1. Introduction

Development of transport has significantly contributed to the increased use of non-renewable energy sources and air pollution. Substances such as solid particles, carbon oxide, nitric oxides, sulfur oxides and carbon dioxide largely contribute to air pollution. Transport is responsible not only for the emission of harmful substances into the atmosphere but also for the noise generated by transport means. The natural environment undergoes constant degradation under the influence of harmful emissions from combustion engines. Therefore, the European Commission imposed on the European Union member states the need to introduce legal regulations in this matter. The European Commission has implemented strategies, whose main goal is to achieve sustainable development. This is supposed to create an effective, environmental-friendly and competitive economy. These assumptions also apply to the transport policy of the European Union and involve implementation of respective regulations by the member states. The goals of transport policy, according to the latest documents of the European Union, are more than ever focused on environmental-friendly solutions. The concept of sustainable environment described in an announcement of the European Commission entitled ”Strategy for sustainable and smart mobility—European transport on the road to the future” provides a vision and assumptions concerning the development of transport. Environment-friendly transport policy should give preference to ecological and safe transport means and also promote use of intermodal transport, that is, substitution of road transport with other transport systems. Additionally, implementation of the rules and regulations set out in the environment protection documents is being monitored and analyzed for the purpose of updating a given strategy. Modified strategies lead to more efficient management of natural resources. However, the effects of changes that have already been introduced on the basis of applicable law still indicate unsustainability tendencies which lead to irreversible, negative changes in the field of energy consumption, natural resources exhaustion, transport and others. Sustainable transport means using transport means that minimize the emission of substances that degrade the natural environment, whereas sustainable development of transport is a concept assuming integration of economic and social goals from the perspective of the European Union transport policy and its member states. The biggest challenge for the common transport policy of the European Union is to provide balance for the development of different kinds of transport. Pollution that comes from the transport sector is more dangerous than industrial emissions. This is due to the fact that harmful gases are emitted close to the ground [

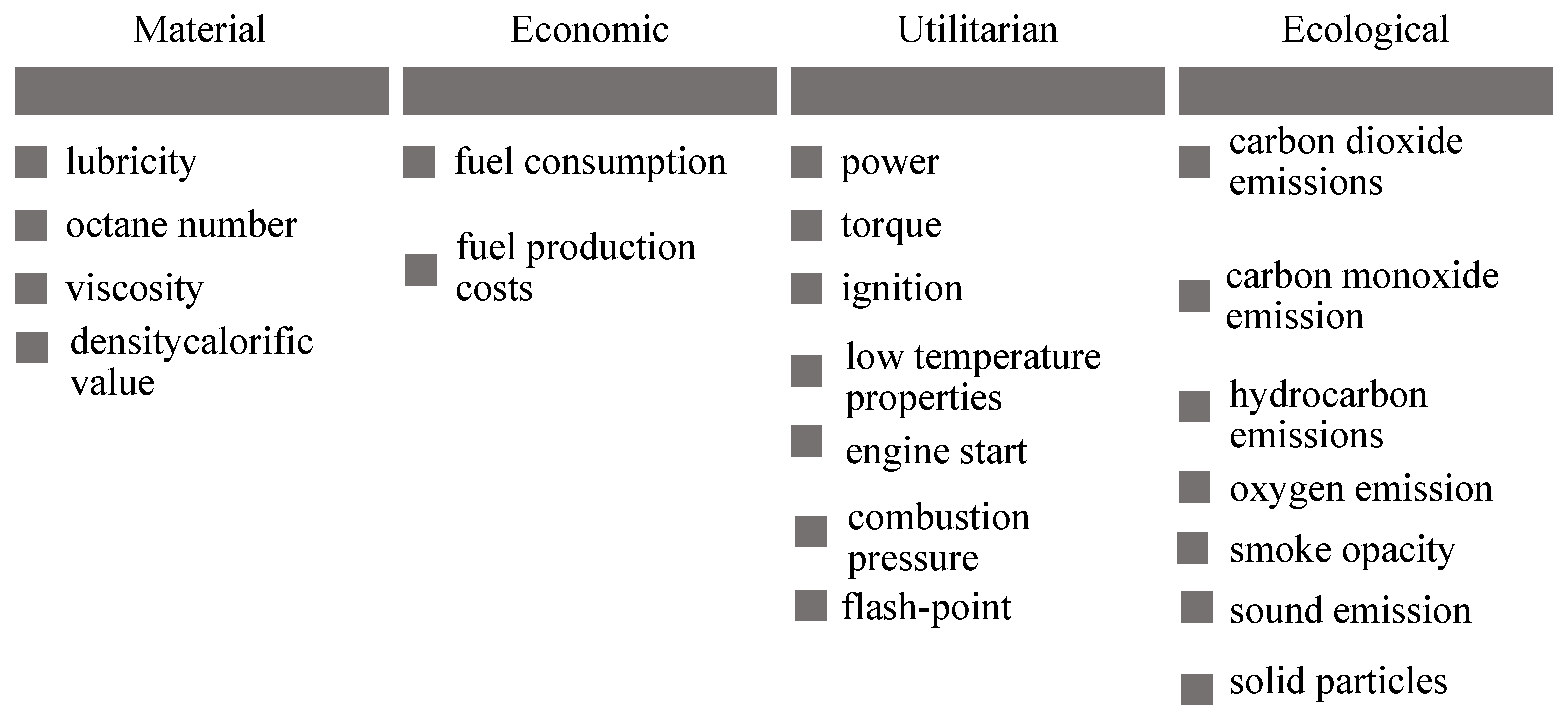

1]. The emission of vehicle pollution depends on numerous factors, which are presented in

Figure 1.

Emission of pollution from the transport sector is considered to be one of the most harmful factors due to its high concentration at a low height. The sources of air pollution affecting the quality of air include particulate matter PM 10 and PM 2.5, polycyclic aromatic hydrocarbons, nitric oxides and benzopyrene. Air pollution factors listed in

Figure 2 are measured based on the emission and concentration of harmful exhaust compounds generated while driving. These include nitric oxides, nitrogen oxides (NOx), carbon oxides (CO), particulate matter (PM), sulfur oxides (SO

2), lead (Pb) and soot [

3].

The use of biofuels to power combustion engines of motor vehicles is a method to reduce the negative environmental impact of the transport sector. Bio-additives to traditional fuels are becoming more and more popular. They are of natural origin or come from recycling. In the case of spark-ignition engines, the most widely used alternative fuel is ethanol of different compositions. Biofuel consists of all liquid, solid and gaseous energy media which are produced from biological materials, and their chemical energy is released during the combustion process [

4]. Materials that are most commonly used for biofuel production include natural oils, animal fat, starch, ethyl alcohol and cellulose. In general, production of biofuels involves adjusting their properties to the requirements of combustion engines (technological, structural and technical) in which they undergo combustion. The structural requirements of an engine that need to correspond to the properties of biofuels are injection pressure, compression degree, ignition advance angle, valve opening and fuel dose. Other publications by the author of this study include results of self-ignition drive unit tests [

5,

6,

7,

8]. Fuels that are most commonly used in spark-ignition engines are of natural origin. Exhaustibility of these fuels imposes the need to search for alternative solutions. Other equally important arguments in favor of renewable fuels are of an ecological nature, that is, the harmful emission of exhaust gas components and soot particles into the natural environment. The type of fuel mixture to be used depends on the combustion engine structure. The most common fuel used in combustion engines is ethanol fuel. The application of biofuels for drive unit fueling is one of the ways to reduce greenhouse gases, which was standardized by the Directive of European Parliament and Council 2009/28/WE of 23 April 2009 on promoting the use of energy from renewable resources. Ecological aspects of fuels from renewable sources are inseparably connected with transport development [

9,

10]. The development of transport involves a bigger energy demand, which leads to a fuel consumption increase by about 3% yearly [

11]. This, in turn, causes degradation of the natural environment by exhaust emission components such as carbon oxides, carbon dioxides, hydrocarbons, nitric oxides and particular matter. Bioethanol is the most frequently used biofuel for powering spark-ignition engines. Bioethanol is a dehydrated alcohol obtained from fermentation of plant products [

12]. Bioethanol can be produced not only from biomass but also from biodegradable waste fractions. There are three generations of bioethanol [

13]: I generation biofuels produced from edible plants such as cereals, potatoes, sugar beets and molasses; II generation biofuels from edible plant waste, which need to undergo the process of hydrolysis and fermentation; and III generation biofuels from algae.

Table 1 shows the types of bioethanol used for spark-ignition engine fueling.

