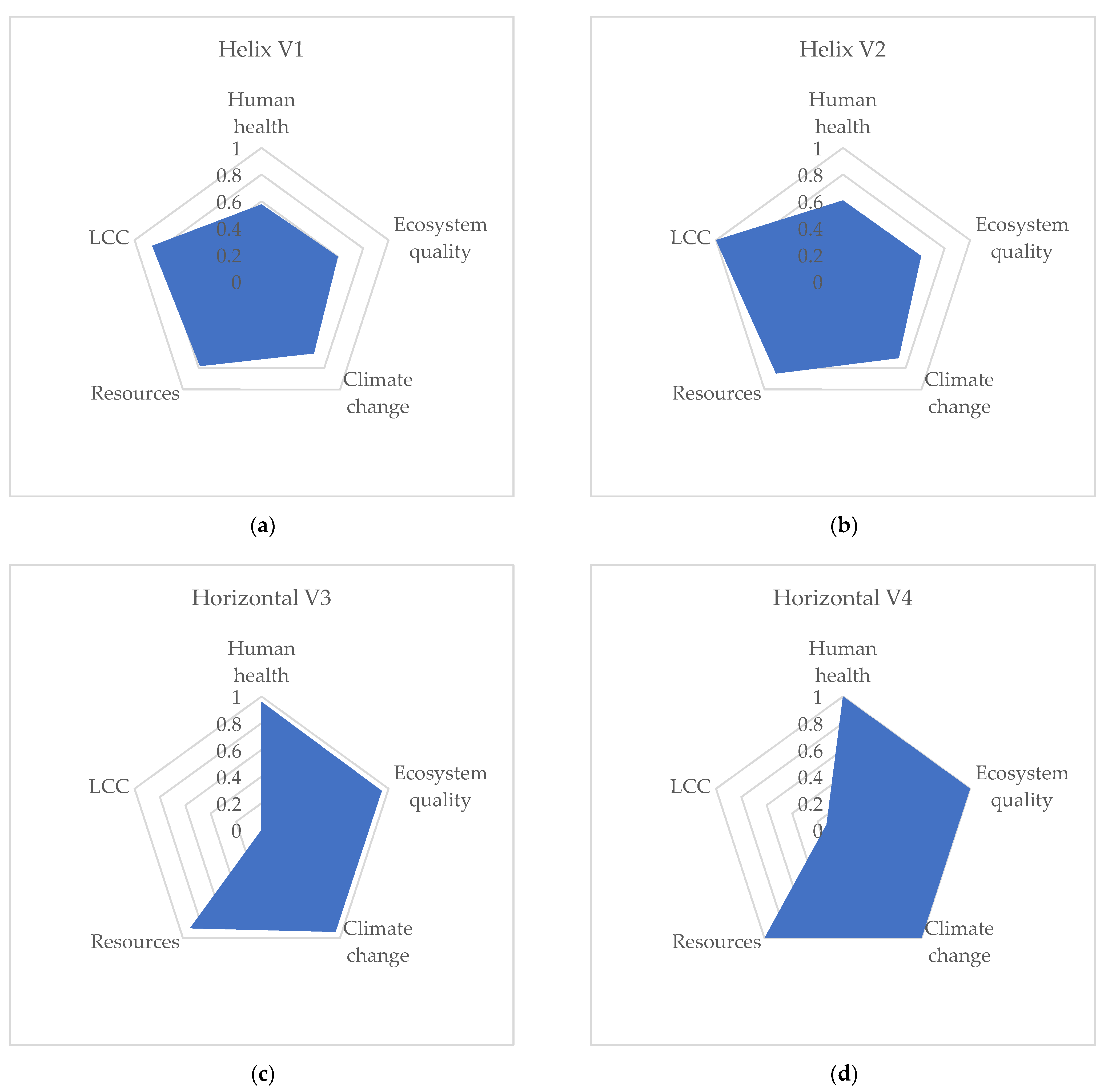

3.1. Life Cycle Impact Assessment by the Use of IMPACT 2002+

3.2. LCC Results

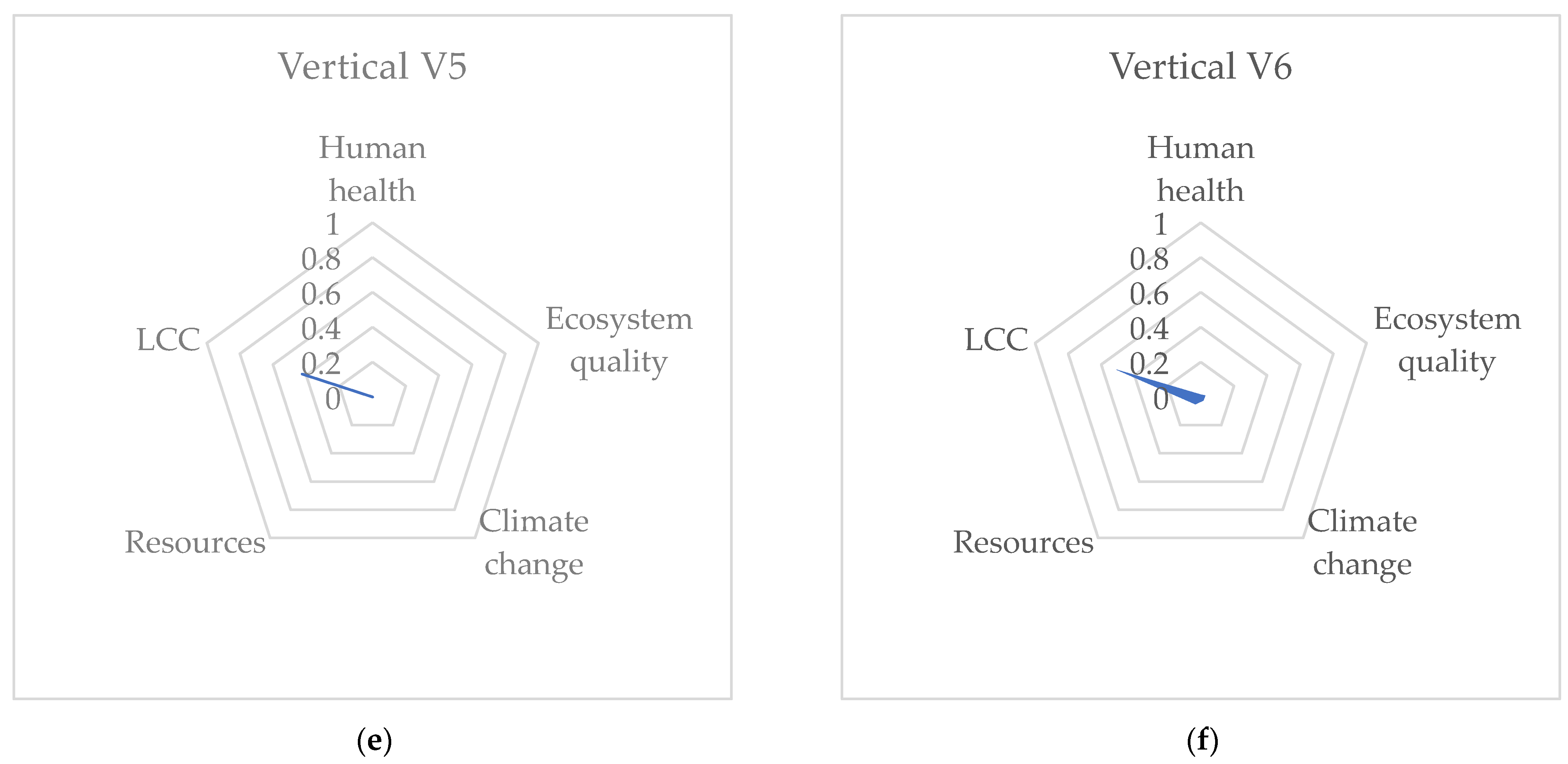

3.3. WSM Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ASHP | Air source heat pump |

| COP | Coefficient of Performance |

| GHE | Ground heat exchanger |

| GHG | Greenhouse gases |

| GSHP | Ground source heat pump |

| HP | Heat pump |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LCC | Life Cycle Cost |

| MCA | Multi-criteria analysis |

| PE-XA-UV | Cross linked polyethylene pipe with an anti-UV layer |

| Pt | Points |

| PV | Photovoltaic |

| SCOP | Seasonal Coefficient of Performance |

References

- Ahmed, N.; Khan, T.I.; Augustine, A. Climate change and environmental degradation: A serious threat to global security. Eur. J. Soc. Sci. 2018, 3, 161–172. [Google Scholar] [CrossRef]

- Fawzy, S.; Osman, A.I.; Doran, J.; Rooney, D.W. Strategies for mitigation of climate change: A review. Environ. Chem. Lett. 2020, 18, 2069–2094. [Google Scholar] [CrossRef]

- European Commission. A European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal (accessed on 5 November 2023).

