Abstract

Concentration of solar energy may be obtained by reflection, refraction, or a combination of the two. The collectors of a reflection system are designed to concentrate the sun’s rays onto a photovoltaic cell or steam tube. Refractive lenses concentrate light by having it travel through the lens. The sun’s rays are partially reflected and then refracted via a hybrid technique. Hybrid focus techniques have the potential to maximize power output. Fresnel lenses are an efficient tool for concentrating solar energy, which may then be used in a variety of applications. Development of both imaging and non-imaging devices is occurring at this time. Larger acceptance angles, better concentration ratios with less volume and shorter focal length, greater optical efficiency, etc., are only some of the advantages of non-imaging systems over imaging ones. This study encompasses numerical, experimental, and numerical and experimental studies on the use of Fresnel lenses in various solar energy systems to present a comprehensive picture of current scientific achievements in this field. The framework, design criteria, progress, and difficulties are all dissected in detail. Accordingly, some recommendations for further studies are suggested.

1. Introduction

The rising need for energy in the modern world calls for the responsible and effective use of solar power [1,2,3,4]. However, high efficiency in the transmission of solar energy is limited by the relatively weak solar radiation experienced by Earth’s surface [5]. As a result, there is a lot of interest in finding ways to make the most of solar concentrators [6,7]. Concentrated solar thermal [8], photovoltaic [9], and photo-thermal [10] have been studied using various solar concentrators. To make the most of solar energy, it is crucial to perfect high-concentration solar concentrators (HSC) [11].

Water desalination systems and the usage of sun distillers (also known as solar stills) have benefited greatly from the widespread development of solar energy technology in recent decades [12]. If you live in an area with abundant solar irradiation, this kind of desalination system is widely regarded as a green and efficient way to purify water on a modest scale [13,14]. Moreover, this class of device is considered a low-carbon technology with considerable promise in freshwater production based on alternative energy [15]. Both the academic and business worlds have taken an interest in thermal solar energy in particular. By 2050, they might account for up to half of all new power production worldwide [16].

In total, 76% of all industrial energy contributes to producing heat, the majority of which (57%) operates at temperatures below 400 °C [17]. Concentrated systems are the only way to obtain solar thermal energy at the temperatures required for most industrial operations, which may be up to 250 °C. Approximately 60% of heat required in numerous industries, including the food, textile, and chemical sectors, is satisfied at temperatures below 250 °C. Concentrated solar technologies are expected to have a 500 million GJ potential in industry by 2050, according to the United Nations Industrial Development Organization (UNIDO) [18].

Parabolic cookers are less common since they are cumbersome to use while full, requiring the user to follow the sun every ten minutes [19]. Over the last several years, researchers have explored numerous indirect forms of cooker prototypes in an effort to find solutions to this problem. The collector for indirect prototypes is stored in a separate location from the cooking chamber [20]. Most high-temperature solar cookers use traditional reflecting parabolas to concentrate sunlight onto a cooking container [21]. This is because frying and baking require high temperatures (above 200 °C). The focus point of such parabolic reflectors must be tracked often along two axes, and the receiver must be permanently mounted there. Despite the high-temperature output, the use of such concentrators for cooking is limited by the need for frequent adjustments to the focal position and an inadequate approach to handling at the receiver. The Scheffler concentrator, the Scheffler-type solar concentrator, and the high-temperature concentrator [22,23] are all examples of fixed-focus solar concentrators that overcome this constraint.

The impact of numerous different solar still designs was studied by Chaurasiya et al. (2022) [24]. Among the several iterations of the concept, combining Fresnel lenses with a single-slope, single-basin passive solar still boosts output by 638.02%. When using a PV/T collector in conjunction with hybrid solar, the output is boosted by 370%. The most impressive increase is 676%, shown by a tubular design including a semi-circular trough filled with black cloth and coupled with an external reflector. A passive cascade single-basin single-slope solar system was found to be the most suitable design for residential use, while a wick paired with tubular solar was found to be the most productive design for industrial use.

Comparing competing technologies such as parabolic trough collectors (PTC) with Fresnel lens concentrators reveals unique benefits and things to keep in mind for each method of solar energy harvesting. Concentrators using Fresnel lenses, characterized by their lightweight and flat construction, are an effective way to focus sunlight onto a small focal point. This makes them especially appropriate for uses where portability and user-friendliness are essential, such as solar cooking. On the one hand, PTC systems use curved mirrors to direct sunlight onto a receiver tube that holds a heat-transfer fluid. Fresnel lens concentrators have the following benefits: ease of use, affordability, and appropriateness for small-scale applications. They work effectively in off-grid and decentralized environments. On the other hand, PTC systems are excellent at producing solar power on a big scale by effectively absorbing sunlight and turning it into energy [25,26].

Kasaeian et al. (2018) [27] conducted an in-depth analysis of trough and Fresnel-based solar thermal systems and presented their findings. Their study included the examination of trough and Fresnel lenses, broken up into three portions and labeled as experimental, hybrid research, and analytical–simulation efforts. In light of this, the results of the experiments were compiled into several tables, one for each of the aforementioned categories. The study pointed out a few holes in the existing research and offered some recommendations for further efforts.

To the authors’ knowledge, a rigorous assessment of Fresnel lens utilization, taking into account the most recent design advances, limits, obstacles, and modeling for implementing the Fresnel lens in various solar energy systems, has not yet been thoroughly discussed in the open literature. Therefore, the purpose of this study is to extensively discuss the design elements, materials, and auxiliary equipment of Fresnel lenses that are used as solar energy systems. In this regard, the acquired developments of Fresnel lenses and their limitations are also discussed. Fresnel lenses have a wide variety of uses; therefore, this paper focuses on detailing their applications and utilized methods of development. Accordingly, it is fair to admit that the findings of the current study would help direct future studies and pave the way for the widespread implementation of solar energy systems equipped with Fresnel lenses in a variety of settings.

2. Review Method

A systematic literature review is conducted to provide an overview of the studies that investigated the advancements in Fresnel lens technology across diverse solar energy applications such as solar stills, solar collectors, solar sterilization, solar cookers, and solar-pumped lasers. This makes it possible to provide an overview. The review is completed by critically examining the existing academic literature. Some of the databases that have been searched for academic, peer-reviewed content are ResearchGate, Google Scholar, Scopus, SpringerLink, and ScienceDirect. The keywords used to filter and find relevant articles were Fresnel lens, solar energy, solar still, solar cooker, solar desalination, solar sterilization, and solar-pumped lasers. Despite no restrictions on when the articles needed to be published, consideration was given to just include the most recent articles published between 2011 and 2023 to address the most cutting-edge research.

2.1. Fresnel Lens Technology in Solar Still Applications

Fresnel lens technology is one of the most significant developments in the field of solar still applications, transforming the method of turning polluted or salty water into drinkable supplies. The main reason for its importance is that the lens can effectively focus sunlight, which speeds up the evaporation process in solar stills. In this situation, there are numerous benefits to using Fresnel lenses. Because of these lenses, solar stills can be used in a variety of environments due to their more compact and lightweight structure. Higher freshwater yields result from improved evaporation efficiency brought on by the greater concentration of sunshine. Furthermore, the potential for larger-scale solar still deployment is enhanced by the economical nature of Fresnel lens technology. Nonetheless, in order to guarantee dependable and constant performance, it is imperative to recognize related difficulties, such as possible heat management problems and the requirement of ideal optical systems. To maximize their performance, though, issues like heat management and optical efficiency need to be resolved. Notwithstanding these difficulties, the advantages of Fresnel lens technology in solar still applications highlight its potential to reduce water scarcity issues and offer long-term freshwater production options. The following demonstrates the most relevant studies of the implication of Fresnel lens technology in solar still applications.

Abdelsalam and Abdel-Mesih (2014) [28] hypothesized and experimentally tested the augmentation of incoming solar radiation falling on the top glass surface of the still by focusing more solar radiation to warm the flowing feedwater to the solar still system. This was conducted to increase the amount of solar energy that could be harvested from the sun. The findings of the experimental investigation show that the incorporation of linear Fresnel lenses roughly tripled the production of distilled water and enhanced the efficiency of a solar still by approximately 68.76% when compared to a typical non-concentrating solar still. In addition, the use of linear Fresnel lenses approximately tripled the productivity of a solar still.

A solar-powered desalination system that makes use of Fresnel lenses was developed by Sales (2017) [29]. Contaminated salt water served as the sample for the experimental investigation, and the desalination process was carried out with the help of the apparatus that had been constructed. The sun concentrator, the solar still, and the condenser system were the three components that made up the desalination system. Acrylic plastic was used in the construction of the Fresnel lens, which served as an efficient solar concentrator. Solar stills built using bottles of a dark tint were efficient at collecting the sun’s rays and turning them into usable heat. The vapor could be successfully condensed by the system consisting of polybutylene and polystyrene, even if the temperature was at room temperature. The amount of time required for the evaporation of the salt water was found to be 293 s, and the angle at which the lens should be positioned was 36.420°. The quantity of salt water that was contained inside the solar still was directly related to the amount of condensate that was collected. The intended setup achieved a mean efficiency of 34.82% at its maximum possible level.