Properties of the fuel mixtures determine their applicability in drive units. They are also optimization determinants for exhaust emission components, the engine performance and its functional qualities. The fuel is supposed to provide the vehicle with technical capability, appropriate performance parameters and comply with emission norms in the engine life cycle. As mentioned earlier, the basic fuel used in spark-ignition combustion engines is gasoline; however, a pro-ecological approach involves the need to search for alternative sources of fuel, which can be ethanol or a mixture of 85% of ethanol and 15% of unleaded gasoline [

15,

16,

17]. The most important differences between these mixtures are presented in

Table 2. The literature provides a number of studies of drive units fueled by a mixture of gasoline and ethanol [

18,

19,

20,

21,

22,

23,

24,

25]. The authors of many publications claim that the structure of spark-ignition engines allows the use of only a mixture with ethanol addition up to 10%. In order to reduce the risk of drive unit damage, it is advisable to modify its control unit. Modifications of the engine computer system are supposed to adjust it to a given fuel mixture. They are mostly applied to the fuel-injection system by changing the injection advance angle [

26,

27,

28]. Tests of drive units powered by the E85 fuel mixture indicate problems with the engine starting at low temperatures. In the literature, one can also find results of tests of fuel components which were carried out in real road conditions [

28,

29,

30,

31]. The results of tests of gasoline with ethanol mixture-powered vehicles indicate a reduction in the emission of individual exhaust components, such as carbon dioxide, carbon oxide, nitric oxides and hydrocarbons. Moreover, the tests indicate an increase in fuel consumption by about 30% [

11,

32,

33,

34].

Currently, the progress in bioethanol production technology makes it possible to produce it from biomass depending on its content. Biomass used for bioethanol production needs to include carbohydrates (sugars) or polycarbohydrates (polysacharides) and starches.

In the case of spark-ignition engines, the most popular biofuel is a mixture of 10% ethanol and 90% gasoline (E10) and of 85% ethanol and 15% gasoline (E85). In 2025, the European Commission plans to introduce E20/E25 biofuel [

33]. Bioethanol is produced during the process of fermentation mostly of sugar beets or cereal plants. The effect of this chemical process is a 15% water solution of ethanol with the addition of other alcohols. Pure ethanol is produced from distillation (96% ethanol and 4% water). To utilize ethanol as engine fuel, it is necessary to dehydrate it as the presence of water in the fuel causes corrosion of the drive unit elements.

Table 3 shows a classification of ethanol fuels due to its share in the fuel mixture in spark-ignition engines. As compared to conventional fuels, bioethanol is characterized by the following [

35]:

- –

lower calorific value;

- –

less air needed to the mixture combustion;

- –

higher octane number;

- –

lower ignition energy;

- –

bigger susceptibility to corrosion;

- –

bigger susceptibility to dissolution of engine rubber elements.

Classic designs of spark-ignition engines are adjusted to E10. According to the European Directive, this is the E10 mixture that is now in commercial use. When it comes to applying mixtures with more ethanol additive, it is necessary to introduce changes to the engine computer systems. Emission of the exhaust gas components into the natural environment largely depends on the quality of the fuel transformation into useful work during the operation of the engine [

16,

17,

18,

19,

20].

Emission tests for compression-ignition engines powered by bioethanol are carried out on a chassis dynamometer under specified conditions. The experimental object was a technical device (vehicle), which should be interpreted as a whole due to the tasks related to preparing the object for research and the place where the research was conducted. The facility was prepared for the experiment in accordance with the recommendations of the chassis dynamometer manufacturer, and the procedures were supplemented with the use of additional equipment in the form of measurement probes necessary to collect information on individual operational parameters. The experimental factors in the studies were controlled and changed spontaneously during the study. The results were collected in an established manner that ensured their safe storage. The measurement results were recorded according to the following conditions: the method of recording the results was clear and unambiguous, the method of recording the results did not select them or blur the variability of their values, and the method of recording the results was constant for the entire experimental cycle. The measurement of the operational parameters of combustion engines was carried out according to a specific schedule:

- –

the vehicle was mounted on a dynamometer and secured with belts to prevent it from sliding off the rollers during measurement;

- –

before starting the tests, the engines were warmed up (the coolant had a temperature of about 850 °C). The coolant value was checked before each measurement;

- –

sensors and probes are connected to the vehicle (pressure sensor, temperature sensor, particulate measurement probe and exhaust gas component measurement probes);

- –

a test measurement was performed (in order to automatically determine the position of the gearbox and final drive for idle run by the dynamometer system);

- –

during the measurements, adjustments were made to the engine control system software (increasing fuel dose, increasing air boost, changing the ignition timing);

- –

during the tests, the blowing system was turned on, which simulated the actual air movement for a moving vehicle;

- –

the vehicle was accelerated (in the highest gear) until maximum revolutions were reached, then the drive was disconnected by disengaging the gearbox lever without changing the engaged gear. The vehicle lost speed due to the inertia force of the accelerated roller, and losses in the drive system were measured.

Results of tests of hydrocarbons HC, CO, NO

x and CO

2 for E10 fuel and unleaded gasoline are included in

Table 4.

Many test results available in the literature indicate a reduction in the emission of hydrocarbons and carbon oxides while using bioethanol for engine fueling. The results obtained for nitric oxides differ as NO

x emission can drop, rise or remain at the same level, which can be caused by faster combustion of fuel, lower flame temperature or higher absorption of heat in the engine cylinder [

15]. Due to a high octane number of bioethanol, it is possible to increase the engine compression ratio [

15]. Best adjusted to bioethanol combustions are FFV (flexible fuel vehicle), engines whose power increases by about 17% and torque by 10% after application of E85 fuel [

20]. Other ethanol–gasoline fuel mixtures can also be used to power this type of engine, but E85 is the most commonly used. The biggest advantage of these engines is their adjustment to the fuel mixture by modification of the engine control system. The use of bioethanol as the only fuel or ethanol as an additive to gasoline causes exhaust emission reduction and has a positive effect on the environment. According to the literature analysis, ethanol fuels can be used both in classic engines (fuels with a smaller concentration of ethanol) and FFV engines (E85 fuel). The FFV engine was modified to enable its being powered both with conventional fuel and bioethanol.

The goal of this study is to provide an assessment model to describe a spark-ignition engine powered by E100 fuel. The developed model takes into account adjustments of the drive unit computer system to improve the engine performance. The research hypothesis of the study was the following: does modification of the computer system powered by E100 fuel have a positive influence on the engine performance parameters (power and torque), exhaust emission and noise emission?

Research on ethanol-fueled power units is widely considered, but no model in the literature has been found that would allow for the evaluation of an engine that would be powered by E100 fuel and would introduce changes to the regulation of the fuel-injection software. The combined analysis of two variables allows you to select the most appropriate setting when feeding a given mixture, which is an innovative approach to the analyzed topic.

2. Materials and Methods

A literature analysis of individual groups of combustion engine parameters was carried out for the needs of this study. Characteristics attributed to the engines were used as evaluation criteria of these drive units. These characteristics provided the basis for assigning the given values. Evaluation criteria were used for verification of efficiency of these drive units and making the best possible decisions. Based on the literature analysis, four groups of criteria for assessment of piston combustion engines were identified: material criterion, economic criterion, utilitarian criterion and an ecological one. The most significant criteria selected for drive unit assessment are presented in

Figure 2.

There is quite a big number of criteria for evaluation of piston combustion engines, which makes it difficult to identify the most important parameters and the best fueling method (fuel mixture). The study includes an analysis of some selected parameters. The utilitarian criterion for such parameters as power and torque decreases along with an increase in the bio component additive to the base fuel. Maintaining these parameters at the manufacturer’s level while using biofuels is possible through modification of the engine’s Electronic Control Unit (ECU). Modification of the computer control system is supposed to indicate to what degree it affects the engine performance parameters. Regulations of the computer control system of the spark-ignition engine are presented in

Table 5. Regulations of a spark-ignition engine mainly involve increasing the fuel dose and the ignition advance angle.

Modifications of the spark-ignition engine computer control system involved connecting an external computer to the vehicle deck computer by means of OBD (On-Board Diagnostics) socket. The engine deck computer did not have to be disassembled.

