Abstract

As the global demand for renewable energy continues to rise, biogas production has emerged as a promising solution for sustainable energy generation. This review article presents the advantages of biogas technologies (mainly agricultural, based on waste of animal and plant origin) and extensively discusses the main principles of biogas production in the anaerobic digestion (AD). In this respect, the main parameters of the process, which require monitoring and decisive for its efficiency are described, therefore: temperature, pH value, retention time and organic loading rate (OLR). The principles of substrate selection are also discussed and the necessity and advantages of the use of organic waste according to the model of a circular economy and the concept of sustainable development, are indicated. It is emphasized that according to the new European regulations, the crops classified as food cannot be considered energy crops. The part on biogas production is summarised with an explanation of the necessity to treat and purify biogas. Biogas purification is important from the point of view of the efficiency of its conversion into electricity. A special place in this paper is devoted to the design, construction, functioning and operation of biogas plants, based on both scientific and practical aspects. In conclusion of this chapter, the economic aspects and profitability of operating biogas plants are discussed. Cost and benefit analyses are the major tool used for the systematic evaluation of the financial costs and potential benefits associated with the operation of biogas plants. The important fact is that the return on investment can be achieved within a few years, provided the activities are well-planned and executed. In addition to the fundamental issues of the operation of biogas plants, this article presents the global situation regarding the development of biogas plants, discussing in detail the specific needs and limitations on different continents. It is a interesting and extensive part of this article. The global agricultural biogas market is at very different levels of development. Most such installations are located in Asia and Europe. China has the highest number of biogas plants, with more than 100,000 biogas plants, followed by Germany with over 10,000 plants. In addition to the 100,000 biogas plants, China also has a large number of household biogas units, which gives a total of approx. 40 million operating units. The article concludes with a discussion of opportunities and barriers to the development of biogas plants, pointing to: financial issues, access to feedstock, political regulations, public awareness and the geopolitical situation. The most frequently cited reasons for investment failure include economic problems, lack of professional knowledge.

1. Introduction

In today’s world, energy is a crucial and valuable commodity. As the planet’s traditional energy sources are finite and rapidly declining, the need to explore alternative and sustainable sources of energy has become pressing [1]. Biogas energy, being affordable and accessible, is one of the most promising alternative energy sources, alongside wind and solar energy [2]. Unlike wind and solar energy, biogas energy does not require specialized infrastructure, making it a viable option for countries and regions with diverse topography [3,4]. Biogas, as an energy source independent of weather conditions, is crucial for the stability and security of energy supplies in the future. Biomass can therefore be considered a renewable energy source with the greatest energy potential. An important step in this area is the use of all available biomass raw materials from by-product production and waste. However, the cost of setting up a biogas plant is an important factor to consider.

Biogas is produced naturally from organic materials through AD process. While the biogas generated in the world contributes to global warming, as it is primarily composed of methane, its production has been applied in domestic and agricultural settings. The use of biogas as an energy source has a long history dating back to the 19th century. The first recorded use of biogas was in 1859, when Sir William Thomson observed the production of methane from organic matter in a closed container [5]. The first large-scale biogas plant was established in India in the early 20th century, where it was used for cooking and lighting [6]. In recent years, biogas production has become increasingly widespread in Europe, North America, and Asia, with countries such as Germany, China, and the United States leading the way in terms of biogas production capacity [7,8]. In many countries, government policies have been implemented to support the adoption of biogas as a renewable energy source, and there has been a growing trend towards the use of biogas in combined heat and power systems, which use the heat generated during energy production for heating and hot water [9,10]. Despite its potential, the use of biogas as an energy source remains limited due to a variety of technical, economic, market, institutional, sociocultural, and environmental obstacles [11].

The worsening geopolitical situation and climate change are forcing an energy transition in which biogas plants play a significant role. Today, there is an intensive search for waste materials to act as the main substrate instead of maize silage or crops typically used for energy purposes [12,13]. However, the availability of feedstock from organic waste varies regionally. Areas with limited waste resources will therefore face challenges in terms of biogas production. It should also be noted that the setting up of a biogas plant requires significant initial investment and insufficient political support may hinder the development of biogas production [14]. Regulations on sourcing feedstock, waste handling and energy prices can have a decisive impact on the viability of a project. It should be emphasized that biogas installations, in addition to electricity, produce heat that can be effectively used in various ways. In times of instability on the electricity and heat supply market, a biogas plant can guarantee heat supplies. The heat generated as a result of the operation of cogeneration units can be used not only for heating buildings, but also in drying processes, e.g., of digestate [9].

The aim of this paper is to present the advantages of biogas technologies and the principles of implementing biogas production, including the optimisation and monitoring of AD process. Particular attention is paid to the specific characteristics of biogas plants, including the type of plants in operation, their design, functioning and operation, as well as economic aspects and profitability. The paper also presents the perspectives and limitations of biogas plant development, taking into account selected regions of the world. The novelty of this article is a detailed discussion of the diverse and dynamic situation on continents such as Europe, Asia and Africa.

2. Biogas and Its Importance

Growing concerns about the environment, coupled with the rising energy demands of a burgeoning global population, have prompted countries worldwide to prioritize sustainable energy sources such as biomass [15,16]. This trend is particularly evident in the Europe Union, where the adoption of renewable energy has witnessed a marked increase in recent years. From 8.5% in 2005, the use of renewable energy has surged to nearly 17% in 2015, as measured by gross final energy consumption [17].

2.1. Biogas Characteristics

Biogas is a gas mixture that results from the decomposition of organic matter, such as plant material, by bacteria and archaea in the absence of oxygen [18]. This gas contains varying amounts of methane (CH4), typically ranging from 50% to 70%, along with carbon dioxide (CO2) making up 20% to 40% and other gases such as ammonia (NH3), nitrogen (N2), oxygen (O2), hydrogen sulphide (H2S), hydrogen (H2), and carbon monoxide (CO) [19]. However, the precise composition of biogas can vary depending on the origin of the organic waste and the production methods used [20]. Biogas is a sustainable source of energy that can be produced from several sources, including animal manure, sewage sludge, industrial waste, energy crops, organic waste from landfills and municipal waste and municipal waste [21].

Annually, a considerable amount of methane, ranging from 590 to 880 million tons, is released into the atmosphere globally due to microbial decomposition. Biogenic sources contribute to approximately 90% of the total methane emissions, with wetlands, livestock farming, and rice cultivation being the major contributors [22]. Therefore, the use of biogas as a renewable energy source offers a potential solution to mitigate the environmental impact of methane emissions from biogenic sources. By utilizing methane from biogenic sources for energy production, it is possible to reduce the amount of methane released into the atmosphere and provide a sustainable source of energy.

2.2. Types and Advantages of Biogas Technologies

Biogas production technologies generally take into account the following sources of origin—from sewage treatment plants, landfills and agriculture. The choice of biogas production technology depends primarily on the type of substrates being processed. Therefore, technological solutions can be divided according to specific criteria, which include: total solids content in the fermentation chamber (wet AD and dry AD systems), process temperature (mesophilic AD and thermophilic AD), number of process stages (ingle-stage AD and multi-stage AD), degree of separation of individual phases of the process (single-phase AD and multi-phase AD) and method of dosing substrates (continuous and batch processes) [5,19,20].

There is a widespread acknowledgment that the utilization of biogas technology offers a trifecta of advantages. Specifically, it serves as a viable energy source for cooking, lighting, and other applications, as well as an effective means of generating bio-fertilizers to bolster agricultural yields and enhance the environment [23].

Saracevic et al. (2019) have suggested that biogas production could be a crucial solution for energy supply and help to mitigate the negative impacts of fossil fuel usage [24]. The burning of fossil fuels has caused a substantial increase in CO2 concentrations in the atmosphere since the industrial are began [25], which has had a significant impact on climate change. Biogas, however, can serve as an alternative energy source by producing both heat and electricity through cogeneration systems or supplying local gas networks, thereby substituting for natural gas derived from fossil fuels [26].

In addition to being a source of energy, the production of biogas presents several advantages for waste management. As the global population continues to expand, there is a corresponding increase in the amount of waste generated. This surge in waste production poses a considerable obstacle for authorities in their quest to identify appropriate landfill locations to meet the growing demand for waste management, particularly in developing nations [27]. When biogas is generated from biomass, it helps to decrease the risk of groundwater pollution that can result from waste disposal [28]. Biomass, and especially waste biomass, is a valuable source of energy. The types of technology strategies for biogas production is closely related to the availability of substrates.

The implementation of biogas technologies for waste management and energy production practices, within the context of a circular economy, can contribute significantly to the economy. The circular economy is based on the principles of sustainable production and consumption, as opposed to the current linear economy, which is not considered the optimal model for our planet. It has become evident that the linear model is incompatible with the goals of sustainable development, and its continued use poses a threat to the well-being of future generations [29].

Biogas plants offer communes a significant opportunity to develop in multiple ways. They increase the income of both inhabitants and the local government and provide benefits to agriculture and rural areas. As mentioned by Pilarska et al. (2019) [30], agricultural biogas plants create a new market for local agricultural production, generate diversified income sources and new job opportunities, and facilitate the effective and eco-friendly management of farming by-products and residues.

Above all, biogas is an environmentally friendly option that includes reducing greenhouse gas (GHG) emissions, avoiding methane emissions, replacing fossil fuels, recycling nutrients, and minimizing odors [31]. The gas produced through the process of bio-digestion is clean and non-polluting, which helps to mitigate the impact of GHGes (GHG). Even though burning biogas releases CO2, the amount of CO2 generated is equivalent to the amount of CO2 produced during the AD process that converts the organic material. As a result, biogas is a zero-emission energy source that effectively combats global warming [31]. Biogas plants effectively reduce the greenhouse effect by capturing and utilizing methane emissions as fuel, which helps to curb the impact of this harmful gas [32].