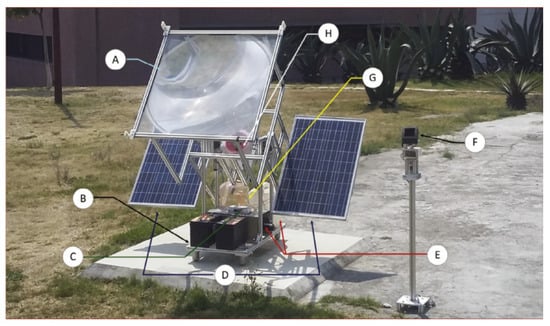

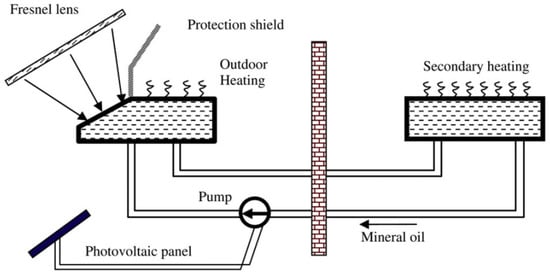

An active solar distiller was devised and constructed by Palomino-Resendiz et al. (2018) [30]. The distiller was made up of a Fresnel lens concentrator and an auxiliary photovoltaic energy collector, as depicted in Figure 1. These two components worked together to provide an electrical water-preheating process. A robotic system with three degrees of freedom was used to direct the orientation of the light concentrator and the photovoltaic system. This allowed the sun tracking and focus tasks of the concentration process to be completed successfully. The design made use of concurrent engineering methods in order to optimize the overall behavior of the system responsible for the collection of energy and the distillation of water. This strategy called for a number of distinct evaluations, including optical, structural, thermal, and dynamic modeling, all of which were ultimately meant to feed into the primary design. The system was then certified by a variety of tests pertaining to the process of energy collection and the quality of the water that was produced as a consequence, which led to an energetically independent and effective system capable of providing an alternative distillation process. The use of solar radiation was increased to its full potential when solar concentrators were equipped with Fresnel lenses. In comparison to passive methods, the solar distillation process (also known as water heating) can be substantially sped up by the thermal energy that is produced as a consequence.

Figure 1.

A hybrid distillation system in which (A) is the Fresnel lens, (B) are the batteries, (C) is the charge con-troller, (D) are the photovoltaic modules, (E) are the control system and electrical heater, (F) is the solar sensor, (G) are the tanks and pump, and (H) are the heat exchanger and focus system [30].

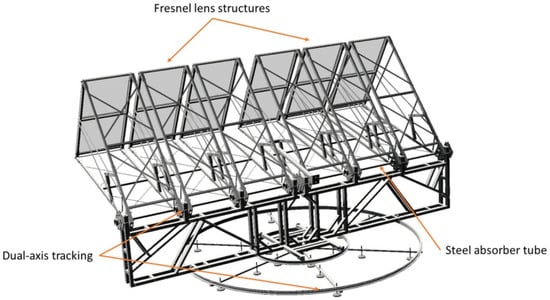

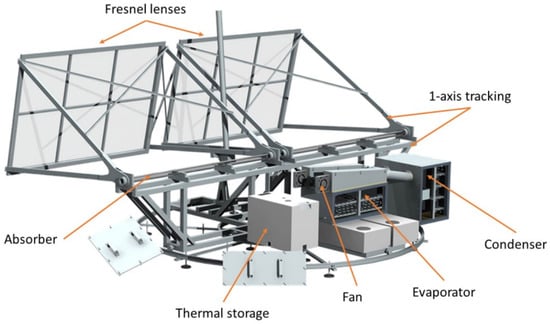

Sansom et al. (2018) [31] detailed the construction of a compact thermal desalination device that might be put to use in refugee camps or in other urgent settings, such as those that could arise in the aftermath of natural catastrophes. The steps of heat evaporation and condensation were separated for the purpose of increasing the process’ overall efficiency, and the process was driven by PMMA concentrating Fresnel lenses, considering the longevity of the PMMA lenses. It was estimated that the design would be able to generate up to 100 L of fresh water per day in MENA locations with DNI > 700 W/m2 during the course of 8 h, provided that the efficiency is at least 50%. Figure 2 and Figure 3 show the structures of the top-level CAD designs of the V1 prototype solar front-end and Version V2 desalination prototype, respectively.

Figure 2.

Top-level CAD design of V1 prototype solar front-end [31].

Figure 3.

Version V2 desalination prototype top-level [31].

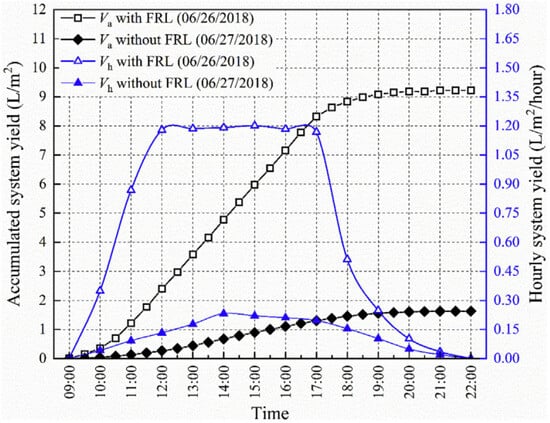

A refraction-based technique was developed by Mu et al. (2019) [32] for focusing sunlight to increase the amount of clean water that can be produced by a traditional solar still. The Fresnel lens was included in a single-basin, single-slope solar still in order to refract the incoming sunlight to a focal point that was consistently situated on the bottom of the basin (Figure 4). Two very significant and outstanding discoveries were made as a result of the Fresnel lens being implemented. The first thing that was seen was something called a high hourly productivity window, or HHPW for short. This was a period of time in which the proposed system generated clean water at a rate that was both very consistent and quite high. The occurrence of a phenomenon known as nucleate boiling, which is thought to dramatically boost the heat transfer coefficient for the phase change process of the basin water, was the second of these two occurrences. As a consequence of this, with the increased heat input and the high heat transfer rate, the utilization of the Fresnel lens achieved a significant increase in pure water production (L/m2/day) of approximately 467%, as well as a significant improvement in daily efficiency of approximately 84.7%, in comparison to a conventional system that did not make use of Fresnel lens, as can be seen in Figure 5. This was accomplished by an increase in the heat input. To investigate the effect that the operating parameters have on the performance of the system, a number of experiments were carried out. A linear and inverse association was found between the daily output of the system and the water depth (dw) in the basin. The use of forced air cooling was shown to have a good influence on system performance and resulted in an increase in distillate production. It was also discovered that raising dw and/or providing a forced air-cooling effect might benefit from increasing η.

Figure 4.

Picture of experimental setup [32].

Figure 5.

System accumulation and hourly yields without Fresnel lens [32].

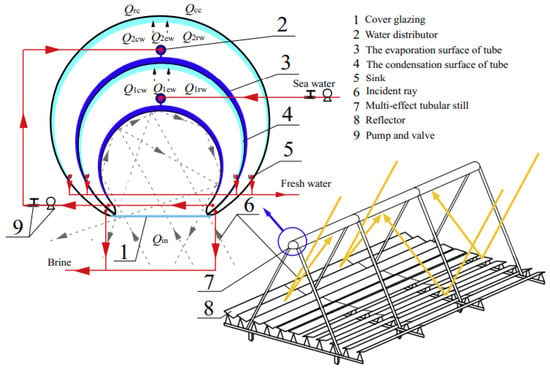

Gang et al. (2019) [33] introduced a multi-eccentric tube desalination system that was heated directly by a linear Fresnel reflector field to increase productivity (Figure 6). Within the confines of this particular system, solar radiation was sent straight to the desalination unit. In order to accept concentrated solar energy and transmit it to a falling water film, the inside wall of the tube was coated with an absorbing material and then placed within the cylindrical hollow. This created a receiver for the energy. An indoor experimental eccentric tube still was created and put through its paces under a variety of heating temperatures ranging from 400 to 1600 W in order to validate the performance of the system in a variety of contexts. The desalination apparatus utilized a two-layer casing construction that was designed to be conductive for the purpose of recovering lost heat. Important factors like vacuum temperature and energy supply were investigated while the machine was operating in its default settings. When the heating power was 1600 W, the findings assured that the maximum cumulative yield of the first effect was approximately 28.27 kg, while the maximum PR of the system reached roughly 1.41 and 1.07 kg when the system was operated at its maximum capacity. When using an evacuated tube solar collector, the results of the outdoor experiments revealed that the cumulative output of the unit was approximately 11.35 kg for 24 h, and the maximum performance ratio (PR) was approximately 2.88. This was determined using the collector. According to the submitted theoretical and practical study, a two-effect tubular desalination system for linear Fresnel reflectors with a capacity of 63.68 kg/d was suggested.

Figure 6.

Two-eccentric tubular still working mechanism and energy transfer schematic map [33].

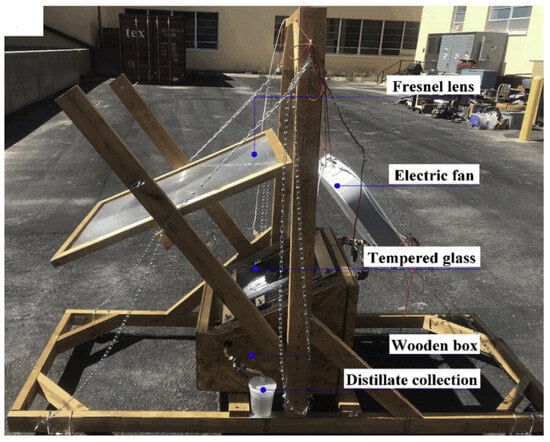

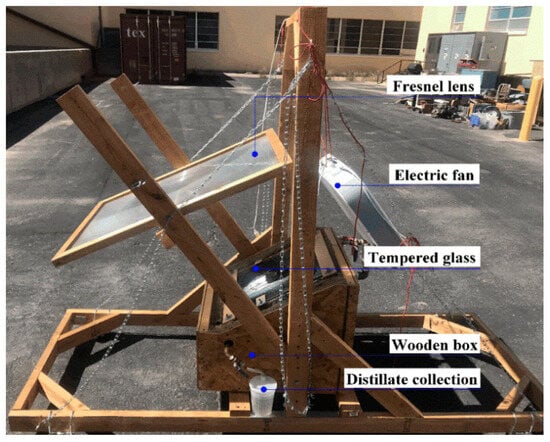

A theoretical model was developed by Johnson et al. (2019) [34] to predict the temperatures and productivity of a single-slope, single-basin solar still in the presence of an external solar boost. To verify the numerical model, certain experiments were carried out in the New Mexico area located at 32.32199° N and 106.7637° W (Figure 7). During the studies, a point-focusing Fresnel lens was used in order to maximize the amount of solar energy absorbed. It was discovered that by adding the Fresnel lens to the still, a large increase in the productivity of the still could be attained. Parametric research in which the water depth was varied showed that the Fresnel lens was more effective for use at greater water depths. In addition, the Fresnel lens has the potential to contribute to an increase in the solar still’s total efficiency.