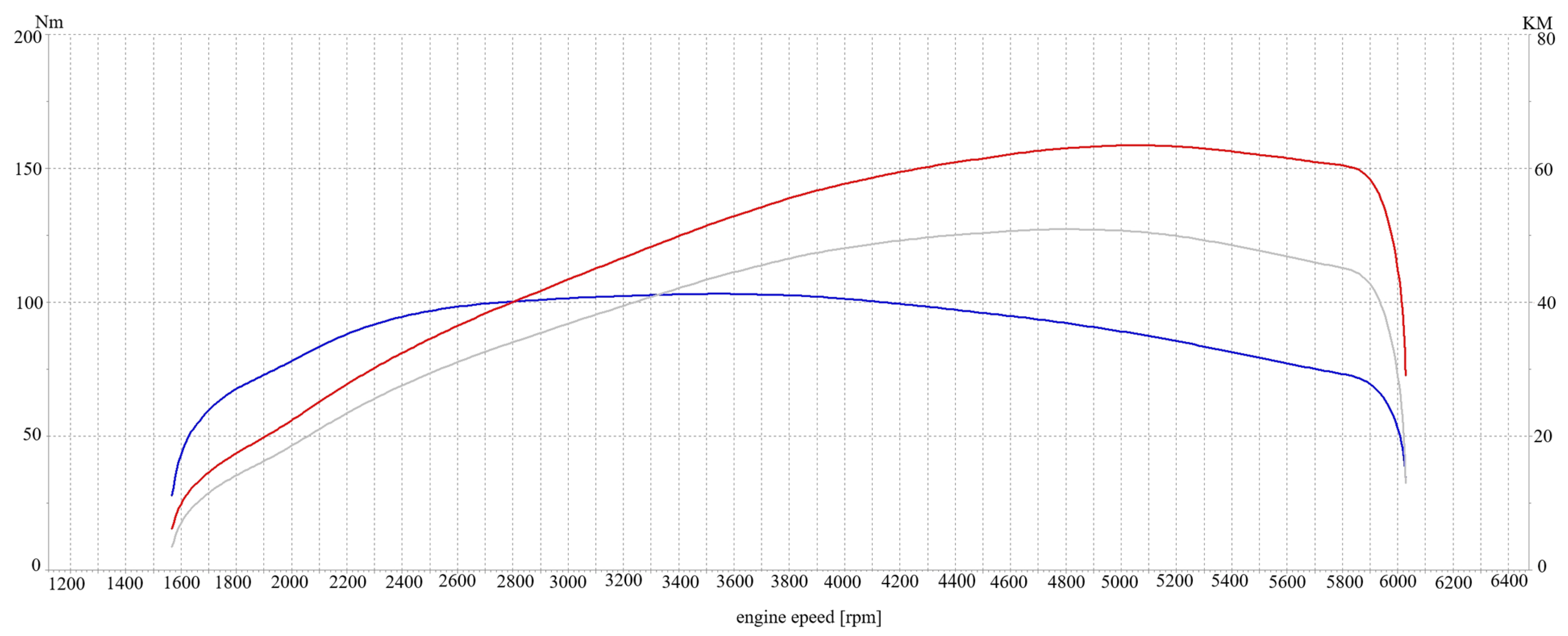

The research object was an 8-valve spark-ignition engine with multi-point fuel injection, cylinder capacity 1242 cm

3, power 44 kW and maximum torque 102 Nm. Technical data of the tested drive unit are shown in

Table 6. Characteristics of a self-ignition combustion engine are presented in

Figure 3. The red line on the graph indicates the engine power, while the blue line indicates the torque.

Modifications of the fuel supply systems of the tested engines allowed non-invasive fuel supply. The changes included:

- –

fuel supply system;

- –

installation of an additional fuel tank;

- –

computer software.

The changes did not disrupt the engine structure. They were applied only to the accessory and the software. Modifications connected with the supply of fuel to the engine involved installing an external fuel tank and disconnecting fuel supply from the original tank. No additional fuel pump or fuel filters were fixed. The fuel supply system was connected directly to the engine from the external fuel tank. The supply pump fixed in the vehicle sucked the fuel mixture from the external tank, then the fuel flowed through the initial filter and was directed to the fine-mesh filter. The mixture was fed to the supply chamber and pressed to the injectors. The injector was responsible for adjustment of the initial injection and the fuel dose. Standard filters designed for a given engine type were used. Excess fuel left after measurements was directed to the external tank through a return fuel line. After each mixture change, the engine worked for about 10 min at idle to remove the rest of previous fuel from the supply system. The same procedure was applied in self-ignition and spark-ignition engines.

The criteria to be analyzed and evaluated were accepted based on a literature analysis, including power, torque, noise emission, particulate matter contained in the exhaust emission, carbon oxides, carbon dioxides, hydrocarbons and oxygen. Functional parameters were tested during simulation of road conditions on a chassis dynamometer with an eddy current brake. This provided data necessary for determination of characteristics of the engine performance, such as power and torque. Torque transferred onto the crank shaft was measured by means of the chassis dynamometer, and the engine power was calculated based on the rotational speed of the crankshaft and the torque value. The measurement was affected by air humidity, temperature and atmospheric pressure. The results were recalculated, according to the current norm, into corrected values (25 °C and 1000 hPa). The measurement of the exhaust component concentration was taken with the use of an exhaust emission analyzer. The tests enabled determination of the number of exhaust components that were released into the environment in the form of exhaust gases. The analyzer meets the requirements of the European Parliament Directive 22/2004WE. It measured the toxicity degree of the exhaust emission and defined values, such as HC, O

2 (oxygen), CO and CO

2. The measurement of solid particle emission (with dimensions exceeding 100 mm) was carried out using an optical method involving measuring intensity of the light bean going through the exhaust gas emission stream (comparison of infrared absorption between a standard inert gas and the tested compound). During tests performed with the use of a measurement probe, the analyzer collected exhaust gases coming from the engine outlet system and redirected them to a gauge. The measurement of noise emitted by the engine was performed by a sonometer with a built-in spectral analyzer which meets the requirements of [

39,

40] norms. Evaluation of the noise depended on its duration time and level. Due to time variability of the noise level, acoustic pressure was sampled in set periods of time. The values of the engine acoustic parameters were determined by an orientation method for determination of the acoustic power level.