- Leibowicz, B.D.; Lanham, C.M.; Brozynski, M.T.; Vázquez-Canteli, J.R.; Castejón, N.C.; Nagy, Z. Optimal decarbonization pathways for urban residential building energy services. Appl. Energy 2018, 230, 1311–1325. [Google Scholar] [CrossRef]

- Berrill, P.; Wilson, E.J.; Reyna, J.L.; Fontanini, A.D.; Hertwich, E.G. Decarbonization pathways for the residential sector in the United States. Nat. Clim. Chang. 2022, 12, 712–718. [Google Scholar] [CrossRef]

- Elavarasan, R.M.; Pugazhendhi, R.; Irfan, M.; Mihet-Popa, L.; Khan, I.A.; Campana, P.E. State-of-the-art sustainable approaches for deeper decarbonization in Europe–An endowment to climate neutral vision. Renew. Sustain. Energy Rev. 2022, 159, 112204. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Available online: https://www.irena.org/Innovation-landscape-for-smart-electrification/Power-to-heat-and-cooling/Status (accessed on 12 November 2023).

- Güneralp, B.; Zhou, Y.; Ürge-Vorsatz, D.; Gupta, M.; Yu, S.; Patel, P.L.; Fragkias, M.; Li, X.; Seto, K.C. Global scenarios of urban density and its impacts on building energy use through 2050. Proc. Natl. Acad. Sci. USA 2017, 114, 8945–8950. [Google Scholar] [CrossRef] [PubMed]

- Connolly, D.; Lund, H.; Mathiesen, B.V. Smart energy Europe: The technical and economic impact of one potential 100% renewable energy scenario for the European Union. Renew. Sustain. Energy Rev. 2016, 60, 1634–1653. [Google Scholar] [CrossRef]

- Yan, H.; Wang, R.; Zhang, C.; Xu, Z.; Hu, B.; Shao, Z. The role of heat pump in heating decarbonization for China carbon neutrality. Carbon Neutrality 2022, 1, 40. [Google Scholar] [CrossRef]

- Dong, S.; Zhao, H.; Zheng, Y.; Ni, L. Carbon reduction analysis of electric heat pumps in carbon neutrality in China. Sustain. Cities Soc. 2023, 97, 104758. [Google Scholar] [CrossRef]

- Borge-Diez, D.; Icaza, D.; Trujillo-Cueva, D.F.; Açıkkalp, E. Renewable energy driven heat pumps decarbonization potential in existing residential buildings: Roadmap and case study of Spain. Energy 2022, 247, 123481. [Google Scholar] [CrossRef]

- Witkowska, A.; Krawczyk, D.A.; Rodero, A. Analysis of the Heat Pump Market in Europe with a Special Regard to France, Spain, Poland and Lithuania. Environ. Clim. Technol. 2021, 25, 840–852. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Available online: https://www.iea.org/commentaries/global-heat-pump-sales-continue-double-digit-growth (accessed on 12 November 2023).

- European Heat Pump Association (EHPA). Available online: https://www.ehpa.org/2023/02/08/ehpa_news/port-pc-2022-was-the-year-of-heat-pumps-in-poland/ (accessed on 15 November 2023).

- Valancius, R.; Singh, R.M.; Jurelionis, A.; Vaiciunas, J. A review of heat pump systems and applications in cold climates: Evidence from Lithuania. Energies 2019, 12, 4331. [Google Scholar] [CrossRef]

- Sewastianik, S.; Gajewski, A. Energetic and ecologic heat pumps evaluation in Poland. Energies 2020, 13, 4980. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, F.; Ma, Z.; Wang, X.; Wu, X. Research of heat and moisture transfer influence on the characteristics of the ground heat pump exchangers in unsaturated soil. Energy Build. 2016, 130, 140–149. [Google Scholar] [CrossRef]