Figure 7.

Solar still improved with a Fresnel lens [34].

Hashemi et al. (2020) [35] studied the effectiveness of a nanofluid-based solar still with a dual-axis solar tracker system (STS) from a number of angles, including freshwater production throughout the day and night, efficiency and cost during the day and night, and hourly performance. The proposed solar still had three Fresnel lens concentrators, an active automated STS, and a conventional solar still (CSS). Moreover, the impact of deionized water and MWCNTs/water nanofluid with two mass fractions of 0.15 and 0.3% on freshwater productivity were investigated to determine the best heat transfer fluid (HTF). The CSS with an internal condenser yielded 2180 mL/(m2 day), 560 mL/(m2 night), and 2740 mL/(m2 day) every day in total fresh water. However, the CSS combined with the STS and the Fresnel lens generated 5310, 1080, and 6390 mL/(m2 day) of fresh water daily, nightly, and altogether. Furthermore, the findings showed that compared to utilizing pure water as HTF, employing an MWCNTs/water nanofluid with a mass fraction of 0.3% increases fresh-water productivity by 31.6, 7.4, and 27.5%, respectively. The findings indicated that the daily average efficiency is raised by around 9.56 and 17.85% when utilizing the nanofluid with a mass fraction of 0.15 and 0.3%, respectively, compared to that of pure water as HTF.

Feedwater’s local temperature and evaporation rate were both increased using a Fresnel lens, as described by Choong et al. (2020) [36]. The feedwater was focused on using flat Fresnel lenses mounted atop a double-sloped passive solar still. The number of Fresnel lenses was altered in the trials, and the standard solar still was compared to the modified solar still. The feedwater was a saline solution with a concentration of 20,000 ppm. The study’s ultimate goal was to be put into practice so that freshwater may be produced in Malaysia’s normal climate. Compared to employing a single big Fresnel lens, combining two smaller ones increased the freshwater output per unit of solar irradiation by 39%. The generated water’s TDS level was 37 ppm, which is well within the safe limit established by the World Health Organization for use in human consumption.

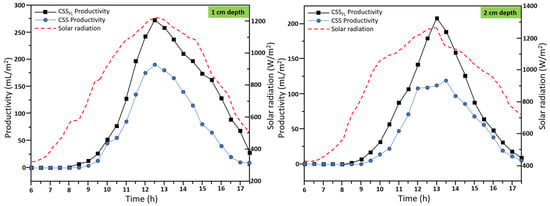

AlKtranee et al. (2020) [37] discussed how using the Fresnel lens method can improve the efficiency of a CSS. The authors tested the impact of Fresnel lenses on CSS production in Basra, Iraq (30.5258° N latitude and 47.7738° E longitude), in real-world circumstances. It was found that the CSS demonstrated a significant improvement in generating output when compared to the CSSFL, which is a manually adjusted traditional single-slop-basin type solar still. During the months of July and September of 2019, researchers examined the effects of daily sun radiation and temperature change on distillate production and the efficiency of both traditional and modified solar stills operating in 1 and 2 cm of salt water, respectively. According to Figure 8, the trial findings revealed that the CSSFL outperformed the CSS by 68.6 percentage points at 1 cm depth and by 59.5 percentage points at 2 cm depth throughout the month of July. Furthermore, the CSS and the CSSFL at 1 cm depth had a daily average thermal efficiency of 21% and 36%, respectively.

Figure 8.

July experiments: 1 and 2 cm depth productivity [37].

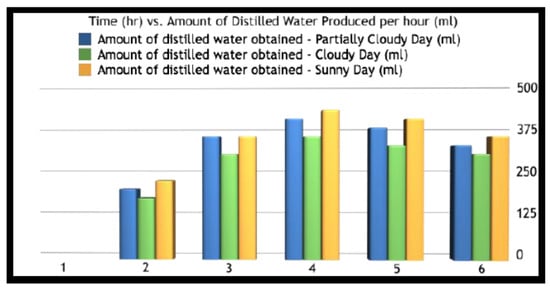

Johnson and Srinivas (2020) [38] used a Fresnel lens to concentrate sunlight and salt water, two resources that can be found almost anywhere, into steam. Water was heated in a copper tube using concentrated sunlight from a sun tracker, and the heat was transferred to the water via a condenser made of spiral tubing. LDR sensors and a high-torque servo motor helped to optimize sun irradiance. The “Adruino Uno” micro controller was programmed to make use of readings from the LDR sensors as they were being taken. The equipment was put through its paces in both the north and south directions on overcast, partly cloudy, and clear days. Figure 9 shows that the quantity of water distilled increased, decreased, and stabilized with increasing solar irradiation during three days with variable solar albedo. Even though the black paint on the copper boiler increased the output of distilled water, there was still noticeable heat loss. The system averaged a daily output of 1.6 L of water, with a boiler capacity of 3.18 L and a 345 mm × 345 mm rectangular Fresnel lens. A wider aperture lens and targeted copper duct insulation might further reduce heat loss from the system. Heat transfer efficiency might be improved by installing a baffle for the heater and fins on the condenser.

Figure 9.

Hourly distilled water production [38].

Conventional passive solar stills have been used for desalination in the tropical climate of Malaysia. Ho et al. (2021) [39] presented a refraction-based concentration of solar irradiation as a means to increase the performance of these stills. The performance of two passive, double-slope single basin solar stills connected with a Fresnel lens (FRL) and phase change material (PCM) was evaluated in terms of efficiency and productivity. Both prototypes exhibited a pattern that was comparable in terms of the enhancement of efficiency and production. The theoretical values of daily water yield were well represented by the experimental results, which indicated good agreement. The maximum water yield measured from a prototype paired with FRL was 3.19 L per square meter per day. When compared to designs that are more traditional, FRL increased the efficiency to 37%, up from 28%. The conventional still was compared to the experimental still, and the conventional still was found to have productivity that was 60% lower. The impact of PCM energy storage was the subject of further research, which was carried out. PCM, by itself, was able to steady the process while simultaneously increasing output. When compared to a traditional still, the FRL-connected PCM system achieved a level of efficiency that was 32% higher.

A bubbling humidification–dehumidification (HDH) desalination system heated directly by focused sunshine was reported by Xiao et al. (2021) [40]. Its simple construction and operation were increased by sending focused sunlight straight into a bubbling humidification chamber, thereby eliminating the need for a circulation pipeline and solar receivers. A Fresnel lens solar concentrator, a humidifying chamber, and a dehumidifying chamber made up the HDH system. The theory of operation and architectural layout of the bubbling chambers were discussed. To heat the saltwater directly, a cylindrical Fresnel lens was employed to concentrate sunlight inside the humidification chamber. To provide enough heat and moisture transmission, bubbles were generated underwater when air escaped through the perforated wall of the submerged pipe. To validate the design and investigate the performance characteristics, experimental testing was conducted under various situations. The findings demonstrated that at peak sun irradiation of 980 W/m2, freshwater production peaked at approximately 1.24 L per hour per square meter. Under sunny circumstances in Beijing in October, the average thermal efficiency approached 69%, allowing for cumulative production of 5.61 L/day/m2. Additionally, in steady-state conditions, the average thermal efficiency was approximately 71%. Due to the efficient heat and moisture transfer increase provided by direct solar heating and bubbling, the proposed bubbling HDH desalination system offered comparatively greater freshwater production.

A Fresnel lens was used in an experiment by Bhambare et al. (2021) [41] to improve the performance of a standard single-slope solar still (SSSS) with a single basin. The effort attempted to improve the efficiency of a traditional single-basin SSSS without compromising the system’s usability. The device’s ease of use is especially welcome in Oman’s rural areas. The current device used a Fresnel lens that could be adjusted in place of a standard single-basin SSSS. This modification allowed our institute to conduct tests both with and without the Fresnel lens. The experimental apparatus was built from readily available materials and oriented north to south. After being set in place with the Fresnel lens and frame in the morning, they stayed there all day without being moved. The investigation was conducted with a constant water depth in the basin of 0.02 m. Single-basin SSSSs with Fresnel lenses produced 3–3.5 times as much distillate as conventional SSSSs. On the whole, the system was nearly 32.19% more efficient than the usual method.

Anbumeenakshi et al. (2022) [42] used a Fresnel lens to focus solar energy into a location in order to raise the local temperature of the feed water and the pace at which it evaporated. In the experimental investigation, salty water was used as the sample, and desalination was performed on it using the apparatus that had been constructed for this task. The use of Fresnel lenses in conjunction with copper rods resulted in an improvement in the efficiency of the solar-gathering process. Specifically, the Fresnel lens was used to concentrate and make the most of the solar energy that fell onto the copper plate. The heat from the copper plate was then transferred to the water tank via a copper coil, and the resulting steam was then condensed. The water that was desalinated after being condensed was collected separately.

Table 1 shows a summary of the conducted studies on Fresnel lens application in solar stills.

Table 1.

Outline of studies on Fresnel lens technology in solar stills.

2.2. Fresnel Lens Technology in Solar Collectors

A paradigm shift in the way solar energy is harnessed for many uses is provided by Fresnel lens technology, which is at the cutting edge of advancement in solar collector applications. Here, Fresnel lenses play a crucial role because they effectively focus sunlight onto a narrow focal point, considerably raising the temperature that solar collectors attain. There are several benefits to incorporating Fresnel lens technology into solar collectors. These lenses make it possible to create a more efficient and economical design, making it easier to concentrate sunlight and thus capture energy. The higher temperatures reached improve the solar collector’s total effectiveness, making it a more powerful and long-lasting source of heat for a variety of uses, including home heating and industrial activities. The following discusses the most relevant studies of the implication of Fresnel lens technology in solar collector applications.

In order to efficiently and uniformly illuminate 10 × 10 mm2 HIT (heterojunction intrinsic thin layer) silicon solar cells, Jang et al. (2014) [43] presented a new design for 50 × 50 mm2 medium-CPV (concentrated photovoltaic) lenses that generate linear-type Fresnel patterns. The scientists optimized the lighting design tools in Light Tools to achieve an optical efficiency of 85~87%. In order to create CPV modules, lenses are being manufactured and evaluated for their practical optical efficiency.