3. Results

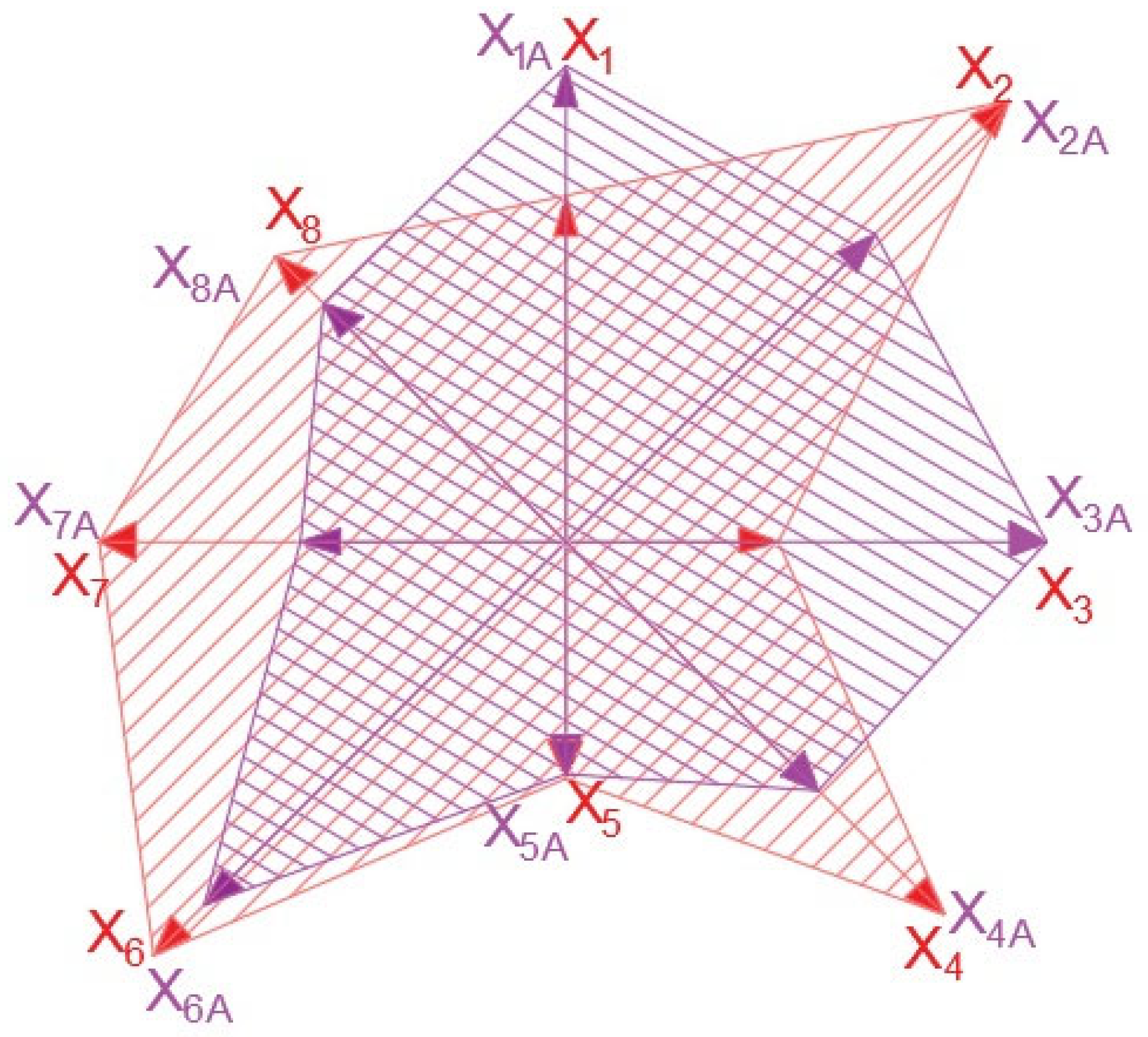

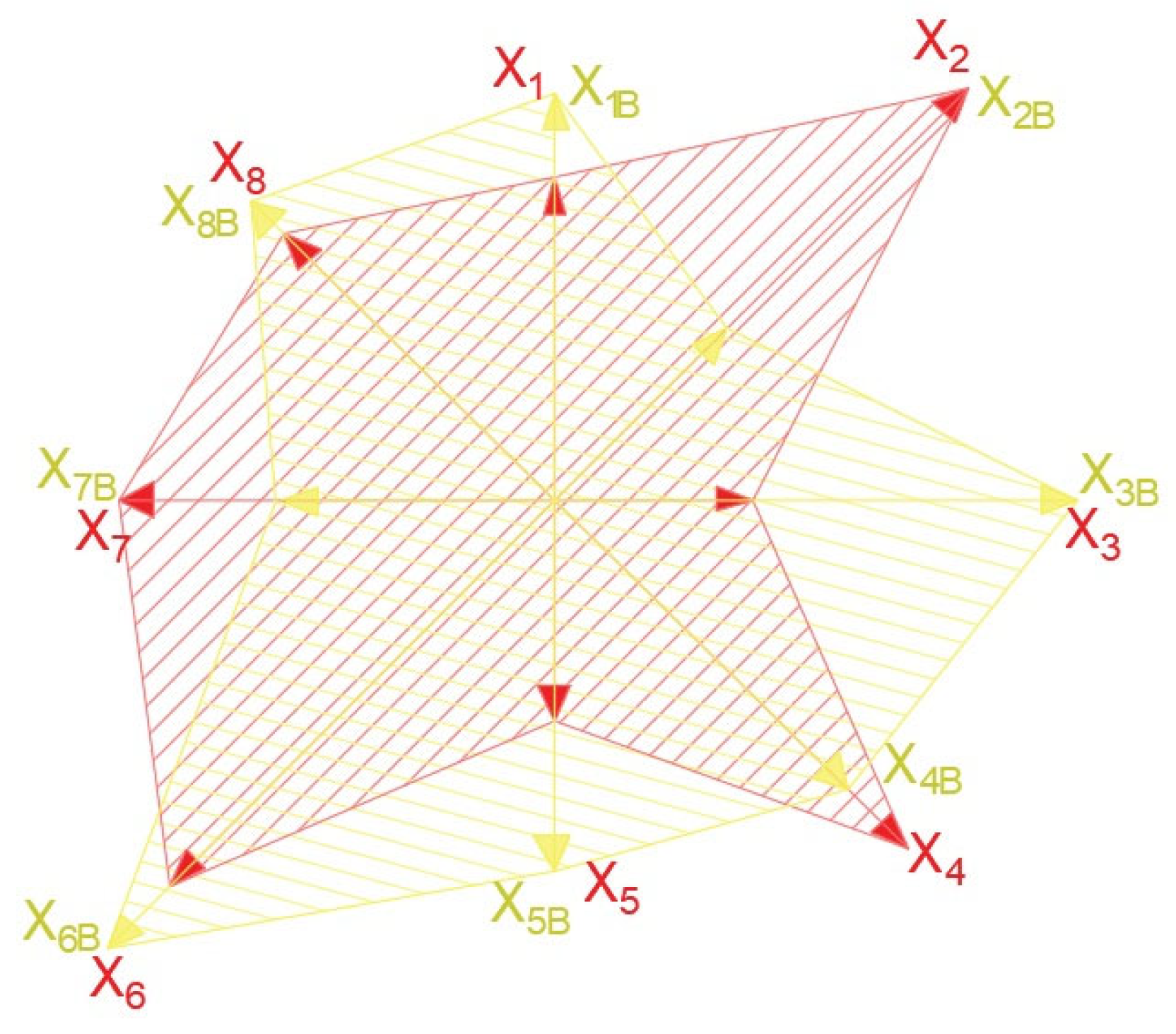

The test results were analyzed, and the analysis was used for the development of an evaluation model. The model was used for the selection of engine control system regulations that have the most significant impact on the drive unit performance parameters, including power, torque, exhaust emission components (carbon oxides, carbon dioxides, oxygen, hydrocarbons), solid particles contained in the exhaust gases and emission of noise generated by the drive unit. The analysis was carried out for the E100 fuel mixture engine fueled by pure ethanol with no gasoline addition. The analyzed regulations of the engine computer system software corresponding to the fuel mixture were independent variables, whereas E100 fuel was the dependent variable . Dependent variables were the values of performance parameters obtained from the tests. Due to the statistical significance of the results, measurements were repeated 30 times.

To develop a model for evaluation of the spark-ignition engine operation, multi-criteria optimization analysis (MOA) was applied. The model was used for comparison of test results obtained for individual adjustments of the engine control system with the reference point. The reference point was accepted to be the manufacturer’s standard software. The multi-criteria analysis involved structuring the evaluation criteria in a given order and determining their quality by assigning them corresponding results. Application of MOA allowed identification of quantitative and qualitative criteria that make up the multi-criteria evaluation model, determination of a weight system for a given criterion, calculation of the overall evaluation for a given variant and its interpretation. The criteria domains were defined on the basis of the variability range of their arguments according to the method used. The variability range was divided into six intervals, whose size increased in direct proportion to the distance from the optimum. Depending on the type, the criteria were described by different functions. A universal method for assessing the criteria fulfillment degree was used in the model. Due to the fuzzy character of the characteristics describing the criteria, it was not possible to precisely define the criteria fulfillment degree. The abovementioned inaccuracy was modeled by fuzzy extension of the method used. Each criterion was described by a fuzzy set, where the membership function defined the criterion fulfillment degree through its individual features (parameters). Individual sets were transformed into fuzzy normal sets. The analytic hierarchy process (AHP) was used for determination of the significance of each grade by assigning to it a grading scale presented in

Table 7. Weight definition inaccuracy, due to the application of the AHP method, was taken into consideration in the evaluation process by presenting the values by a fuzzy triangular number. The medium of the determined fuzzy numbers was 10% of the weight variability range.