Biogas systems provide a cost-saving opportunity for farms, dairies, and businesses by converting waste into a profitable source of energy. Waste can be utilized to generate heat, electricity, or fuel for vehicles, reducing dependence on foreign oil, lowering GHG emissions, improving environmental quality, and supporting local employment. Furthermore, biogas systems reduce the need for petrochemicals and mined fertilizers and offer the chance to recycle valuable nutrients back into the food system, thus improving the prospects of the agricultural sector and the energy security of the nation [33]. Overall, biogas plants offer numerous benefits to society, farmers, and consumers.

3. Main Principles in Biogas Production

Biogas is produced through AD, which occurs when organic matter is broken down by methanogens or anaerobic organisms in a closed system, such as an anaerobic digester, biodigester, or bioreactor [34]. The AD process involves several microbiological, biochemical, and physical–chemical processes, and is considered the most environmentally sustainable methods for treating biowaste. Anaerobic digestion not only diverts biodegradable materials from landfills, but also produces bioenergy and by-products like soil biofertilizers [35]. Bacteria play a crucial role in producing biogas during the anaerobic degradation of organic materials [36].

Biogas production efficiency is a crucial process parameter. Li et al. (2019) demonstrated that optimizing biogas production can lead to higher biogas yields, increased economic benefits, and reduced environmental impact [37]. The authors noted that several factors, such as feedstock composition, hydraulic retention time, temperature, and pH, can significantly influence biogas efficiency.

One of the main principles of biogas production is substrate selection. The type and quality of the organic matter used as a substrate can have a significant impact on biogas production rates and the overall efficiency of the biogas system. Zhang et al. (2017) evaluated the impact of feedstock composition on biogas production efficiency [38]. According to a study by Ndiweni et al. (2019), substrates that are high in organic matter content and low in lignin content (such as livestock manure) tend to produce higher biogas yields than substrates that are lower in organic matter (such as crop residues) [39].

Finally, the storage and use of biogas is an important consideration in biogas production. As evaluated in the study by Kifukwe et al. (2013) on biogas systems in Tanzania, the efficiency of biogas use can depend on factors such as the type of stove or burner used and the method of biogas storage [40]. They suggest that properly designed and maintained biogas storage and use systems can help ensure that the biogas produced is used in an efficient and safe manner.

Overall, these principles suggest that proper substrate selection, digester design, process conditions, and biogas storage and use are all important factors in maximizing biogas production rates and ensuring the efficiency and safety of biogas systems.

3.1. Fundamentals of Anaerobic Digestion

AD is a metabolic process that involves an association of microorganisms under anaerobic conditions, with a redox potential of ≤200 mV, to convert organic matter into methane and CO2 [41]. As a complex dynamic system involving microbiological, biochemical, and physical–chemical processes, AD has been identified as the most sustainable method for treating biowaste. In addition to diverting biodegradable materials from landfills, AD also produces bioenergy and potential by-products such as soil biofertilizers [35]. The process occurs naturally in the absence of oxygen and can be utilized to treat several raw materials, including industrial and municipal wastewater, agro-industrial, municipal, food activities, and vegetal wastes, to produce biogas [42,43].

Accurate estimation of the methane potential of different substrates is crucial to optimize the AD process. The research conducted by Pilarski et al. (2020) aimed to assess the potential of different substrates, namely maize silage, pig manure, potato waste, and sugar beet pulp, for biogas production [2]. To achieve this, they introduced a tool called the Biochemical Methane Potential Correction Coefficient (BMPCC), which allows for the estimation of methane production and optimization of the biogas production process. BMPCC is used in the biogas industry to estimate the amount of methane that can be produced from different types of organic substrates through AD and measures the efficiency of a biogas plant in converting organic matter into methane.

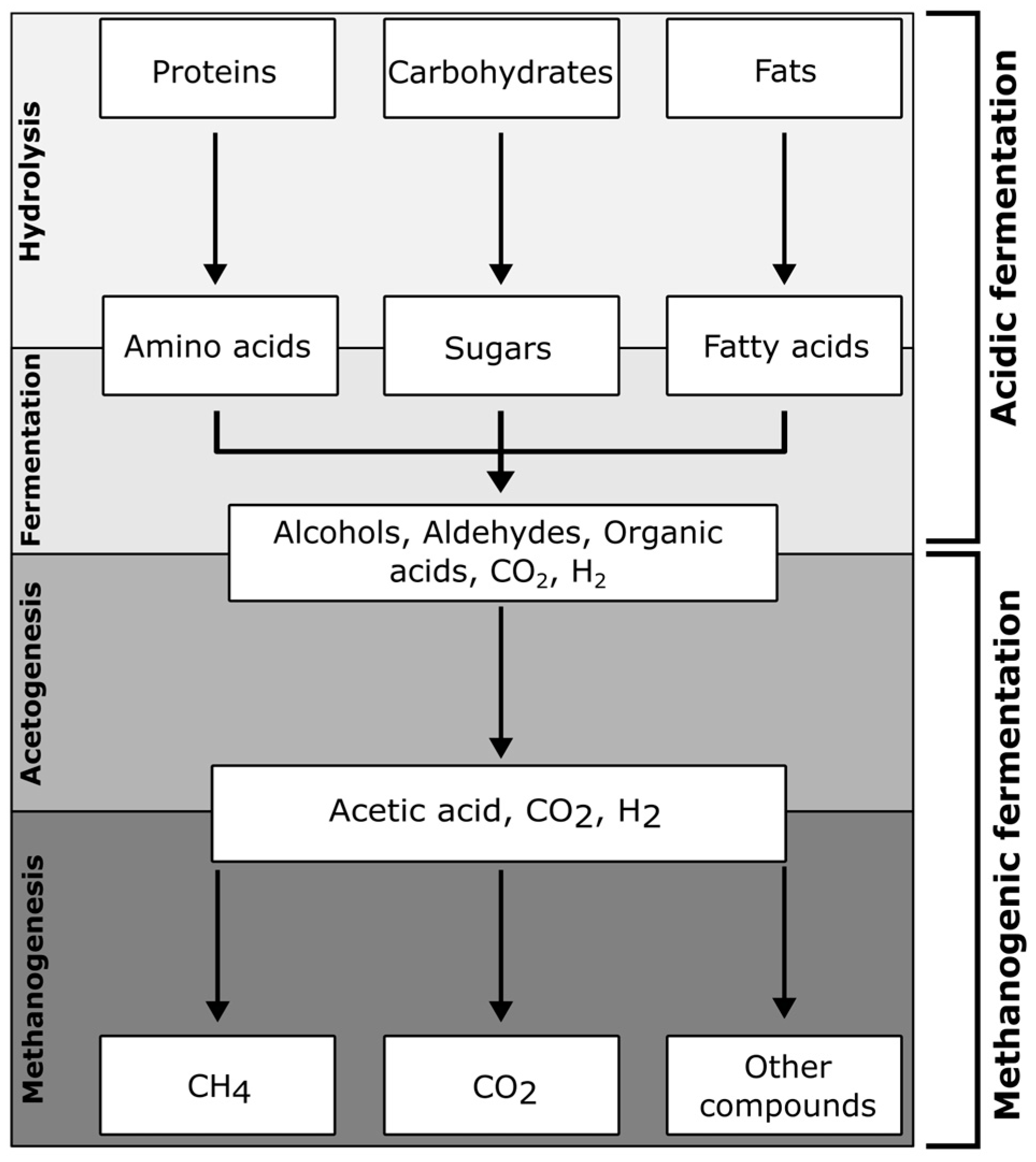

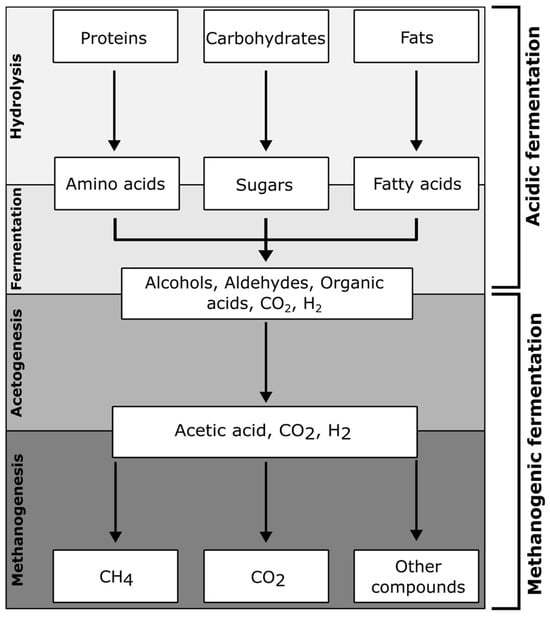

Anaerobic digestion can be categorized into four phases, namely hydrolysis, acidogenesis, acetogenesis, and methanogenesis (see Figure 1). These phases involve the coordinated activity of different groups of microorganisms in syntropy and may require distinct environmental conditions.

Figure 1.

Stages of anaerobic digestion process, original scheme.

The hydrolysis phase is the initial step of anaerobic digestion, where organic matter or polymers are broken down into smaller mono- and oligomers. This phase converts several polymers, such as carbohydrates, lipids, nucleic acids, and proteins, into simpler and simpler soluble monomers like glucose, glycerol, purines, and pyridines through the action of extracellular enzymes secreted by hydrolytic bacteria [44].