- Noorollahi, Y.; Saeidi, R.; Mohammadi, M.; Amiri, A.; Hosseinzadeh, M. The effects of ground heat exchanger parameters changes on geothermal heat pump performance—A review. Appl. Therm. Eng. 2018, 129, 1645–1658. [Google Scholar] [CrossRef]

- Li, B.; Han, Z.; Bai, C.; Hu, H. The influence of soil thermal properties on the operation performance on ground source heat pump system. Renew. Energy 2019, 141, 903–913. [Google Scholar] [CrossRef]

- Torres-Rodríguez, A.; Morillón-Gálvez, D.; Aldama-Ávalos, D.; Morales-Ramírez, J.D.; Kerdan, I.G. Predicting the thermal behaviour of sands considering its moisture content and grain size with applications to geothermal heat pump installations. Energy Build. 2019, 194, 85–104. [Google Scholar] [CrossRef]

- Çetin, G.; Özkaraca, O.; Keçebaş, A. Development of PID based control strategy in maximum exergy efficiency of a geothermal power plant. Renew. Sust. Energy Rev. 2021, 137, 110623. [Google Scholar] [CrossRef]

- Liu, Z.; Du, Y.; Song, C.; Yang, X.; Yan, J. Effect of soil moisture content on thermal performance of ground source heat exchangers: An electromagnetism topology-based analysis. Energy Rep. 2023, 10, 3914–3928. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- Gundes, S. The use of life cycle techniques in the assessment of sustainability. Procedia Soc. Behav. Sci. 2016, 216, 916–922. [Google Scholar] [CrossRef]

- Bonamente, E.; Aquino, A. Life-cycle assessment of an innovative ground-source heat pump system with upstream thermal storage. Energies 2017, 10, 1854. [Google Scholar] [CrossRef]

- Biglarian, H.; Saidi, M.H.; Abbaspour, M. Economic and environmental assessment of a solar-assisted ground source heat pump system in a heating-dominated climate. Int. J. Sci. Environ. Technol. 2019, 16, 3091–3098. [Google Scholar] [CrossRef]

- Smith, M.; Bevacqua, A.; Tembe, S.; Lal, P. Life cycle analysis (LCA) of residential ground source heat pump systems: A comparative analysis of energy efficiency in New Jersey. Sustain. Energy Technol. Assess. 2021, 47, 101364. [Google Scholar] [CrossRef]

- Eguiarte, O.; Garrido-Marijuán, A.; de Agustín-Camacho, P.; del Portillo, L.; Romero-Amorrortu, A. Energy, environmental and economic analysis of air-to-air heat pumps as an alternative to heating electrification in Europe. Energies 2020, 13, 3939. [Google Scholar] [CrossRef]

- Panagiotidou, M.; Aye, L.; Rismanchi, B. Alternative Heating and Cooling Systems for the Retrofit of Medium-Rise Residential Buildings in Greece. Energy Technol. 2021, 9, 2100377. [Google Scholar] [CrossRef]

- Violante, A.C.; Donato, F.; Guidi, G.; Proposito, M. Comparative life cycle assessment of the ground source heat pump vs air source heat pump. Renew. Energy 2022, 188, 1029–1037. [Google Scholar] [CrossRef]

- Sewastianik, S.; Gajewski, A. An Environmental Assessment of Heat Pumps in Poland. Energies 2021, 14, 8104. [Google Scholar] [CrossRef]

- Miralles, J.A.L.; García, R.L.; Carnicero, J.M.P.; Martínez, F.J.R. Comparative study of heat pump system and biomass boiler system to a tertiary building using the Life Cycle Assessment (LCA). Renew. Energy 2020, 152, 1439–1450. [Google Scholar] [CrossRef]

- Lin, H.; Clavreul, J.; Jeandaux, C.; Crawley, J.; Butnar, I. Environmental life cycle assessment of heating systems in the UK: Comparative assessment of hybrid heat pumps vs. condensing gas boilers. Energy Build. 2021, 240, 110865. [Google Scholar] [CrossRef]

- Sevindik, S.; Spataru, C.; Domenech Aparisi, T.; Bleischwitz, R. A comparative environmental assessment of heat pumps and gas boilers towards a circular economy in the UK. Energies 2021, 14, 3027. [Google Scholar] [CrossRef]