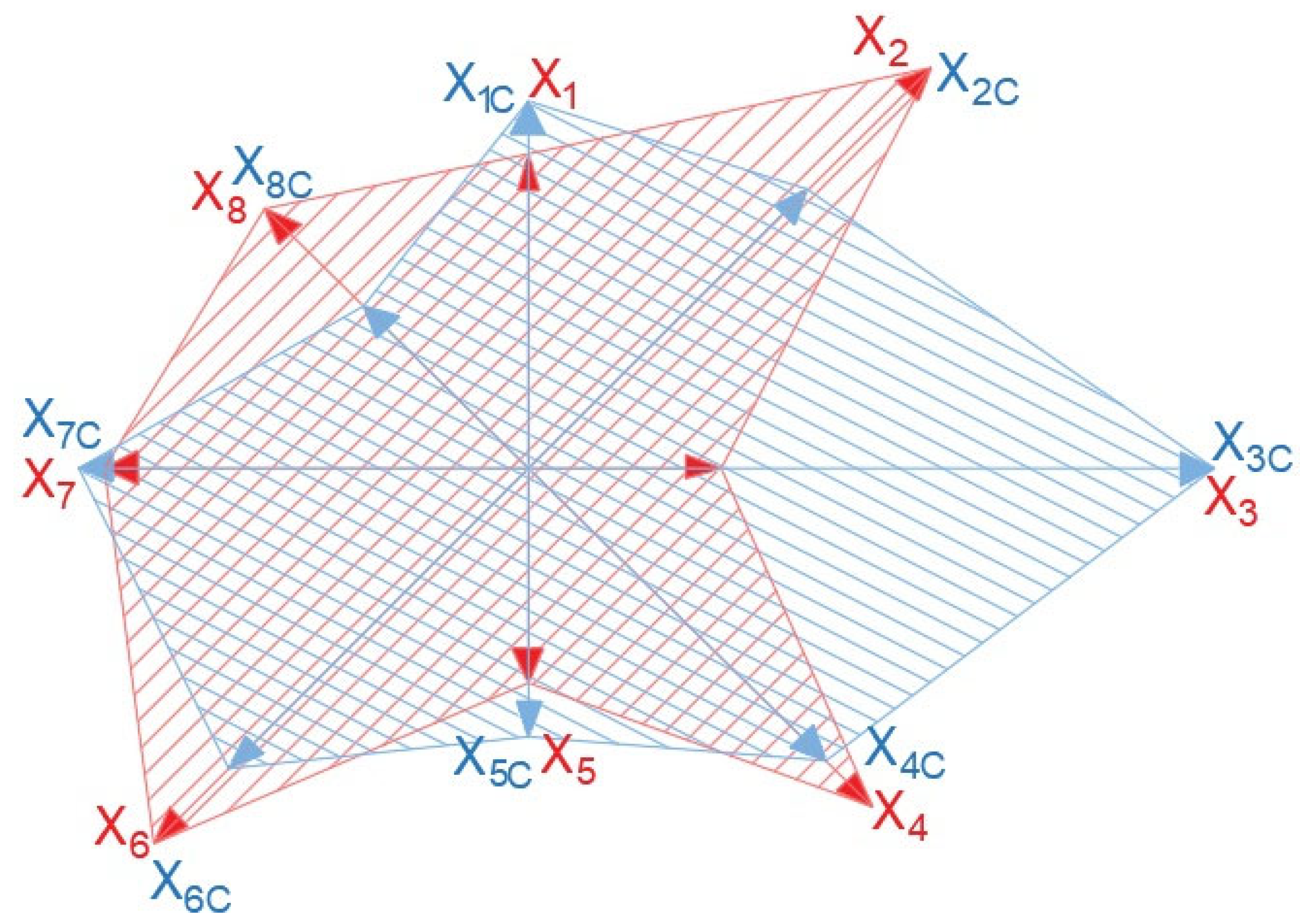

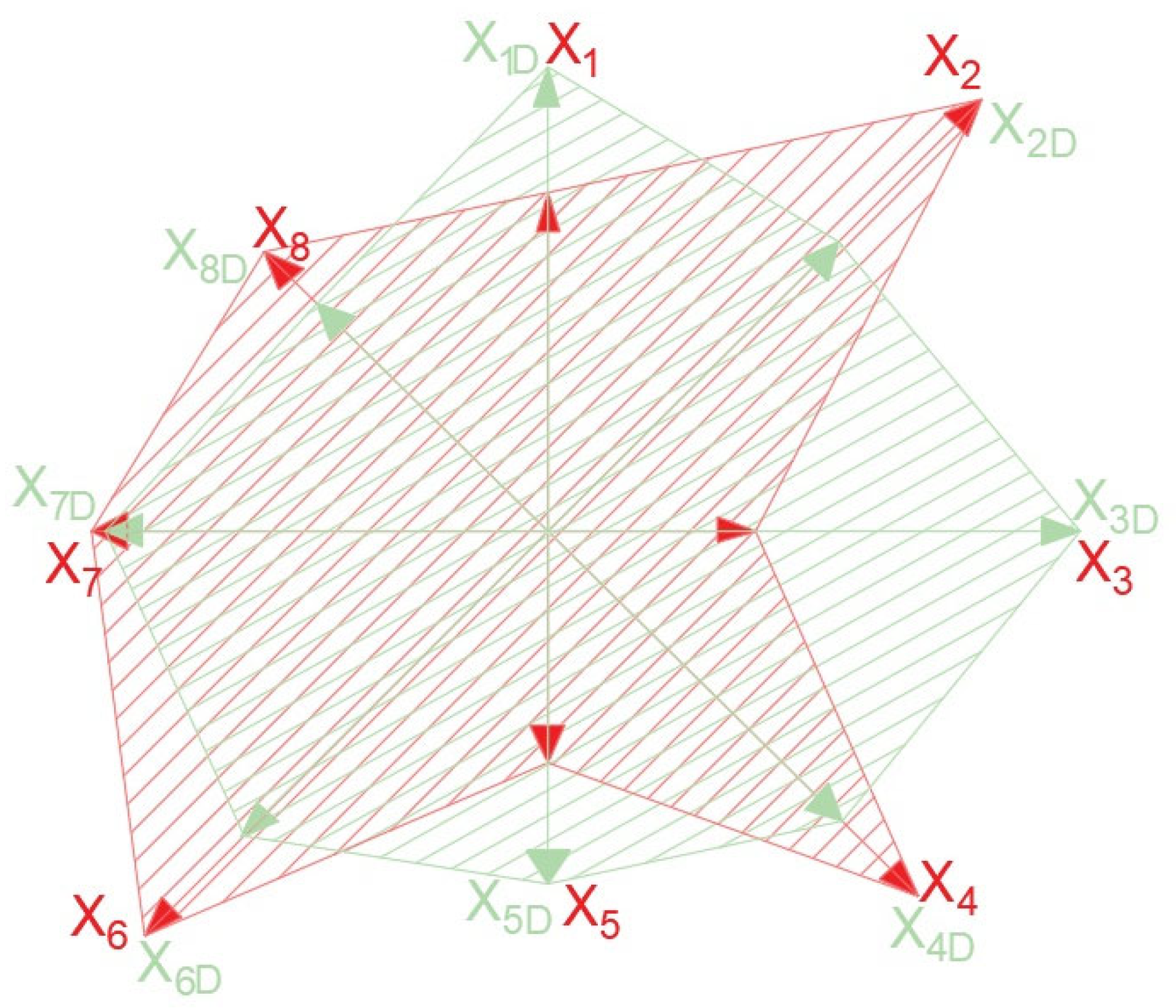

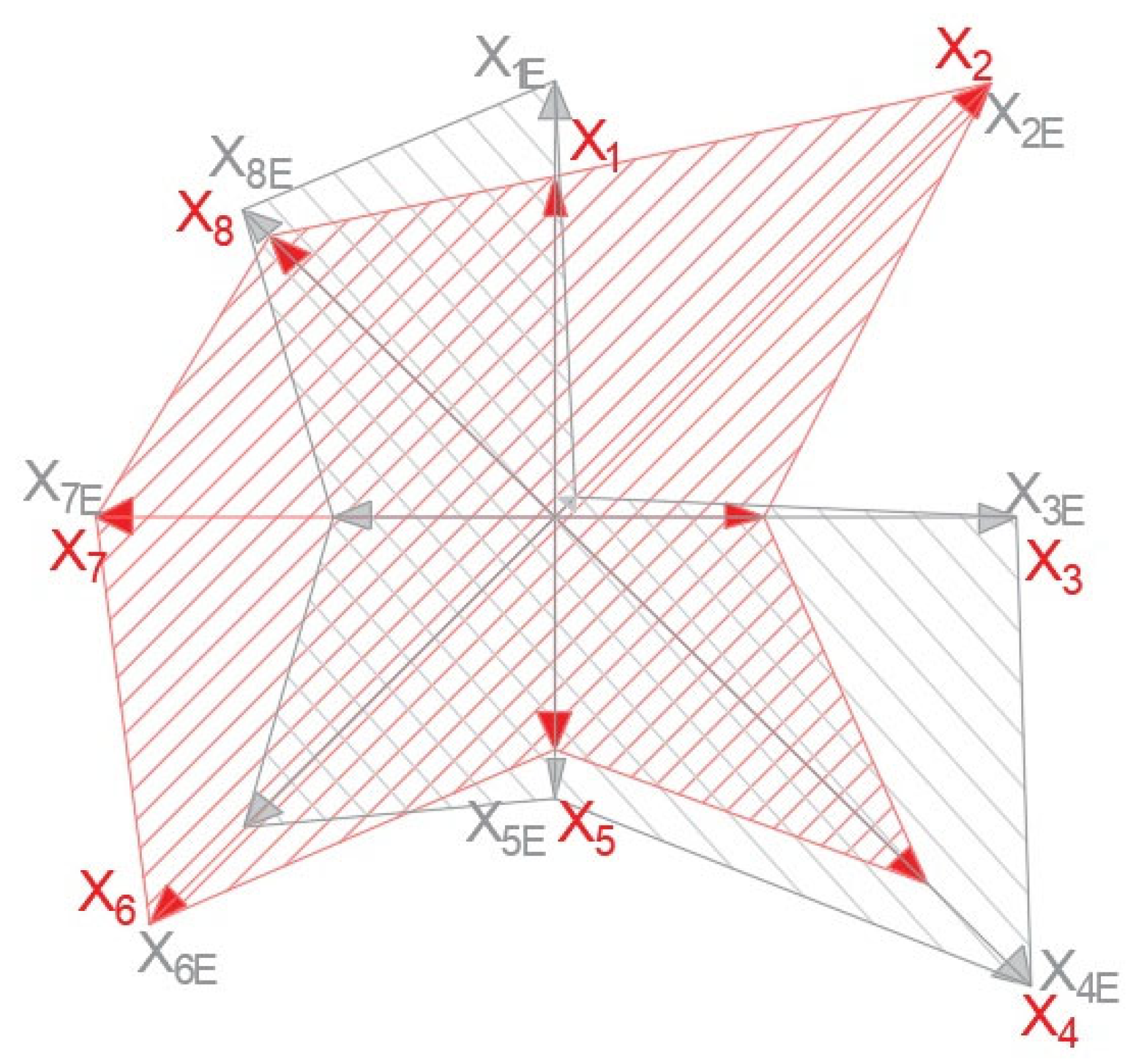

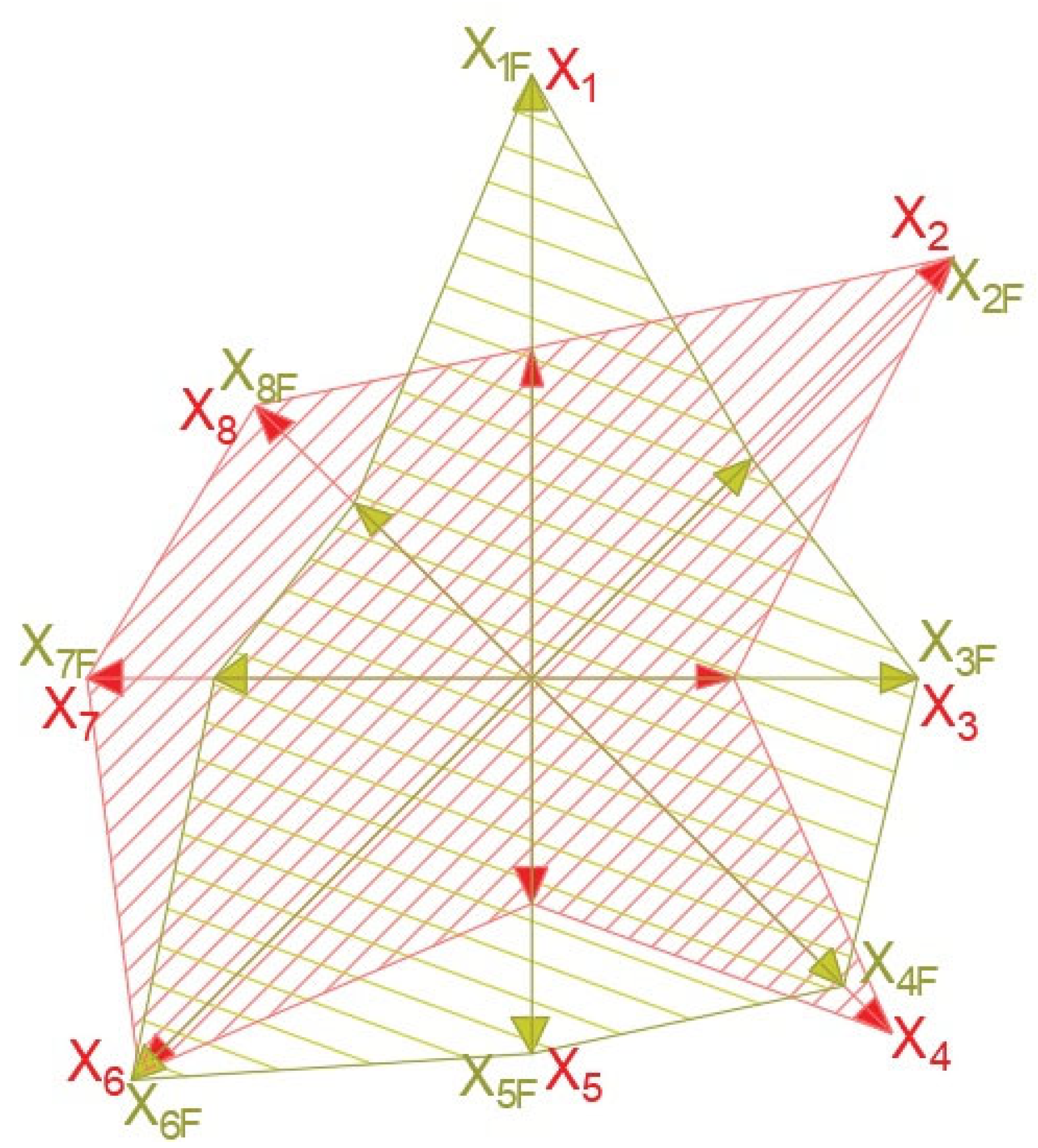

Eight variants were analyzed (performance parameters of the drive unit). In order to compare the performance parameter values of different engine control system software adjustments with the reference point, standardized values of component vectors were defined. One-dimension vectors, denoted by variable

X, were random variables representing the values of the engine control system software regulation. The analyzed parameters reflect evaluation of the spark-ignition engine, and then the discussed vector assumed the following form:

The random variable defined for the studied drive unit was:

Values of individual weights and an explanation of each component of the form vector are presented in

Table 8. The table also presents boundary values (minimum and maximum) for individual performance parameters of the twelve regulations of the vehicle computer software.

In order to standardize the measurement results, their values were normalized into a <0÷10> interval. For standardization of the performance parameters, it was necessary to define an arithmetic mean from the measurements and determine the minimum and maximum for a given parameter. The results obtained for the analyzed parameters and individual fuel mixtures are presented in

Table 9.