A model for a new linear Fresnel lens collector with dual-axis tracking capabilities was provided by Perini et al. (2017) [44]. The primary goal was to analyze this technology experimentally and theoretically to identify its performance curve. The mathematical model incorporated the concentrator’s optical model and the receiver pipe’s heat transfer model. The effectiveness of this instrument was confirmed by experimental data gathered using a prototype set up in Bourne, UK, as a proof of concept. The collector’s efficiency was determined for operation in the temperature range of 40–90 °C. The findings indicated that the collector can only operate at an overall efficiency of less than 20%. The lens system’s optical losses accounted for 47% of the total energy lost. The Fresnel lenses caused these effects by a combination of absorption, reflection, and diffraction. Since only moderate temperatures (up to 90 °C) were at play, thermal radiation and convection only contributed to 6% of the total.

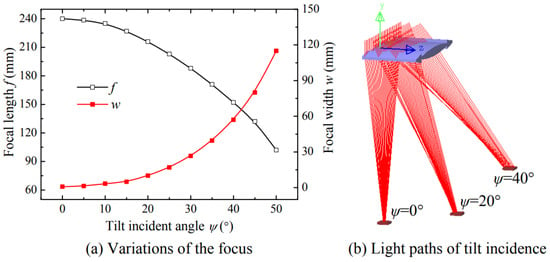

Ma et al. (2020) [45] described a zoomable Fresnel lens (ZFL) that uses tensile deformation as a potential solution to the issue of the focal length being shorter due to tilted sun incidence. The authors designed and evaluated the ZFL sample, which was 95 mm wide and had a focal length of 240 mm. It was discovered that there would be a 75% increase in the focal length if the breadth of the ZFL was lengthened by 30%, as illustrated in Figure 10. Additionally, the variation was shown to be linear. During the zooming process, the focus may maintain its position on the focal plane created for it even when the tilt incidence angle shifts from 0° to 40°. In the case of the receiver with a width of 10 mm and an elongation of 20 mm, the minimum interception coefficient under normal incidence was 85%. According to the results of the heat collecting test, the ZFL should have begun to stretch after the tilt incident angle reached 25°. The maximum elongation of 20 mm can accommodate a tilt incidence angle of approximately 50°, which is 2.5 times more than the ZFL in its undeformed state. In addition, the expansion of the ZFL’s illumination area that occurs during the stretching process may effectively compensate for the energy that is lost due to the deformation process. ZFL often considerably improves the allowable tilt incident angle by approximately 2.5 times, which results in the linear-focusing Fresnel lens having roughly 6.7 h of effective working time each day.

Figure 10.

Undeformed ZFL focus variations [45].

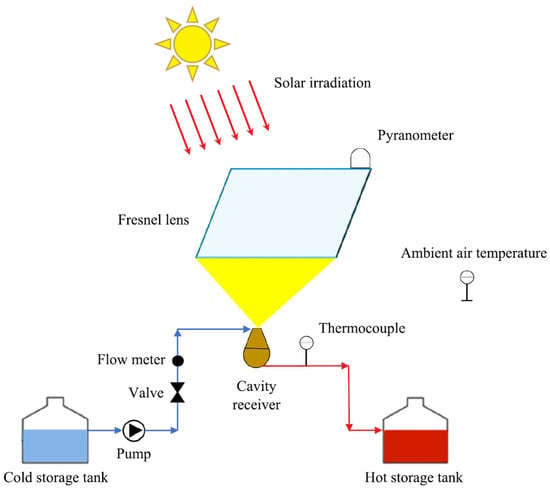

Kaddoura and Zeaiter (2019) [46] investigated the design of a solar cavity receiver using a mathematical model that was constructed to assess the thermal performance and seasonal energy storage of the receiver. In order to investigate how heat is transferred inside the improved shape, a computational fluid dynamics (CFD) simulation for fluid flow and radiation transport was carried out. The findings of the modeling were tested experimentally (Figure 11) in outdoor conditions while utilizing eight different flow rates for the heat transfer fluid and four different sun irradiation levels ranging from 500 to 1000 W/m2. With the help of this model, the authors were able to make accurate forecasts regarding the thermal efficiency of the receiver, the outlet temperature of the heat transfer fluid, and the amount of thermal energy that was stored throughout each month of the year. The investigation revealed that the laboratory-scale Fresnel lens has the capability to cause a rise of 200 °C in the temperature of the heat transfer fluid. During the winter and summer months, respectively, it is anticipated that the quantity of thermal energy stored would vary between 2 and 7.2 kWh/m2 per day, with a thermal efficiency that will range between 93.6% and 97.2%.

Figure 11.

Schematic of experimental setup prototype [46].

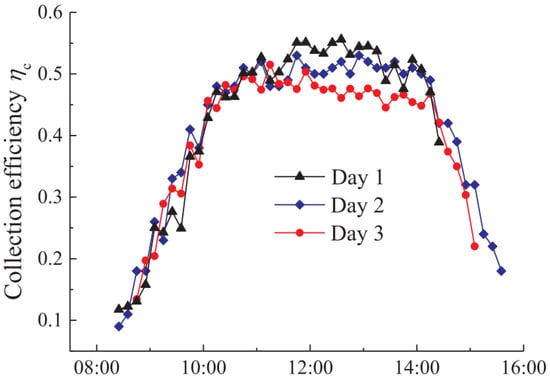

To obtain the optimal form of the Fresnel lens, Ma et al. (2020) [47] introduced a revolutionary technique that simplifies refractions on prisms. To streamline things, the authors utilized a single refraction on the top surface instead of two refractions on the top and bottom. The optimal Fresnel lens form was described by a differential equation. It was demonstrated that the differential equation’s unique solution is a collection of confocal curves. In particular, when the entire refracted angle was less than 30°, the ideal curves were close to their basic circle; therefore, it was permissible to utilize the basic circle as the profile of the Fresnel lens. Then, a Fresnel lens was created after carefully planning its construction. Modeling and experimentation were mostly used to analyze the focal length change during the tilt incidence. The location of the receiver can be raised, and a straightforward mirror secondary reflector can be added, resulting in an enhanced effective tilt incidence angle of 7° to 32°. The experimental data demonstrated that the Fresnel solar concentrator performs optimally between the hours of 10 a.m. and 1 p.m. As can be shown in Figure 12, the collection efficiencies were around 0.53, 0.48, and 0.44 at stable output temperatures of 125 °C, 150 °C, and 170 °C, respectively.

Figure 12.

Efficiency variations [47].

In the Chinese solar greenhouse’s unused space, Wu et al. (2020) [48] installed a cylindrical Fresnel lens concentrating photovoltaic/thermal (CPV/T) system. Between the summer and winter solstices, the mechanism adjusts such that the sun’s rays always strike the lens at a right angle. This row of Fresnel lenses simply blocks some of the direct light coming in from the north side of the greenhouse and does not interfere with the plants’ photosynthetically active radiation. The percentage of non-planting area used was 18.2%. When the axial incidence angle was within 10°, optical modeling showed that the acceptance rate had no impact. Cylindrical Fresnel lenses have superior focusing abilities over their elliptical and parabolic counterparts. A concentrating photovoltaic/thermal system using a gallium arsenide concentrating cell as the receiver was tested in real-world conditions. The test findings suggested that under clear-sky circumstances, the highest efficiency of thermal and electrical power was approximately 55%, while the greatest efficiency of power production was around 18% between 11:00 and 13:00.

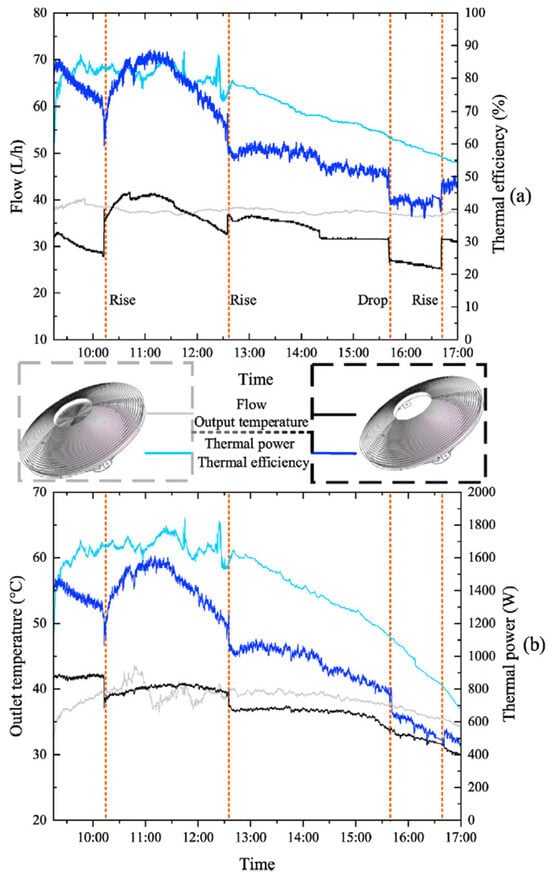

An annular Fresnel solar concentrator with a circular Fresnel lens (AFSCFL) was created and investigated by Liang et al. (2021) [49]. The AFSCFL primarily comprised an annular Fresnel solar concentrator (AFSC), one circular Fresnel lens, and a receiver (Figure 13). A set of annular mirrors was used to create the AFSC. In the exact middle of the AFSC sat the circular Fresnel lens. The AFSCFL and the AFSC were modeled in studies of simulation. The findings indicated that the AFSCFL’s receiver experienced 9.49%, 10.70%, and 9.49% more solar power, average radiation, and maximum radiation, respectively, compared to the AFSC. In addition, a test bench was built to examine the AFSCFL’s sun-collecting efficiency. Experiments with varying and constant flows through the AFSC and AFSCFL were conducted for comparison. The findings demonstrated that the AFSCFL’s thermal efficiency might be 20% greater than that of the AFSC under low solar radiation conditions. The AFSCFL and AFSC both achieved equal thermal efficiencies under the high solar radiation situation, as depicted in Figure 14.

Figure 13.

Experimental AFSCFL pictures [49].

Figure 14.

Thermal performance of (a) AFSC and (b) AFSCFL constant-flow studies [49].