Acidogenesis is the second stage in AD where acidogenic bacteria break down the products of hydrolysis into methanogenic substrates which is called acetogenesis. Simple sugars, amino acids, and fatty acids are degraded into acetate, CO2, and hydrogen (70%), as well as volatile fatty acids and alcohols (30%) [44,45].

Acetogenic bacteria in the third phase convert acidogenic compounds into hydrogen, CO2, and acetate, leading to an increase in hydrogen ions that lowers the aqueous medium’s pH [30,46]. The optimal pH for acetogenic microorganisms is approximately 6, and they are slow-growing and vulnerable to variations in organic loadings and environmental factors during acetic and propionic acid production [47,48].

Methanogenesis plays a crucial role in the AD process, as it is responsible for generating approximately 70% of the methane used in AD [48]. This process involves the conversion of hydrogen and CO2 into methane by CO2-reducing and hydrogen oxidizing methanogens, while acetolactic methanogens utilize acetate to produce methane [49]. Archaea, specifically methanogens, use a variety of substrates, including acetate, hydrogen, CO2, methanol, methylamines, and formate, to produce methane and CO2. These end products are then utilized by methanogenic bacteria to produce biogas, which typically consists of 50–75% methane (CH4), 25–50% CO2, and trace amounts of nitrogen, hydrogen, and hydrogen sulfide.

In her pioneering study, Pilarska et al. (2018) examined a never-before-studied type of waste substrate, namely confectionery waste, for its potential to produce biogas through the AD process [50]. The confectionery industry generates big quantities of this waste on a continuous basis, resulting in hundreds of tons of solid waste every year. The findings of the study indicate that confectionery waste has significant potential as a valuable resource for energy production, while also providing a solution for the management of this particular type of food waste.

In summary, one of the main benefits of AD is its ability to capture and utilize methane, a potent GHG that contributes to climate change. As environmental concerns continue to increase, AD is expected to play a vital role in the renewable energy sector.

3.2. Key Parameters of the Process

In the AD process, several critical parameters must be considered and controlled to ensure an optimal fermentation process. These factors are mainly, pH of feedstock, temperature, retention time, flow rate of feed, and nutrient supply [51]. Failure to maintain these parameters within an acceptable range may impede or halt the biogas production process. Additionally, it is important to ensure anaerobic conditions, uniform temperature, and a consistent nutrient supply to facilitate efficient substrate degradation by bacteria [18].

Feedstocks used for biogas production exhibit significant variability in terms of composition, digestibility, and other characteristics, being necessary an understanding of their properties to determine the appropriate process steps, temperature, pH, moisture content, and available organic materials [31].

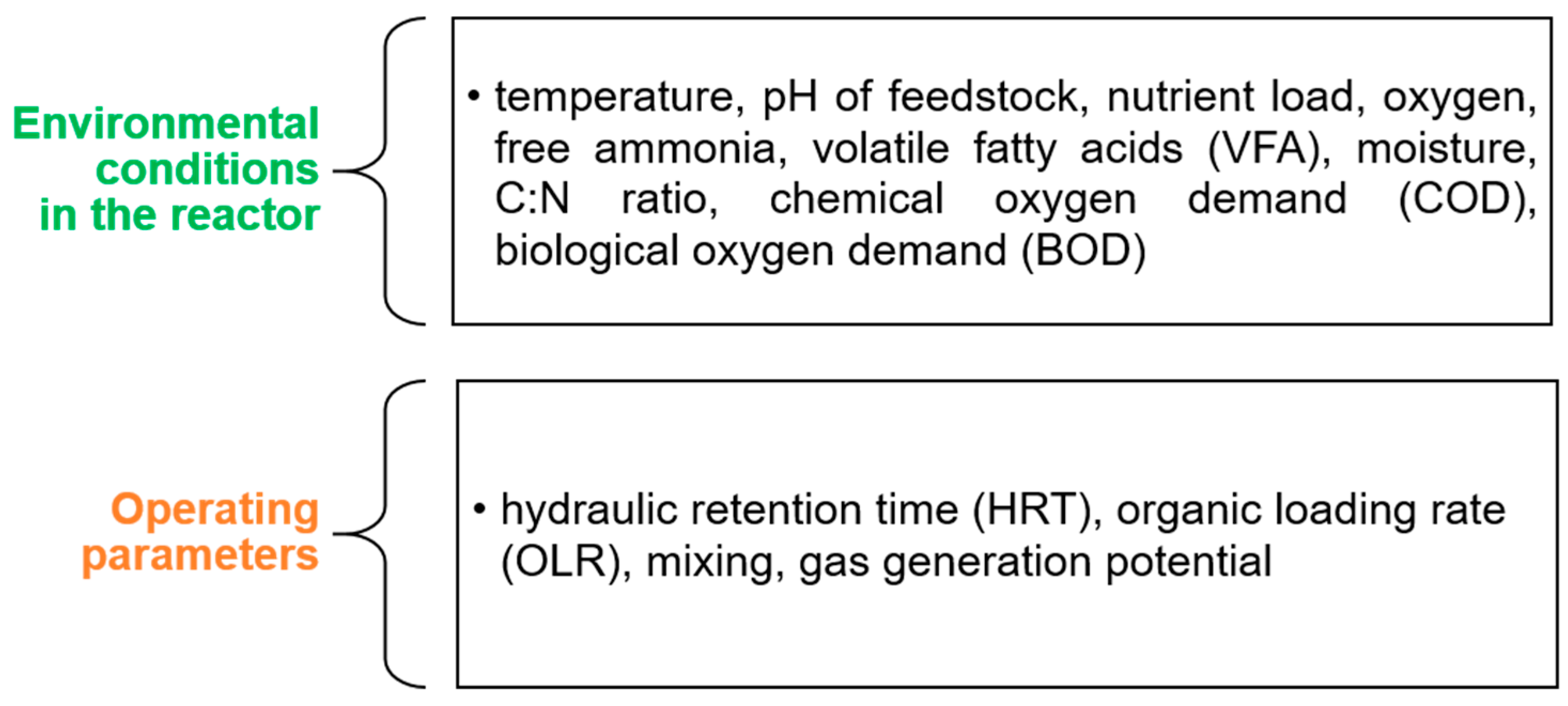

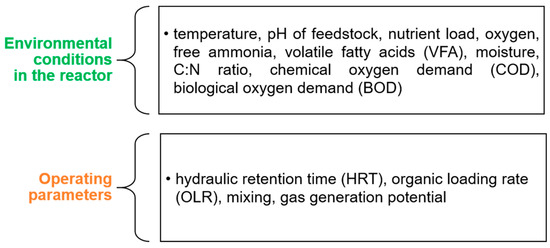

Figure 2 shows the parameters categorized in 2 groups as environmental conditions in the reactor and operating parameters.

Figure 2.

The scheme of main conditions affecting AD (VFA—volatile fatty acids, C:N ratio—carbon:nitrogen ratio, COD—chemical oxygen demand, BOD—biological oxygen demand), original diagram.

Temperature is a crucial factor that affects both the physicochemical properties of anaerobic substrates and the growth rate and metabolism of microorganisms, thereby impacting the population dynamics in a biodigester [34]. The microbial community, process kinetics, stability, and methane yield are significantly influenced by temperature. Lower temperatures decrease microbial growth, substrate utilization rates, and biogas production, leading to energy exhaustion, intracellular substance leakage, or complete lysis. Conversely, high temperatures reduce biogas yield due to volatile gases, particularly ammonia, suppressing methanogenic activities [52]. AD is commonly performed at either mesophilic (35 °C) or thermophilic (55 °C) temperatures, each with distinct advantages [53,54]. Regular temperature monitoring is necessary, and the choice between mesophilic and thermophilic temperatures should depend on the desired outcome and the microorganisms used for waste treatment [55].

The pH value is another vital factor that plays a decisive role in the organic matter decomposition process as it affects the chemical reactions and bacterial flora activity [50]. Optimal pH values differ during the several stages of the AD process due to biological transformation. During the acetogenesis stage, the pH level can drop below 5 due to the production of organic acids. The ideal pH range for maximum biogas yield in AD is relatively wide at 6.5–7.5, although this range may vary depending on factors such as substrate and digestion techniques [56]. Maintaining a constant pH level is critical, and equilibrium buffers such as calcium carbonate or lime must be added to the system to achieve this.

Retention time (RT) is an important parameter in AD that refers to the duration of time that the feedstock remains within the reactor. A longer retention time provides a greater degree of sludge stabilization, leading to a more stable digestion process. It also enables contact between the biomass and the liquid flow, allowing for better treatment and higher biogas yields. To achieve the optimum performance of mesophilic microorganisms, the hydraulic retention time typically ranges from 10 to 40 days, whereas for thermophilic microorganisms, the time required is usually shorter, approximately 14 days [56]. Equation (1) is used to calculate the retention time, which is the ratio between the biodigester volume and the feeding flow rate [41].

where:

HRT—Hydraulic retention time (day),

V—Biodigester volume (m3),

Q—Feeding flow rate (m3·day−1).

To determine the efficiency and stability of AD processes, the organic loading rate (OLR) plays a significant role as it directly affects microbial activity and degradation rates [53]. In this regard, maintaining an appropriate OLR is essential to avoid system overload, inhibit biomass growth, and prevent substrate accumulation, which can negatively impact the process performance. Therefore, monitoring and controlling OLR is critical for optimizing biogas production and ensuring a stable AD process [34,41].