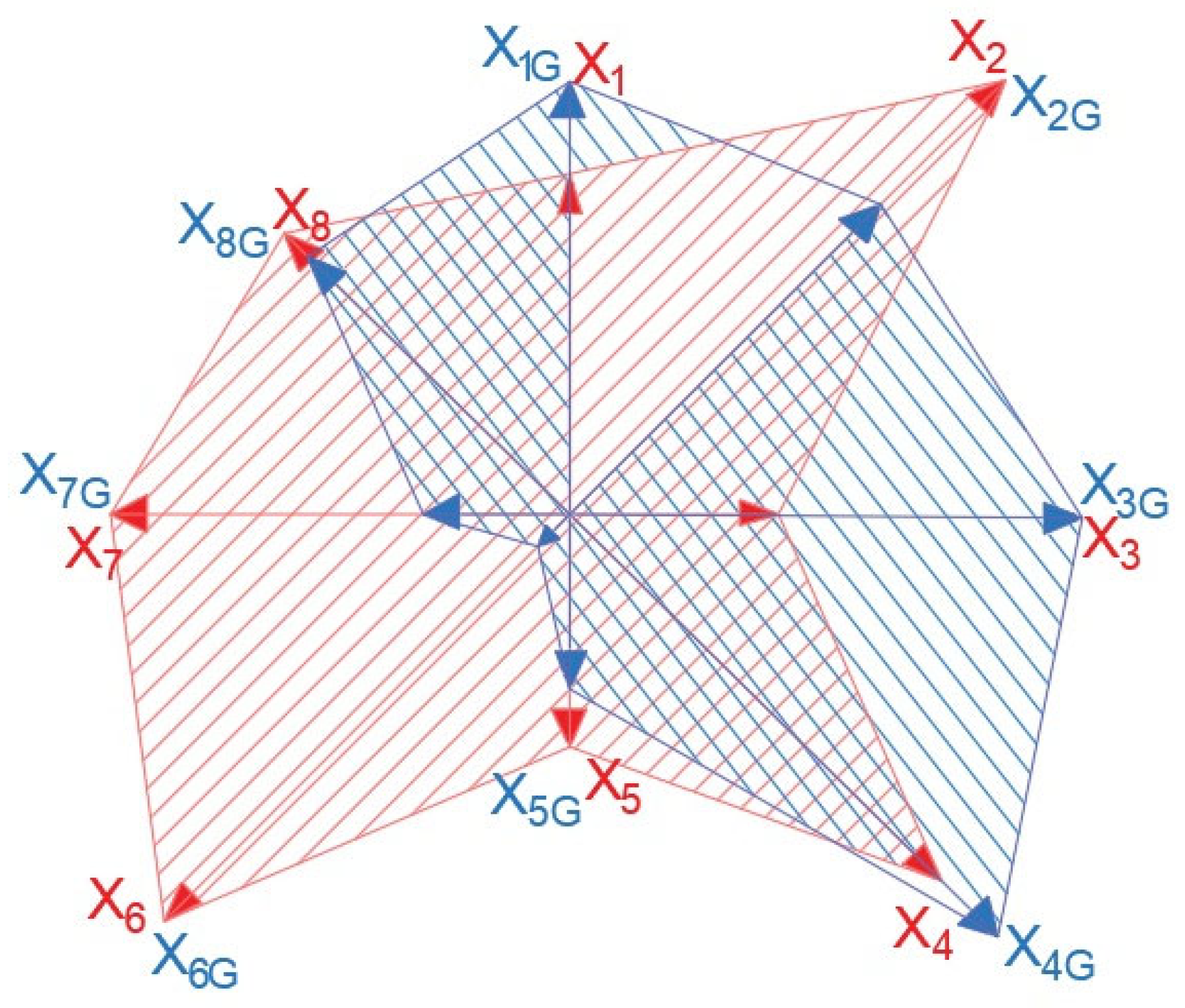

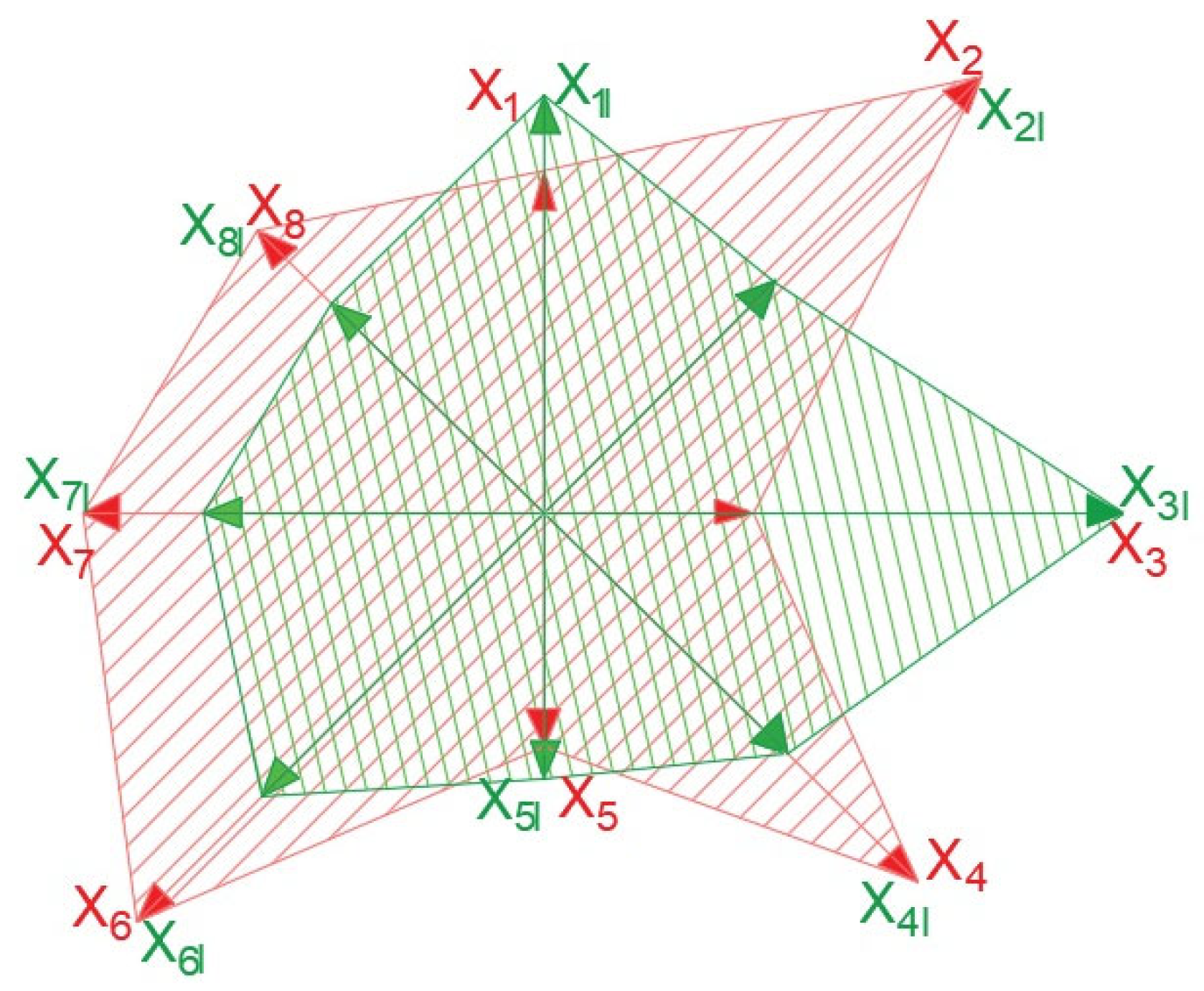

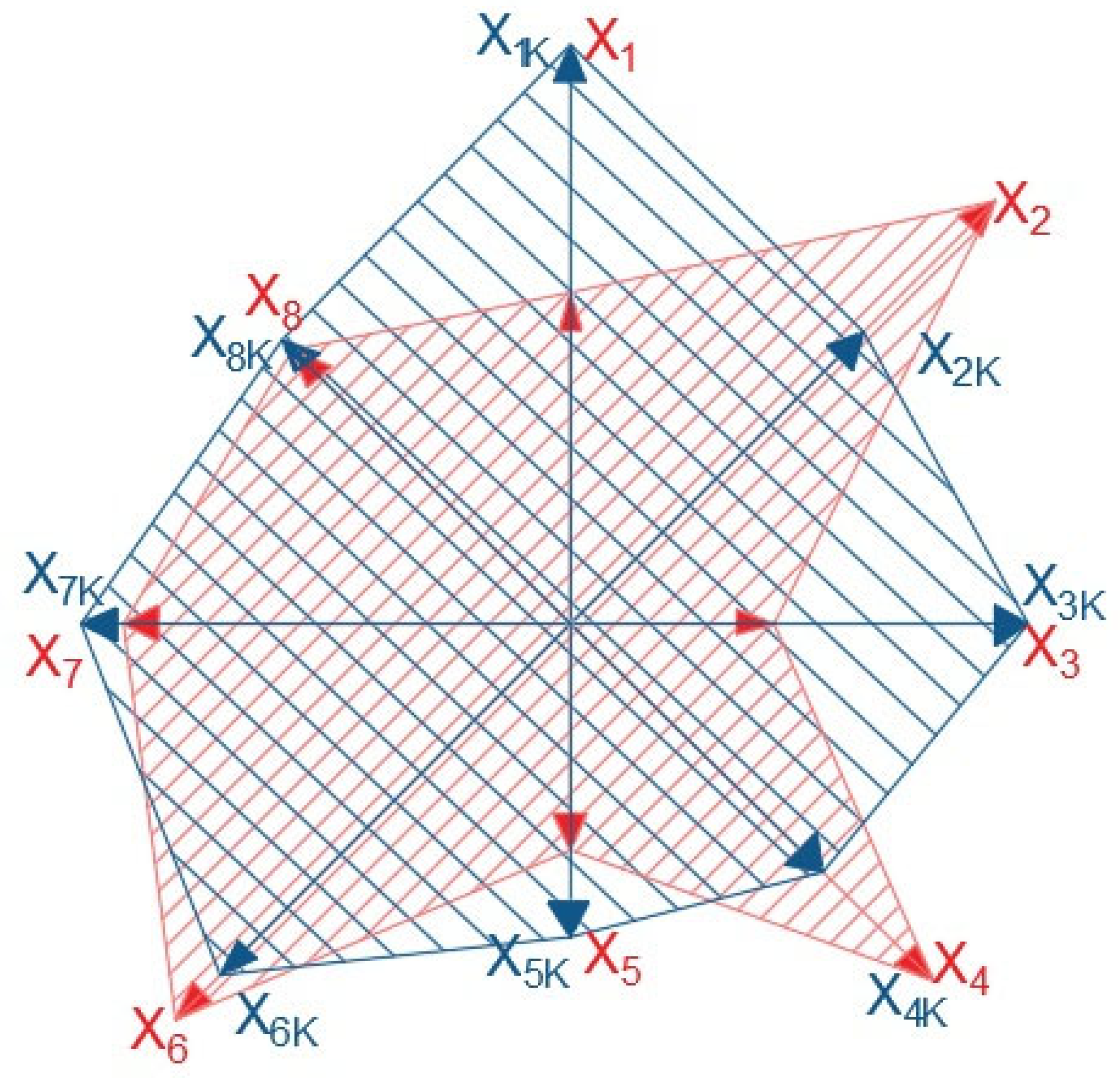

The above-presented results obtained for the performance parameters make it possible to compare and refer them to the base fuel, that is, unleaded gasoline without the ethanol additive. Standardized results of the spark-ignition engine measurements for individual fuel blends are presented in a graphic form in

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13 and

Figure 14. The schemes show difference between the lengths of the vector components, which indicates parameters that changed after changing the fuel blend.