- Naumann, G.; Schropp, E.; Gaderer, M. Life cycle assessment of an air-source heat pump and a condensing gas boiler using an attributional and a consequential approach. Procedia CIRP 2022, 105, 351–356. [Google Scholar] [CrossRef]

- Nitkiewicz, A.; Sekret, R. Comparison of LCA results of low temperature heat plant using electric heat pump, absorption heat pump and gas-fired boiler. Energy Convers. Manag. 2014, 87, 647–652. [Google Scholar] [CrossRef]

- Famiglietti, J.; Toppi, T.; Pistocchini, L.; Scoccia, R.; Motta, M. A comparative environmental life cycle assessment between a condensing boiler and a gas driven absorption heat pump. Sci. Total Environ. 2021, 762, 144392. [Google Scholar] [CrossRef]

- Riva, C.; Roumpedakis, T.C.; Kallis, G.; Rocco, M.V.; Karellas, S. Life cycle analysis of a photovoltaic driven reversible heat pump. Energy Build. 2021, 240, 110894. [Google Scholar] [CrossRef]

- Marinelli, S.; Lolli, F.; Butturi, M.A.; Rimini, B.; Gamberini, R. Environmental performance analysis of a dual-source heat pump system. Energy Build. 2020, 223, 110180. [Google Scholar] [CrossRef]

- Li, H.; Bi, Y.; Qin, L.; Zang, G. Absorption solar-ground source heat pump: Life cycle environmental profile and comparisons. Geothermics 2020, 87, 101850. [Google Scholar] [CrossRef]

- Żelazna, A.; Kosaryha, D. The influence of the type of heat exchanger on the environmental and economic efficiency of brine-to-water heat pump. AIP Conf. Proc. 2023, 2887, 020016. [Google Scholar] [CrossRef]

- PN-EN 12831-1:2017-08; Energy Performance of Buildings—Method for Calculating the Design Thermal Load—Part 1: Thermal Load, Module M3-3. PKN: Warsaw, Poland, 2017.

- Available online: https://portpc.pl (accessed on 10 September 2023).

- Available online: http://www.wp-opt.pl/walidacja.html (accessed on 26 September 2023).

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. LCA 2003, 8, 324. [Google Scholar] [CrossRef]

- Lee, M.; Ham, S.H.; Lee, S.; Kim, J.; Kim, Y. Multi-objective optimization of solar-assisted ground-source heat pumps for minimizing life-cycle cost and climate performance in heating-dominated regions. Energy 2023, 270, 126868. [Google Scholar] [CrossRef]

- Shaaban, M.; Scheffran, J.; Böhner, J.; Elsobki, M.S. Sustainability Assessment of Electricity Generation Technologies in Egypt Using Multi-Criteria Decision Analysis. Energies 2018, 11, 1117. [Google Scholar] [CrossRef]

- Rey Martínez, F.R.; Velasco Gómez, E.; Navas García, L.M.; Sanz Requena, J.F.; Navas Gracia, L.M.; Hernández Navarro, S.; Correa Guimaraes, A.; Martín Gil, J. Life cycle assessment of a semi-indirect ceramic evaporative cooler vs. a heat pump in two climate areas of Spain. Appl. Energy 2011, 88, 914–921. [Google Scholar] [CrossRef]

- Aresti, L.; Florides, G.A.; Skaliontas, A.; Christodoulides, P. Environmental Impact of Ground Source Heat Pump Systems: A Comparative Investigation From South to North Europe. Front. Built Environ. 2022, 8, 914227. [Google Scholar] [CrossRef]

- D’Agostino, D.; Parker, D.; Melià, P. Environmental and economic implications of energy efficiency in new residential buildings: A multi-criteria selection approach. Energy Strategy Rev. 2019, 26, 100412. [Google Scholar] [CrossRef]