In the event of high feeding volumes in AD systems, the bacteria that are responsible for the hydrolysis and acidogenesis phases tend to produce a significant amount of volatile fatty acids (VFA) within a short period of time. This high level of VFA production results in the acidification of the medium, which in turn inhibits the hydrolysis process. Furthermore, the high VFA concentration also hinders the performance of the methanogenic bacteria, as they are unable to convert the substrates produced by the earlier stages into methane. The outcome of this is a decline in the overall biogas production. Equation (2) is the formula determining organic loading rate (OLR) [8].

where:

OLR—organic loading rate, kgVS·(m3·day)−1,

Q—daily flow, kg·day−1,

VS—volatile solids, kgVS·(kg)−1.

Microorganisms involved in anaerobic degradation have specific nutritional requirements regarding macronutrients, micronutrients, and vitamins. The concentration and availability of these components are essential factors that influence the growth rate and metabolic activity of different microbial populations. These components have species-specific minimum and maximum concentrations that can be challenging to determine due to the diversity of microbial cultures and their varying adaptability [48,50]. To maximize methane production from substrates, it is imperative to ensure that the microorganisms receive an optimal supply of nutrients.

3.3. Substrates for Biogas Production

Biogas production is a potential replacement for conventional fossil fuels, and substrates are essential components in this process. Substrates refer to organic materials utilized as feedstocks for AD, where microorganisms break down organic matter without oxygen to generate biogas.

The type of substrate used in biogas production plays a crucial role in determining the efficiency and yield of the process. Different substrates have varying characteristics that affect their biodegradability and methane production potential. Factors such as availability, cost, and environmental impact must also be considered when selecting a substrate.

The substrate must meet certain requirements to be suitable for the process. Firstly, the substrate must have a high content of easily biodegradable organic matter. It must also have a low concentration of inhibitory substances such as heavy metals, pesticides, and antibiotics. Thirdly, the substrate must be available in sufficient quantities and reasonably priced, which means that the substrate must be locally available, and the cost of transport and processing must not exceed the value of the biogas produced.

Biogas production involves several types of substrates, which can be classified into four primary categories: agricultural waste, municipal and industrial waste, and energy crops [31,57].

The first type of substrate is agricultural waste, which includes crop residues, animal manure, and other organic waste from farms. These substrates are readily available and can be easily collected, making them a popular choice for biogas production. However, the composition of agricultural waste can vary depending on the type of crop or animal, which can affect the quality and quantity of biogas produced [31,58].

Table 1 provides information on several types of agricultural waste and their respective energy potentials. The data indicates that poultry manure exhibits the highest biogas yield, with 140 Nm3 of biogas produced per ton of substrate, and a methane yield of 90 Nm3 per ton of substrate. On the other hand, cattle slurry demonstrates the lowest values, with biogas and methane yields of 25 Nm3 and 14 Nm3 per ton of substrate, respectively.

Table 1.

Gas and methane yield from several types of farm manure average values, based on [58].

Municipal waste is the next potential substrate for biogas production, which households, commercial establishments, and institutions, including schools and hospitals generate. This waste includes a mix of organic and inorganic materials, such as food waste, paper, plastic, glass, and metals.

Since municipal waste is a readily available and abundant source of organic material, which makes it is an attractive option for biogas production. The use of municipal waste for biogas production can also help to waste management and loading of landfills, which reduces GHG emissions and improve air quality. The method of AD is currently the most commonly utilized approach for the mineralization of organic matter in sludge at biological waste treatment plants. However, some challenges associated with using municipal waste as a substrate are the presence of contaminants in the waste, such as heavy metals and plastics, which can inhibit the biogas production process or result in lower quality biogas, and the cost and complexity of separating the organic fraction of the waste from the inorganic fraction, which can make the process less economically viable [27].

Industries such as agro-industries, food industries, fodder, and breweries produce vast amounts of organic waste, by-products, and residues. Additionally, biorefineries generate organic-loaded wastewater sludges that require treatment or disposal. To address this issue, these organic wastes can be utilized as a feedstock for AD. Organic feedstocks for AD can come from a variety of sources, such as pomace from winemaking, animal feed, breweries, sugar refineries, and fruit processing plants. Even the wastewater from dairies and waste from slaughterhouses can be used to produce bioenergy [32].

In 2010, the global production of bioethanol was approximately 95 million m3. However, a significant challenge associated with producing high volumes of bioethanol is the generation of large amounts of effluents. Therefore, effective strategies are required to manage and treat the AD effluent to minimize its environmental impact [51].

The use of energy crops (renewable raw materials) in the production of power from biogas has received a lot of attention ever since the Renewable Energy Sources Act (EEG) was first amended in 2004. The majority of recently built biogas plants now use energy crops as a consequence of this [58].

Energy crops are crops grown specifically for the purpose of producing bioenergy, such as biogas or biofuels. These crops are typically fast-growing, high-yielding plants that have a high energy content and can be converted into several forms of renewable energy. Examples of energy crops include cardoon, giant reed, hemp, jerusalem artichoke, linseed, miscanthus, sorghum, switchgrass, acacia, maritime pine, paulownia, populus, willow, among others [59]. In Germany, maize (also known as corn) is primarily utilized in agricultural biogas plants as a substrate of choice [18]. It should be emphasized, however, that according to the new European regulations, the crops classified as food cannot be considered energy crops [60]. Food as a priority should not compete with energy production. However, only surplus, or residual material can be used for energy production from this type of crop. Energy crops must be non-food crops and species that must be planted in soils with low risk of ILUC (Indirect Land Use Change) therefore, marginal soils considered non-agricultural soils or low carbon soils [61]. If a food crop is to be used as an energy crop, it must be planted in this type of soil. It is important that energy crops that present a high potential for bioenergy generation and the recuperation of soils with low ILUC risk are identified to fulfill one of the world’s goals, the reduction of GHG Emissions. There is also a growing recognition of the need to adapt bioenergy policy to the principle of cascading use of biomass. The purpose of this rule is to ensure effective management of biomass resources.

3.4. Biogas Treatment and Purification

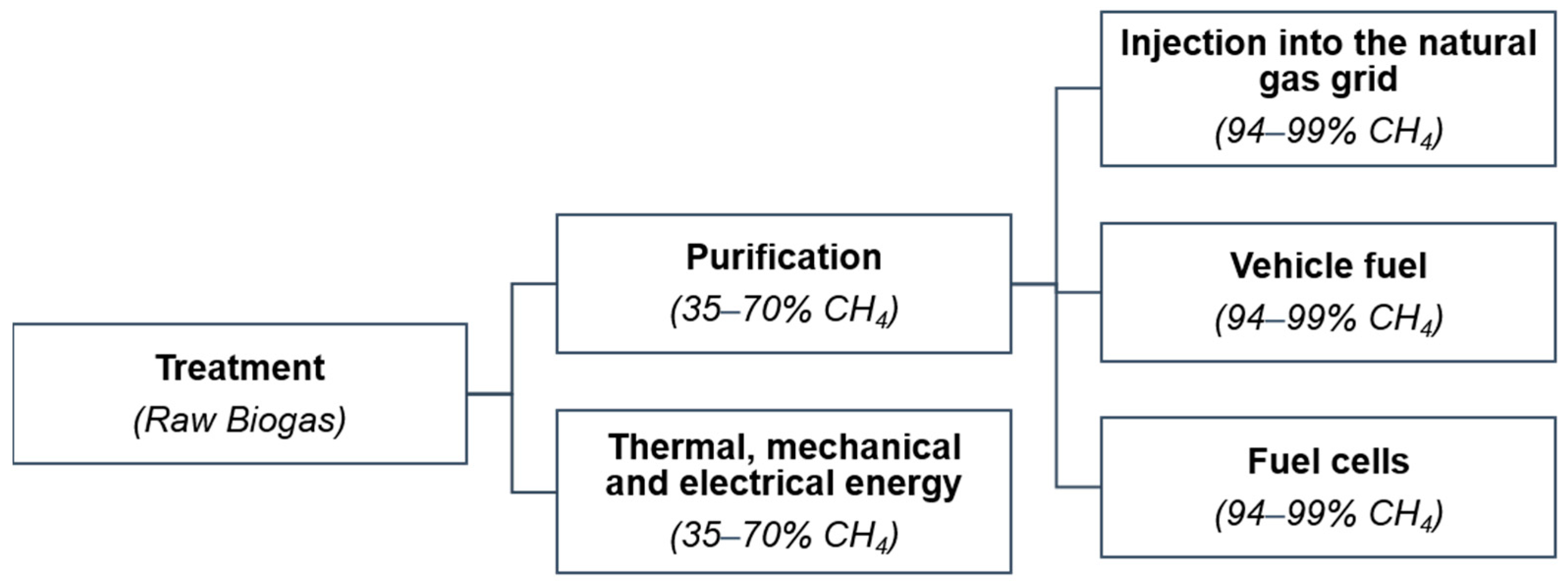

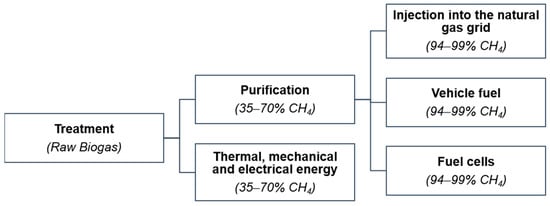

To obtain high-quality methane gas from biogas, it is necessary to subject the biogas to a series of essential processes. One such process is biogas purification, which involves the removal of impurities including, but not limited to, water vapor, CO2, hydrogen sulfide (H2S), and other trace gases from the biogas (Figure 3). The purification process enhances the energy content and calorific value of the biogas, rendering it suitable for use in several applications such as cooking, heating, and electricity generation [62].

Figure 3.

Biogas treatment and purification steps for biomethane concentration according for its final use, based on [41].