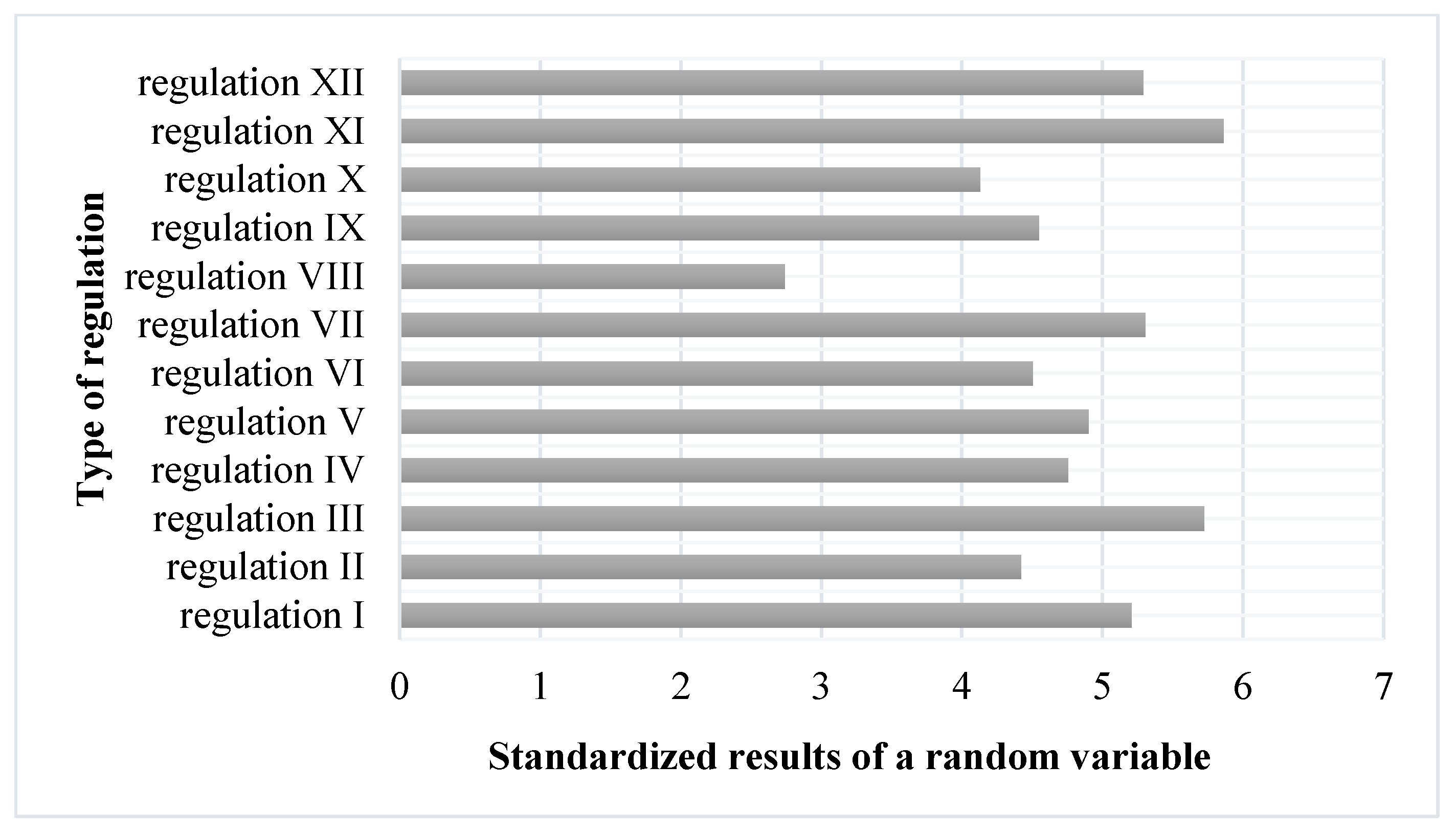

The random variable was determined based on standardized component values of vectors and weights defined for individual parameters. It is presented in

Figure 15.

The methodology for evaluation of the spark-injection engine involved determining only those parameters which were considered to be of biggest importance. The model includes a set of eight performance parameters. The coefficient of scattering of the membership function was accepted to be 20%. The number of fuzzy cross-sections was accepted to be 10, and the method for calculation of scattering assumed a mean square value. Moreover, the AHP analysis was used for determination of the significance limits. Desired and undesired values were defined by minimum and maximum values of performance parameters obtained from the tests. Mean values of twelve regulations of the drive unit computer software were evaluated according to the criteria that were used for studying the tested performance parameters. The test results are shown in

Table 10.

Based on equal weights for all the parameter weights obtained from the AHP analysis, the most significant parameter was identified.

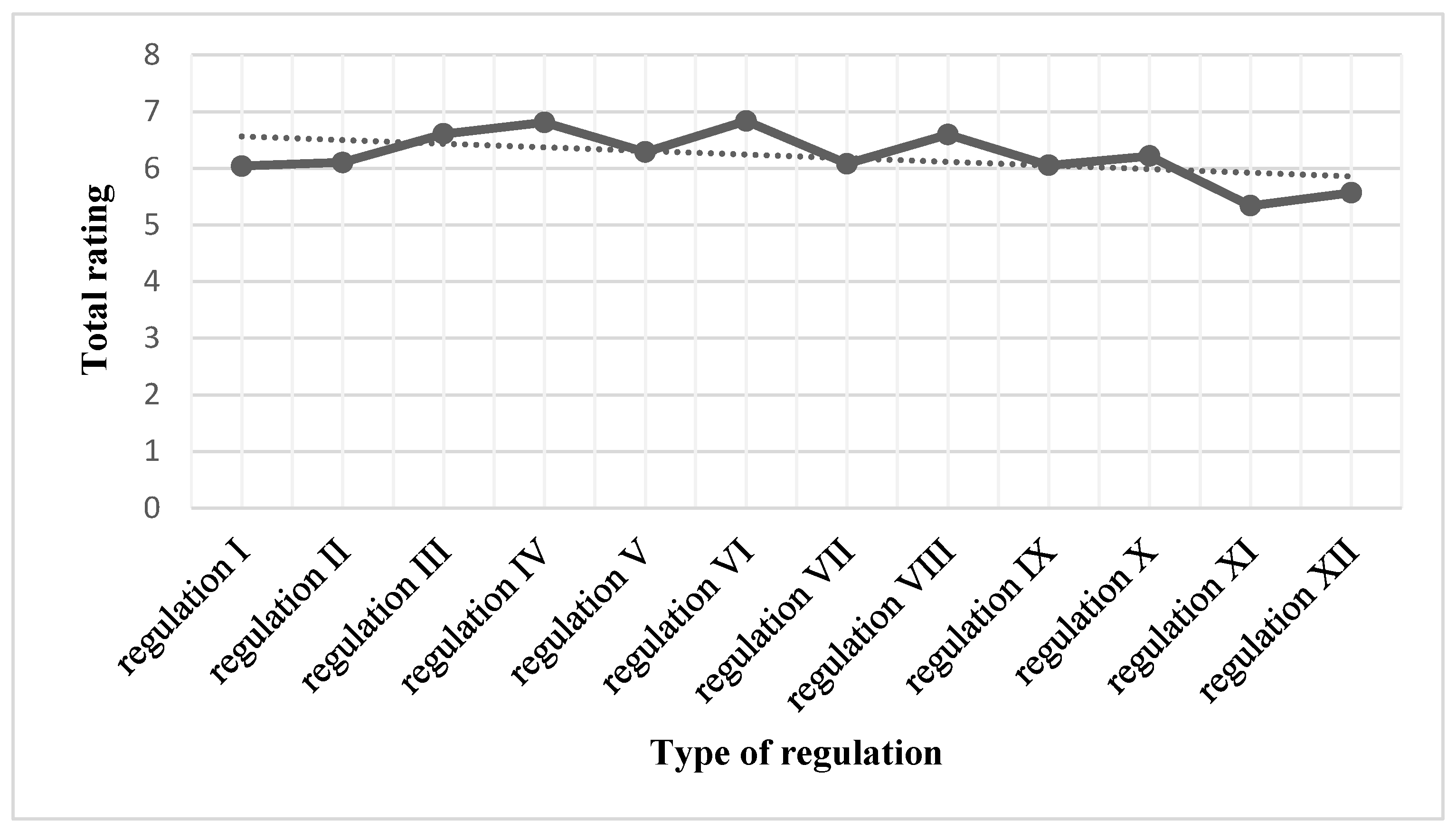

Table 11 shows values of the overall rating (quality) for individual variants. Graphic interpretation of the overall rating values for individual regulations of the computer control system software of the tested drive unit are presented in

Figure 16.

The ratings presented in

Table 10 are measures of the dependence of the model output value on its input value. Each analyzed parameter was assigned equal weights to make it possible for them to be referred to each other. The evaluation indicates actual values of individual parameters for twelve regulations of the vehicle control system software. Moreover, it indicates how these values oscillate in the range between the minimum and maximum ones. In the case of power and torque, the rating was best for regulation X, regulation XI and regulation XII. For noise emission, the best results were found for regulation V, regulation VI and regulation X. For solid particles, the best results were found for regulations V, VI and VIII. In the case of exhaust emission components, the best results for carbon oxides were achieved with the use of regulations III, IV and VI, whereas for carbon dioxides, regulations II, III and X were the most beneficial. Regulations VI, VIII and X were the best for hydrocarbons. Oxygen, the most neutral exhaust emission component, remained at the same level for most of the regulations, except for the lowest results obtained for regulations IV and X.