To avoid the need for beam splitters or nanofluids, Kiyaee et al. (2021) [50] created a polymethyl methacrylate spectral splitting Fresnel lens (SSFL) for linear concentration. This lens focuses only the desired portion of the spectrum onto the cell while diffracting the rest. At a concentration factor of 10×, several SSFLs were evaluated to focus radiation with wavelengths ranging from 400 to 1150 nm to 800 to 1150 nm onto a silicon solar cell. Comsol multiphysics simulations were used to describe optical and heat transmission, and the resulting models were then checked against published experimental data. Assumed factors led the authors to choose an SSFL with a 600–1150 nm spectral range and an optical efficiency of 81%, which not only boosted weighted energy production by 14% but also decreased cell temperature by 48 °C.

Beltagy (2021) [51] demonstrated the optical optimization of a Fresnel-type solar prototype (Figure 15). Parametric research and sizing calculations were used to assess the effects of the glass and the receiver’s shape on performance, optimizing the system accordingly. By examining the data in the form of tables and curves, the authors were able to figure out how to set up our solar prototype in the most efficient way possible. Theoretical and experimental results were improved with this setup. Several LFR-based thermal power plants have been developed and sold on the strength of this ideal layout. In addition, various numerical models have been checked and double-checked with the use of sophisticated and trustworthy measurement tools. Glass removal increased yearly optical efficiency by 5.6% (from 40.49% to 42.75%), according to estimates. Furthermore, an increase in the number of absorber tubes from one to two increased the yearly optical efficiency by 15.5% (from 40.49% to 46.79%).

Figure 15.

Geometrically modeled arrangement [51].

The first large-scale Fresnel lens solar collector field was studied by Jensen et al. (2022) [52]. In Lendemarke, Denmark, 144 solar collectors with dual-axis tracking provided energy for the local district heating network. The solar collector field’s thermal efficiency was measured using a quasi-dynamic test setup. Heat losses from the collectors were found to account for 50% of the overall heat losses of the solar field, and peak efficiency was found to be 11% lower than with a brand-new collector. The soiling of the collectors after a year of outdoor usage without cleaning was the primary reason for the drop in peak efficiency. In addition, the system’s yearly performance was calculated with the use of a TRNSYS simulation model confirmed using measurement data. In 2020, at an output temperature of 90 °C and an input temperature of 50 °C, heat production was 373 kWh/m2 (relative to aperture area). The effect of changing the ground cover ratio, the average collector temperature, and the soiling level on the yearly heat production were also analyzed. In contrast to flat-plate collectors, the sensitivity analysis demonstrated that the collectors’ ability to generate heat at temperatures over 100 °C was marginally unaffected by variations in the mean collector temperature.

Without the need for mechanically monitoring the sun, Gupta et al. (2022) [53] suggested and experimentally proved the use of a combination of two big Fresnel lenses and six segmented mirrors to concentrate sunlight inside a shared region. The suggested technology was put to use to efficiently heat water using solar thermal power. To maximize sunlight collection in the morning, at midday, and in the evening, two lenses were positioned at an angle that put them in direct line of sight with the sun. The receiver unit was also exposed to direct sunshine throughout the day since there is enough of a height difference between the Fresnel lenses and the receiver unit to prevent any shadowing. The effectiveness of the solar thermal system was considerably enhanced by the daytime concentration of sunshine. This is because, with the aid of the suggested system, the solar thermal receiver was not only exposed to focused sunlight but also direct sunlight. The fluid in the common space was heated quickly by a thermal receiver device installed in the room. The suggested concentrating system on the receiver unit was evaluated, along with the system design in ZEMAX employing ray optics and the experimental analysis of direct and collected incoming solar radiations. A single big Fresnel lens and segmented mirrors were compared to the proposed system’s thermal performance. When compared to a simple focusing lens, the suggested system’s immediate thermal efficiency was much higher, by as much as 20%.

The design parameters of Fresnel lenses were investigated and simulated by Bachhav et al. (2022) [54]. Operating in varying outside temperatures was considered early in the design process. Next, the effect of the focal length shift was simulated and analyzed. It was thought that each Fresnel lens groove has a different wavelength design to mitigate the chromatic aberration behavior caused by the dispersion connection between the refractive index of the material and the wavelength. The best solar spectrum was between 0.54 m and 1.04 m, and the golden wavelength technique was utilized to identify the optimal wavelength design in this region. The findings were promising. The flux distribution and dispersion of the sun spectrum were both enhanced by the strategy of picking various wavelengths for each concentric ring.

Ahmadpour et al. (2022) [55] focused on maximizing the efficiency of the developed linear Fresnel reflector solar concentrator (LFRSC). A secondary reflector should direct the reflected light toward the absorber tube after the main mirrors have been bent slightly to increase focus. Consequently, a secondary reflector with a new construction composed of two simple reflectors was presented. More than 97% accuracy in modeling LFRSC performance was achieved with the application of a robustness approach based on Monte Carlo Ray Tracing (MCRT) for the simulation of LFRSC behavior. Next, the authors examined the pros and cons of three distinct situations, including mini-, mid-, and mega-optimization modules. Then, the enhanced optimization of prey by predators algorithm (IPPOA) was presented and implemented. Although comparable results were shown when using different approaches on the small-size module, the efficiency achieved using the IPPOA was 47.13%. The IPPOA achieved an efficiency of 42.5% for medium-sized organizations, which is lower than the efficiency achieved by small- and large-sized organizations. The larger case’s mirrors were also wider than those of small casesThe total IPPOA efficiency in the third optimization scenario was 47.88. Therefore, case three (fully optimized) was regarded as the high-efficiency model, whereas case one (small size) was selected as the cost-effective model.

The latest iteration in a series of optimizations performed on a solar prototype using Fresnel-type concentration and the new form proposed by Beltagy (2023) [56] constitute a double parabolic concentrator (DPC). The factors that affect the prototype’s performance were studied using an optimization approach. The purpose of this experiment was to compare the efficiency of several solar prototypes. To this end, a parametric study and optimization were conducted to assess the impact of altering the prototype’s focal length, aperture, spacing, and tube position, as well as the performance of the secondary reflector, the double parabolic concentrator (DPC). Monte Carlo ray tracing (MCRT) was used to describe the solar field’s many characterizing parameters. The ideal DPC is not a double parabola, as shown by the optimization results. Furthermore, the new form of DPC provided the optical efficiency of the receiver, which approached 100%, meaning that all photons which pass the glass are absorbed by the tube, and a power increase of 10% to 13% was conducted compared to the current form.

An LFL-CPC (linear Fresnel lens coupling compound parabolic concentrator) was investigated by Zhang et al. (2023) [57]. Using the linear Fresnel lens theory and the Monte Carlo ray tracing (MCRT) technique, the LFL-CPC surface structure was optimized. The experimental testing of the LFL-CPC’s laser showed that its light-gathering performance agrees with its theoretical blueprint. The LFL-CPC has better weather adaptation than an S-CPC (standard CPC, S-CPC) because it has a wider reception angle and can concentrate sun beams efficiently across all incidence angles. The LFL-CPC is superior to an S-CPC in terms of beam radiation collecting efficiency and duration, with a maximum effective daily increase of 36.1% in June. Furthermore, an LFL-CPC is more favorable to the long-term stable operation of the non-imaging concentrator integrated system because the energy flux distribution on the absorber is more uniform than that of an S-CPC, and the peak value of energy on the absorber surface is lower than that of an S-CPC.

In order to design the best Fresnel lenses for solar photovoltaic modules, Antonov et al. (2023) [58] created a mathematical model method for plane-focusing microprismatic lenses. Specialized plane-focusing lens concentrators were the intended target of the computational set. To facilitate their mass production by thermo-pressing, the optical and geometric properties of these microprism lens concentrators were fine-tuned. Our simulation findings show that the diamond micro-cutting process was used to make samples of customized lens concentrators from optical polycarbonate. Data from experiments comparing these materials’ optical and lighting properties to those predicted theoretically were in perfect agreement. With a smaller focal distance, these lenses have lower overall light transmittance.

Table 2 presents a summary of the associated studies of Fresnel lens technology in solar collectors, highlighting the most important findings.

Table 2.

Outline of studies on Fresnel lens technology in solar collectors.

2.3. Fresnel Lens Technology in Solar Sterilization

Fresnel lens technology has emerged as a key player in solar sterilization applications, offering a cutting-edge method of using sun radiation to disinfect. The key to its significance is the great sunlight concentration these lenses provide, which makes it possible to sterilize water and medical supplies quickly and effectively. There are many compelling reasons to use Fresnel lens technology in solar sterilizing. Sterilization machines may now be designed to be smaller and more portable thanks to these lenses, which can be used in a range of environments, particularly those with limited resources or in distant locations. Furthermore, the higher intensity of concentrated sunlight improves disinfection by guaranteeing the removal of dangerous bacteria. Moreover, the use of Fresnel lenses in solar sterilization guarantees that medical devices and water are effectively disinfected. The most pertinent research on the use of Fresnel lens technology in solar sterilizing applications is covered in the following sections.

In 2023, Shahid et al. [59] assessed the optically active desalination method. To keep the water reservoir at a constant temperature during desalination, the proposed system rotated the light funnel axially independent of incoming light intensity. Optimizing algorithms utilizing the least-squares criteria were used to design control systems for the three-axis movement of Fresnel lenses, which significantly decreased tracking error. Using a copper slab and a specially designed nano honeycomb layer, the water reservoir was kept at a constant temperature of 250 °C. On top of the reservoir, a textured glass surface helped cut down on sun reflections. Top Fresnel lenses focus light rays, while a parallel beam of focused light from a bottom Fresnel lens enters the reservoir and strikes a copper slab, evaporating the desalinated water and keeping the water supply pure.