H2S is a corrosive and toxic gas with a foul odor [63]. It can pose a significant threat to human health, as prolonged exposure to low concentrations of H2S (between 15 and 50 ppm) can lead to mucosal irritation in the respiratory tract, resulting in symptoms such as headaches, dizziness, and nausea [64]. Furthermore, the presence of H2S in biogas can cause corrosion in storage tanks, metallic pipes, and combustion engines, leading to the deterioration of biogas production infrastructure [65]. As a result, removing H2S from biogas is crucial in ensuring the safety of human health and the longevity of the production infrastructure.

According to Wellinger et al. (2013), CO2 is a significant component of biogas, with a volume ranging from 20% to 30% in substrates derived from agricultural residues [51]. However, the presence of CO2 has a direct impact on the energy potential of biogas. This is because CO2 is inert in terms of combustion, and it occupies space that could be filled with more combustible gases. Therefore, the removal of CO2 from biogas is critical for optimizing its energy potential and ensuring its suitability for use in several applications.

Wellinger et al. (2013) mentions that ammonia (NH3) is a prevalent contaminant in biogas originating from agricultural residues, typically occurring in concentrations ranging from 50 mg·m−3 to 100 mg·m−3 [51]. Ammonia is known to have corrosive and toxic properties. When NH3 is incompletely combusted in engines, it can lead to the release of nitrogen oxides (NOx) into the atmosphere. These NOx compounds contribute to the formation of acid rain and can result in respiratory problems [66].

Biogas purification for energy applications is important from the point of view of the efficiency of its conversion into electricity [41]. This process mainly involves the removal of hydrogen sulphide and water, which negatively affect the functioning and life of energy devices, causing their corrosion. The techniques used for water removal from biogas also enable the removal of impurities such as particulate matter and foam. The most commonly applied methods for the physical separation of water from biogas include condensation and chemical drying. It should be emphasized that the selection of an appropriate treatment technology for biogas depends on several factors, including the flow rate of the biogas produced, the composition of the biogas, and most importantly, the desired level of biogas purification.

The changes in methane levels throughout the biogas treatment process are depicted in Figure 3.

The content of individual biogas components is not constant, but depends on the specificity of the technological process being implemented and the type of input material. Of particular importance is the methane content in biogas, which determines its calorific value. It should be noted that purifying biogas to match the parameters of natural gas involves additional financial outlays. It is estimated that treatment installations cost twice as much as purchasing a cogeneration unit. However, in order to be injected into the network, biomethane must meet very stringent quality requirements—uniform for all types of gases introduced.

4. Biogas Plants

Agricultural biogas plants have a long history, beginning with early advancements in biogas technology and its application in agricultural contexts. Throughout history, several societies have used organic waste to make biogas, a renewable energy source. However, modern agricultural biogas plants as we know them today have changed greatly as a result of scientific and technological advances.

There is evidence that biogas was used to heat bath water in Assyria as early as the 10th century B.C.E, and that AD of solid waste was used in ancient China [67]. However, well-documented attempts to harness AD of biomass by human date back to the mid-nineteenth century, when digesters were erected in New Zealand and India, with a sewage sludge digester built in Exeter, UK in the 1890s to power streetlamps [5].

4.1. Overview of Common Biogas Plant Types

Biogas plants are facilities that use organic waste to produce renewable energy in the form of biogas. Although there are many sizes and designs of biogas facilities, they all work on the same fundamental AD concept. The most common biogas plant types include batch systems, continuous stirred tank reactors, plug-flow digesters, and covered lagoons [68,69]. The choice of biogas plant type depends on factors such as the type and quantity of feedstock available, the required energy production, and local regulations [68].

One of the most widely used and practical application of biogas plants are agricultural plants. Facilities that process feedstock obtained from agricultural sources are referred to as agricultural biogas plants. Such factories often make use of organic resources including animal manure and slurries, vegetable leftovers and residues, as well as waste from the food and fishing sectors. The majority of agricultural biogas plants in Europe use animal dung and slurries from the production of cattle and pigs as their primary feedstock.

Agricultural AD plants may be divided into three groups according to their size, purpose, and location. Families or small towns can benefit from family-scale biogas facilities, which are normally extremely tiny. The energy requirements of a farm or a group of farms are met by small, medium, or large-scale farm-scale biogas facilities. The medium to large-scale centralized or cooperative co-digestion facilities are often made to manage a variety of organic waste streams and have several uses [44].

Commercial-scale biogas plants are another option for meeting the energy demands of sizable industrial sites or cities, in addition to the categories mentioned above. To create biogas, these facilities often combine several organic waste sources, such as municipal, industrial, and agricultural waste [70].

In general, a variety of factors, such as the accessibility and cost of energy sources, governmental regulations and energy policies, and regional climatic conditions, affect the design and technology of biogas facilities. A biogas plant’s design and technology are greatly influenced by its size, purpose, and location.

4.2. Analysis and Implications for Biogas Plant Design

Designing a biogas plant is a complex process that demands careful consideration of several factors. Analyzing the raw materials that are to be utilized to create biogas and the particular demands of the biogas plant itself is often part of the design process.

Biogas plant design involves analyzing and understanding the chemical composition and characteristics of the input substrates, as well as the operating conditions required for efficient biogas production [71]. The analysis of the substrate can determine the potential biogas yield and the appropriate mix of substrates to optimize production [72].

To ensure maximum energy efficiency, a biogas plant must be evaluated and optimized using an energy balance approach. However, reliable data for comparing different technologies are often unavailable, and most studies only consider electricity or heat demand while ignoring fuel demand for transport. It is important to note that there is a correlation between electricity, fuel, and heat demand, which can vary depending on substrate parameters and seasonal fluctuations [73].

The energy demand of a biogas plant depends on several factors such as substrate transport and storage, substrate pre-treatment, and the type of technology used in the plant. These factors can significantly affect the amount of electricity, heat, and fuel required to operate the plant. For instance, different types of biogas plant technologies have varying energy demands. Continuously stirred tank reactors (CSTRs) and dry batch digesters, for example, differ in their electricity and fuel consumption due to their unique designs and operation methods. The energy demands associated with each process step in a biogas plant also vary and depend on the specific characteristics of the substrates and the treatment of biogas and residues [74].

Pre-treating substrates before feeding them into the biogas plant can boost biogas yields by up to 20%. However, the energy consumption of the treatment system can offset the benefits if not properly accounted for. Therefore, it is crucial to calculate the energy demand of the pre-treatment process and assess the expected energy output of the plant. It is also worth noting that the energy demand of pre-treatment varies depending on the type of substrate being treated [74]. According to VDI (2006), the electricity demand for feedstock with higher solid content such as energy crops is slightly higher, ranging from 19 to 27 kWhel per MWhHi of biogas produced [75].

Once the energy demands of a biogas plant are determined, the next step is to evaluate the energy supply needed for the plant’s operation. This involves planning for the supply of electricity, heat, and fuel to meet the plant’s energy demands [73]. The energy supply can come from both external sources, such as the grid or a generator, and internal resources, such as a biogas burner or excess heat from single aggregates.

Proper planning and evaluation of the energy supply can help ensure efficient and cost-effective operation of the biogas plant. Therefore, biogas plant design must be approached with a holistic view, considering all relevant factors to achieve maximum energy efficiency and cost-effectiveness.

4.3. Administrative Aspects of the Construction of Biogas Plants

There are several administrative considerations that must be made while constructing biogas facilities. Regulations pertaining to zoning, health, safety, and the environment must all be followed when building biogas facilities.

4.3.1. Legal Assessment and Permit Acquisition

A vital step in building a biogas plant is getting the necessary permissions and approvals from the local government. It entails obtaining the required licenses, permissions, and approvals from local governmental organizations, environmental protection organizations, and other pertinent authorities. These authorizations and permits guarantee that the biogas plant’s development and operation adhere to regional laws and norms [76].

Once the required paperwork is prepared, it is delivered to the relevant municipal agencies in charge of approving and granting permissions. The local government, environmental protection organizations, health organizations, or other pertinent departments maybe some of these. In-depth details regarding the project, such as its site, design, environmental impact, and adherence to relevant legislation, are included in the application.

To promote the establishment and operation of the plants, particular incentives are frequently given to them. Feed-in tariffs (FITs) are a popular type of financial incentive. Feed-in tariffs are set, long-term payment rates are given to owners or operators of biogas plants in exchange for the renewable energy they produce. These prices are usually higher than the market rate for electricity and are locked in for a predetermined time, frequently between 10 and 20 years. Developers are more likely to invest in biogas infrastructure since FITs offer a steady and predictable cash stream [77].

4.3.2. Environmental Regulations

Environmental regulations and emissions management are crucial factors in the operation of biogas facilities, ensuring their environmentally friendly operation. To reduce any negative effects on the environment, policy frameworks are created to specify the rules and principles. These regulations cover important subjects like air emissions, wastewater management, odor control, and the preservation of soil and groundwater [78].

Regulations within policy frameworks set specific standards for biogas plant emissions, including methane, CO2, nitrogen oxides (NOx), sulfur dioxide (SO2), and volatile organic compounds (VOCs) [78]. Regulations to reduce odor emissions from biogas facilities are included in policy frameworks to manage potential odor issues. AD might result in the emission of odorous substances. Operators may be compelled to use odor control devices like biofilters or activated carbon filters to reduce odors and safeguard adjacent communities [79].

4.3.3. Health and Safety Considerations

When building biogas facilities, health and safety concerns are of highest importance in order to prioritize worker safety and reduce potential risks. When building a biogas plant, a number of important issues related to health and safety must be taken into consideration.