- Aresti, L.; Christodoulides, P.; Florides, G.A. An investigation on the environmental impact of various Ground Heat Exchangers configurations. Renew. Energy 2021, 171, 592–605. [Google Scholar] [CrossRef]

| V1 | V2 | V3 | V4 | V5 | V6 | ||

|---|---|---|---|---|---|---|---|

| Type of exchanger | helix | helix | horizontal | horizontal | vertical | vertical | |

| Pipe material | PE-XA-UV | ||||||

| Diameter of pipes between HP and brine distributor | mm | 40 × 2.4 | 40 × 2.4 | 40 × 2.4 | 50 × 4.6 | 40 × 2.4 | 50 × 4.6 |

| Number of loops | 4 | 3 | 3 | 3 | 2 | 2 | |

| Diameter of pipes after brine distributor (loop) | mm | 32 × 2.9 | 32 × 2.9 | 32 × 2.9 | 40 × 2.4 | 32 × 2.9 | 40 × 2.4 |

| Length of each loop | m | 150 | 200 | 100 | 100 | 64 | 64 |

| Total mass of pipes | kg | 122 | 162 | 66 | 75 | 28.08 | 32.2 |

| Total mass of valves (cast iron) | kg | 7.14 | 7.14 | 7.14 | 7.14 | 7.14 | 7.14 |

| Volume of heat exchanger (brine) | dm3 | 347.1 | 335.1 | 181.7 | 251.22 | 142.9 | 202.3 |

| Pressure loss in the circuit | Pa | 6947.8 | 9532.8 | 6782.8 | 5792.8 | 7728.8 | 6171.2 |

| Pump lifting head | mH2O | 0.71 | 0.97 | 0.69 | 0.59 | 0.79 | 0.63 |

| Yearly energy consumption of circulation pump | kWh | 29.4 | 31.5 | 29.4 | 29.4 | 31.5 | 29.4 |

| Volume of earthworks | m3 | 38 | 34.5 | 384.75 | 384.75 | 9.2 | 9.2 |

| Length of drilling | m | - | - | - | - | 118 | 118 |

| Mass of PE manhole | kg | 85 | 85 | 85 | 85 | 85 | 85 |

| SCOP | - | 4.54 | 4.54 | 4.43 | 4.43 | 4.69 | 4.69 |

| Yearly energy consumption of heat pump | kWh | 1580.48 | 1580.48 | 1619.72 | 1619.72 | 1529.93 | 1529.93 |

| Circulation pump | 40 W, included in Ecoinvent production processes | ||||||

| Heat pump | 6 kW, included in Ecoinvent production processes, adopted from 10 kW | ||||||

| Expansion vessel | 18 dm3, included in Ecoinvent production processes, adopted from 25 dm3 | ||||||

| Variant | V1 | V2 | V3 | V4 | V5 | V6 |

|---|---|---|---|---|---|---|

| Type of exchanger | helix | helix | horizontal | horizontal | vertical | vertical |

| 5% | 12.540 | 12.564 | 12.774 | 12.828 | 11.980 | 11.984 |

| Mean | 12.892 | 12.918 | 13.118 | 13.164 | 12.307 | 12.324 |

| 95% | 13.355 | 13.374 | 13.550 | 13.577 | 12.717 | 12.805 |

| Variant | V1 | V2 | V3 | V4 | V5 | V6 | |

|---|---|---|---|---|---|---|---|

| Type of exchanger | helix | helix | horizontal | horizontal | vertical | vertical | |

| Ci | Euro | 14,490.44 | 14,350.67 | 10,386 | 11,244.89 | 12,756.44 | 13,349.11 |

| Co | Euro | 430.22 | 464.89 | 438.89 | 426.67 | 418.89 | 409.11 |

| LCC | Euro | 24,013.78 | 24,641.56 | 20,100.89 | 20,689.11 | 22,028.89 | 22,405.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Żelazna, A.; Gołębiowska, J.; Kosaryha, D. Multi-Criteria Study on Ground Source Heat Pump with Different Types of Heat Exchangers. Energies 2024, 17, 602. https://doi.org/10.3390/en17030602

Żelazna A, Gołębiowska J, Kosaryha D. Multi-Criteria Study on Ground Source Heat Pump with Different Types of Heat Exchangers. Energies. 2024; 17(3):602. https://doi.org/10.3390/en17030602

Chicago/Turabian StyleŻelazna, Agnieszka, Justyna Gołębiowska, and Dmytro Kosaryha. 2024. "Multi-Criteria Study on Ground Source Heat Pump with Different Types of Heat Exchangers" Energies 17, no. 3: 602. https://doi.org/10.3390/en17030602

APA StyleŻelazna, A., Gołębiowska, J., & Kosaryha, D. (2024). Multi-Criteria Study on Ground Source Heat Pump with Different Types of Heat Exchangers. Energies, 17(3), 602. https://doi.org/10.3390/en17030602