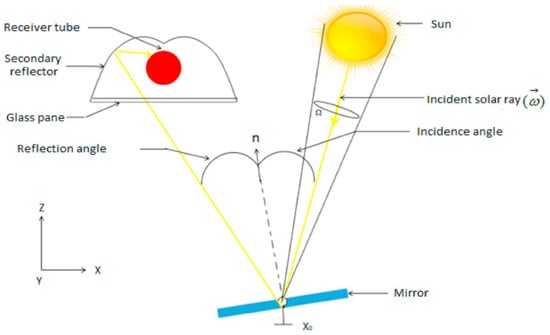

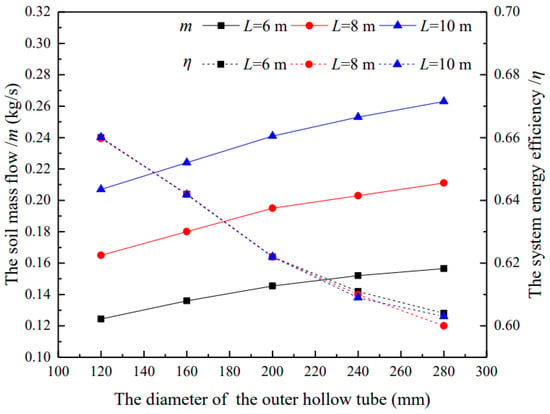

To continuously sterilize soil, Zhao et al. (2018) [60] developed a regenerative solar soil disinfection system using manufactured Fresnel lenses. At the outset, the system’s framework and underlying logic were presented. Second, the authors used the experimental and optical simulation results to investigate the optimal receiver placement and optical system performance. Third, MATLAB, a simulation program, was used to examine the system’s thermal performance in light of the system’s thermodynamic model. According to the findings, the light acceptance rate of the Fresnel lens-based regenerative solar soil sterilization system was more than 0.99 when the sun’s zenith angle was within 2° and the azimuth angle varied between −35° and 35°. Furthermore, the effectiveness in the 6-m-long tube was 64.2% when the maximum disinfection temperature was 85 °C and sun irradiation was 1000 W/m2. The disinfection soil mass flow was 1.36 kg/s. When I = 1000 W/m2, Do = 160 mm, and Tin = 298 K, as shown in Figure 16, the trend of the soil temperature fluctuation is essentially the same under the varied lengths of the tube. The soil temperature increased as long as the outer hollow tube was used to heat it, but the rate of increase decreased.

Figure 16.

The soil temperature in the outer and inner hollow tubes varies with system length when I = 1000 W/m2, Do = 160 mm, and Tin = 298 K [60].

Ige et al. (2021) [61] designed a low-power decontamination system for use in the therapeutic setting in a rural area. Fresnel lenses in a multi-baffle multi-pass chamber were used to boost radiation power in the developed sterilizer. Using Fuzzy logic control, the authors were able to implement a smart ventilation plan that kept the chamber at a consistent pressure and temperature. The correctness of the Fuzzy logic controller was tested by simulation using Simulink after it was written in MATLAB using the toolbox for fuzzy logic. The device’s performance analysis revealed that it could achieve a sterilization temperature of 169.69 °C under ideal conditions (an ambient temperature of 27 °C and a solar radiation intensity of 1362 W/m2), well within the range for effective dry heat sterilization to occur (140 to 170 °C). The results of the constructed sterilizer showed that a dry air sterilizer controlled by fuzzy logic could reach a temperature inside the heating chamber of less than 150 °C, which might be appropriate for sanitizing previously used surgical equipment.

Fresnel lenses were utilized to enhance the sun disinfection process by Bathusha and Rajapreetha (2021) [62]. The sun disinfection process can be sped up with the use of a Fresnel lens by increasing the temperature dramatically. A setup Fresnel lens was created to carry out the disinfecting operation. By aiming the sun at the water sample for a certain amount of time, the thermal efficiency can be calculated. To calculate thermal efficiency, the authors considered factors like fluid temperatures and collector area. The thermal efficiency was used to calculate the pasteurization temperature. SODIS and the Fresnel lens method were used to disinfect the water. The bacteria in the samples were identified using a standard plate count assay. According to the findings, a Fresnel lens with a finer groove pitch performs better. In order to maximize the decrease of microorganisms, a Fresnel lens with a finer groove pitch is preferable. The Fresnel lens system managed to reach 45 °C, the ideal temperature for pasteurization. Comparatively, the SODIS procedure only removes 68% of microorganisms, whereas the Fresnel lens removes 100%.

The solar autoclave designed and modeled by Mohsen et al. (2023) [63] can create high-temperature wet steam under pressure (6 bars at 160 °C) from a cylinder of clean water for around 22.5 min during testing intervals. A square spot Fresnel lens (31 cm × 31 cm) and an oval reflecting dish (100 cm wide by 90 cm deep) focus the sun’s rays onto the cylinder, heating its inside. This steam then served as a heating element, exchanging heat with the water contained inside the sterilization cylinder to produce sterilization steam. Seven to ten minutes were needed to generate sterilization steam in the sterilizing drum, with that steam reaching 2.1 bars and 121 °C; this meant that it took about half an hour to reach sterilization conditions. Adding another fifteen minutes for the sterilization cycle brought the total time to 45 min. Based on measurements taken every hour starting at precisely 10:00 a.m., the connection between the internal temperature change and time is shown in Figure 17. The recorded period began with a gradual increase in temperature, followed by a period of rapid warming.

Figure 17.

Heat absorber cylinder temperature [63].

Table 3 shows the related studies of the utilization of Fresnel lens technology in solar sterilization.

Table 3.

Outline of studies on Fresnel lens application in solar sterilization.

2.4. Fresnel Lens Technology in Solar Cookers

The use of Fresnel lens technology in solar cooking represents a significant development in environmentally responsible and sustainable cooking methods. These lenses provide a revolutionary approach to using solar energy for cooking because of their ability to condense sunlight optimally, which raises cooking temperatures and speeds up food preparation. This not only increases the solar cookers’ efficiency in general but also makes them more useful for a larger variety of cooking duties. Furthermore, the mobility of solar cookers with Fresnel lenses is improved by their lightweight and compact design, which makes them appropriate for a variety of environments, especially in remote or resource-poor locations. By lowering dependency on non-renewable energy sources, Fresnel lens technology in solar cooking not only advances sustainability but also tackles environmental issues related to traditional food preparation techniques. All things considered, the incorporation of Fresnel lens technology into solar cookers represents a significant advancement in the promotion of affordable and sustainable energy sources for global cooking demands.

Figure 18 shows a solar cooking stove prototyped by Valmiki et al. (2011) [64] that employs a huge Fresnel lens to concentrate sunlight. Fresnel lenses are inexpensive and readily accessible, and this technique illustrates their great safety and efficiency for solar cooking and heating. The focal point of the lens is where the heat from the stove is absorbed permanently. The Fresnel lens is rotated in both the zenith and azimuth directions by the sun tracking system. Two rotating arms keep the lens in place while the platform it rests on rotates both vertically and horizontally to achieve tracking. The arms rotate in the zenith plane to follow the sun’s path while the platform rotates in the azimuth plane. Low heat loss and excellent energy efficiency are made possible by solar tracking, which enables the Fresnel lens to focus sunlight on a stationary, compact heat-receiving region. The heat is utilized to keep a cooktop surface at temperatures as high as 300 °C, making it suitable for a wide variety of culinary applications in a way that is both safe and easy to use.

Figure 18.

Solar thermal loop schematic [64].

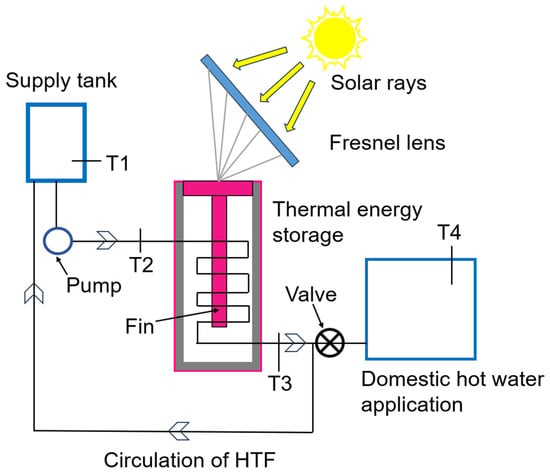

Senthil and Cheralathan (2012) [65] used a Fresnel lens to directly heat the thermal mass via conduction heat transfer through a fin to a PCM for solar thermal energy storage, as depicted in Figure 19. Many factors were considered by the research team, including the optimal mass flow rate of heat transfer fluid, various configurations of fins, and heat transfer tubes (HTF) for enhanced heat transfer throughout the overall system, as well as the design of solar storage and the orientation and accurate tracking of Fresnel lenses. Paraffin wax was shown to be one of the potential PCM choices for residential applications in the practical temperature range of 50 °C to 70 °C by its thermal behavior during charging and discharging operations. The temperature response of the multiple-pass HTF tubes is 2–5% quicker, although the temperature decrease is only slightly more dramatic than that of the single-pass HTF tube. Because of the phase shift along the axis of the container, PCM’s temperature behavior was not constant throughout the container’s interior. Since melting occurs more rapidly than the discharge procedure, there is a need to boost the efficiency of the retrieval process.

Figure 19.

Fresnel lens solar thermal energy storage [65].