A thorough risk analysis ought to be done both before and throughout the building phase. In order to do this, possible risks related to site conditions, equipment use, material handling, and other construction operations must be identified. Risks including exposure to poisonous substances, confined spaces, electrical dangers, and falls should all be assessed, and the necessary precautions should be taken to reduce or eliminate them [76].

4.4. Operation of Biogas Plants

The efficient production of biogas from organic feedstock requires a number of procedures and phases throughout the operation of a biogas plant.

The gathering and preparation of organic feedstock, such as agricultural waste, food waste, manure from livestock, or special energy crops, is the first step in the operation of a biogas plant. The feedstock is then put inside a sealed digester, where anaerobic bacteria use the lack of oxygen to break down the organic material. Biogas, largely made up of methane and CO2, is a result of this AD process [8].

According to Wu et al. (2021), carefully controlling operational parameters is essential to a biogas plant’s efficient operation [80]. Controlling the temperature is essential for maintaining mesophilic or thermophilic conditions, which maximize microbial activity. The retention period, or the amount of time the feedstock is kept in the digester, gives organic matter enough time to break down and produce biogas. A successful feedstock mixing process guarantees even distribution and boosts microbial activity.

To guarantee effective plant operation, continuous monitoring of operating parameters, gas composition, and system performance is required. To maximize plant performance and lifetime, equipment must receive regular maintenance and servicing. The wellbeing of the workforce is guaranteed, and the negative effects on the environment are reduced, through adherence to environmental rules and health and safety protocols [81]

Moreover, personnel with knowledge of process monitoring, maintenance, and troubleshooting are needed to operate a biogas facility. Biogas plants may make a substantial contribution to the generation of sustainable energy, waste management, and the reduction of GHG emissions with the right operational practices and attentive maintenance.

In conclusion, the running of a biogas plant necessitates the intricate interaction of several processes, variables, and management techniques. AD can be used to produce biogas, which is a renewable energy source that also encourages environmentally responsible waste disposal. A greener and more sustainable future can be greatly aided by the efficient operation of biogas facilities.

4.5. Economic Aspects and Profitability

When determining the viability of a biogas plant as a sustainable energy investment, the financial factors and profitability of the facility must be considered. The initial investment, operational expenses, income generation, and potential profit incentives are all factors in assessing a biogas plant’s economic sustainability.

Cost and benefit analyses are the major tool used for the systematic evaluation of the financial costs and potential benefits associated with the establishment and operation of biogas plants. These analyzes are extremely necessary when determining the economic viability and potential of these plants as sources of renewable energy [82]. These analyses involve contrasting the expenses of developing and managing a biogas plant with the amount of energy that can be produced by the plant and the potential revenue streams that may be generated from it [83].

The main goal of the analyses is to determine whether the advantages of the plant outweigh the expenses. Below are some main elements that are often taken into account in a cost-benefit analysis of a biogas plant.

- Investment Costs

This comprises the initial financial outlay needed to build the biogas plant, such as equipment, infrastructure, land, and permits. It also takes into account any additional costs connected with upgrading or altering existing facilities to suit the biogas plant [84]. The cost of investing in a biogas installation can reach several million or even more than ten million zloty. The return on investment can be achieved within a few years, provided the activities are well-planned and executed. Financial support and subsidies are therefore an indispensable part of investment. When investing in a biogas plant, it is important to properly organise the system for managing waste from residents in the surrounding areas [9,53]. The possibilities of achieving the required recycling levels should be analysed, recognising both the opportunities and the problems involved.

- Operating Costs

These include continuous costs for running the biogas plant on a daily basis, such as labor, feedstock acquisition, maintenance, utilities, and waste management. It also takes into account any costs associated with regulatory compliance and quality control [85]. Wear and tear on the engine or loader necessitates their repair or replacement. The costs associated with the need to supply electricity to power the biogas plant must also be taken into account. In general, biogas plants are high-risk investments, requiring professional management throughout the investment life cycle [2,9]. The most significant groups of risk factors involve regulatory instability, the location of the biogas plant and the difficulties of maintaining and restoring the microbial community and managing the digestate.

Despite the rather high costs associated with both the construction and maintenance of a biogas plant, it should be considered a fairly cost-effective investment. First and foremost, this should be considered in terms of long-term investments.

- Availability and Costs of Feedstock

The availability and cost of feedstock, such as agricultural waste, energy crops, or organic waste, are critical factors in the economic feasibility of a biogas plant. The examination considers the availability, dependability, and cost of obtaining the required feedstock [86]. The most economical of the proposed solutions is the construction of biogas plants at their source, i.e., near production plants, sewage treatment plants or livestock farms, which provide continuous access to substrates in the form of waste. It is a low-cost and continuous source of raw material supply, free of logistical costs [53,60].

- Production and Utilization of Energy

This includes the biogas plant’s energy output and utilization efficiency. It takes into account elements such as the AD process’s conversion efficiency, the plant’s electricity and heat demand, and the potential for energy self-sufficiency or grid integration [87,88]. An important issue of efficient energy management is certainly the use of heat for a wider range of purposes besides the typical technological ones, including heating or drying—in areas located close to the biogas plant. Implementing measures to increase the efficiency of cogeneration systems is the basis for the optimal use of the primary energy stored in substrates.

- Environmental and Social Benefits

The analysis considers the environmental and social benefits of the biogas plant. This includes factors such as reduced GHG emissions, improved waste management, and potential job generation, community development and stimulation of local demand (suppliers for biogas plants) [78]. Biogas plants make a significant contribution to environmental safety through the utilisation of methane extracted from landfill sites, assisting in the treatment of municipal wastewater, and increasing the energy management of agricultural by-products while reducing the odours of agricultural production. Of all renewable energy sources, biogas is the one that offers the greatest potential for cooperation with local authorities and society [89,90]. These wide-ranging waste disposal options, or reductions in waste management costs, fall into the category of both social and environmental benefits.

5. Global Prospects and Barriers in the Development of Biogas Plants

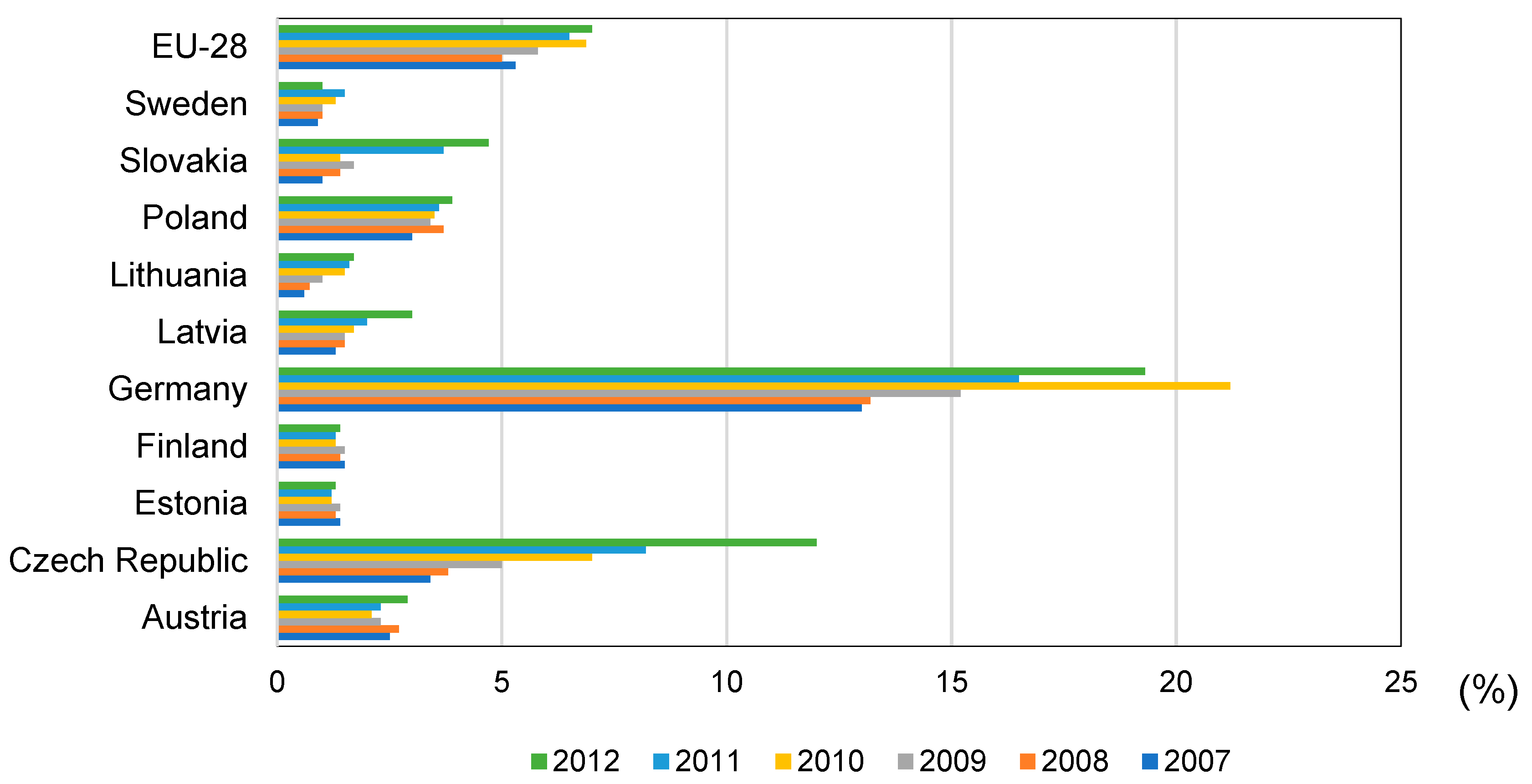

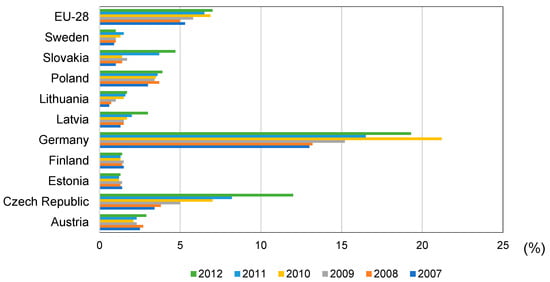

In recent times, biogas production has seen a remarkable rise in adoption, driven by its environmental benefits and efficacy as “waste-to-energy” solution [91]. In fact, it is considered to play a significant role in achieving the EU’s ambitious renewable energy targets [92]. This development has been particularly observed in the United States and the European Union, while progress in Asian and other nations has been comparatively slower [17]. Thanks to institutional and legal support, technological advancements, and small farmers’ associations [93] Germany leads biogas production in EU, with 61% share and over 7000 plants in 2010, 84% of which use co-digestion methods with crops and animal waste slurry [94].

Figure 4 illustrates the proportion of biogas energy generated within the overall renewable energy production across European countries from 2007 to 2012 [93]. According the data from 2012, Germany, the UK, and Italy were the leading producers of biogas in the EU with 77% of total production, but other countries have increased biogas plant numbers for diversified energy sources. In 2012, the EU achieved 6.8% of energy from biogas, with Germany holding the largest share at over 19%, thanks to institutional and legal support, technological advancements, and small farmers’ associations [93]. The Czech Republic also had a significant share, while Estonia, Finland, and Sweden have around half a percent. It should be emphasized that more recent literature reports indicate a similar trend [7,8,17]: the current leaders countries in biogas production in the EU, are: Germany, United Kingdom, Italy, Czech Republic and France.

Figure 4.

Percentage of biogas energy in the renewable energy mix across chosen EU countries, based on [93].

Currently, the Russian-Ukrainian conflict has intensified the urgency of accelerating rating the European Union’s transition to energy self-sufficiency and given the European biogas sector a vital strategic role. The growth in European biogas output observed between 2021 and 2022 primarily reflects the investment decisions made after the rollout of the REPowerEU plan [95]. The plan was launched in May 2022 and aims to protect EU citizens and businesses from energy shortages, accelerate the transition to clean energy and retrench European pur chases of Russian hydrocarbons. Measures related to renewable energy and energy efficiency include i.a. increasing EU’s 2030 target to 45% renewables in the EU mix, up from the current target of 40%. The preliminary estimates carried out for 2022 showed almost 15.8 Mtoe (M—mega) primary energy produced in European Union countries [96]. As in previous years, methanation biogas from non-hazardous waste and raw plant matter (other biogas) is the main category responsible for the increase in Europe’s increased biogas output (see Table 2). Landfills and sewage sludge gas are also significant sources of biogas. The study finds that France and Denmark contributed the most to the 2022 increase in EU biogas output. German biogas output, which was subject to a statistical upward revision in 2021 slipped very slightly between 2021 and 2022 (by 0.6%). Nonetheless, Germany is still far and away the leading EU biogas producer country and accounted for 51.4% of the EU total in 2022, ahead of Italy with 12.9% and France with 10.3%. Taking into account biogas production per capita, then Denmark leads the field with 117.3/1000 inhabitants (inh.), ahead of Germany (97.4 toe/1000 inh.), Czech Republic (56.8 toe/1000 inh.) and Italy (34.4 toe/1000 inh.). France comes in 8th (24 toe/1000 inh.), behind Finland, Latvia and Slovakia [96].

Table 2.

Primary production from biogas in the European Union in 2022 (in ktoe), based on [96].

As far as Poland is concerned, Lewandowski et al. (2006) mentioned that despite the potential benefits of biogas plants, Poland’s biogas share in renewable energy sources is only 2%, which can be attributed to a slow industry development caused by several factors, such as social protests, inexperienced investors, and bureaucratic hurdles [97]. Additionally, the low income for farmers has led to talent loss and economic weakness in the agricultural sector. However, the agricultural biogas sector is growing due to increasing demand for renewable energy, the rising costs of traditional energy, and the need for efficient waste management solutions. Some investors have already recognized the potential of biogas plants in Poland and the government has introduced policies and incentives to support the sector’s growth [98]. Poland’s situation in this respect is assessed to be much worse, compared to other countries (for example Western Europe) or comparable to countries in Asia or even Africa. For example, in Bangladesh, an Asian country, despite the availability of raw materials for biogas production, the development of biogas production is also very slow [99]. The result of the research indicates a lack of coordination among stakeholders and an immature biogas market, where the main barriers are a lack of awareness on how to use waste efficiently and the absence of a feed-in tariff policy. The need to adapt to climate change is seen as the most important motivating factor here. These results were found to be similar to other studies conducted in developing countries of similar socio-economic status, including Indonesia, where a lack of financial resources is cited as the most common reason for the stagnation in biogas investment development [100].

The article by Ghimire (2013) presents the number of biogas plants installed in Asia and Africa [101]. In Asia, the data reveals an overall increase in the number of biogas plants installed from 2008 to 2009 across all seven countries listed. Notably, Vietnam and Nepal stands out with the highest number of biogas plants among the Asian countries. The situation in these countries could be achieved thanks to the Netherlands Development Organisation and the Biogas Support Programme, launched in 1992. The success of BSP in Nepal (1992) encouraged SNV to support domestic biogas production in Vietnam in 2003, followed by other Asian countries: Bangladesh, Cambodia, Lao PDR, Pakistan and Indonesia [101]. A similar upward trend, thanks to the presence of SNV in the biogas sector, can be noted in several African countries (where the substantial technical potential of about 18.5 million households is recorded). However, compared to Asian countries, biogas development in Africa has been fairly modest so far, due to a number of challenges, in particular high investment costs, limited access to credit facilities and the much lower purchasing power of potential households. Rwanda, specifically, holds the distinction of having the highest number of biogas plants among the African countries listed. The information presented is important because it represents breakthrough changes in the area of biogas development for countries in Asia and Africa. At the same time, the situation in the indicated countries has not changed radically for years, the reasons for which are presented in the following parts of the article.

The lack of education and aware ness in not knowing the importance of using biogas technology by the rural population living in the countries of sub-Saharan Africa (SSA), lead them with severe health issues in using renewable biomass such as fire wood, cattle dung cakes, crop residues directly for their domestic consumption. Water is essential for both the installation and operation of biogas plants. The scarcity of water in most of the land locked countries within SSA region hinders the widespread adoption of biogas technology. Public awareness and general education further impede the progress of biogas technology in most of the developing countries within SSA region [102]. Nevertheless, the literature data also points to some African countries seeking to produce clean energy. Thus, Ghana is an example of a country facing urgent development challenges in energy, sanitation, environment and agriculture [103]. The country sees the development of biogas plants as a means of improving sanitation (manure-fed household biogas plants in operation), reducing GHG emissions (biogas plants at cattle farms), recovering nutrients and creating new jobs. Although the biogas industry is not growing rapidly here, new investments are being made thanks to current subsidies and bank support [104]. Shane et al., (2015) on the other hand, critically list an entire range of obstacles in their article on the situation in Zambia [105]. The study carried out by this author, proved that there is a theoretical biogas potential of 76PJ per year from animal manure and crop residues. This is sufficient to provide energy for cooking and lighting in more than 3 million households. In turn Burkina Faso, West Africa (Ouagadougou Biogas Plant, OUA) is a country with abundant biomass resources, but its efficient use of biomass is limited, and it has only recently started to use biogas for electricity generation, beginning in 2016. According to the International Energy Agency (IEA), as of 2020, only 21% of the population has access to electricity, and 11% of the population uses clean cooking fuels, making Burkina Faso one of the lowest-ranked countries in West Africa in terms of access to clean energy [106].The OUA biogas plant treats 140,000 tons of human feces and 3000 tons of seasonal mixed organic waste per year, producing 1,080,000 m3 of biogas, 2,160,000 kWh of electricity, and 2500 tons of organic fertilizer per year. However, the mentioned lack of a regulatory framework and specific biogas strategies, monetary policies that are unfavourable to investors, insufficient expertise, resistance to change due to the culture and traditions of the local people, high costs of installing and maintaining biogas digesters, inadequate management and lack of monitoring of installed digesters and, finally, the lack of incentives and social equity hinder the sustainable implementation of biogas production in African countries. The resolution of the aforementioned problems is a prerequisite for the development of the biogas sector.

Across East Africa, particularly in rural areas, more than 95% of households claim that they use solid fuels as their primary energy source [107]. Biogas is an alternative for households with access to sufficient and suitable organic feedstocks [108]. Worldwide, there are around 50 million biogas systems installed to produce gas for cooking. Most of these systems operate in Asia, particularly in China [109,110,111] and India [108,109]. It should be noted that it is China that currently has the largest number of biogas plants, reaching up to 40 million operating plants. The majority of these are household biogas units based on underground, non-insulated digesters with capacities ranging from a dozen to several dozen cubic metres. A very large number of Chinese farms own biogas plants. They use animal manure and organic residues from the household as feedstock. Biogas is used, as mentioned above—for cooking and heating, but also for lighting. There are up to 100,000 non-mobile, large-scale installations producing several to more than ten thousand cubic metres of biogas per day in China. In 2015, the National Development and Reform Commission of the People’s Republic of China (NDRC) reported that 41.93 million small-scale biogas plants were installed. During the project phase, more or less 110,000 biogas plants were built. In contrast, a paradigm shift of centralized biogas plants for gas supply and power generation was also observed [112]. This step resulted in the successful integration of natural gas with renewable Biogas in the pipeline network. The coverage for household users was more than 74% [113]. The Chinese government has envisioned establishing 128,976 small and medium-scale, 10,122 large-scale centralized and 43 million household biogas plants. The overall biogas production goal is 207 Million cm3 respectively. The subsidies on offer in China are a powerful incentive for investment. India, on the other hand, currently has only 56 operational biogas-based power plants, and most are concentrated in three states: Maharashtra, Kerala, and Karnataka [114]. To provide context, approximately five million family biogas plants have been installed under the biogas development program. In addition to these family-oriented biogas systems, 400 off-grid biogas power plants operate with a collective power generation capacity of around 5.5 MW [115].