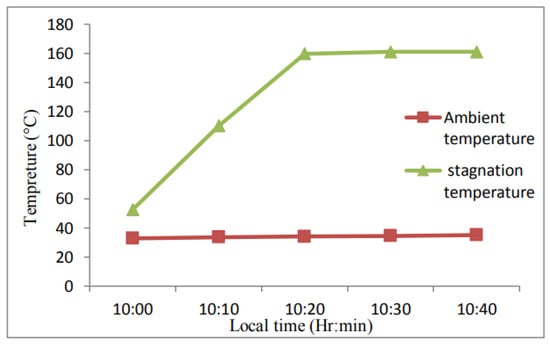

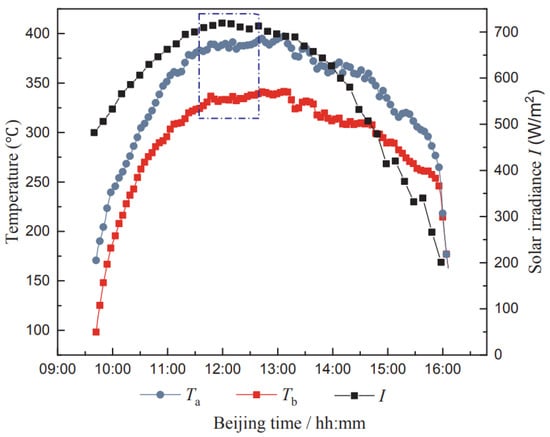

Using a curved Fresnel lens as the concentrator, Zhao et al. (2018) [66] created a revolutionary portable solar cooker. The meal may be heated using the solar cooker’s ability to concentrate sunlight onto an evacuated tube collector. Cooking temperatures can be increased, and time spent in the kitchen reduced thanks to the high concentration ratio and the ability to manually follow the sun in both the zenith and azimuth angles. A software model of the system’s optical performance was built, and the system’s heat transfer model was shown. The results showed that the greatest average temperature of the system without load may reach around 361 °C when direct irradiance is I = 712 W/m2. Additionally, the solar cooker’s efficacy was evaluated using four distinct 0.5 kg sample items, including sweet potato, pork (all lean), yam, and radish. Beijing, located at 116.3° E and 40° W, was the site of all the tests. During the no-load phase of testing, the ambient temperature was 0 °C, and the wind speed was about 2 m/s. Figure 20 depicts the time-varying irradiance and temperature of the working medium. Increasing irradiance led to a corresponding increase in air temperature while decreasing irradiance led to a corresponding decrease in air temperature.

Figure 20.

Irradiance and temperature of the working medium vary with local time [66].

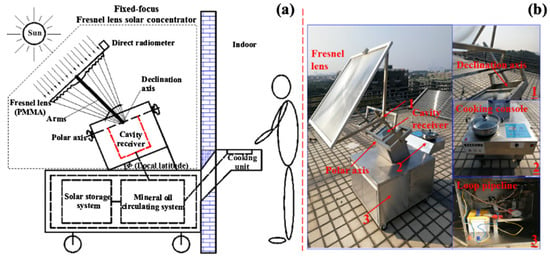

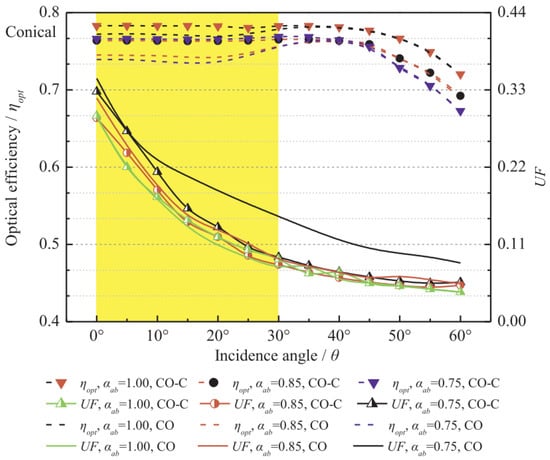

Wang et al. (2019) [67] presented a solar cooker with a fixed-focus Fresnel lens solar concentrator and a cavity receiver (Figure 21). To improve the system’s optical efficiency, a fixed cavity receiver equipped with a bottom reflecting cone was employed. Cavity receivers with a spherical, cylindrical, or conical bottom reflective cone have average optical efficiencies of 72.23%, 68.37%, and 76.40%, respectively, whereas conventional cavity receivers with the same shape have average efficiencies of 68.49%, 31.91%, and 74.61%, respectively. The earlier three had large increases of 3.74%, 36.46%, and 1.79%. Furthermore, compared to the other three angles, the cavity receiver with a bottom reflecting cone angle of 90° was able to store more of the energy that is sent from the concentrator. Optical efficiency can be enhanced by increasing the reflectivity of the bottom reflecting cone and the absorptivity of the surface of the cavity receiver. As can be seen in Figure 22, the optical efficiency and flux uniformity are primarily affected by the absorptivity of the surface of the cavity receiver and the incidence angle of concentrated sunlight.

Figure 21.

(a) Schematic and (b) photograph of fixed-focus Fresnel lens solar cooker [67].

Figure 22.

Cavity receiver surface absorptivity affects fixed-focus optical performance. A Fresnel lens solar concentrator/conical cavity receiver [67].

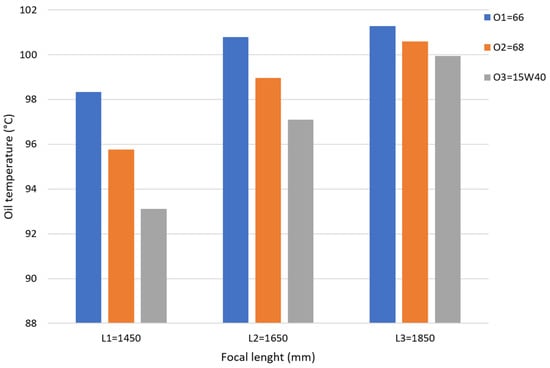

The solar Fresnel lens system was created by Dere et al. (2019) [68]. The FLSC system, which uses a Fresnel lens to concentrate sunlight, has a heat exchanger, a cooking pot connected to a fluid pipe network, and insulation installed on both of its mirrors. Research on a solar Fresnel lens system with two axes was carried out with the intention of using it for cooking. Water temperature in a cooking pot was investigated as a function of many variables, including flow rate, focal length, and oil type. Lens focal lengths of 1450, 1650, and 1850 mm, oil types of 66, 68, and 15W40, and oil flow rates of 0.5, 1, and 1.5 lpm were the options. Tea, rice, eggs, mung dal, tur dal, and chicken were among the foods tested, and their individual cooking times ranged from 20 to 75 min. Figure 23 displays the results of an optimization process that determined the optimal oil temperature (108.60 °C) and water temperature (102.261 °C) for optimum efficiency in a cooking pot.

Figure 23.

Oil type and lens focal length affect cooking pot temperature (°C) [68].

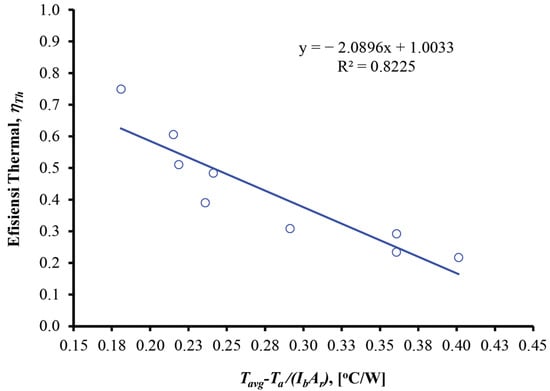

The thermal performance of a solar cooker equipped with a spot Fresnel lens for solar thermal energy concentrators was studied by Asrori et al. (2020) [69]. Scientists improved the Fresnel solar cooker (FSC) by designing a new cooking pot that acts as an absorber of solar thermal from a spot Fresnel lens, then determining how different pot temperatures affect the FSC’s thermal efficiency in the field through heating and cooling tests. The experiments were carried out during August and September of 2019 at Brawijaya University in East Java, Indonesia (7.9553° S, 112.6145° E). Fresnel lenses focus on direct normal irradiance (DNI) with the use of a manual azimuth tracker. Based on measurements taken from an experimentally fabricated conical cavity receiver, the average stagnation temperature in a cooking pot was 267.35 °C. Because of its superior heat transmission capabilities and minimal heat losses, the conical cavity form of the receiver is well-suited for use in the FSC. The FSC has a thermal efficiency of 27.72%. Figure 24 shows the impact of the optical efficiency factor on the thermal efficiency when it begins to diminish until the conclusion of the process.

Figure 24.

Fresnel solar cooker heat efficiency [69].

Two Fresnel lens magnifiers (FLMGs) were shown to be used with a standard box-type solar cooker (BTSC) by Engoor et al. (2022) [70]. The FLMG was included to compare the BTSC’s cooking power with that attained without it. The modified cooker had a standardized cooking power of 46.87 W at a temperature difference of 50 °C, as determined by plotting the standardized cooking power against the temperature difference in accordance with the international testing technique. With a 48.7% increase in solar irradiance concentration, Basmati rice may be cooked in only 58 min. The cost and environmental impact of using the stove were calculated by contrasting it with LPG use for a household of four. It was determined that the cooker would pay for itself in 3.35 years. The monthly CO2 savings were calculated to be 8.26 kg.

Using a Fresnel lens to concentrate direct normal irradiance onto the receiver/absorber within a cooking vessel, Asrori et al. (2022) [71] created, built, and assessed the efficiency of a solar cooker. An automated sun tracker setup controlled by hydraulic actuators is one way to boost the efficiency of the Fresnel solar concentrator. Every 5 and 10 min, the solar tracker was adjusted to a new position. The Fresnel lens used in the concentrated solar cooker has a 0.78 m2 capturing area and a 0.88 focal ratio. The primary parts of this solar cooker were a big Fresnel lens that focuses sunlight onto a cooking stove, a solar collector (receiver) in the form of a cone-shaped stove, and a hydraulic actuator-type solar tracker unit. According to preliminary measurements, the focal point temperature at the receiver was 930.10 °C, and the solar radiation was 789.00 W/m2. A solar cooker with a solar tracker that rotates every 10 min has a thermal efficiency of 12.7%, whereas a solar cooker with a solar tracker that rotates every 5 min has a thermal efficiency of 33.66%. The solar cooker’s thermal efficiency improved dramatically by a whopping 2.65 times.

The thermal study of a box-type solar cooker (BTSC) combined with two Fresnel lens magnifiers (FLMG) was carried out by Engoor et al. (2022) [72]. It was developed in MATLAB as a time-dependent numerical model based on heat balances happening at several locations inside the cooker. The first figure of merit (F1) and the second figure of merit (F2) tests were conducted on FLMGs in accordance with international testing protocols to ensure their efficacy. The BTSC moved up from the B grade category to the A grade because the initial figure of merit value improved from 0.11 to 0.12 m2 °C/W. The FLMG improved heat exchange to the load in the cooking vessel, as shown by a rise in the second figure of merit from 0.43 to 0.45. Adding the FLMG caused the BTSC’s temperature to rise across the board. The solar cooker was able to properly prepare Basmati rice after 58 min.

Asrori et al. (2023) [73] created a sun tracker for use with a Fresnel solar cooker (FSC). A cooking pot with a conical hollow receiver cover may concentrate direct normal irradiance (DNI) with the help of a poly methyl methacrylate (PMMA) Fresnel lens. Both modeling and experimentation were used to examine the FSC’s thermal performance. The slowing down of the temperature distribution is one effect of the simulations showing that the focus point becomes disoriented. The findings of the experiments demonstrated that direct normal irradiance (DNI) affects the temperature at the Fresnel’s focal point. Focal heating results from an increase in sun radiation. The results of the tests suggested that a focal temperature of Tf = 1064.00 °C can be achieved with a DNI = 862.50 W/m2.

Wang (2023) [74] studied the effectiveness of a fixed-focus Fresnel lens solar concentrator/conical cavity receiver system with and without a glass cover, taking into account a variety of incidence angles. The optical performance was obtained by first developing optical models of the system in TracePro® 7.0. The thermal performance of the system was then tested using an experimental configuration. Data demonstrated a substantial improvement in optical efficiency across systems with and without a glass cover. For an incidence angle between zero and twenty degrees, there is no change in the gap between them. There is a significant difference in the time constants of the system with and without a glass cover, with the former ranging from 29 to 33 s and the latter from 48 to 59 s. The system protected by glass is more thermally efficient throughout a wider temperature range. Table 4 presents studies on Fresnel lens application in solar cookers.

Table 4.

Outline of studies on Fresnel lens application in solar cooker.

2.5. Solar-Pumped Lasers by Fresnel Lenses

Fresnel lens-based solar-pumped lasers present a viable way to harvest solar energy for laser applications. Their main benefit is that they can properly concentrate sunlight, which makes them an environmentally safe and sustainable laser power source. There are a number of potential uses for this method, including remote sensing and telecommunications. Nevertheless, this technique comes with a number of drawbacks. One significant drawback is that sunlight is irregular, which means that solar-pumped lasers are reliant on the availability of sunshine and the state of the weather. It can also be difficult to achieve and sustain the exact alignment needed for peak performance. High temperatures produced during the concentration process could cause problems with thermal management, which would reduce the overall dependability and efficiency of solar-pumped lasers [75,76].

Using a Cr-co-doped Nd:yttrium aluminum garnet ceramic and Fresnel lens focusing on natural sunlight, Yabe et al. (2007) [77] were able to produce a slope efficiency of solar-pumped laser that ranged from 11% to 14%. A Fresnel lens of 1.3 m2 was used to generate laser power of 24.4 watts. In comparison to the results obtained with the mirror collector, the highest output for the unit area of sunlight was 18.7 W∕m2, which is 2.8 times more than prior findings. By making use of the Cr3+ ion, it was possible to achieve effective energy transmission and absorption throughout the solar spectrum to the Nd3+ ion. Both Cr-co-doped and non-doped laser media were used to test the fluorescence yield at 1064 nm for a variety of pumping wavelengths. The results of these measurements indicate that the laser output from sunlight is projected to be enhanced by 1.8 times.

The researchers Liang and Almeida (2011) [78] demonstrated a significant improvement in the efficiency of solar laser collecting using a Fresnel lens that was both cost-effective and a single-crystal rod that was the most extensively used Nd:YAG. Fresnel lenses with a diameter of 0.9 m are used to concentrate the solar radiation from the sun. A dielectric secondary concentrator that is completely internally reflective is used in order to couple the concentrated solar radiation that originates from the focal zone to an Nd:YAG rod that has a diameter of 4 mm and is contained inside a conical pumping cavity. The power output of the laser is 12.3 W cw, which corresponds to a collection efficiency of 19.3 W/m2. This is 2.9 times more than the findings obtained with the Nd:YAG single-crystal medium during the previous experiment. Additionally, a slope efficiency of 3.9%, which is a record high, is observed. By pumping a Nd:YAG rod with a diameter of 3 mm, the quality of the laser beam is significantly increased.

A way to pump a high-power solar-pumped laser that is both straightforward and effective was presented by Dinh et al. (2012) [79]. This system makes use of a hybrid pumping cavity in conjunction with a liquid light-guide lens (LLGL). To gather natural sunlight, a Fresnel lens with a diameter of 2 × 2 m is used as the main concentrator. A laser power of 120 W cw and a total slope efficiency of 4.3% are reached by including an Nd:YAG rod with a diameter of 6 mm into a laser light-guided laser (LLGL) with a diameter of 14 mm. The collecting efficiency that corresponds to this is 30.0 W/m, which is 1.5 times higher than the record that was previously held. Compared to the results obtained from Cr:Nd:YAG ceramics, this one is surprisingly superior. The reason for this is that the scattering coefficient of Cr:Nd:YAG ceramics is 0.004 cm, which is twice as great as the scattering coefficient of the Nd:YAG crystal, despite the fact that both products have comparable saturation gains.

A considerable improvement in the brightness of a solar-pumped laser beam was shown by Liang and Almeida (2013) [80] by the use of a Fresnel lens with a diameter of 1.0 m and a Nd:YAG single-crystal rod with a diameter of 3 mm. In the beginning, the Fresnel lens on a solar tracker is responsible for focusing the solar radiation that is streaming in. In order to further compress the focused solar radiation along the narrow laser rod that is contained inside a V-shaped pumping cavity, a big aspheric lens and a two-dimensional complementary photon counting concentrator are then coupled. Finally, 2.3 W continuous-wave (cw) TEM00 (M2 ≤ 1.1) solar laser power is generated, making it possible to achieve a laser beam brightness figure of merit of 1.9 W. This result is 6.6 times greater than the previous record. It is possible to generate 8.1 W cw of laser power for multimode operation, which is equivalent to a 143% increase in collecting efficiency.

A considerable increase in solar-pumped laser collection efficiency was reported by Cai et al. (2023) [81]. This improvement was based on the end-side pumping of a Ce:Nd:YAG/YAG grooved bonded crystal rod that was 95 mm in length and had a diameter of 6 mm. A Fresnel lens, a quartz cooling-water tube, and a gold-plated conical cavity were the components that made up the solar-energy collecting and concentration system. This system was intended to maximize pump light absorption while simultaneously minimizing thermal effects in the Ce:Nd:YAG laser medium. It has been shown that a Fresnel lens solar-energy collecting and concentration system can be used to pump Ce:Nd:YAG crystal. An effective solar collecting area of 0.69 m2 resulted in the generation of 26.93 watts of continuous-wave laser power, which corresponds to a slope efficiency of 6.33%. The collection efficiency of 38.8 W/m2 was 1.21 times greater than the greatest number recorded in the past for Fresnel lens solar collecting. This achievement also sets a new record for single-beam solar-pumped lasers.

Table 5 shows studies on solar-pumped lasers by Fresnel lenses.

Table 5.

Outline of studies on solar-pumped lasers by Fresnel lenses.

3. Challenges and Suggested Techniques of Improvement

This paper covered a broad range of research that was connected to the topic at hand, including simulations and experiments that made use of a wide number of experimental designs and settings. The key findings of this research can provide insight into future directions, emerging trends, and new applications for Fresnel lenses in a variety of solar energy systems. According to the findings of this research, more exploration is likely to be required in order to overcome the many challenges that now prevent the widespread use of Fresnel lenses in solar energy systems such as solar stills, solar collectors, solar sterilizers, solar cookers, and solar-pumped lasers. Some of these challenges are listed below:

- Although Fresnel lenses have been used in a number of solar energy systems, their usage in residential applications is often not viable due to their high cost. One of the primary obstacles to extensive domestic adoption of home systems has been the general perception of their high costs and low efficiencies.

- The initial investment cost for solar energy systems such as the solar collector is much higher than that of conventional solar energy systems. This is due to the restricted availability of solar energy systems as well as their high cost.

- The global demand for energy systems is expected to see a dramatic uptick over the next several years, according to projections. As a result of the rise in demand, eco-friendly alternatives, such as the implementation of various energy systems using Fresnel lenses, need to be researched.

- When it comes to Fresnel lens technology, optical losses are an important factor to take into account since they might affect the system’s overall effectiveness. The sunlight’s reflection, absorption, and scattering as it travels through or interacts with the lens components are some of the causes of these losses. To optimize the concentration and exploitation of sunlight for particular purposes such as solar cooking, solar sterilization, or solar power generation, control and minimization of optical losses are essential.

- The requirement to maintain the exact alignment of the Fresnel lens with the incident sunlight is an important aspect that contributes to optical losses. Disturbances in alignment may cause light to escape the focal point, decreasing the effectiveness of concentration.

Referring to the above challenges, the following suggestions are made to potentially improve the usage of Fresnel lenses in a variety of solar energy systems:

- In order for researchers to make changes, it is required to conduct an analysis of certain thermodynamic features of the process.

- Developing an appropriate system that can automatically track the position of the lens lever.

- It is important to explore the optimal area and arrangement, as well as the number of lenses used.

- By incorporating an additional source of heat inside the basin, it is possible to make up for the dearth of solar radiation that occurs during the colder months and to boost production during the warmer months.

- It is possible to install heat sink material inside the basin so that it may accept the concentrated sunbeam produced by the lenses and then transmit the energy in a significant manner to the salt water that is contained within the basin.

- Cooking with the sun. Individually and as a whole, the proposed small community-based solar cooker contains a great deal of simplicity of use, is user-friendly, and has characteristics that are operationally practical. Verifying its cost-effectiveness, proving the extra energy-saving advantages, and conducting an exergy analysis of the system are going to be the primary focuses of study in the future.

- There is still the possibility of tracking on either a single or dual axis. The use of dual-axis tracking in its present form incurs an extra expense. On the other hand, closed-loop dual-axis tracking systems may be created using open-source software and hardware in a way that is both straightforward and easy to use. In the case of the software, LightTools 2023.03 optical simulation software (its ray tracing theory is based on Monte Carlo principle) can be used to simulate optical performance of a solar cocker system using MATLAB [82].

- Additionally, new modules of lenses may be clustered in order to be moved using the tracking and control system that is already in place.

- It is possible to cut down on the amount of time required to reach the starting boiling temperature by increasing the size of the Fresnel lens and improving the heat transmission into the boiler.