As far as Azerbaijan is concerned, despite having abundant renewable energy resources of all types, the adoption of alternative energy is still limited in the country, due to the abundancy of natural gas [116]. This is a situation that differs in a way from that previously presented concerning other countries in Europe, Asia or Africa. In the aforementioned country, the Ministry of Natural Resources claims that biogas is not a feasible option due to the availability of natural gas and the absence of an energy shortage that would necessitate the use of alternative sources [117]. Nevertheless, Azerbaijan currently operates several biogas plants, including the first installation in the Guba region with a 5-cubic-meter volume capable of producing 7–8 cubic meters of biological gas daily. In 2011, the experimental Gobustan hybrid station was commissioned with a total capacity of 5.5 MW, powered by three wind turbines generating 2.7 MW, solar panels producing 1.8 MW, and a biogas power plant generating 1 MW. The hybrid station now provides electricity to the Gobustan landfill in full.

The above data highlight a notable transition toward sustainable energy practices, as countries increasingly acknowledge the imperative to reduce their dependence on non-renewable energy sources. Hasanov et al. (2023) [118] proposed biogas production as a pivotal solution for energy supply, offering a means to mitigate the detrimental effects of fossil fuel consumption, as the burning of these fuels has substantially elevated CO2 and other GHG concentrations in the atmosphere since the industrial era’s onset [119], exerting a profound influence on climate change. Azerbaijan takes this issue in particular into account [120].

Biogas production offers several advantages for waste management and the circular economy, including income diversification, job creation, and eco-friendly management of agricultural by-products and residues [121,122]. However, several obstacles limit its use as an energy source. These barriers encompass a lack of awareness and understanding among stakeholders, which hinders incentives and investments. Biogas can be costlier than natural gas and fossil fuels and faces competition from abundant natural gas. Technical challenges, such as addressing the gas-liquid mass transport issue during methane conversion, and emissions during the AD process, which can lead to GHG penalties when not managed effectively, also pose challenges [91].

Bhatt and Tao (2020) [91] mentioned that to increase biogas production and energy efficiency, several pretreatment methods can be employed. For instance, physical pretreatment involves mechanical and thermal energy applications to disrupt waste materials, while chemical pretreatment utilizes chemical substrates to break down waste for easier downstream processing. Biological pretreatment, on the other hand, leverages microbial consortia or enzymes to enhance waste hydrolysis. Furthermore, optimizing operational parameters, such as enhancing Chemical Oxygen Demand (COD) reduction rates through factors like loading rates, temperature, and pH control, is essential.

A thorough assessment of biogas technologies from both economic and environmental perspectives is necessary to better understand the trade-offs between biogas yields and the costs associated with implementing these methods. This evaluation can aid in making biogas production more competitive with natural gas prices. It is important to assess the organic waste availability, ensuring technical feasibility, and conducting cost-benefit analysis in order to promote biogas utilization. Analyzing local energy demand guides the alignment of biogas supply with community needs. Crucially, engaging local stakeholders, including farmers and waste management facilities, fosters collaboration and supports successful biogas adoption [123,124].

With regard to existing barriers to biogas market development, an analysis based on the work of authors from different countries clearly indicates the presence of technical, economic, market-related, institutional, socio-cultural and environmental barriers [11,100,125]. These groups cover the issues cited in the earlier sections of this part of the paper and apply to both developed and developing countries. However, problems classified in this way combine interdependent factors and often require complex solutions, particularly for developing countries where the situation is more difficult. It is important to involve relevant authorities and institutions, including governments, financial and R&D institutions, as well as lobby groups, the media and local communities. Current trends and developments point to the need for a platform for informed discussions and exchanges (debates, conferences, meetings) with representatives of politics, science, local government, business/investors and private stakeholders.

The global agricultural biogas market is at very different levels of development [5]. Most such installations are located in Asia and Europe [101,126,127,128]. Australia, New Zealand, Africa and the Americas mostly have pilot biogas plants located in the vicinity of scientific research institutes, although in Africa the installations are far more practical [101,107,129,130]. In Asia, the highest biogas production is recorded in China and India [11,100]. The installations there are technically uncomplicated. In Japan and Korea, the biogas market is similar to that in Western Europe—it is highly dynamic and technologically advanced [131,132,133,134]. Among European countries, Germany is the undisputed leader in the biogas sector, with considerable potential also accumulated in Italy and the UK, as well as the Scandinavian countries, including Denmark [93,135,136].

One of the most up-to-date reports on the global development of biogas production [137] confirms that China has the highest number of biogas plants, with more than 100,000 biogas plants, followed by Germany with over 10,000 plants. As mentioned earlier, to the 100,000 biogas plants, China also has a considerable number of household biogas units. In countries like Australia and the UK, landfills are the largest source for biogas production, while they are only a minor contributor in countries like Germany and Switzerland, indicating the low level of landfilling of organic waste material. How to provide the report, in most of the countries, biogas is mainly used for heat and electricity generation. Sweden stands out, with more than half of the produced biogas being used as vehicle fuel. Germany is second in absolute numbers in terms of biogas as a transport fuel. Germany and Sweden have had the largest markets for biomethane in recent years, but a growing interest is seen in other countries as well. UK has now taken over the second position from Sweden, using more and more biomethane for heat and electricity production, but also as vehicle fuel. Financial support systems are very different from country to country. Various systems with feed-in tariffs, investment grants and tax exemptions exist. A clear correlation between the financial support system and the way biogas is utilised is evident in most of the countries. In countries like the UK, Germany and Austria, feed-in tariffs for electricity have led to most of the biogas being used to produce electricity, while the system with tax exemption in Sweden favours utilisation of the biogas (biomethane) as a vehicle fuel. In several countries, financial support systems have led to an increased share of biogas in the gas grids. Another more important conclusion of the document under consideration [137] was the current implementation of many innovative biogas projects going on, including dry digestion, CO2 utilisation and cross-sectoral synergies.

6. Conclusions

The current geopolitical situation and the associated global energy crisis have led to an increase in the importance of renewable energy carriers. Biogas plants offer a viable opportunity to increase environmental safety by disposing of methane released in landfills, stabilising municipal wastewater and managing agricultural by-products while reducing the odour of agricultural production. Of all renewable energy sources, biogas is the one that offers the greatest potential for cooperation with local authorities and society.

However, operating a biogas plant can present difficulties and is not always cost-effective. Nonetheless, some steps can be taken to optimise the digestion process itself to increase the efficiency of organic matter decomposition into biogas. To this end, the approach to biogas plants needs to change. They should be treated as biochemical industrial plants requiring efficient technological supervision. Qualified staff and sound knowledge of the AD process have the potential to make them successful. It is in the interest of biogas plant owners to maximise the production of biogas with the highest possible content of methane as an energy carrier.

Scientists, investors and some politicians are aware of the potential of biogas plants to become a sustainable source of energy, but despite educating the public on the issue, there is no shortage of opponents to such investments. A good business model plan for a biogas plant, covering the social, environmental, economic and logistical spheres, is at the heart of the venture. When investing in a biogas plant, it is important to properly organise the waste management system, the collection of electricity and, importantly, the management of thermal energy, eliminating losses as far as possible. It is worth considering the viability of entry of biogas plants into energy cooperatives, where the electricity or biogas, or heat produced is balanced by the own needs of the energy cooperative and its members, at a local level. The ultimate aim of this idea is to ensure energy independence, regardless of the prevailing geopolitical climate, and financial security of investment.

Developing countries on different continents, mainly in central and eastern Europe, Asia and Africa, report the presence of numerous factors hindering the development of biogas plants: technical, economic, market-related, institutional, socio-cultural and environmental ones. The most frequently cited reasons for investment failure include economic problems, lack of professional knowledge. Failure to address the problems that are repeatedly pointed out leaves little chance for the dynamic and global development of biogas plants. Currently, the country with the largest number of operating biogas plants is China. They are followed by the European leader in biogas production—Germany. Australia, New Zealand, Africa and the Americas mostly have pilot biogas plants located in the vicinity of scientific research institutes, nevertheless in Africa the installations are far more practical.

Author Contributions

Conceptualization, A.A.P. and G.G.; Formal analysis, A.A.P., K.P. and A.K.-W.; Resources, A.A.P., G.G., A.K.-W. and K.B.; Data curation, J.D. and K.P.; Writing—original draft, G.G. and A.A.P.; Writing—review & editing, A.A.P., J.D. and K.P. and G.G.; Visualization, G.G. and A.K-W.; Supervision, A.A.P. and K.B.; Project administration, A.A.P.; Funding acquisition, A.A.P. and K.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Higher Education’s programme: Regional Initiative Excellence (RID) in the years 2019–2022 (No. 005/RID/2018/19), financing amount 1,200,000,000 PLN.

Data Availability Statement

No new data were created or analysed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References